change wheel MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 283 of 334

X

Read the tire pressure and compare it with

the recommended value on the loading

information table or th etire pressure table

(Y page 278).

X If the tire pressure is too low, increase it to

the recommended value.

X If the tire pressure is too high, release air

by pressing down the metal pin in the valve.

Use the tip of a pen, for example. Then,

chec kthe tire pressure again using the tire

pressure gauge.

X Screw the valve cap onto the valve.

X Repeatt he steps for the other tires. Tire pressure monitor

Important safety notes G

WARNING

Each tire, including the spare (if provided),

should be checked at least once a month

when cold and inflated to the pressure

recommended by the vehicle manufacturer

on the Tire and Loading Information placard

on the driver's door B-pillar or the tire

pressure label on the inside of the fuel filler

flap. If your vehicle has tires of a different size

than the size indicated on the Tire and Loading

Information placard or the tire pressure label,

you should determine the proper tire pressure

for those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire

pressure telltale when one or more of your

tires are significantly underinflated.

Accordingly, when the low tire pressure

telltale illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly underinflated tire causes the tire

to overheat and can lead to tire failure.

Underinflation also reduces fuel efficiency

and tire tread life, and may affect the vehicle's

handling and stopping ability. Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the

driver's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the

vehicle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal

low tire pressure as intended. TPMS

malfunctions may occur for a variety of

reasons, including the installation of

incompatible replacement or alternate tires

or wheels on the vehicle that prevent the

TPMS from functioning properly. Always

check the TPMS malfunction telltale after

replacing one or more tires or wheels on your

vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to

continue to function properly.

Vehicles with a tire pressure monitor are

equipped with sensors in the wheels that

monitor the tire pressure of all four tires. The

tire pressure monitor monitors the pressure

in all four tires; you set this pressure when

you activate the tire pressure monitor. The

tire pressure monitor warns you when the

pressure drops in one or more of the tires. The

tire pressure monitor only functions if the

corresponding sensors are installed to all

wheels.

You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire

pressure. Tire pressure

281Wheels and tires Z

Page 285 of 334

message. The

000Atire pressure loss warning

lamp in the instrument cluster (Y page 218)

lights up.

The tire pressure is show nin2red rectangles.

The pressure of the tire concerned is shown

in one of the two rectangles (Y page 192).

Additionally, a warning tone sounds.

Each tire that is affected by a significant loss

of pressure is highlighted in the pressure

display.

Restarting the tire pressure monitor When you restart the tire pressure monitor,

the currently set tire pressure are taken as

reference values for monitoring.

In most cases, the tire pressure monitor

detects the new reference values

automatically, e.g. after you have:

R changed the tire pressure

R changed wheels or tires

R installed new wheels or tires

However, you can also define reference

values manually as described here.

Before restarting the tire pressure

monitor:

X Set the tire pressure to the value

recommended on the Tire and Loading

Information placard or the tire pressure

table on the B-pillar on the driver's side

(Y page 278).

Observe the notes on tire pressure when

doing so (Y page 278).

X Make sure that the tire pressure is correct

on all four wheels. Restarting the tire pressure monitor

(vehicles without steering wheel

buttons):

X

Turn the key to position 2in the ignition

lock.

X Press the 0004menu button on the

instrument cluster repeatedly until the

display shows the following message:

+CAL- TPMS X

Press the 000Ebutton on the instrument

cluster.

The display shows:

OK TPMS The tire pressure monitor activation

process has begun. The tire pressures

measured for the individual wheels are

stored as the new reference values,

provided that the tire pressure monitor

considers them to be plausible.

If you wish to cancel the restart:

X Press the 000Fbutton or the 0004menu button

on the instrument cluster.

The activation process is canceled

automatically if 30 seconds elapse with no

input.

Restarting the tire pressure monitor

(vehicles with steering wheel buttons):

X Turn the key to position 2in the ignition

lock.

X Press the 0010or0007 button on the

steering wheel repeatedly until the

standard display is shown (Y page 182).

X Press the 0001or0009 button on the

steering wheel repeatedly until the current

pressure of the individual tires is displayed

or the display shows the following

message:

Tire pres. displayed after driving

for several minutes

X

Press the 0007reset button on the

instrument cluster.

The display shows the following message: Tire pressure

283Wheels and tires Z

Page 297 of 334

Traction

Traction is the result of friction between the

tires and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximu mpermissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are

distributed over the tire tread. If the tire tread

is level with the bars, the wear limit of 000Bin

(1.6 mm) has been reached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over

designated seat positions in avehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle. Flat tire

General notes

Your vehicle may be equipped with Premium

tire sealant or with a spare wheel. The spare

wheel is under the vehicle at the rear

(Y page 308). The Premium tire sealant is

located in the stowage compartment in the

right-hand door sill (Y page 264).

