MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1121 of 1232

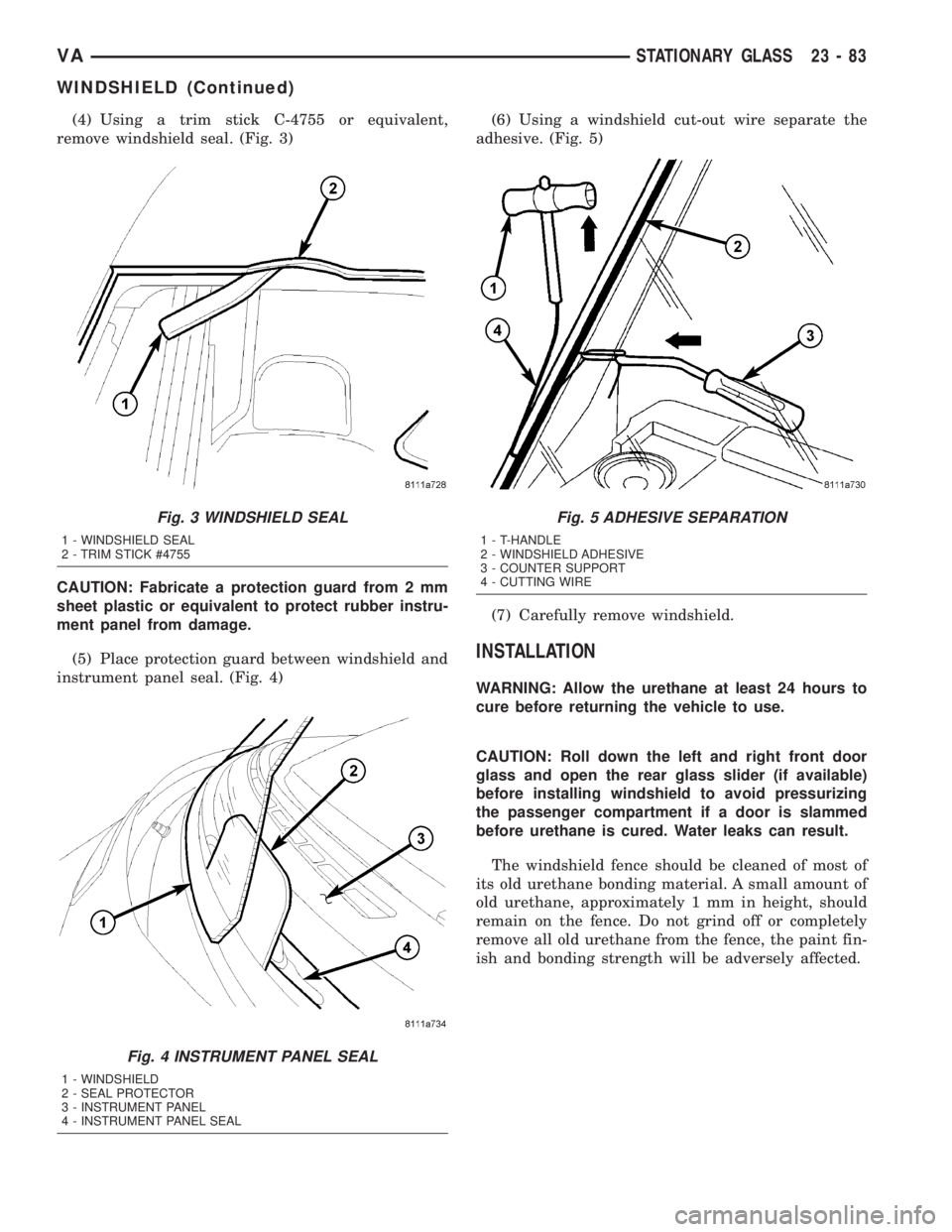

(4) Using a trim stick C-4755 or equivalent,

remove windshield seal. (Fig. 3)

CAUTION: Fabricate a protection guard from 2 mm

sheet plastic or equivalent to protect rubber instru-

ment panel from damage.

