torque MITSUBISHI 3000GT 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 357 of 1146

EMISSION CONTROL - Exhaust Gas Recirculation IEGR) Svstem17-13

GM159

QQQQQQ7FMnn4EGR VALVE

M17lCKJ

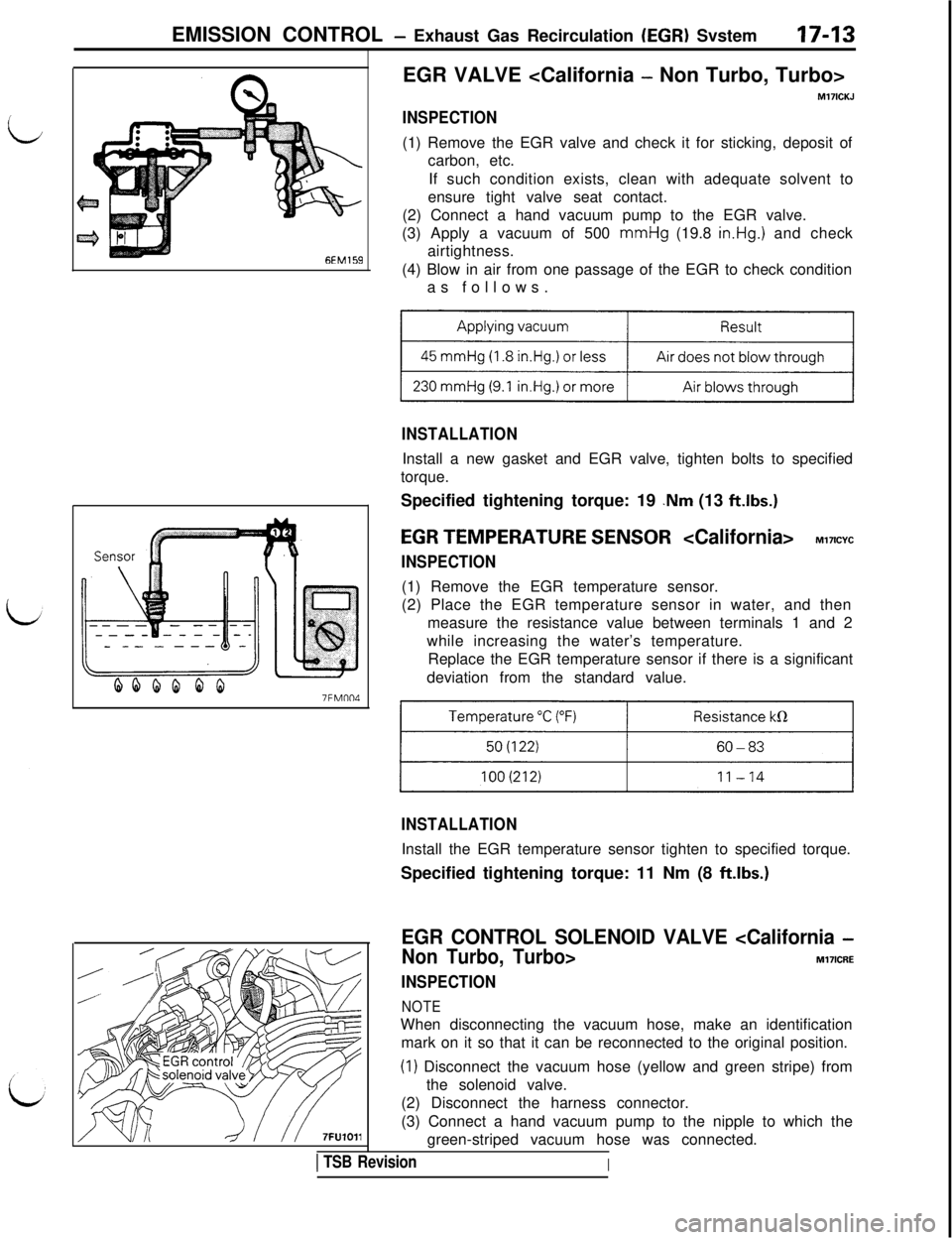

INSPECTION(1) Remove the EGR valve and check it for sticking, deposit of

carbon, etc.

If such condition exists, clean with adequate solvent to

ensure tight valve seat contact.

(2) Connect a hand vacuum pump to the EGR valve.

(3) Apply a vacuum of 500 mmHg (19.8 in.Hg.) and check

airtightness.

(4) Blow in air from one passage of the EGR to check condition

as follows.

INSTALLATIONInstall a new gasket and EGR valve, tighten bolts to specified

torque.

Specified tightening torque: 19

.Nm (13 ft.lbs.)

EGR TEMPERATURE SENSOR

INSPECTION(1) Remove the EGR temperature sensor.

(2) Place the EGR temperature sensor in water, and then

measure the resistance value between terminals 1 and 2

while increasing the water’s temperature.

Replace the EGR temperature sensor if there is a significant

deviation from the standard value.

INSTALLATIONInstall the EGR temperature sensor tighten to specified torque.

Specified tightening torque: 11 Nm (8

ftlbs.)

EGR CONTROL SOLENOID VALVE

INSPECTION

NOTEWhen disconnecting the vacuum hose, make an identification

mark on it so that it can be reconnected to the original position.

(1) Disconnect the vacuum hose (yellow and green stripe) from

the solenoid valve.

(2) Disconnect the harness connector.

(3) Connect a hand vacuum pump to the nipple to which the

green-striped vacuum hose was connected.

