relay MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 156 of 1146

13-50FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

OPERATIONControl Relay Operation

l Drives the fuel pump during cranking and engine operation.

l

When the ignition switch is set to START, current flows from the ignition switch through the control relay

coil to ground. This turns on the control relay switch and drive power is supplied from the battery throughthe control relay switch to the fuel pump.

lWhile the engine is running, the engine control unit keeps the power transistor on and energizes the

control relay coil so that drive power is supplied to the fuel pump.

Fuel Pump Relay No. 2 Operation

lChange the fuel pump discharge in two stages by ON-OFF operation of the relay switch for fuel pumprelay No. 2.

lIf the amount of inlet air is small (the engine load is low), the engine control unit turns on the power

transistor to energize the coil of fuel pump relay No. 2, sending drive power to the fuel pump through the

resistor. If the amount of inlet air is large (the engine load is high), the engine control unit turns off thepower transistor to send drive power directly to the fuel pump without passing through the resistor.

INSPECTIONUsing Multi-use Tester

Function

ActuatortestItem No.

Operation

Check conditionCheck itemNormal condition

07Fuel pump isdriven to cir-l Engine crankingHold return hose withl Forced drive of fuelPulsation is felt

culate fuelfingers to feel pulsationpump

Check is made for aboveindicating fuel flow

two conditionsListen to pump operating

sound near fuel tankOperating sound isheard

I/IIII

cFunctionItem No.Operation

Check conditionNormal condition

Actuatortest

13Turn the fuel pump relayNo. 2 from OFF to ONIgnition switch: ONOperating soundis heard.

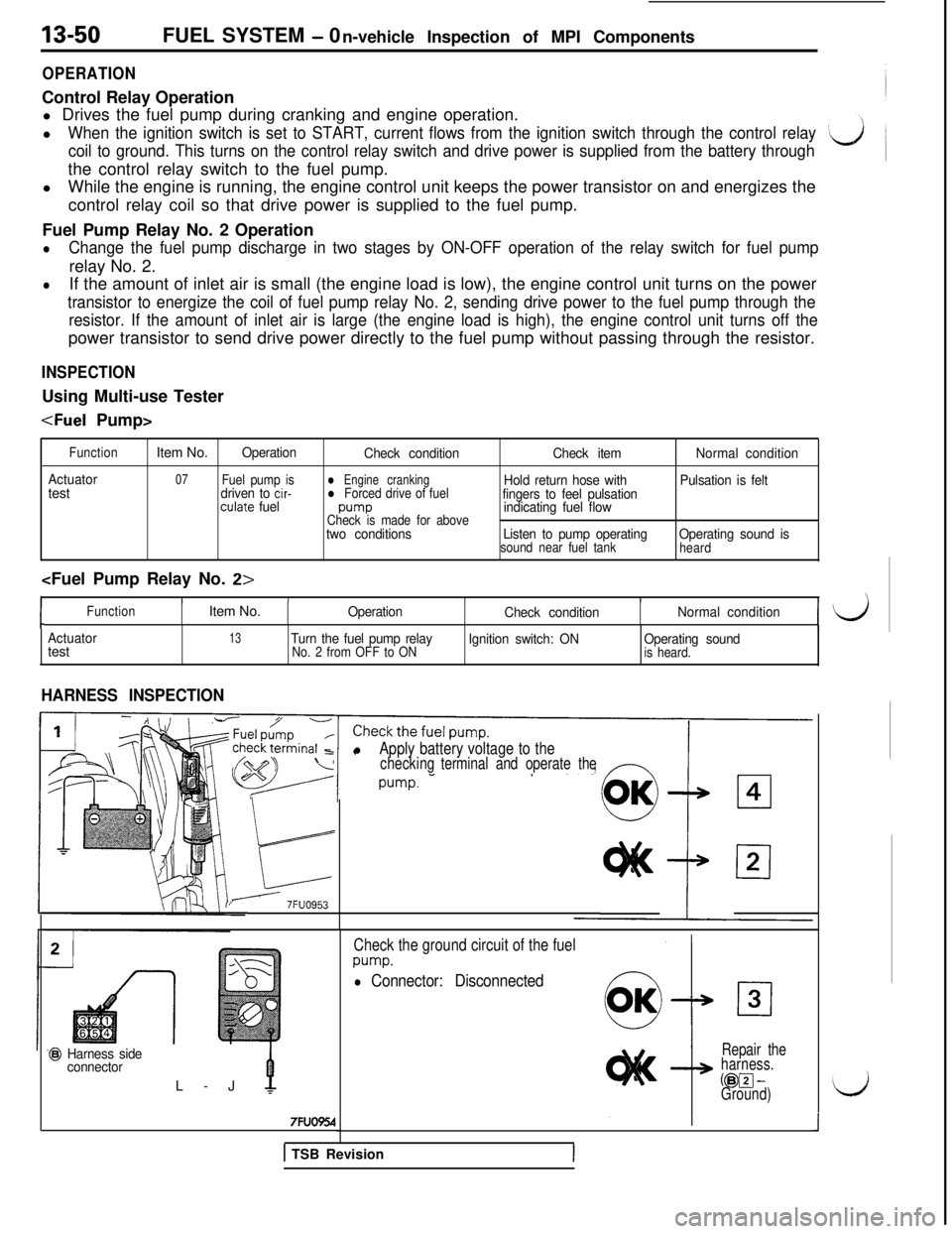

HARNESS INSPECTION

k

J------ 7FUO953

lApply battery voltage to thecheckingterminal and operate the

Check the ground circuit of the fuel

pump.

l Connector: Disconnected

@I Harness side

connectorL-J

7FUO554

Repair the

harness.