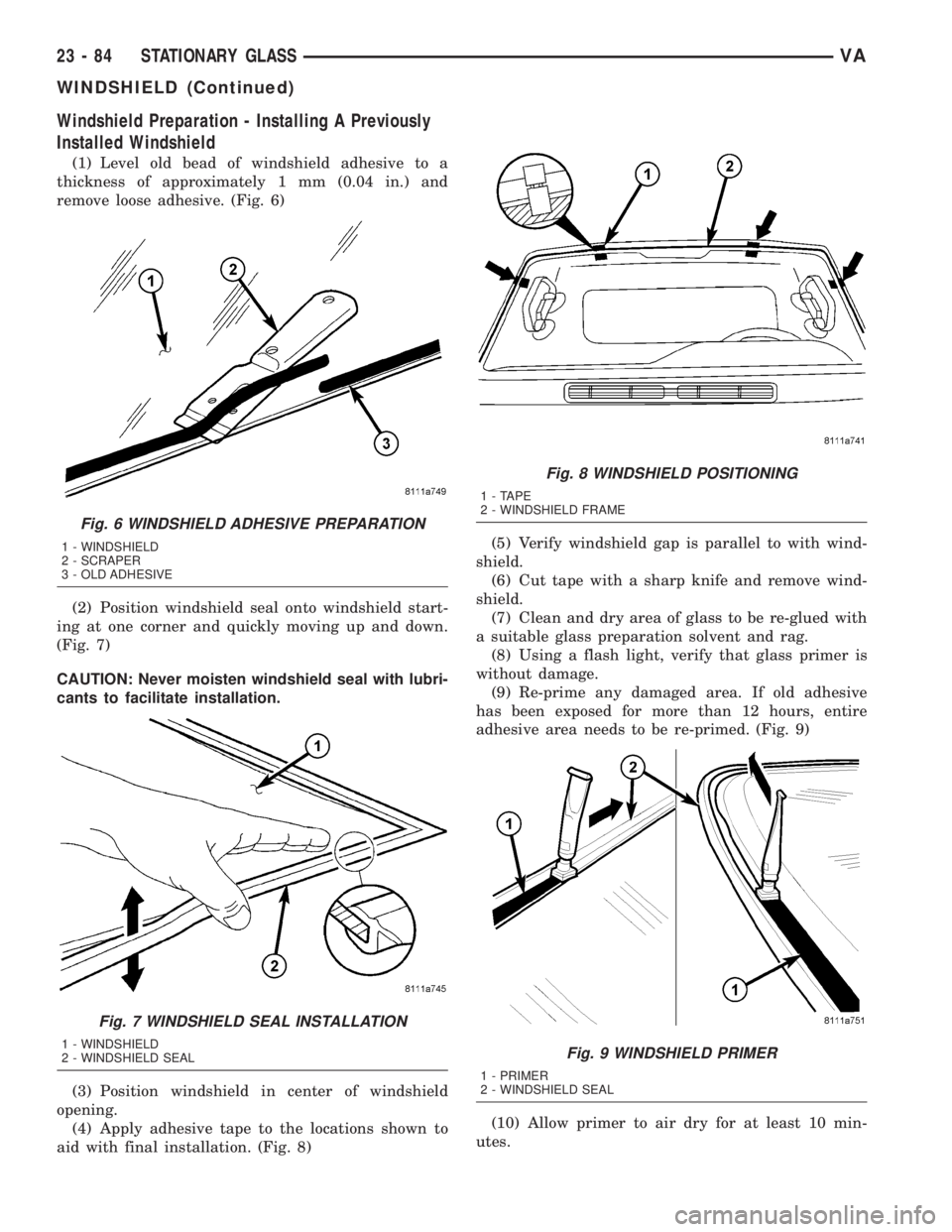

(5) Place protection guard between windshield and

instrument panel seal. (Fig. 4)(6) Using a windshield cut-out wire separate the

adhesive. (Fig. 5)

(7) Carefully remove windshield.

INSTALLATION

WARNING: Allow the urethane at least 24 hours to

cure before returning the vehicle to use.

CAUTION: Roll down the left and right front door

glass and open the rear glass slider (if available)

before installing windshield to avoid pressurizing

the passenger compartment if a door is slammed

before urethane is cured. Water leaks can result.

The windshield fence should be cleaned of most of

its old urethane bonding material. A small amount of

old urethane, approximately 1 mm in height, should

remain on the fence. Do not grind off or completely

remove all old urethane from the fence, the paint fin-

ish and bonding strength will be adversely affected.

Fig. 3 WINDSHIELD SEAL

1 - WINDSHIELD SEAL

2 - TRIM STICK #4755

Fig. 4 INSTRUMENT PANEL SEAL

1 - WINDSHIELD

2 - SEAL PROTECTOR

3 - INSTRUMENT PANEL

4 - INSTRUMENT PANEL SEAL

Fig. 5 ADHESIVE SEPARATION

1 - T-HANDLE

2 - WINDSHIELD ADHESIVE

3 - COUNTER SUPPORT

4 - CUTTING WIRE

VASTATIONARY GLASS 23 - 83

WINDSHIELD (Continued)

Page 1122 of 1232

Windshield Preparation - Installing A Previously

Installed Windshield

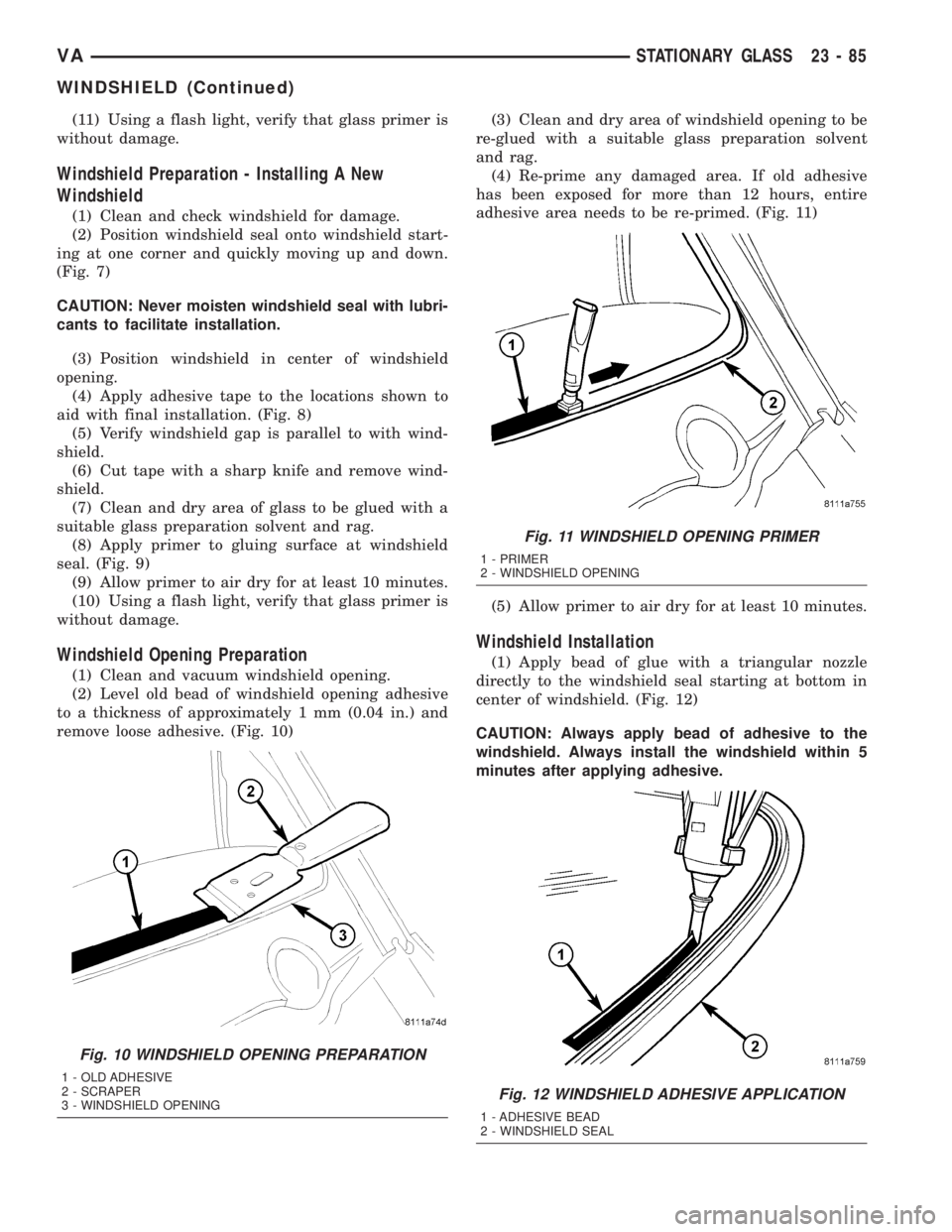

(1) Level old bead of windshield adhesive to a

thickness of approximately 1 mm (0.04 in.) and

remove loose adhesive. (Fig. 6)

