MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 2091 of 2305

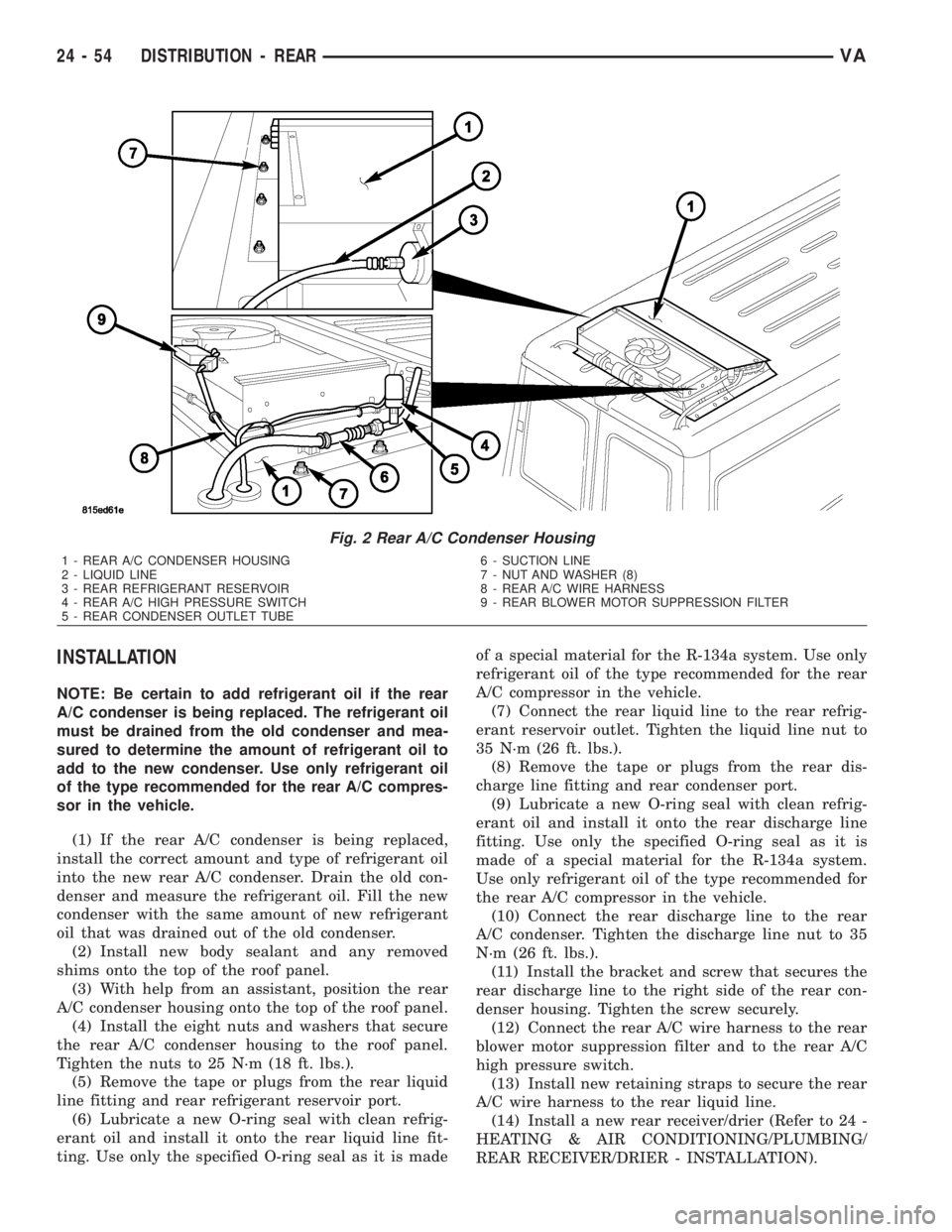

INSTALLATION

NOTE: Be certain to add refrigerant oil if the rear

A/C condenser is being replaced. The refrigerant oil

must be drained from the old condenser and mea-

sured to determine the amount of refrigerant oil to

add to the new condenser. Use only refrigerant oil

of the type recommended for the rear A/C compres-

sor in the vehicle.

(1) If the rear A/C condenser is being replaced,

install the correct amount and type of refrigerant oil

into the new rear A/C condenser. Drain the old con-

denser and measure the refrigerant oil. Fill the new

condenser with the same amount of new refrigerant

oil that was drained out of the old condenser.

(2) Install new body sealant and any removed

shims onto the top of the roof panel.

(3) With help from an assistant, position the rear

A/C condenser housing onto the top of the roof panel.

(4) Install the eight nuts and washers that secure

the rear A/C condenser housing to the roof panel.

Tighten the nuts to 25 N´m (18 ft. lbs.).

(5) Remove the tape or plugs from the rear liquid

line fitting and rear refrigerant reservoir port.

(6) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear liquid line fit-

ting. Use only the specified O-ring seal as it is madeof a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the rear

A/C compressor in the vehicle.

(7) Connect the rear liquid line to the rear refrig-

erant reservoir outlet. Tighten the liquid line nut to

35 N´m (26 ft. lbs.).

(8) Remove the tape or plugs from the rear dis-

charge line fitting and rear condenser port.

(9) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear discharge line

fitting. Use only the specified O-ring seal as it is

made of a special material for the R-134a system.

Use only refrigerant oil of the type recommended for

the rear A/C compressor in the vehicle.

(10) Connect the rear discharge line to the rear

A/C condenser. Tighten the discharge line nut to 35

N´m (26 ft. lbs.).

(11) Install the bracket and screw that secures the

rear discharge line to the right side of the rear con-

denser housing. Tighten the screw securely.

(12) Connect the rear A/C wire harness to the rear

blower motor suppression filter and to the rear A/C

high pressure switch.

(13) Install new retaining straps to secure the rear

A/C wire harness to the rear liquid line.

(14) Install a new rear receiver/drier (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

REAR RECEIVER/DRIER - INSTALLATION).

Fig. 2 Rear A/C Condenser Housing

1 - REAR A/C CONDENSER HOUSING

2 - LIQUID LINE

3 - REAR REFRIGERANT RESERVOIR

4 - REAR A/C HIGH PRESSURE SWITCH

5 - REAR CONDENSER OUTLET TUBE6 - SUCTION LINE

7 - NUT AND WASHER (8)

8 - REAR A/C WIRE HARNESS

9 - REAR BLOWER MOTOR SUPPRESSION FILTER

24 - 54 DISTRIBUTION - REARVA

Page 2092 of 2305

(15) Reconnect the negative battery cable.

