MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 741 of 1232

DESCRIPTION SPECIFICATION

Engine 2.7L CDI

Engine Description 5 Cylinder In-Line Engine

With 4-Valve Technology

Air Intake Turbo-Charged Engine

with Charge Air Cooling

Fuel Injection System Common Rail Diesel

Injection (CDI)

Fuel Diesel

Firing Order 1-2-4-5-3

Rated Output 125/4200 kW at RPM

Torque 400/1600-2400 Nm at

RPM

Maximum Speed 4800 RPM

Compression Ratio 19:1

Bore/Stroke 88.0/88.4 mm

Eff. Displacement 2688 cm3

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPRESSION

TESTING ENGINE

(1) Warm up engine to operating temperature

(approx. 80 ÉC, 176ÉF).

(2) Shut off engine.

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Remove glow plugs (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/GLOW PLUG - REMOVAL).

(5) Crank engine several times with the starter to

eliminate combustion residues in the cylinders.

(6) Insert compression tester adapter #8927 (Refer

to 9 - ENGINE - SPECIAL TOOLS) with check valve

installed into glow plug hole of cylinder to be tested.

(7) Connect compression tester hose adapter #9295

to compression gauge and test compression pressure

by cranking engine with starter for at least 8 revolu-

tions.

(8) Carry out test procedure at the remaining cyl-

inders in the same way.

(9) Compare pressure readings obtained with the

specified pressures. If the pressure reading is below

the minimum compression pressure or if the permis-

sible difference between the individual cylinders is

exceeded. Refer to cylinder leak down test.

(10) Remove compression tester and adapter from

cylinder head.

(11)

Install glow plugs (Refer to 8 - ELECTRICAL/IG-

NITION CONTROL/GLOW PLUG - INSTALLATION).

(12) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

COMPRESSION SPECIFICATIONS

Maximum Compression 29-35 bar (420-507 psi)

Minimum Compression 18bar (261 psi)

Permissible Difference

Between Cylinders 3bar ( 44 psi)

STANDARD PROCEDURE - CYLINDER LEAK

DOWN TEST

(1) Warm engine to operating temperature.

WARNING: DO NOT OPEN COOLING SYSTEM UNLESS

COOLANT TEMPERATURE IS BELOW 90C (194ÉF).

RISK OF INJURY TO SKIN AND EYES AS A RESULT OF

SCALDING WITH HOT COOLANT WHICH SPLASHES

OUT. RISK OF POISONING FROM SWALLOWING

COOLANT. OPEN CAP SLOWLY AND RELEASE PRES-

SURE. STORE COOLANT IN PROPER CONTAINERS

ONLY. WEAR PROTECTIVE GLOVES, CLOTHING AND

EYE PROTECTION.

NOTE: Turn cap carefully as far as first detent,

release pressure, then unscrew cap.

(2) Open cooling system cap at coolant recover

pressure container.

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Unscrew oil filler cap.

(5) Remove glow plugs (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/GLOW PLUG - REMOVAL).

NOTE: Crank engine at crankshaft in direction of

rotation of the engine (clockwise).

(6) Position cylinder to be tested to ignition Top

Dead Center (DTC).

NOTE: Calibrate cylinder leak down tester and

remove check valve in screw-in fitting.

(7) Connect cylinder leak down tester and follow

INSPECTING Instruction.

INSPECTING

NOTE: If crankshaft rotates, install retaining lock for

crankshaft/ring gear.

(1) Pressurize cylinder with compressed air and

read off pressure loss at cylinder leak tester. If exces-

sive pressure loss exists, determine possible cause

(Refer to 9 - ENGINE - STANDARD PROCEDURE).

NOTE: If the retaining lock is installed, remove it,

rotate engine and install lock once again.

(2) Carry out test of other cylinders in the firing

order of engine.

VAENGINE 9 - 3

ENGINE (Continued)

Page 742 of 1232

CYLINDER LEAK DOWN VALUES

CYLINDER LEAK DOWN

PERMISSIBLE TOTAL

LOSS 25%

CYLINDER LEAK DOWN

PERMISSIBLE LOSS AT

VALVES AND CYLINDER

HEAD 10%

CYLINDER LEAK DOWN

PERMISSIBLE LOSS AT

PISTON AND RINGS 20%

STANDARD PROCEDURE - DETERMINING

CYLINDER PRESSURE LOSS

If an increased pressure loss was found with the

cylinder leak test, inspect the engine by listening at

the cylinder head gasket, air intake area, exhaust, oil

fill opening and where injectors and glow plugs enter

the cylinder head. Also check the engine coolant in

the radiator or expansion reservoir for the formation

of bubbles.

Possible causes for the pressure loss are:

POSSIBLE CAUSE FOR PRESSURE LOSS

CONDITION POSSIBLE

CAUSESCORRECTION

AIR LOSS

THROUGH

GLOW PLUG,

INJECTOR,

ADJACENT

CYLINDERS,

OR AIR

BUBBLES IN

COOLANT1. Sealing

SurfacesRepair Sealing

Surfaces

2. Gaskets 2. Replace

Component or

Gasket

3. Cylinder

Head Gasket3. Replace

Cylinder Head

Gasket

AIR LOSS

THROUGH AIR

INTAKE AREA1. Sealing

Surfaces1. Remove

Cylinder Head

for Further

Inspection

2. Intake Valves

and Seats2. Replace

Valves, Guides

or Seats

CONDITION POSSIBLE

CAUSESCORRECTION

AIR LOSS

THROUGH

EXHAUSTSealing

SurfacesRemove

Cylinder Head

for Further

Inspection

2. Exhaust

Valves and

Seats2. Replace

Valves, Guides

or Seats

AIR LOSS

THROUGH OIL

FILL OPENING1. Sealing

SurfacesRemove Engine

for Further

Inspection

2. Pistons,

Piston Rings2. Replace

Pistons or

Piston Rings

It is possible to pin point the pressure loss of the

relevant cylinder by spraying with clean engine oil.

Engine oil seals off the gap between the piston and

cylinder wall briefly. If a reduced pressure loss now

occurs for a short time, the cause is very likely to be

the pistons, piston rings or cylinder contact surfaces

of the relevant cylinder.

Determining the cause can be falsified by the posi-

tion of the piston ring joints. If suspicion exists that

the loss of pressure is caused by the piston ring

joints being positioned directly one above the other,

fit the parts to the engine and repeat this test after

running the engine for a short time.

