check engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 837 of 1146

STEERING - Service Adjustment Procedures37A-9

LL:13N002E

FluId f[uctuatlon

While

engineWhile engme

runningstopped13uo13:

Return ho

Vinyl hose13AO142

j

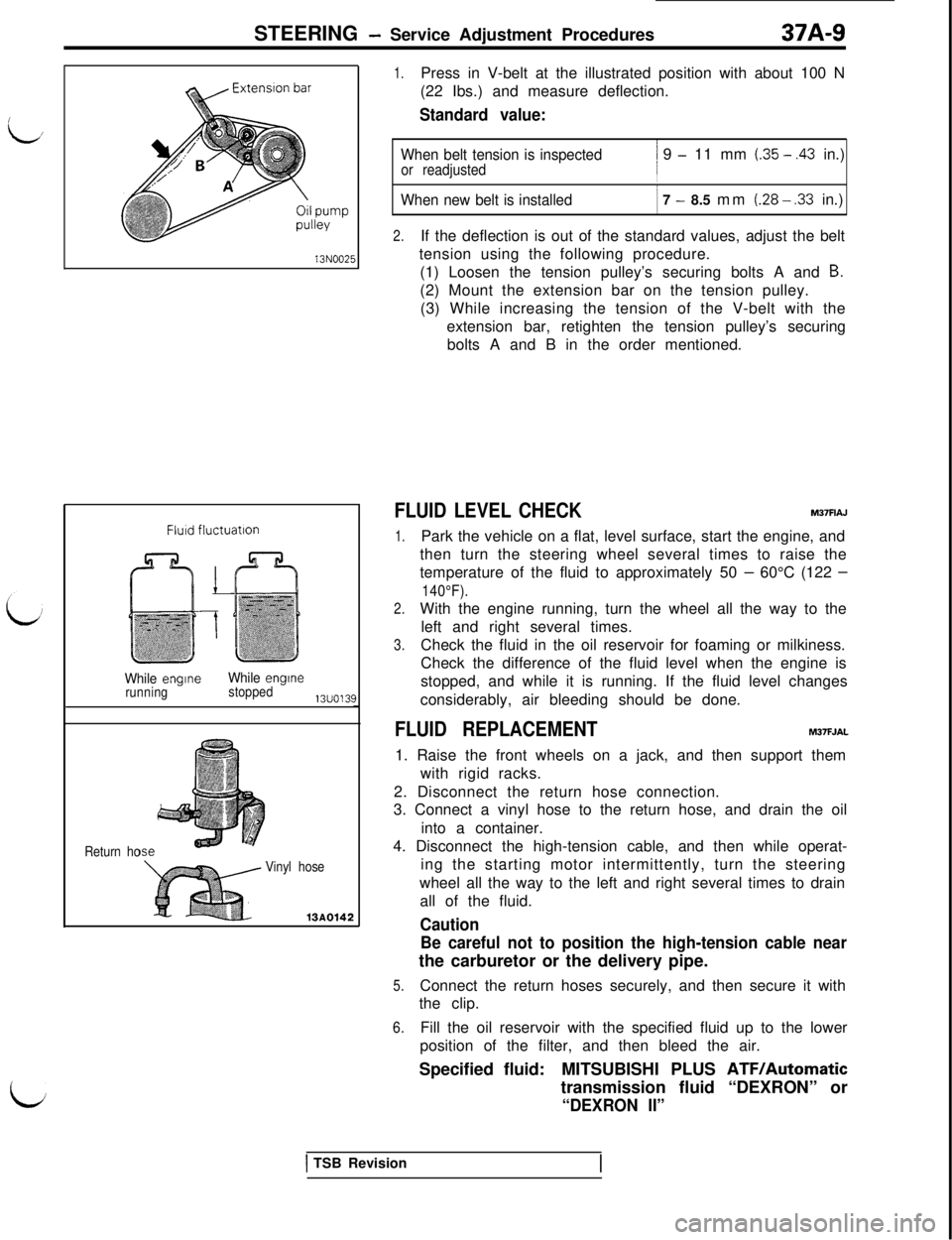

1.Press in V-belt at the illustrated position with about 100 N

(22 Ibs.) and measure deflection.

Standard value:

When belt tension is inspectedor readjusted

When new belt is installed

/ 9 - 11 mm (.35 - .43 in.)

I

’ 7 - 8.5 mm (.28 - .33 in.)

2.If the deflection is out of the standard values, adjust the belt

tension using the following procedure.

(1) Loosen the tension pulley’s securing bolts A and

B.(2) Mount the extension bar on the tension pulley.

(3) While increasing the tension of the V-belt with the

extension bar, retighten the tension pulley’s securing

bolts A and B in the order mentioned.