1 TSB RevisionI

Page 363 of 1146

CLUTCH - Service Adjustment Procedures21-5

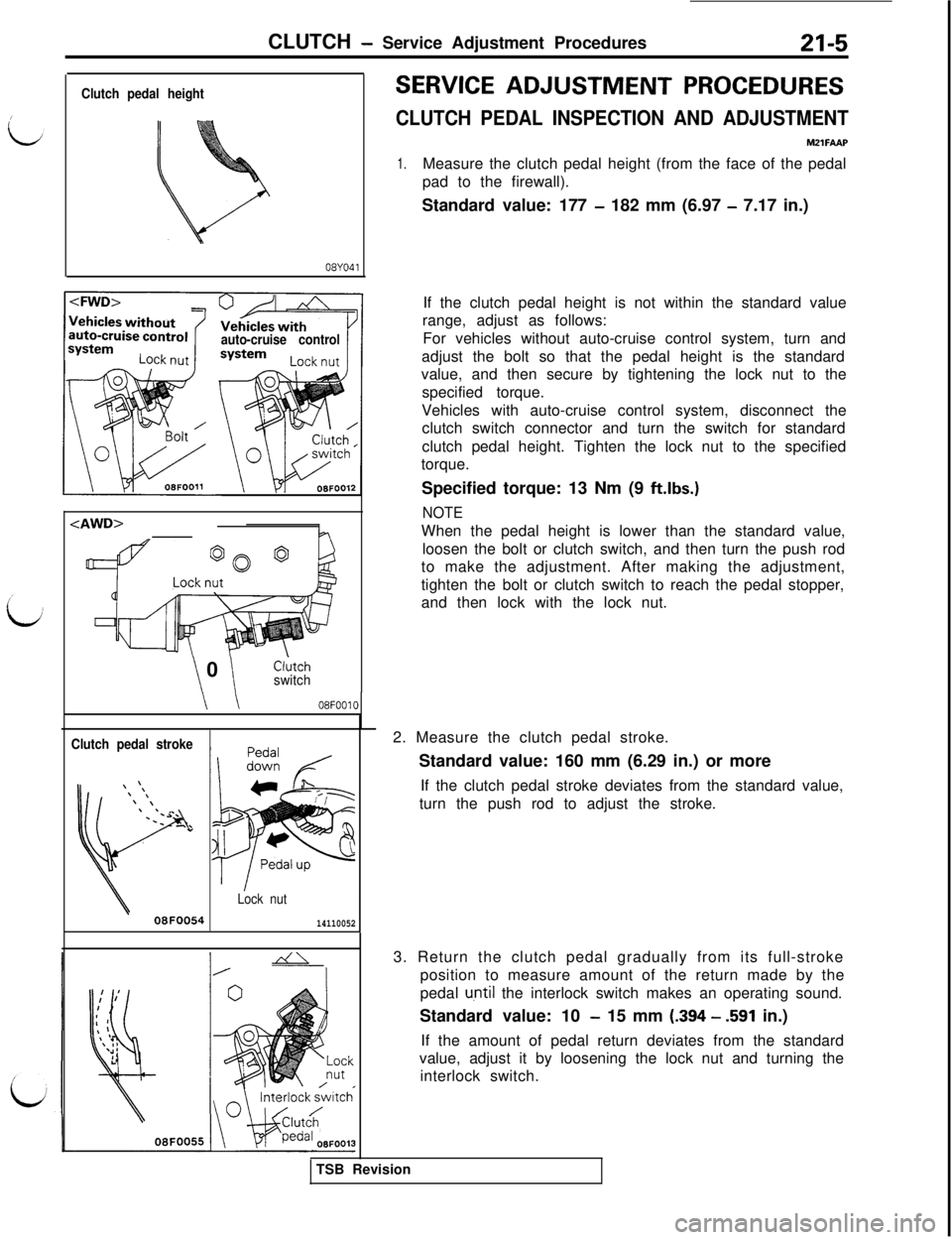

Clutch pedal height

08YO41

auto-cruise control

\ \ 0Cl;tchswitch

\ \08F0010

Clutch pedal stroke

Lock nut

08F005414110052

SERVICE ADJUSTMENT PROCEDURES

CLUTCH PEDAL INSPECTION AND ADJUSTMENTMZlFAAP

1.Measure the clutch pedal height (from the face of the pedal

pad to the firewall).

Standard value: 177

- 182 mm (6.97 - 7.17 in.)

If the clutch pedal height is not within the standard value

range, adjust as follows:

For vehicles without auto-cruise control system, turn and

adjust the bolt so that the pedal height is the standard

value, and then secure by tightening the lock nut to the

specified torque.

Vehicles with auto-cruise control system, disconnect the

clutch switch connector and turn the switch for standard

clutch pedal height. Tighten the lock nut to the specified

torque.

Specified torque: 13 Nm (9

ft.lbs.)

NOTEWhen the pedal height is lower than the standard value,

loosen the bolt or clutch switch, and then turn the push rod

to make the adjustment. After making the adjustment,

tighten the bolt or clutch switch to reach the pedal stopper,

and then lock with the lock nut.

2. Measure the clutch pedal stroke.

Standard value: 160 mm (6.29 in.) or more

If the clutch pedal stroke deviates from the standard value,

turn the push rod to adjust the stroke.

3. Return the clutch pedal gradually from its full-stroke

position to measure amount of the return made by the

pedal

u,ntil the interlock switch makes an operating sound.

Standard value: 10

- 15 mm (.394 - .591 in.)

If the amount of pedal return deviates from the standard

value, adjust it by loosening the lock nut and turning the

interlock switch.