REMOVAL

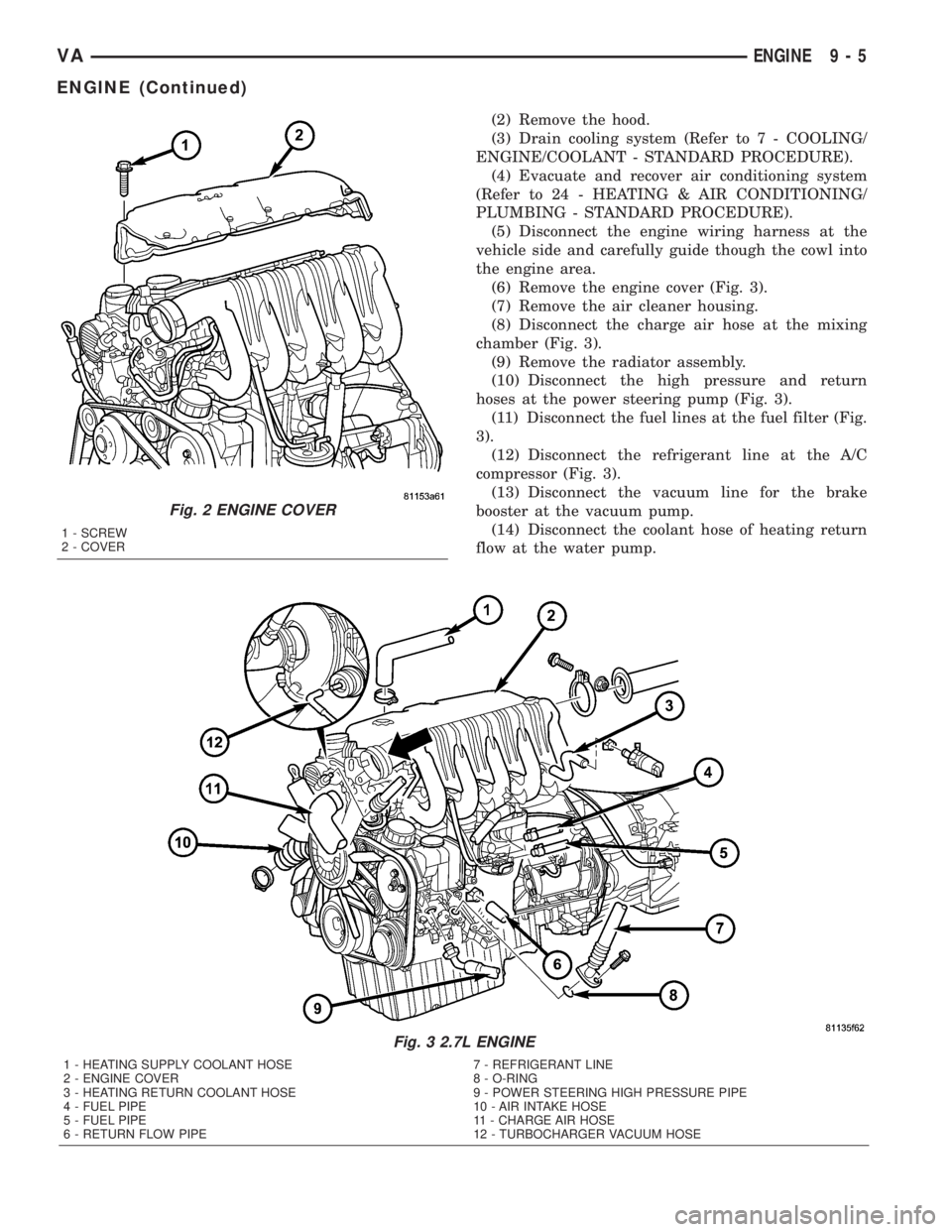

REMOVAL - ENGINE COVER

(1) Remove the retaining screws and remove cover

(Fig. 2).

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC (194ÉF). OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES, AND EYE WEAR.

CAUTION: STORE OR DISCARD ALL FLUIDS IN

SUITABLE AND APPROPRIATELY MARKED CON-

TAINERS.

(1) Disconnect the negative battery cable.

9 - 4 ENGINEVA

ENGINE (Continued)

Page 743 of 1232

(2) Remove the hood.

(3) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(4) Evacuate and recover air conditioning system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE).

(5) Disconnect the engine wiring harness at the

vehicle side and carefully guide though the cowl into

the engine area.

(6) Remove the engine cover (Fig. 3).

(7) Remove the air cleaner housing.

(8) Disconnect the charge air hose at the mixing

chamber (Fig. 3).

(9) Remove the radiator assembly.

(10) Disconnect the high pressure and return

hoses at the power steering pump (Fig. 3).

(11) Disconnect the fuel lines at the fuel filter (Fig.

3).

(12) Disconnect the refrigerant line at the A/C

compressor (Fig. 3).

(13) Disconnect the vacuum line for the brake

booster at the vacuum pump.

(14) Disconnect the coolant hose of heating return

flow at the water pump.

Fig. 3 2.7L ENGINE

1 - HEATING SUPPLY COOLANT HOSE 7 - REFRIGERANT LINE

2 - ENGINE COVER 8 - O-RING

3 - HEATING RETURN COOLANT HOSE 9 - POWER STEERING HIGH PRESSURE PIPE

4 - FUEL PIPE 10 - AIR INTAKE HOSE

5 - FUEL PIPE 11 - CHARGE AIR HOSE

6 - RETURN FLOW PIPE 12 - TURBOCHARGER VACUUM HOSE

Fig. 2 ENGINE COVER

1 - SCREW

2 - COVER

VAENGINE 9 - 5

ENGINE (Continued)

Page 744 of 1232

(15) Disconnect the coolant hose of the heater sup-

ply at the coolant pipe at the side of the cylinder

head (Fig. 3).

(16) Disconnect the vacuum hose at the turbo-

charger (Fig. 3).

(17) Disconnect the air inlet hose at the turbo-

charger (Fig. 3).

(18) Raise and support the vehicle.

(19) Disconnect the front exhaust at the turbo-

charger.