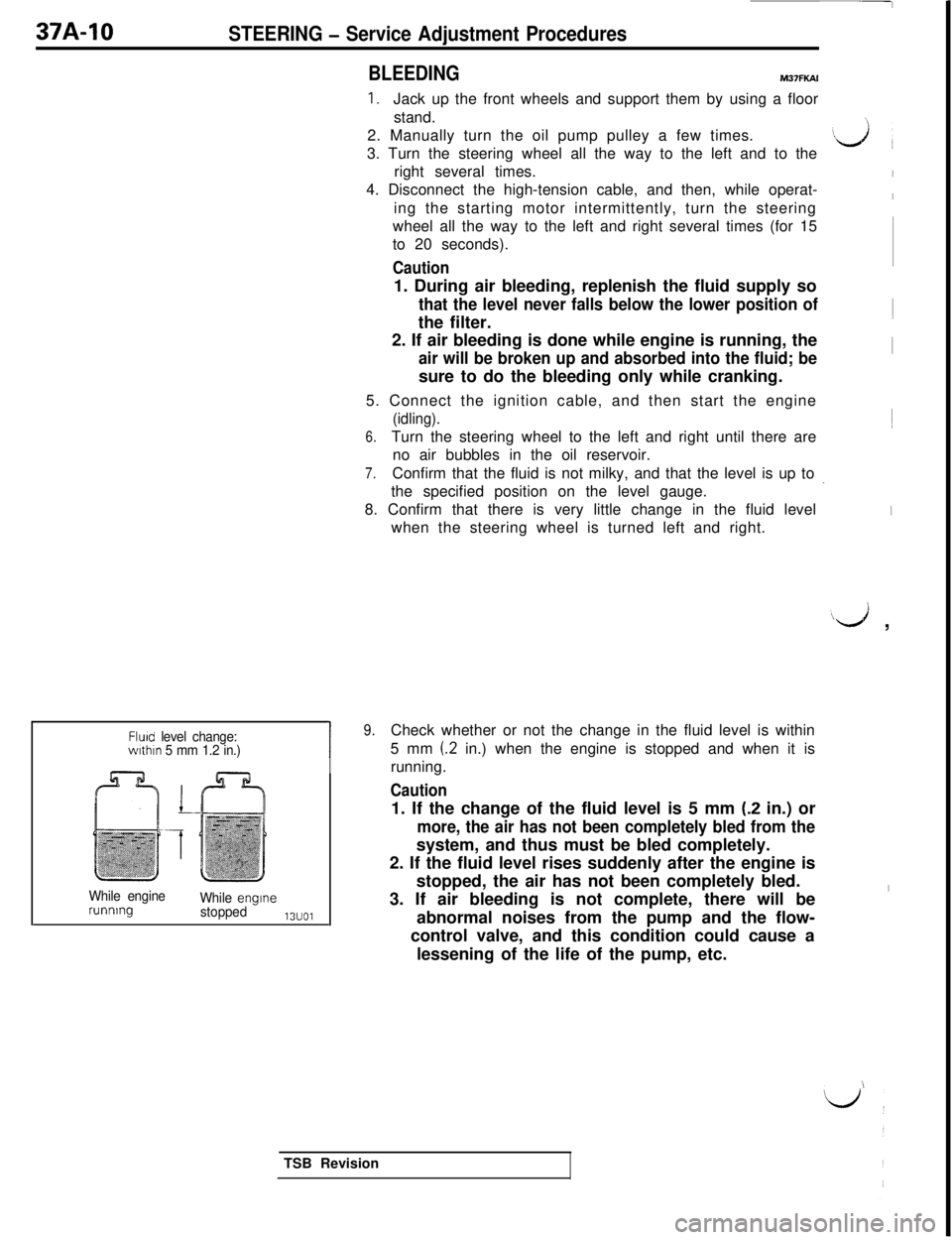

FLUID LEVEL CHECKM37FlAJ

1.Park the vehicle on a flat, level surface, start the engine, and

then turn the steering wheel several times to raise the

temperature of the fluid to approximately 50

- 60°C (122 -

140°F).

2.With the engine running, turn the wheel all the way to the

left and right several times.

3.Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine is

stopped, and while it is running. If the fluid level changes

considerably, air bleeding should be done.

FLUID REPLACEMENTM37FJAL1. Raise the front wheels on a jack, and then support them

with rigid racks.

2. Disconnect the return hose connection.

3. Connect a vinyl hose to the return hose, and drain the oil

into a container.

4. Disconnect the high-tension cable, and then while operat-

ing the starting motor intermittently, turn the steering

wheel all the way to the left and right several times to drain

all of the fluid.

Caution

Be careful not to position the high-tension cable nearthe carburetor or the delivery pipe.

5.Connect the return hoses securely, and then secure it with

the clip.

6.Fill the oil reservoir with the specified fluid up to the lower

position of the filter, and then bleed the air.

Specified fluid:MITSUBISHI PLUS ATF/Automatic

transmission fluid “DEXRON” or

“DEXRON II”

1 TSB Revision

Page 838 of 1146

37A-10STEERING - Service Adjustment Procedures

BLEEDINGM37FKAl

1.Jack up the front wheels and support them by using a floor

stand.

2. Manually turn the oil pump pulley a few times.

3. Turn the steering wheel all the way to the left and to the

right several times.

4. Disconnect the high-tension cable, and then, while operat-

ing the starting motor intermittently, turn the steering

wheel all the way to the left and right several times (for 15

to 20 seconds).

Caution1. During air bleeding, replenish the fluid supply so

that the level never falls below the lower position ofthe filter.

2. If air bleeding is done while engine is running, the

air will be broken up and absorbed into the fluid; besure to do the bleeding only while cranking.

5. Connect the ignition cable, and then start the engine

(idling).

6.Turn the steering wheel to the left and right until there are

no air bubbles in the oil reservoir.

7.Confirm that the fluid is not milky, and that the level is up to

the specified position on the level gauge.

8. Confirm that there is very little change in the fluid level

when the steering wheel is turned left and right.

Fluid level change:wlthln 5 mm 1.2 in.)I

9.Check whether or not the change in the fluid level is within

5 mm

(.2 in.) when the engine is stopped and when it is

Irunning.

Caution

While enginerunningWhile enginestopped13UOl1. If the change of the fluid level is 5 mm

I.2 in.) or

more, the air has not been completely bled from thesystem, and thus must be bled completely.

2. If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled.

3. If air bleeding is not complete, there will be

abnormal noises from the pump and the flow-

control valve, and this condition could cause a

lessening of the life of the pump, etc.

LJ

I

I~

I~

I

LJ ,

I

\TSB Revision

Page 839 of 1146

STEERING - Service Adjustment Procedures37A-11

Shut-off valve

Pressure gauge(FuW dose)

