MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 771 of 1232

(10) Position piston of #1 cylinder to ignition TDC.

(11) Install camshafts and check basic position

(Refer to 9 - ENGINE/CYLINDER HEAD/CAM-

SHAFT(S) - INSTALLATION).

(12) Install top guide rail (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(13) Install front cover at cylinder head (Refer to 9

- ENGINE/CYLINDER HEAD - INSTALLATION).

(14) Install timing chain tensioner with new gas-

ket (Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLATION)

(15) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(16) Install glow plugs (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/GLOW PLUG - INSTALLA-

TION).

WARNING: SERVICE VEHICLES IN A WELL VENTI-

LATED AREA AND AVOID IGNITION SORCES. RISK

OF INJURY TO SKIN AND EYES FROM FUEL JET

FLOWING OUT.

(17) Install injectors (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(18) Reconnect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN ADIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(19) Start the engine and inspect for leaks.Care

must be taken to observe the fuel system warning

(Refer to 14 - FUEL SYSTEM - WARNING)

(20) Install engine cover (Refer to 9 - ENGINE

COVER - INSTALLATION).

INSTALLATION - VALVES

WARNING: Valves must be kept in their original

positions in cylinder head. Failure to do so will

result in engine damage.

NOTE: Inspect all valves, springs and retainers for

wear or damage. Replace as necessary.

(1) Install valves in their original position in the

cylinder head.

(2) Install lower valve spring retainer.

(3) Install valve stem seal.

(4) Install valve spring.

(5) Install valve spring retainer.

NOTE: Using tool, screw retaining fork into

threaded edge of cylinder head and position thrust

piece vertically at the top of each valve spring

retainer.

NOTE: Ensure that the valve keepers are seated

properly.

(6) Using a suitable valve spring compressor, com-

press valve spring and install valve keepers.

(7) Repeat steps 3 through 7 for each valve as nec-

essary.

(8) Remove valve assembly from cylinder head.

(9) Install cylinder head on engine block (Refer to

9 - ENGINE/CYLINDER HEAD - INSTALLATION).

(10) Install glow plugs (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/GLOW PLUG - INSTALLA-

TION).

(11) Connect negative battery cable.

WARNING: US EXTREME CAUTION WHEN THE

ENGINE IS IN OPERATION. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(12) Start engine and check for leaks. Care must

be taken to observe the fuel system warning (Refer to

14 - FUEL SYSTEM - WARNING)

(13) Install engine cover (Refer to 9 - ENGINE

COVER - INSTALLATION).

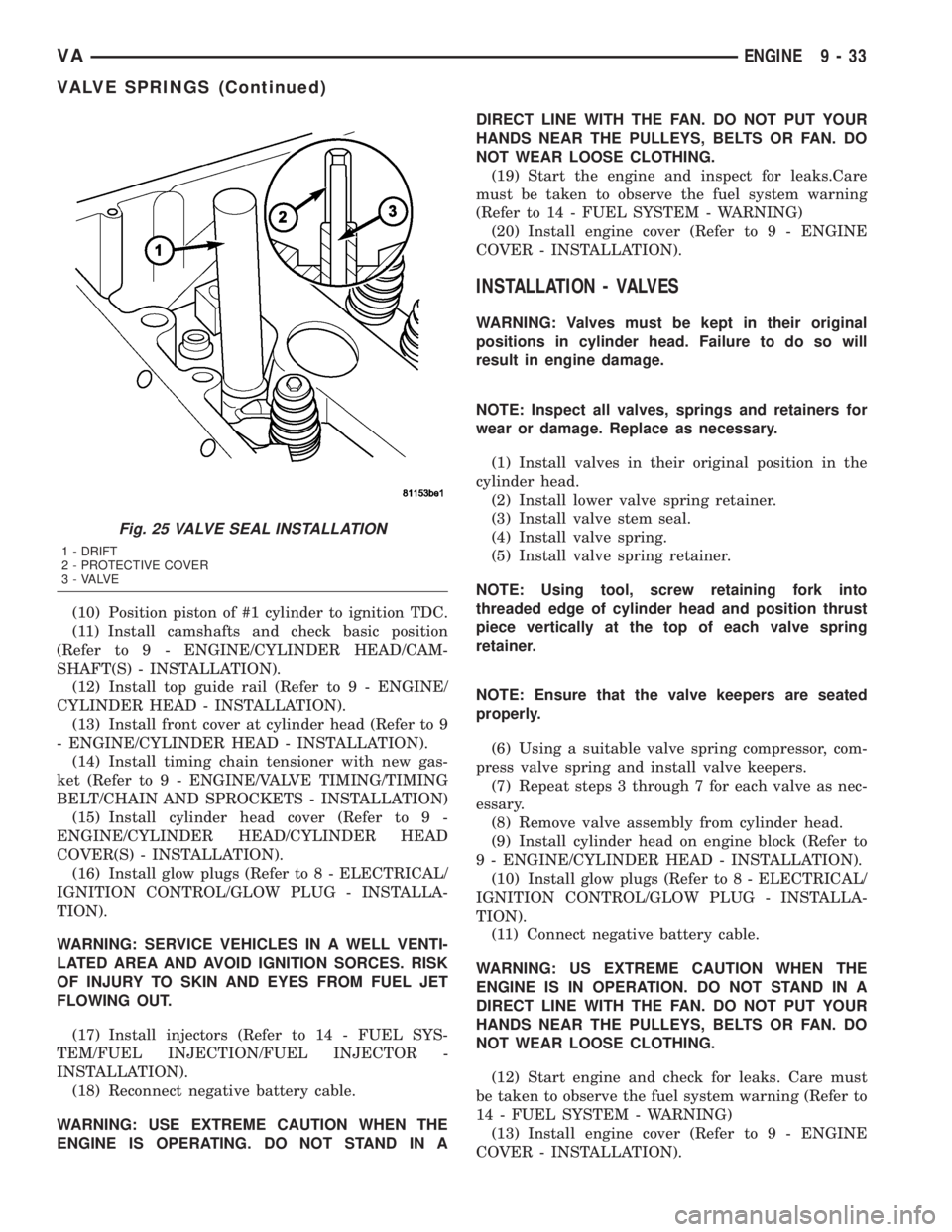

Fig. 25 VALVE SEAL INSTALLATION

1 - DRIFT

2 - PROTECTIVE COVER

3 - VALVE

VAENGINE 9 - 33

VALVE SPRINGS (Continued)

