relay MITSUBISHI 3000GT 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 495 of 1146

AUTOMATIC TRANSAXLE - Troubleshootinn23-43

CONVERTER STALL TESTStall test consist of determining maximum engine

speed obtained at full throttle in “D” and

“I?”positions. This test checks torque converter

statoroverrunning clutch operation, and holding ability of

transaxle clutches and low-reverse brake.

Caution

During this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature

[70 - 80°C (160 -

18O”F)I. Engine coolant should also be at normal

operating temperature

[80 - 90°C (180 - 19O”F)l.2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds at

a time. If more than one stall test is required,

operate engine at approximately 1,000 rpm in

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed: 2,200

- 3,200 rpm

7.Place selector lever to “R” position and perform

stall test by the same procedure as in foregoing

item.

Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutch

or overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.

Stall Speed Above Specification in “R”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping.

In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance, etc. If these are good, torque

converter is faulty.

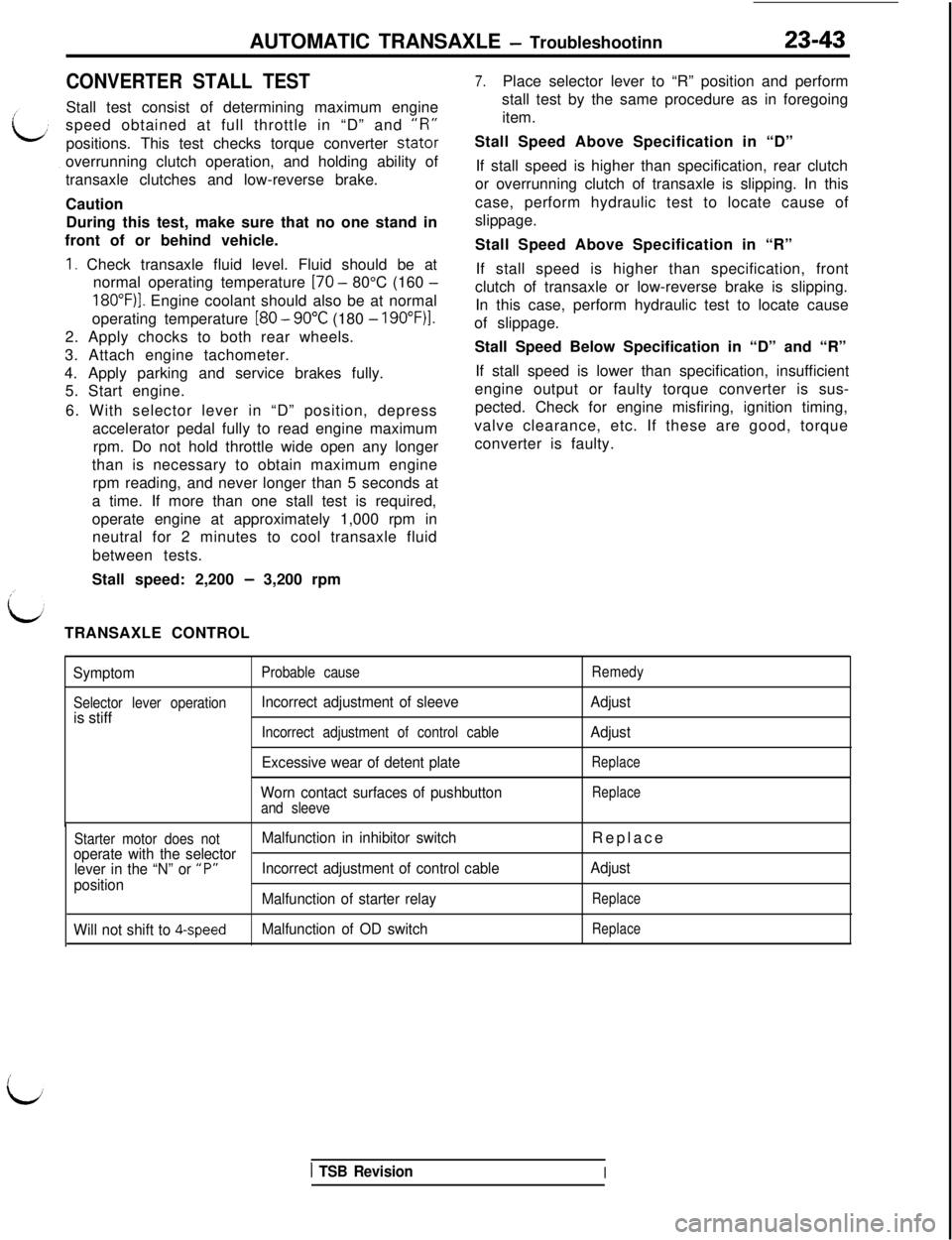

TRANSAXLE CONTROL

Symptom

Selector lever operationis stiff

Probable cause

Incorrect adjustment of sleeve

Remedy

Adjust

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton

and sleeve

Adjust

Replace

Replace

Starter motor does notMalfunction in inhibitor switchReplace

operate with the selector

lever in the “N” or “P”Incorrect adjustment of control cableAdjust

position

Will not shift to

4-speed

Malfunction of starter relay

Malfunction of OD switchReplace

Replace

1 TSB RevisionI

Page 684 of 1146

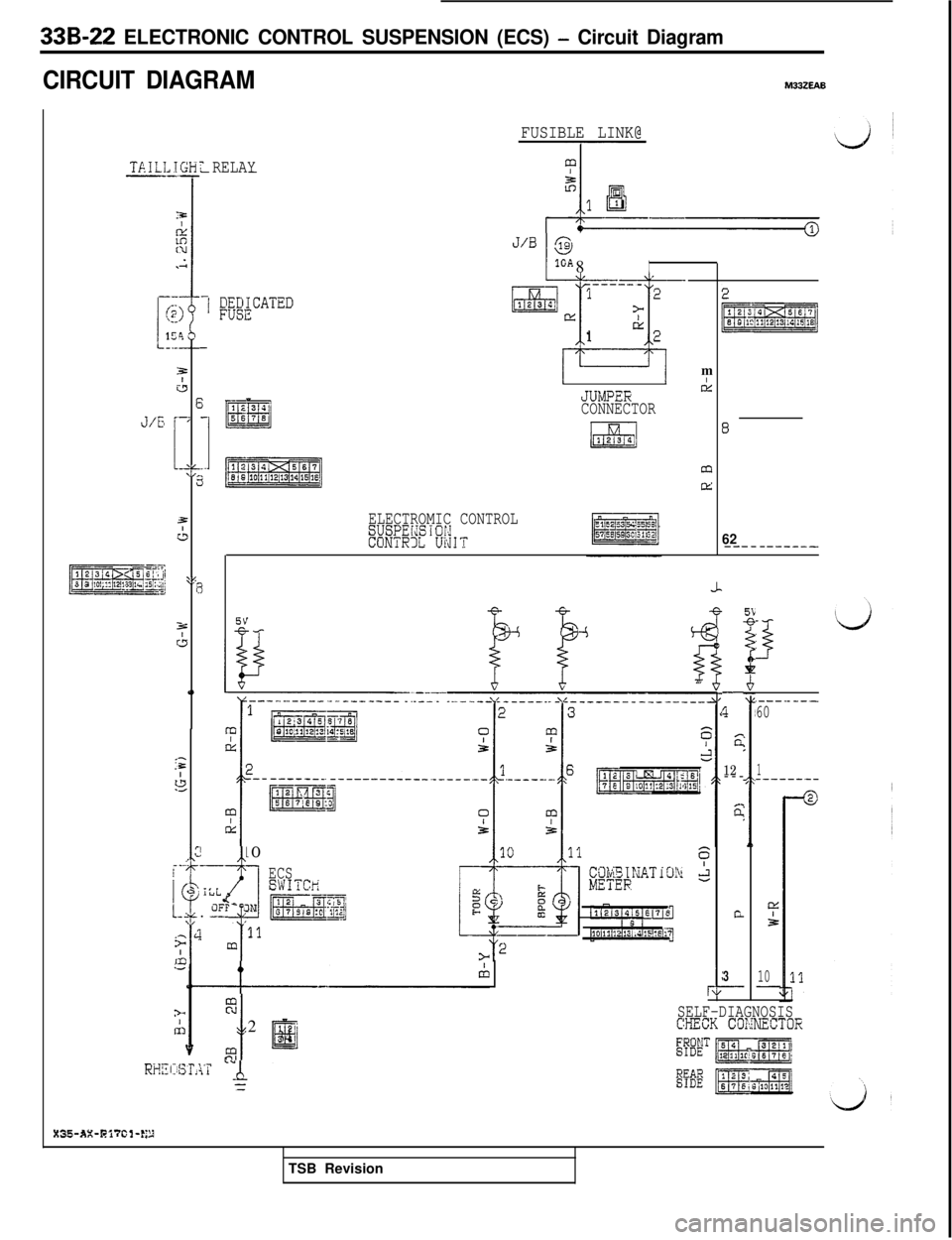

33B-22 ELECTRONIC CONTROL SUSPENSION (ECS) - Circuit Diagram

CIRCUIT DIAGRAMM33ZEAB

TAILL-_

-

!

!-1

J/G

pyspq3 2 10’1? 12!~3 Ir. Eli

,lGH-.-

3&

Eiv,I

1 \L-2

E

s=

43

21_r

%c;

0

,-:=

J.4

T RELAY--

-1 F;;;CATED

-

1234

-m5578

__p7zERmj

FUSIBLE LINK@J/B

@

I 81GAI

ELECTROMIC CONTROLSUSPEldSiOi,dCONTRllL Ui'dIT

----- -m12123E>[1:

II

1u2m

II

JUIvPERBCONNECTOR

LEd1254

m

M

,p 10___. _

lt f“u 1

0, iLL

1-L. ET- JN

i;4 m'llm

i I

ECSSWITCr;

pg&-jqq-.

E

t2

12’

II334

%

-

rk

8

62-------____

-

q

ET

12---c.

