battery MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 152 of 1146

13-46FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTIONUsing Multi-use Tester

FunctionItem No.DriveCheck condition

Check contentNormal statedActuator test 07

Fuel pump isl Engine cranking

Hold return hose withPulsation is felt

driven to cir-l Forced drive of fuelculate fuelfingers to feel pulsation

pump

Check is made forindicating fuel flow

above two conditions

Listen to pump operating

sound near fuel tankOperating sound isheard

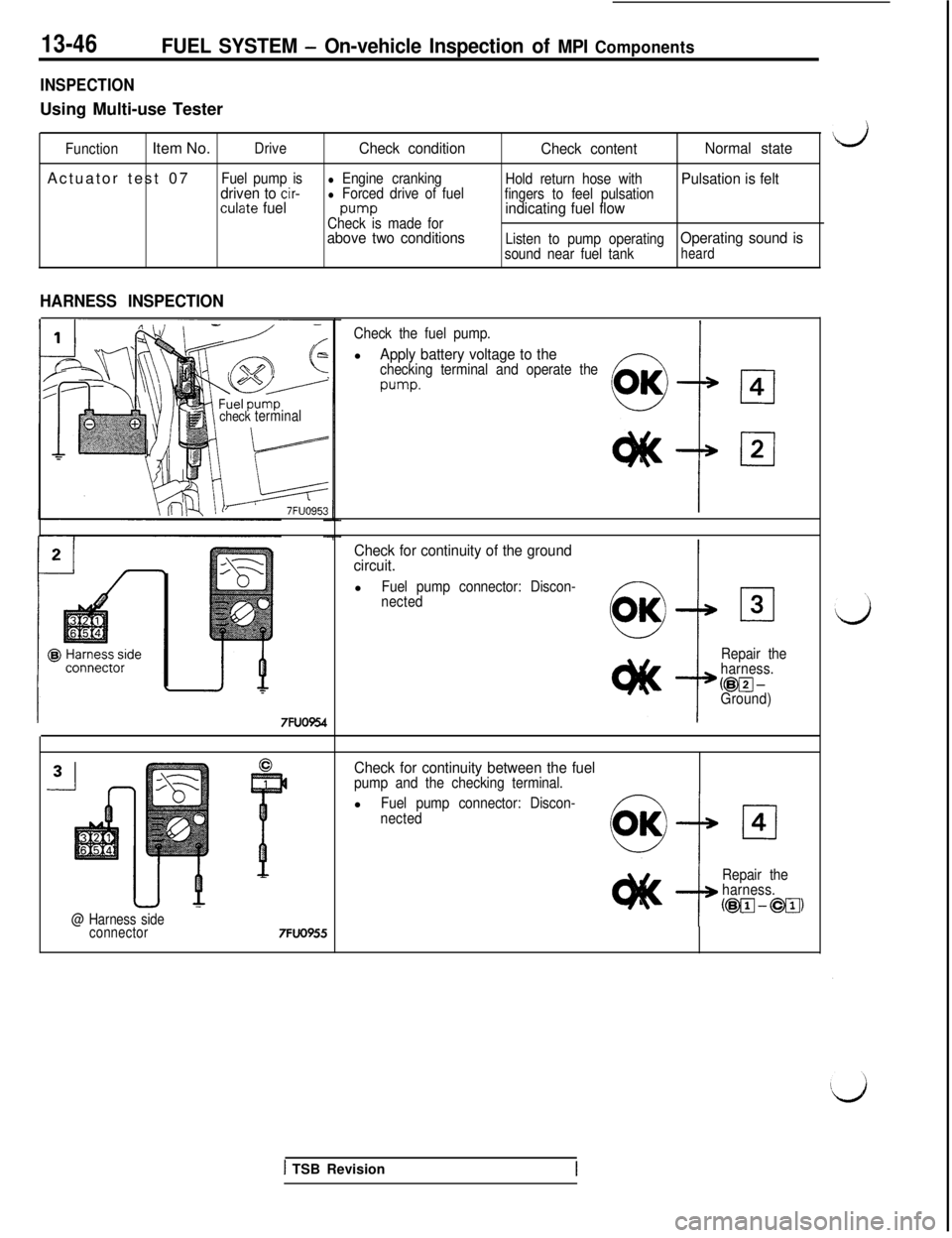

HARNESS INSPECTION

check terminal

7FUO954

@ Harness side

connector7FUO955

Check the fuel pump.l

Apply battery voltage to thechecking terminal and operate the

w-w

Check for continuity of the ground

circuit.l

Fuel pump connector: Discon-

nected

Repair the

harness.

@FJ-Ground)

Check for continuity between the fuelpump and the checking terminal.l

Fuel pump connector: Discon-

nectedcl4

Repair the

harness.

@vJ-@g)

1 TSB Revision

Page 156 of 1146

13-50FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

OPERATIONControl Relay Operation

l Drives the fuel pump during cranking and engine operation.

l

When the ignition switch is set to START, current flows from the ignition switch through the control relay

coil to ground. This turns on the control relay switch and drive power is supplied from the battery throughthe control relay switch to the fuel pump.

lWhile the engine is running, the engine control unit keeps the power transistor on and energizes the

control relay coil so that drive power is supplied to the fuel pump.

Fuel Pump Relay No. 2 Operation

lChange the fuel pump discharge in two stages by ON-OFF operation of the relay switch for fuel pumprelay No. 2.

lIf the amount of inlet air is small (the engine load is low), the engine control unit turns on the power

transistor to energize the coil of fuel pump relay No. 2, sending drive power to the fuel pump through the

resistor. If the amount of inlet air is large (the engine load is high), the engine control unit turns off thepower transistor to send drive power directly to the fuel pump without passing through the resistor.