(2) Position windshield seal onto windshield start-

ing at one corner and quickly moving up and down.

(Fig. 7)

CAUTION: Never moisten windshield seal with lubri-

cants to facilitate installation.

(3) Position windshield in center of windshield

opening.

(4) Apply adhesive tape to the locations shown to

aid with final installation. (Fig. 8)(5) Verify windshield gap is parallel to with wind-

shield.

(6) Cut tape with a sharp knife and remove wind-

shield.

(7) Clean and dry area of glass to be re-glued with

a suitable glass preparation solvent and rag.

(8) Using a flash light, verify that glass primer is

without damage.

(9) Re-prime any damaged area. If old adhesive

has been exposed for more than 12 hours, entire

adhesive area needs to be re-primed. (Fig. 9)

(10) Allow primer to air dry for at least 10 min-

utes.

Fig. 6 WINDSHIELD ADHESIVE PREPARATION

1 - WINDSHIELD

2 - SCRAPER

3 - OLD ADHESIVE

Fig. 7 WINDSHIELD SEAL INSTALLATION

1 - WINDSHIELD

2 - WINDSHIELD SEAL

Fig. 8 WINDSHIELD POSITIONING

1 - TAPE

2 - WINDSHIELD FRAME

Fig. 9 WINDSHIELD PRIMER

1 - PRIMER

2 - WINDSHIELD SEAL

23 - 84 STATIONARY GLASSVA

WINDSHIELD (Continued)

Page 1123 of 1232

(11) Using a flash light, verify that glass primer is

without damage.

Windshield Preparation - Installing A New

Windshield

(1) Clean and check windshield for damage.

(2) Position windshield seal onto windshield start-

ing at one corner and quickly moving up and down.

(Fig. 7)

CAUTION: Never moisten windshield seal with lubri-

cants to facilitate installation.

(3) Position windshield in center of windshield

opening.

(4) Apply adhesive tape to the locations shown to

aid with final installation. (Fig. 8)

(5) Verify windshield gap is parallel to with wind-

shield.

(6) Cut tape with a sharp knife and remove wind-

shield.

(7) Clean and dry area of glass to be glued with a

suitable glass preparation solvent and rag.

(8) Apply primer to gluing surface at windshield

seal. (Fig. 9)

(9) Allow primer to air dry for at least 10 minutes.

(10) Using a flash light, verify that glass primer is

without damage.

Windshield Opening Preparation

(1) Clean and vacuum windshield opening.

(2) Level old bead of windshield opening adhesive

to a thickness of approximately 1 mm (0.04 in.) and

remove loose adhesive. (Fig. 10)(3) Clean and dry area of windshield opening to be

re-glued with a suitable glass preparation solvent

and rag.

(4) Re-prime any damaged area. If old adhesive

has been exposed for more than 12 hours, entire

adhesive area needs to be re-primed. (Fig. 11)

(5) Allow primer to air dry for at least 10 minutes.

Windshield Installation

(1) Apply bead of glue with a triangular nozzle

directly to the windshield seal starting at bottom in

center of windshield. (Fig. 12)

CAUTION: Always apply bead of adhesive to the

windshield. Always install the windshield within 5

minutes after applying adhesive.

Fig. 10 WINDSHIELD OPENING PREPARATION

1 - OLD ADHESIVE

2 - SCRAPER

3 - WINDSHIELD OPENING

Fig. 11 WINDSHIELD OPENING PRIMER

1 - PRIMER

2 - WINDSHIELD OPENING

Fig. 12 WINDSHIELD ADHESIVE APPLICATION

1 - ADHESIVE BEAD

2 - WINDSHIELD SEAL

VASTATIONARY GLASS 23 - 85

WINDSHIELD (Continued)