n

G

3-

I

.---._-__60

1------.--

Q2A

10-

SELF-DIAGNOSISCXECK COKNECTOR

X35-AX-Bi?Gl-E,TSB Revision

Page 723 of 1146

L,

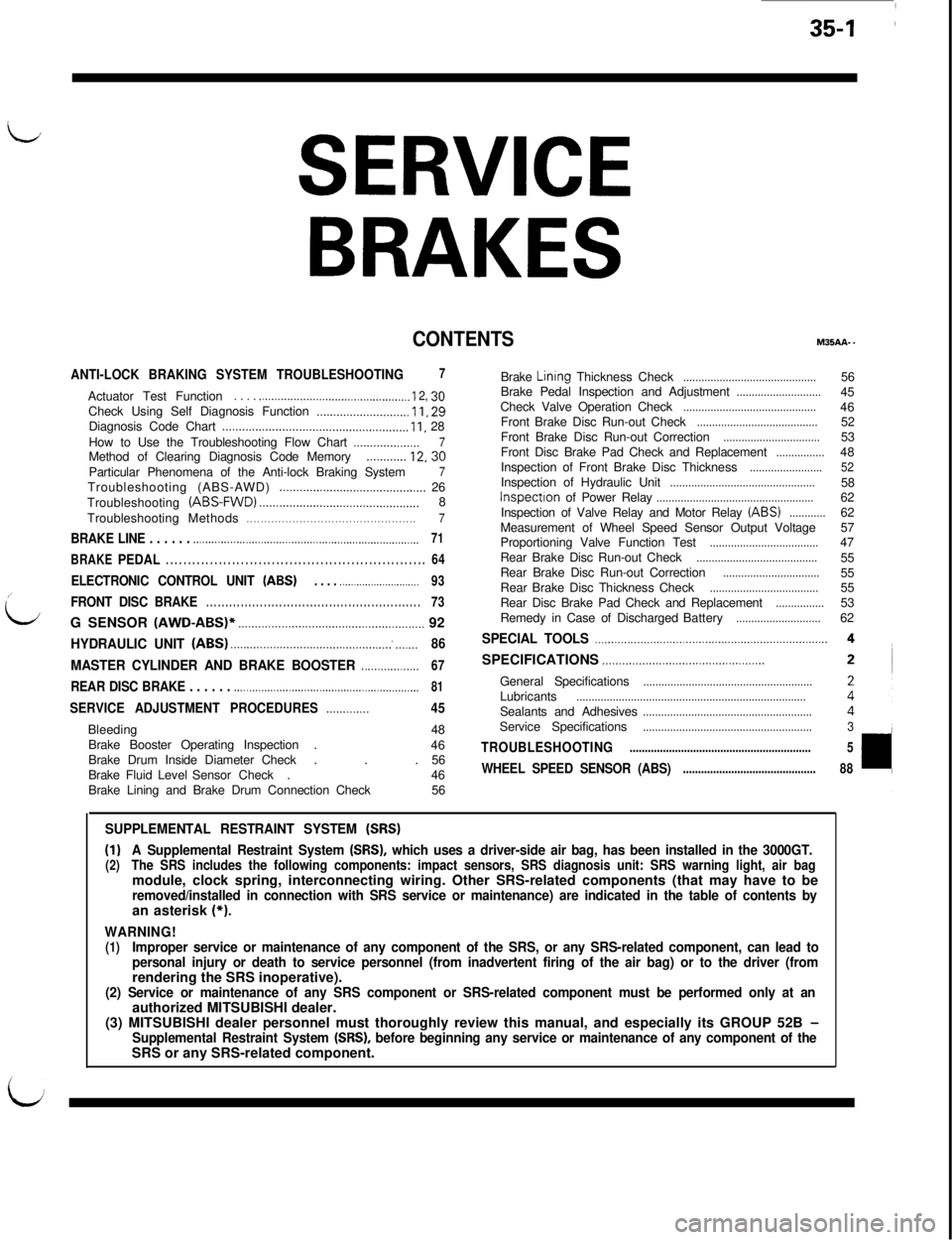

SERVICE

BRAKES

CONTENTSM35AA..

ANTI-LOCK BRAKING SYSTEM TROUBLESHOOTING7Actuator Test Function

. . . . ..___..._____.__................................ I 2, 36Check Using Self Diagnosis Function __._.....,_._.._____........ 11, 28

Diagnosis Code Chart ..,,........,......_..................................,. 1 I, 28

How to Use the Troubleshooting Flow Chart

_____.___......._._.7Method of Clearing Diagnosis Code Memory._.,._...... 12, 30

Particular Phenomena of the Anti-lock Braking System

7Troubleshooting (ABS-AWD) ._______._.._...........................,... 26

Troubleshooting (ABS-FWD) ______.._._........_...........,.....,.....,....8

TroubleshootingMethods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

BRAKE LINE . . . . . . .._.......................................................................71

BRAKEPEDAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

ELECTRONIC CONTROL UNIT (ABS). . . . .._._..___..__._............93/

L

FRONT DISC BRAKE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73G SENSOR (AWD-ABS)’

____.____.___.__._._.................,,......,.....,.... 92

HYDRAULIC UNIT (ABS) .___.._._._._.______.............,...,,..........~ .,_____86

MASTER CYLINDER AND BRAKE BOOSTER ..__.._____.._____67SPECIFICATIONS ._....._.___.....................................

REAR DISC BRAKE . . . . . . .._..._._.___................................................81

SERVICE ADJUSTMENT PROCEDURES..___........45Bleeding48

Brake Booster Operating Inspection.

46

Brake Drum Inside Diameter Check. . .56

BrakeFluidLevelSensor Check.46

Brake Lining and Brake Drum Connection Check56Brake

Linrng Thickness Check............................................Brake Pedal Inspection and Adjustment............................Check Valve Operation Check............................................Front Brake Disc Run-out Check........................................Front Brake Disc Run-out Correction................................Front Disc Brake Pad Check and Replacement................Inspection of Front Brake Disc Thickness........................Inspection of Hydraulic Unit................................................Inspectton of Power Relay....................................................Inspection of Valve Relay and Motor Relay (ABS)............Measurement of Wheel Speed Sensor Output Voltage

Proportioning Valve Function Test

....................................Rear Brake Disc Run-out Check........................................Rear Brake Disc Run-out Correction................................Rear Brake Disc Thickness Check....................................Rear Disc Brake Pad Check and Replacement................Remedy in Case of DischargedBattery............................56

45

46

52

53

48

5258

62

62

57

47

55

55

55

53

62

SPECIAL TOOLS ..__.......___..........................................................General Specifications

........................................................Lubricants............................................................................Sealants and Adhesives........................................................Service Specifications........................................................3