Page 772 of 1232

ENGINE BLOCK

STANDARD PROCEDURE

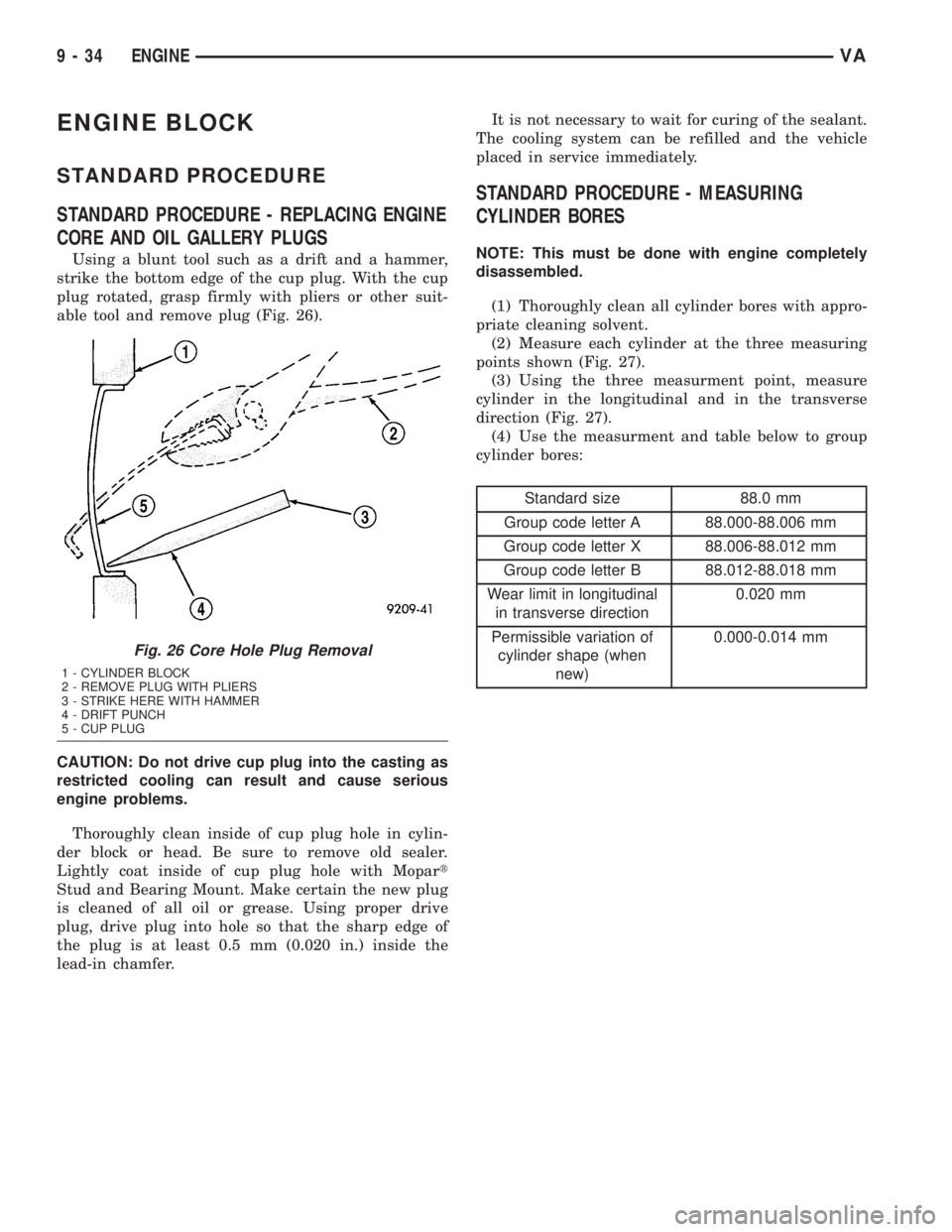

STANDARD PROCEDURE - REPLACING ENGINE

CORE AND OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 26).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

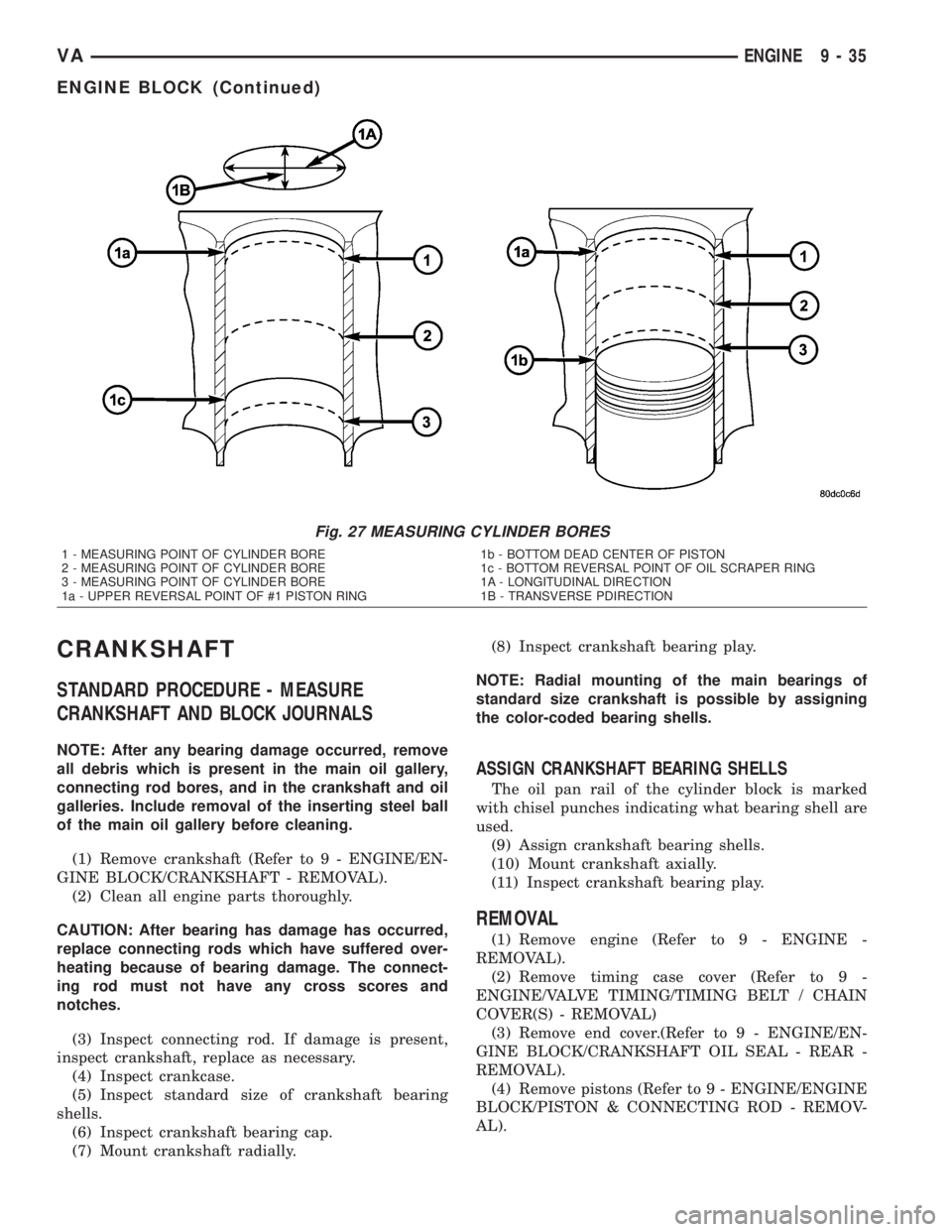

STANDARD PROCEDURE - MEASURING

CYLINDER BORES

NOTE: This must be done with engine completely

disassembled.