TSB Revision

Page 380 of 1146

21-22CLUTCH - Clutch Cover and Disc

APPLYgrease

6CLOlE

lir#LClutch disc

Clutch cover

assembly

v-l6CL02EITSB Revision

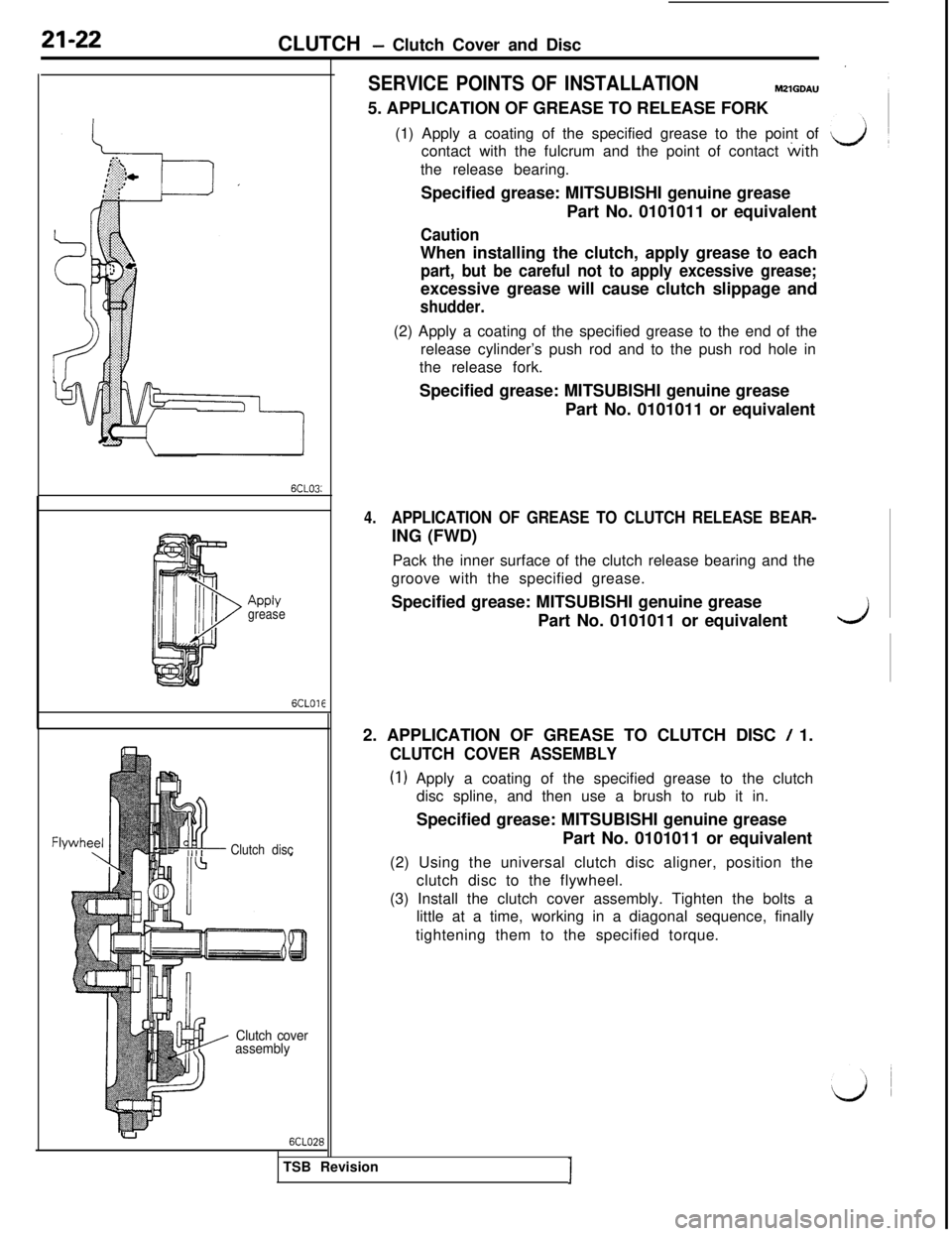

SERVICE POINTS OF INSTALLATIONMZIGDAU5. APPLICATION OF GREASE TO RELEASE FORK

(1) Apply a coating of the specified grease to the point of

contact with the fulcrum and the point of contact

withthe release bearing.

Specified grease: MITSUBISHI genuine grease

Part No. 0101011 or equivalent

CautionWhen installing the clutch, apply grease to each

part, but be careful not to apply excessive grease;excessive grease will cause clutch slippage and

shudder.(2) Apply a coating of the specified grease to the end of the

release cylinder’s push rod and to the push rod hole in

the release fork.

Specified grease: MITSUBISHI genuine grease

Part No. 0101011 or equivalent

4.APPLICATION OF GREASE TO CLUTCH RELEASE BEAR-ING (FWD)

Pack the inner surface of the clutch release bearing and the

groove with the specified grease.

Specified grease: MITSUBISHI genuine grease

Part No. 0101011 or equivalent

2. APPLICATION OF GREASE TO CLUTCH DISC

/ 1.

CLUTCH COVER ASSEMBLY

(1) Apply a coating of the specified grease to the clutch

disc spline, and then use a brush to rub it in.

Specified grease: MITSUBISHI genuine grease

Part No. 0101011 or equivalent

(2) Using the universal clutch disc aligner, position the

clutch disc to the flywheel.