INSPECTIONUsing Multi-use Tester

Function

ActuatortestItem No.

Operation

Check conditionCheck itemNormal condition

07Fuel pump isdriven to cir-l Engine crankingHold return hose withl Forced drive of fuelPulsation is felt

culate fuelfingers to feel pulsationpump

Check is made for aboveindicating fuel flow

two conditionsListen to pump operating

sound near fuel tankOperating sound isheard

I/IIII

cFunctionItem No.Operation

Check conditionNormal condition

Actuatortest

13Turn the fuel pump relayNo. 2 from OFF to ONIgnition switch: ONOperating soundis heard.

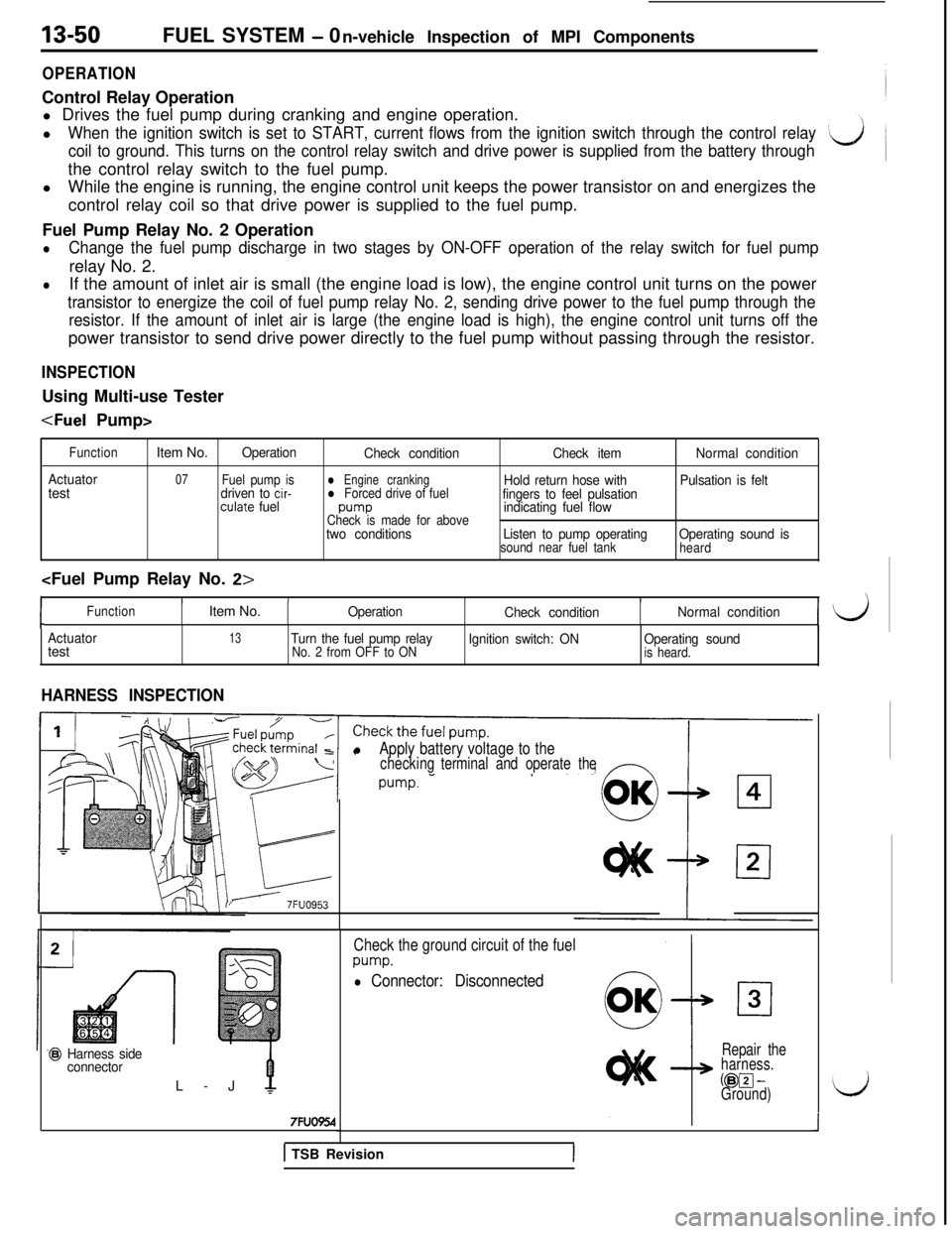

HARNESS INSPECTION

k

J------ 7FUO953

lApply battery voltage to thecheckingterminal and operate the

Check the ground circuit of the fuel

pump.

l Connector: Disconnected

@I Harness side

connectorL-J

7FUO554

Repair the

harness.

