MITSUBISHI 3000GT 1991 Service Manual

3000GT 1991

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57085/w960_57085-0.png

MITSUBISHI 3000GT 1991 Service Manual

Trending: hood release, fuel cap, wiring, flat tire, washer fluid, seats, 4WD

Page 141 of 1146

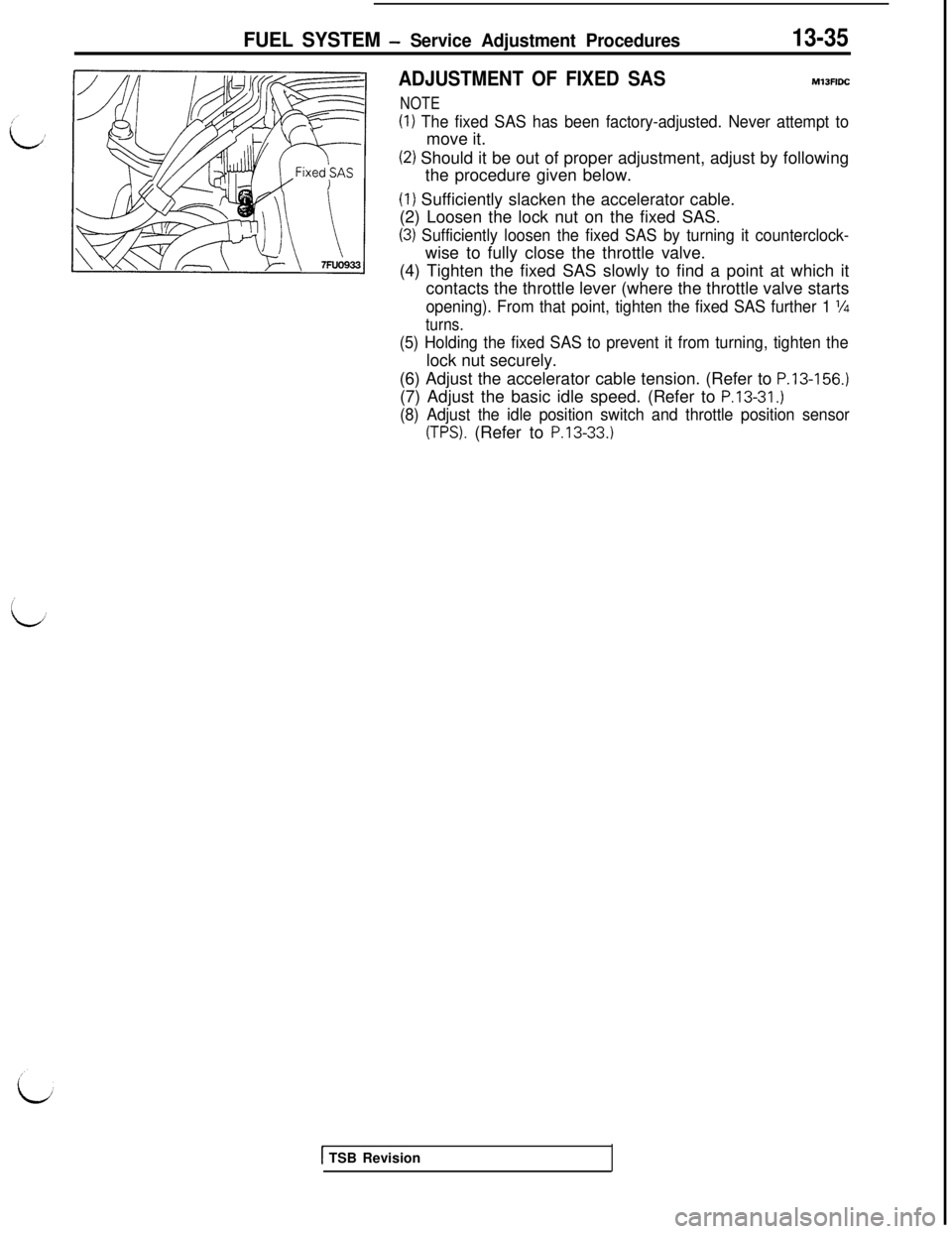

FUEL SYSTEM - Service Adjustment Procedures13-35

ADJUSTMENT OF FIXED SASMlJFlDC

NOTE

(1) The fixed SAS has been factory-adjusted. Never attempt tomove it.

(2) Should it be out of proper adjustment, adjust by following

the procedure given below.(I) Sufficiently slacken the accelerator cable.

(2) Loosen the lock nut on the fixed SAS.

(3) Sufficiently loosen the fixed SAS by turning it counterclock-wise to fully close the throttle valve.

(4) Tighten the fixed SAS slowly to find a point at which it

contacts the throttle lever (where the throttle valve starts

opening). From that point, tighten the fixed SAS further 1 l/4

turns.

(5) Holding the fixed SAS to prevent it from turning, tighten thelock nut securely.

(6) Adjust the accelerator cable tension. (Refer to

P.13-156.)(7) Adjust the basic idle speed. (Refer to

P.13-31.)

(8) Adjust the idle position switch and throttle position sensor

(TPS). (Refer to P.13-33.)