Page 1124 of 1232

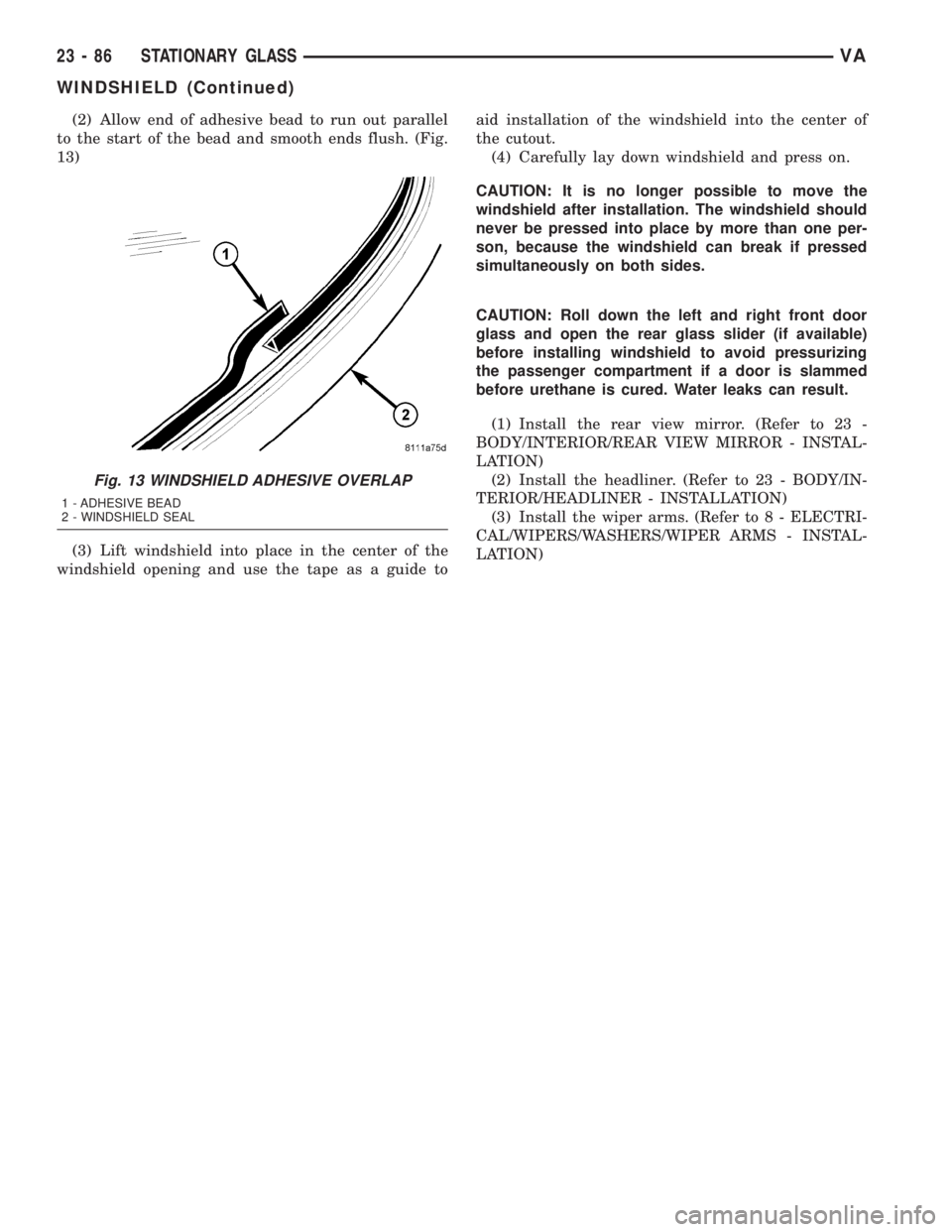

(2) Allow end of adhesive bead to run out parallel

to the start of the bead and smooth ends flush. (Fig.

13)

(3) Lift windshield into place in the center of the

windshield opening and use the tape as a guide toaid installation of the windshield into the center of

the cutout.

(4) Carefully lay down windshield and press on.

CAUTION: It is no longer possible to move the

windshield after installation. The windshield should

never be pressed into place by more than one per-

son, because the windshield can break if pressed

simultaneously on both sides.

CAUTION: Roll down the left and right front door

glass and open the rear glass slider (if available)

before installing windshield to avoid pressurizing

the passenger compartment if a door is slammed

before urethane is cured. Water leaks can result.

(1) Install the rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR - INSTAL-

LATION)

(2) Install the headliner. (Refer to 23 - BODY/IN-

TERIOR/HEADLINER - INSTALLATION)

(3) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

Fig. 13 WINDSHIELD ADHESIVE OVERLAP

1 - ADHESIVE BEAD

2 - WINDSHIELD SEAL

23 - 86 STATIONARY GLASSVA

WINDSHIELD (Continued)

Page 1125 of 1232

WEATHERSTRIP/SEALS

TABLE OF CONTENTS

page page

FRONT DOOR INNER BELT WEATHERSTRIP

REMOVAL.............................87

INSTALLATION.........................87

FRONT DOOR OUTER BELT WEATHERSTRIP

REMOVAL.............................87INSTALLATION.........................87

DOOR OPENING SEALS

REMOVAL.............................87

INSTALLATION.........................87

FRONT DOOR INNER BELT

WEATHERSTRIP

REMOVAL

(1) Remove the front door trim panel. (Refer to 23

- BODY/DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the inner belt weatherstrip.

INSTALLATION

(1) Install the inner belt weatherstrip.

(2) Install the trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

FRONT DOOR OUTER BELT

WEATHERSTRIP

REMOVAL

(1) Remove door glass. (Refer to 23 - BODY/DOOR

- FRONT/DOOR GLASS - REMOVAL)

(2) Remove screws at window channel and remove

channel.

(3) Remove outer belt weatherstrip.

INSTALLATION

(1) Install outer belt weatherstrip.

(2) Install glass run channel and install the

screws.

(3) Install the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - INSTALLATION)

DOOR OPENING SEALS

REMOVAL

(1) Open door and separate the door opening seal

from the door opening flange.

INSTALLATION

(1) Position the seal to the bottom of the door

opening, with bulb facing outboard, starting the

installation at the center of the lower flange. Press

the seal onto the sill flange and work around the

perimeter of the door opening until fully seated.

Work in one direction, smoothing the seal to avoid

puckers or wrinkles.

(2) When installing a new weatherstrip on the

front door opening, remove the tear strip starting at

the splice and moving around the front of the door to

the back of the opening.