(3) Install the clutch cover assembly. Tighten the bolts a

little at a time, working in a diagonal sequence, finally

tightening them to the specified torque.I

Page 405 of 1146

MANUAL TRANSAXLE

22-25

L

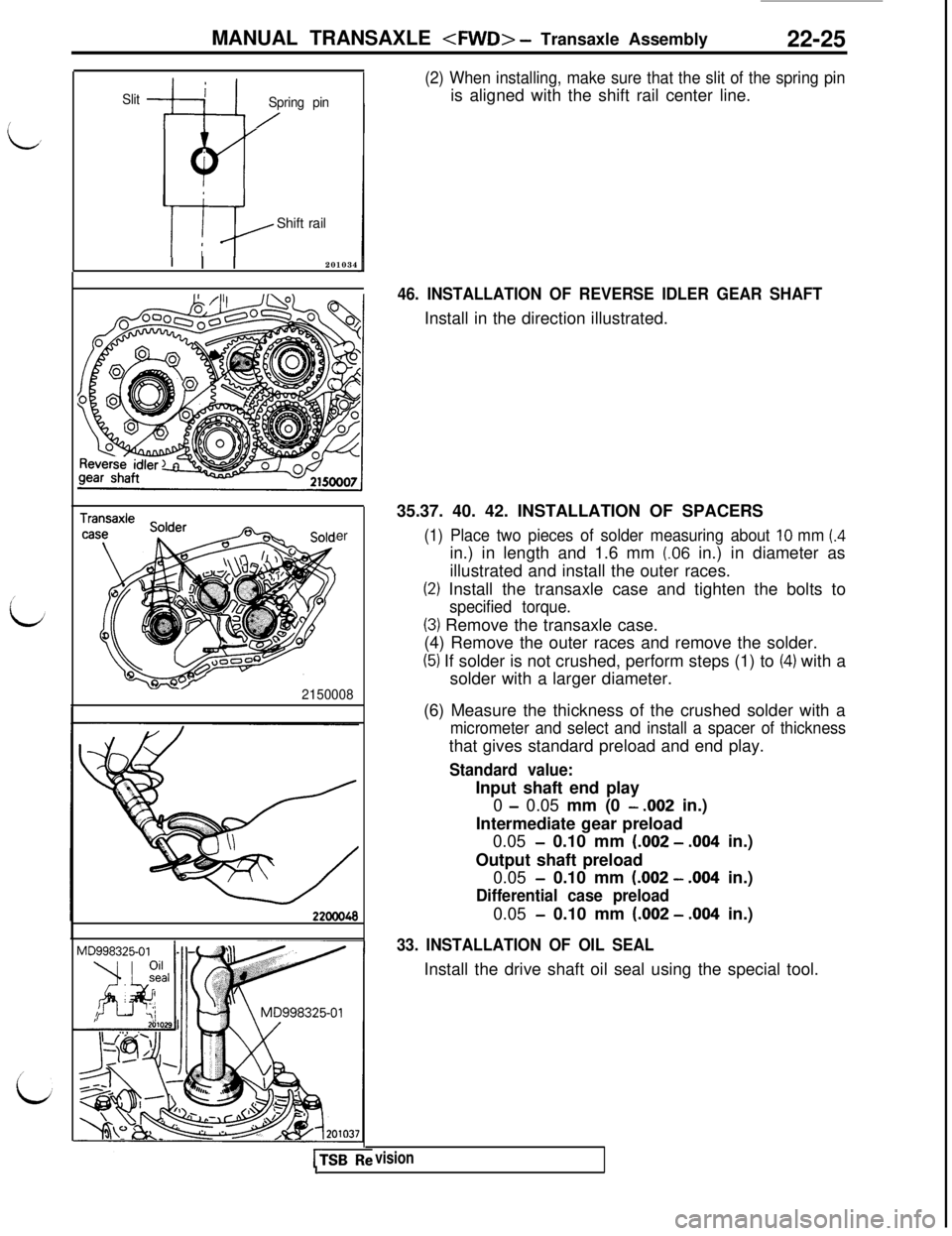

Slit

#Jl

Spring pin

/

II-+Shift rail1 I I201034

er

2150008

MD998325-01

(2) When installing, make sure that the slit of the spring pinis aligned with the shift rail center line.

46. INSTALLATION OF REVERSE IDLER GEAR SHAFTInstall in the direction illustrated.

35.37. 40. 42. INSTALLATION OF SPACERS

(1) Place two pieces of solder measuring about 10 mm (.4in.) in length and 1.6 mm

(.06 in.) in diameter as

illustrated and install the outer races.

(2) Install the transaxle case and tighten the bolts to

specified torque.

(3) Remove the transaxle case.

(4) Remove the outer races and remove the solder.

(5) If solder is not crushed, perform steps (1) to (4) with a

solder with a larger diameter.

(6) Measure the thickness of the crushed solder with a

micrometer and select and install a spacer of thicknessthat gives standard preload and end play.

Standard value:Input shaft end play

0

- 0.05 mm (0 - .002 in.)

Intermediate gear preload

0.05

- 0.10 mm (.002 - .004 in.)

Output shaft preload

0.05

- 0.10 mm (.002 - .004 in.)

Differential case preload0.05

- 0.10 mm (.002 - .004 in.)

33. INSTALLATION OF OIL SEALInstall the drive shaft oil seal using the special tool.

visionI

Page 406 of 1146

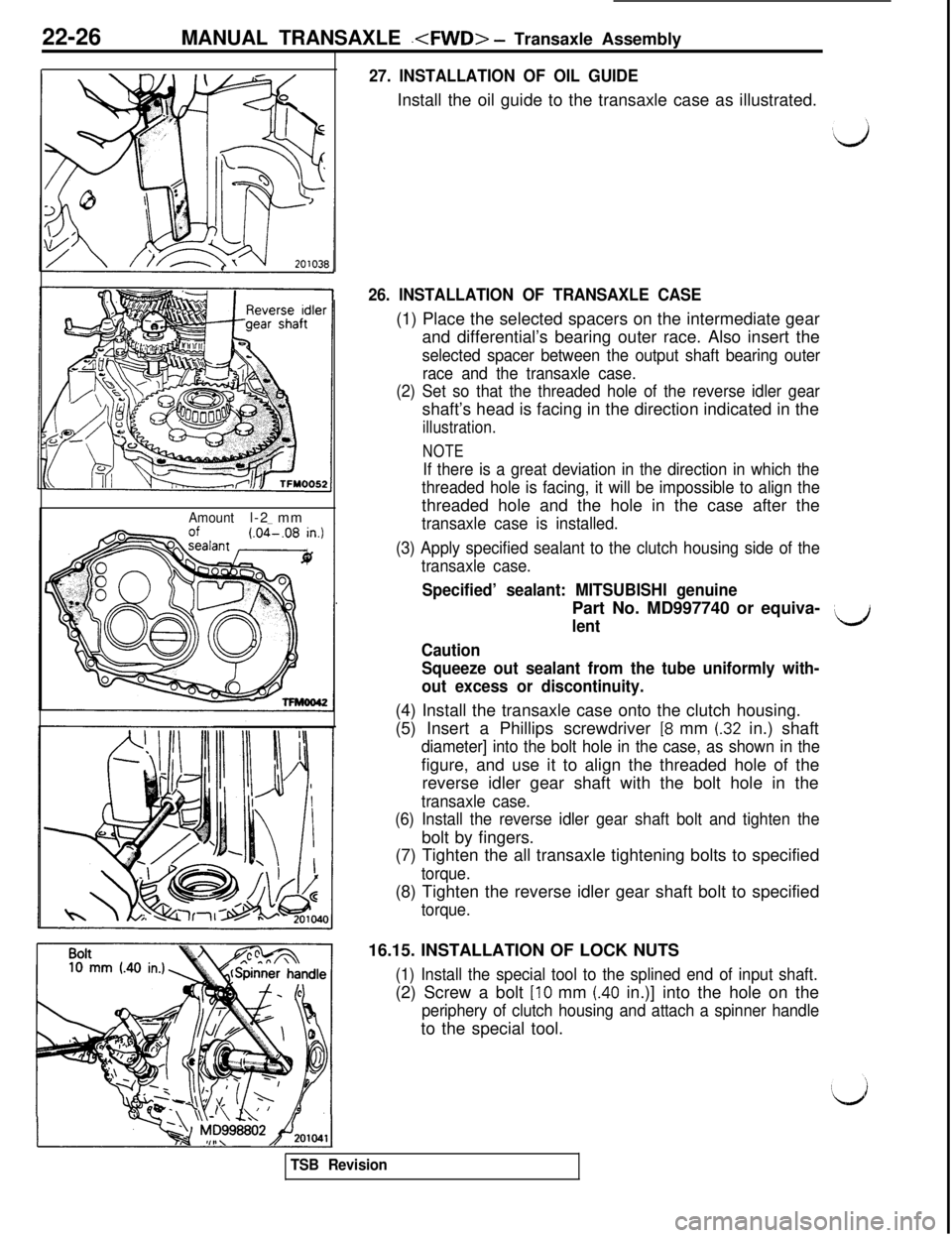

22-26MANUAL TRANSAXLE .