You can find information on changing/

mounting wheels in the "Wheel change"

section (Y page 303).

When you replace a tire, we recommend that

you also replace the tire valve. Please observe

the safety-relevant information on tire valve

(Y page 280). Vehicle preparation

X Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X Switch on the hazard warning lamps if the

vehicle poses a hazard to passing vehicles.

X Turn the fron twheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not

endangered as they do so.

X Make sure that no one is near the danger

area while a wheel is being changed.

Anyone who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements. Using Premium tire sealant

Using Premium tire sealant You can use Premium tire sealant to seal

punctures of up to 0.23 in (6 mm), particularly

those in the tire tread. Tire sealant can be

used at outside temperatures down to

002722 ‡ (002730 †).

G

WARNING

In the following situations, the tire sealant is

unable to provide sufficient breakdown

assistance, as it is unable to seal the tire

properly:

R there are cuts or punctures in the tire larger

than those mentioned above.

R the wheel rim is damaged.

R you have driven at very low tire pressures

or on a flat tire.

There is a risk of an accident. Flat tire

295Wheels and tires

Z

Page 298 of 334

Do not drive any further. Contact a qualified

specialis tworkshop. G

WARNING

The tire sealant is harmful and causes

irritation. It must not come into contact with

your skin, eyes or clothing or be swallowed.

Do not inhale TIREFIT fumes. Keep tire sealant

away from children. There is a risk of injury.

If you come into contact with the tire sealant,

observe the following:

R Rinse off the tire sealant from your skin

immediately with water.

R If the tire sealant comes into contact with

your eyes, immediately rinse them

thoroughly with clean water.

R If tire sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water. Do not induce vomiting,

and seek medical attention immediately.

R Immediately change out of clothing which

has come into contact with tire sealant.

R If an allergic reaction occurs, seek medical

attention immediately.

In addition, observe the manufacturer's

safety instructions on the sticker on the tire

inflation compressor and on the sticker on the

tire sealant bottle.

The tire sealant is water-soluble. If tire sealant

escapes, you can wash it off with water.

i Have the tire sealant replaced every

8y ears at a qualified specialist workshop.

! The tire inflation compressor should only

be connected to the 12 V socket in the

center console. You may otherwise

damage the vehicle's electrics.

! Do not operate the tire inflation

compressor for longer than 20 minutes at

a time without a break. The tire inflation

compressor may otherwise overheat.

The tire inflation compressor can be

operated again once it has cooled down. H

Environmental note

Have the used tire sealant bottle disposed of

professionally, e.g. at aqualified specialist

workshop.

X Prepare the vehicle as described

(Y page 295).

X If possible, remove the foreign object that

has pierced the tire, e.g .the screw or the

nail.

It is beneficial to the sealing process if the

foreign body that has pierced the tire is

removed.

X Remove the Premium tire sealant, the

accompanying

"max 50 mph"("max80 km/h") sticker and

the tire inflation compressor from the

stowage compartmentint he right-hand

doorway (Y page 264).

X Affix the sticker within the driver's field of

vision. Tire inflation compressor

0005

Switch

0006 Angled connecting piece

0026 Tire inflation compressor hose

0025 Flap

0023 Pressure gauge with pressure release

screw

0024 Connector with cable

X Open flap 0025on the tire inflation

compressor.

X Pull connector 0024and hose 0026with

pressure gauge 0023from the housing. 296

Flat tireWheels and tires

Page 304 of 334

and/or valve tool, warning triangle and

warning lamps in the vehicle.

X Pull away immediately.

This enables the tire sealan tto distribute

inside the tire and create a more effective

seal.

X After driving for approximately 3 minutes,

stop the vehicle at a suitable location, e.g.

at a car park or gas station.

X Check the tire pressure again.

The tire pressure must be at least

300 kPa (3.0 bar/43.5 psi). G

WARNING

If the required tire pressure is not reached

after driving for a short period, the tire is too

badly damaged. The tire sealant cannot repair

the tire in this instance. Damaged tires and a

tire pressure that is too low can significantly

impair the vehicle's braking and driving

characteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

i The Mercedes-Benz Service24h

telephone numbers can be found on a

sticker in the driver's door entrance area

and in the vehicle Maintenance Booklet.

i If you check the tire pressure with the tire

inflation compressor, connect angled valve

adapter 0006on tire inflation compressor

hose 0026directly to the tire valve. The tire

pressure will increase when you switch the

tire inflation compressor on. You can

reduce the tire pressure by opening the

pressure release screw on pressure gauge

0023.