(16) Evacuate the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(17) Charge the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(18) Install the rear air filter (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION -

REAR/AIR FILTER - INSTALLATION).

(19) Install the cover onto the rear A/C condenser

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C CON-

DENSER COVER - INSTALLATION).

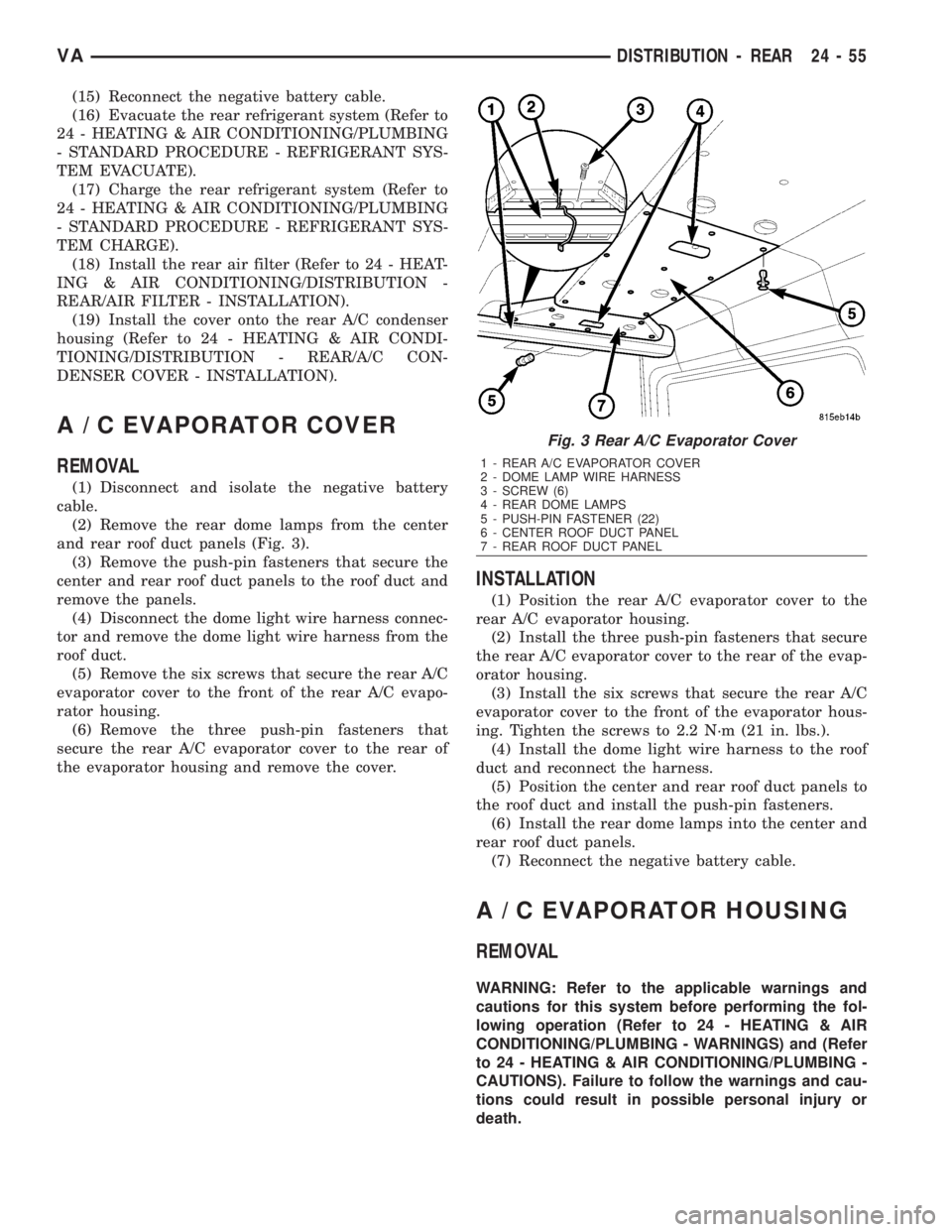

A/CEVAPORATOR COVER

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the rear dome lamps from the center

and rear roof duct panels (Fig. 3).

(3) Remove the push-pin fasteners that secure the

center and rear roof duct panels to the roof duct and

remove the panels.

(4) Disconnect the dome light wire harness connec-

tor and remove the dome light wire harness from the

roof duct.

(5) Remove the six screws that secure the rear A/C

evaporator cover to the front of the rear A/C evapo-

rator housing.

(6) Remove the three push-pin fasteners that

secure the rear A/C evaporator cover to the rear of

the evaporator housing and remove the cover.

INSTALLATION

(1) Position the rear A/C evaporator cover to the

rear A/C evaporator housing.

(2) Install the three push-pin fasteners that secure

the rear A/C evaporator cover to the rear of the evap-

orator housing.

(3) Install the six screws that secure the rear A/C

evaporator cover to the front of the evaporator hous-

ing. Tighten the screws to 2.2 N´m (21 in. lbs.).

(4) Install the dome light wire harness to the roof

duct and reconnect the harness.

(5) Position the center and rear roof duct panels to

the roof duct and install the push-pin fasteners.

(6) Install the rear dome lamps into the center and

rear roof duct panels.

(7) Reconnect the negative battery cable.

A/CEVAPORATOR HOUSING

REMOVAL

WARNING: Refer to the applicable warnings and

cautions for this system before performing the fol-

lowing operation (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNINGS) and (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTIONS). Failure to follow the warnings and cau-

tions could result in possible personal injury or

death.

Fig. 3 Rear A/C Evaporator Cover

1 - REAR A/C EVAPORATOR COVER

2 - DOME LAMP WIRE HARNESS

3 - SCREW (6)

4 - REAR DOME LAMPS

5 - PUSH-PIN FASTENER (22)

