sensor MITSUBISHI 3000GT 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 268 of 1146

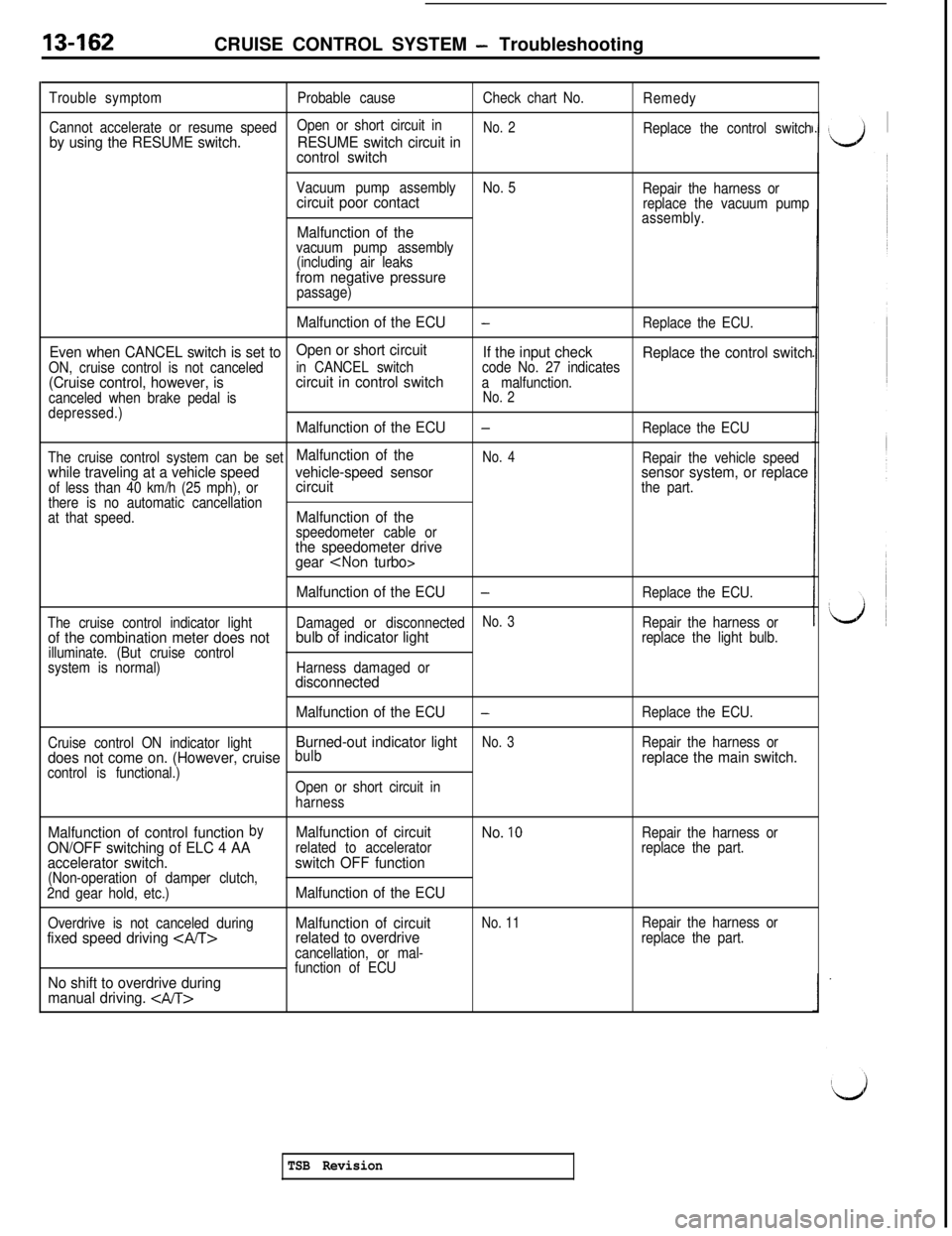

13-162CRUISE CONTROL SYSTEM - Troubleshooting

Trouble symptomProbable causeCheck chart No.

Remedy

Cannot accelerate or resume speedOpen or short circuit in

No. 2by using the RESUME switch.RESUME switch circuit inReplace the control switch

control switch

Vacuum pump assemblyNo. 5circuit poor contactRepair the harness or

replace the vacuum pump

Malfunction of thevacuum pump assembly

(including air leaks

from negative pressurepassage)assembly.

Malfunction of the ECU-Replace the ECU.

Even when CANCEL switch is set toON, cruise control is not canceled

Open or short circuit

in CANCEL switchIf the input check

Replace the control switch

(Cruise control, however, iscode No. 27 indicatescircuit in control switch

canceled when brake pedal isa malfunction.

depressed.)No. 2

Malfunction of the ECU-Replace the ECU

The cruise control system can be set

Malfunction of theNo. 4while traveling at a vehicle speedvehicle-speed sensorRepair the vehicle speed

of less than 40 km/h (25 mph), or

circuitsensor system, or replace

there is no automatic cancellationthe part.

at that speed.Malfunction of thespeedometer cable orthe speedometer drive

gear

Malfunction of the ECU

-Replace the ECU.

The cruise control indicator light

No. 3

of the combination meter does notDamaged or disconnectedbulb of indicator lightRepair the harness or

illuminate. (But cruise controlreplace the light bulb.

system is normal)Harness damaged or

disconnected

Malfunction of the ECU

-Replace the ECU.

Cruise control ON indicator light

No. 3

does not come on. (However, cruiseBurned-out indicator lightbulbRepair the harness or

control is functional.)replace the main switch.

Open or short circuit in

harness

Malfunction of control functionby

ON/OFF switching of ELC 4 AA

accelerator switch.

(Non-operation of damper clutch,

2nd gear hold, etc.)

Overdrive is not canceled during

fixed speed driving

No shift to overdrive during

manual driving.

Malfunction of circuitrelated to acceleratorswitch OFF function

Malfunction of the ECU

Malfunction of circuit

related to overdrive

cancellation, or mal-

function of ECU

No. IO

No. 11Repair the harness or

replace the part.

Repair the harness or

replace the part.