@pJ-Ground)

J

1 TSB Revision

Page 159 of 1146

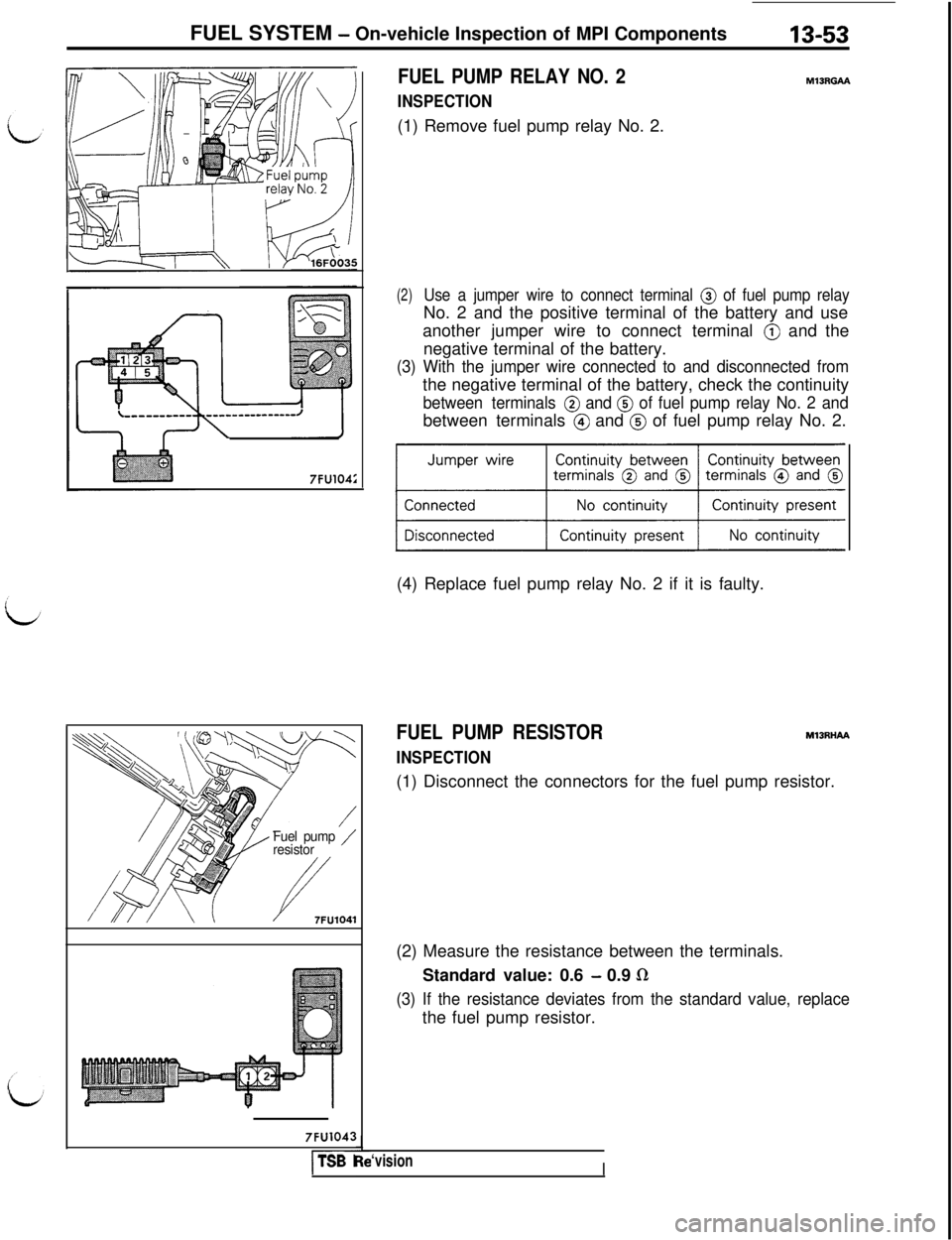

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-53

7FU104:

Fuel pump /resistor

///I/ \\/7FU1041

7FU1043

I-TSB I

FUEL PUMP RELAY NO. 2

INSPECTION(1) Remove fuel pump relay No. 2.

M13RGAh

(2)Use a jumper wire to connect terminal @ of fuel pump relayNo. 2 and the positive terminal of the battery and use

another jumper wire to connect terminal

@ and the

negative terminal of the battery.

(3) With the jumper wire connected to and disconnected fromthe negative terminal of the battery, check the continuity

between terminals @ and @ of fuel pump relay No. 2 andbetween terminals

@ and @ of fuel pump relay No. 2.

(4) Replace fuel pump relay No. 2 if it is faulty.

FUEL PUMP RESISTOR

INSPECTION

MlBRHAA(1) Disconnect the connectors for the fuel pump resistor.

(2) Measure the resistance between the terminals.

Standard value: 0.6

- 0.9 LR

(3) If the resistance deviates from the standard value, replacethe fuel pump resistor.