Amountl-2 mm

27. INSTALLATION OF OIL GUIDEInstall the oil guide to the transaxle case as illustrated.

26. INSTALLATION OF TRANSAXLE CASE(1) Place the selected spacers on the intermediate gear

and differential’s bearing outer race. Also insert the

selected spacer between the output shaft bearing outer

race and the transaxle case.

(2) Set so that the threaded hole of the reverse idler gearshaft’s head is facing in the direction indicated in the

illustration.

NOTE

If there is a great deviation in the direction in which the

threaded hole is facing, it will be impossible to align thethreaded hole and the hole in the case after the

transaxle case is installed.

(3) Apply specified sealant to the clutch housing side of the

transaxle case.

Specified’ sealant: MITSUBISHI genuinePart No. MD997740 or equiva-

lentLJ

Caution

Squeeze out sealant from the tube uniformly with-

out excess or discontinuity.(4) Install the transaxle case onto the clutch housing.

(5) Insert a Phillips screwdriver

[8 mm (.32 in.) shaft

diameter] into the bolt hole in the case, as shown in thefigure, and use it to align the threaded hole of the

reverse idler gear shaft with the bolt hole in the

transaxle case.

(6) Install the reverse idler gear shaft bolt and tighten thebolt by fingers.

(7) Tighten the all transaxle tightening bolts to specified

torque.(8) Tighten the reverse idler gear shaft bolt to specified

torque.16.15. INSTALLATION OF LOCK NUTS

(1) Install the special tool to the splined end of input shaft.(2) Screw a bolt

[lo mm (.40 in.)] into the hole on the

periphery of clutch housing and attach a spinner handleto the special tool.

TSB Revision

Page 407 of 1146

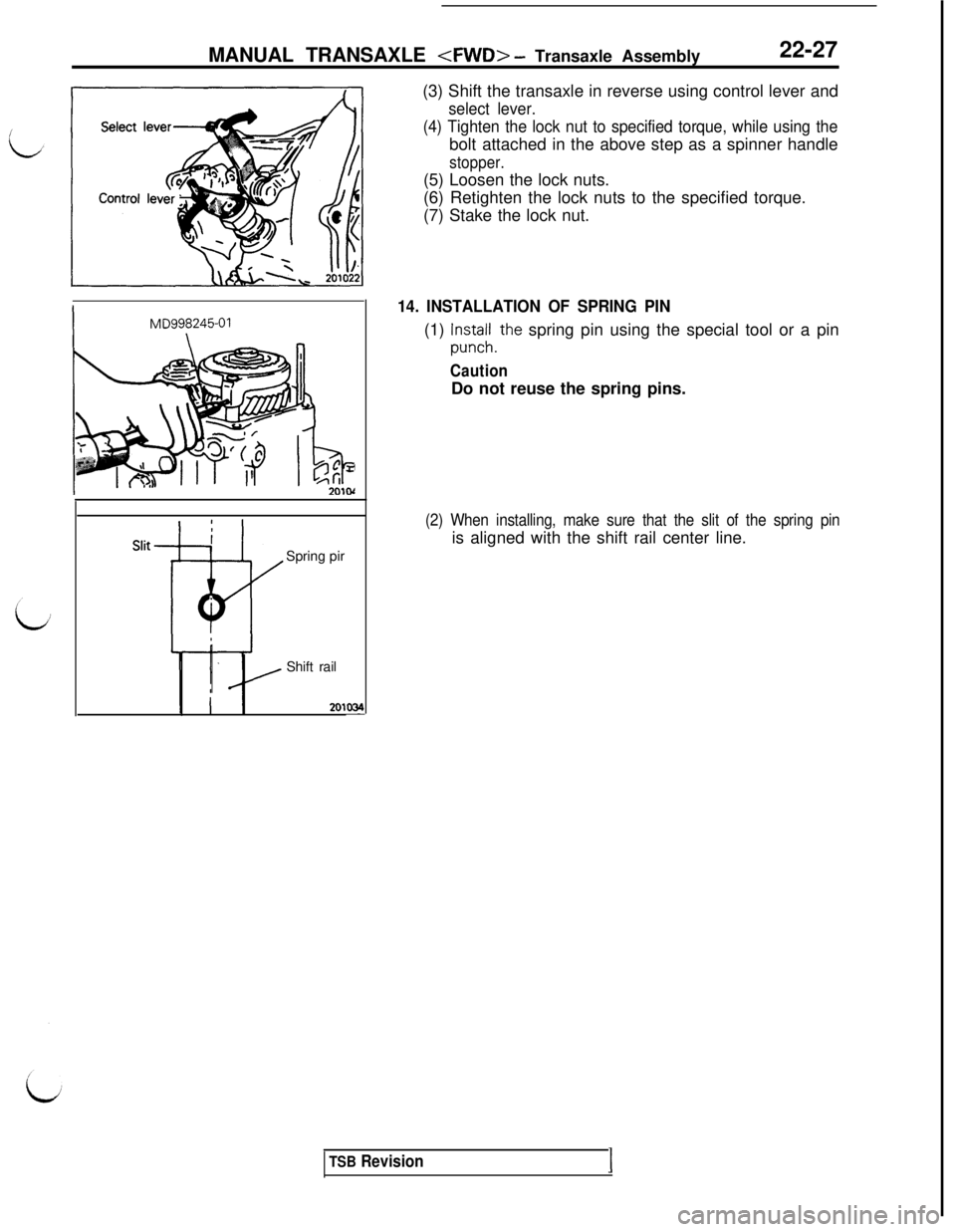

MANUAL TRANSAXLE

(3) Shift the transaxle in reverse using control lever and

select lever.

(4) Tighten the lock nut to specified torque, while using thebolt attached in the above step as a spinner handle

stopper.(5) Loosen the lock nuts.

(6) Retighten the lock nuts to the specified torque.

(7) Stake the lock nut.

IMD998245-01Spring pir

Shift rail

14. INSTALLATION OF SPRING PIN(1)

rr;‘tl.the spring pin using the special tool or a pin

CautionDo not reuse the spring pins.

(2) When installing, make sure that the slit of the spring pinis aligned with the shift rail center line.

