MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 181 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

L

L

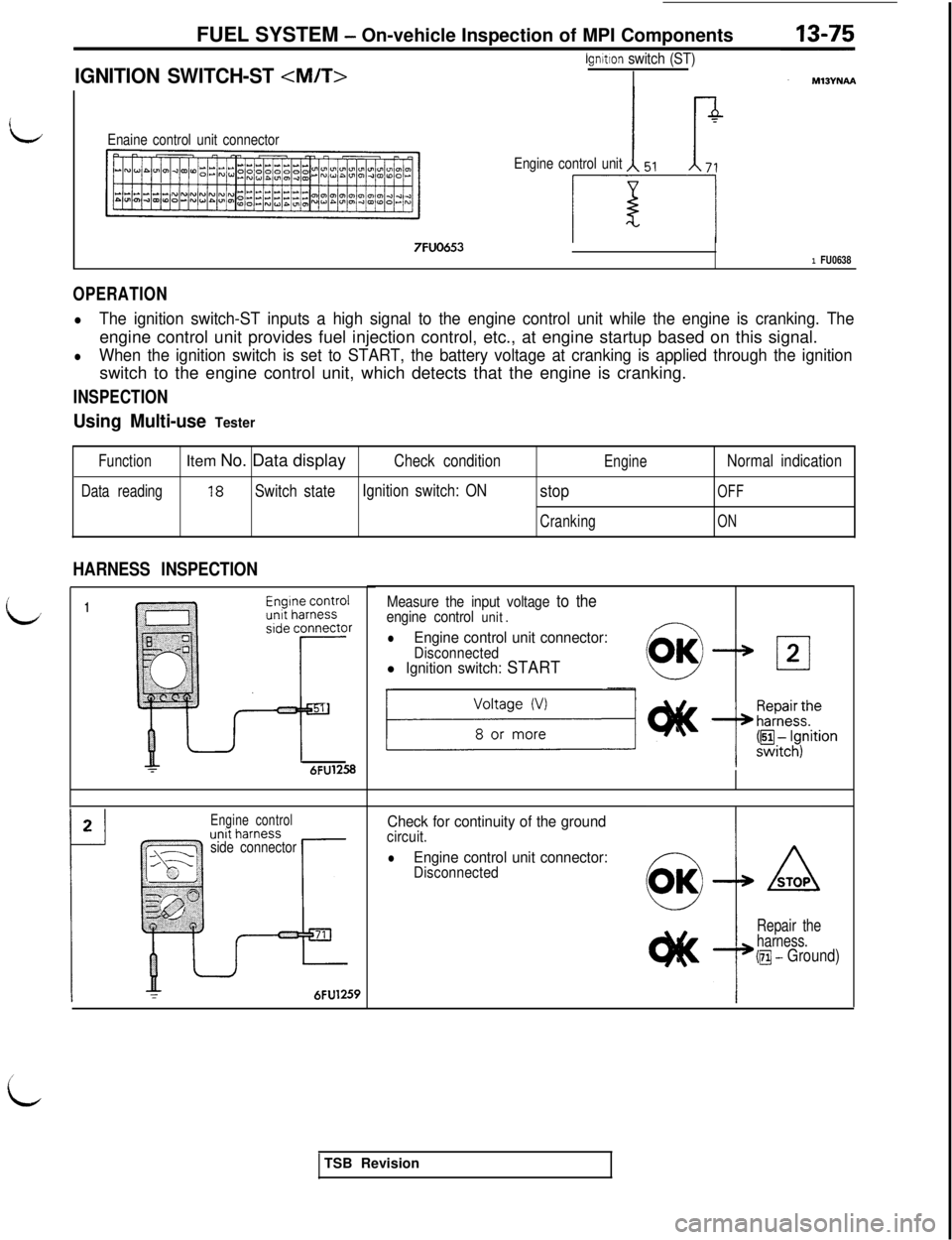

IGNITION SWITCH-ST

lgnitlon switch (ST)

I

Enaine control unit connector

7FUO653

Engine control unit

1 FU0638

OPERATION

lThe ignition switch-ST inputs a high signal to the engine control unit while the engine is cranking. Theengine control unit provides fuel injection control, etc., at engine startup based on this signal.

lWhen the ignition switch is set to START, the battery voltage at cranking is applied through the ignitionswitch to the engine control unit, which detects that the engine is cranking.