‘visionI

Page 181 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

L

L

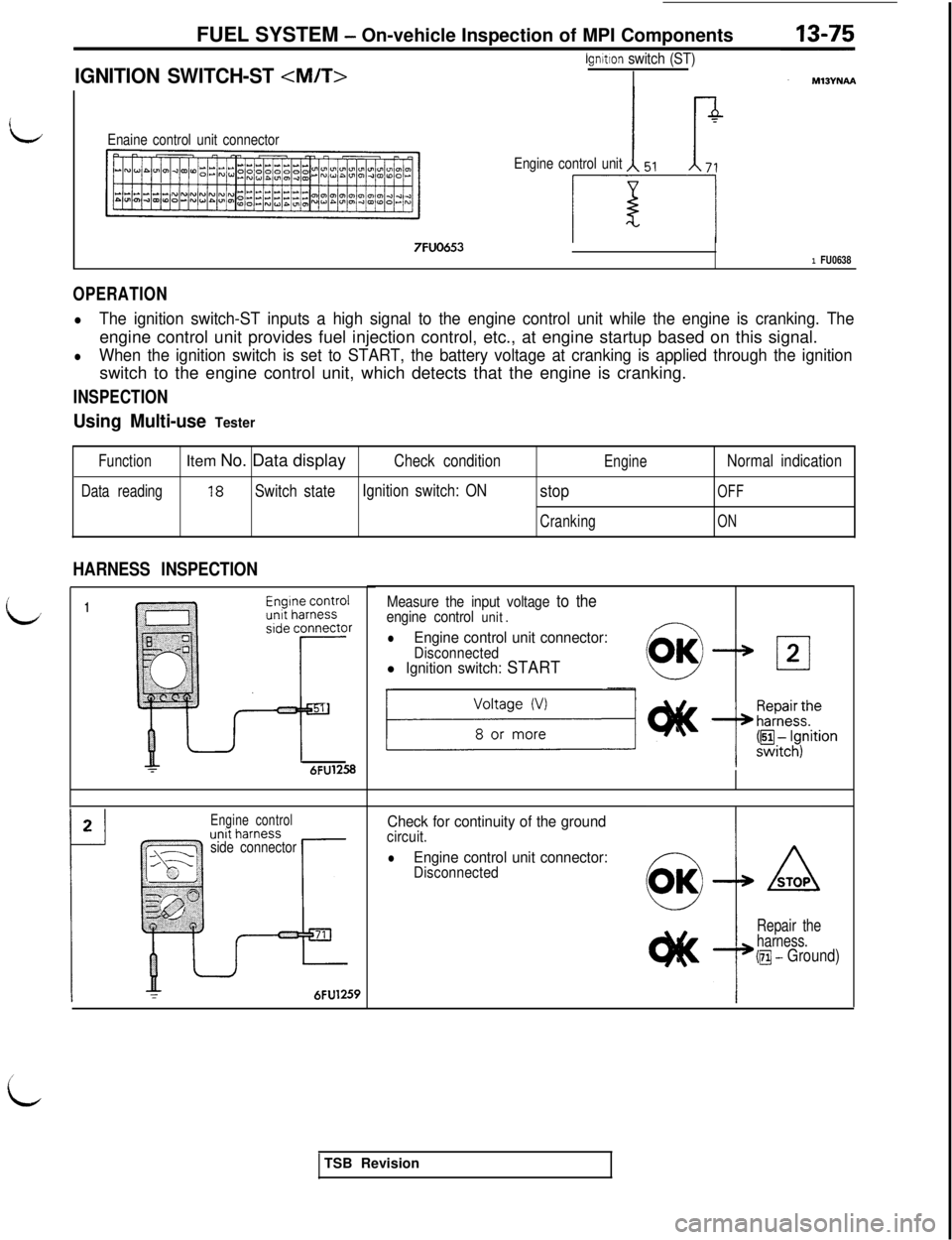

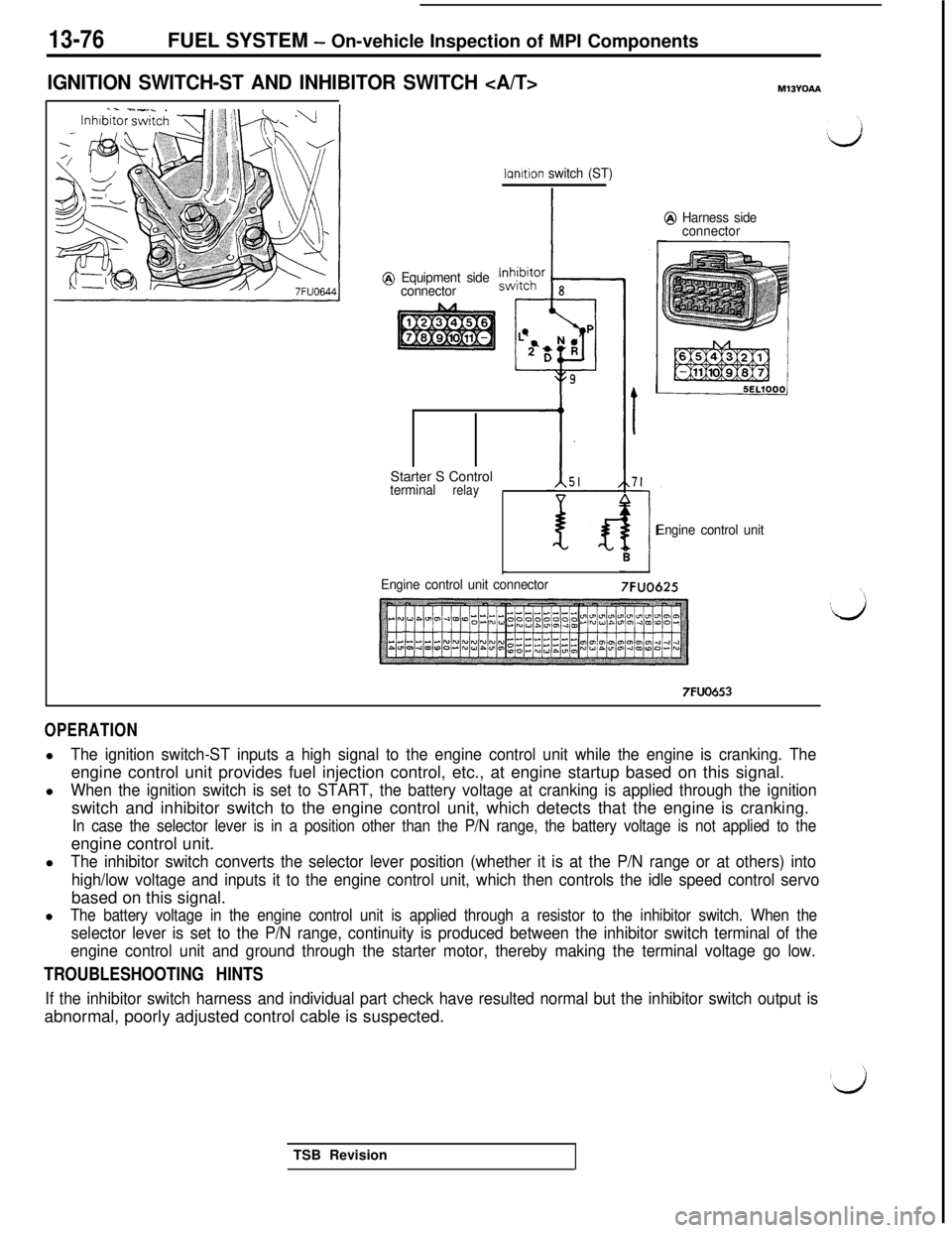

IGNITION SWITCH-ST

lgnitlon switch (ST)