6 - CENTER ROOF DUCT PANEL

7 - REAR ROOF DUCT PANEL

VADISTRIBUTION - REAR 24 - 55

Page 2093 of 2305

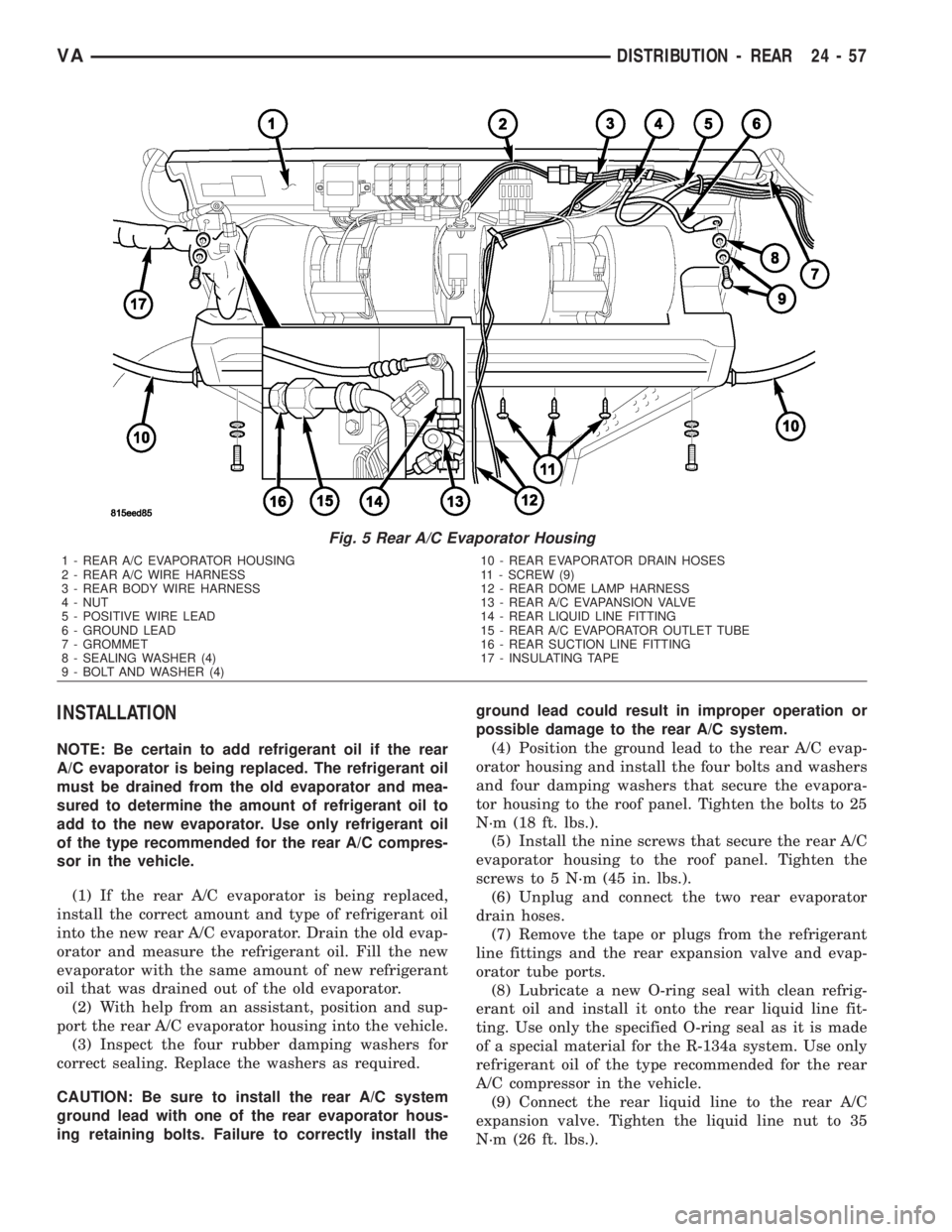

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(3) Recover the refrigerant from the rear refriger-

ant system (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(4) Remove the cover from the rear A/C condenser

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C CON-

DENSER COVER - REMOVAL).

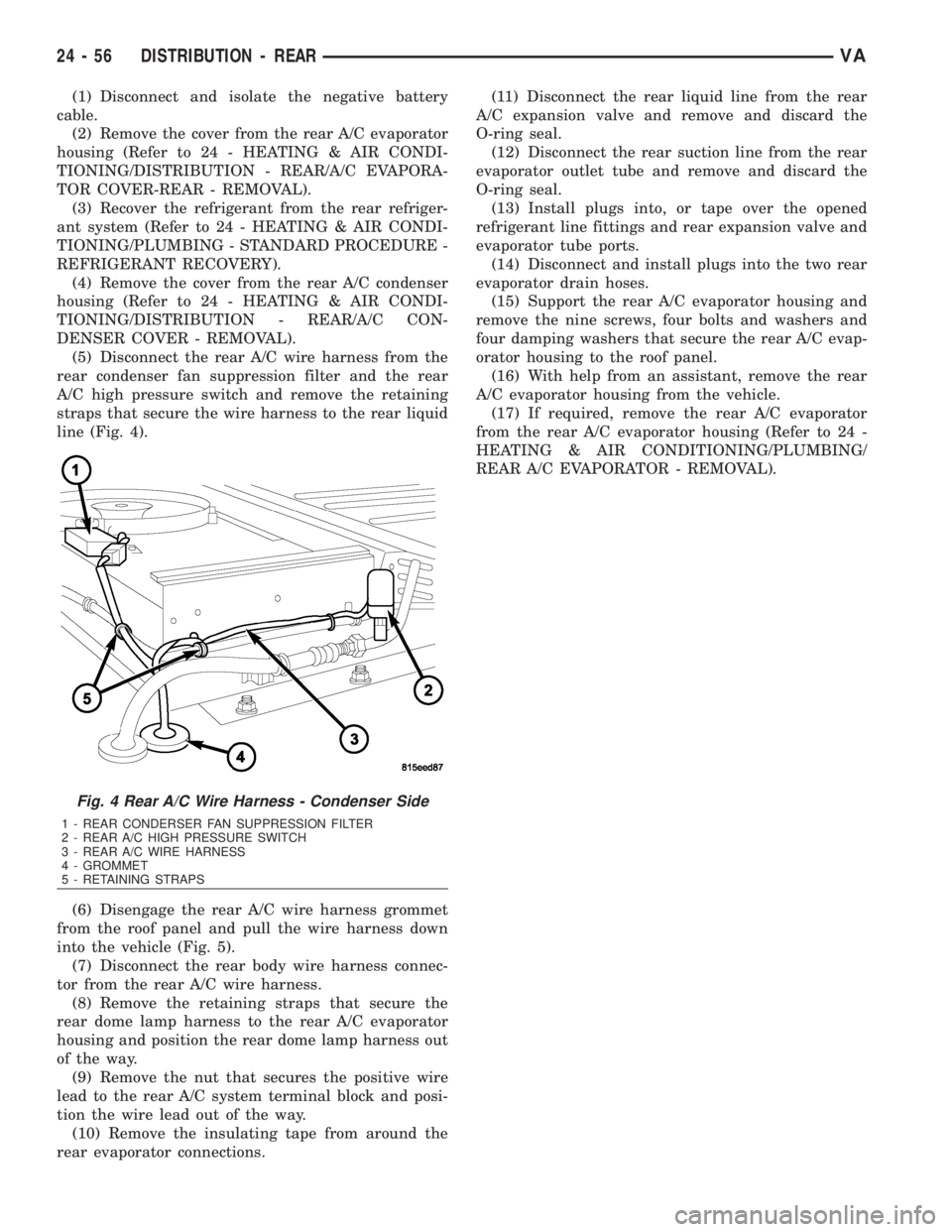

(5) Disconnect the rear A/C wire harness from the

rear condenser fan suppression filter and the rear

A/C high pressure switch and remove the retaining

straps that secure the wire harness to the rear liquid

line (Fig. 4).