INSPECTION

Using Multi-use Tester

FunctionItem No. Data displayCheck conditionEngineNormal indication

Data reading18Switch stateIgnition switch: ONstopOFF

CrankingON

HARNESS INSPECTION

1

L6FU1258

2

1

Engine control

side connector

IY-6FU1259

Measure the input voltage to theengine control unit.nlEngine control unit connector:Disconnectedl Ignition switch: START

Check for continuity of the groundcircuit.

lEngine control unit connector:Disconnected

Repair the

harness.

(m - Ground)

iTSB Revision

Page 182 of 1146

Page 183 of 1146

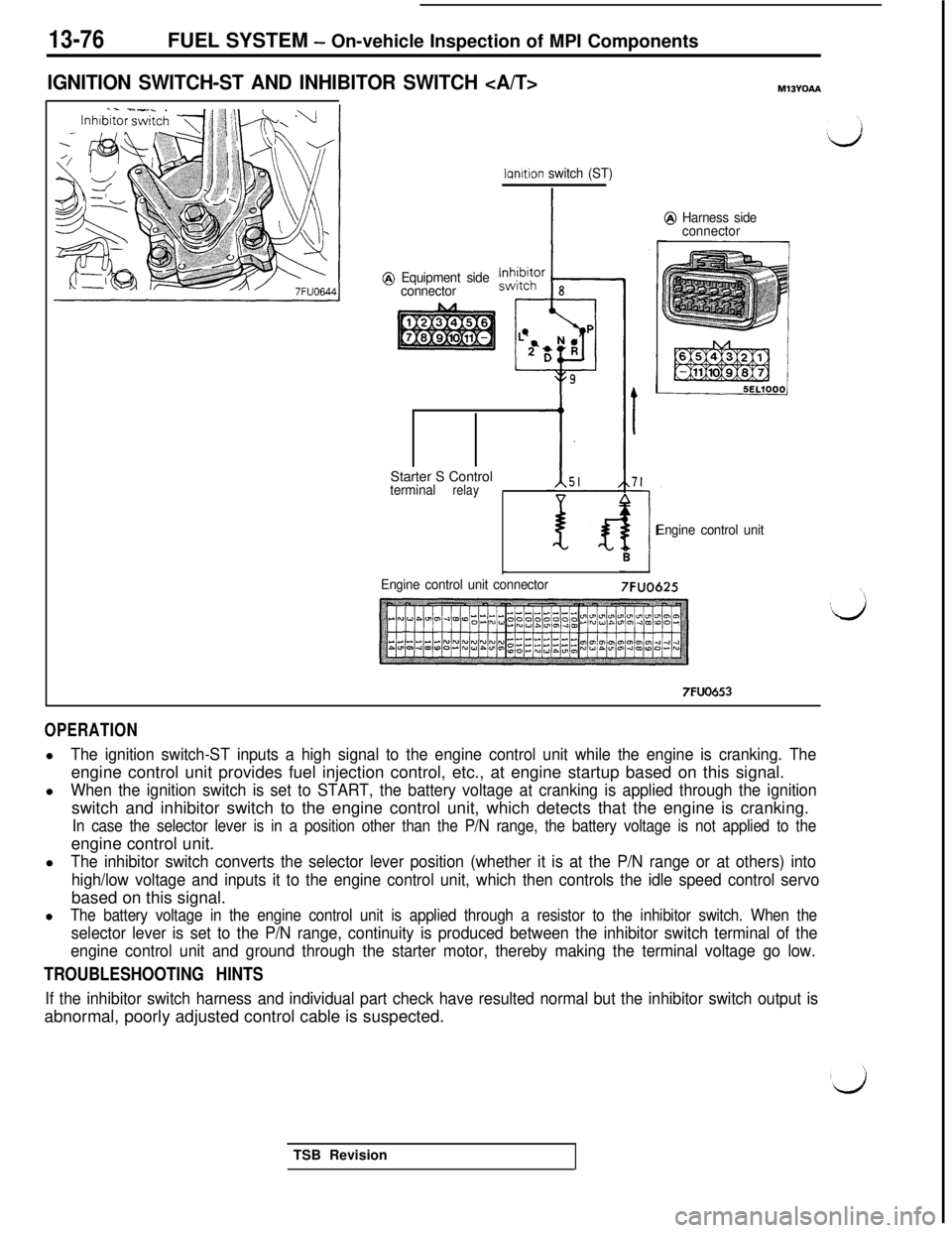

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-77INSPECTION

Using Multi-use Tester

LIGNITION SWITCH-ST

FunctionItem No. Data displayCheck conditionEngineNormal rndrcation

Data reading18Switch stateIgnition switch: ON

stopOFF

CrankingONINHIBITOR SWITCH

FunctionItem No. Data displayCheck conditionSelect lever positionNormal indicationData reading 29

Shift

Ignition switch: ONP or NP or Nposition

D.2,L or RD.2.L or RHARNESS INSPECTION

@ Harness sideconnector

OlA0206

2

@ Harness srdeconnectorl

Engine control unit connector:

Connectedl

InhibItor switch connector: Dis-6a

L-J

cl3

connectedl Ignition switch: ON

Repair the

harness.Voltage

(VI@El - El)

OlA0206LII

Engine control

unit harness

side connector

Measure the power supply voltage of

the inhibitor switch.