1 TSB Revision

Page 142 of 1146

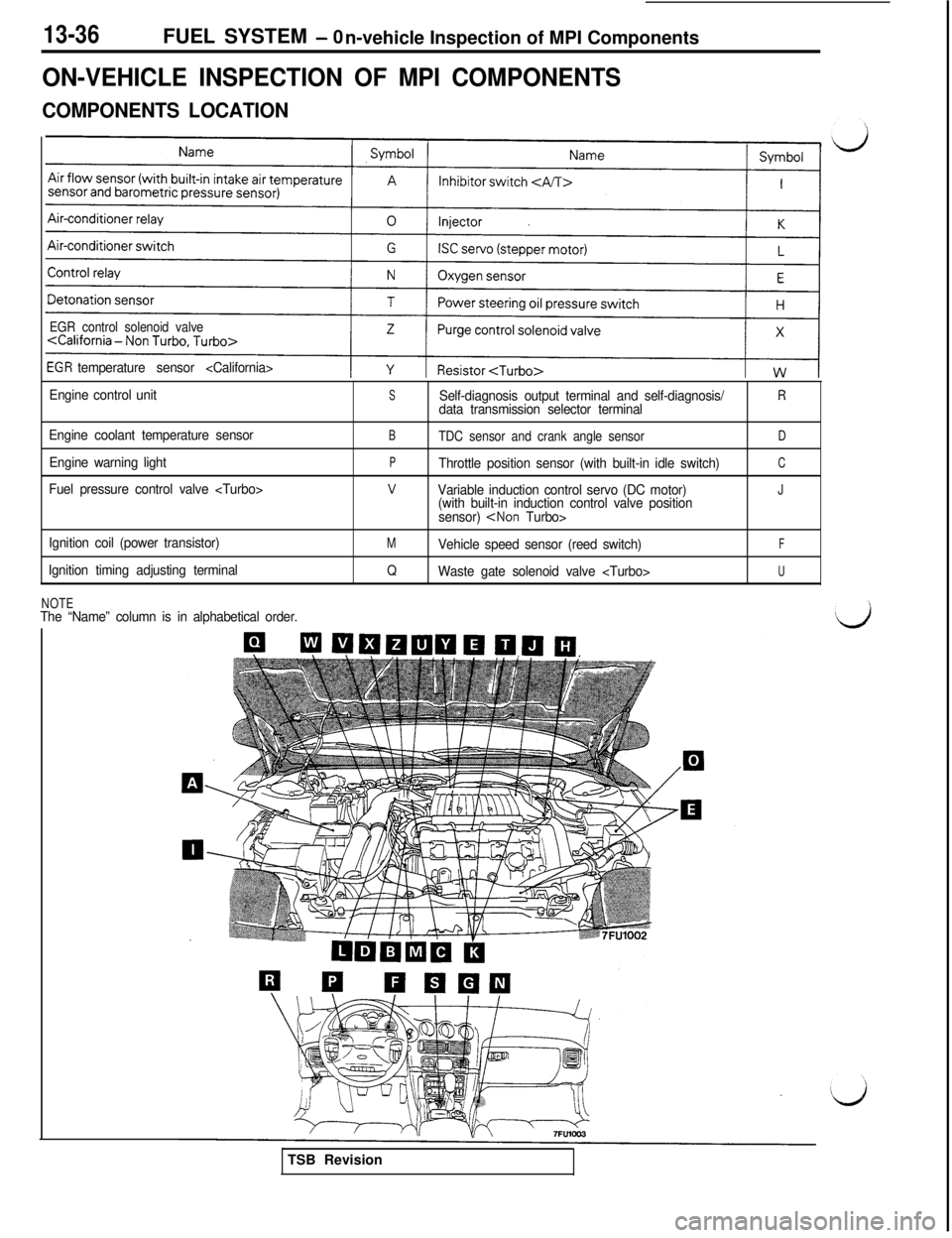

13-36FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

ON-VEHICLE INSPECTION OF MPI COMPONENTS

COMPONENTS LOCATION

EGR control solenoid valve

temperature sensor

Engine control unit

Engine coolant temperature sensor

Engine warning light

Fuel pressure control valve

Ignition coil (power transistor)

Ignition timing adjusting terminal

SSelf-diagnosis output terminal and self-diagnosis/Rdata transmission selector terminal

BTDC sensor and crank angle sensorD

PThrottle position sensor (with built-in idle switch)C

vVariable induction control servo (DC motor)J(with built-in induction control valve position

sensor)