Temperature

Shut-off valve

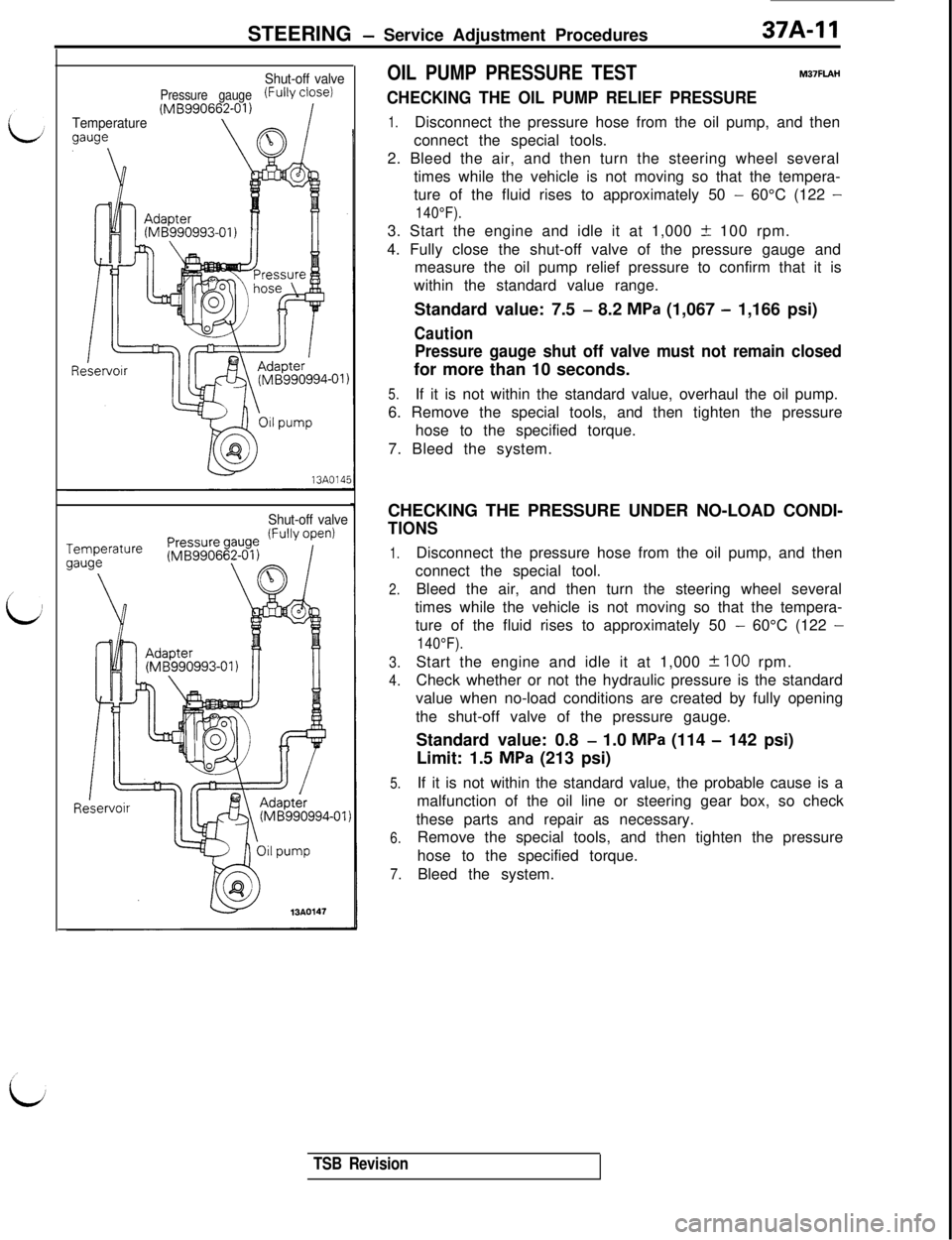

OIL PUMP PRESSURE TESTM37FLAl-l

CHECKING THE OIL PUMP RELIEF PRESSURE

1.Disconnect the pressure hose from the oil pump, and then

connect the special tools.

2. Bleed the air, and then turn the steering wheel several

times while the vehicle is not moving so that the tempera-

ture of the fluid rises to approximately 50

- 60°C (122 -

140°F).3. Start the engine and idle it at 1,000

+ 100 rpm.

4. Fully close the shut-off valve of the pressure gauge and

measure the oil pump relief pressure to confirm that it is

within the standard value range.

Standard value: 7.5

- 8.2 MPa (1,067 - 1,166 psi)

Caution

Pressure gauge shut off valve must not remain closedfor more than 10 seconds.

5.If it is not within the standard value, overhaul the oil pump.

6. Remove the special tools, and then tighten the pressure

hose to the specified torque.

7. Bleed the system.

CHECKING THE PRESSURE UNDER NO-LOAD CONDI-

TIONS

1.

2.

3.

4.

5.

6.

7.Disconnect the pressure hose from the oil pump, and then

connect the special tool.

Bleed the air, and then turn the steering wheel several

times while the vehicle is not moving so that the tempera-

ture of the fluid rises to approximately 50

- 60°C (122 -

140°F).Start the engine and idle it at 1,000

+ 100 rpm.

Check whether or not the hydraulic pressure is the standard

value when no-load conditions are created by fully opening

the shut-off valve of the pressure gauge.

Standard value: 0.8

- 1.0 MPa (114 - 142 psi)

Limit: 1.5

MPa (213 psi)

If it is not within the standard value, the probable cause is a

malfunction of the oil line or steering gear box, so check

these parts and repair as necessary.

Remove the special tools, and then tighten the pressure

hose to the specified torque.

Bleed the system.

TSB Revision

Page 840 of 1146

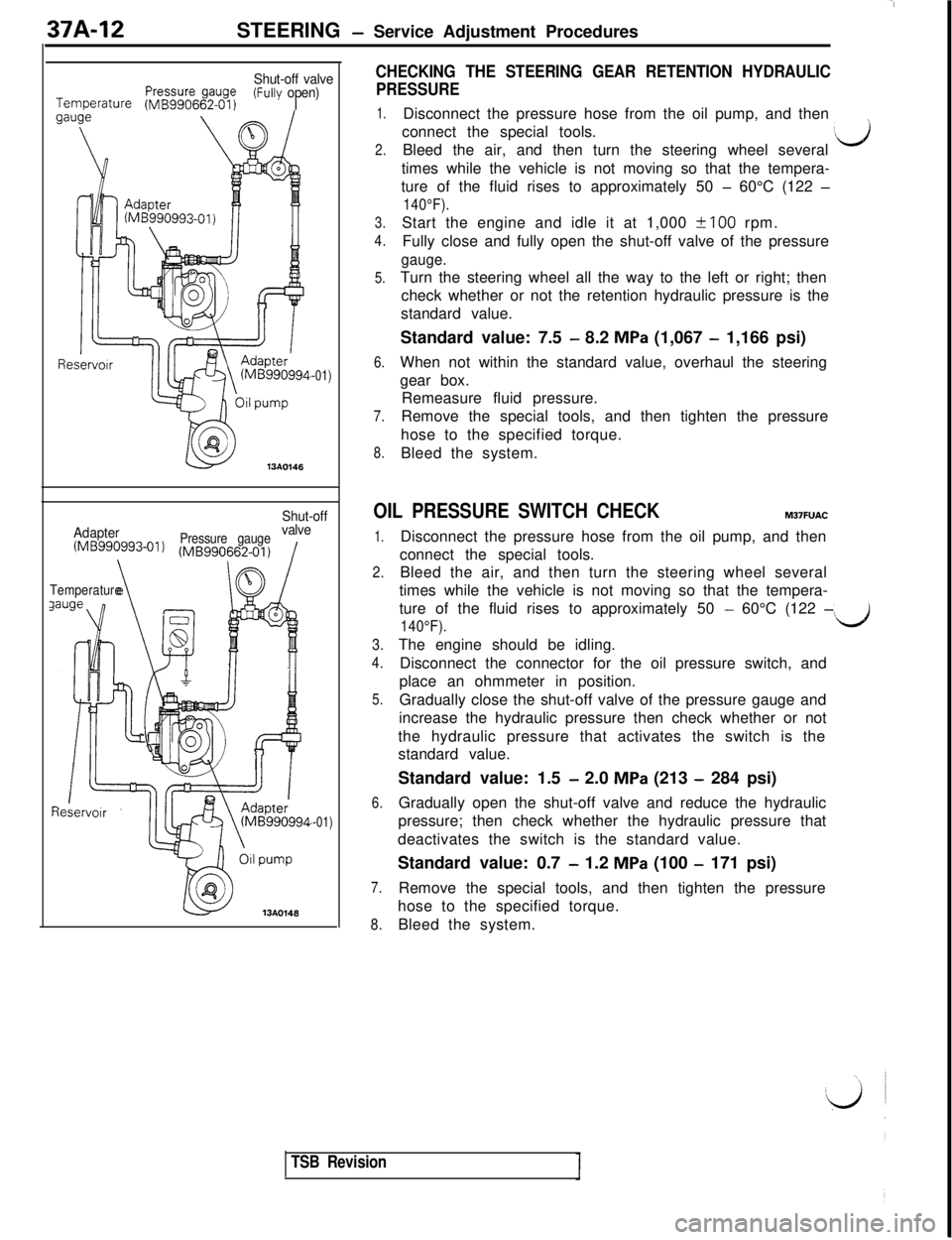

37A-12STEERING - Service Adjustment Procedures

Shut-off valvePressure gaugeTemperature (MB990662-01)(Fully open)I

13AO146

-01)

Shut-off

Adapter

Pressure gaugevalve

(MB990993-01)(MB990662-01) /

\Temperature

1310148

-01)

CHECKING THE STEERING GEAR RETENTION HYDRAULIC

PRESSURE

1.