-lEngine control unit connector:

Disconnectedl

lnhibrtor switch connector: Dis-

connectedl Ignition switch: START

Voltage

(V)

rLlltXK IlIt:Lpower supplycircuit.

Measure the inhibitor switch terminalinput voltage.

Measure the input voltage of enginecontrol unit.lEngine control unrt connector:DisconnectedlFer;it;r switch connector: Con-

1 TSB Revision

Page 184 of 1146

![MITSUBISHI 3000GT 1991 Service Manual 13-78FUEL SYSTEM - 0n-vehicleInspection of MPI Components

VEHICLE SPEED SENSORMIBYPM

Vehrcle speed sensor

(reed switch\)Speedometer

Terminal voltage

(V)

@ Equipment side

Vehicle speed [km/h (mph)]

16 MITSUBISHI 3000GT 1991 Service Manual 13-78FUEL SYSTEM - 0n-vehicleInspection of MPI Components

VEHICLE SPEED SENSORMIBYPM

Vehrcle speed sensor

(reed switch\)Speedometer

Terminal voltage

(V)

@ Equipment side

Vehicle speed [km/h (mph)]

16](/img/19/57085/w960_57085-183.png)

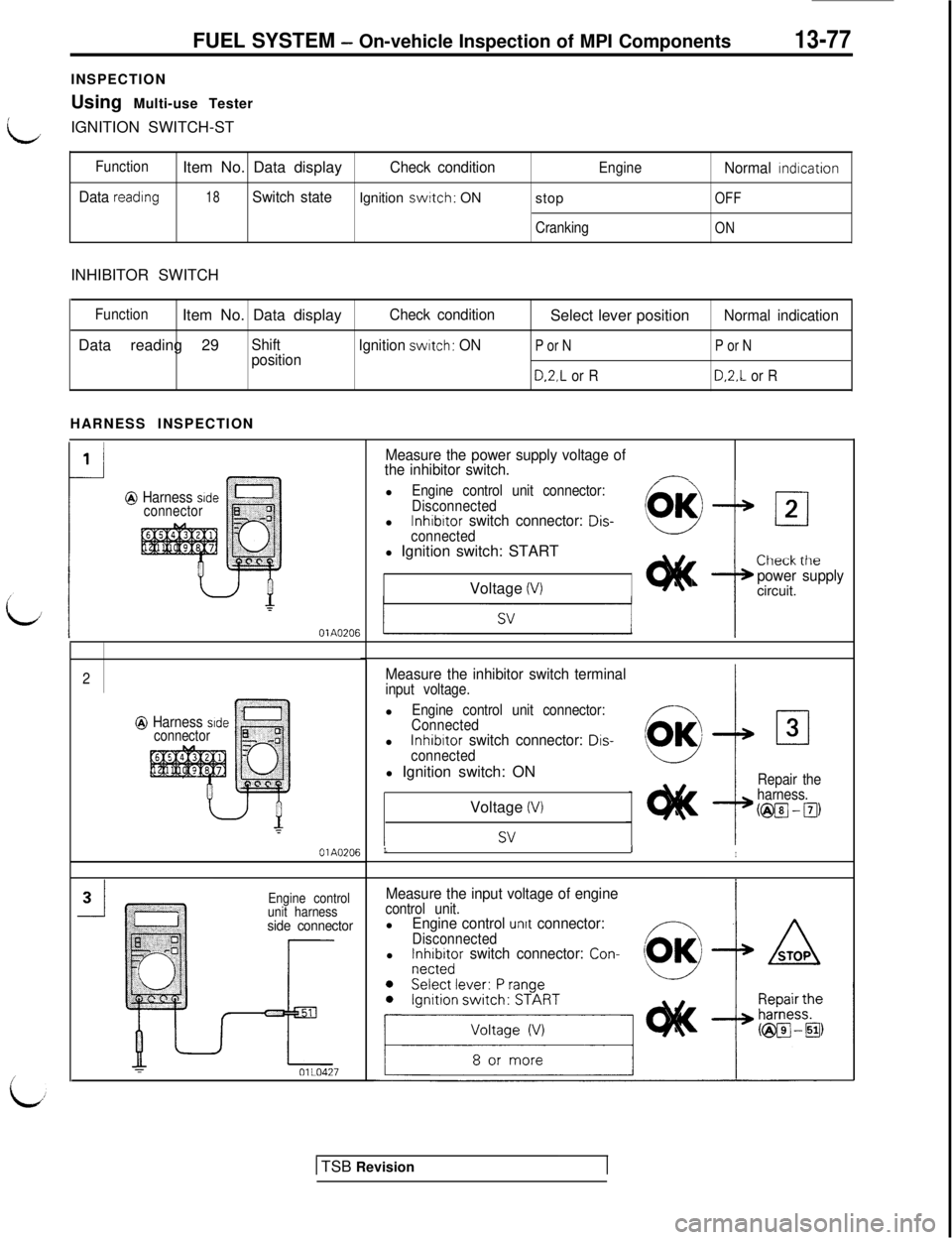

13-78FUEL SYSTEM - 0n-vehicleInspection of MPI Components

VEHICLE SPEED SENSORMIBYPM

Vehrcle speed sensor

(reed switch\)Speedometer

Terminal voltage

(V)

@ Equipment side

Vehicle speed [km/h (mph)]

162461

Engine control unit

7FUO925

Engine control unit connector7FUO653

OPERATION

lThe vehicle speed sensor which is located in the speedometer converts the vehicle speed into a pulse

signal and inputs it to the engine control unit, which then provides the idle speed control, etc. based on

this signal.

lThe vehicle speed sensor generates the vehicle speed signal by repeatedly opening and closing betweenthe voltage of about 5 V applied from the engine control unit and ground using a reed switch.