TROUBLESHOOTING............................................................5

WHEEL SPEED SENSOR (ABS)............................................88

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

i

Page 730 of 1146

35-8SERVICE BRAKES -Anti-lock Braking System Troubleshooting

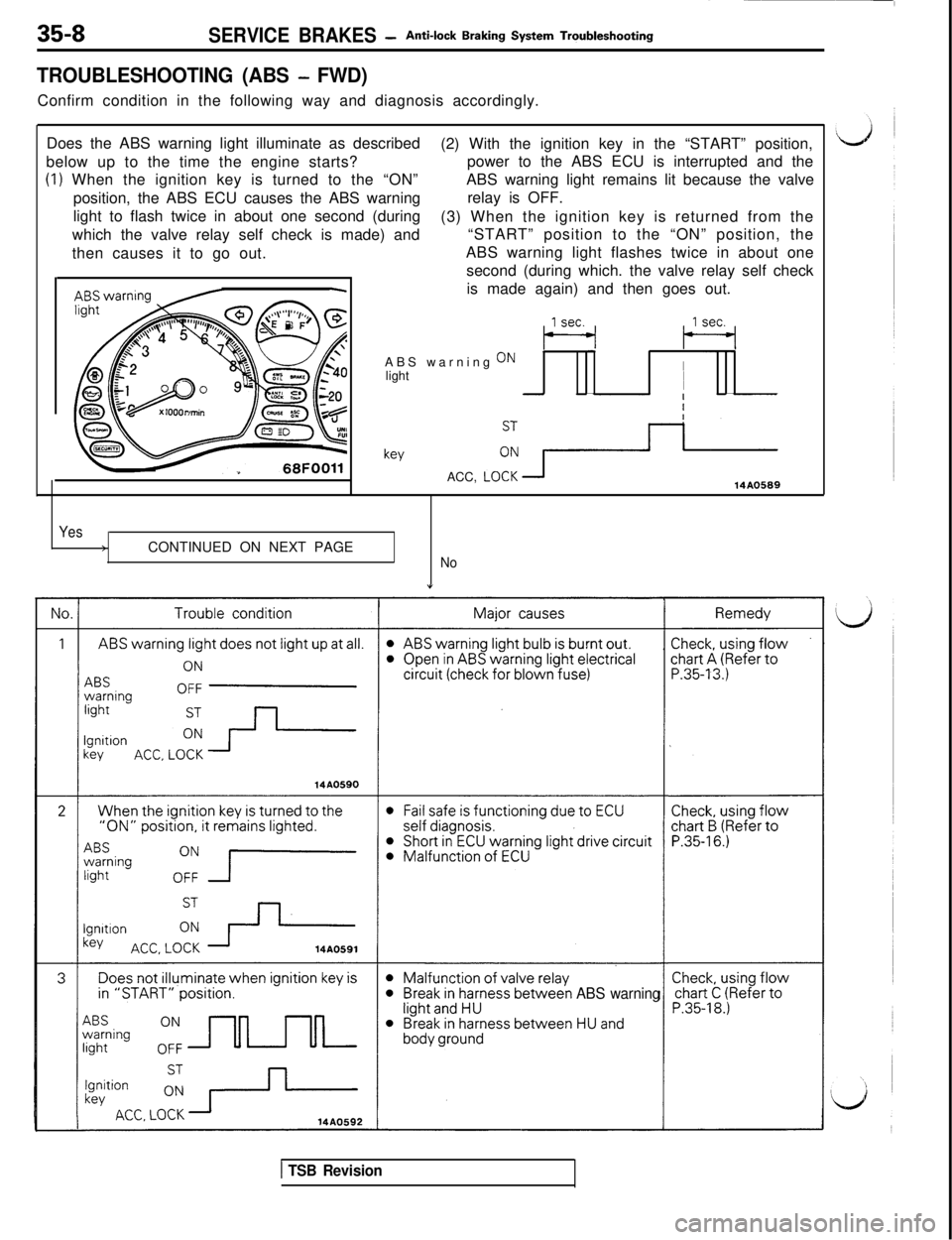

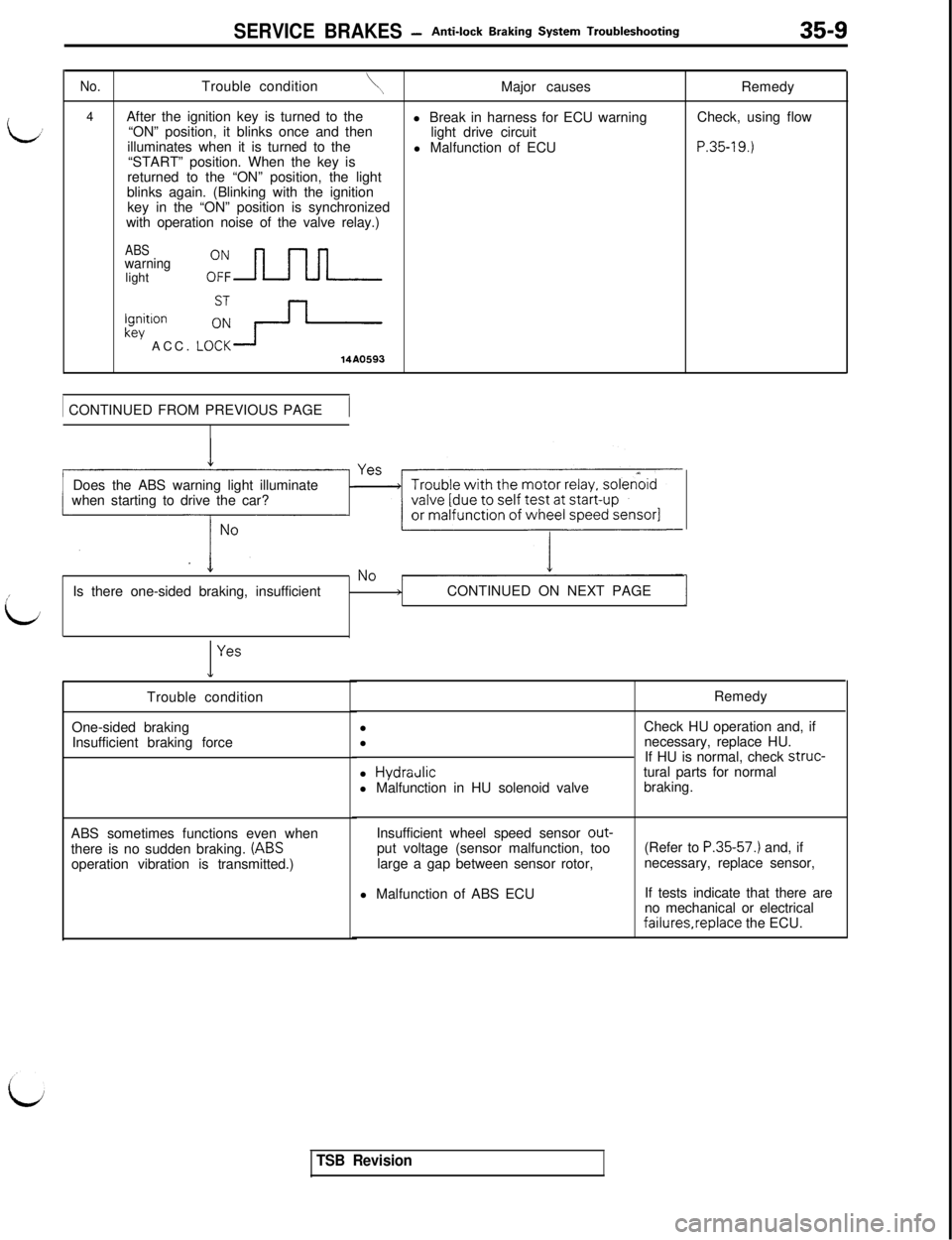

TROUBLESHOOTING (ABS - FWD)Confirm condition in the following way and diagnosis accordingly.