VAWEATHERSTRIP/SEALS 23 - 87

Page 1126 of 1232

BODY STRUCTURE

TABLE OF CONTENTS

page page

GAP AND FLUSH

SPECIFICATIONS.......................88OPENING DIMENSIONS

SPECIFICATIONS.......................90

GAP AND FLUSH

SPECIFICATIONS

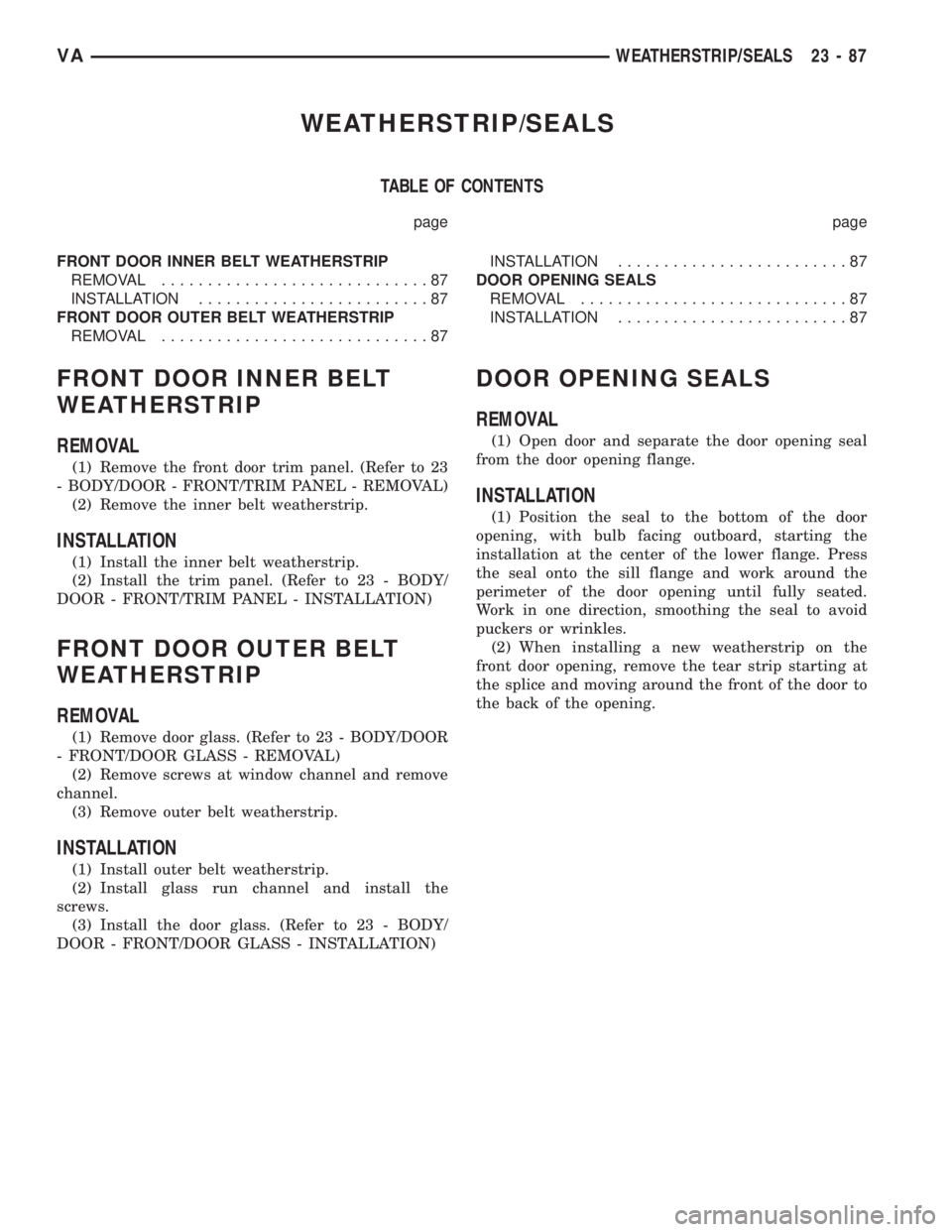

GAP & FLUSH DIMENSIONS INDEX

DESCRIPTION FIGURE

FRONT DOORS 1

SLIDING DOORS 2

REAR DOORS 3

NOTE:

All measurements are in mm.

LOCATION GAP FLUSH

1 Door at top. 7

0.5FLUSH

2 Door at upper b-pillar. 7

0.5Up to max 1 mm

recessed, at

rear with 1 mm

overlap (wind

noise)