2.

3.

4.

5.

6.

7.

8.Disconnect the pressure hose from the oil pump, and then

/connect the special tools.

Bleed the air, and then turn the steering wheel several

‘dtimes while the vehicle is not moving so that the tempera-

ture of the fluid rises to approximately 50

- 60°C (122 -

140°F).Start the engine and idle it at 1,000

& 100 rpm.

Fully close and fully open the shut-off valve of the pressure

gauge.Turn the steering wheel all the way to the left or right; then

check whether or not the retention hydraulic pressure is the

standard value.

Standard value: 7.5

- 8.2 MPa (1,067 - 1,166 psi)

When not within the standard value, overhaul the steering

gear box.

Remeasure fluid pressure.

Remove the special tools, and then tighten the pressure

hose to the specified torque.

Bleed the system.

OIL PRESSURE SWITCH CHECKM37FUAC

1.

2.

3.

4.

5.

6.

7.

8.Disconnect the pressure hose from the oil pump, and then

connect the special tools.

Bleed the air, and then turn the steering wheel several

times while the vehicle is not moving so that the tempera-

ture of the fluid rises to approximately 50

- 60°C (122 -

140°F).dThe engine should be idling.

Disconnect the connector for the oil pressure switch, and

place an ohmmeter in position.

Gradually close the shut-off valve of the pressure gauge and

increase the hydraulic pressure then check whether or not

the hydraulic pressure that activates the switch is the

standard value.

Standard value: 1.5

- 2.0 MPa (213 - 284 psi)

Gradually open the shut-off valve and reduce the hydraulic

pressure; then check whether the hydraulic pressure that

deactivates the switch is the standard value.

Standard value: 0.7

- 1.2 MPa (100 - 171 psi)

Remove the special tools, and then tighten the pressure

hose to the specified torque.

Bleed the system.

TSB Revision

Page 863 of 1146

4-WHEEL STEERING SYSTEM (4WS) - Troubleshooting

TROUBLESHOOTING

37B-3

M37EMKBefore inspecting, check the following items:

l Oil pump drive belt tension

lEnsure that the suspension has not been mod-@Power steering fluid level, and air in the system