MVehicle speed sensor (reed switch)F

QWaste gate solenoid valve U

NOTEThe “Name” column is in alphabetical order.TSB Revision

Page 143 of 1146

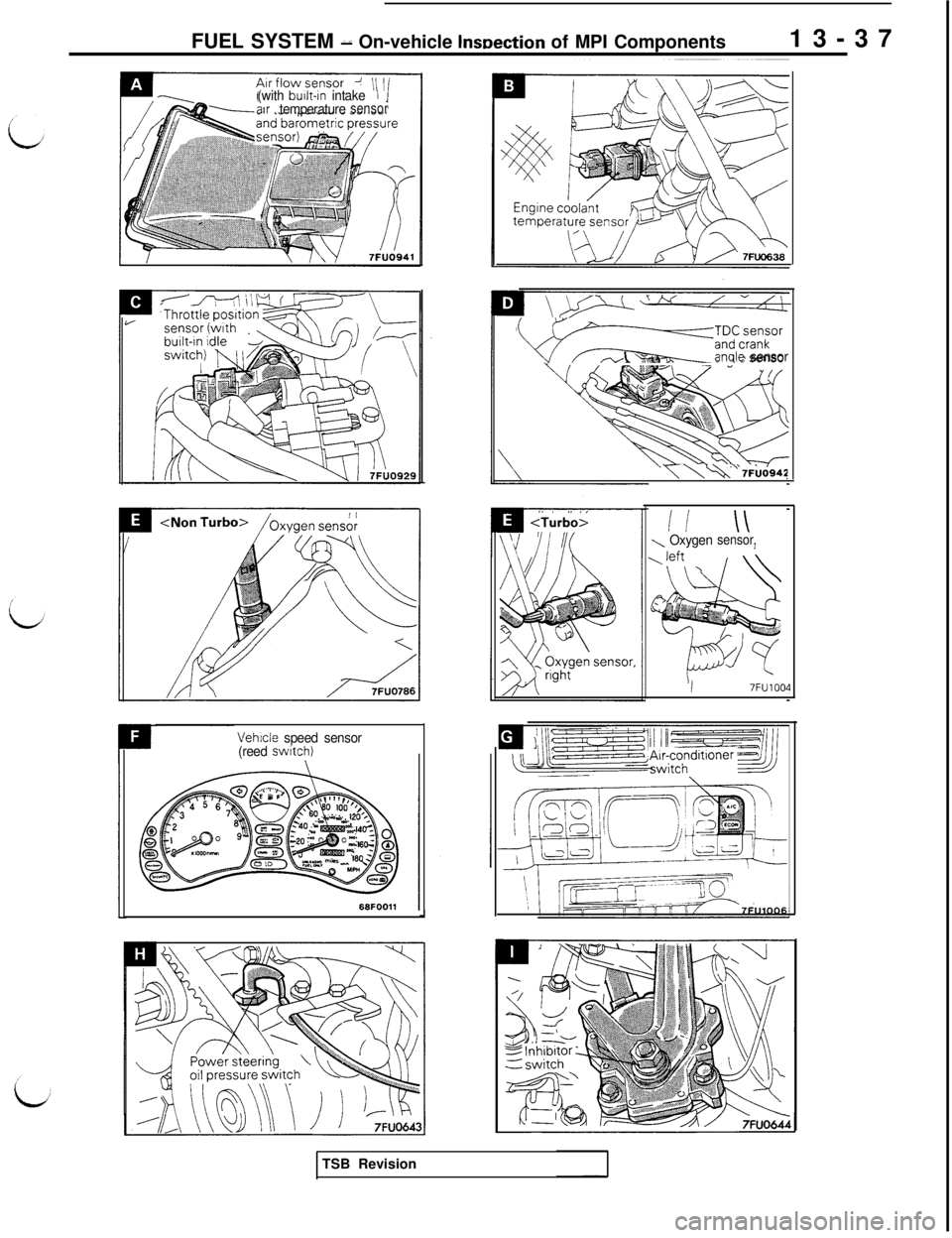

FUEL SYSTEM d On-vehicle lnwection of MPI Components13-37(with built-in intakeIair temperaturesensor

Vehicle speed sensor

(reed switch)J

wF~~::~:~~or- A.anale sensor

y\\ v 7Fbd942

ii \\\ Oxygensensor,

I7FU1004

//

\:/TSB Revision

Page 144 of 1146

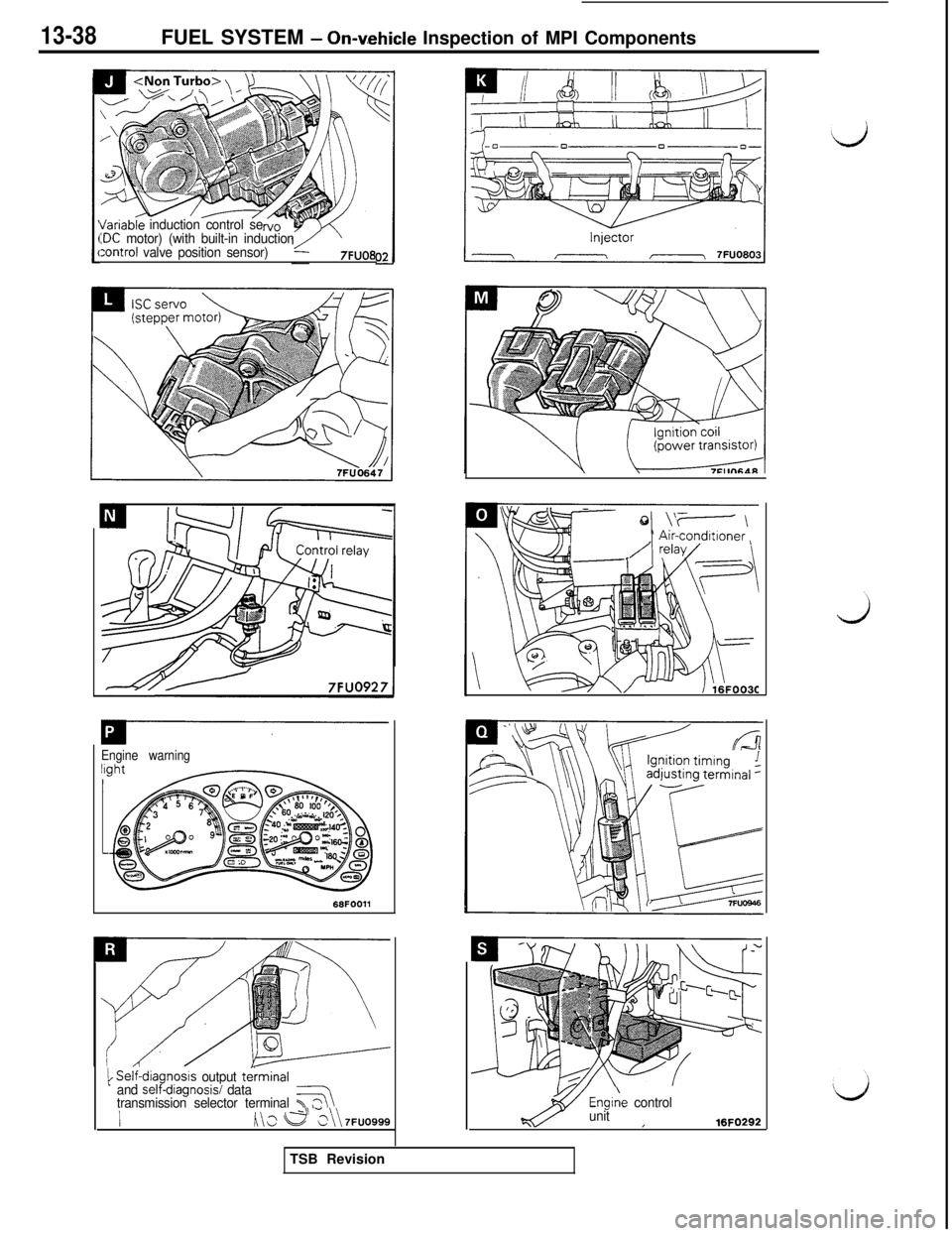

13-38FUEL SYSTEM - Onaehicle Inspection of MPI Components

I/ariableinduction control se:DC motor) (with built-in induction:ontrol valve position sensor)7FUO8