TROUBLESHOOTING HINTS

If there is an open or short circuit in the vehicle speed sensor signal circuit, the engine may stall when thevehicle is decelerated to stop.

HARNESS INSPECTION

unit harness

side connectorCheck the vehicle speed sensor out-

put circuit for continuity.

lEngine control unit connector:

Disconnected

lMove the vehicle.

TSB Revision

1

d

Page 185 of 1146

FUEL SYSTEM - On-vehicle lnwection of MPI ComDonents

2Measure the power supply voltage ofthe vehicle speed sensor.

@ Harness sidel Connector: Dlsconnectedl Ignition switch: ON

8)

6FU1265l Connector: Disconnected

SENSOR INSPECTIONRefer to GROUP 54

- Meters and Gauges.

TSB Revision

Page 186 of 1146

13-80FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

POWER STEERING OIL PRESSURE SWITCHMlOYQAA

B

$-

Engine control unit

'107

@ Harness side

connector

ml-

Power steering oil

Pressure switch

7FUO536700-2.000 1.500-2.000(100-284) (213-284)Pressure [kPa (psi)]

0, l.oIu

OPERATIONl

The power steering oil pressure switch converts presence/absence of power steering load into low/high

voltage and inputs it to the engine control unit, which then controls the idle speed control servo based on

this signal.l The battery voltage in the engine control unit is applied through a resistor to the power steering oil

pressure switch. Steering operation causes the power steering oil pressure to increase, turning the

switch on. As a result, continuity is produced between the battery voltage applied and ground. This

causes the power steering oil pressure terminal voltage to go from high to low.