TSB Revision

Page 272 of 1146

13466CRUISE CONTROL SYSTEM - Troubleshooting

I I4Inspection of vehicle speed sensor circuitI

IGNITIONSWITCH(IG1)

5”

El

CRUISE

CONTROL

3UNIT

cl!AI

g6pl!Ezq@zla

;i

d

“m ;ygmq%q

?

VEHICLE

SPEED

SENSOR

xX35-AR-RI304P

19Y

*

$

&

~E$iJ

0z

L

COMBINATION

METER

KX35-AK-Rl3Yla

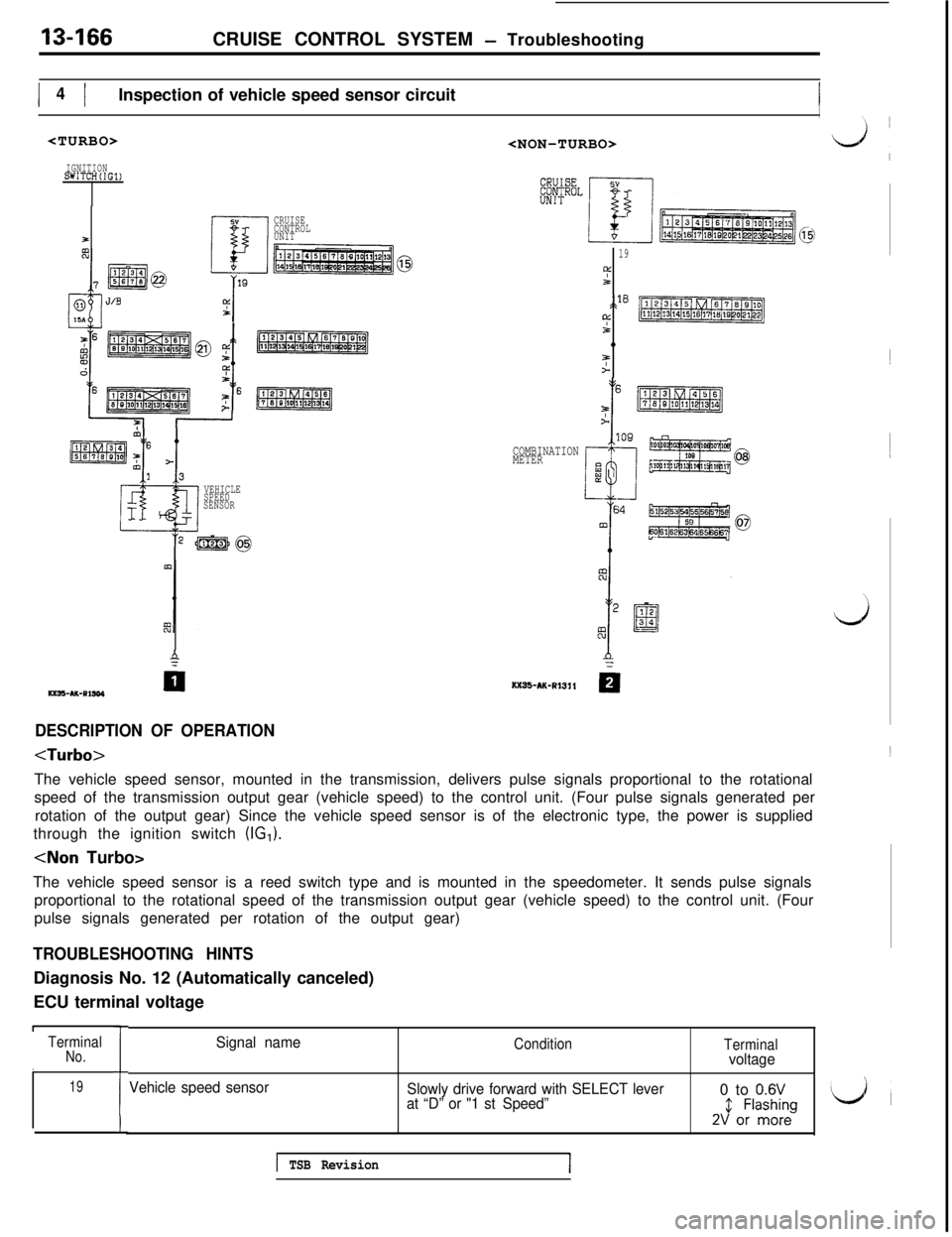

DESCRIPTION OF OPERATION

The vehicle speed sensor, mounted in the transmission, delivers pulse signals proportional to the rotational

speed of the transmission output gear (vehicle speed) to the control unit. (Four pulse signals generated per

rotation of the output gear) Since the vehicle speed sensor is of the electronic type, the power is supplied

through the ignition switch (IG,).

The vehicle speed sensor is a reed switch type and is mounted in the speedometer. It sends pulse signals

proportional to the rotational speed of the transmission output gear (vehicle speed) to the control unit. (Four

pulse signals generated per rotation of the output gear)

TROUBLESHOOTING HINTSDiagnosis No. 12 (Automatically canceled)