(1) Thoroughly clean all cylinder bores with appro-

priate cleaning solvent.

(2) Measure each cylinder at the three measuring

points shown (Fig. 27).

(3) Using the three measurment point, measure

cylinder in the longitudinal and in the transverse

direction (Fig. 27).

(4) Use the measurment and table below to group

cylinder bores:

Standard size 88.0 mm

Group code letter A 88.000-88.006 mm

Group code letter X 88.006-88.012 mm

Group code letter B 88.012-88.018 mm

Wear limit in longitudinal

in transverse direction0.020 mm

Permissible variation of

cylinder shape (when

new)0.000-0.014 mm

Fig. 26 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

9 - 34 ENGINEVA

Page 773 of 1232

CRANKSHAFT

STANDARD PROCEDURE - MEASURE

CRANKSHAFT AND BLOCK JOURNALS

NOTE: After any bearing damage occurred, remove

all debris which is present in the main oil gallery,

connecting rod bores, and in the crankshaft and oil

galleries. Include removal of the inserting steel ball

of the main oil gallery before cleaning.

(1) Remove crankshaft (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT - REMOVAL).

(2) Clean all engine parts thoroughly.

CAUTION: After bearing has damage has occurred,

replace connecting rods which have suffered over-

heating because of bearing damage. The connect-

ing rod must not have any cross scores and

notches.

(3) Inspect connecting rod. If damage is present,

inspect crankshaft, replace as necessary.

(4) Inspect crankcase.

(5) Inspect standard size of crankshaft bearing

shells.

(6) Inspect crankshaft bearing cap.

(7) Mount crankshaft radially.(8) Inspect crankshaft bearing play.

NOTE: Radial mounting of the main bearings of

standard size crankshaft is possible by assigning

the color-coded bearing shells.

ASSIGN CRANKSHAFT BEARING SHELLS

The oil pan rail of the cylinder block is marked

with chisel punches indicating what bearing shell are

used.

(9) Assign crankshaft bearing shells.

(10) Mount crankshaft axially.

(11) Inspect crankshaft bearing play.

REMOVAL

(1) Remove engine (Refer to 9 - ENGINE -

REMOVAL).

(2) Remove timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(3) Remove end cover.(Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR -

REMOVAL).

(4) Remove pistons (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON & CONNECTING ROD - REMOV-

AL).

Fig. 27 MEASURING CYLINDER BORES

1 - MEASURING POINT OF CYLINDER BORE

2 - MEASURING POINT OF CYLINDER BORE

3 - MEASURING POINT OF CYLINDER BORE

1a - UPPER REVERSAL POINT OF #1 PISTON RING1b - BOTTOM DEAD CENTER OF PISTON

1c - BOTTOM REVERSAL POINT OF OIL SCRAPER RING

1A - LONGITUDINAL DIRECTION

1B - TRANSVERSE PDIRECTION

VAENGINE 9 - 35

ENGINE BLOCK (Continued)

Page 774 of 1232

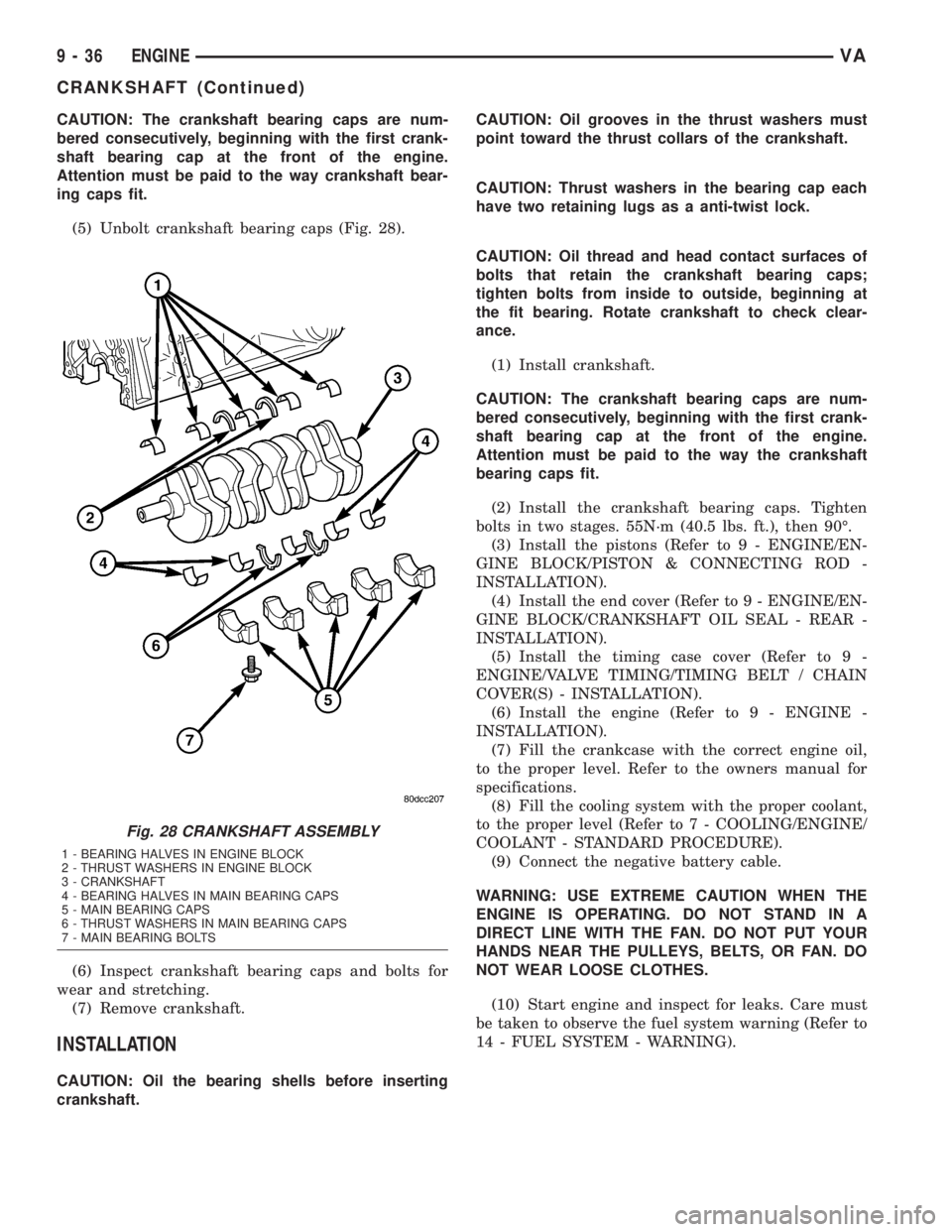

CAUTION: The crankshaft bearing caps are num-

bered consecutively, beginning with the first crank-

shaft bearing cap at the front of the engine.