ified

l Engine

Idle soeed and even idle

lTire and wheel size, specifications, air pressure,

l Oil leakage

balance and amount of wear

l Steering wheel type

l Wheel alignment

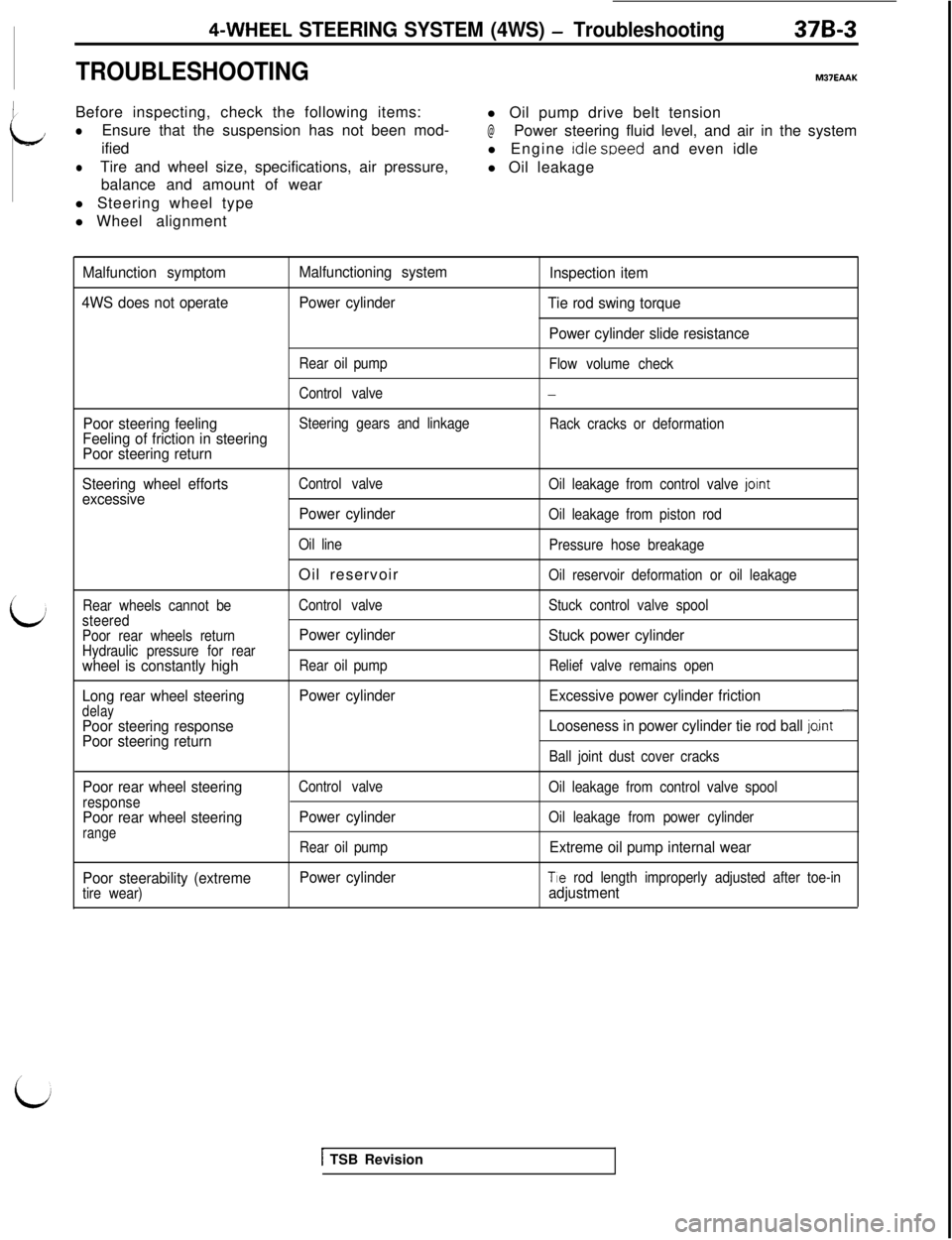

Malfunction symptom

4WS does not operateMalfunctioning system

Power cylinderInspection item

Tie rod swing torque

Power cylinder slide resistance

Rear oil pump

Flow volume check

Control valve

-

Poor steering feelingSteering gears and linkage

Rack cracks or deformationFeeling of friction in steering

Poor steering return

Steering wheel efforts

excessive

Control valve

Oil leakage from control valve jornt

Rear wheels cannot be

steered

Poor rear wheels return

Hydraulic pressure for rear

wheel is constantly high

Long rear wheel steering

delayPoor steering response

Poor steering returnPower cylinder

Oil lineOil reservoir

Control valve

Power cylinder

Rear oil pump

Power cylinder

Oil leakage from piston rod

Pressure hose breakage

Oil reservoir deformation or oil leakage

Stuck control valve spool

Stuck power cylinder

Relief valve remains open

Excessive power cylinder friction-

Looseness in power cylinder tie rod ball jo.int

Ball joint dust cover cracks

Poor rear wheel steeringresponsePoor rear wheel steeringrange

Poor steerability (extremetire wear)Control valve

Power cylinder

Rear oil pump

Power cylinder

Oil leakage from control valve spool

Oil leakage from power cylinder

Extreme oil pump internal wear

Tie rod length improperly adjusted after toe-inadjustment

[ TSB Revision

Page 864 of 1146

37B44-WHEEL STEERING SYSTEM (4WS) -Service Adjustment ProceduresSERVICE ADJUSTMENT PROCEDURES

M37FKAH

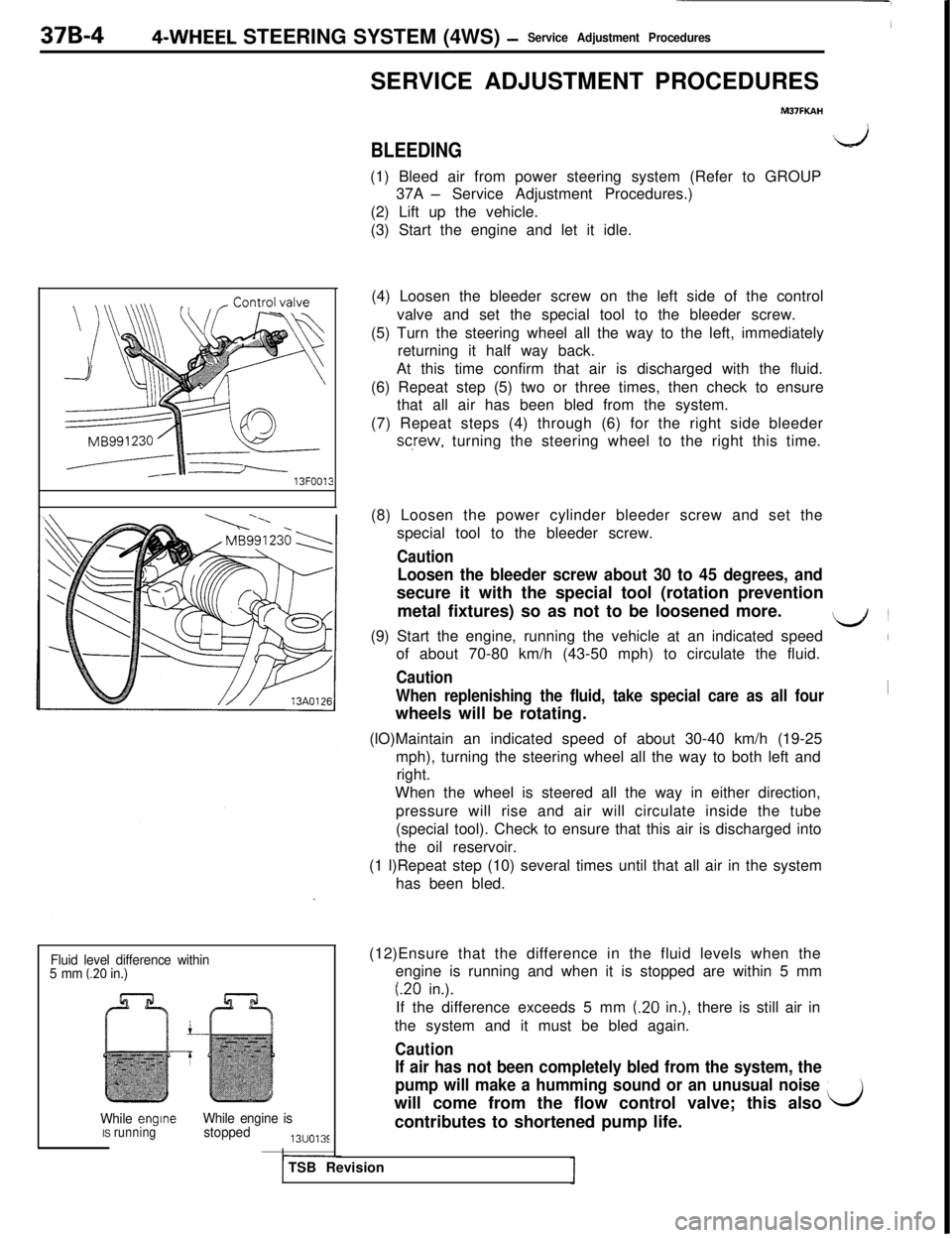

BLEEDING,LJ(1) Bleed air from power steering system (Refer to GROUP

37A

- Service Adjustment Procedures.)

(2) Lift up the vehicle.

(3) Start the engine and let it idle.

(4) Loosen the bleeder screw on the left side of the control

valve and set the special tool to the bleeder screw.

(5) Turn the steering wheel all the way to the left, immediately

returning it half way back.

At this time confirm that air is discharged with the fluid.

(6) Repeat step (5) two or three times, then check to ensure

that all air has been bled from the system.

(7) Repeat steps (4) through (6) for the right side bleeder

sc,rew, turning the steering wheel to the right this time.

(8) Loosen the power cylinder bleeder screw and set the

special tool to the bleeder screw.

Caution

Loosen the bleeder screw about 30 to 45 degrees, andsecure it with the special tool (rotation prevention

metal fixtures) so as not to be loosened more.

(9) Start the engine, running the vehicle at an indicated speed

I/l1Iof about 70-80 km/h (43-50 mph) to circulate the fluid.

-13FOO13

Caution

When replenishing the fluid, take special care as all fourIwheels will be rotating.

Fluid level difference within

5 mm (.20 in.)

While

engineWhile engine isIS runningstopped13lJO13~(lO)Maintain an indicated speed of about 30-40 km/h (19-25

mph), turning the steering wheel all the way to both left and

right.

When the wheel is steered all the way in either direction,

pressure will rise and air will circulate inside the tube

(special tool). Check to ensure that this air is discharged into

the oil reservoir.

(1 l)Repeat step (10) several times until that all air in the system

has been bled.

(12)Ensure that the difference in the fluid levels when the

engine is running and when it is stopped are within 5 mm(.20 in.).

If the difference exceeds 5 mm

(.20 in.), there is still air in

the system and it must be bled again.

Caution

If air has not been completely bled from the system, the

pump will make a humming sound or an unusual noise ,,

will come from the flow control valve; this also

dcontributes to shortened pump life.