Does the ABS warning light illuminate as described

(2) With the ignition key in the “START” position,

below up to the time the engine starts?power to the ABS ECU is interrupted and the

(1) When the ignition key is turned to the “ON”ABS warning light remains lit because the valve

position, the ABS ECU causes the ABS warningrelay is OFF.

light to flash twice in about one second (during

(3) When the ignition key is returned from the

which the valve relay self check is made) and“START” position to the “ON” position, the

then causes it to go out.ABS warning light flashes twice in about one

second (during which. the valve relay self check

-is made again) and then goes out.

ABS warning

ONlightII

-I

keyACC,

LO!: +--14A0589

Yes>CONTINUED ON NEXT PAGE

No

”

weenABS warning

1 TSB Revision

Page 731 of 1146

SERVICE BRAKES -Anti-lock Braking System Troubleshooting

L’

No.Trouble condition\4

After the ignition key is turned to the

“ON” position, it blinks once and then

illuminates when it is turned to the

“START” position. When the key is

returned to the “ON” position, the light

blinks again. (Blinking with the ignition

key in the “ON” position is synchronized

with operation noise of the valve relay.)

ABSwarninglight

key ACC. L::+

Ignition

14A05931 CONTINUED FROM PREVIOUS PAGE

1Major causes

l Break in harness for ECU warning

light drive circuit

l Malfunction of ECU

Does the ABS warning light illuminate

when starting to drive the car?

iIs there one-sided braking, insufficient

>CONTINUED ON NEXT PAGEI

I

YesTrouble condition

One-sided braking

Insufficient braking force

ABS sometimes functions even when

there is no sudden braking.

(ABSoperation vibration is transmitted.)Remedy

Check, using flow

P.35-19.)Remedy

l Check HU operation and, if

l necessary, replace HU.

If HU is normal, check struc-

l

HydraJicl Malfunction in HU solenoid valvetural parts for normal

braking.

Insufficient wheel speed sensor put voltage (sensor malfunction, too

large a gap between sensor rotor,

l Malfunction of ABS ECU(Refer to

P.35-57.) and, if

necessary, replace sensor,

If tests indicate that there are

no mechanical or electricalfaiIures,replace the ECU.