(6) Disengage the rear A/C wire harness grommet

from the roof panel and pull the wire harness down

into the vehicle (Fig. 5).

(7) Disconnect the rear body wire harness connec-

tor from the rear A/C wire harness.

(8) Remove the retaining straps that secure the

rear dome lamp harness to the rear A/C evaporator

housing and position the rear dome lamp harness out

of the way.

(9) Remove the nut that secures the positive wire

lead to the rear A/C system terminal block and posi-

tion the wire lead out of the way.

(10) Remove the insulating tape from around the

rear evaporator connections.(11) Disconnect the rear liquid line from the rear

A/C expansion valve and remove and discard the

O-ring seal.

(12) Disconnect the rear suction line from the rear

evaporator outlet tube and remove and discard the

O-ring seal.

(13) Install plugs into, or tape over the opened

refrigerant line fittings and rear expansion valve and

evaporator tube ports.

(14) Disconnect and install plugs into the two rear

evaporator drain hoses.

(15) Support the rear A/C evaporator housing and

remove the nine screws, four bolts and washers and

four damping washers that secure the rear A/C evap-

orator housing to the roof panel.

(16) With help from an assistant, remove the rear

A/C evaporator housing from the vehicle.

(17) If required, remove the rear A/C evaporator

from the rear A/C evaporator housing (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

REAR A/C EVAPORATOR - REMOVAL).

Fig. 4 Rear A/C Wire Harness - Condenser Side

1 - REAR CONDERSER FAN SUPPRESSION FILTER

2 - REAR A/C HIGH PRESSURE SWITCH

3 - REAR A/C WIRE HARNESS

4 - GROMMET

5 - RETAINING STRAPS

24 - 56 DISTRIBUTION - REARVA

Page 2094 of 2305

INSTALLATION

NOTE: Be certain to add refrigerant oil if the rear

A/C evaporator is being replaced. The refrigerant oil

must be drained from the old evaporator and mea-

sured to determine the amount of refrigerant oil to

add to the new evaporator. Use only refrigerant oil

of the type recommended for the rear A/C compres-

sor in the vehicle.

(1) If the rear A/C evaporator is being replaced,

install the correct amount and type of refrigerant oil

into the new rear A/C evaporator. Drain the old evap-

orator and measure the refrigerant oil. Fill the new

evaporator with the same amount of new refrigerant

oil that was drained out of the old evaporator.

(2) With help from an assistant, position and sup-

port the rear A/C evaporator housing into the vehicle.

(3) Inspect the four rubber damping washers for

correct sealing. Replace the washers as required.

CAUTION: Be sure to install the rear A/C system

ground lead with one of the rear evaporator hous-

ing retaining bolts. Failure to correctly install theground lead could result in improper operation or

possible damage to the rear A/C system.

(4) Position the ground lead to the rear A/C evap-

orator housing and install the four bolts and washers

and four damping washers that secure the evapora-

tor housing to the roof panel. Tighten the bolts to 25

N´m (18 ft. lbs.).

(5) Install the nine screws that secure the rear A/C

evaporator housing to the roof panel. Tighten the

screws to 5 N´m (45 in. lbs.).

(6) Unplug and connect the two rear evaporator

drain hoses.

(7) Remove the tape or plugs from the refrigerant

line fittings and the rear expansion valve and evap-

orator tube ports.

(8) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear liquid line fit-

ting. Use only the specified O-ring seal as it is made

of a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the rear

A/C compressor in the vehicle.

(9) Connect the rear liquid line to the rear A/C

expansion valve. Tighten the liquid line nut to 35

N´m (26 ft. lbs.).

Fig. 5 Rear A/C Evaporator Housing

1 - REAR A/C EVAPORATOR HOUSING

2 - REAR A/C WIRE HARNESS

3 - REAR BODY WIRE HARNESS

4 - NUT

5 - POSITIVE WIRE LEAD

6 - GROUND LEAD

7 - GROMMET

8 - SEALING WASHER (4)

9 - BOLT AND WASHER (4)10 - REAR EVAPORATOR DRAIN HOSES

11 - SCREW (9)

12 - REAR DOME LAMP HARNESS

13 - REAR A/C EVAPANSION VALVE

14 - REAR LIQUID LINE FITTING

15 - REAR A/C EVAPORATOR OUTLET TUBE

16 - REAR SUCTION LINE FITTING

17 - INSULATING TAPE

VADISTRIBUTION - REAR 24 - 57

Page 2095 of 2305

(10) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear suction line fit-

ting. Use only the specified O-ring seal as it is made

of a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the rear

A/C compressor in the vehicle.

(11) Connect the rear suction line to the rear evap-

orator outlet tube. Tighten the suction line nut to 35

N´m (26 ft. lbs.).

(12) Install new insulating tape around the rear

evaporator connections.

(13) Install the positive wire lead onto the rear

A/C system terminal block and install the retaining

nut. Tighten the nut securely.

(14) Reposition the rear dome lamp harness and

install the retaining straps that secure the harness

to the rear A/C evaporator housing.

(15) Connect the rear A/C wire harness connector

to the rear body wire harness.

(16) Route the rear A/C wire harness up through

the roof panel and install the grommet.

(17) Connect the rear A/C wire harness to the rear

condenser fan suppression filter and the rear A/C

high pressure switch and install the retaining straps

that secure the wire harness to the rear liquid line.

(18) Reconnect the negative battery cable.

(19) Evacuate the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(20) Charge the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(21) Install the cover onto the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - INSTALLATION).

(22) Install the cover onto the rear A/C condenser

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C CON-

DENSER COVER - INSTALLATION).