TSB Revision

Page 865 of 1146

4-WHEEL STEERING SYSTEM (4WS) -Service Adjustment Procedures37B-5

Rubber hose

13FOOl

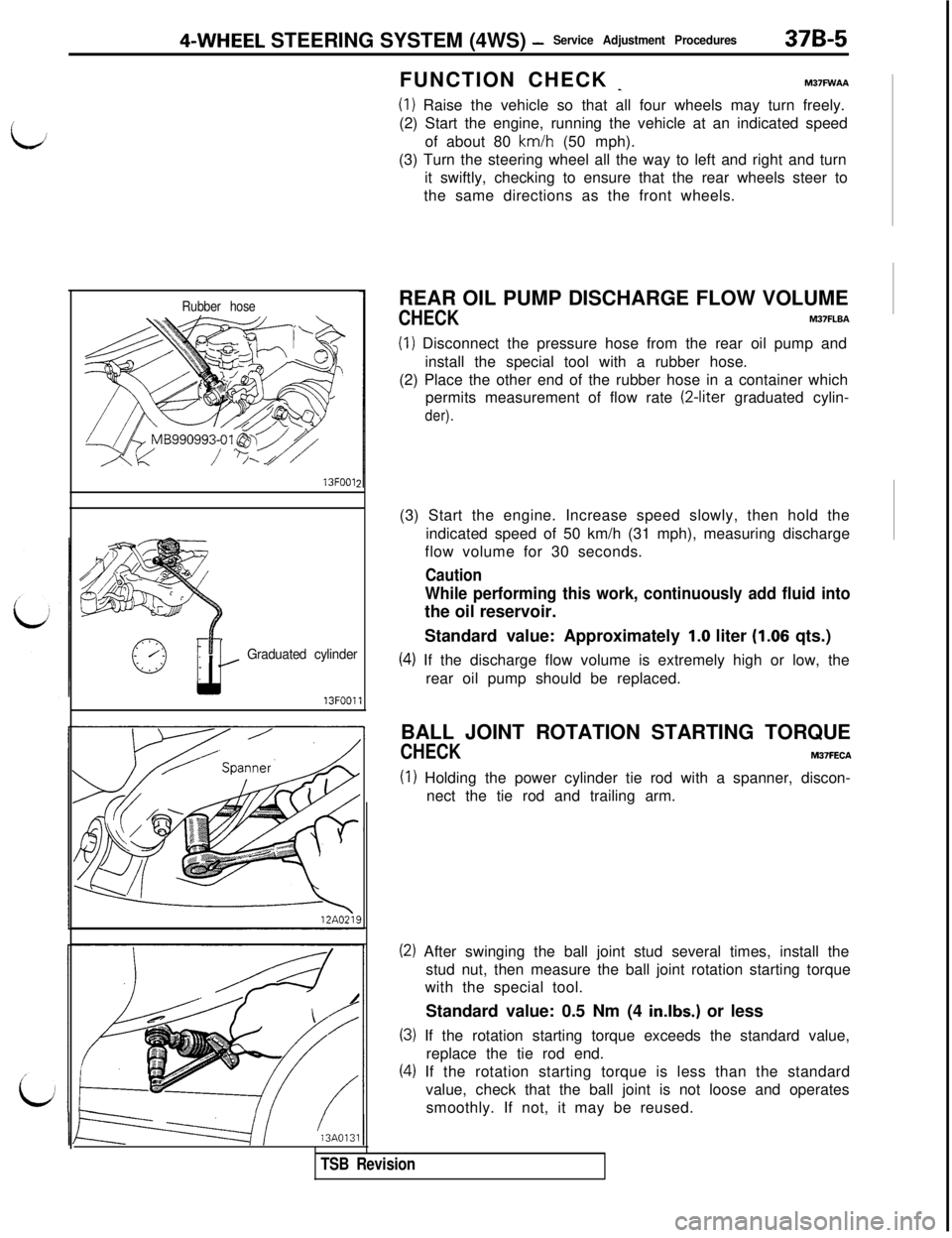

Graduated cylinder13FOOllFUNCTION CHECK

_M37FWAA

(1) Raise the vehicle so that all four wheels may turn freely.

(2) Start the engine, running the vehicle at an indicated speed

of about 80

km/h (50 mph).

(3) Turn the steering wheel all the way to left and right and turn

it swiftly, checking to ensure that the rear wheels steer to

the same directions as the front wheels.

REAR OIL PUMP DISCHARGE FLOW VOLUME

CHECKM37FLBA

(1) Disconnect the pressure hose from the rear oil pump and

install the special tool with a rubber hose.

(2) Place the other end of the rubber hose in a container which

permits measurement of flow rate (2-liter graduated cylin-

der).(3) Start the engine. Increase speed slowly, then hold the

indicated speed of 50 km/h (31 mph), measuring discharge

flow volume for 30 seconds.

Caution

While performing this work, continuously add fluid intothe oil reservoir.

Standard value: Approximately

1.0 liter (1.06 qts.)

(4) If the discharge flow volume is extremely high or low, the

rear oil pump should be replaced.

BALL JOINT ROTATION STARTING TORQUE

CHECKM37FECA

(1) Holding the power cylinder tie rod with a spanner, discon-

nect the tie rod and trailing arm.

(2) After swinging the ball joint stud several times, install the

stud nut, then measure the ball joint rotation starting torque

with the special tool.

Standard value: 0.5 Nm (4

in.lbs.) or less

(3) If the rotation starting torque exceeds the standard value,

replace the tie rod end.

(4) If the rotation starting torque is less than the standard

value, check that the ball joint is not loose and operates

smoothly. If not, it may be reused.