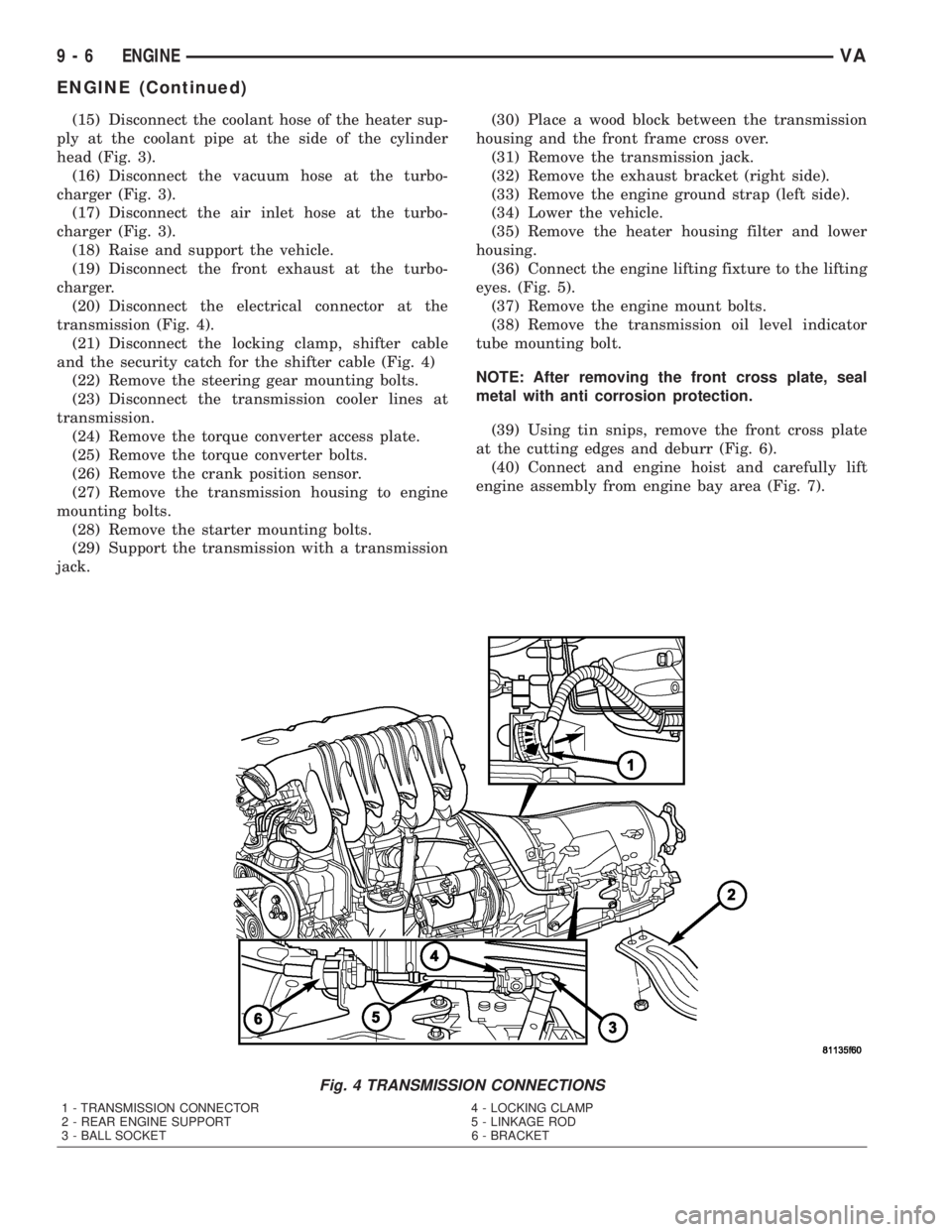

(20) Disconnect the electrical connector at the

transmission (Fig. 4).

(21) Disconnect the locking clamp, shifter cable

and the security catch for the shifter cable (Fig. 4)

(22) Remove the steering gear mounting bolts.

(23) Disconnect the transmission cooler lines at

transmission.

(24) Remove the torque converter access plate.

(25) Remove the torque converter bolts.

(26) Remove the crank position sensor.

(27) Remove the transmission housing to engine

mounting bolts.

(28) Remove the starter mounting bolts.

(29) Support the transmission with a transmission

jack.(30) Place a wood block between the transmission

housing and the front frame cross over.

(31) Remove the transmission jack.

(32) Remove the exhaust bracket (right side).

(33) Remove the engine ground strap (left side).

(34) Lower the vehicle.

(35) Remove the heater housing filter and lower

housing.