If the tire pressure is still at least 300 kPa

(3.0 bar/43.5 psi):

X If possible, inflate the tire to the

recommended tire pressure (Y page 278).

X Drive to the nearest qualified specialist

workshop as soon as possible and have the

tire and tire sealant 0019replaced. Changing wheels

Rotating the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions.

The wheel brakes or suspension components

may also be damaged. There is a risk of

accident.

Rotate front and rear wheels only if the wheels

and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are

located in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the

electronic components.

Only have tires changed at a qualified

specialist workshop.

Always observe the instructions and safety

notes in the "Mounting awheel" section

(Y page 303).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the

intervals in the tire manufacturer's warranty

book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000 to

10,000 km), or earlier if tire wear requires. Do

not change the direction of rotation.

Clean the contac tsurface softhe wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressure and

reactivate the tire pressure monitor if

necessary. 302

Changing wheelsWheels and tires

Page 305 of 334

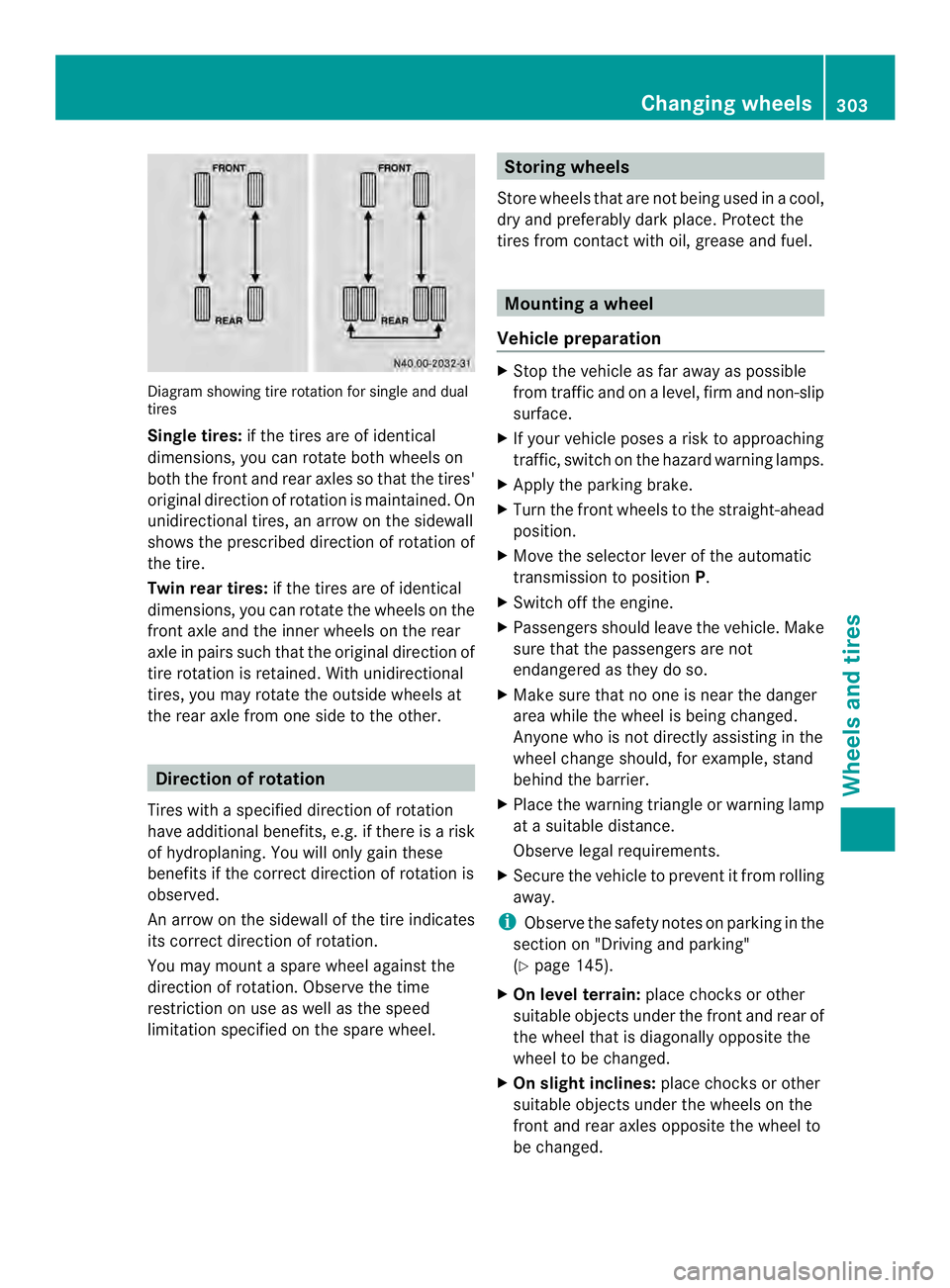

Diagra

mshowing tire rotation for single and dual

tires

Single tires: if the tires are of identical

dimensions, you can rotate both wheels on

both the front and rear axles so that the tires'

original direction of rotation is maintained. On

unidirectional tires, an arrow on the sidewall

shows the prescribed direction of rotation of

the tire.

Twin rear tires: if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear

axle in pairs such that the original direction of

tire rotation is retained. With unidirectional

tires, you may rotate the outside wheels at

the rear axle from one side to the other. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these

benefits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates

its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed

limitation specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Mounting

awheel

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If you rvehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake.

X Turn the fron twheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not

endangered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed.

Anyone who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements.

X Secure the vehicle to prevent it from rolling

away.

i Observe the safety notes on parking in the

section on "Driving and parking"

(Y page 145).

X On level terrain: place chocks or other

suitable objects under the front and rear of

the wheel that is diagonally opposite the

wheel to be changed.

X On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed. Changing wheels

303Wheels and tires Z

Page 306 of 334

X

Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 264).

X Remove the spare wheel from the spare

wheel bracket (Y page 309). Observe the

safety notes in the "Spare wheel" section

(Y page 308).