Engine warning

1 Self-diagn,osls output terminal

and self-dlagnosisi data

transmission selector terminal T37

h\s e >\\ 7FUO999Engiie

control

unit

I16FO292TSB Revision

Page 145 of 1146

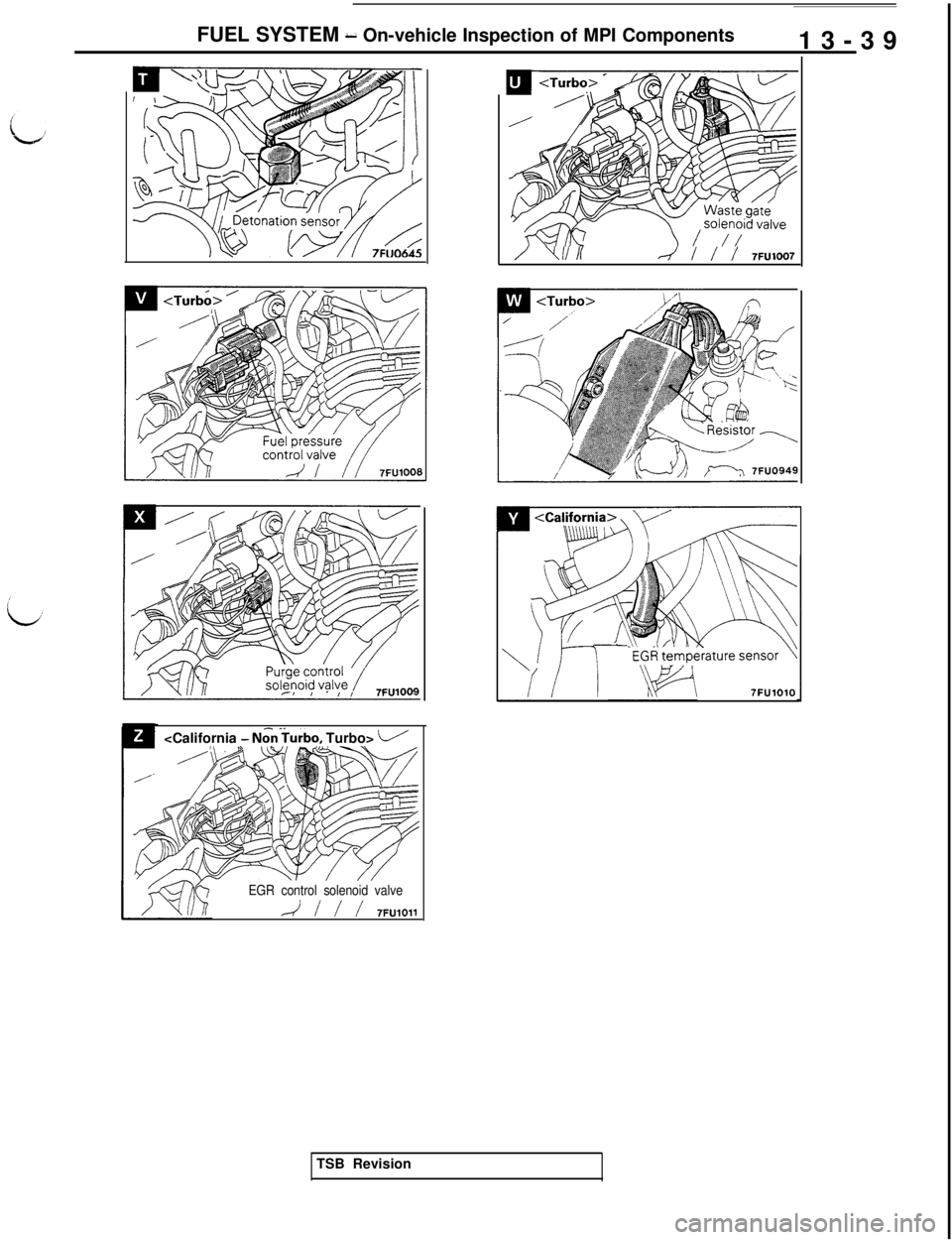

FUEL SYSTEM * On-vehicle Inspection of MPI Components

13-39

- N&Turbo, Turbo> i/

EGR control solenoid valve

A / / / 7FUlOll

/ Ylilr--/ / / / 7FU1007

7FUlOlOTSB Revision

Page 146 of 1146

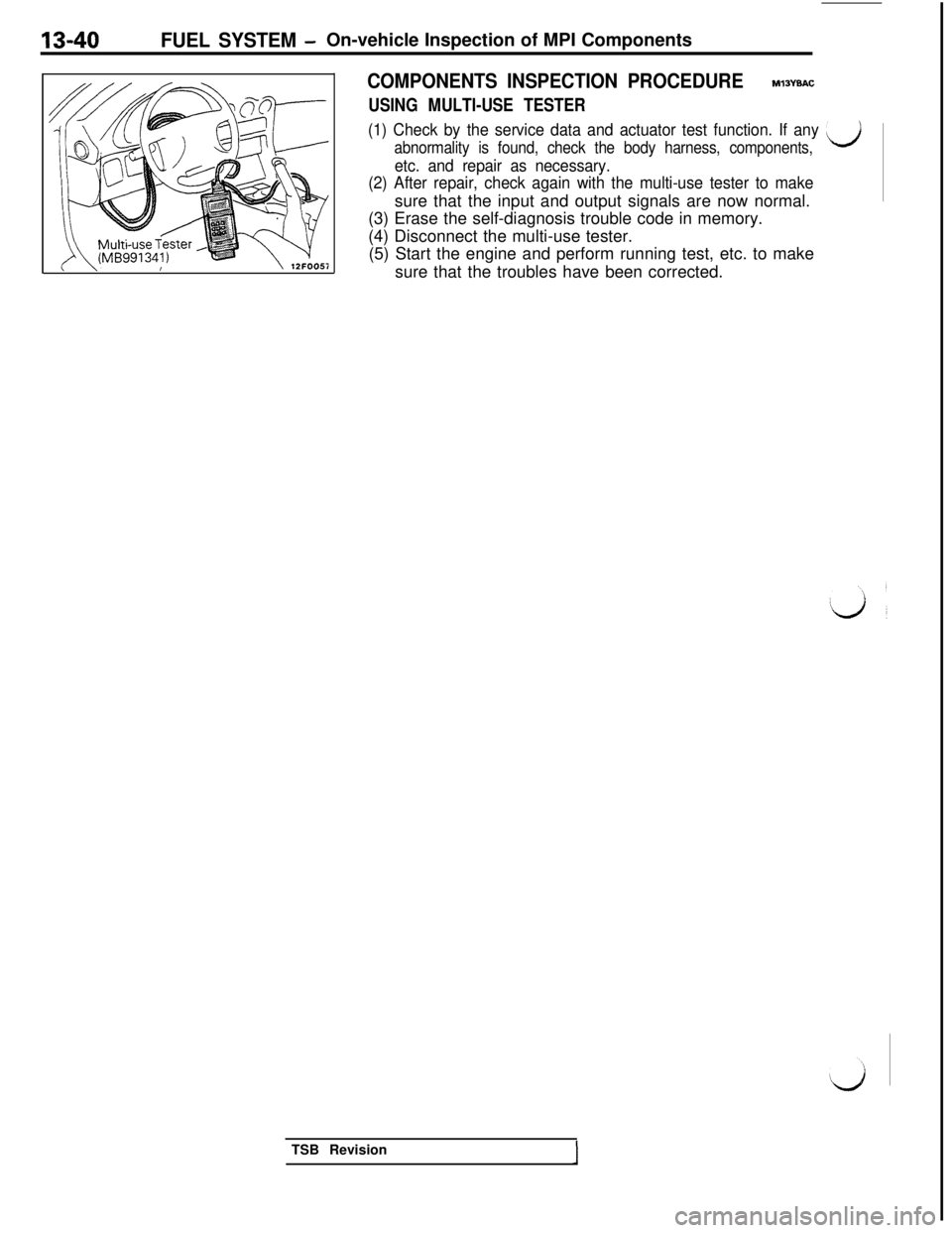

13-40FUEL SYSTEM -On-vehicle Inspection of MPI Components

COMPONENTS INSPECTION PROCEDUREM13YBAC

USING MULTI-USE TESTER

(1) Check by the service data and actuator test function. If any ij

abnormality is found, check the body harness, components,

etc. and repair as necessary.

(2) After repair, check again with the multi-use tester to makesure that the input and output signals are now normal.

(3) Erase the self-diagnosis trouble code in memory.

(4) Disconnect the multi-use tester.