TSB RevisionI

Page 425 of 1146

MANUAL TRANSAXLE

- ometer Driven Gear Assembly22-45

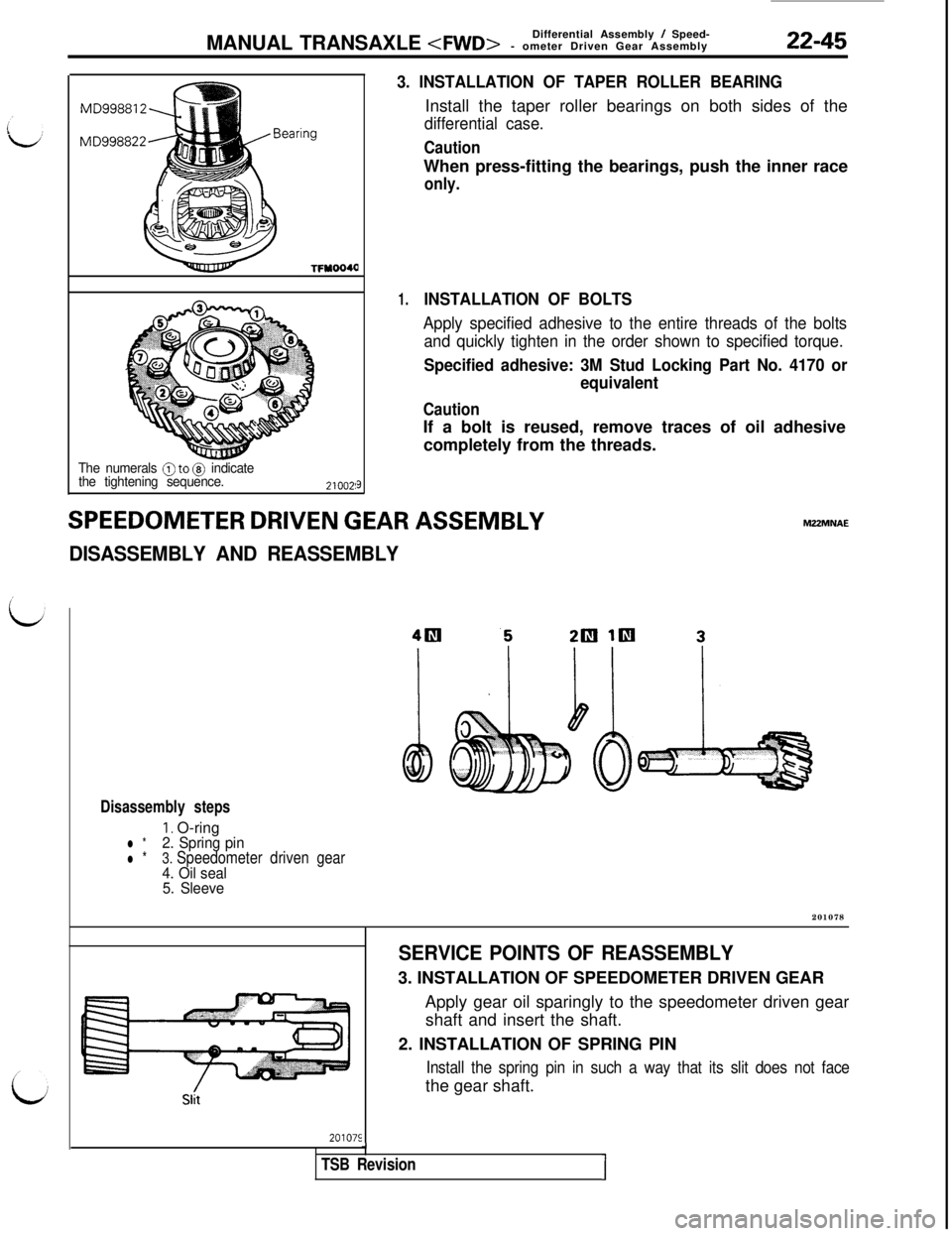

TFYOO4Q

The numerals @to @ indicate

the tightening sequence.

9

SPEEDOMETER DRIVEN GEAR ASSEMBLY

DISASSEMBLY AND REASSEMBLY

3. INSTALLATION OF TAPER ROLLER BEARINGInstall the taper roller bearings on both sides of the

differential case.

CautionWhen press-fitting the bearings, push the inner race

only.

1.INSTALLATION OF BOLTS

Apply specified adhesive to the entire threads of the bolts

and quickly tighten in the order shown to specified torque.

Specified adhesive: 3M Stud Locking Part No. 4170 or

equivalent

CautionIf a bolt is reused, remove traces of oil adhesive

completely from the threads.MZ2MNAE

Disassembly steps

I. O-ringl *2. Spring pin

l *3. Speedometer driven gear4. Oil seal

5. Sleeve201078

201075

SERVICE POINTS OF REASSEMBLY3. INSTALLATION OF SPEEDOMETER DRIVEN GEAR

Apply gear oil sparingly to the speedometer driven gear

shaft and insert the shaft.

2. INSTALLATION OF SPRING PIN

Install the spring pin in such a way that its slit does not facethe gear shaft.