I

Enaine control unit connector

7FUO653

Engine control unit

1 FU0638

OPERATION

lThe ignition switch-ST inputs a high signal to the engine control unit while the engine is cranking. Theengine control unit provides fuel injection control, etc., at engine startup based on this signal.

lWhen the ignition switch is set to START, the battery voltage at cranking is applied through the ignitionswitch to the engine control unit, which detects that the engine is cranking.

INSPECTION

Using Multi-use Tester

FunctionItem No. Data displayCheck conditionEngineNormal indication

Data reading18Switch stateIgnition switch: ONstopOFF

CrankingON

HARNESS INSPECTION

1

L6FU1258

2

1

Engine control

side connector

IY-6FU1259

Measure the input voltage to theengine control unit.nlEngine control unit connector:Disconnectedl Ignition switch: START

Check for continuity of the groundcircuit.

lEngine control unit connector:Disconnected

Repair the

harness.

(m - Ground)

iTSB Revision

Page 182 of 1146

Page 186 of 1146

13-80FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

POWER STEERING OIL PRESSURE SWITCHMlOYQAA

B

$-

Engine control unit

'107

@ Harness side

connector

ml-

Power steering oil

Pressure switch

7FUO536700-2.000 1.500-2.000(100-284) (213-284)Pressure [kPa (psi)]

0, l.oIu

OPERATIONl

The power steering oil pressure switch converts presence/absence of power steering load into low/high

voltage and inputs it to the engine control unit, which then controls the idle speed control servo based on

this signal.l The battery voltage in the engine control unit is applied through a resistor to the power steering oil

pressure switch. Steering operation causes the power steering oil pressure to increase, turning the

switch on. As a result, continuity is produced between the battery voltage applied and ground. This

causes the power steering oil pressure terminal voltage to go from high to low.