TSB Revision

Page 187 of 1146

FUEL SYSTEM- On-vehicle Inspection of MPI Components13-81

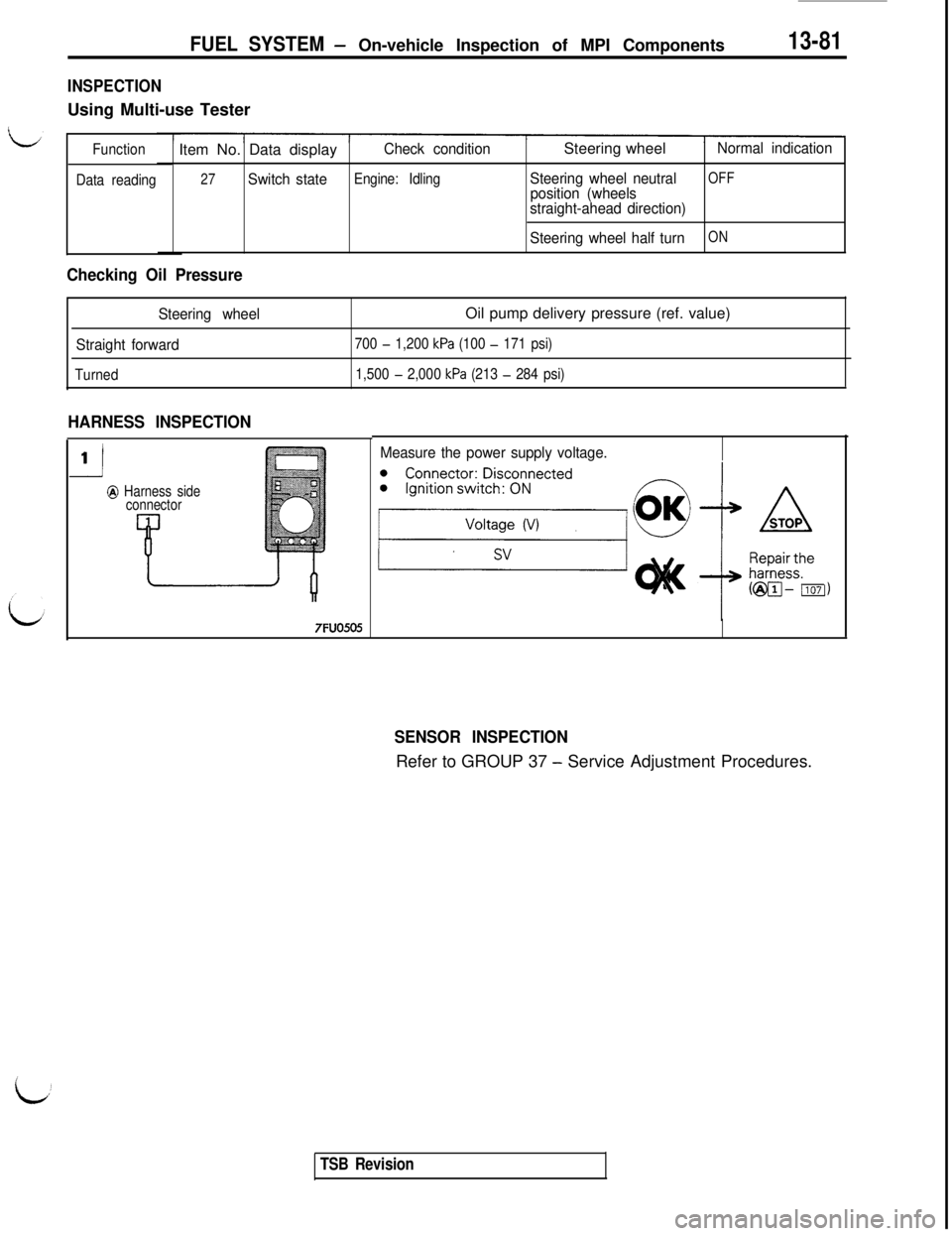

INSPECTIONUsing Multi-use Tester

Function

Data readingItem No. Data displayCheck conditionSteering wheelNormal indication

27Switch stateEngine: IdlingSteering wheel neutralOFFposition (wheels

straight-ahead direction)

Steering wheel half turn

ON

Checking Oil Pressure

Steering wheelOil pump delivery pressure (ref. value)

Straight forward700 - 1,200 kPa (100 - 171 psi)

Turned1,500

- 2,000 kPa (213 - 284 psi)

HARNESS INSPECTION

i1

@ Harness side

connector

Measure the power supply voltage.

SENSOR INSPECTIONRefer to GROUP 37

- Service Adjustment Procedures.