J

TSB RevisionI

Page 431 of 1146

MANUAL TRANSAXLE

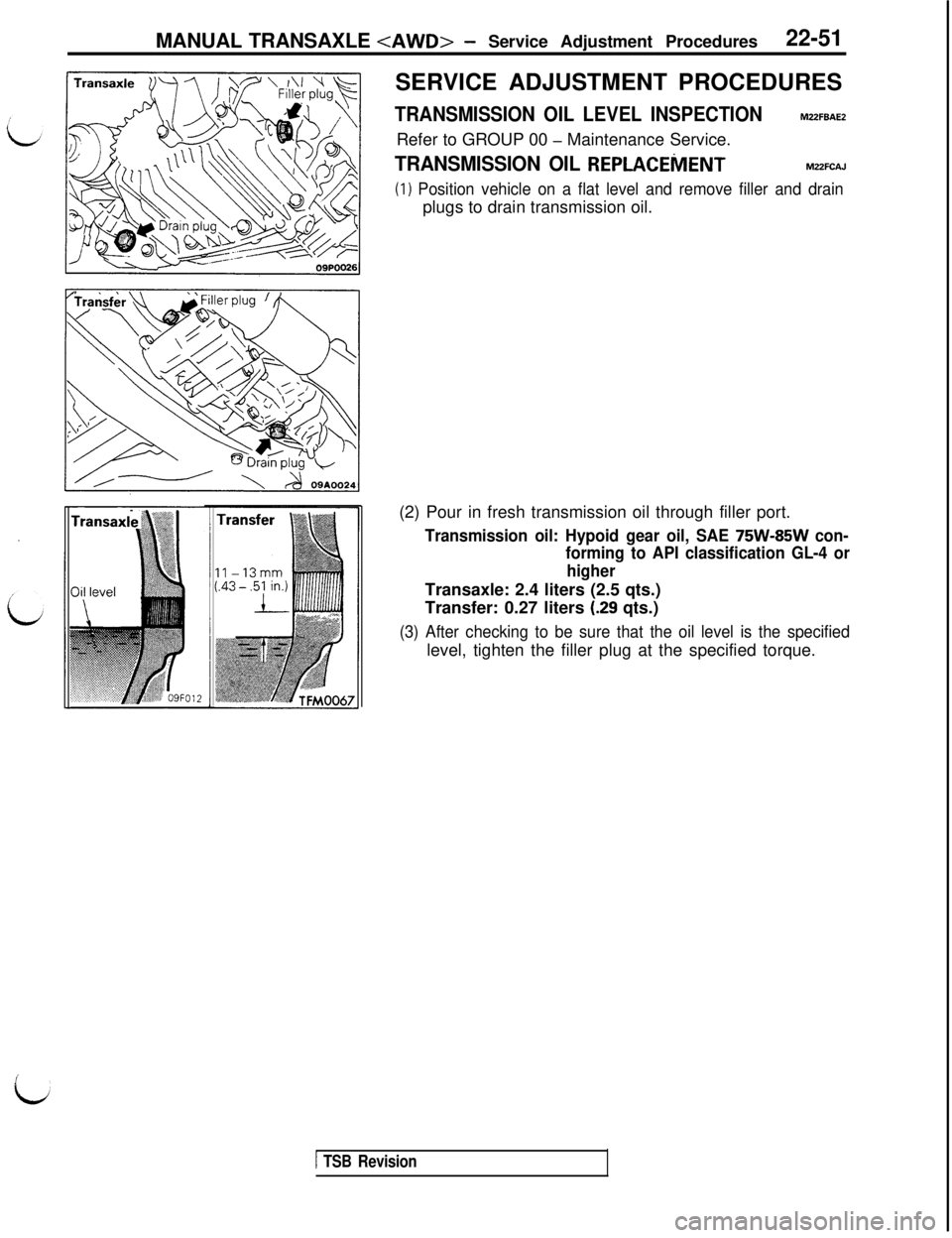

TRANSMISSION OIL LEVEL INSPECTIONM22FBAE2

Refer to GROUP 00

- Maintenance Service.

TRANSMISSION OIL REPLACEiVlENTMUFCAJ

(I) Position vehicle on a flat level and remove filler and drainplugs to drain transmission oil.

(2) Pour in fresh transmission oil through filler port.

Transmission oil: Hypoid gear oil, SAE 75W-85W con-

forming to API classification GL-4 or

higherTransaxle: 2.4 liters (2.5 qts.)

Transfer: 0.27 liters

(.29 qts.)

(3) After checking to be sure that the oil level is the specifiedlevel, tighten the filler plug at the specified torque.