TSB Revision

Page 873 of 1146

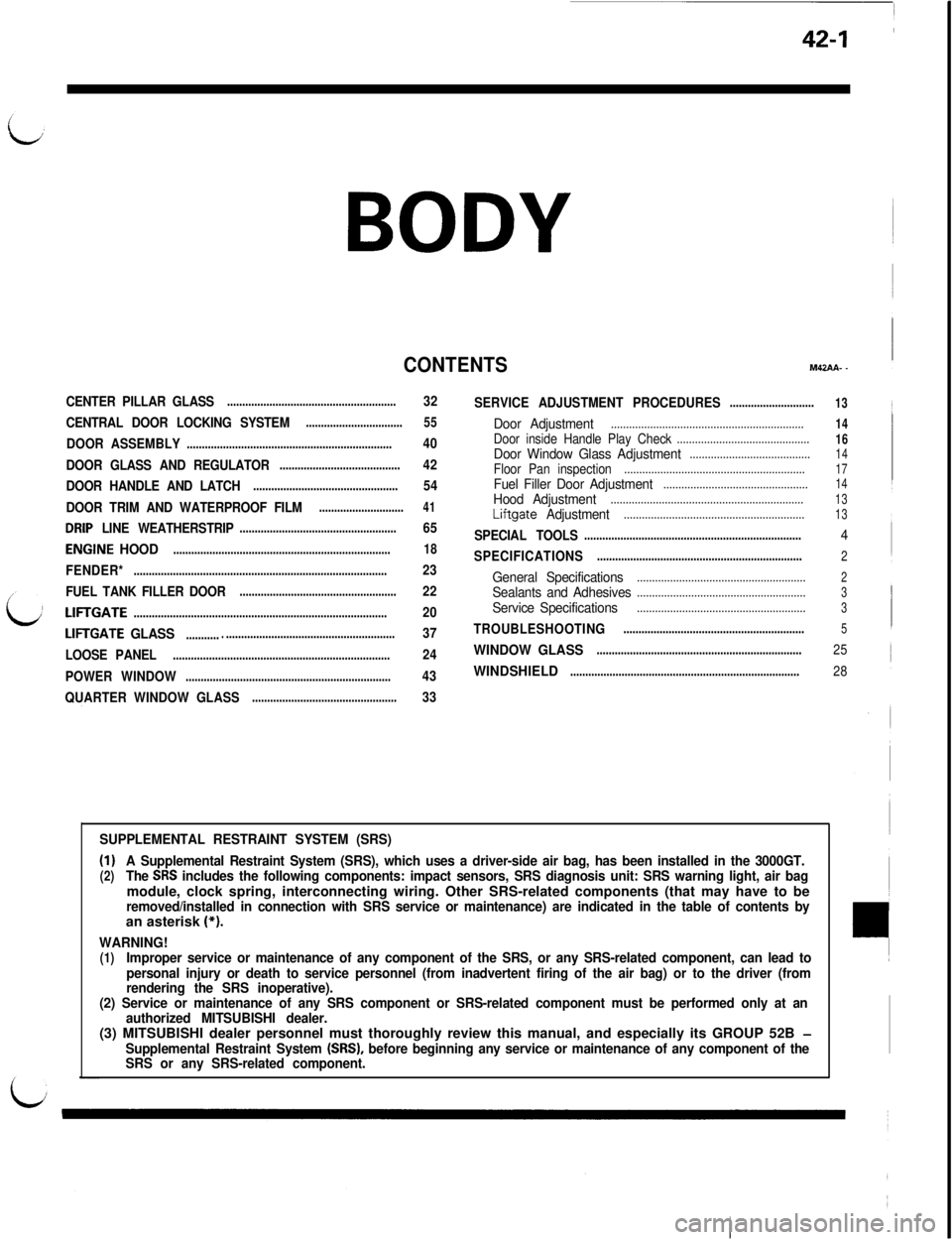

42-1

BODY

CONTENTSM42AA- -

CENTER PILLAR GLASS........................................................32

CENTRAL DOOR LOCKING SYSTEM

................................55

DOOR ASSEMBLY....................................................................40

DOOR GLASS AND REGULATOR

........................................42

DOOR HANDLE AND LATCH

................................................54

DOOR TRIM AND WATERPROOF FILM

............................41

DRIP LINE WEATHERSTRIP....................................................65

ENGINE HOOD........................................................................18

FENDER*....................................................................................23

FUEL TANK FILLER DOOR

....................................................22

LIFTGATE....................................................................................20

LIFTGATE GLASS....................................................................37

LOOSE PANEL

........................................................................24

POWER WINDOW

....................................................................43

QUARTER WINDOW GLASS

................................................33SERVICE ADJUSTMENT PROCEDURES

............................

Door Adjustment................................................................Door inside Handle Play Check............................................Door Window Glass Adjustment........................................Floor Pan inspection............................................................Fuel Filler Door Adjustment................................................Hood Adjustment................................................................Liftgate Adjustment............................................................

SPECIAL TOOLS........................................................................

SPECIFICATIONS....................................................................

General Specifications........................................................Sealants and Adhesives........................................................

ServiceSpecifications........................................................

TROUBLESHOOTING............................................................

WINDOW GLASS....................................................................

WINDSHIELD............................................................................

13

14

16

14

17

14

13

13

4

2

2

3

3

5

25

28

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of the

SRS or any SRS-related component.