TSB Revision

Page 188 of 1146

13-82FUEL SYSTEM - On-vehicle Inspection of MPI Components

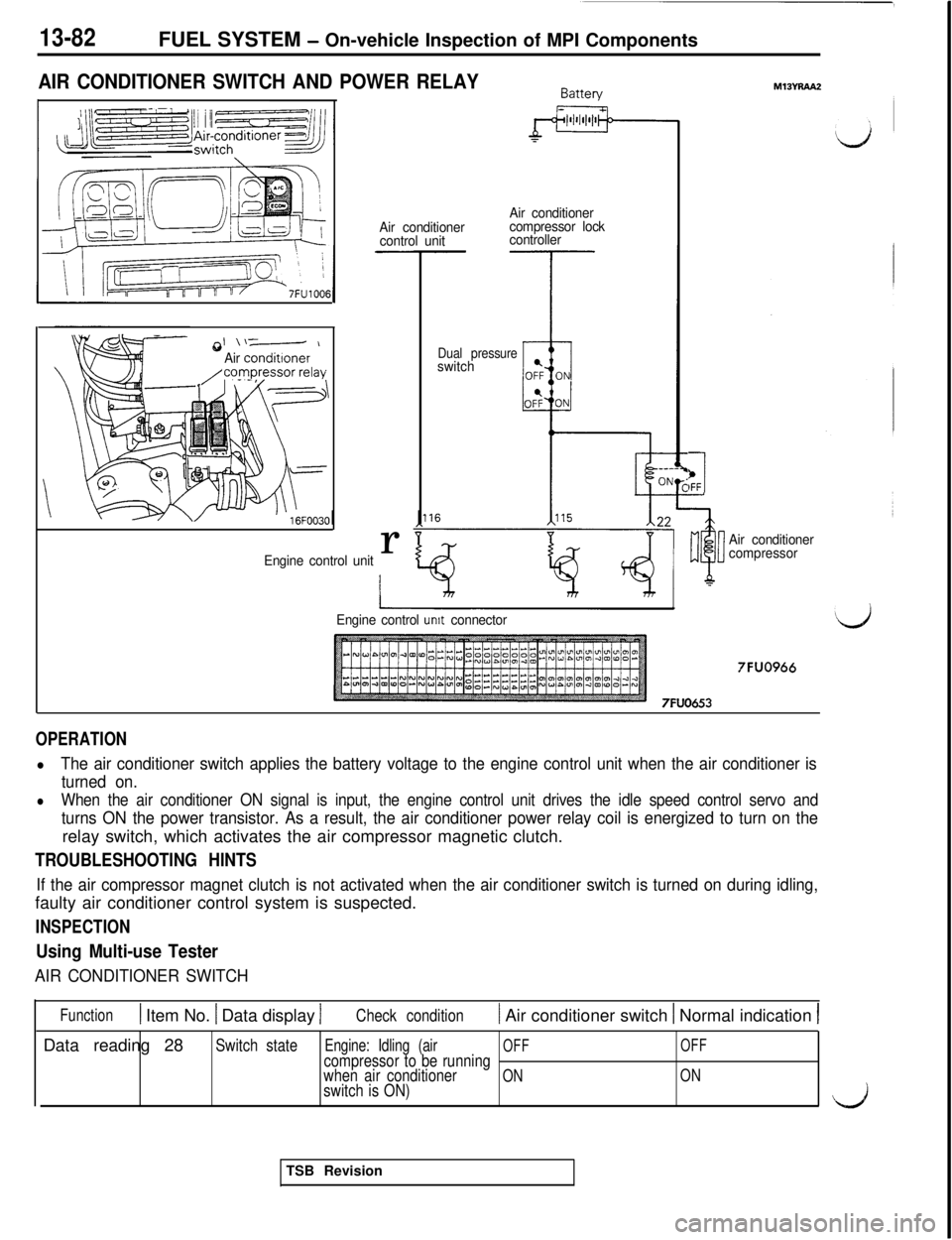

AIR CONDITIONER SWITCH AND POWER RELAY

\

*I \\-- \

Air conditronerAir conditioner

control unitAir conditioner

compressor lock

controllerr

Engine control unit

Dual pressureswitch

M13YRAA2

b1IFF

Air conditioner

compressor

Engine control

unit connector

7FUO966

7FUO653

OPERATION

lThe air conditioner switch applies the battery voltage to the engine control unit when the air conditioner is

turned on.

lWhen the air conditioner ON signal is input, the engine control unit drives the idle speed control servo and

turns ON the power transistor. As a result, the air conditioner power relay coil is energized to turn on therelay switch, which activates the air compressor magnetic clutch.

TROUBLESHOOTING HINTS

If the air compressor magnet clutch is not activated when the air conditioner switch is turned on during idling,faulty air conditioner control system is suspected.