ECU terminal voltage

1TerminalNo.I19

i

Signal nameCondition

Terminalvoltage

Vehicle speed sensor

Slowly drive forward with SELECT lever0 to

0.6Vat “D” or "1 st Speed”2J &l;;:neg

1 TSB RevisionI

LjlI~~

\

J1

l/j,

Page 275 of 1146

Page 276 of 1146

13-170CRUISE CONTROL SYSTEM - Troubleshooting

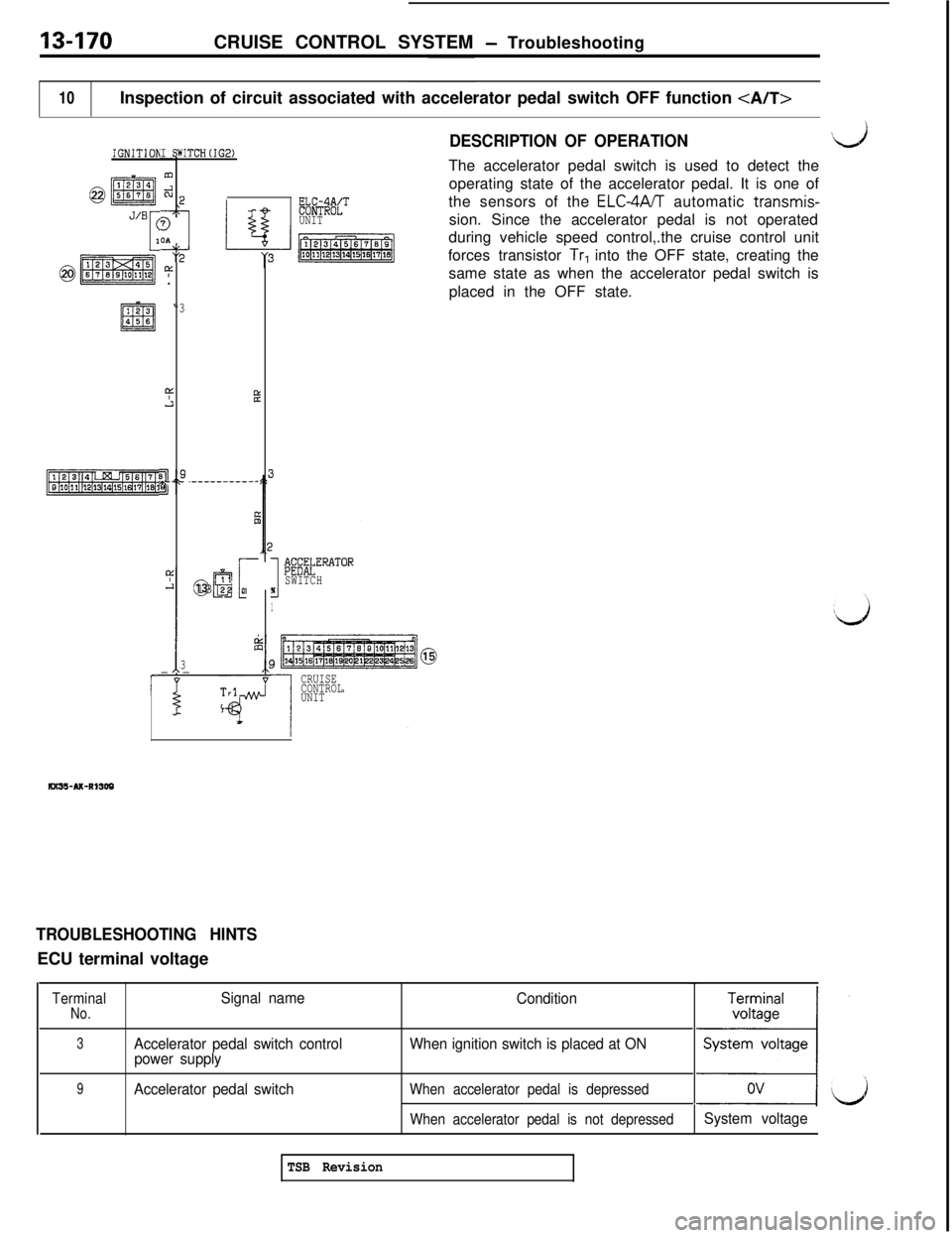

10Inspection of circuit associated with accelerator pedal switch OFF function

IGNITlOiiI sw1:

Ind

,277

?IOA-..A-"2Y

.

“3EL

3,"I\-

2

.-----------

E

r

r

g:-1

13--

ii

KH(IG2)