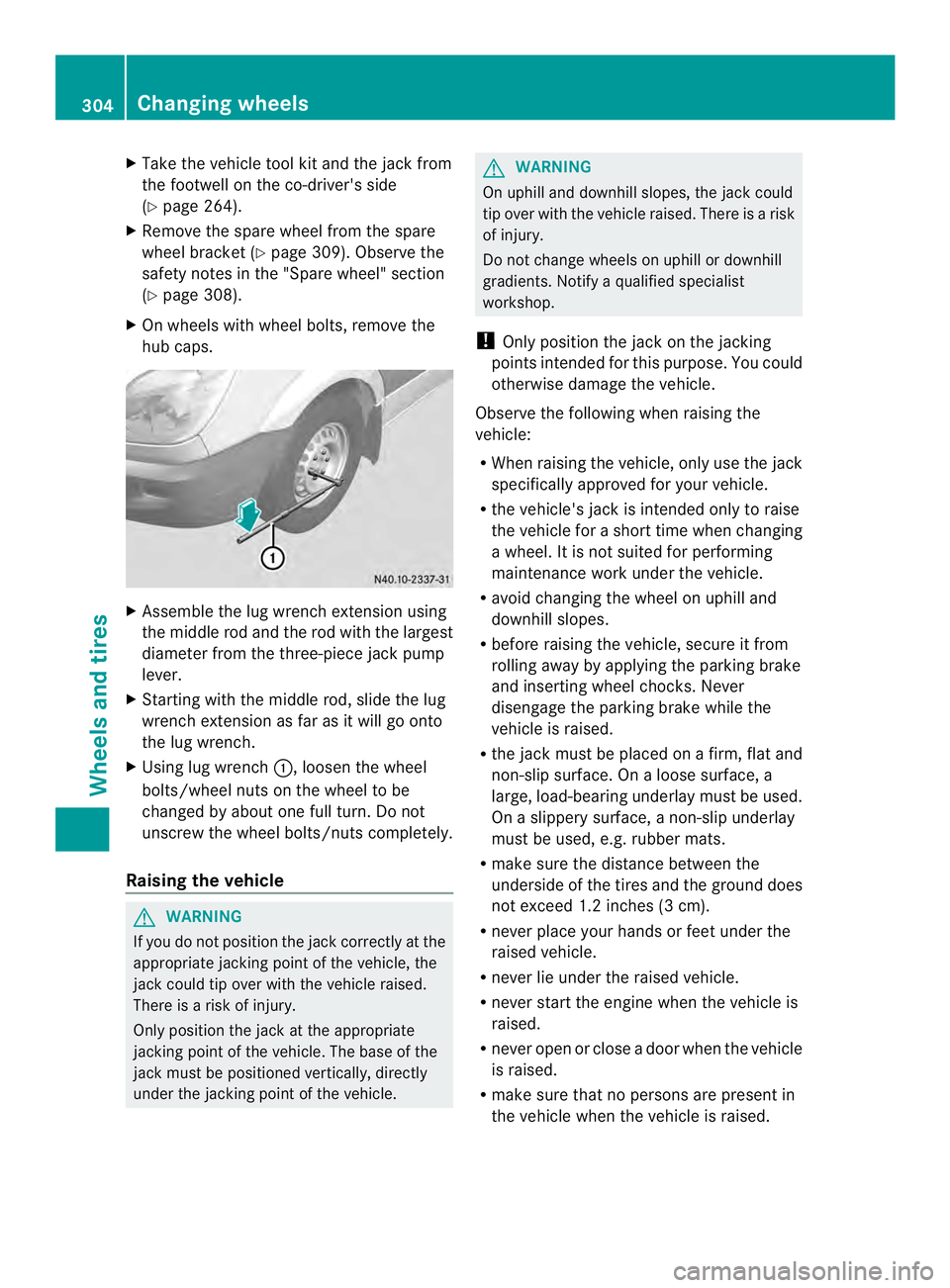

X On wheels with wheel bolts, remove the

hub caps. X

Assemble the lug wrench extension using

the middle rod and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using lug wrench 0005, loosen the wheel

bolts/wheel nuts on the wheel to be

changed by about one full turn. Do not

unscrew the wheel bolts/nuts completely.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle. G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist

workshop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle.

Observe the following when raising the

vehicle:

R When raising the vehicle, only use the jack

specifically approved for your vehicle.

R the vehicle's jack is intended only to raise

the vehicle for a short time when changing

a wheel. It is not suited for performing

maintenance work under the vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never

disengage the parking brake while the

vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R make sure the distance between the

underside of the tires and the ground does

not exceed 1.2 inches (3 cm).

R never place your hands or feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door when the vehicle

is raised.