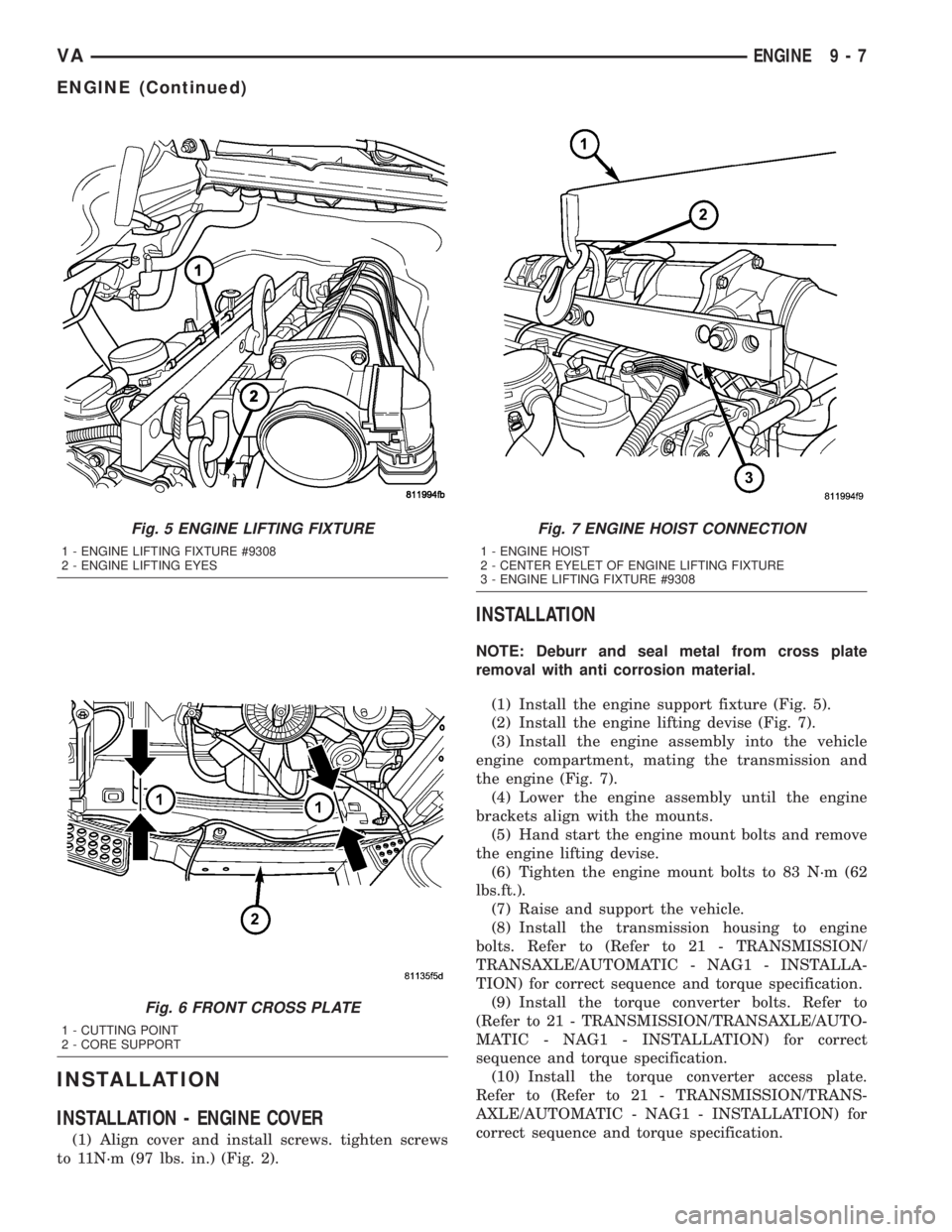

(36) Connect the engine lifting fixture to the lifting

eyes. (Fig. 5).

(37) Remove the engine mount bolts.

(38) Remove the transmission oil level indicator

tube mounting bolt.

NOTE: After removing the front cross plate, seal

metal with anti corrosion protection.

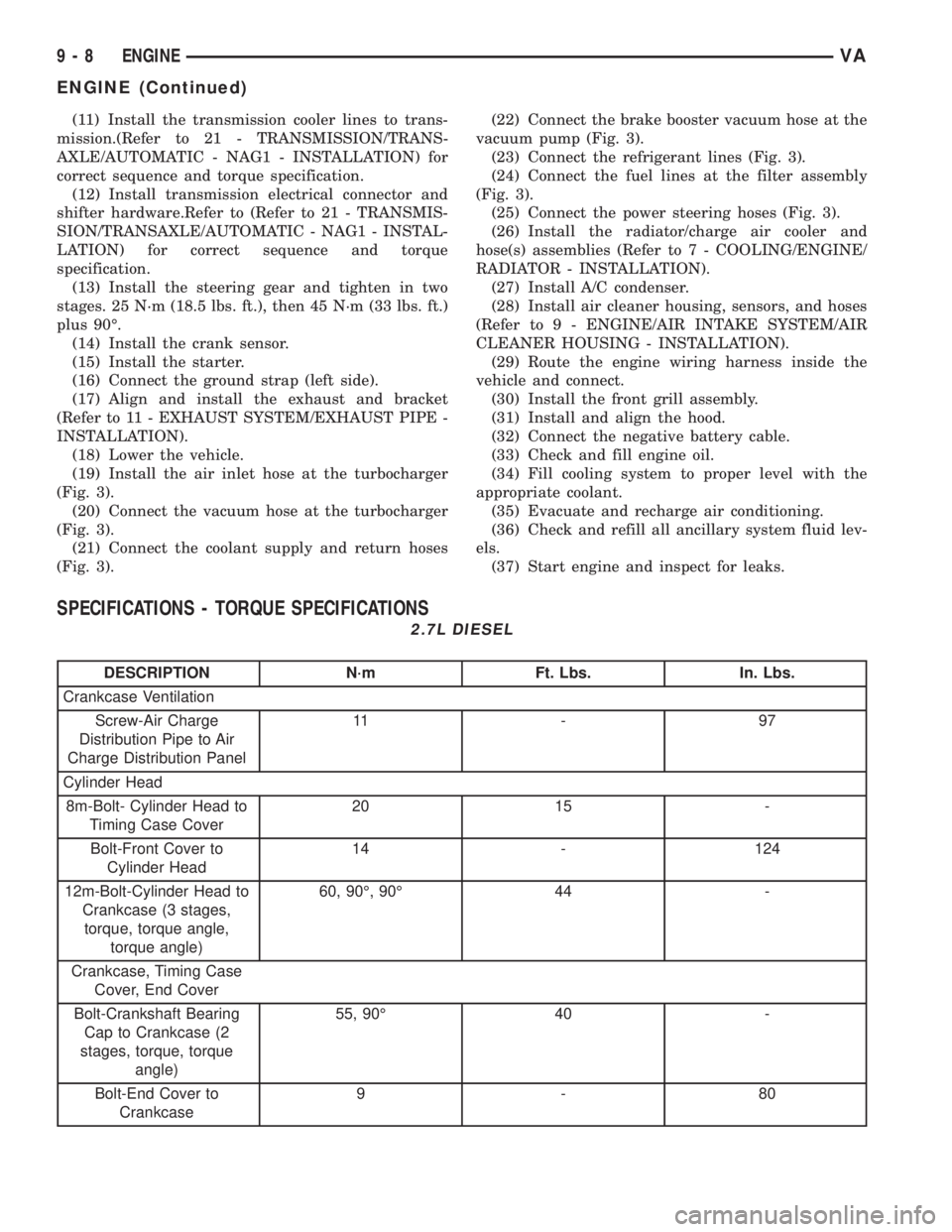

(39) Using tin snips, remove the front cross plate

at the cutting edges and deburr (Fig. 6).