INSPECTION

Using Multi-use Tester

AIR CONDITIONER SWITCH

Function1 Item No. 1 Data display 1Check condition) Air conditioner switch 1 Normal indication IData reading 28

Switch stateEngine: Idling (airOFFOFFcompressor to be running

when air conditionerONONswitch is ON)\k”JTSB Revision

Page 189 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

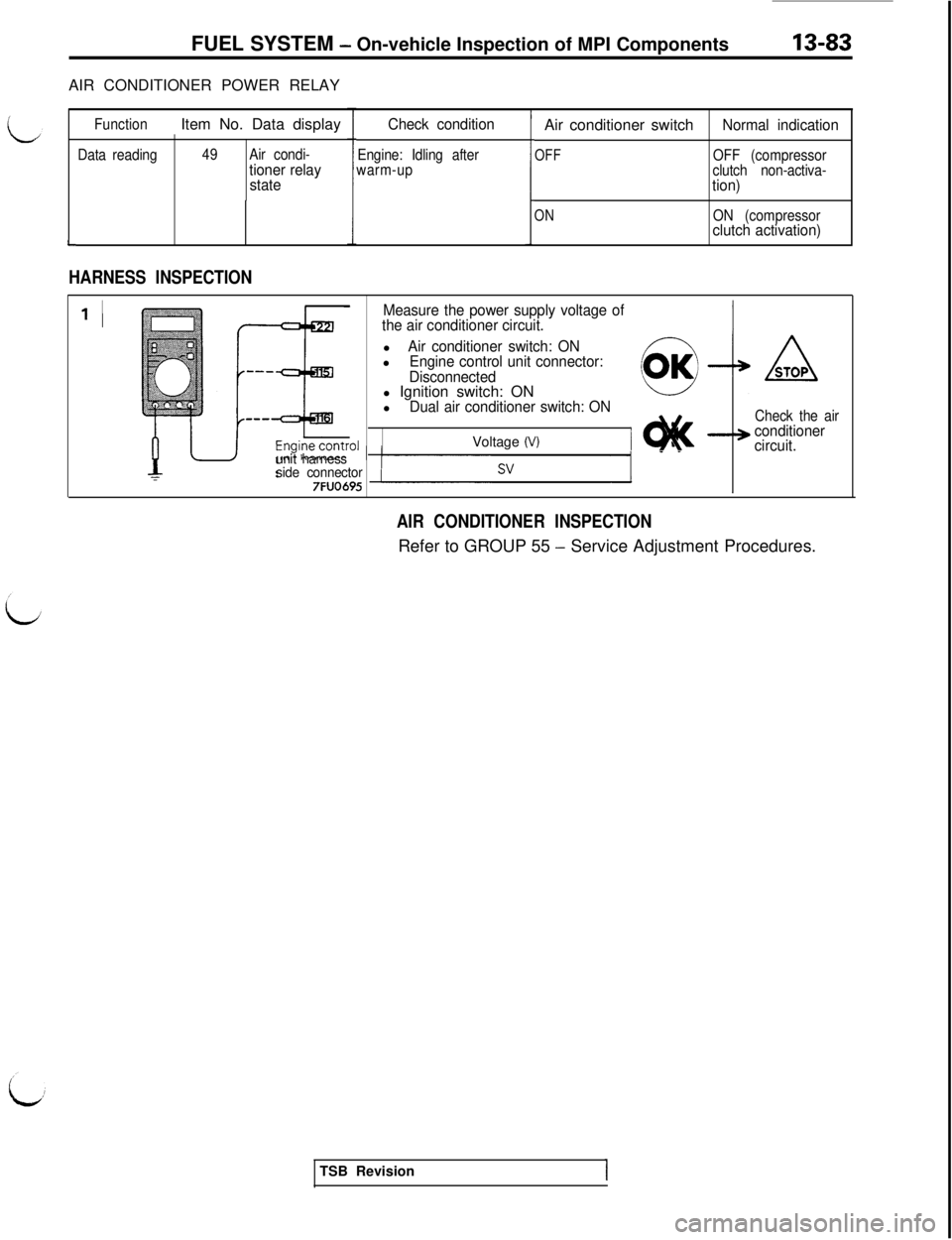

AIR CONDITIONER POWER RELAY

L

FunctionItem No. Data display

Data reading49Air condi-tioner relay

stateCheck conditionEngine: Idling after

warm-up

HARNESS INSPECTIONAir conditioner switch

Normal indication

OFFOFF (compressor

clutch non-activa-

tion)

ONON (compressorclutch activation)

’ I

unit harness

side connector

7FUO695

Measure the power supply voltage of

the air conditioner circuit.l

Air conditioner switch: ONlEngine control unit connector:

Disconnectedl Ignition switch: ON

l

Dual air conditioner switch: ONVoltage

(V)IM

ASTOP

Check the airconditioner

circuit.

AIR CONDITIONER INSPECTIONRefer to GROUP 55

- Service Adjustment Procedures.