TSB Revision

Page 733 of 1146

SERVICE BRAKES -Anti-lock Braking System Troubleshooting

35-11

Adapter

iarness%f&(MB9913771(Mi3991341)\12FOO57

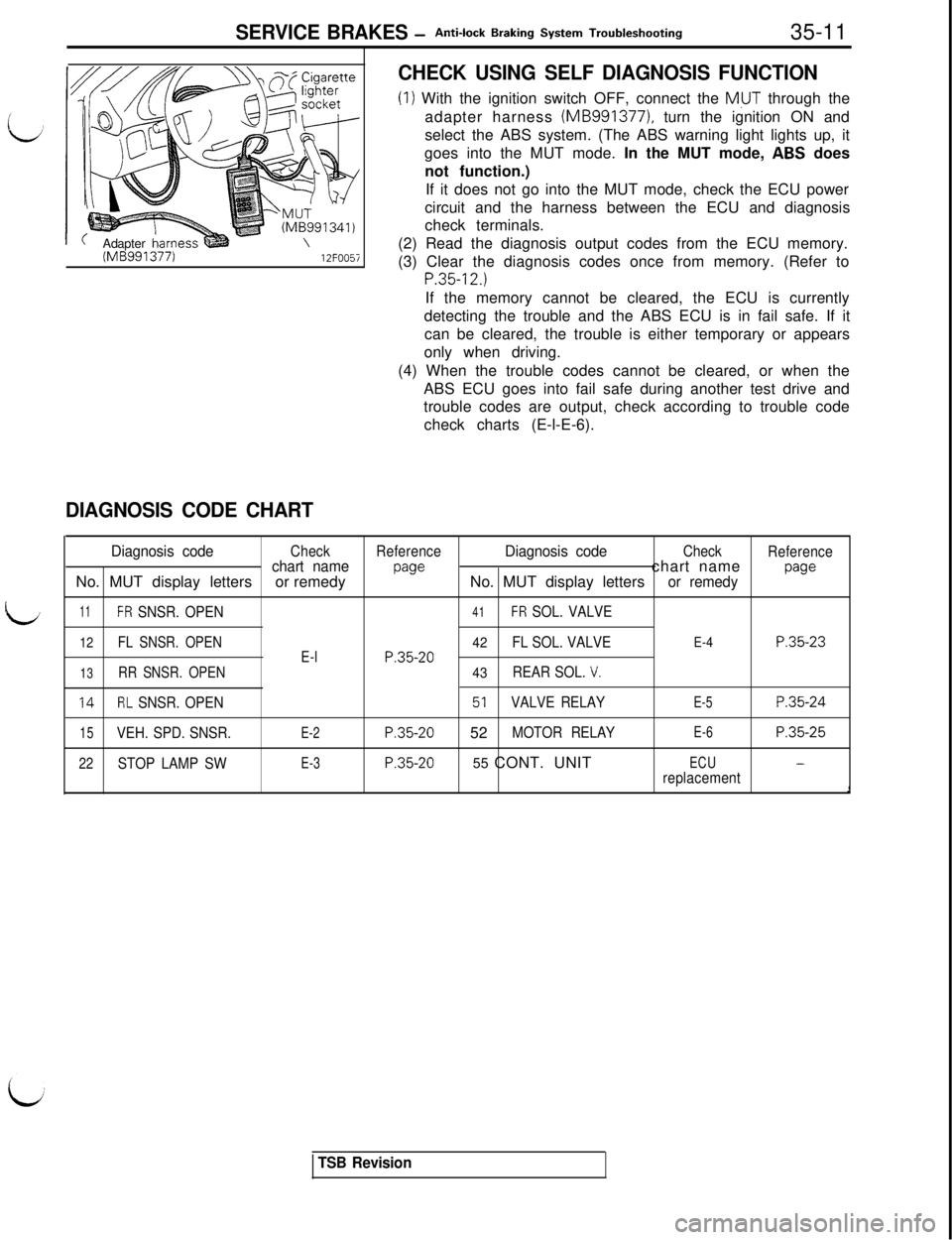

CHECK USING SELF DIAGNOSIS FUNCTION

(1) With the ignition switch OFF, connect the MUT through the

adapter harness

(MB9913771, turn the ignition ON and

select the ABS system. (The ABS warning light lights up, it

goes into the MUT mode. In the MUT mode, ABS does

not function.)

If it does not go into the MUT mode, check the ECU power

circuit and the harness between the ECU and diagnosis

check terminals.

(2) Read the diagnosis output codes from the ECU memory.

(3) Clear the diagnosis codes once from memory. (Refer to

P.35-12.)If the memory cannot be cleared, the ECU is currently

detecting the trouble and the ABS ECU is in fail safe. If it

can be cleared, the trouble is either temporary or appears

only when driving.

(4) When the trouble codes cannot be cleared, or when the

ABS ECU goes into fail safe during another test drive and

trouble codes are output, check according to trouble code

check charts (E-l-E-6).

DIAGNOSIS CODE CHART

Diagnosis codeCheckReferenceDiagnosis codeCheck

Referencechart namepagechart namepawNo. MUT display lettersor remedyNo. MUT display lettersor remedy

L11FR SNSR. OPEN41FR SOL. VALVE

12FL SNSR. OPEN42FL SOL. VALVEE-4P.35-23E-lP.35-2013RR SNSR. OPEN43REAR SOL. V.

14RL SNSR. OPEN51VALVE RELAYE-5P.35-24

15VEH. SPD. SNSR.E-2P.35-20 52MOTOR RELAYE-6P.35-25

22STOP LAMP SWE-3P.35-2055 CONT. UNITECU-

replacementI

TSB Revision

Page 735 of 1146

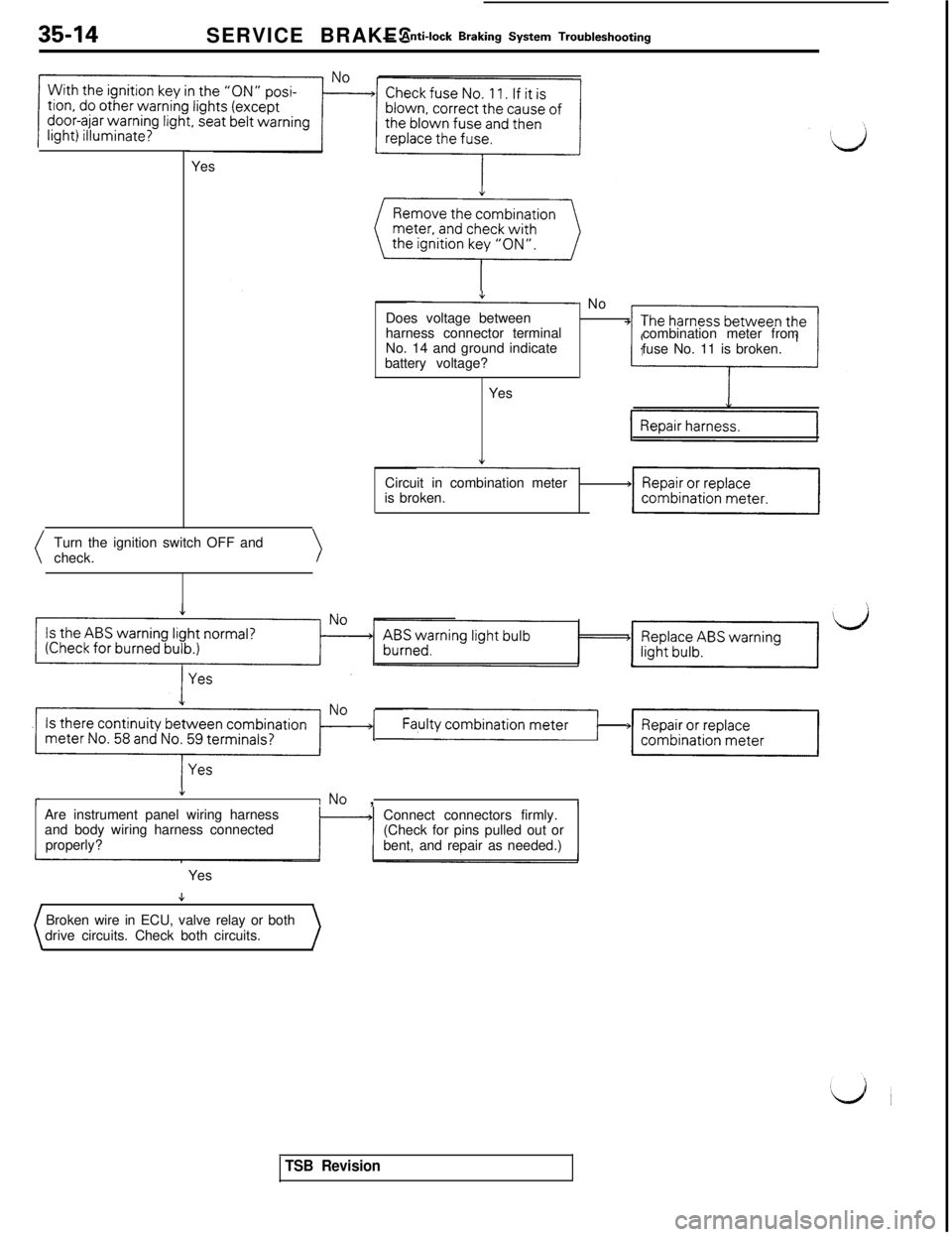

![MITSUBISHI 3000GT 1991 Repair Manual .SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-13 A ABS warning light does not light at all.