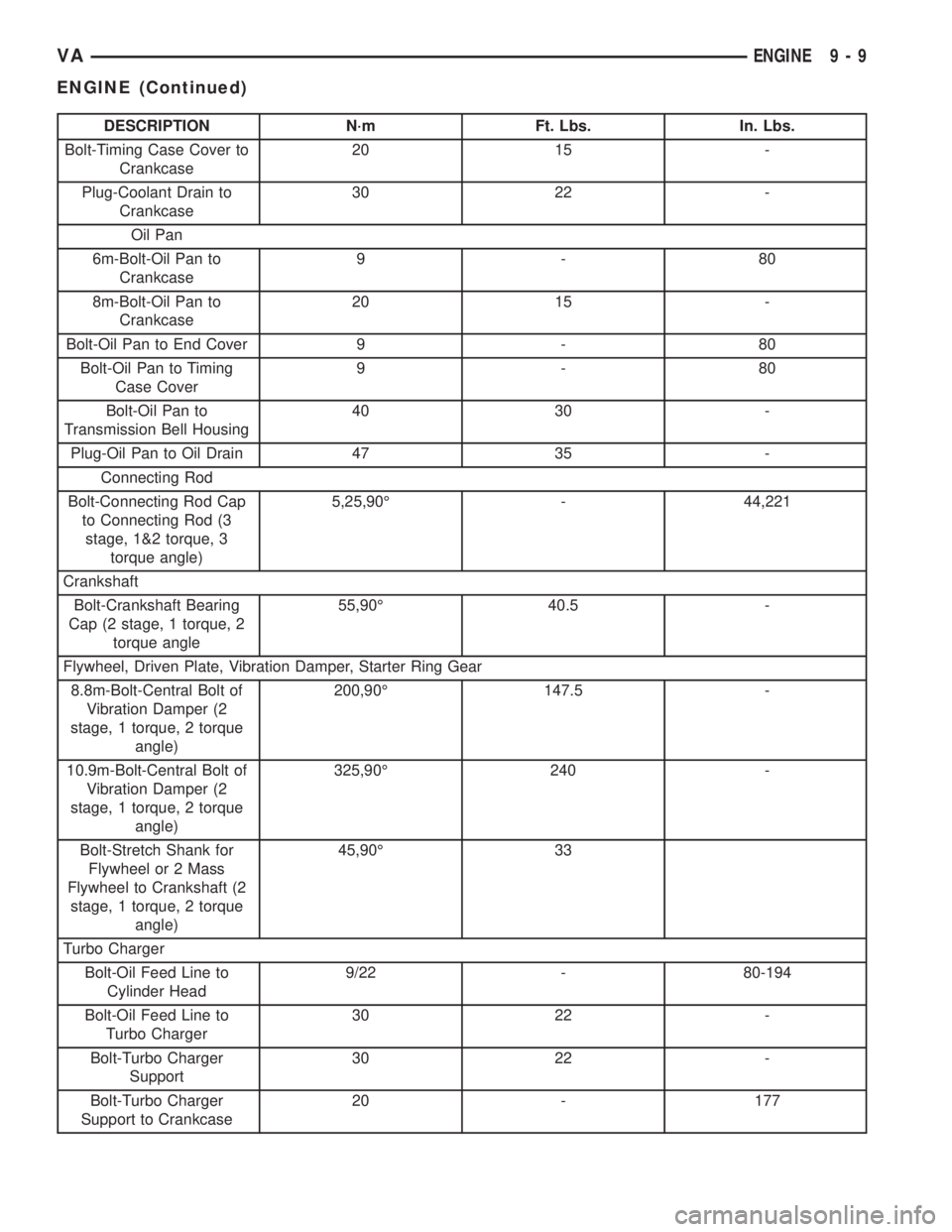

(40) Connect and engine hoist and carefully lift

engine assembly from engine bay area (Fig. 7).

Fig. 4 TRANSMISSION CONNECTIONS

1 - TRANSMISSION CONNECTOR 4 - LOCKING CLAMP

2 - REAR ENGINE SUPPORT 5 - LINKAGE ROD

3 - BALL SOCKET 6 - BRACKET

9 - 6 ENGINEVA

ENGINE (Continued)

Page 745 of 1232

INSTALLATION

INSTALLATION - ENGINE COVER

(1) Align cover and install screws. tighten screws

to 11N´m (97 lbs. in.) (Fig. 2).

INSTALLATION

NOTE: Deburr and seal metal from cross plate

removal with anti corrosion material.

(1) Install the engine support fixture (Fig. 5).

(2) Install the engine lifting devise (Fig. 7).

(3) Install the engine assembly into the vehicle

engine compartment, mating the transmission and

the engine (Fig. 7).

(4) Lower the engine assembly until the engine

brackets align with the mounts.

(5) Hand start the engine mount bolts and remove

the engine lifting devise.

(6) Tighten the engine mount bolts to 83 N´m (62

lbs.ft.).

(7) Raise and support the vehicle.

(8) Install the transmission housing to engine

bolts. Refer to (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - NAG1 - INSTALLA-

TION) for correct sequence and torque specification.

(9) Install the torque converter bolts. Refer to

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - NAG1 - INSTALLATION) for correct

sequence and torque specification.

(10) Install the torque converter access plate.

Refer to (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - NAG1 - INSTALLATION) for

correct sequence and torque specification.

Fig. 5 ENGINE LIFTING FIXTURE

1 - ENGINE LIFTING FIXTURE #9308

2 - ENGINE LIFTING EYES

Fig. 6 FRONT CROSS PLATE

1 - CUTTING POINT

2 - CORE SUPPORT

Fig. 7 ENGINE HOIST CONNECTION

1 - ENGINE HOIST

2 - CENTER EYELET OF ENGINE LIFTING FIXTURE

3 - ENGINE LIFTING FIXTURE #9308

VAENGINE 9 - 7

ENGINE (Continued)

Page 746 of 1232

(11) Install the transmission cooler lines to trans-

mission.(Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - NAG1 - INSTALLATION) for

correct sequence and torque specification.

(12) Install transmission electrical connector and

shifter hardware.Refer to (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - NAG1 - INSTAL-

LATION) for correct sequence and torque

specification.

(13) Install the steering gear and tighten in two

stages. 25 N´m (18.5 lbs. ft.), then 45 N´m (33 lbs. ft.)

plus 90É.

(14) Install the crank sensor.

(15) Install the starter.

(16) Connect the ground strap (left side).

(17) Align and install the exhaust and bracket

(Refer to 11 - EXHAUST SYSTEM/EXHAUST PIPE -

INSTALLATION).

(18) Lower the vehicle.

(19) Install the air inlet hose at the turbocharger

(Fig. 3).

(20) Connect the vacuum hose at the turbocharger

(Fig. 3).

(21) Connect the coolant supply and return hoses

(Fig. 3).(22) Connect the brake booster vacuum hose at the

vacuum pump (Fig. 3).

(23) Connect the refrigerant lines (Fig. 3).

(24) Connect the fuel lines at the filter assembly

(Fig. 3).