TSB Revision

Page 188 of 1146

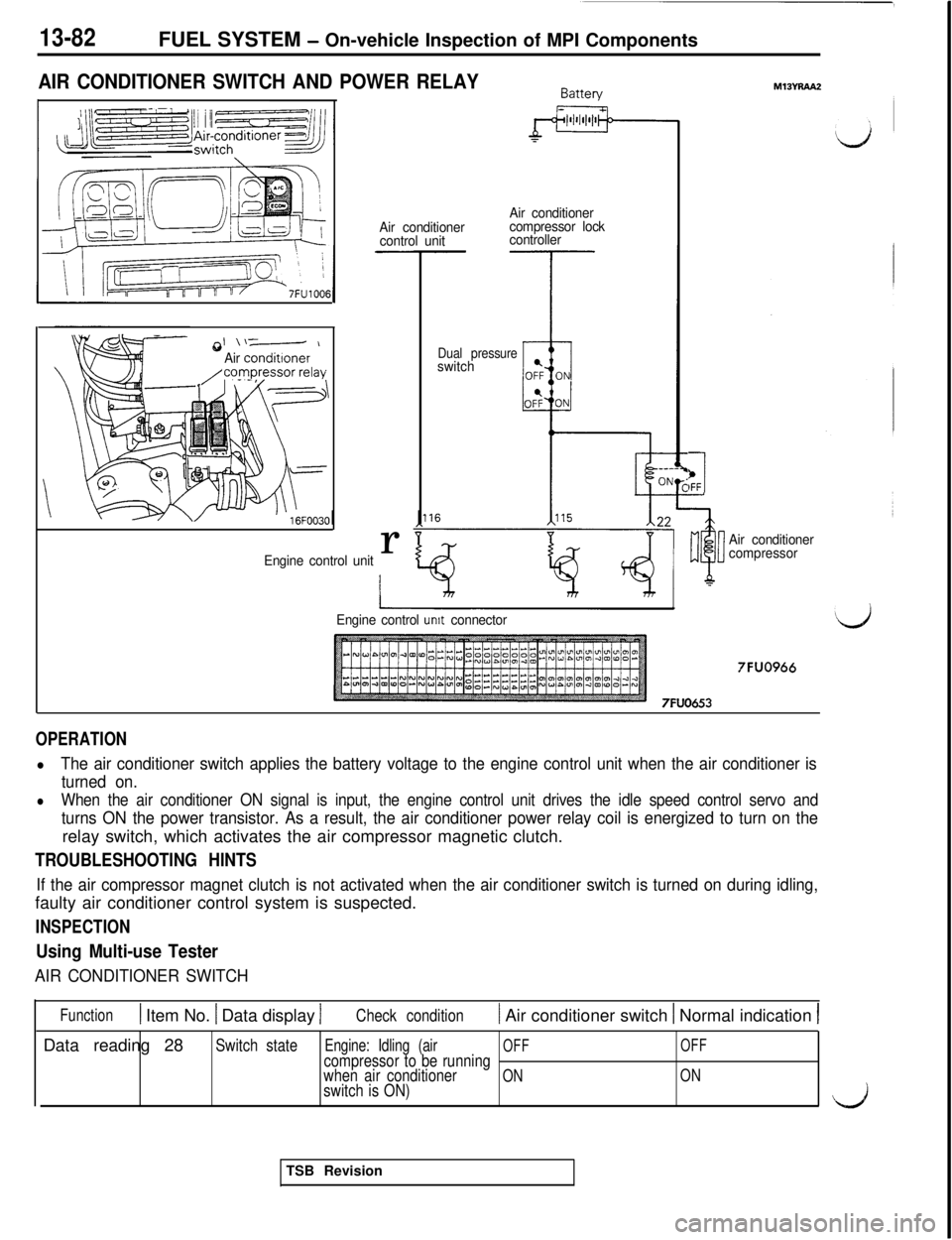

13-82FUEL SYSTEM - On-vehicle Inspection of MPI Components

AIR CONDITIONER SWITCH AND POWER RELAY

\

*I \\-- \

Air conditronerAir conditioner

control unitAir conditioner

compressor lock

controllerr

Engine control unit

Dual pressureswitch

M13YRAA2

b1IFF

Air conditioner

compressor

Engine control

unit connector

7FUO966

7FUO653

OPERATION

lThe air conditioner switch applies the battery voltage to the engine control unit when the air conditioner is

turned on.

lWhen the air conditioner ON signal is input, the engine control unit drives the idle speed control servo and

turns ON the power transistor. As a result, the air conditioner power relay coil is energized to turn on therelay switch, which activates the air compressor magnetic clutch.

TROUBLESHOOTING HINTS

If the air compressor magnet clutch is not activated when the air conditioner switch is turned on during idling,faulty air conditioner control system is suspected.

INSPECTION

Using Multi-use Tester

AIR CONDITIONER SWITCH

Function1 Item No. 1 Data display 1Check condition) Air conditioner switch 1 Normal indication IData reading 28

Switch stateEngine: Idling (airOFFOFFcompressor to be running

when air conditionerONONswitch is ON)\k”JTSB Revision

Page 192 of 1146

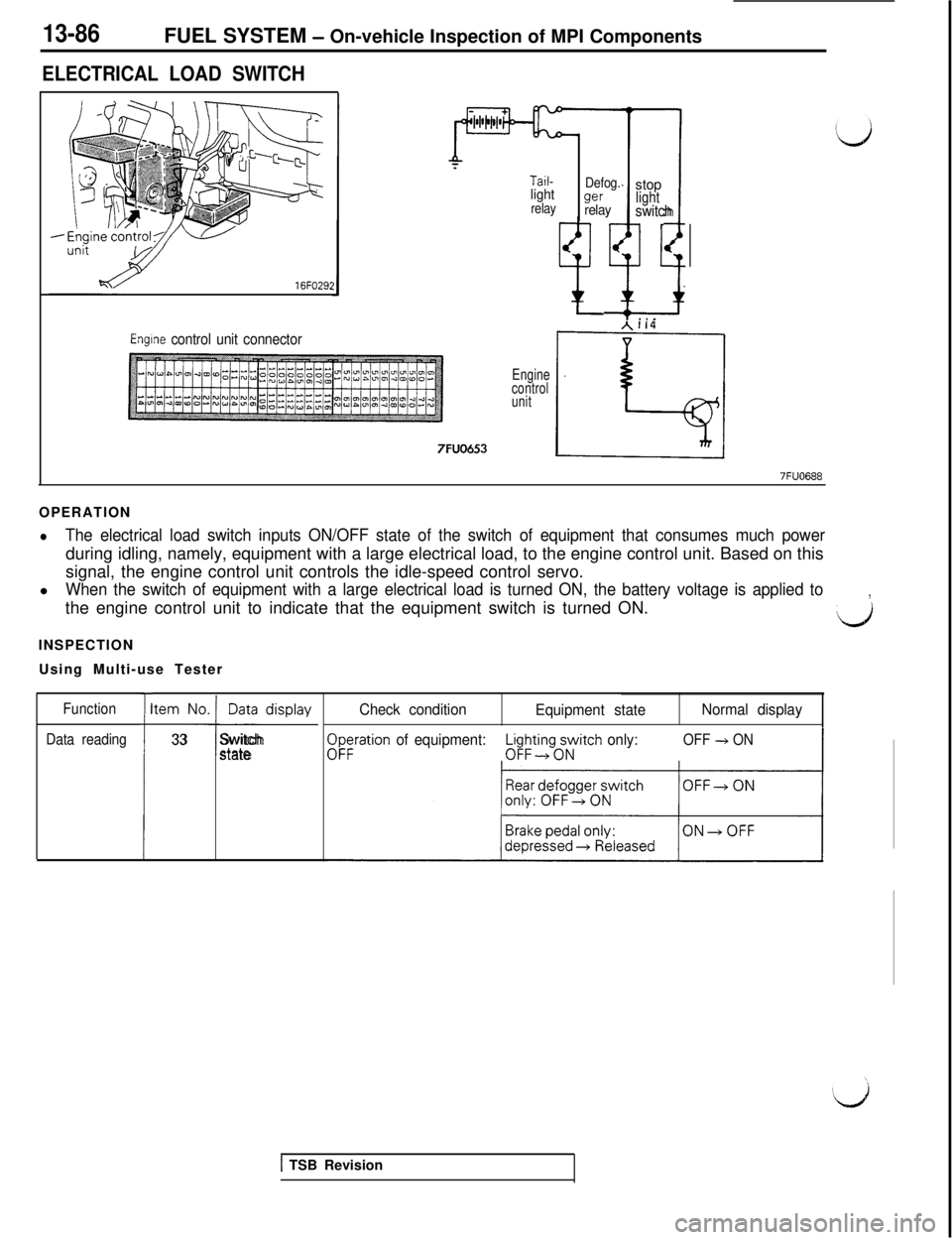

13-86FUEL SYSTEM - On-vehicle Inspection of MPI Components

ELECTRICAL LOAD SWITCH16FO29;

Tail-lightrelayDefog.wrelaystoplight

t;1

switch

ti* . .