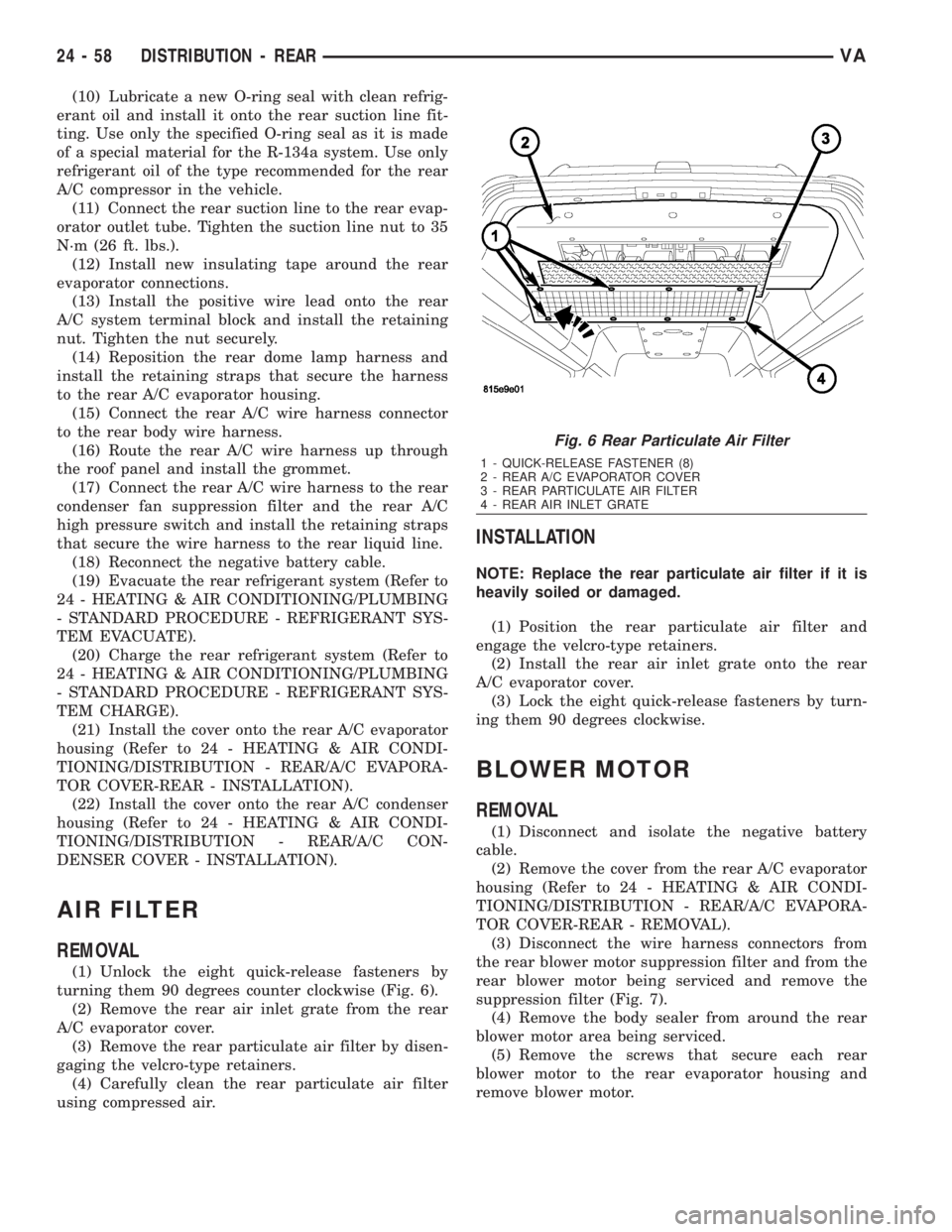

AIR FILTER

REMOVAL

(1) Unlock the eight quick-release fasteners by

turning them 90 degrees counter clockwise (Fig. 6).

(2) Remove the rear air inlet grate from the rear

A/C evaporator cover.

(3) Remove the rear particulate air filter by disen-

gaging the velcro-type retainers.

(4) Carefully clean the rear particulate air filter

using compressed air.

INSTALLATION

NOTE: Replace the rear particulate air filter if it is

heavily soiled or damaged.

(1) Position the rear particulate air filter and

engage the velcro-type retainers.

(2) Install the rear air inlet grate onto the rear

A/C evaporator cover.

(3) Lock the eight quick-release fasteners by turn-

ing them 90 degrees clockwise.