(25) Connect the power steering hoses (Fig. 3).

(26) Install the radiator/charge air cooler and

hose(s) assemblies (Refer to 7 - COOLING/ENGINE/

RADIATOR - INSTALLATION).

(27) Install A/C condenser.

(28) Install air cleaner housing, sensors, and hoses

(Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR

CLEANER HOUSING - INSTALLATION).

(29) Route the engine wiring harness inside the

vehicle and connect.

(30) Install the front grill assembly.

(31) Install and align the hood.

(32) Connect the negative battery cable.

(33) Check and fill engine oil.

(34) Fill cooling system to proper level with the

appropriate coolant.

(35) Evacuate and recharge air conditioning.

(36) Check and refill all ancillary system fluid lev-

els.

(37) Start engine and inspect for leaks.

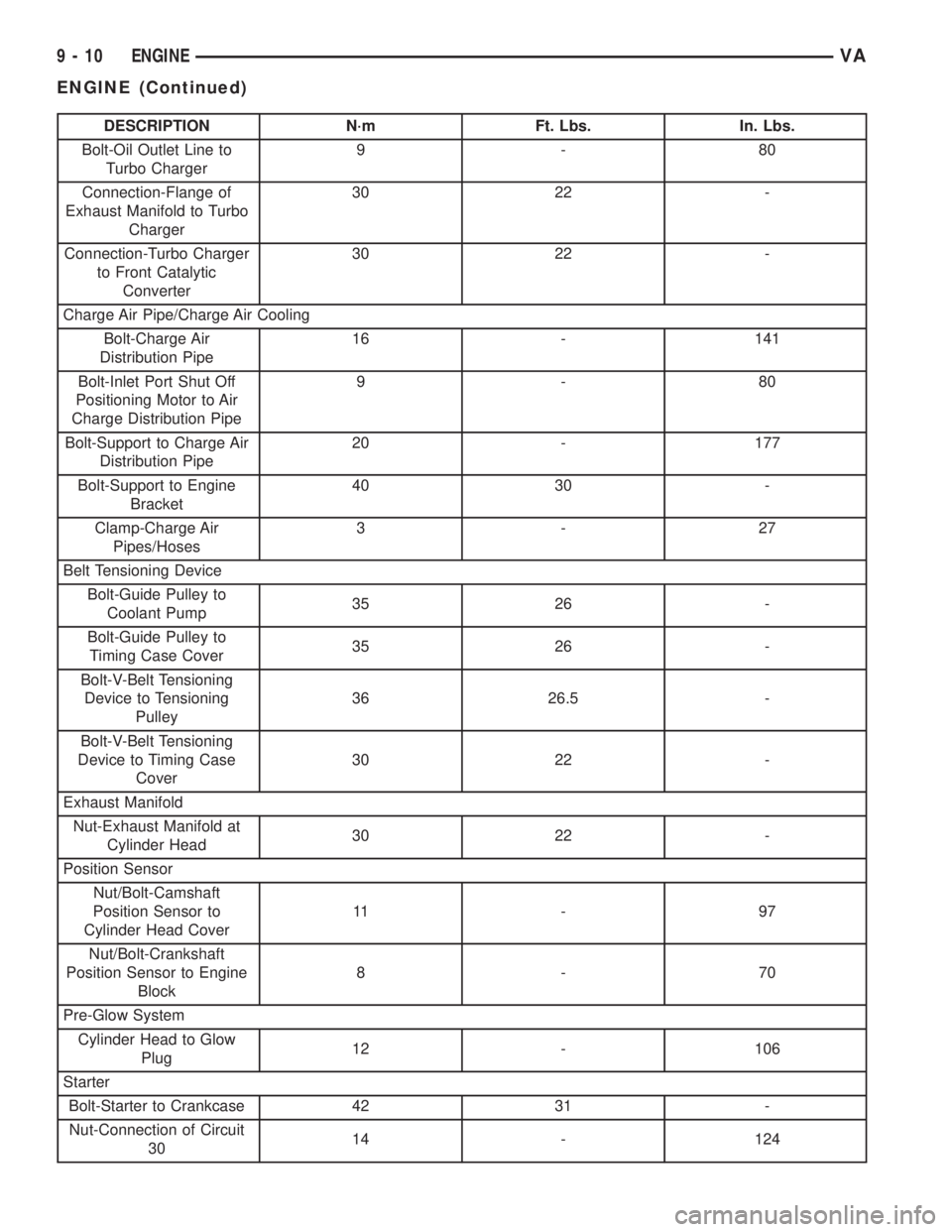

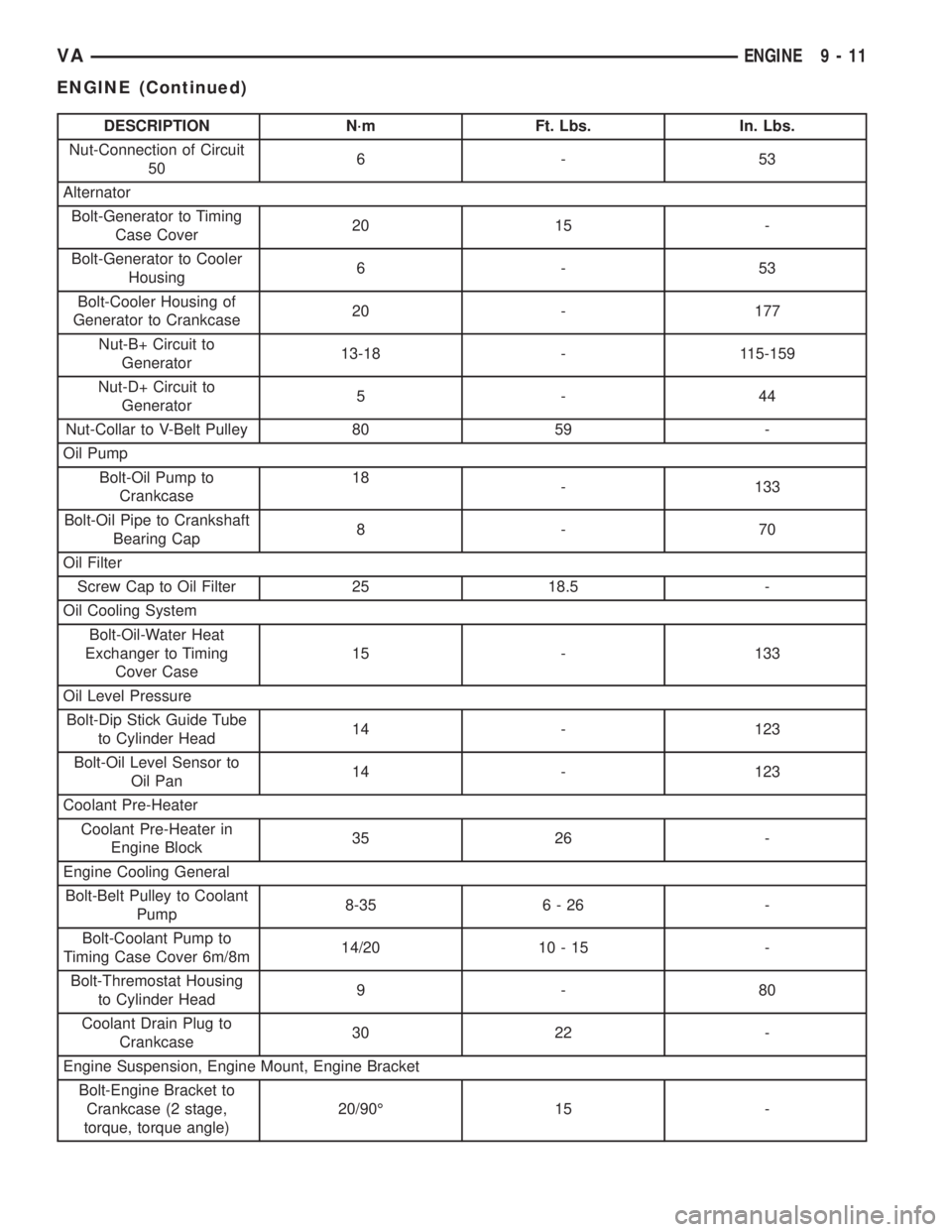

SPECIFICATIONS - TORQUE SPECIFICATIONS

2.7L DIESEL

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Crankcase Ventilation

Screw-Air Charge

Distribution Pipe to Air

Charge Distribution Panel11 - 9 7

Cylinder Head

8m-Bolt- Cylinder Head to

Timing Case Cover20 15 -

Bolt-Front Cover to

Cylinder Head14 - 124

12m-Bolt-Cylinder Head to

Crankcase (3 stages,

torque, torque angle,

torque angle)60, 90É, 90É 44 -

Crankcase, Timing Case

Cover, End Cover

Bolt-Crankshaft Bearing

Cap to Crankcase (2

stages, torque, torque

angle)55, 90É 40 -

Bolt-End Cover to

Crankcase9-80

9 - 8 ENGINEVA

ENGINE (Continued)

Page 747 of 1232

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt-Timing Case Cover to

Crankcase20 15 -

Plug-Coolant Drain to

Crankcase30 22 -

Oil Pan

6m-Bolt-Oil Pan to

Crankcase9-80

8m-Bolt-Oil Pan to

Crankcase20 15 -

Bolt-Oil Pan to End Cover 9 - 80

Bolt-Oil Pan to Timing

Case Cover9-80

Bolt-Oil Pan to

Transmission Bell Housing40 30 -

Plug-Oil Pan to Oil Drain 47 35 -

Connecting Rod

Bolt-Connecting Rod Cap