ORi13 : DI

"CLt-t-fi[T

UNIT

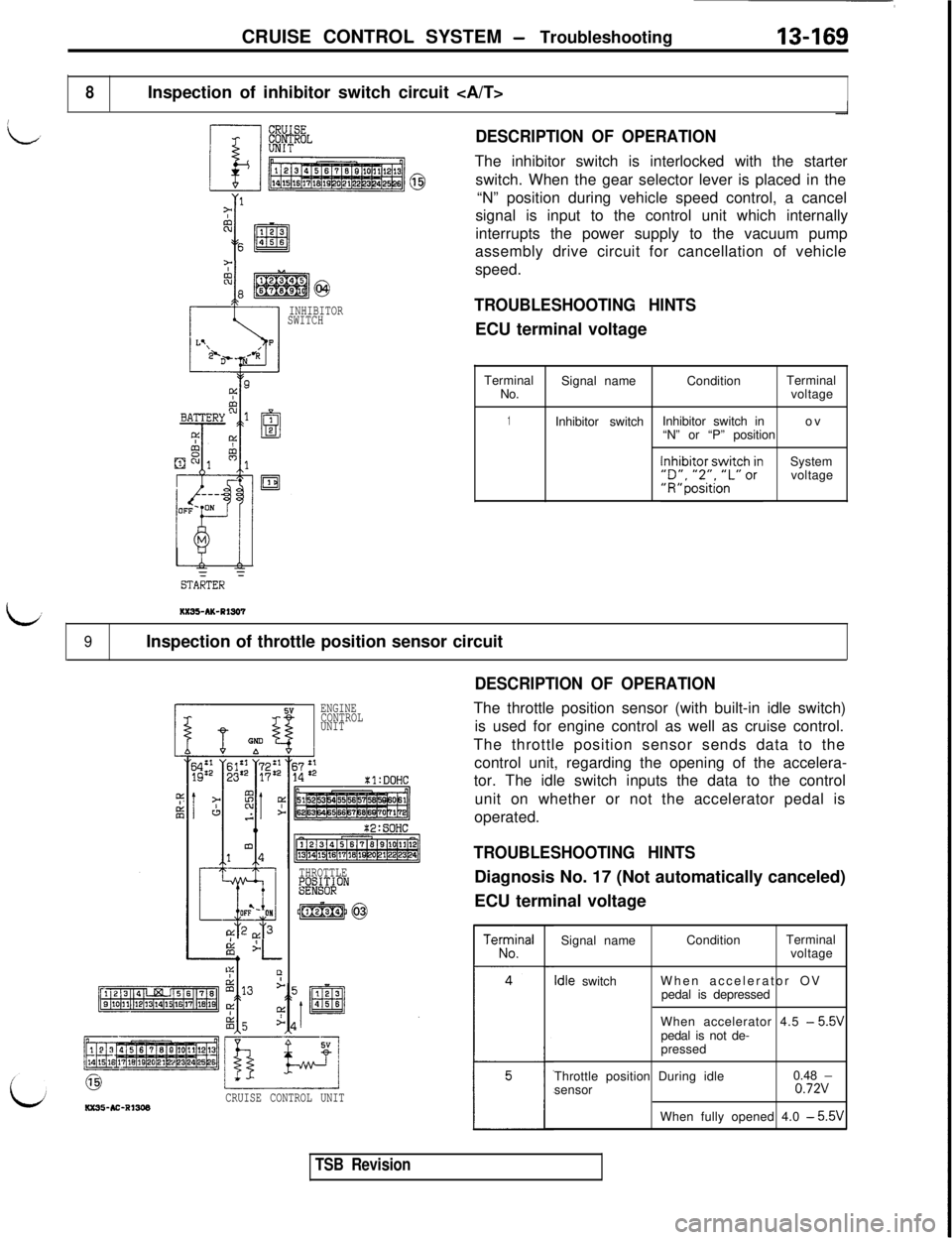

DESCRIPTION OF OPERATION‘\JThe accelerator pedal switch is used to detect the

operating state of the accelerator pedal. It is one of

the sensors of the

ELC4A/T automatic transmis-

sion. Since the accelerator pedal is not operated

during vehicle speed control,.the cruise control unit

forces transistor

Tr, into the OFF state, creating the

same state as when the accelerator pedal switch is

placed in the OFF state.

1

$iK&ERATOR

SWITCHH

1

2

-I

CRUISE

CONTROL

UNIT

TROUBLESHOOTING HINTSECU terminal voltage

TerminalNo.Signal name

Condition

3Accelerator pedal switch control

power supplyWhen ignition switch is placed at ON

9Accelerator pedal switchWhen accelerator pedal is depressed

When accelerator pedal is not depressed

System voltage

TSB Revision

Page 279 of 1146

CRUISE CONTROL SYSTEM - Troubleshooting

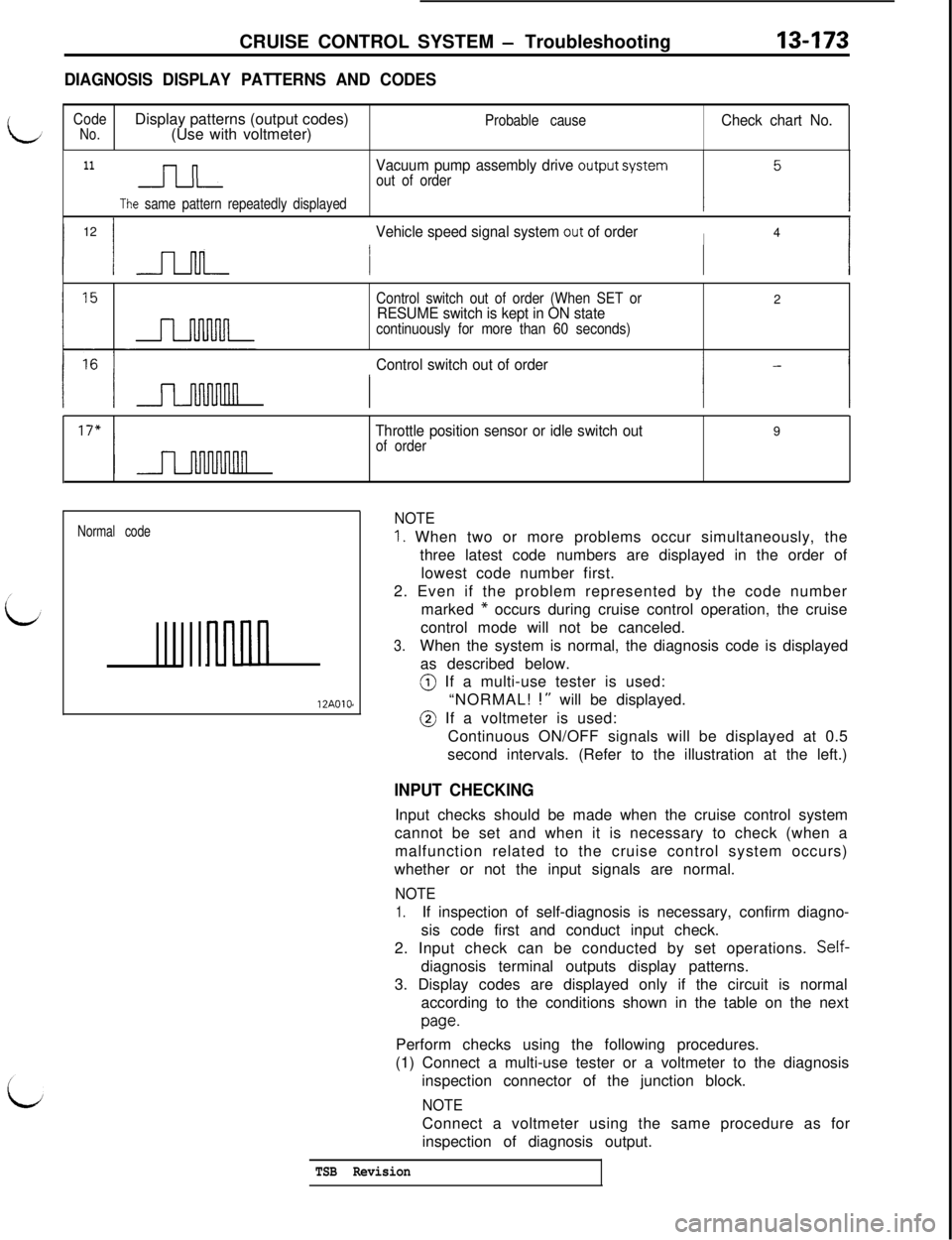

DIAGNOSIS DISPLAY PATTERNS AND CODES

13473

CodeDisplay patterns (output codes)Probable causeCheck chart No.No.(Use with voltmeter)

11l-l n-JILL

The same pattern repeatedly displayed

Vacuum pump assembly drive output systemout of order5

I I12Vehicle speed signal system out of orderI4I

I In

Control switch out of order (When SET or2RESUME switch is kept in ON statecontinuously for more than 60 seconds)

Control switch out of order

Throttle position sensor or idle switch out9

of order

Normal code

12AOlOa

NOTE

1. When two or more problems occur simultaneously, the

three latest code numbers are displayed in the order of

lowest code number first.

2. Even if the problem represented by the code number

marked * occurs during cruise control operation, the cruise

control mode will not be canceled.