Attention must be paid to the way crankshaft bear-

ing caps fit.

(5) Unbolt crankshaft bearing caps (Fig. 28).

(6) Inspect crankshaft bearing caps and bolts for

wear and stretching.

(7) Remove crankshaft.

INSTALLATION

CAUTION: Oil the bearing shells before inserting

crankshaft.CAUTION: Oil grooves in the thrust washers must

point toward the thrust collars of the crankshaft.

CAUTION: Thrust washers in the bearing cap each

have two retaining lugs as a anti-twist lock.

CAUTION: Oil thread and head contact surfaces of

bolts that retain the crankshaft bearing caps;

tighten bolts from inside to outside, beginning at

the fit bearing. Rotate crankshaft to check clear-

ance.

(1) Install crankshaft.

CAUTION: The crankshaft bearing caps are num-

bered consecutively, beginning with the first crank-

shaft bearing cap at the front of the engine.

Attention must be paid to the way the crankshaft

bearing caps fit.

(2) Install the crankshaft bearing caps. Tighten

bolts in two stages. 55N´m (40.5 lbs. ft.), then 90É.

(3) Install the pistons (Refer to 9 - ENGINE/EN-

GINE BLOCK/PISTON & CONNECTING ROD -

INSTALLATION).

(4) Install the end cover (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR -

INSTALLATION).

(5) Install the timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(6) Install the engine (Refer to 9 - ENGINE -

INSTALLATION).

(7) Fill the crankcase with the correct engine oil,

to the proper level. Refer to the owners manual for

specifications.

(8) Fill the cooling system with the proper coolant,

to the proper level (Refer to 7 - COOLING/ENGINE/

COOLANT - STANDARD PROCEDURE).

(9) Connect the negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(10) Start engine and inspect for leaks. Care must

be taken to observe the fuel system warning (Refer to

14 - FUEL SYSTEM - WARNING).

Fig. 28 CRANKSHAFT ASSEMBLY

1 - BEARING HALVES IN ENGINE BLOCK

2 - THRUST WASHERS IN ENGINE BLOCK

3 - CRANKSHAFT

4 - BEARING HALVES IN MAIN BEARING CAPS

5 - MAIN BEARING CAPS

6 - THRUST WASHERS IN MAIN BEARING CAPS

7 - MAIN BEARING BOLTS

9 - 36 ENGINEVA

CRANKSHAFT (Continued)

Page 775 of 1232

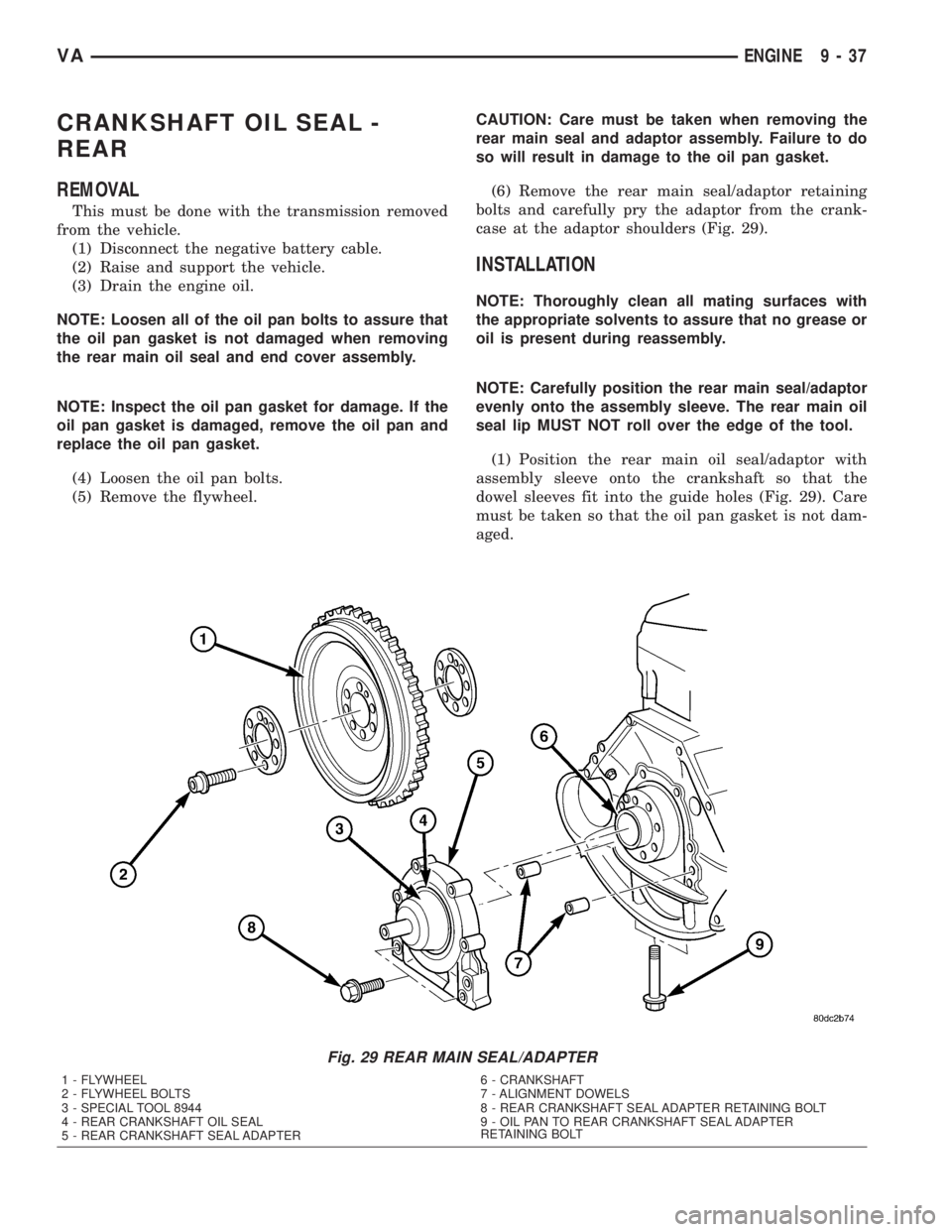

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

This must be done with the transmission removed

from the vehicle.

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Drain the engine oil.

NOTE: Loosen all of the oil pan bolts to assure that

the oil pan gasket is not damaged when removing

the rear main oil seal and end cover assembly.

NOTE: Inspect the oil pan gasket for damage. If the

oil pan gasket is damaged, remove the oil pan and

replace the oil pan gasket.

(4) Loosen the oil pan bolts.

(5) Remove the flywheel.CAUTION: Care must be taken when removing the

rear main seal and adaptor assembly. Failure to do

so will result in damage to the oil pan gasket.

(6) Remove the rear main seal/adaptor retaining

bolts and carefully pry the adaptor from the crank-

case at the adaptor shoulders (Fig. 29).

INSTALLATION

NOTE: Thoroughly clean all mating surfaces with

the appropriate solvents to assure that no grease or

oil is present during reassembly.