R make sure that no persons are present in

the vehicle when the vehicle is raised. 304

Changing wheelsWheels and tires

Page 308 of 334

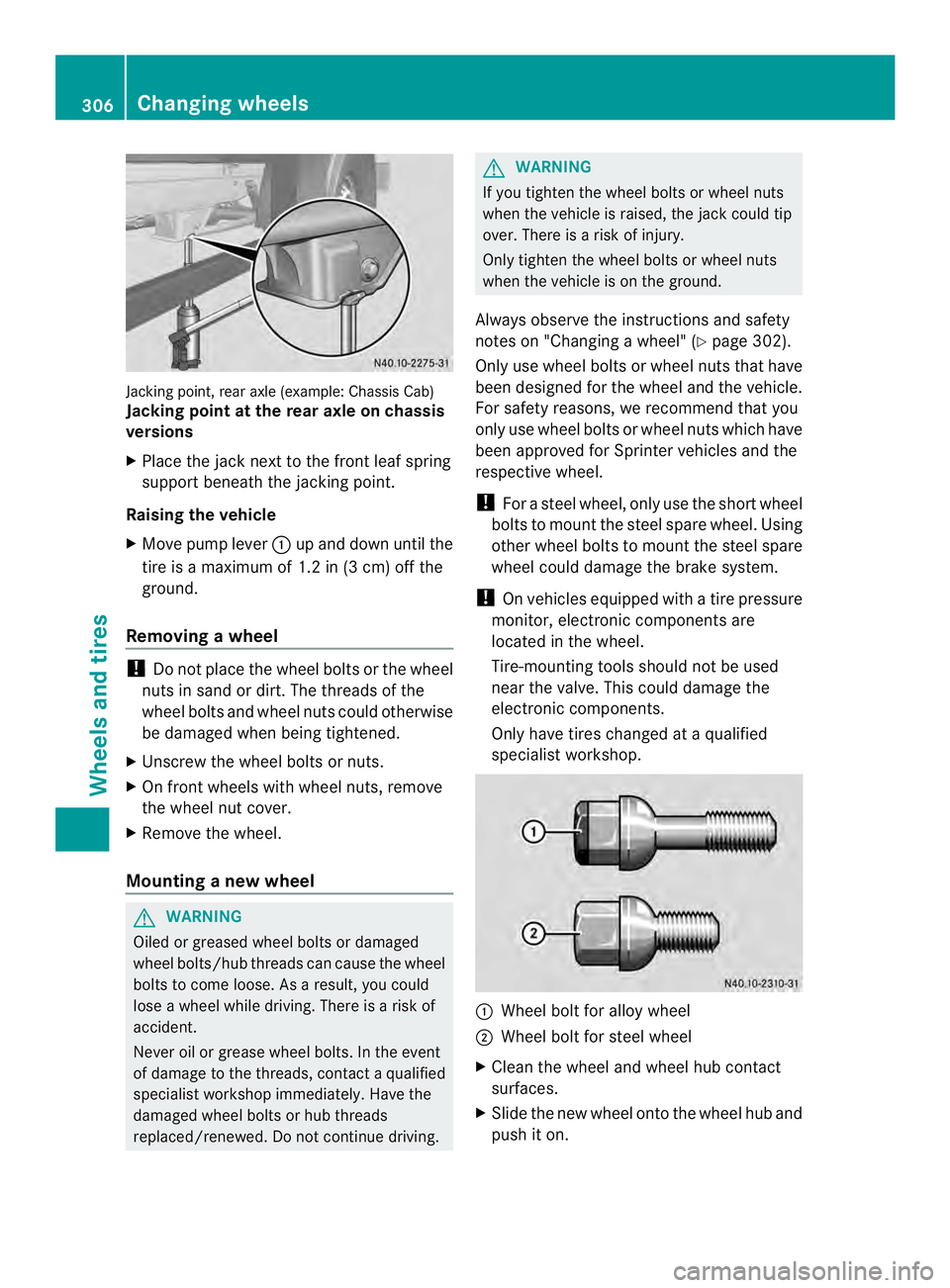

Jacking point, rear axle (example: Chassis Cab)

Jacking point at the rear axle on chassis

versions

X

Place the jack next to the front leaf spring

suppor tbeneath the jacking point.

Raising the vehicle

X Move pump lever 0005up and down until the

tire is a maximum of 1.2 in (3 cm) off the

ground.

Removing awheel !

Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the

wheel bolts and wheel nuts could otherwise

be damaged whe nbeing tightened.

X Unscrew the wheel bolts or nuts.

X On fron twheels with wheel nuts, remove

the wheel nut cover.

X Remove the wheel.

Mounting anew wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel

bolts to come loose .As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a qualified

specialist workshop immediately.H ave the

damaged wheel bolts or hub threads

replaced/renewed. Do no tcontinue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (Y page 302).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle.

For safety reasons, we recommend that you

only use wheel bolts or wheel nuts which have

been approved for Sprinter vehicles and the

respective wheel.

! For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

! On vehicles equipped with a tire pressure

monitor, electronic components are

located in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the

electronic components.

Only have tires changed at a qualified

specialist workshop. 0005

Wheel bolt for alloy wheel

0006 Wheel bolt for steel wheel

X Clean the wheel and wheel hub contact

surfaces.

X Slide the new wheel onto the wheel hub and

push it on. 306

Changing wheelsWheels and tires

Page 309 of 334

Wheels with centering by wheel bolts:

X Vehicles with alloy wheels: take the short

wheel bolts that fit the steel spare wheel

out of the vehicle tool kit.

X Screw in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

X Fron twheels with wheel nut covers: press

the wheel nut covers onto the wheel nuts.

X Screw in the three wheel nuts over the

fixing discs of the wheel nut cover.

X Turn the wheel so that the wheel bolts are

in the middle of the holes.

X Screw on the rest of the wheel nuts.

X Slightly tighten all the wheel nuts.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle

rod as far as it will go onto the lug wrench.