(5) Start the engine and perform running test, etc. to make

sure that the troubles have been corrected.

TSB Revision

Page 147 of 1146

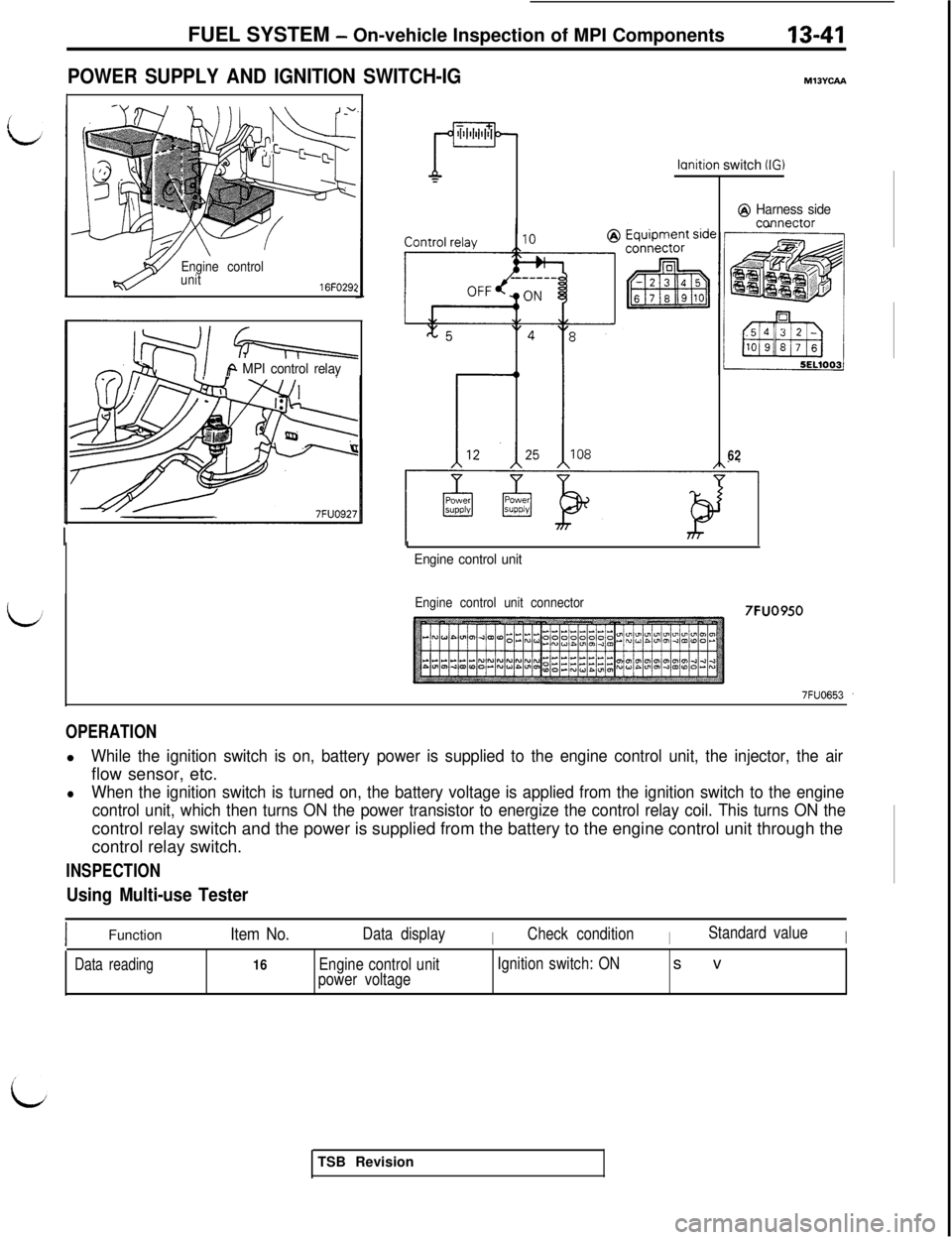

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-41

POWER SUPPLY AND IGNITION SWITCH-IG

Engine control

unit

16FO29:

Q-i=++=

iA MPI control relay

ml3Yuu

lcmition switch (IG)

@ Harness sideccmnector

62

I

Engine control unit

Engine control unit connector7FUO950

OPERATIONl

While the ignition switch is on, battery power is supplied to the engine control unit, the injector, the airflow sensor, etc.

lWhen the ignition switch is turned on, the battery voltage is applied from the ignition switch to the engine

control unit, which then turns ON the power transistor to energize the control relay coil. This turns ON thecontrol relay switch and the power is supplied from the battery to the engine control unit through the

control relay switch.