TSB Revision

Page 190 of 1146

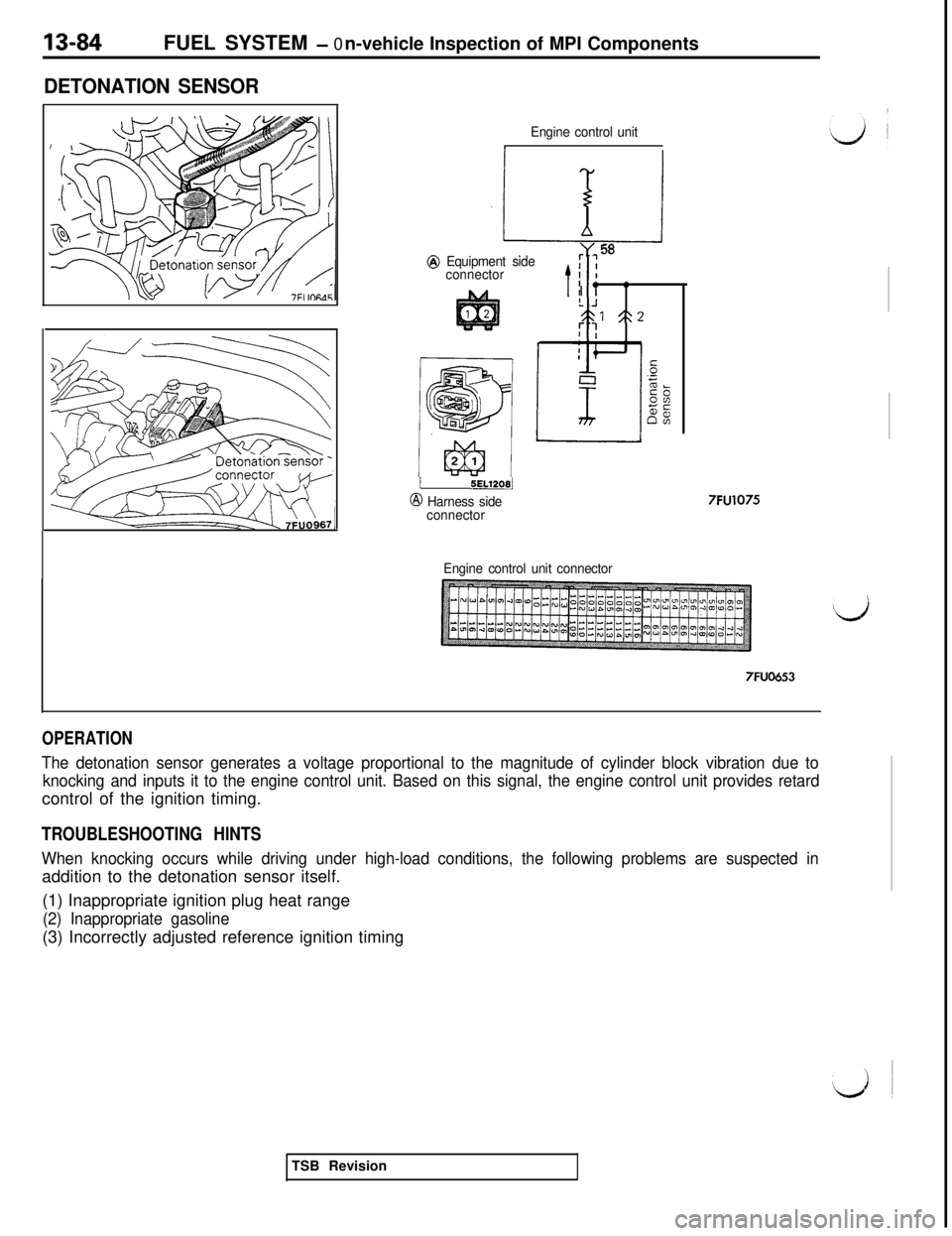

13-84FUEL SYSTEM - 0n-vehicle Inspection of MPI Components

DETONATION SENSOR

Engine control unitN

/J-l

@ Equipment side58: :connectorI I

t- =I IL .J531 5:2::

i SEL1208j

@ Harness side

connector7FU1075

Engine control unit connector

7FUO653

OPERATION

The detonation sensor generates a voltage proportional to the magnitude of cylinder block vibration due to

knocking and inputs it to the engine control unit. Based on this signal, the engine control unit provides retardcontrol of the ignition timing.

TROUBLESHOOTING HINTS

When knocking occurs while driving under high-load conditions, the following problems are suspected inaddition to the detonation sensor itself.

(1) Inappropriate ignition plug heat range

(2) Inappropriate gasoline(3) Incorrectly adjusted reference ignition timing

TSB Revision