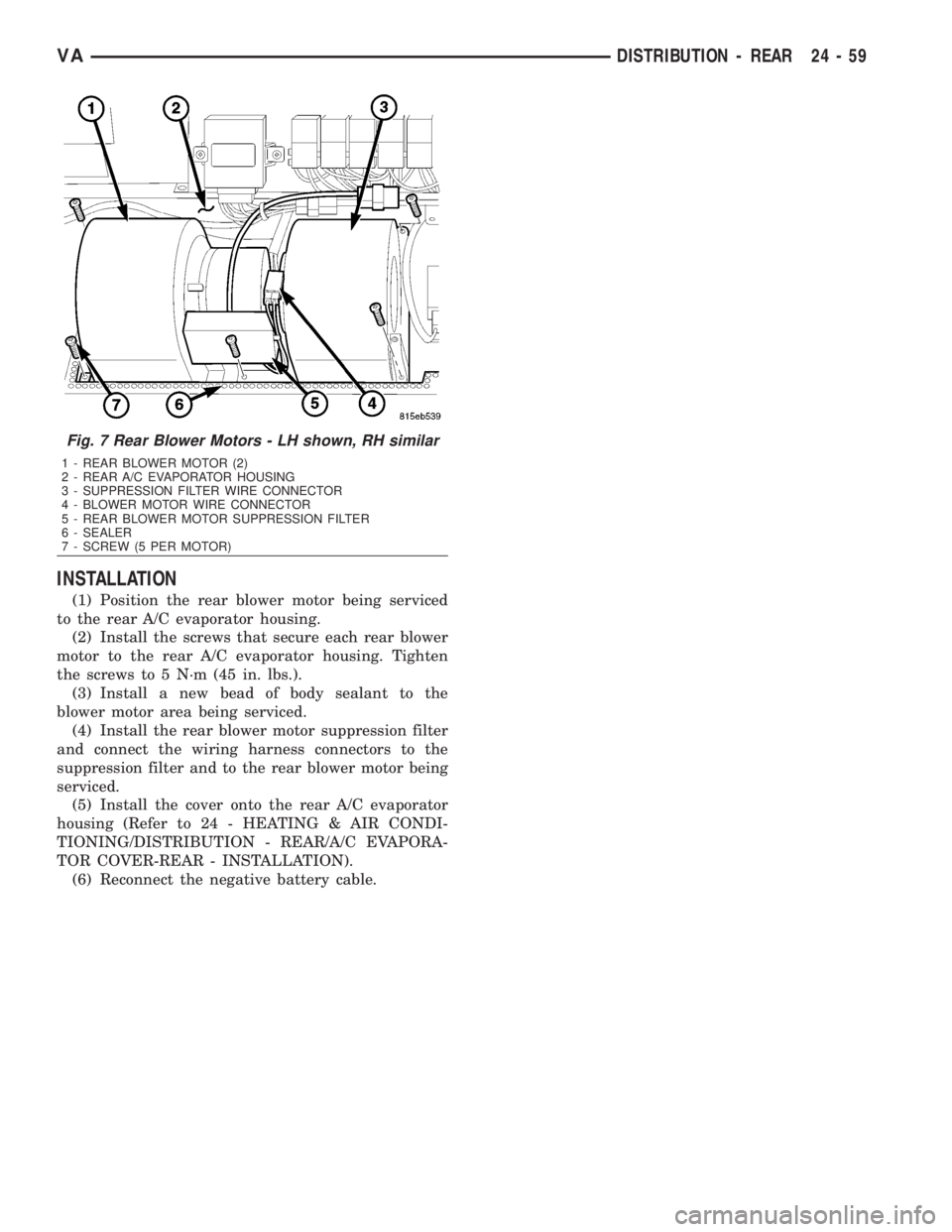

BLOWER MOTOR

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(3) Disconnect the wire harness connectors from

the rear blower motor suppression filter and from the

rear blower motor being serviced and remove the

suppression filter (Fig. 7).

(4) Remove the body sealer from around the rear

blower motor area being serviced.

(5) Remove the screws that secure each rear

blower motor to the rear evaporator housing and

remove blower motor.

Fig. 6 Rear Particulate Air Filter

1 - QUICK-RELEASE FASTENER (8)

2 - REAR A/C EVAPORATOR COVER

3 - REAR PARTICULATE AIR FILTER

4 - REAR AIR INLET GRATE

24 - 58 DISTRIBUTION - REARVA

Page 2096 of 2305

INSTALLATION

(1) Position the rear blower motor being serviced

to the rear A/C evaporator housing.

(2) Install the screws that secure each rear blower

motor to the rear A/C evaporator housing. Tighten

the screws to 5 N´m (45 in. lbs.).

(3) Install a new bead of body sealant to the

blower motor area being serviced.

(4) Install the rear blower motor suppression filter

and connect the wiring harness connectors to the

suppression filter and to the rear blower motor being

serviced.

(5) Install the cover onto the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - INSTALLATION).

(6) Reconnect the negative battery cable.

Fig. 7 Rear Blower Motors - LH shown, RH similar

1 - REAR BLOWER MOTOR (2)

2 - REAR A/C EVAPORATOR HOUSING

3 - SUPPRESSION FILTER WIRE CONNECTOR

4 - BLOWER MOTOR WIRE CONNECTOR

5 - REAR BLOWER MOTOR SUPPRESSION FILTER

6 - SEALER

7 - SCREW (5 PER MOTOR)