iJ[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lig MITSUBISHI 3000GT 1991 Repair Manual .SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-13 A ABS warning light does not light at all.

iJ[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lig](/img/19/57085/w960_57085-734.png)

.SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-13 'A ABS warning light does not light at all.

iJ[Explanation][Hint]

When it does not light up at all, there is a strongIf other warning lights do not light up either, fuse is

possibility that there is trouble with ABS warningprobably blown.

light or with power to the light.

id

r

f%ER RELAY

110

* ::h=g

6

::5

d

.-2=

?Et0

~

2____--..-

?EI

5fir 4

I

4 -

IGNITIONSWITCH(IG2)m!--

mj:

JSIBLE LINK0tiB

2

L__---------___

0

Lp1%

%2

j:(L-R)dg

6-k

&h+&"..L"Ei SOLENOID1:

G-R

G-R

^ -tl- - D

HH H?bb

IN:IGl)-

59

1

ki@iNATION

iB

ABS-ECU

Kxss-AK-RSGOIA

1 TSB RevisionI

Page 736 of 1146

SERVICE BRAKES- Anti-lock Braking System Troubleshooting

Yes

Turn the ignition switch OFF and

check.

4- No

Does voltage between

harness connector terminal

No. 14 and ground indicate

battery voltage?combination meter from

fuse No. 11 is broken.

Yes

ylCircuit in combination meter

is broken.

Is there continuity between combination

meter No. 58 and No 59 terminals7

.rT/“I./ Faulty1 +I[&

r,No ,IAre instrument panel wiring harness

and body wiring harness connected

properly?Connect connectors firmly.

(Check for pins pulled out or

bent, and repair as needed.)

Yes

Broken wire in ECU, valve relay or both

drive circuits. Check both circuits.

TSB Revision

Page 737 of 1146

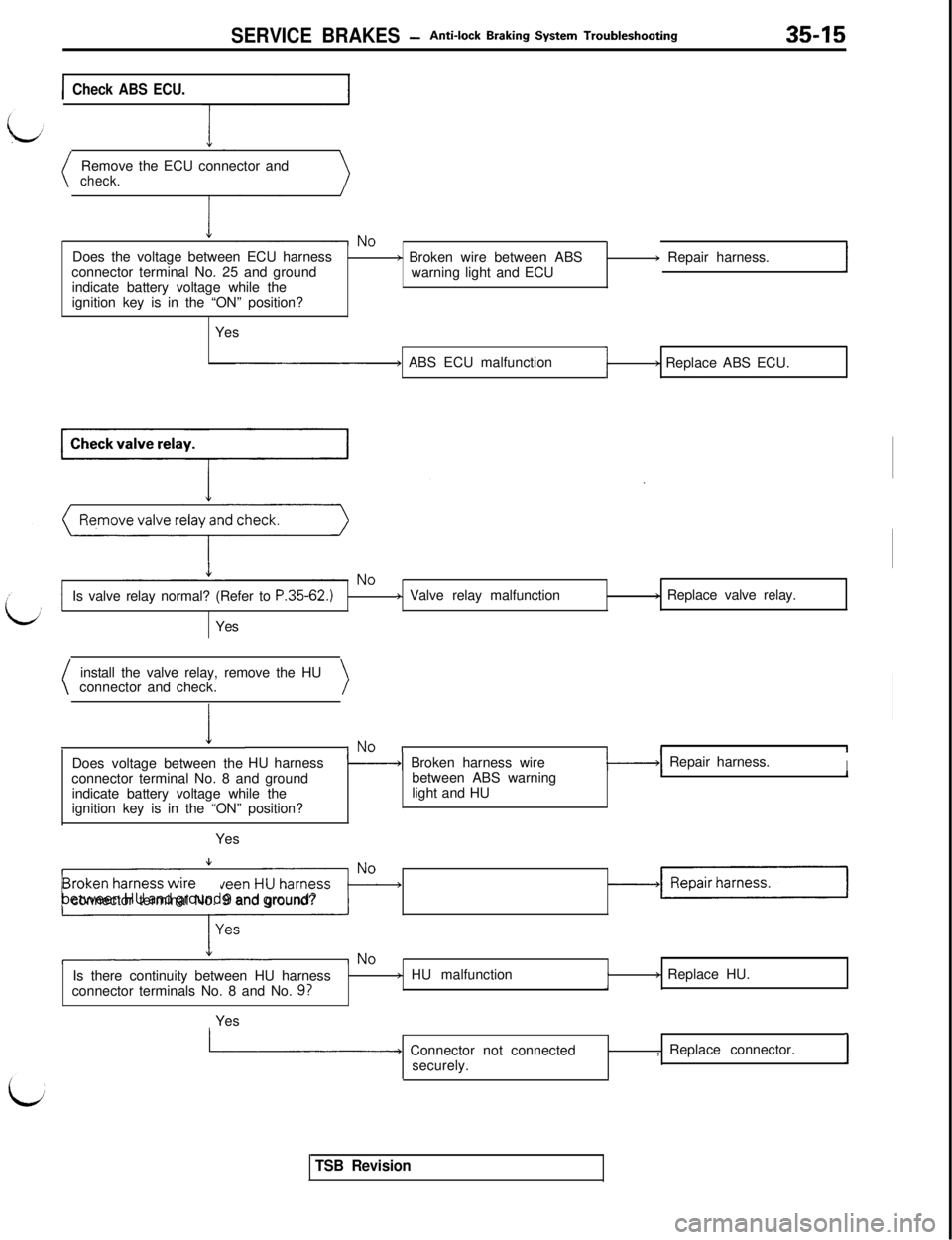

SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-15

ICheck ABS ECU.Remove the ECU connector and

check.Does the voltage between ECU harness

connector terminal No. 25 and ground

indicate battery voltage while the

ignition key is in the “ON” position?