Engine control unit connector

Engine

control

unit7FUO653

7FUO688OPERATION

lThe electrical load switch inputs ON/OFF state of the switch of equipment that consumes much powerduring idling, namely, equipment with a large electrical load, to the engine control unit. Based on this

signal, the engine control unit controls the idle-speed control servo.

l

When the switch of equipment with a large electrical load is turned ON, the battery voltage is applied tothe engine control unit to indicate that the equipment switch is turned ON.,

LJINSPECTION

Using Multi-use Tester

Function

Data reading

I

tem No. Data display

-I-

33Switchstate

Check condition

Equipment stateNormal display

$;ration of equipment:L$ing;Atch only:OFF + ON-3

1 TSB Revision

Page 194 of 1146

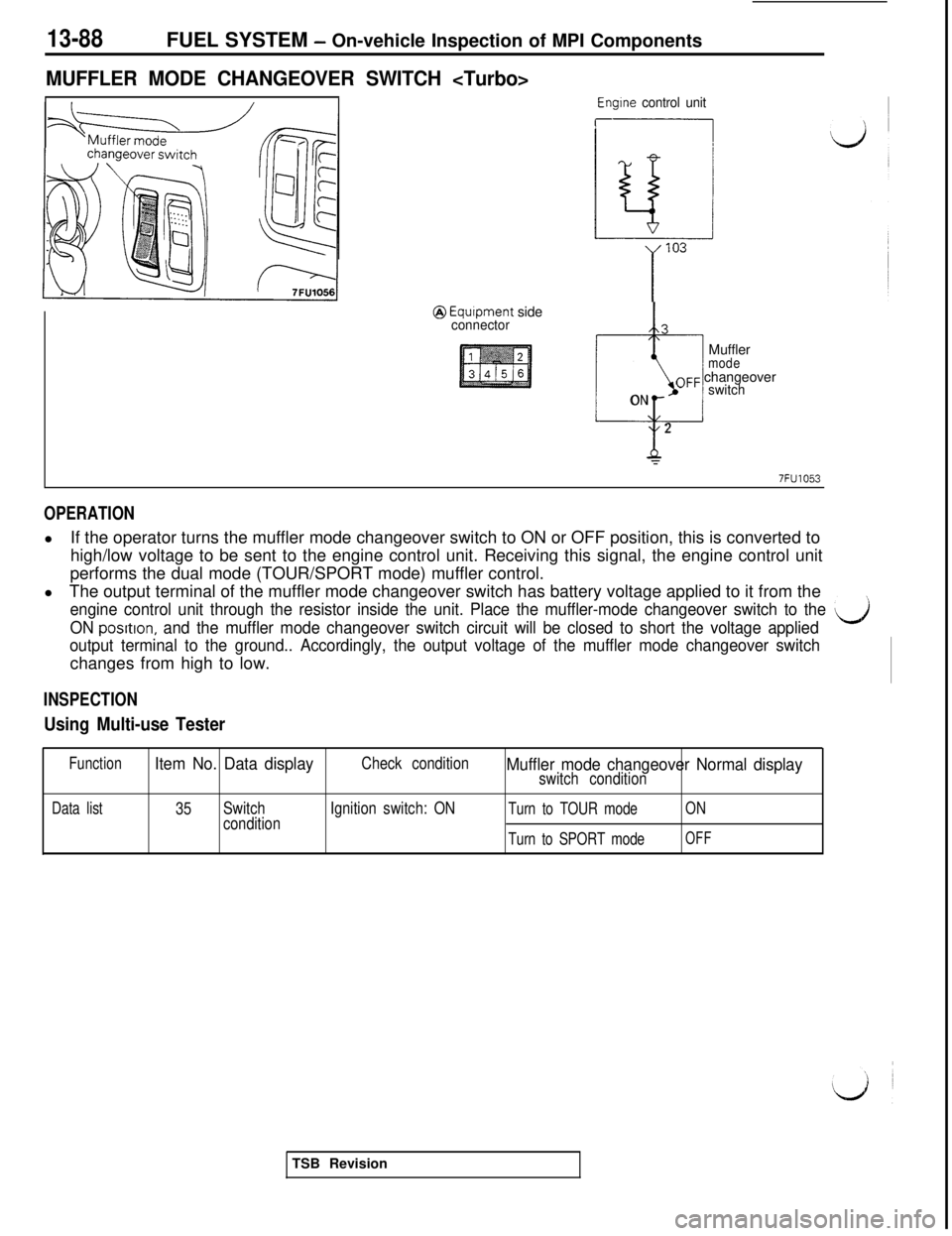

13-88FUEL SYSTEM - On-vehicle Inspection of MPI Components

MUFFLER MODE CHANGEOVER SWITCH

Engine control unit

r

@ Equipment sideconnector3

-Muffler

modeOFF changeover

ONswitch

2

r

7FU1053

OPERATIONlIf the operator turns the muffler mode changeover switch to ON or OFF position, this is converted to

high/low voltage to be sent to the engine control unit. Receiving this signal, the engine control unit

performs the dual mode (TOUR/SPORT mode) muffler control.

lThe output terminal of the muffler mode changeover switch has battery voltage applied to it from the

engine control unit through the resistor inside the unit. Place the muffler-mode changeover switch to the ‘LJj

ON posrtton, and the muffler mode changeover switch circuit will be closed to short the voltage applied

output terminal to the ground.. Accordingly, the output voltage of the muffler mode changeover switchchanges from high to low.