3 Door at bottom. 8

0.5FLUSH

4 Door at wheelhouse. 7

0.5FLUSH

5 Door ridge at

wheelhouse and

b-pillar.Ð FLUSH

6 Door at a-pillar. 8

0.5FLUSH

Fig. 1 FRONT DOOR

23 - 88 BODY STRUCTUREVA

Page 1127 of 1232

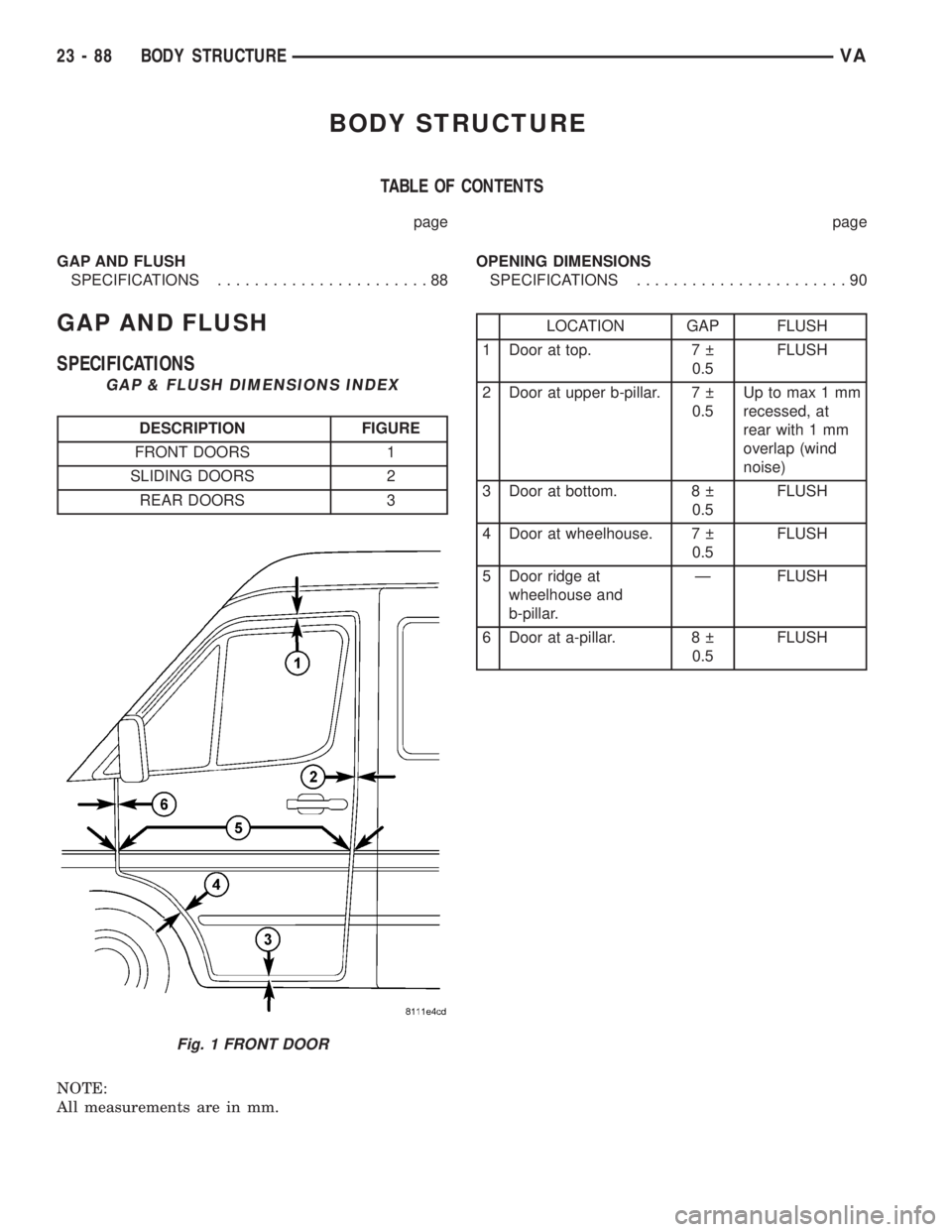

NOTE:

All measurements are in mm.

LOCATION GAP FLUSH

1 Sliding doors at top and

bottom7

0.5FLUSH

2 Sliding doors at sides to body 7

0.5FLUSH

3 Door ridge at b-pillar and side

panelÐ FLUSH

without

offsetNOTE:

All measurements are in mm.LOCATION GAP FLUSH

1 Rear doors at top 13

0.5FLUSH

2 Right rear door to left rear

door8 0.5 FLUSH

3 Rear doors (both sides) to

rear body8 0.5 FLUSH

4 Rear doors at bottom 8 0.5 Ð

Fig. 2 SLIDING DOORFig. 3 REAR DOOR

VABODY STRUCTURE 23 - 89

GAP AND FLUSH (Continued)

Page 1128 of 1232

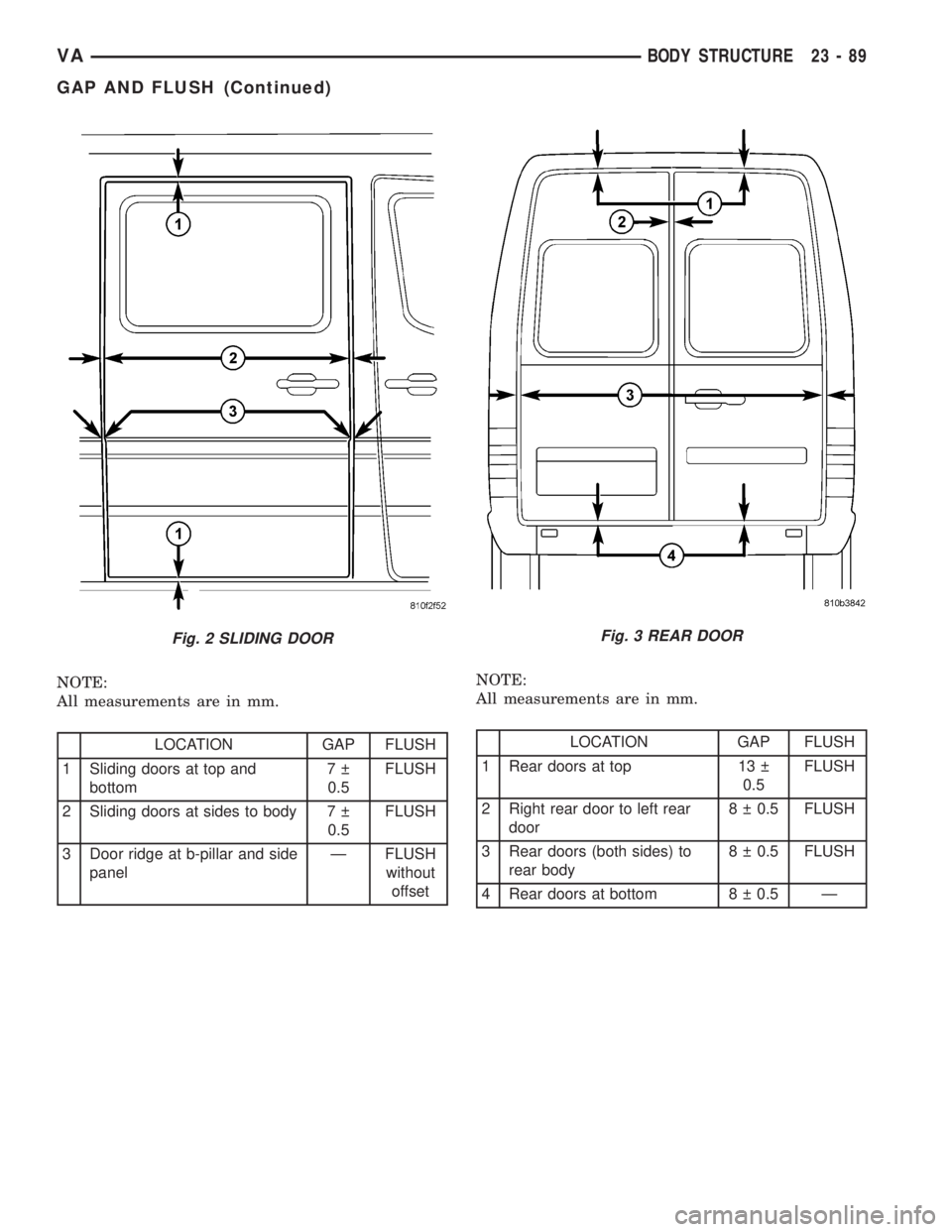

OPENING DIMENSIONS

SPECIFICATIONS

BODY OPENING DIMENSIONS INDEX

DESCRIPTION FIGURE

WINDSHIELD OPENING 4

Fig. 4 WINDSHIELD OPENING

23 - 90 BODY STRUCTUREVA

Page 1129 of 1232

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS.......................1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