to Connecting Rod (3

stage, 1&2 torque, 3

torque angle)5,25,90É - 44,221

Crankshaft

Bolt-Crankshaft Bearing

Cap (2 stage, 1 torque, 2

torque angle55,90É 40.5 -

Flywheel, Driven Plate, Vibration Damper, Starter Ring Gear

8.8m-Bolt-Central Bolt of

Vibration Damper (2

stage, 1 torque, 2 torque

angle)200,90É 147.5 -

10.9m-Bolt-Central Bolt of

Vibration Damper (2

stage, 1 torque, 2 torque

angle)325,90É 240 -

Bolt-Stretch Shank for

Flywheel or 2 Mass

Flywheel to Crankshaft (2

stage, 1 torque, 2 torque

angle)45,90É 33

Turbo Charger

Bolt-Oil Feed Line to

Cylinder Head9/22 - 80-194

Bolt-Oil Feed Line to

Turbo Charger30 22 -

Bolt-Turbo Charger

Support30 22 -

Bolt-Turbo Charger

Support to Crankcase20 - 177

VAENGINE 9 - 9

ENGINE (Continued)

Page 748 of 1232

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt-Oil Outlet Line to

Turbo Charger9-80

Connection-Flange of

Exhaust Manifold to Turbo

Charger30 22 -

Connection-Turbo Charger

to Front Catalytic

Converter30 22 -

Charge Air Pipe/Charge Air Cooling

Bolt-Charge Air

Distribution Pipe16 - 141

Bolt-Inlet Port Shut Off

Positioning Motor to Air

Charge Distribution Pipe9-80

Bolt-Support to Charge Air

Distribution Pipe20 - 177

Bolt-Support to Engine

Bracket40 30 -

Clamp-Charge Air

Pipes/Hoses3-27

Belt Tensioning Device

Bolt-Guide Pulley to

Coolant Pump35 26 -

Bolt-Guide Pulley to

Timing Case Cover35 26 -

Bolt-V-Belt Tensioning

Device to Tensioning

Pulley36 26.5 -

Bolt-V-Belt Tensioning

Device to Timing Case

Cover30 22 -

Exhaust Manifold

Nut-Exhaust Manifold at

Cylinder Head30 22 -

Position Sensor

Nut/Bolt-Camshaft

Position Sensor to

Cylinder Head Cover11 - 9 7

Nut/Bolt-Crankshaft

Position Sensor to Engine

Block8-70

Pre-Glow System

Cylinder Head to Glow

Plug12 - 106

Starter

Bolt-Starter to Crankcase 42 31 -

Nut-Connection of Circuit

3014 - 124

9 - 10 ENGINEVA

ENGINE (Continued)