NOTE: Carefully position the rear main seal/adaptor

evenly onto the assembly sleeve. The rear main oil

seal lip MUST NOT roll over the edge of the tool.

(1) Position the rear main oil seal/adaptor with

assembly sleeve onto the crankshaft so that the

dowel sleeves fit into the guide holes (Fig. 29). Care

must be taken so that the oil pan gasket is not dam-

aged.

Fig. 29 REAR MAIN SEAL/ADAPTER

1 - FLYWHEEL

2 - FLYWHEEL BOLTS

3 - SPECIAL TOOL 8944

4 - REAR CRANKSHAFT OIL SEAL

5 - REAR CRANKSHAFT SEAL ADAPTER6 - CRANKSHAFT

7 - ALIGNMENT DOWELS

8 - REAR CRANKSHAFT SEAL ADAPTER RETAINING BOLT

9 - OIL PAN TO REAR CRANKSHAFT SEAL ADAPTER

RETAINING BOLT

VAENGINE 9 - 37

Page 776 of 1232

(2) Install the rear main seal/adaptor to crankcase

bolts and tighten to 9´Nm (80 lbs.in) (Fig. 29).

(3) Tighten the M6 oil pan bolts to 9N´m (80 lbs

in) and the M8 bolts to 20 N´m (15 lbs ft).

(4) Install the fly wheel and tighten bolts in two

stages (Fig. 29). 45N´m (33 lbs. ft.) then 90É.

(5) Install the oil pan drain plug and tighten to

25N´m (18 lbs ft).

(6) Lower the vehicle.

(7) Fill the crankcase with the correct engine oil,

to the proper level. Refer to owners manual for spec-

ifications.

(8) Connect the negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(9) Start the engine and inspect for leaks.

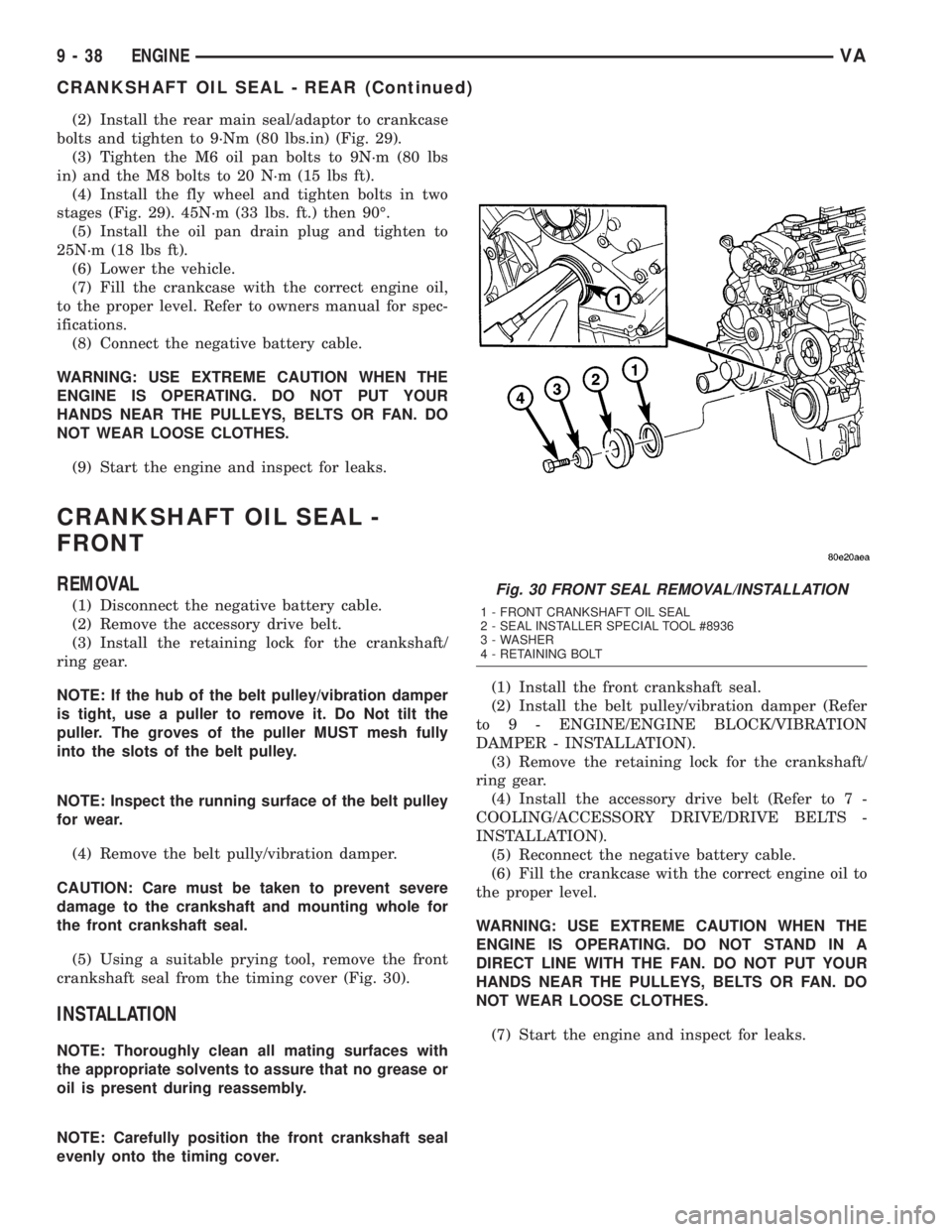

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the accessory drive belt.

(3) Install the retaining lock for the crankshaft/

ring gear.

NOTE: If the hub of the belt pulley/vibration damper

is tight, use a puller to remove it. Do Not tilt the

puller. The groves of the puller MUST mesh fully

into the slots of the belt pulley.

NOTE: Inspect the running surface of the belt pulley

for wear.

(4) Remove the belt pully/vibration damper.

CAUTION: Care must be taken to prevent severe

damage to the crankshaft and mounting whole for

the front crankshaft seal.

(5) Using a suitable prying tool, remove the front

crankshaft seal from the timing cover (Fig. 30).

INSTALLATION

NOTE: Thoroughly clean all mating surfaces with

the appropriate solvents to assure that no grease or

oil is present during reassembly.

NOTE: Carefully position the front crankshaft seal

evenly onto the timing cover.(1) Install the front crankshaft seal.

(2) Install the belt pulley/vibration damper (Refer

to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(3) Remove the retaining lock for the crankshaft/

ring gear.

(4) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(5) Reconnect the negative battery cable.

(6) Fill the crankcase with the correct engine oil to

the proper level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(7) Start the engine and inspect for leaks.