Page 891 of 1146

BODY -Engine Hood42-I Y18FOOW

!I

II

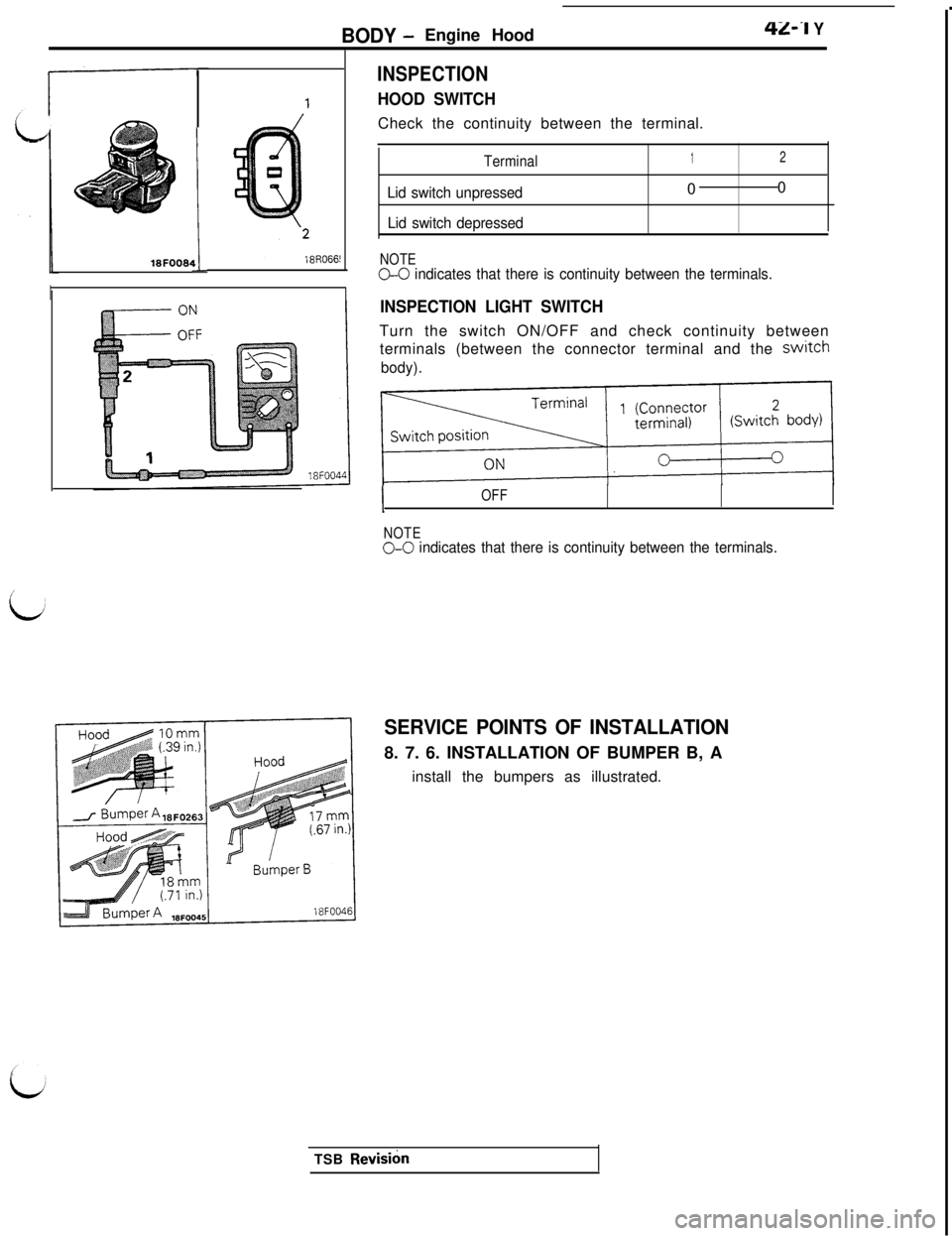

INSPECTION

HOOD SWITCHCheck the continuity between the terminal.

Terminal

Lid switch unpressed

Lid switch depressed

1200

NOTEG-0 indicates that there is continuity between the terminals.

INSPECTION LIGHT SWITCHTurn the switch ON/OFF and check continuity between

terminals (between the connector terminal and the

switch

body).

IOFF

NOTE

O-0 indicates that there is continuity between the terminals.

t

SERVICE POINTS OF INSTALLATION8. 7. 6. INSTALLATION OF BUMPER B, A

install the bumpers as illustrated.

TSB

Revish

Page 1027 of 1146

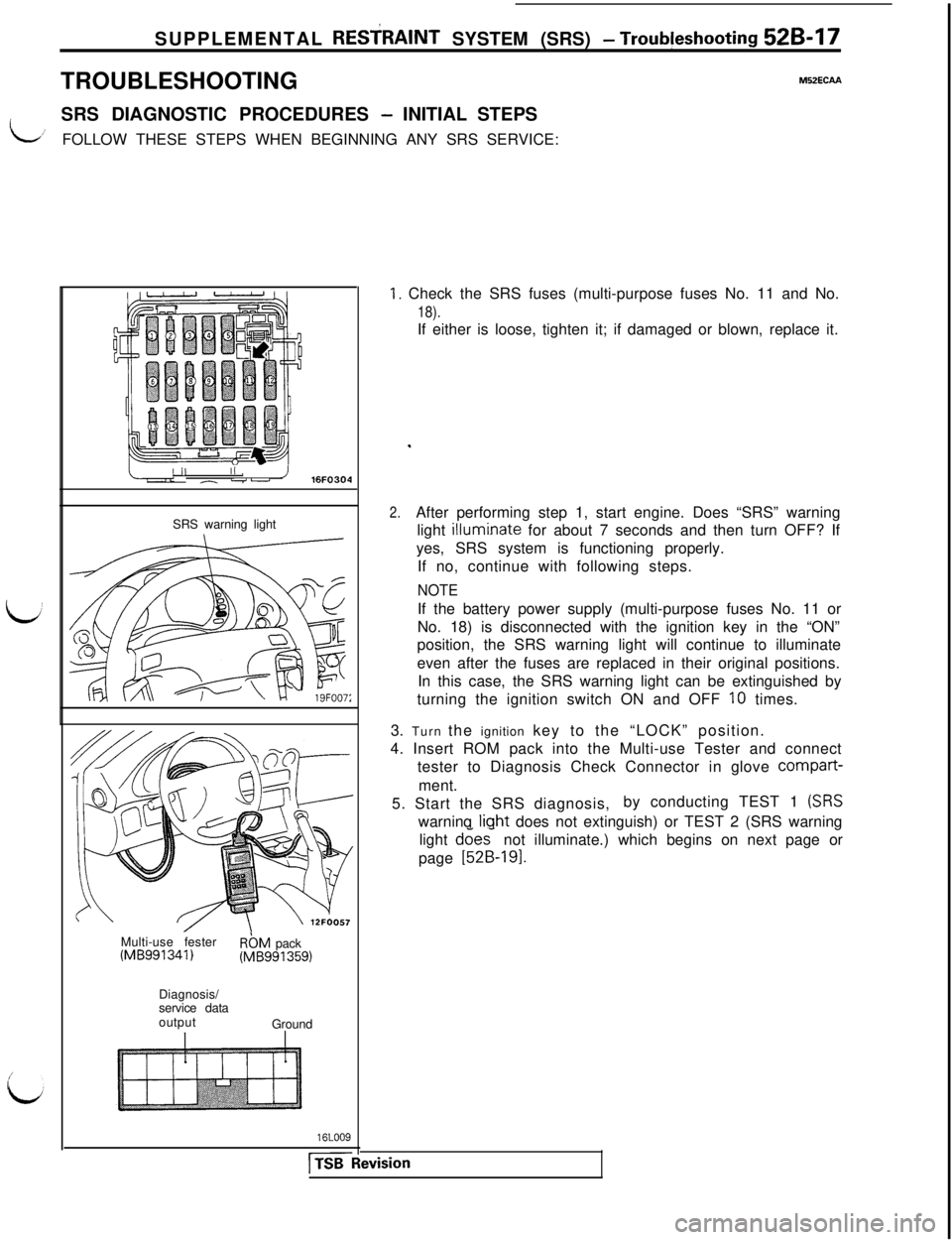

SUPPLEMENTAL RESfRAlNT SYSTEM (SRS) - Troub!eshooting 52B-17TROUBLESHOOTING

M52ECAA

idSRS DIAGNOSTIC PROCEDURES

- INITIAL STEPS’FOLLOW THESE STEPS WHEN BEGINNING ANY SRS SERVICE:

/II/ ,- -u’ 16FO304

SRS warning light

Multi-use fester

(MB991341)RbM pack(MB991359)

Diagnosis/

service data

output

Ground

16LOO9

[TSB

1. Check the SRS fuses (multi-purpose fuses No. 11 and No.

18).If either is loose, tighten it; if damaged or blown, replace it.

.

2.After performing step 1, start engine. Does “SRS” warning

light

illumi.nate for about 7 seconds and then turn OFF? If

yes, SRS system is functioning properly.

If no, continue with following steps.

NOTEIf the battery power supply (multi-purpose fuses No. 11 or

No. 18) is disconnected with the ignition key in the “ON”

position, the SRS warning light will continue to illuminate

even after the fuses are replaced in their original positions.

In this case, the SRS warning light can be extinguished by

turning the ignition switch ON and OFF

10 times.

3. Turn the ignition key to the “LOCK” position.

4. Insert ROM pack into the Multi-use Tester and connect

tester to Diagnosis Check Connector in glove compart-

ment.

5. Start the SRS diagnosis,by conducting TEST 1

(SRSwarninq liqht does not extinguish) or TEST 2 (SRS warning

light does- not illuminate.) which begins on next page or

page

[52B-191.

ivision