3.When the system is normal, the diagnosis code is displayed

as described below.@ If a multi-use tester is used:

“NORMAL!

! I’ will be displayed.@ If a voltmeter is used:

Continuous ON/OFF signals will be displayed at 0.5

second intervals. (Refer to the illustration at the left.)

INPUT CHECKINGInput checks should be made when the cruise control system

cannot be set and when it is necessary to check (when a

malfunction related to the cruise control system occurs)

whether or not the input signals are normal.

NOTE

1.If inspection of self-diagnosis is necessary, confirm diagno-

sis code first and conduct input check.

2. Input check can be conducted by set operations.

Self-diagnosis terminal outputs display patterns.

3. Display codes are displayed only if the circuit is normal

according to the conditions shown in the table on the next

paw.Perform checks using the following procedures.

(1) Connect a multi-use tester or a voltmeter to the diagnosis

inspection connector of the junction block.

NOTEConnect a voltmeter using the same procedure as for

inspection of diagnosis output.

TSB Revision

Page 281 of 1146

CRUISE CONTROL SYSTEM - Troubleshooting

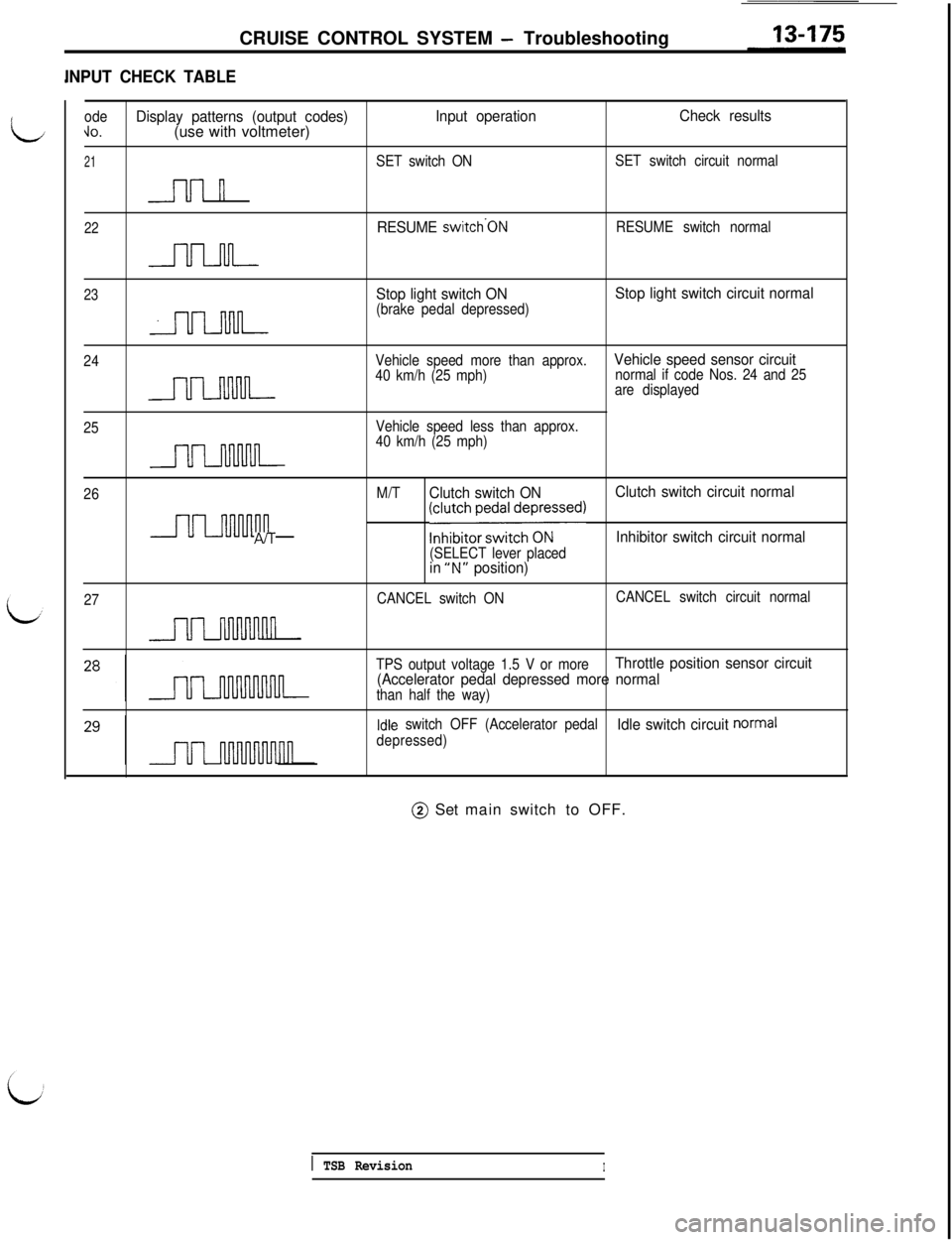

INPUT CHECK TABLE

odeDisplay patterns (output codes)Input operationCheck results40.(use with voltmeter)

21SET switch ONSET switch circuit normal

n

22RESUME switch.ONRESUME switch normal

23

nn

Stop light switch ON(brake pedal depressed)

Stop light switch circuit normal

24Vehicle speed more than approx.

40 km/h (25 mph)Vehicle speed sensor circuitnormal if code Nos. 24 and 25

are displayed

25Vehicle speed less than approx.

40 km/h (25 mph)

26M/T

Clutch switch ON

-1~ ~~;~~o~~i~~~~;sed’

(SELECT lever placedin “N” position)Clutch switch circuit normal

Inhibitor switch circuit normal

27CANCEL switch ONCANCEL switch circuit normal

TPS output voltage 1.5 V or more

Throttle position sensor circuit

(Accelerator pedal depressed more normal

than half the way)

Idle switch OFF (Accelerator pedalIdle switch circuit normal

depressed)@ Set main switch to OFF.