Fig. 30 FRONT SEAL REMOVAL/INSTALLATION

1 - FRONT CRANKSHAFT OIL SEAL

2 - SEAL INSTALLER SPECIAL TOOL #8936

3 - WASHER

4 - RETAINING BOLT

9 - 38 ENGINEVA

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 777 of 1232

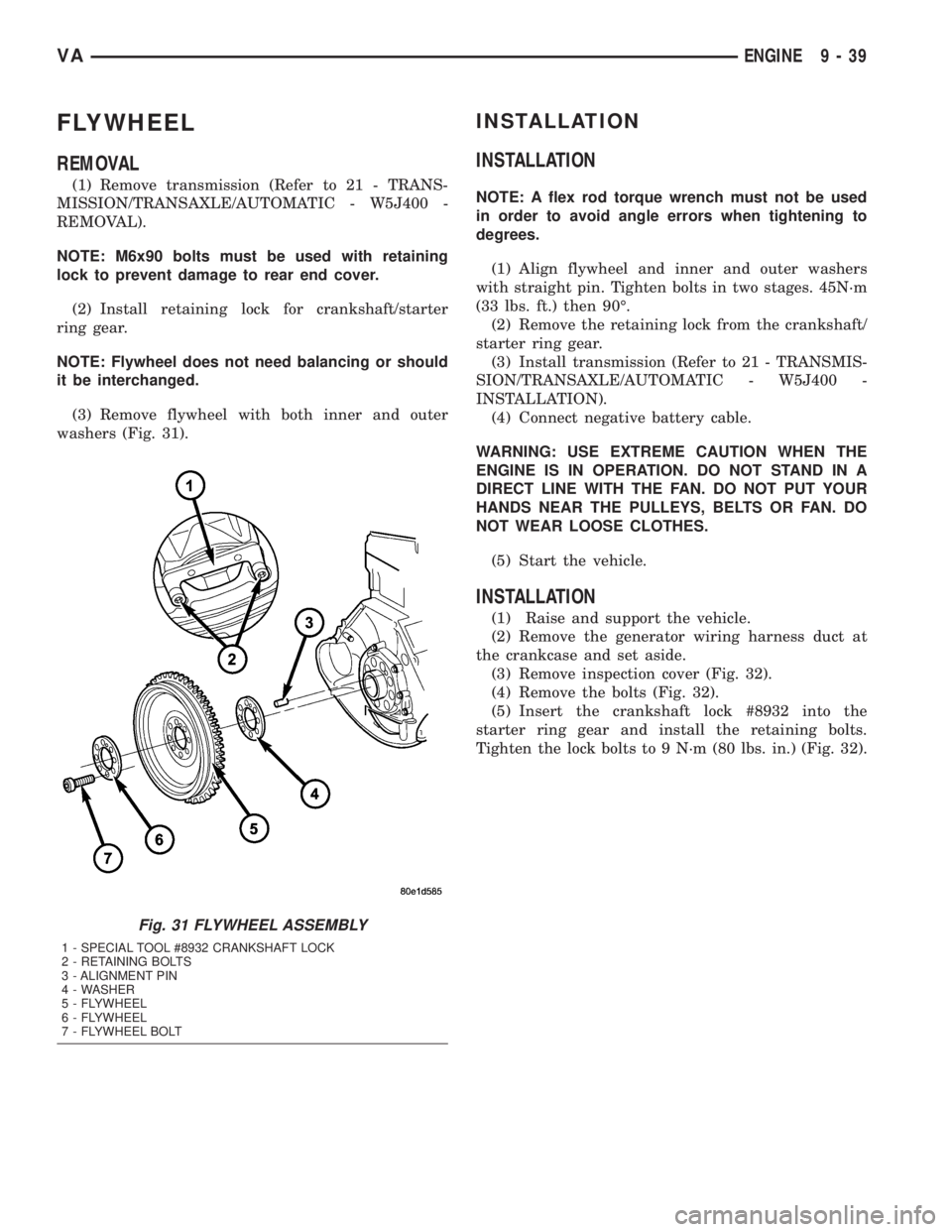

FLYWHEEL

REMOVAL

(1) Remove transmission (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - W5J400 -

REMOVAL).

NOTE: M6x90 bolts must be used with retaining

lock to prevent damage to rear end cover.

(2) Install retaining lock for crankshaft/starter

ring gear.

NOTE: Flywheel does not need balancing or should

it be interchanged.

(3) Remove flywheel with both inner and outer

washers (Fig. 31).

INSTALLATION

INSTALLATION

NOTE: A flex rod torque wrench must not be used

in order to avoid angle errors when tightening to

degrees.

(1) Align flywheel and inner and outer washers

with straight pin. Tighten bolts in two stages. 45N´m

(33 lbs. ft.) then 90É.

(2) Remove the retaining lock from the crankshaft/

starter ring gear.

(3) Install transmission (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - W5J400 -

INSTALLATION).

(4) Connect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS IN OPERATION. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(5) Start the vehicle.