The rods may otherwise bend and be

distorted to such an extent that they can

no longer be used as a pump lever for the

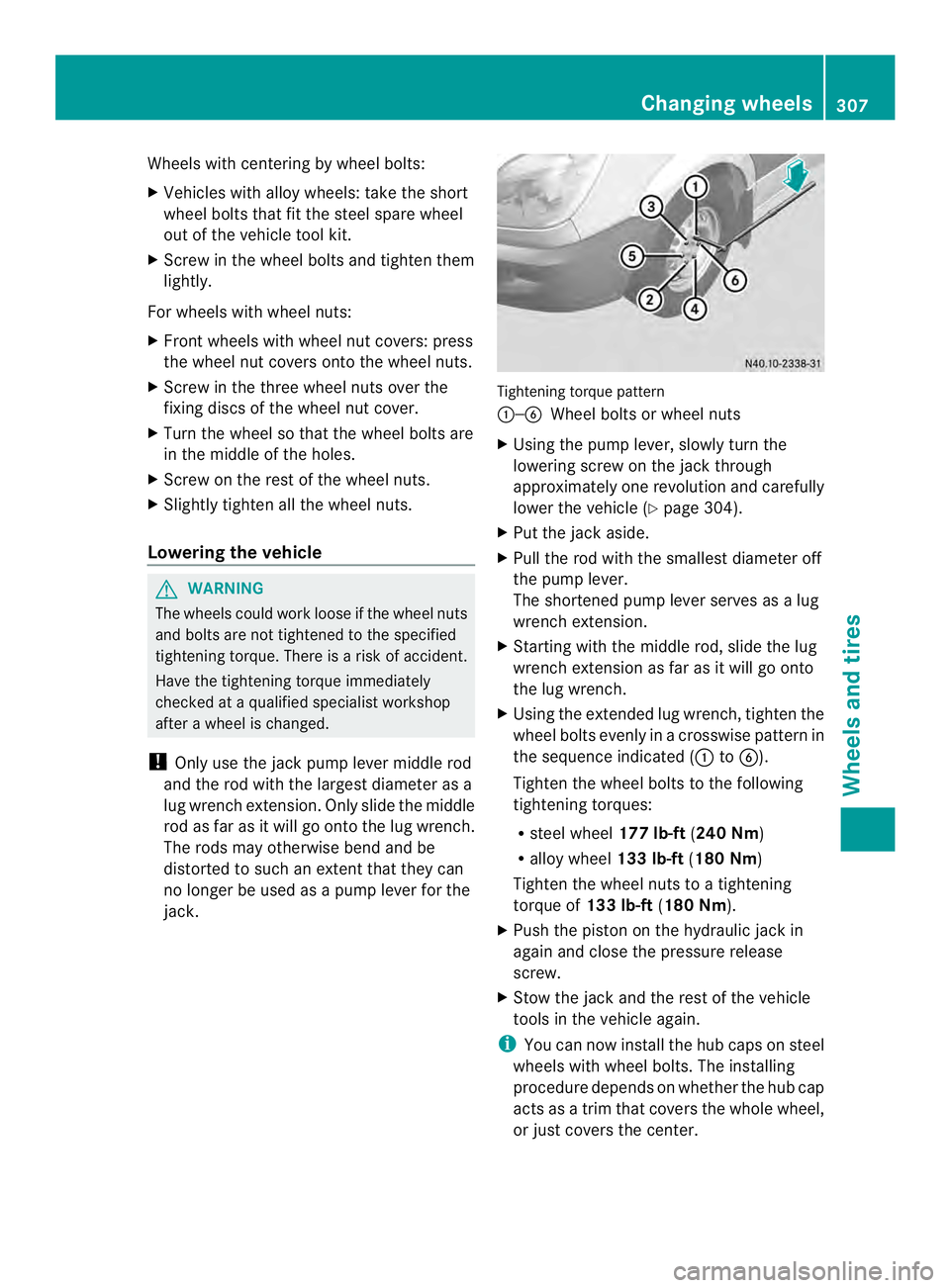

jack. Tightening torque pattern

0005—0024

Wheel bolts or wheel nuts

X Using the pump lever, slowly turn the

lowering screw on the jack through

approximately one revolution and carefully

lower the vehicle (Y page 304).

X Put the jack aside.

X Pull the rod with the smallest diameter off

the pump lever.

The shortened pump lever serves as a lug

wrench extension.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated (0005 to0024).

Tighten the wheel bolts to the following

tightening torques:

R steel wheel 177 lb-ft(240 Nm)

R alloy wheel 133 lb-ft(180 Nm)

Tighten the wheel nuts to atightening

torque of 133 lb-ft (180 Nm).

X Push the piston on the hydraulic jac kin

again and close the pressure release

screw.

X Stow the jack and the rest of the vehicle

tools in the vehicle again.

i You can now install the hub caps on steel

wheels with wheel bolts. The installing

procedure depends on whether the hub cap

acts as a trim that covers the whole wheel,

or just covers the center. Changing wheels

307Wheels and tires Z

Page 311 of 334

R

only use a spare wheel that differs from the

wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correc twheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size,

do not exceed the maximum speed of

80 km/h. General notes

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

The procedure for mounting the spare wheel

is described in "Mounting awheel"

(Y page 303).

The following should be checked regularly,

particularly prior to long journeys:

R the tire pressure of the spare wheel, which

should then be corrected if necessary

(Y page 278).