VADISTRIBUTION - REAR 24 - 59

Page 2097 of 2305

PLUMBING

TABLE OF CONTENTS

page page

PLUMBING

DESCRIPTION.........................61

OPERATION...........................61

WARNINGS...........................61

CAUTIONS............................62

DIAGNOSIS AND TESTING

REFRIGERANT SYSTEM LEAKS..........62

STANDARD PROCEDURE

REFRIGERANT SYSTEM SERVICE

EQUIPMENT.........................63

REFRIGERANT SYSTEM RECOVERY......64

REFRIGERANT SYSTEM EVACUATE......64

REFRIGERANT SYSTEM CHARGE........64

A/C COMPRESSOR

DESCRIPTION.........................66

OPERATION...........................66

DIAGNOSIS AND TESTING

A/C COMPRESSOR NOISE..............66

REMOVAL

DENSO 7SBU16C A/C COMPRESSOR.....67

DENSO 10S17 A/C COMPRESSOR........68

INSTALLATION

DENSO 7SBU16C A/C COMPRESSOR.....68

DENSO 10S17 A/C COMPRESSOR........69

A/C CONDENSER

DESCRIPTION.........................69

OPERATION...........................69

REMOVAL.............................70

INSTALLATION.........................70

A/C DISCHARGE LINE

REMOVAL.............................71

INSTALLATION.........................71

A/C EVAPORATOR

DESCRIPTION.........................72

OPERATION...........................72

REMOVAL.............................72

INSTALLATION.........................73

A/C EXPANSION VALVE

DESCRIPTION.........................73

OPERATION...........................73

DIAGNOSIS AND TESTING

A/C EXPANSION VALVE................74

REMOVAL.............................74

INSTALLATION.........................74

ELECTRIC COOLANT PUMP

DESCRIPTION.........................75

OPERATION...........................75

REMOVAL.............................75

INSTALLATION.........................76HEATER CORE

DESCRIPTION.........................76

OPERATION...........................76

REMOVAL.............................76

INSTALLATION.........................77

LIQUID LINE

REMOVAL.............................77

INSTALLATION.........................79

RECEIVER/DRIER

DESCRIPTION.........................79

OPERATION...........................79

REMOVAL.............................80

INSTALLATION.........................80

REFRIGERANT

DESCRIPTION.........................80

OPERATION...........................80

REFRIGERANT OIL

DESCRIPTION.........................81

OPERATION...........................81

STANDARD PROCEDURE

REFRIGERANT OIL LEVEL..............81

SUCTION LINE

REMOVAL.............................81

INSTALLATION.........................82

WAT E R VA LV E

REMOVAL.............................83

INSTALLATION.........................83

REAR A/C CONDENSER FAN

REMOVAL.............................83

INSTALLATION.........................84

REAR A/C EVAPORATOR

REMOVAL.............................84

INSTALLATION.........................85

REAR A/C EXPANSION VALVE

DESCRIPTION.........................85

OPERATION...........................85

REMOVAL.............................86

INSTALLATION.........................87

REAR DISCHARGE LINE

DESCRIPTION.........................88

REMOVAL.............................88

INSTALLATION.........................90

REAR LIQUID LINE

DESCRIPTION.........................91

REMOVAL.............................91

INSTALLATION.........................93

REAR RECEIVER/DRIER

REMOVAL.............................94

INSTALLATION.........................94

24 - 60 PLUMBINGVA

Page 2098 of 2305

REAR REFRIGERANT RESERVOIR

REMOVAL.............................95

INSTALLATION.........................95

REAR SUCTION LINE

DESCRIPTION.........................96

REMOVAL.............................96

INSTALLATION.........................98

REFRIGERANT LINE COUPLER

DESCRIPTION.........................98OPERATION...........................98

REMOVAL.............................99

INSTALLATION.........................99

UNDERBODY LINES

REMOVAL............................100

INSTALLATION........................102

PLUMBING

DESCRIPTION

The refrigerant lines and hoses are used to carry

the refrigerant between the various air conditioning

system components. A barrier hose design with a

nylon tube, which is sandwiched between rubber lay-

ers, is used for the R-134a air conditioning system on

this vehicle. This nylon tube helps to further contain

the R-134a refrigerant, which has a smaller molecu-

lar structure than R-12 refrigerant. The ends of the

refrigerant hoses are made from lightweight alumi-

num or steel, and commonly use braze-less fittings.

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

OPERATION

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

The refrigerant lines and hoses cannot be repaired

and, if faulty or damaged, they must be replaced.

WARNINGS

WARNING: The A/C system contains refrigerant

under high pressure. Repairs should only be per-

formed by qualified service personnel. Severe per-

sonal injury or death may result from improper

service procedures.

WARNING: Avoid breathing the refrigerant and

refrigerant oil vapor or mist. Exposure may irritate

the eyes, nose, and/or throat. Wear eye protectionwhen servicing the A/C refrigerant system. Serious

eye injury can result from direct contact with the

refrigerant. If eye contact occurs, seek medical

attention immediately.

WARNING: Do not expose the refrigerant to open

flame. Poisonous gas is created when refrigerant is

burned. An electronic leak detector is recom-

mended. Severe personal injury or death may result

from improper service procedures.

WARNING: If accidental system discharge occurs,

ventilate the work area before resuming service.

Large amounts of refrigerant released in a closed

work area will displace the oxygen and cause suf-

focation and death.

WARNING: The evaporation rate of R-134a refriger-

ant at average temperature and altitude is extremely

high. As a result, anything that comes in contact

with the refrigerant will freeze. Always protect the

skin or delicate objects from direct contact with the

refrigerant.

WARNING: The R-134a service equipment or the

vehicle refrigerant system should not be pressure

tested or leak tested with compressed air. Some

mixtures of air and R-134a have been shown to be

combustible at elevated pressures. These mixtures

are potentially dangerous, and may result in fire or

explosion causing property damage, personal injury

or death.

WARNING: The engine cooling system is designed

to develop internal pressures of 97 to 123 kilopas-

cals (14 to 18 pounds per square inch). Do not

remove or loosen the coolant pressure cap, cylin-

der block drain plugs, radiator drain, radiator

hoses, heater hoses, or hose clamps while the

engine cooling system is hot and under pressure.

Allow the vehicle to cool for a minimum of 15 min-

utes before opening the cooling system for service.

Failure to observe this warning can result in seri-

ous burns from the heated engine coolant.

VAPLUMBING 24 - 61

Page 2099 of 2305

CAUTIONS

CAUTION: Never add R-12 to a refrigerant system

designed to use R-134a. Do not use R-12 equipment

or parts on a R-134a A/C system. These refrigerants

are not compatible and damage to the A/C system

will result.

CAUTION: Never use R-12 refrigerant oil in a A/C

system designed to use R-134a refrigerant oil.

These refrigerant oils are not compatible and dam-

age to the A/C system will result.

CAUTION: The use of A/C system sealers may

result in damage to A/C refrigerant recovery/evacu-

ation/recharging equipment and/or A/C system.

Many federal, state/provincial and local regulations

prohibit the recharge of A/C systems with known

leaks. DaimlerChrysler recommends the detection

of A/C system leaks through the use of approved

leak detectors and fluorescent leak detection dyes.

Vehicles found with A/C system sealers should be

treated as contaminated and replacement of the

entire A/C refrigerant system is recommended. A/C

systems found to be contaminated with A/C system

sealers, A/C stop-leak products or seal conditioners

voids the warranty for the A/C system.

CAUTION: Recover the refrigerant before opening

any fitting or connection. Open the fittings with

caution, even after the system has been dis-

charged. Never open or loosen a connection before

recovering the refrigerant.

CAUTION: If equipped, do not remove the second-

ary retention clip from any spring-lock coupler con-

nection while the refrigerant system is under

pressure. Recover the refrigerant before removing

the secondary retention clip. Open the fittings with

caution, even after the system has been dis-

charged. Never open or loosen a connection before

recovering the refrigerant.

CAUTION: The internal parts of the A/C system will

remain stable as long as moisture-free refrigerant

and refrigerant oil is used. Abnormal amounts of

dirt, moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities. Before disconnecting a component,

clean the outside of the fittings thoroughly to pre-

vent contamination from entering the refrigerant

system. Keep service tools and the work area clean.

Do not open the refrigerant system or uncap areplacement component until you are ready to ser-

vice the system. Immediately after disconnecting a

component from the refrigerant system, seal the

open fittings with a cap or plug. This will prevent

contamination from entering the A/C system.

CAUTION: Refrigerant oil will absorb moisture from

the atmosphere if left uncapped. Do not open a

container of refrigerant oil until you are ready to

use it. Replace the cap on the oil container immedi-

ately after using. Store refrigerant oil only in a

clean, airtight, and moisture-free container.

CAUTION: Do not overcharge the refrigerant sys-

tem. Overcharging will cause excessive compressor

head pressure and can cause compressor noise

and A/C system failure.

DIAGNOSIS AND TESTING

REFRIGERANT SYSTEM LEAKS

WARNING: R-134a service equipment or vehicle A/C

system should not be pressure tested or leak tested

with compressed air. Mixture of air and R-134a can

be combustible at elevated pressures. These mix-

tures are potentially dangerous and may result in

fire or explosion causing property damage, per-

sonal injury or death.

Avoid breathing A/C refrigerant and lubricant vapor

or mist. Exposure may irritate eyes, nose and

throat. Use only approved service equipment meet-

ing SAE requirements to discharge R-134a system.