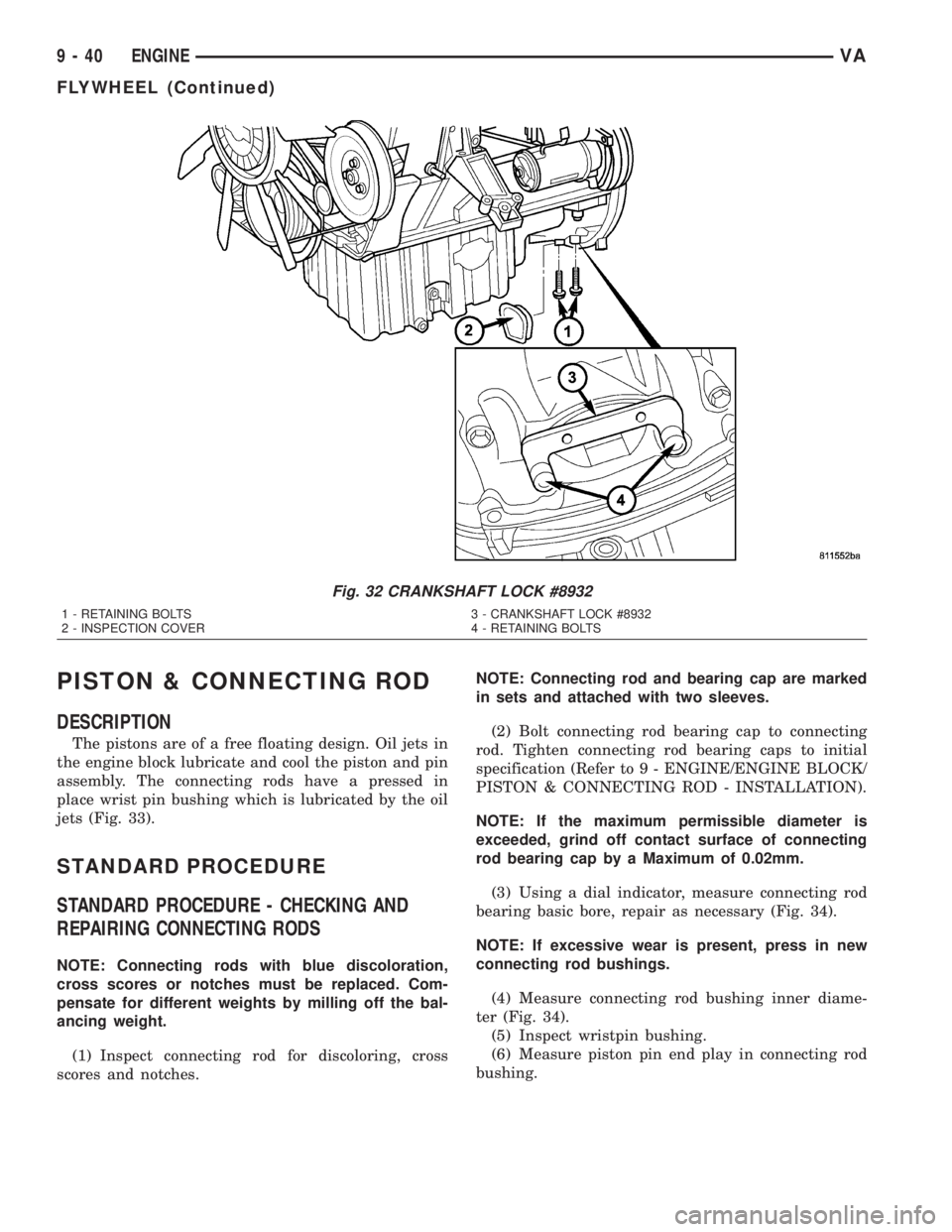

INSTALLATION

(1) Raise and support the vehicle.

(2) Remove the generator wiring harness duct at

the crankcase and set aside.

(3) Remove inspection cover (Fig. 32).

(4) Remove the bolts (Fig. 32).

(5) Insert the crankshaft lock #8932 into the

starter ring gear and install the retaining bolts.

Tighten the lock bolts to 9 N´m (80 lbs. in.) (Fig. 32).

Fig. 31 FLYWHEEL ASSEMBLY

1 - SPECIAL TOOL #8932 CRANKSHAFT LOCK

2 - RETAINING BOLTS

3 - ALIGNMENT PIN

4 - WASHER

5 - FLYWHEEL

6 - FLYWHEEL

7 - FLYWHEEL BOLT

VAENGINE 9 - 39

Page 778 of 1232

PISTON & CONNECTING ROD

DESCRIPTION

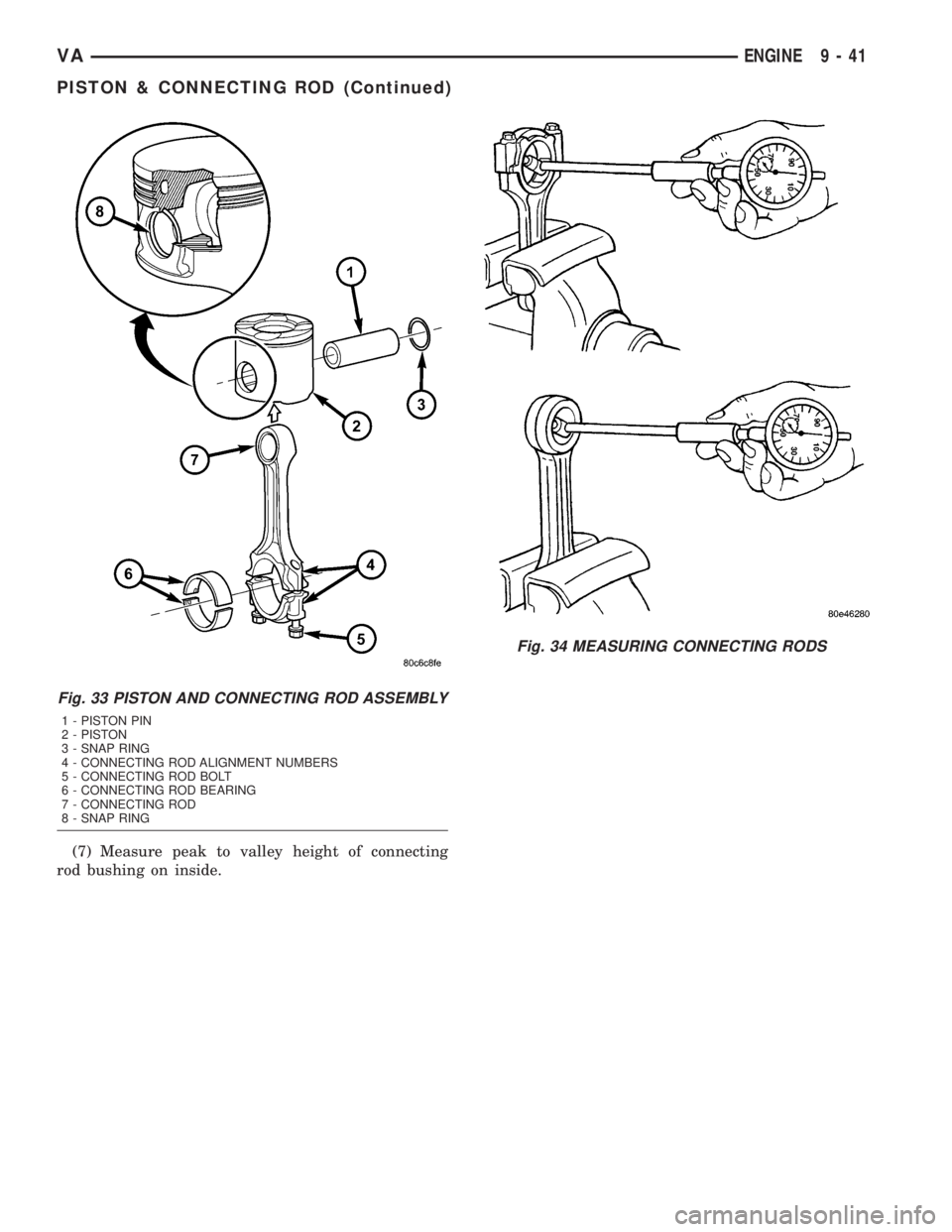

The pistons are of a free floating design. Oil jets in

the engine block lubricate and cool the piston and pin

assembly. The connecting rods have a pressed in

place wrist pin bushing which is lubricated by the oil

jets (Fig. 33).

STANDARD PROCEDURE

STANDARD PROCEDURE - CHECKING AND

REPAIRING CONNECTING RODS

NOTE: Connecting rods with blue discoloration,

cross scores or notches must be replaced. Com-

pensate for different weights by milling off the bal-

ancing weight.

(1) Inspect connecting rod for discoloring, cross

scores and notches.NOTE: Connecting rod and bearing cap are marked

in sets and attached with two sleeves.

(2) Bolt connecting rod bearing cap to connecting

rod. Tighten connecting rod bearing caps to initial

specification (Refer to 9 - ENGINE/ENGINE BLOCK/

PISTON & CONNECTING ROD - INSTALLATION).

NOTE: If the maximum permissible diameter is

exceeded, grind off contact surface of connecting

rod bearing cap by a Maximum of 0.02mm.

(3) Using a dial indicator, measure connecting rod

bearing basic bore, repair as necessary (Fig. 34).