1 TSB RevisionI

Page 282 of 1146

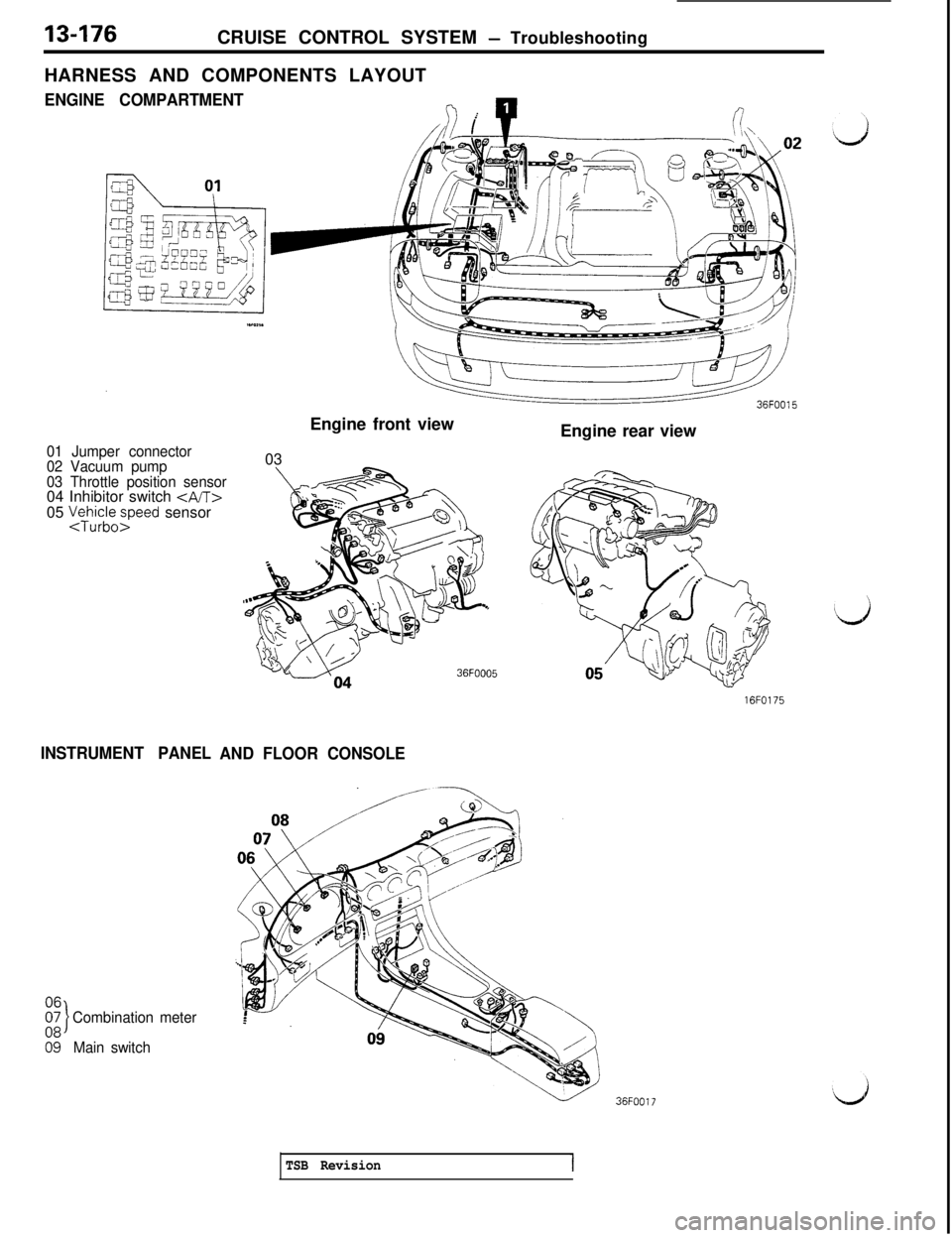

13-176CRUISE CONTROL SYSTEM - Troubleshooting

HARNESS AND COMPONENTS LAYOUT

ENGINE COMPARTMENT

01 Jumper connector

02 Vacuum pump

03 Throttle position sensor04 Inhibitor switch

05

VeTkFo;peed sensor

INSTRUMENT PANEL

AND FLOOR CONSOLE

Combination meter

Main switchEngine front view

03

36FOOO5Engine rear view

16FO175

36FOO17

TSB Revision

Page 289 of 1146

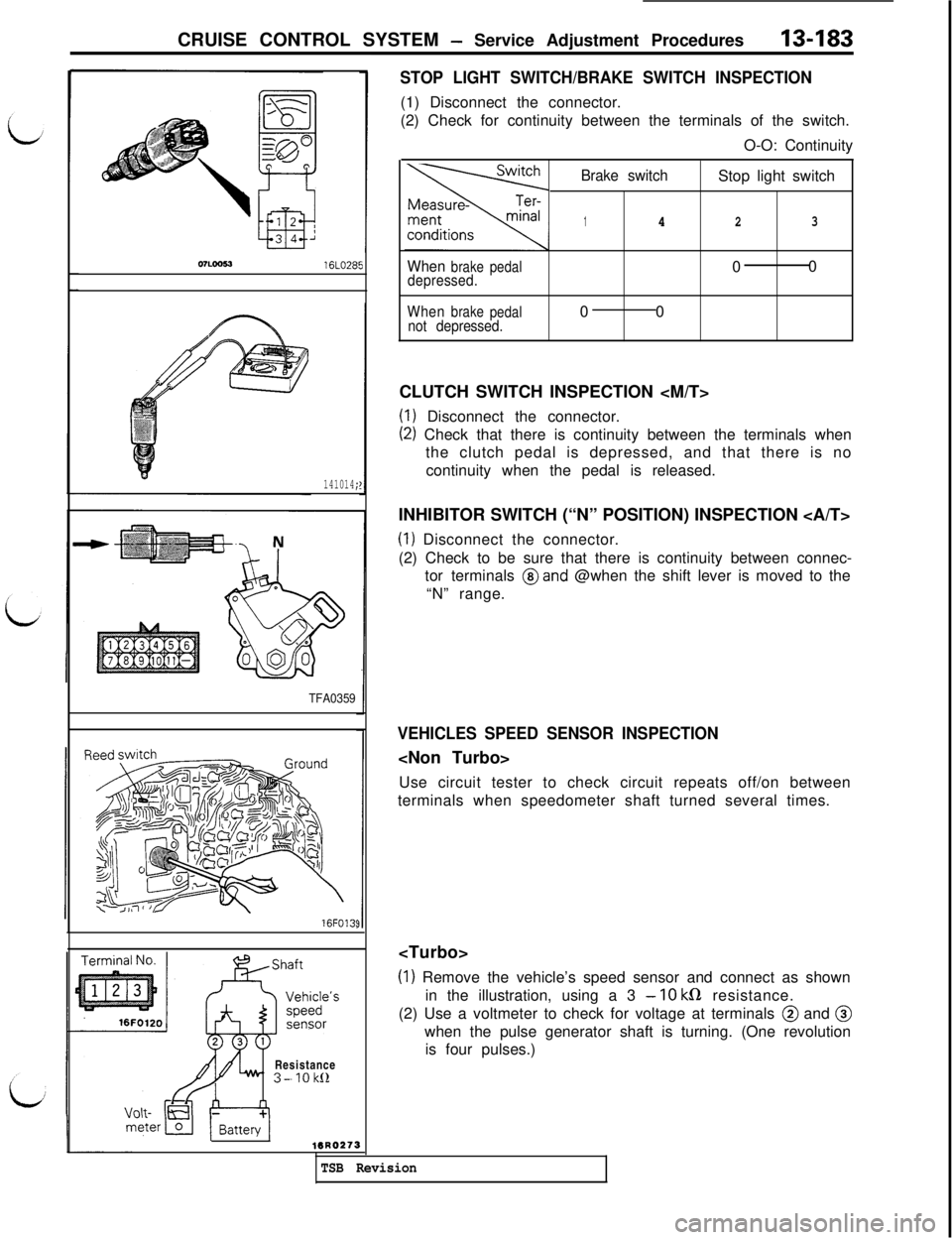

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-183

onoo5J16LO285

141014;

TFA0359

16FO13LResistance

3--1Okl2

STOP LIGHT SWITCH/BRAKE SWITCH INSPECTION(1) Disconnect the connector.

(2) Check for continuity between the terminals of the switch.

O-O: Continuity

Brake switchStop light switch

1423

Whenbrakepedal00depressed.

When

brake

pedal00not depressed.CLUTCH SWITCH INSPECTION

(I) Disconnect the connector.

(2) Check that there is continuity between the terminals when

the clutch pedal is depressed, and that there is no

continuity when the pedal is released.