OPERATION - HEATER AND AIR

CONDITIONER........................2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FUNCTION

TEST................................3

DIAGNOSIS AND TESTING - A/C

PERFORMANCE TEST..................3DIAGNOSIS AND TESTING - HEATER

PERFORMANCE.......................4

SPECIFICATIONS

A/C SYSTEM..........................5

CONTROLS - FRONT......................8

CONTROLS - REAR......................22

DISTRIBUTION - FRONT...................31

DISTRIBUTION - REAR....................39

PLUMBING.............................43

CABIN HEATER.........................72

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating-

air conditioning system, the engine cooling system

must be properly maintained. The use of a bug

screen is not recommended. Any obstructions in front

of the radiator or condenser will reduce the perfor-

mance of the air conditioning and engine cooling sys-

tems.

The engine cooling system includes the radiator,

thermostat, heater core, heater hoses and the engine

coolant pump. Refer to Cooling for more information

before opening or attempting any service to the

engine cooling system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

A automatic temperature control (ATC) single zone

type heating-air conditioning system is standard

equipment on this model. A manually controlled rear

air conditioning system is available as a factory-in-

stalled option.

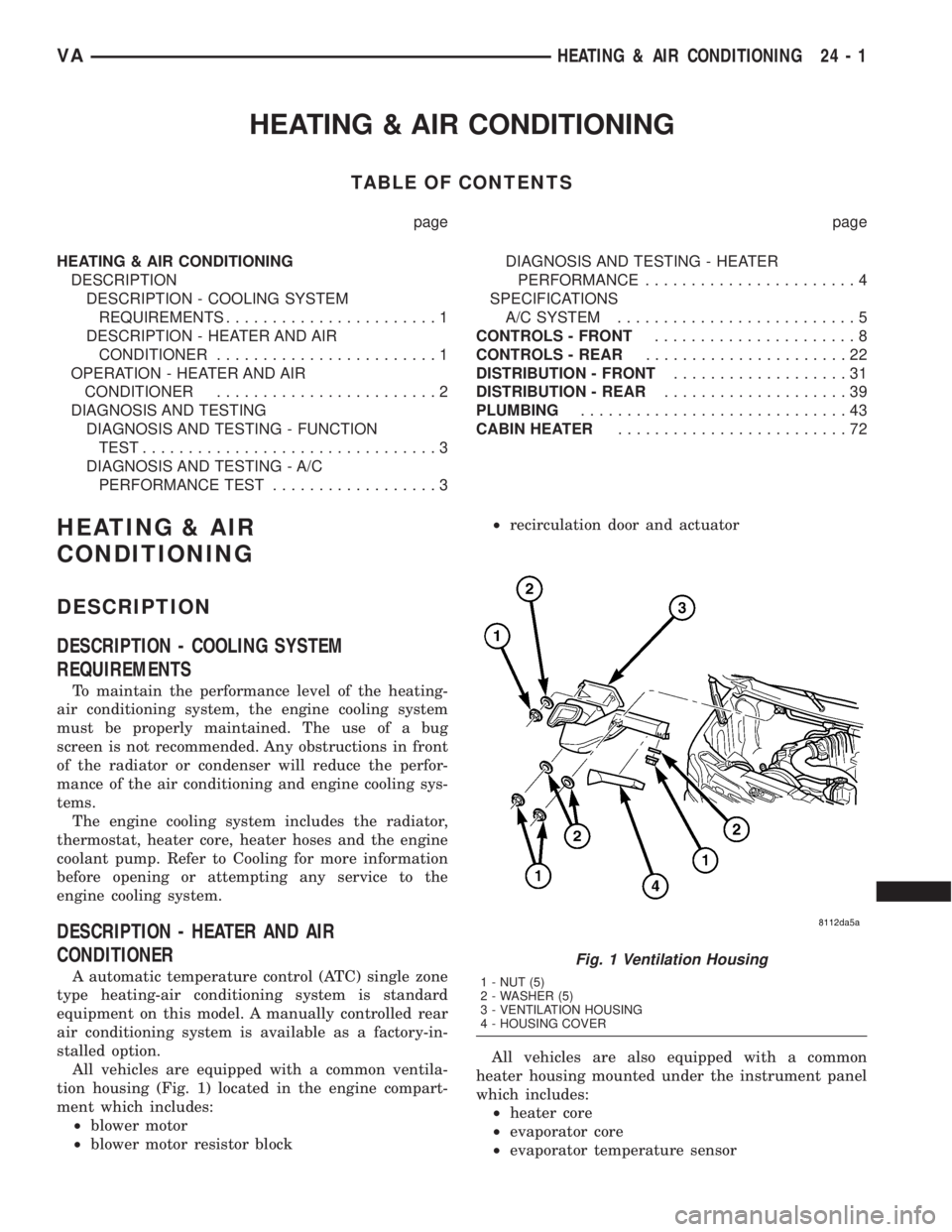

All vehicles are equipped with a common ventila-

tion housing (Fig. 1) located in the engine compart-

ment which includes:

²blower motor

²blower motor resistor block²recirculation door and actuator

All vehicles are also equipped with a common

heater housing mounted under the instrument panel

which includes:

²heater core

²evaporator core

²evaporator temperature sensor

Fig. 1 Ventilation Housing

1 - NUT (5)

2 - WASHER (5)