If accidental system discharge occurs, ventilate

work area before resuming service.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a Refrig-

erant System Charge Level test (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING -

DIAGNOSIS AND TESTING - REFRIGERANT SYS-

TEM CHARGE LEVEL) or by completely evacuating

and recharging the A/C system. If the A/C liquid line

pressure is found to be less than 345 kPa (50 psi)

while performing the Refrigerant System Charge

Level test, proceed to the System Empty procedure

below. If liquid line pressure is found to be greater

than 345 kPa (50 psi), proceed to the System Low

procedure. If the refrigerant system is empty or low

in refrigerant charge, a leak at any line fitting or

component seal is likely. A review of the fittings,

lines and components for oily residue is an indication

of the leak location. To detect a leak in the refriger-

ant system, perform one of the following procedures

as indicated by the symptoms.

24 - 62 PLUMBINGVA

Page 2100 of 2305

SYSTEM EMPTY

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approximately 28 in Hg.)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM EVACUATE). Determine if the

system holds a vacuum for 15 minutes. If vacuum is

held, a leak is probably not present. If system will

not maintain vacuum level, proceed to Step 2.

(2) Prepare and dispense 0.284 kilograms (10

ounces) of R-134a refrigerant into the evacuated

refrigerant system (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE) and

proceed to Step 1 of the System Low procedure.

SYSTEM LOW

(1) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(2) Operate the heating-A/C system with the

engine at idle under the following conditions for at

least five minutes.

²Doors or windows open

²Transmission in Park

²A/C-heater controls set to outside air, full cool,

panel mode, high blower and with A/C compressor

engaged

CAUTION: A leak detector only designed for R-12

refrigerant will not detect leaks in a R-134a refriger-

ant system.

(3) Shut the vehicle Off and wait 2-7 minutes.

Then use an electronic leak detector that is designed

to detect R-134a refrigerant and search for leaks. Fit-

tings, lines or components that appear to be oily usu-

ally indicate a refrigerant leak. To inspect the A/C

evaporator for leaks, insert the leak detector probe

into the drain tube opening or an air outlet. A dye for

R-134a is available to aid in leak detection. Use only

DaimlerChrysler approved refrigerant dye.

STANDARD PROCEDURE

REFRIGERANT SYSTEM SERVICE EQUIPMENT

WARNING: Eye protection must be worn when ser-

vicing an A/C refrigerant system. Turn off (rotate

clockwise) all valves on the equipment being used,

before connecting to or disconnecting from the

refrigerant system. Failure to observe these warn-

ings may result in possible personal injury.

WARNING: Refer to the applicable warnings and

cautions for this system before performing the fol-

lowing operation (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNINGS) and (Referto 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTIONS). Failure to follow the warnings and cau-

tions could result in possible personal injury or

death.

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the

equipment manufacturer for proper care and use of

this equipment.

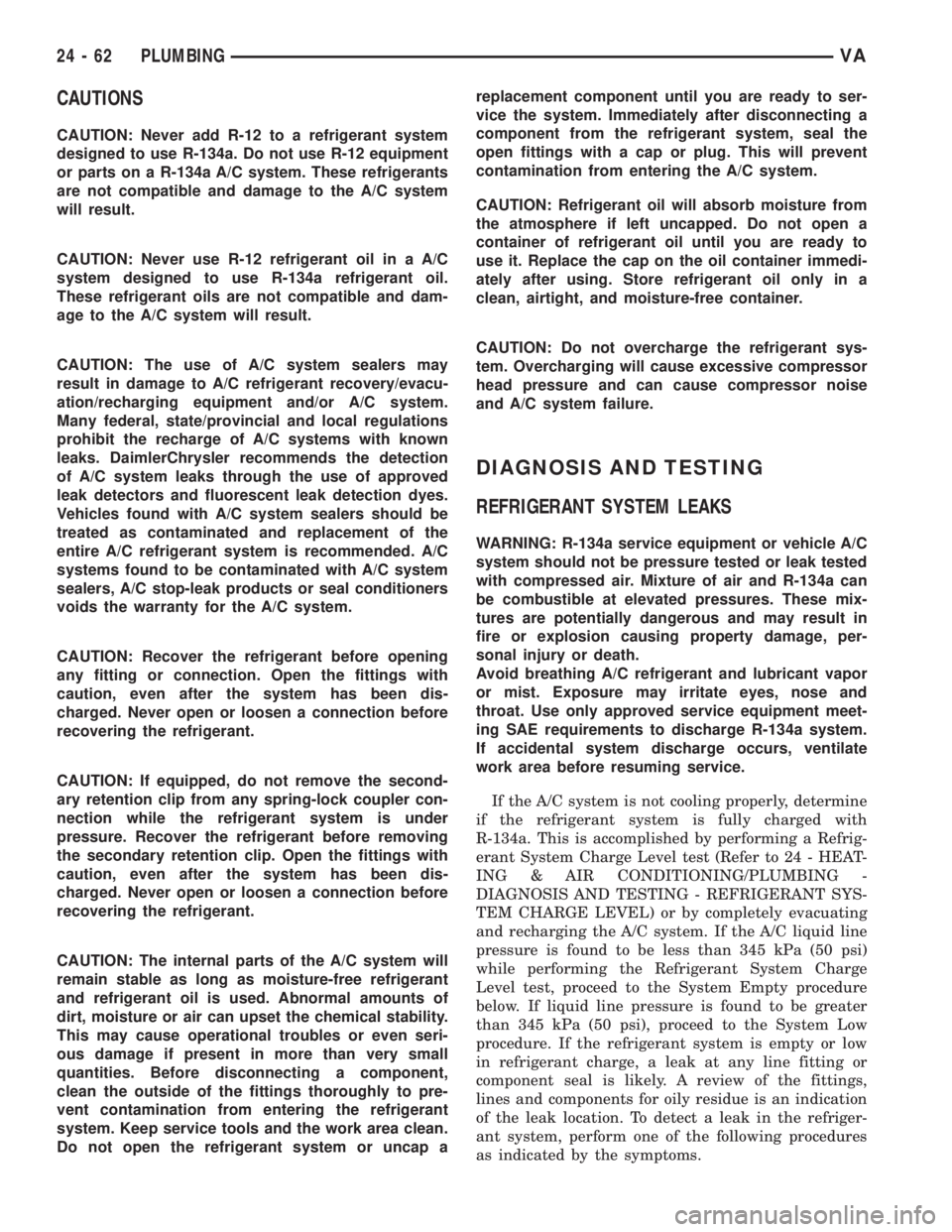

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 1). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

Fig. 1 Manifold Gauge Set - Typical

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/ BLACK

STRIPE)

4 - HIGH PRESSURE HOSE (RED W/ BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/ BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

VAPLUMBING 24 - 63