R the fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6years at the latest,

regardless of wear. This also applies to the

spare wheel.

i If you have mounted a spare wheel, the

tire pressure monitor (Y page 281) will not

function for this wheel. The spare wheel is

not equipped with a sensor for monitoring

tire pressure. Removing and installing the spare

wheel

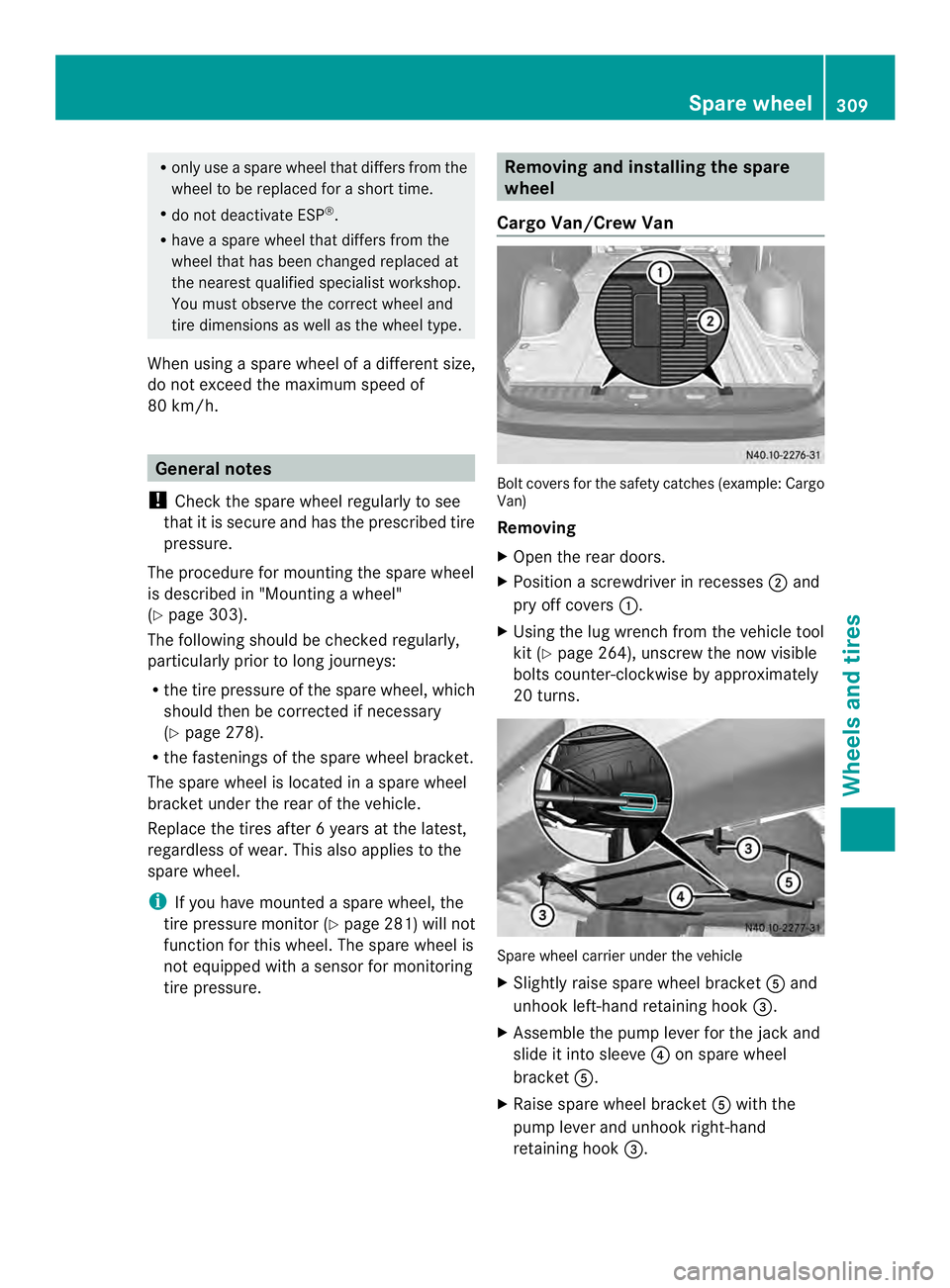

Cargo Van/Crew Van Bolt covers for the safety catches (example: Cargo

Van)

Removing

X

Open the rear doors.

X Position a screwdriver in recesses 0006and

pry off covers 0005.

X Using the lug wrench from the vehicle tool

kit (Y page 264), unscrew the now visible

bolts counter-clockwise by approximately

20 turns. Spare wheel carrier under the vehicle

X

Slightly raise spare wheel bracket 0023and

unhook left-hand retaining hook 0026.

X Assemble the pump lever for the jack and

slide it into sleeve 0025on spare wheel

bracket 0023.

X Raise spare wheel bracket 0023with the

pump lever and unhook right-hand

retaining hook 0026. Spare wheel

309Wheels and tires Z