INHIBITOR SWITCH (“N” POSITION) INSPECTION

(1) Disconnect the connector.

(2) Check to be sure that there is continuity between connec-

tor terminals

@and @when the shift lever is moved to the

“N” range.

VEHICLES SPEED SENSOR INSPECTION

Use circuit tester to check circuit repeats off/on between

terminals when speedometer shaft turned several times.

(1) Remove the vehicle’s speed sensor and connect as shown

in the illustration, using a 3

- 10 kQ resistance.

(2) Use a voltmeter to check for voltage at terminals @ and @

when the pulse generator shaft is turning. (One revolution

is four pulses.)

16R0273

TSB Revision

Page 290 of 1146

13-184CRUISE CONTROL SYSTEM - Service Adjustment Procedures

07AOO51

07A005t07A005i

THROlTLE POSITION SENSOR INSPECTIONFor inspection, refer to

P.13-65.

IDLE POSITION SWITCH INSPECTIONFor inspection, refer to

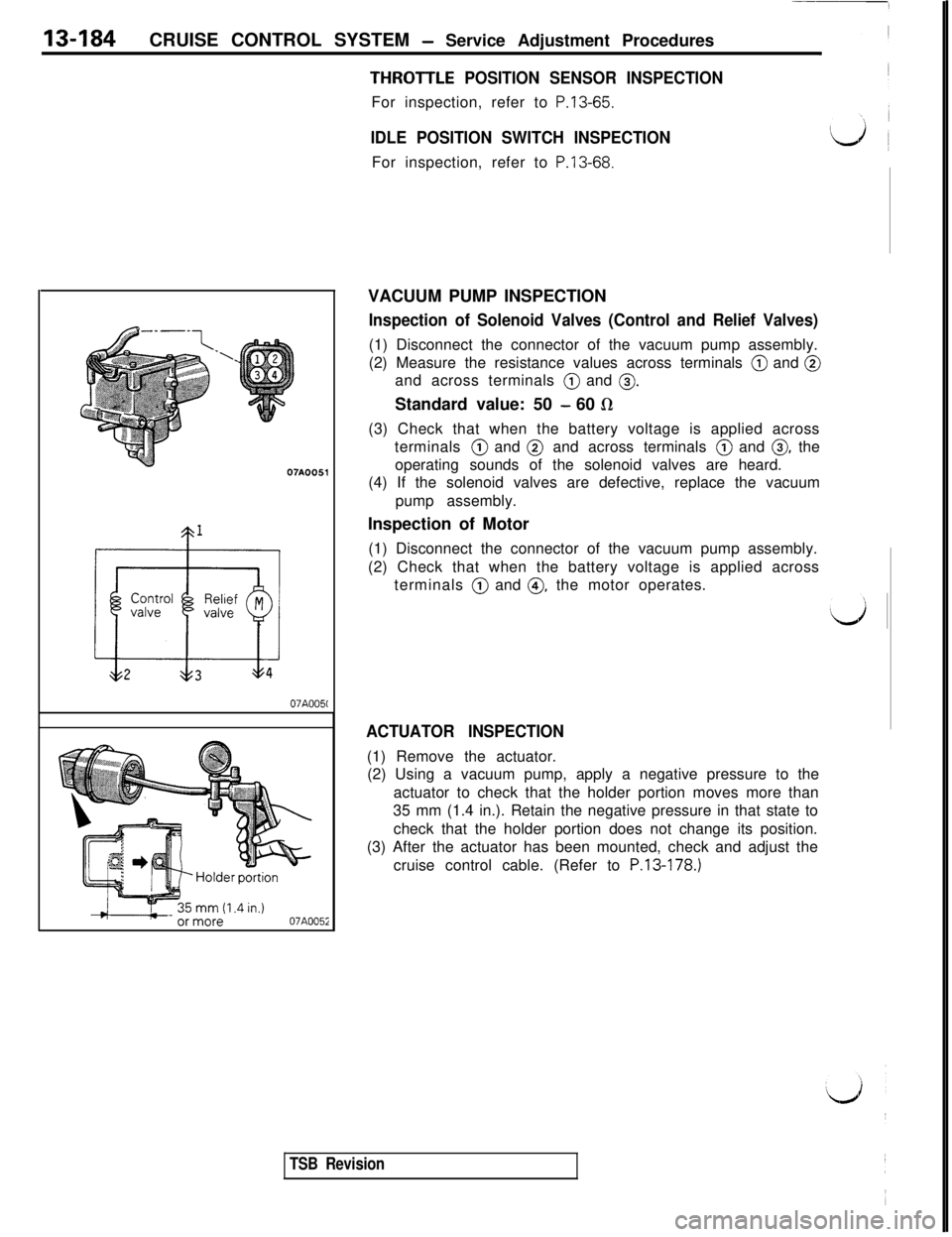

P.13-68.VACUUM PUMP INSPECTION

Inspection of Solenoid Valves (Control and Relief Valves)(1) Disconnect the connector of the vacuum pump assembly.