INSPECTION

Using Multi-use Tester

IFunctionItem No.Data displayICheck conditionIStandard valueI

Data reading16Engine control unit

power voltageIgnition switch: ONsv

TSB Revision

Page 148 of 1146

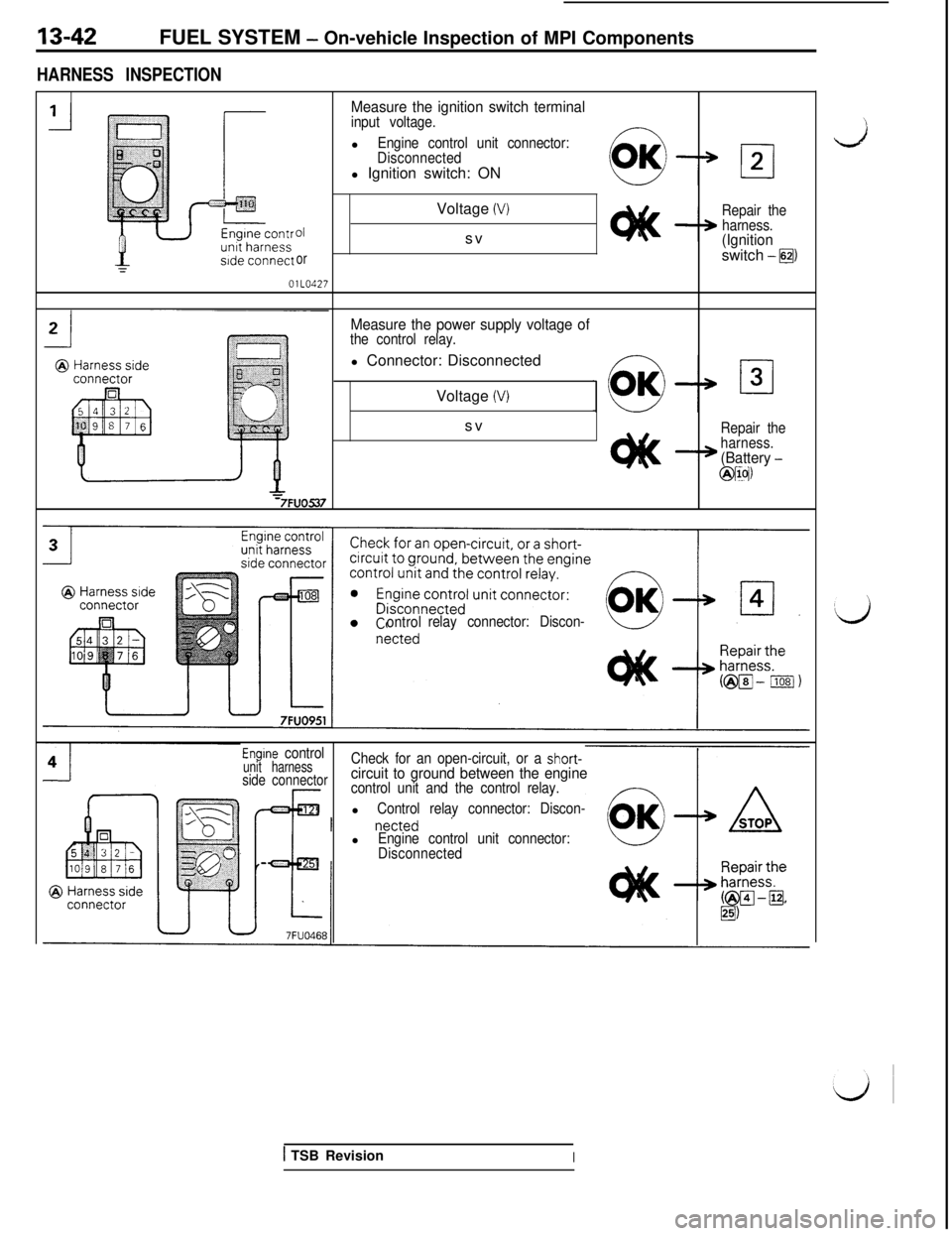

IS-42FUEL SYSTEM - On-vehicle Inspection of MPI Components

HARNESS INSPECTION

Measure the ignition switch terminalinput voltage.l

Engine control unit connector:

Disconnectedl Ignition switch: ON

01

orOlLO427Voltage

(V)svRepair the

harness.

(Ignitionswitch -@I

Measure the power supply voltage ofthe control relay.l Connector: Disconnected

Voltage

(V)sv

Repair the

harness.

(Battery -

@IIN

ontrolrelay connector: Discon-

Engine controlunit harnessCheck for an open-circuit, or a short-

side connectorcircuit to ground between the enginecontrol unit and the control relay.l

Control relay connector: Discon-l

Engine control unit connector:

Disconnected

1 TSB RevisionI

Page 149 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-43OlLO521

01 LO220

011022:

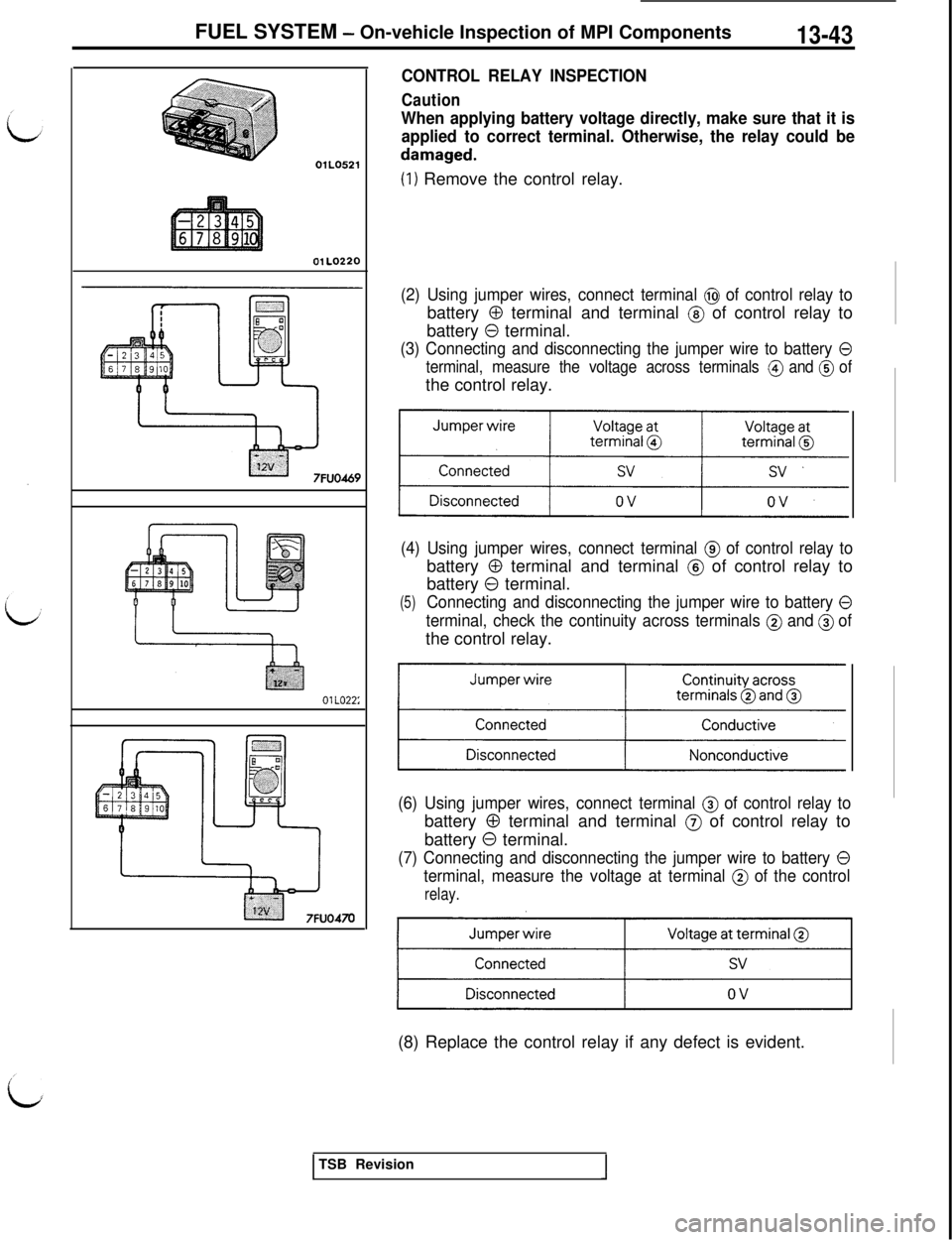

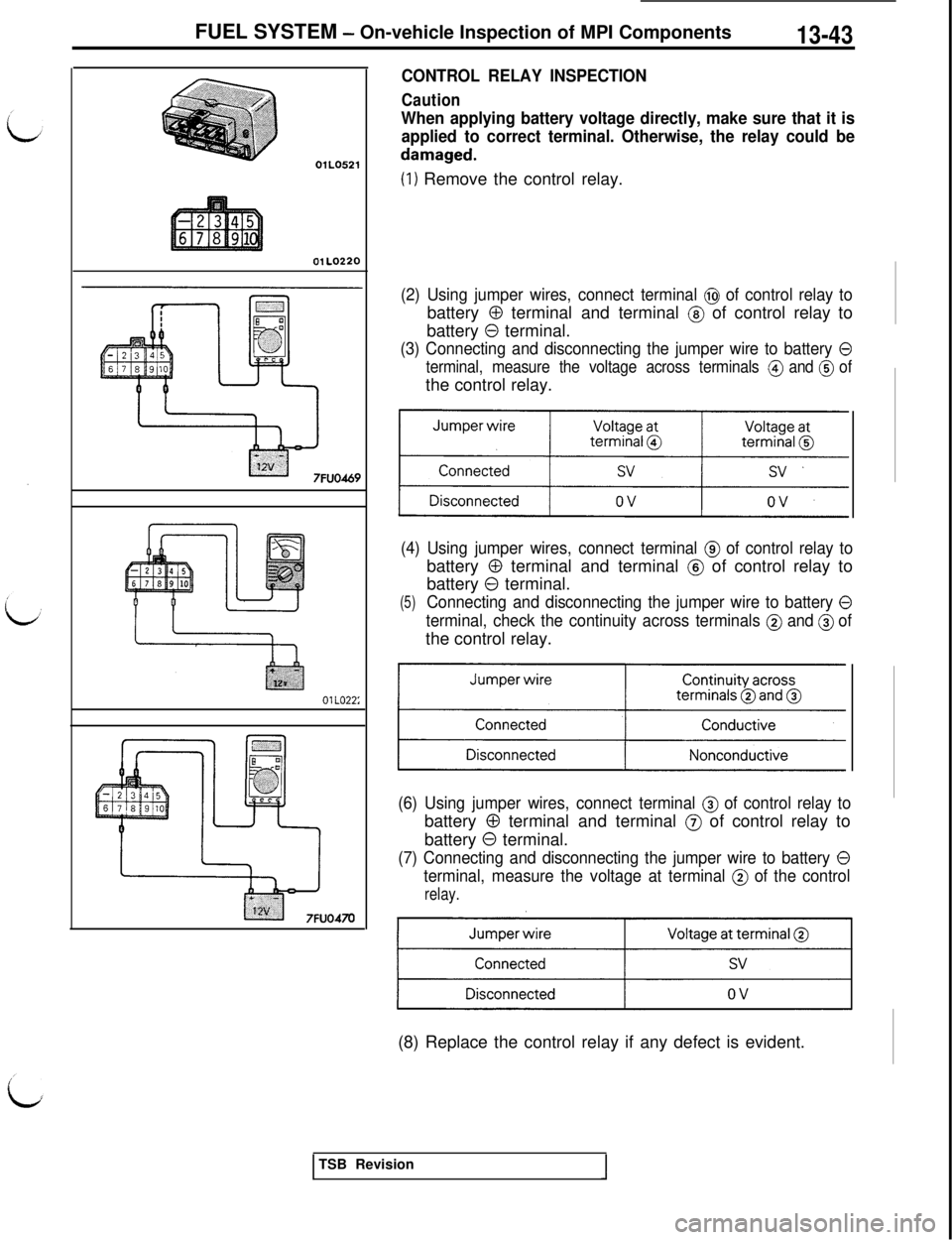

CONTROL RELAY INSPECTION

Caution

When applying battery voltage directly, make sure that it is

applied to correct terminal. Otherwise, the relay could be

damaged.