NOTE: If excessive wear is present, press in new

connecting rod bushings.

(4) Measure connecting rod bushing inner diame-

ter (Fig. 34).

(5) Inspect wristpin bushing.

(6) Measure piston pin end play in connecting rod

bushing.

Fig. 32 CRANKSHAFT LOCK #8932

1 - RETAINING BOLTS 3 - CRANKSHAFT LOCK #8932

2 - INSPECTION COVER 4 - RETAINING BOLTS

9 - 40 ENGINEVA

FLYWHEEL (Continued)

Page 779 of 1232

(7) Measure peak to valley height of connecting

rod bushing on inside.

Fig. 33 PISTON AND CONNECTING ROD ASSEMBLY

1 - PISTON PIN

2 - PISTON

3 - SNAP RING

4 - CONNECTING ROD ALIGNMENT NUMBERS

5 - CONNECTING ROD BOLT

6 - CONNECTING ROD BEARING

7 - CONNECTING ROD

8 - SNAP RING

Fig. 34 MEASURING CONNECTING RODS

VAENGINE 9 - 41

PISTON & CONNECTING ROD (Continued)

Page 780 of 1232

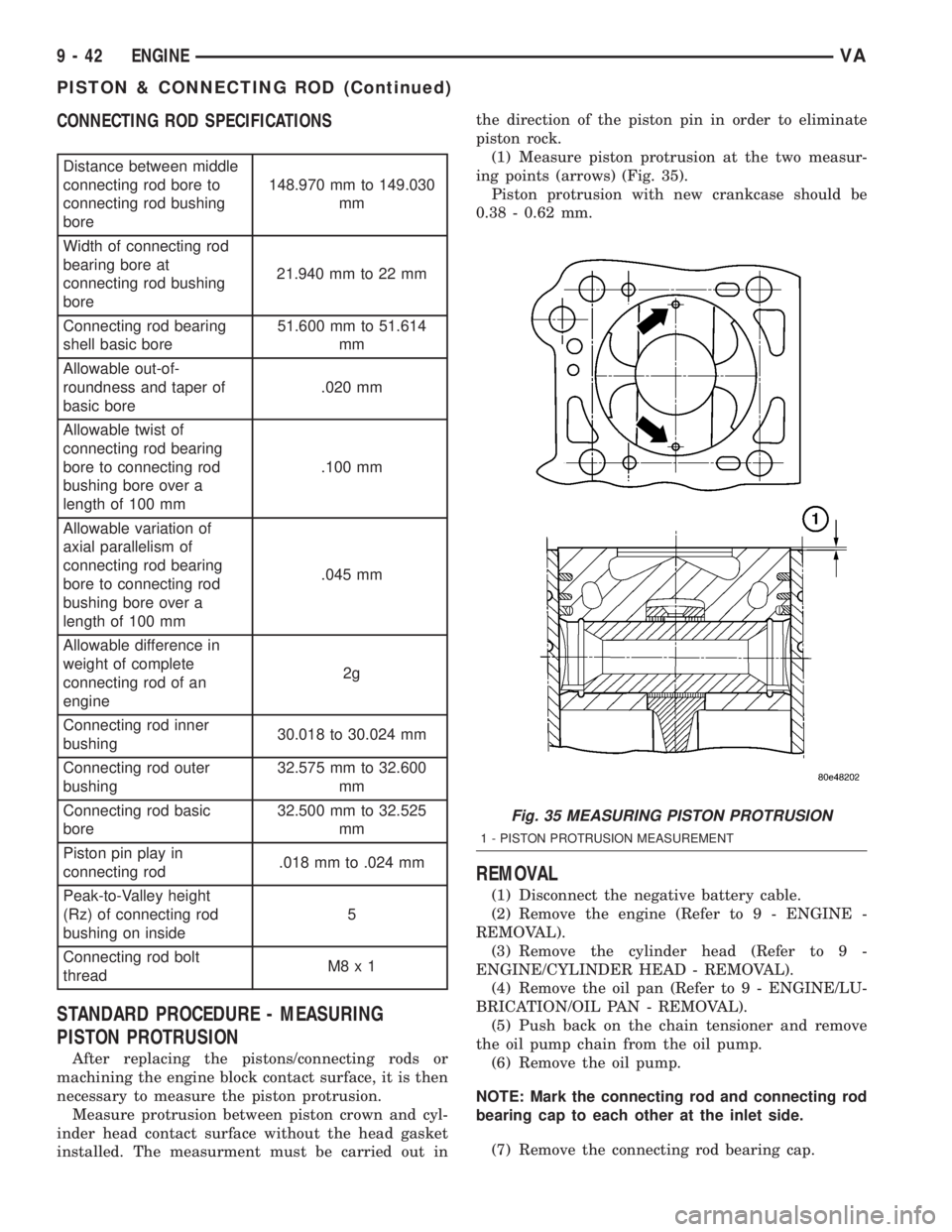

CONNECTING ROD SPECIFICATIONS

Distance between middle

connecting rod bore to

connecting rod bushing

bore148.970 mm to 149.030

mm

Width of connecting rod

bearing bore at

connecting rod bushing

bore21.940 mm to 22 mm

Connecting rod bearing

shell basic bore51.600 mm to 51.614

mm

Allowable out-of-

roundness and taper of

basic bore.020 mm

Allowable twist of

connecting rod bearing

bore to connecting rod

bushing bore over a

length of 100 mm.100 mm

Allowable variation of

axial parallelism of

connecting rod bearing

bore to connecting rod

bushing bore over a

length of 100 mm.045 mm

Allowable difference in

weight of complete

connecting rod of an

engine2g

Connecting rod inner

bushing30.018 to 30.024 mm

Connecting rod outer

bushing32.575 mm to 32.600

mm

Connecting rod basic

bore32.500 mm to 32.525

mm

Piston pin play in

connecting rod.018 mm to .024 mm

Peak-to-Valley height

(Rz) of connecting rod

bushing on inside5

Connecting rod bolt

threadM8x1

STANDARD PROCEDURE - MEASURING

PISTON PROTRUSION

After replacing the pistons/connecting rods or

machining the engine block contact surface, it is then

necessary to measure the piston protrusion.

Measure protrusion between piston crown and cyl-

inder head contact surface without the head gasket

installed. The measurment must be carried out inthe direction of the piston pin in order to eliminate

piston rock.

(1) Measure piston protrusion at the two measur-

ing points (arrows) (Fig. 35).

Piston protrusion with new crankcase should be

0.38 - 0.62 mm.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the engine (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Push back on the chain tensioner and remove

the oil pump chain from the oil pump.

(6) Remove the oil pump.

NOTE: Mark the connecting rod and connecting rod

bearing cap to each other at the inlet side.

(7) Remove the connecting rod bearing cap.

Fig. 35 MEASURING PISTON PROTRUSION

1 - PISTON PROTRUSION MEASUREMENT

9 - 42 ENGINEVA

PISTON & CONNECTING ROD (Continued)