(2) Measure the resistance values across terminals @ and @

and across terminals @ and

0.Standard value: 50

- 60 R

(3) Check that when the battery voltage is applied across

terminals @ and @ and across terminals @ and

0, the

operating sounds of the solenoid valves are heard.

(4) If the solenoid valves are defective, replace the vacuum

pump assembly.

Inspection of Motor

(1) Disconnect the connector of the vacuum pump assembly.

(2) Check that when the battery voltage is applied across

terminals @ and

@, the motor operates.

ACTUATOR INSPECTION(1) Remove the actuator.

(2) Using a vacuum pump, apply a negative pressure to the

actuator to check that the holder portion moves more than

35 mm (1.4 in.). Retain the negative pressure in that state to

check that the holder portion does not change its position.

(3) After the actuator has been mounted, check and adjust the

cruise control cable. (Refer to

P.13-178.)

TSB Revision

Page 292 of 1146

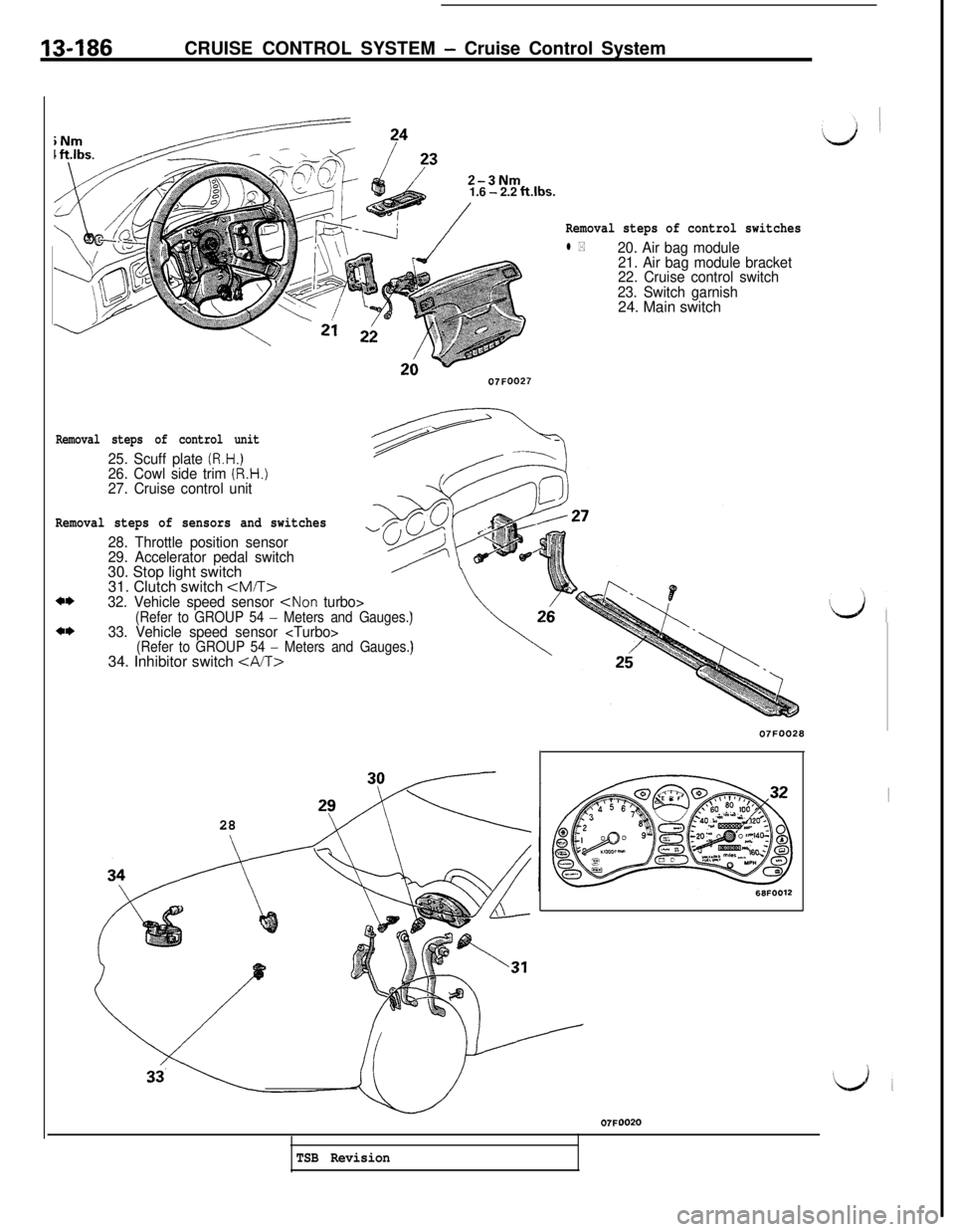

13486CRUISE CONTROL SYSTEM - Cruise Control System

1.6

- 2.2 ft.lbs.

07FOO27

Removal steps of control switches

l *20. Air bag module

21. Air bag module bracket

22. Cruise control switch

23. Switch garnish24. Main switch

Removal steps of sensors and switches

28. Throttle position sensor

29. Accelerator pedal switch30. Stop light switch

31. Clutch switch

4*

4*

Removal steps of control unit

25. Scuff plate (R.H.)26. Cowl side trim (R.H.)27. Cruise control unit34. Inhibitor switch

2807FOO28

68FOO12

07FOO20

TSB Revision