(1) Remove the control relay.

(2) Using jumper wires, connect terminal @ of control relay tobattery

0 terminal and terminal @ of control relay to

battery

0 terminal.

(3) Connecting and disconnecting the jumper wire to battery 0

terminal, measure the voltage across terminals @ and @ ofthe control relay.

(4) Using jumper wires, connect terminal @ of control relay tobattery

0 terminal and terminal @ of control relay to

battery

0 terminal.

(5)Connecting and disconnecting the jumper wire to battery 0

terminal, check the continuity across terminals @ and @ ofthe control relay.

(6) Using jumper wires, connect terminal @ of control relay tobattery

0 terminal and terminal @ of control relay to

battery

0 terminal.

(7) Connecting and disconnecting the jumper wire to battery 0

terminal, measure the voltage at terminal @ of the control

relay.(8) Replace the control relay if any defect is evident.

TSB Revision

Page 150 of 1146

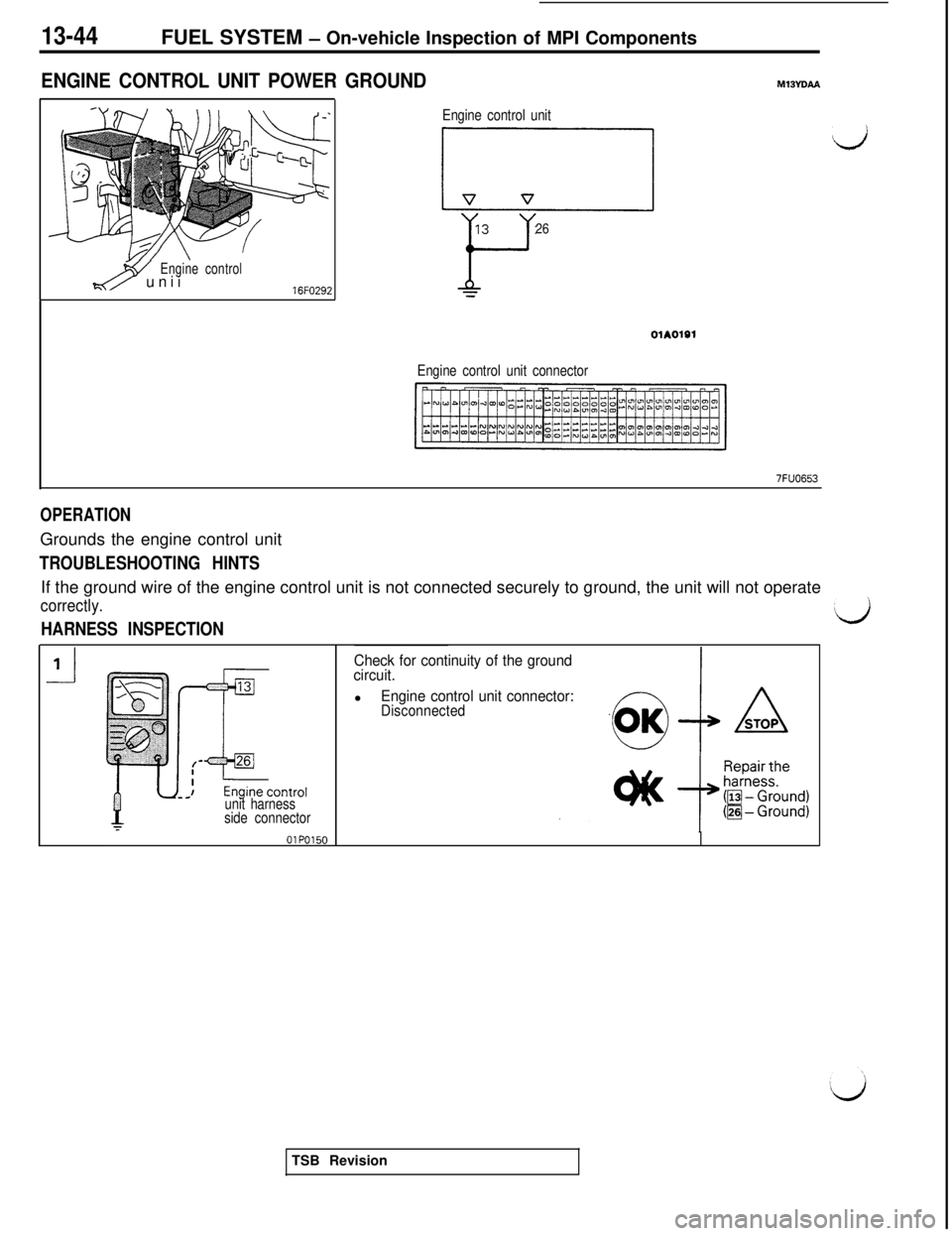

13-44FUEL SYSTEM - On-vehicle Inspection of MPI Components

ENGINE CONTROL UNIT POWER GROUNDMlBYD~

wEngine controld/ unii16FO292

Engine control unit

L-7-l d

1326

Yx

01A01@1

Engine control unit connector

7FUO653

OPERATIONGrounds the engine control unit

TROUBLESHOOTING HINTSIf the ground wire of the engine control unit is not connected securely to ground, the unit will not operate

correctly.

HARNESS INSPECTION

unit harness

side connector

Check for continuity of the ground

circuit.l

Engine control unit connector:DisconnectedTSB Revision

Trending: diagnostic menu, length, oil reset, spark plugs, reset, clock setting, seat adjustment