Yes

b Broken wire between ABS

warning light and ECU) Repair harness.

I ABS ECU malfunctionI) Replace ABS ECU.

Is valve relay normal? (Refer to

P.35-62.)Yes+ Valve relay malfunctionb Replace valve relay.

install the valve relay, remove the HU

connector and check.

IDoes voltage between theINO IHU harness\----+I Broken harness wireII1-1 Repair harness.I

Iconnector terminal No. 8 and ground

indicate battery voltage while the

ignition key is in the “ON” position?between ABS warning

light and HU1IYes

Is there continuity between HU harness

4:~~&?$?%$&ndconnector terminal No. 9 and ground?

Is there continuity between HU harness

connector terminals No. 8 and No.

9?

j HU malfunctionI> Replace HU.

Yes

L Connector not connected

securely., Replace connector.I

TSB Revision

Page 739 of 1146

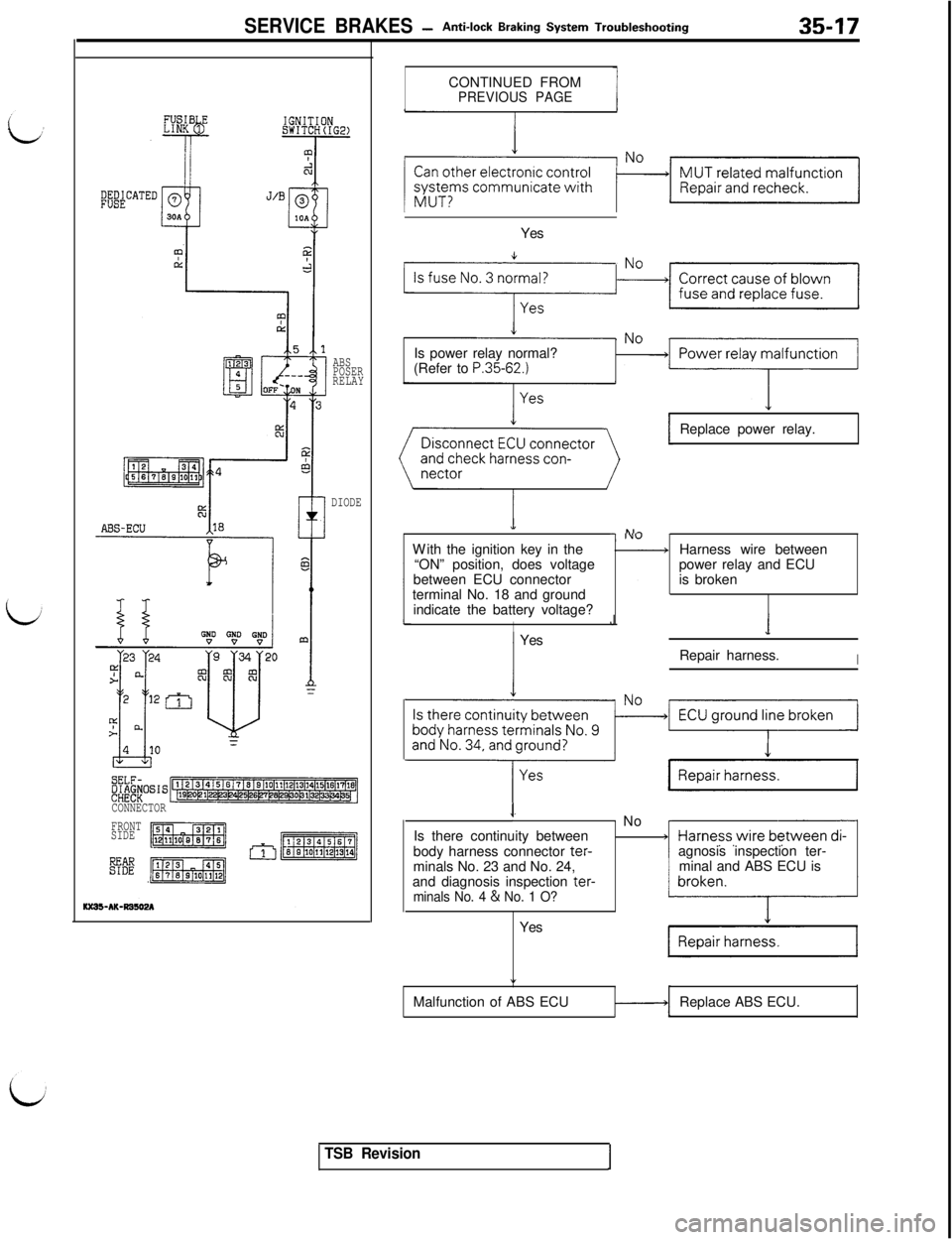

SERVICE BRAKES -Anti-lock Braking System Troubleshooting3547CONTINUED FROM

PREVIOUS PAGE

ABS

POSER

RELAY

DIODE

SELF-LM&OS'S

CONNECTOR

FRONT

SIDEYes

Is power relay normal?

(Refer to

P.35-62.)

-Replace power relay.

With the ignition key in the

“ON” position, does voltage

between ECU connector

terminal No. 18 and ground

indicate the battery voltage?

I

1YesNo

-

I--Harness wire between

power relay and ECU

is brokenJ1Repair harness.

I

~ No

Is there continuity betweenrbody harness connector ter-agnosis inspection ter-

minals No. 23 and No. 24,minal and ABS ECU is

and diagnosis inspection ter-

minals No. 4 & No. 1 O?Yes

”Malfunction of ABS ECUReplace ABS ECU.

TSB Revision