Page 749 of 1232

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Nut-Connection of Circuit

506-53

Alternator

Bolt-Generator to Timing

Case Cover20 15 -

Bolt-Generator to Cooler

Housing6-53

Bolt-Cooler Housing of

Generator to Crankcase20 - 177

Nut-B+ Circuit to

Generator13-18 - 115-159

Nut-D+ Circuit to

Generator5-44

Nut-Collar to V-Belt Pulley 80 59 -

Oil Pump

Bolt-Oil Pump to

Crankcase18

- 133

Bolt-Oil Pipe to Crankshaft

Bearing Cap8-70

Oil Filter

Screw Cap to Oil Filter 25 18.5 -

Oil Cooling System

Bolt-Oil-Water Heat

Exchanger to Timing

Cover Case15 - 133

Oil Level Pressure

Bolt-Dip Stick Guide Tube

to Cylinder Head14 - 123

Bolt-Oil Level Sensor to

Oil Pan14 - 123

Coolant Pre-Heater

Coolant Pre-Heater in

Engine Block35 26 -

Engine Cooling General

Bolt-Belt Pulley to Coolant

Pump8-35 6 - 26 -

Bolt-Coolant Pump to

Timing Case Cover 6m/8m14/20 10 - 15 -

Bolt-Thremostat Housing

to Cylinder Head9-80

Coolant Drain Plug to

Crankcase30 22 -

Engine Suspension, Engine Mount, Engine Bracket

Bolt-Engine Bracket to

Crankcase (2 stage,

torque, torque angle)20/90É 15 -

VAENGINE 9 - 11

ENGINE (Continued)

Page 750 of 1232

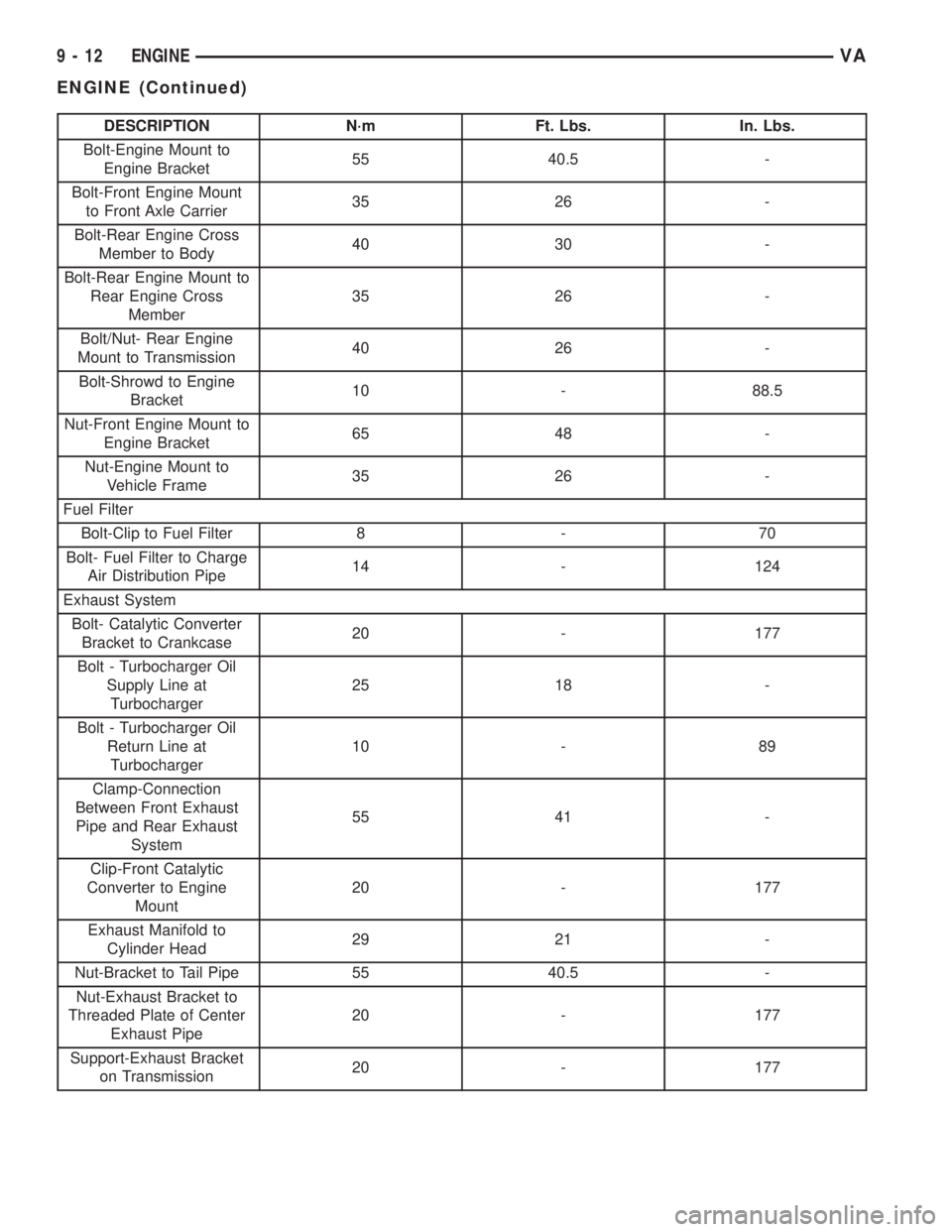

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt-Engine Mount to

Engine Bracket55 40.5 -

Bolt-Front Engine Mount

to Front Axle Carrier35 26 -

Bolt-Rear Engine Cross

Member to Body40 30 -

Bolt-Rear Engine Mount to

Rear Engine Cross

Member35 26 -

Bolt/Nut- Rear Engine

Mount to Transmission40 26 -

Bolt-Shrowd to Engine

Bracket10 - 88.5

Nut-Front Engine Mount to

Engine Bracket65 48 -

Nut-Engine Mount to

Vehicle Frame35 26 -

Fuel Filter

Bolt-Clip to Fuel Filter 8 - 70

Bolt- Fuel Filter to Charge

Air Distribution Pipe14 - 124

Exhaust System

Bolt- Catalytic Converter

Bracket to Crankcase20 - 177

Bolt - Turbocharger Oil

Supply Line at

Turbocharger25 18 -

Bolt - Turbocharger Oil

Return Line at

Turbocharger10 - 89

Clamp-Connection

Between Front Exhaust

Pipe and Rear Exhaust

System55 41 -

Clip-Front Catalytic

Converter to Engine

Mount20 - 177

Exhaust Manifold to

Cylinder Head29 21 -

Nut-Bracket to Tail Pipe 55 40.5 -

Nut-Exhaust Bracket to

Threaded Plate of Center

Exhaust Pipe20 - 177

Support-Exhaust Bracket

on Transmission20 - 177

9 - 12 ENGINEVA

ENGINE (Continued)