3 - VENTILATION HOUSING

4 - HOUSING COVER

VAHEATING & AIR CONDITIONING 24 - 1

Page 1130 of 1232

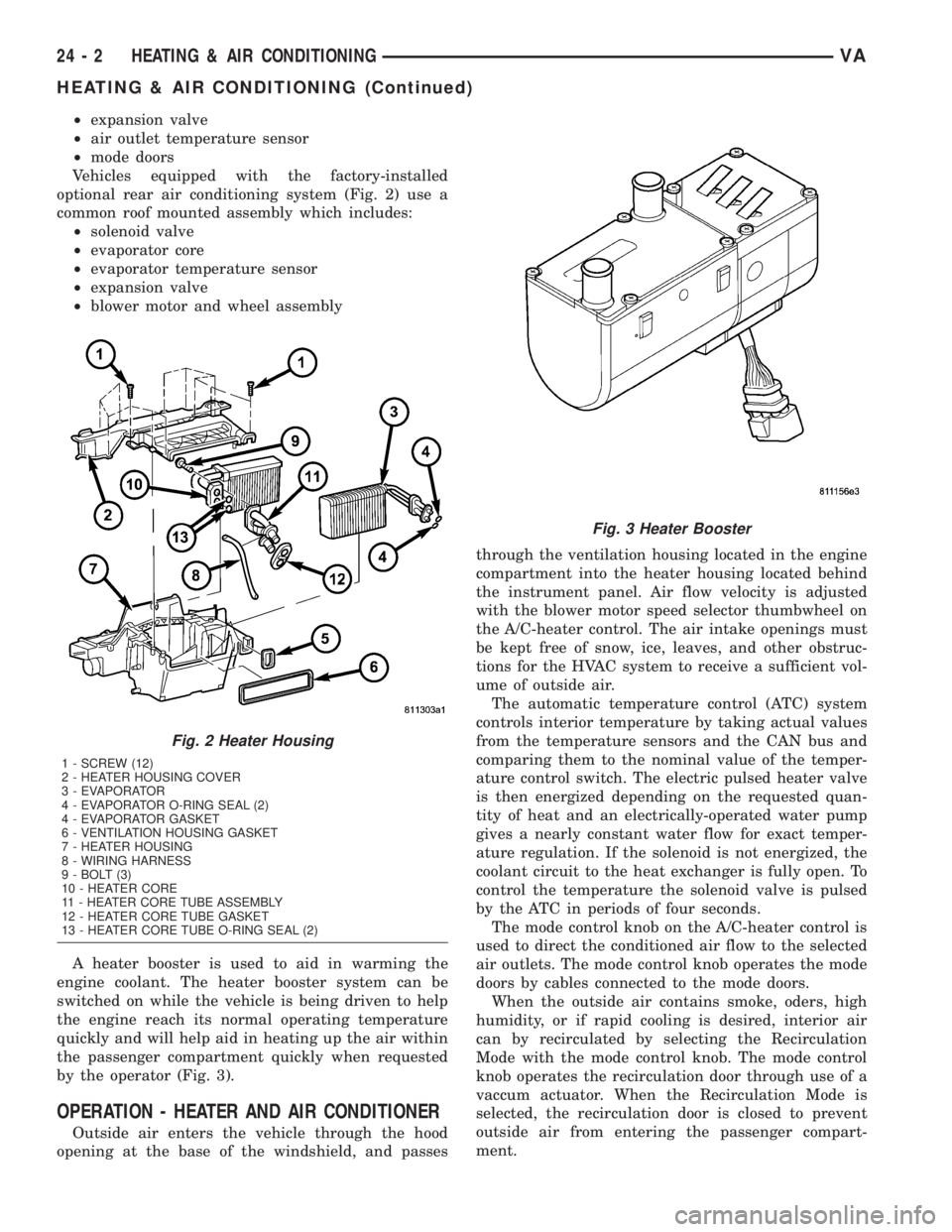

²expansion valve

²air outlet temperature sensor

²mode doors

Vehicles equipped with the factory-installed

optional rear air conditioning system (Fig. 2) use a

common roof mounted assembly which includes:

²solenoid valve

²evaporator core

²evaporator temperature sensor

²expansion valve

²blower motor and wheel assembly

A heater booster is used to aid in warming the

engine coolant. The heater booster system can be

switched on while the vehicle is being driven to help

the engine reach its normal operating temperature

quickly and will help aid in heating up the air within

the passenger compartment quickly when requested

by the operator (Fig. 3).

OPERATION - HEATER AND AIR CONDITIONER

Outside air enters the vehicle through the hood

opening at the base of the windshield, and passesthrough the ventilation housing located in the engine

compartment into the heater housing located behind

the instrument panel. Air flow velocity is adjusted

with the blower motor speed selector thumbwheel on

the A/C-heater control. The air intake openings must

be kept free of snow, ice, leaves, and other obstruc-

tions for the HVAC system to receive a sufficient vol-

ume of outside air.

The automatic temperature control (ATC) system

controls interior temperature by taking actual values

from the temperature sensors and the CAN bus and

comparing them to the nominal value of the temper-

ature control switch. The electric pulsed heater valve

is then energized depending on the requested quan-

tity of heat and an electrically-operated water pump

gives a nearly constant water flow for exact temper-

ature regulation. If the solenoid is not energized, the

coolant circuit to the heat exchanger is fully open. To

control the temperature the solenoid valve is pulsed

by the ATC in periods of four seconds.

The mode control knob on the A/C-heater control is

used to direct the conditioned air flow to the selected

air outlets. The mode control knob operates the mode

doors by cables connected to the mode doors.

When the outside air contains smoke, oders, high

humidity, or if rapid cooling is desired, interior air

can by recirculated by selecting the Recirculation

Mode with the mode control knob. The mode control

knob operates the recirculation door through use of a

vaccum actuator. When the Recirculation Mode is

selected, the recirculation door is closed to prevent

outside air from entering the passenger compart-

ment.

Fig. 2 Heater Housing

1 - SCREW (12)

2 - HEATER HOUSING COVER

3 - EVAPORATOR

4 - EVAPORATOR O-RING SEAL (2)

4 - EVAPORATOR GASKET

6 - VENTILATION HOUSING GASKET

7 - HEATER HOUSING

8 - WIRING HARNESS

9 - BOLT (3)

10 - HEATER CORE

11 - HEATER CORE TUBE ASSEMBLY

12 - HEATER CORE TUBE GASKET

13 - HEATER CORE TUBE O-RING SEAL (2)

Fig. 3 Heater Booster

24 - 2 HEATING & AIR CONDITIONINGVA

HEATING & AIR CONDITIONING (Continued)