1 TSB Revision

Page 445 of 1146

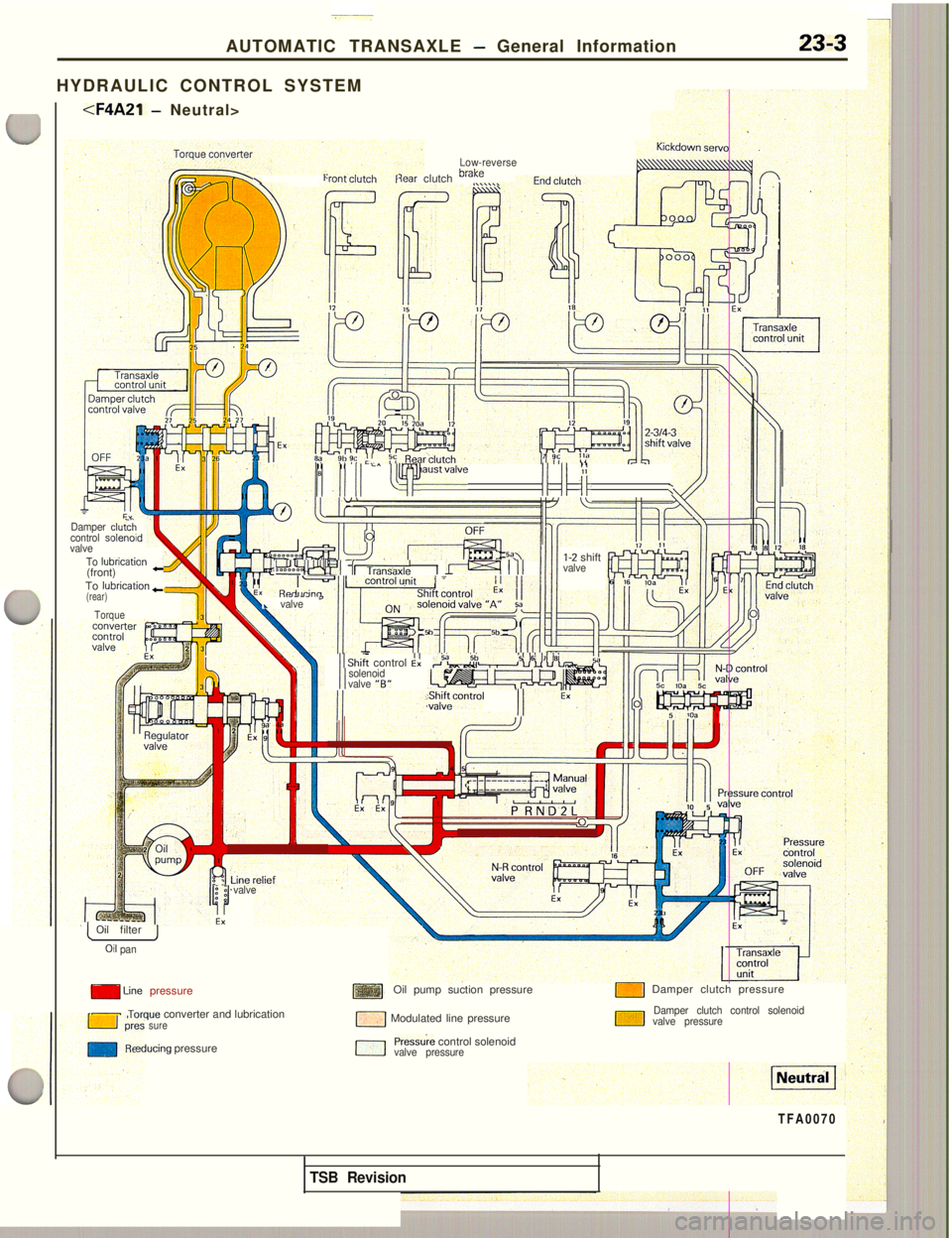

AUTOMATIC TRANSAXLE - General Information23-3HYDRAULIC CONTROL SYSTEM

i

Low-reversehr3b.3\t3ear clutch “IYhFI\\\\\\1

,/I // L1 ji‘erhaustvalve7 ;// j/ .j/,

Damper cluGcontrol solenoidvalve

To lubncatlon(front) cTo lubncatlon ,-=(rear)

Torquel-2 shift

valvek&!&!&I h TransaxldI e 1 11

---- il.valve

I 1 Shik control I!:;?A+;ilEjJJBi,

IIsolenoid

valve “6”S3ivcontroI

I/

i %

\sl

valve

Ex[ 011 filter J

011 pan

m Line pressure

-Tyue converter and lubricationsure

-_ucing pressureOil pump suction pressure

a Modulated line pressure

I”‘rl Damper clutch pressure

mDamper clutch control solenoid

valve pressure

IPressure control solenoidvalve pressureTFA0070

TSB Revision

Page 447 of 1146

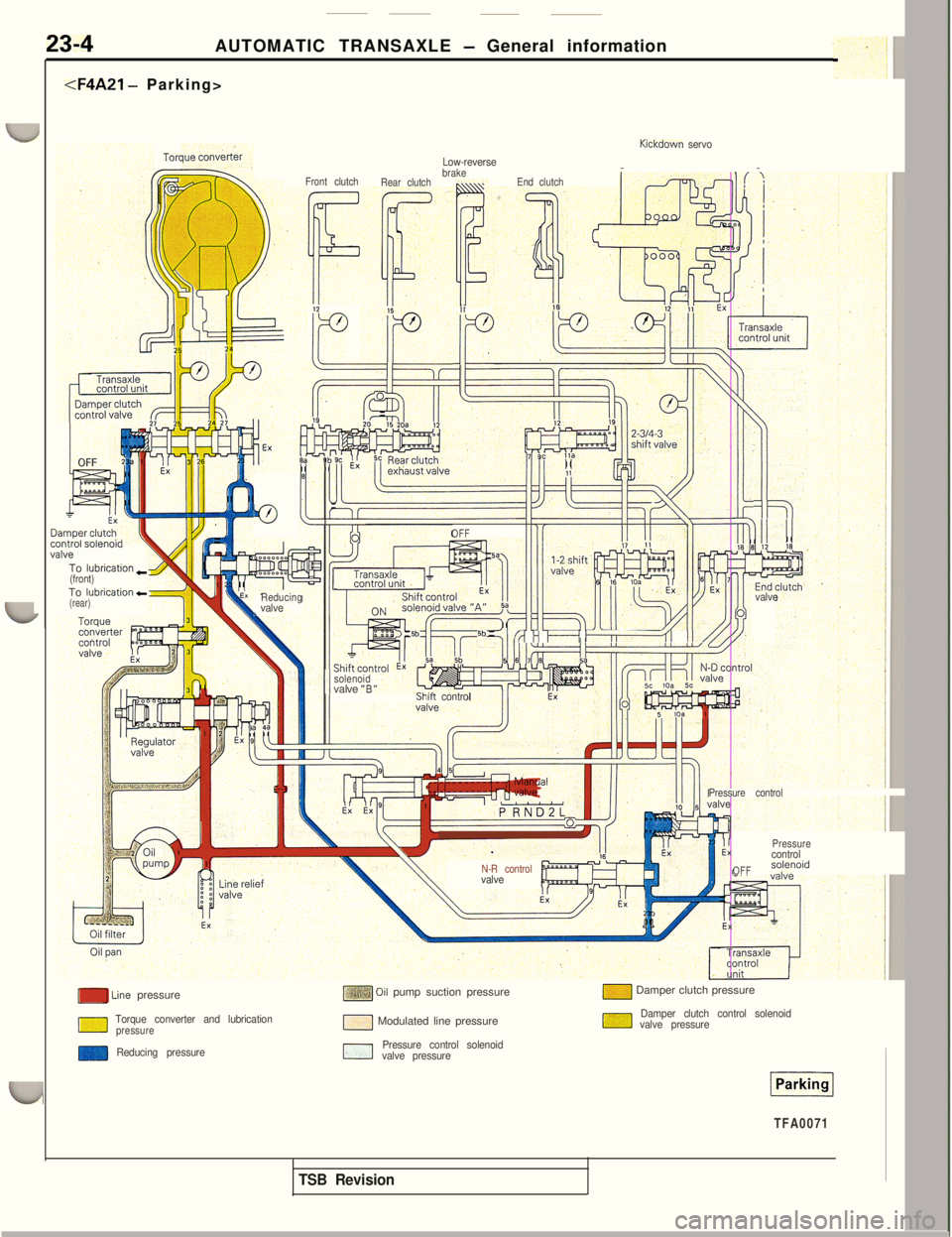

23-4AUTOMATIC TRANSAXLE - General information

Tort-

CCvJ

Kickdown servo--

Low-reversebrake

Rear clutch Front clutch

F12/

!P

End clutchii

/

Ii”

t

OFF

z7szzz

10-IF=?

OFF

snort controlvalve

1'7 H I-------i II/

IIjamper clutcontrol solerwualveTo lubrrcatron c(front)To lubrrcatton c(rear)ReducingL valve

IIsolenoidvalve “B”

Pressure control

N-R control

valve

Pressurecontrol

OFFsolenord

m Oil pump suction pressure

0 Modulated line pressure

0 Damper clutch pressure

@gjJDamper clutch control solenoid

valve pressure

IPressure control solenoid

valve pressure

m Lrne pressure

0Torque converter and lubricationpressure

Reducing pressureTFA0071

TSB Revision