INSPECTION

Using Multi-use Tester

FunctionItem No. Data displayCheck conditionMuffler mode changeover Normal displayswitch condition

Data list35Switch

conditionIgnition switch: ONTurn to TOUR mode

Turn to SPORT modeON

OFFTSB Revision

Page 200 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

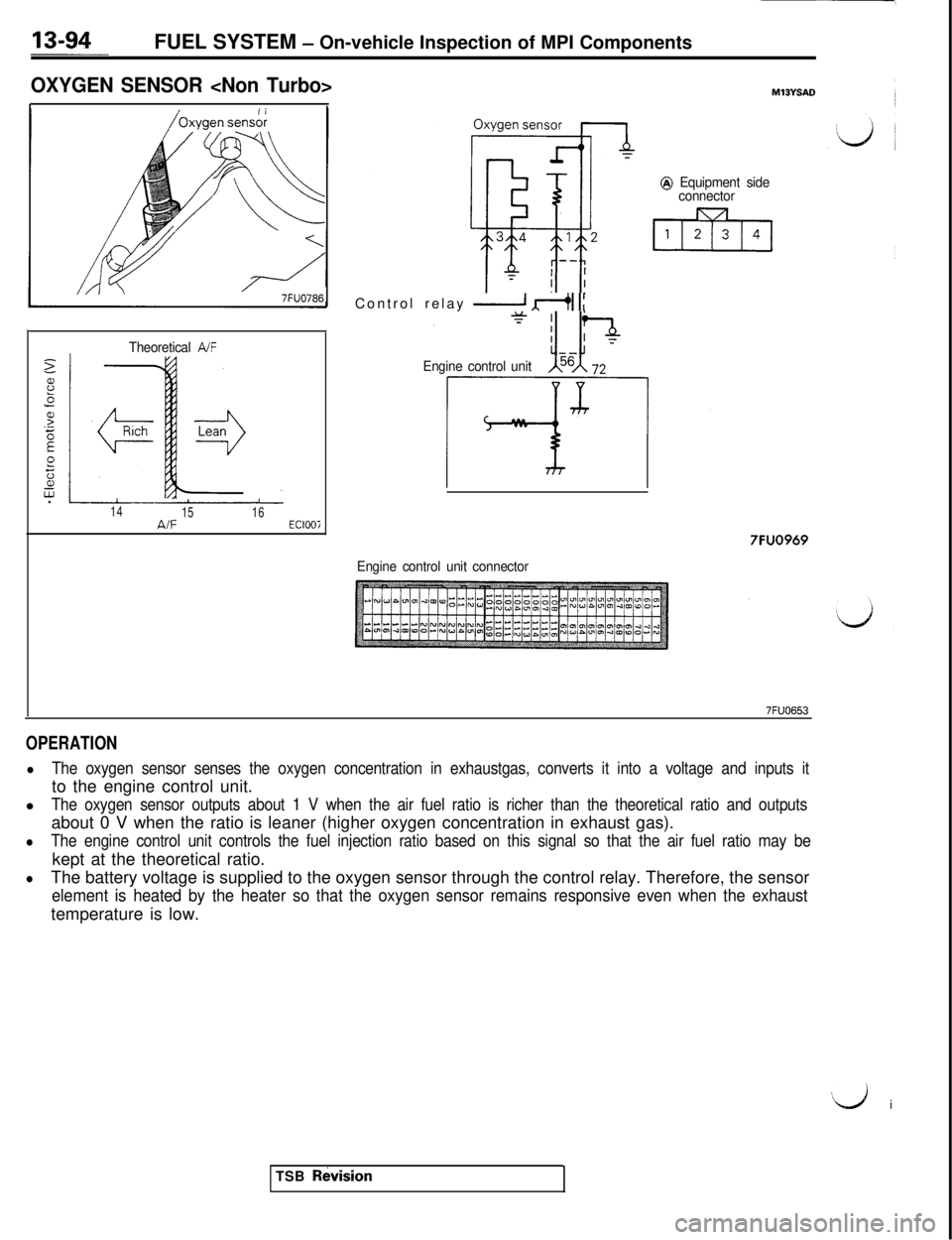

OXYGEN SENSOR

7FUO786

Theoretical A/F

14

1516A/FEClOOiControl relay

2 dI 1:

Engine control unit

@ Equipment side

connector

7FUO969

Engine control unit connector

7FUO653

OPERATION

lThe oxygen sensor senses the oxygen concentration in exhaustgas, converts it into a voltage and inputs itto the engine control unit.

l

The oxygen sensor outputs about 1 V when the air fuel ratio is richer than the theoretical ratio and outputsabout 0 V when the ratio is leaner (higher oxygen concentration in exhaust gas).

lThe engine control unit controls the fuel injection ratio based on this signal so that the air fuel ratio may bekept at the theoretical ratio.

lThe battery voltage is supplied to the oxygen sensor through the control relay. Therefore, the sensor

element is heated by the heater so that the oxygen sensor remains responsive even when the exhausttemperature is low.

‘d i

TSB

RtkisionI