@pJ-Ground)

J

1 TSB Revision

Page 157 of 1146

FUEL SYSTEM- On-vehicle Inspection of MPI Components13-51

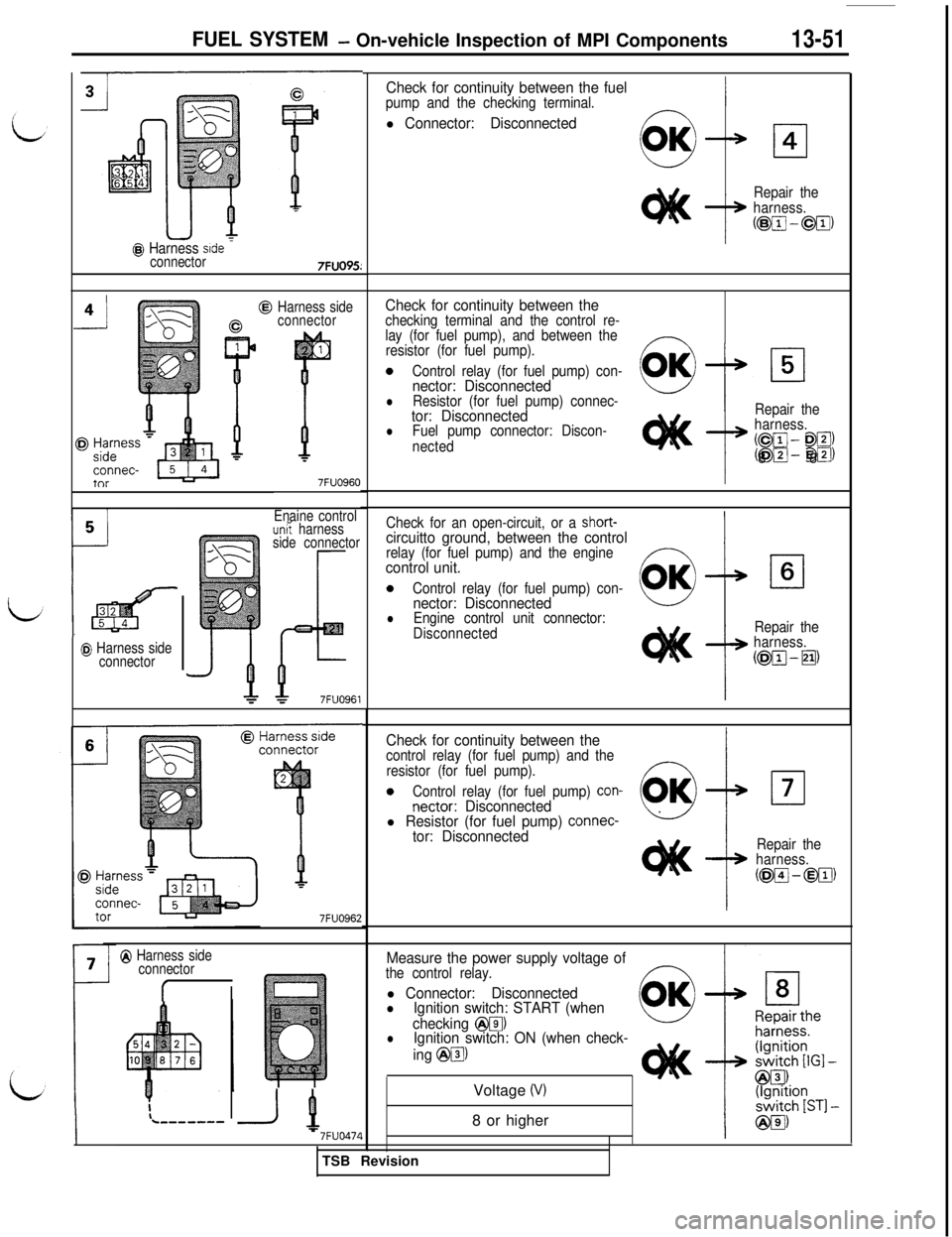

Check for continuity between the fuelpump and the checking terminal.-I

l Connector: Disconnected

@N+ 14

Repair the

harness.

(@lig-@g)

@ Harness srdeconnector7FUO95:

Check for continuity between thechecking terminal and the control re-

lay (for fuel pump), and between the

resistor (for fuel pump).

0Control relay (for fuel pump) con-nector: DisconnectedlResistor (for fuel pump) connec-tor: DisconnectedlFuel pump connector: Discon-

nected

Harness side

connector

7FUO960

0

OK

Repair the

harness.

(Cm- Da)!~m-- E@J)8 8

Enaine controlCheck for an open-circuit, or a short-circuitto ground, between the controlrelay (for fuel pump) and the enginecontrol unit.

0Control relay (for fuel pump) con-nector: Disconnected

un? harness

side connector

lEngine control unit connector:

DisconnectedRepair the

harness.

(@J-m@ Harness side

connector

Check for continuity between thecontrol relay (for fuel pump) and the

resistor (for fuel pump).

0Control relay (for fuel pump) con-nectar: Disconnectedl Resistor (for fuel pump) connec-tor: DisconnectedRepair the

harness.

(@pJ-@iJ)

7FUO962

Measure the power supply voltage ofthe control relay.

@I Harness side

connector

rl Connector: DisconnectedlIgnition switch: START (when

checking

@@IlIgnition switch: ON (when check-

ing

@@IVoltage

(VI8 or higher

1 ‘7FUO47fITSB Revision

Page 158 of 1146

13-52FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

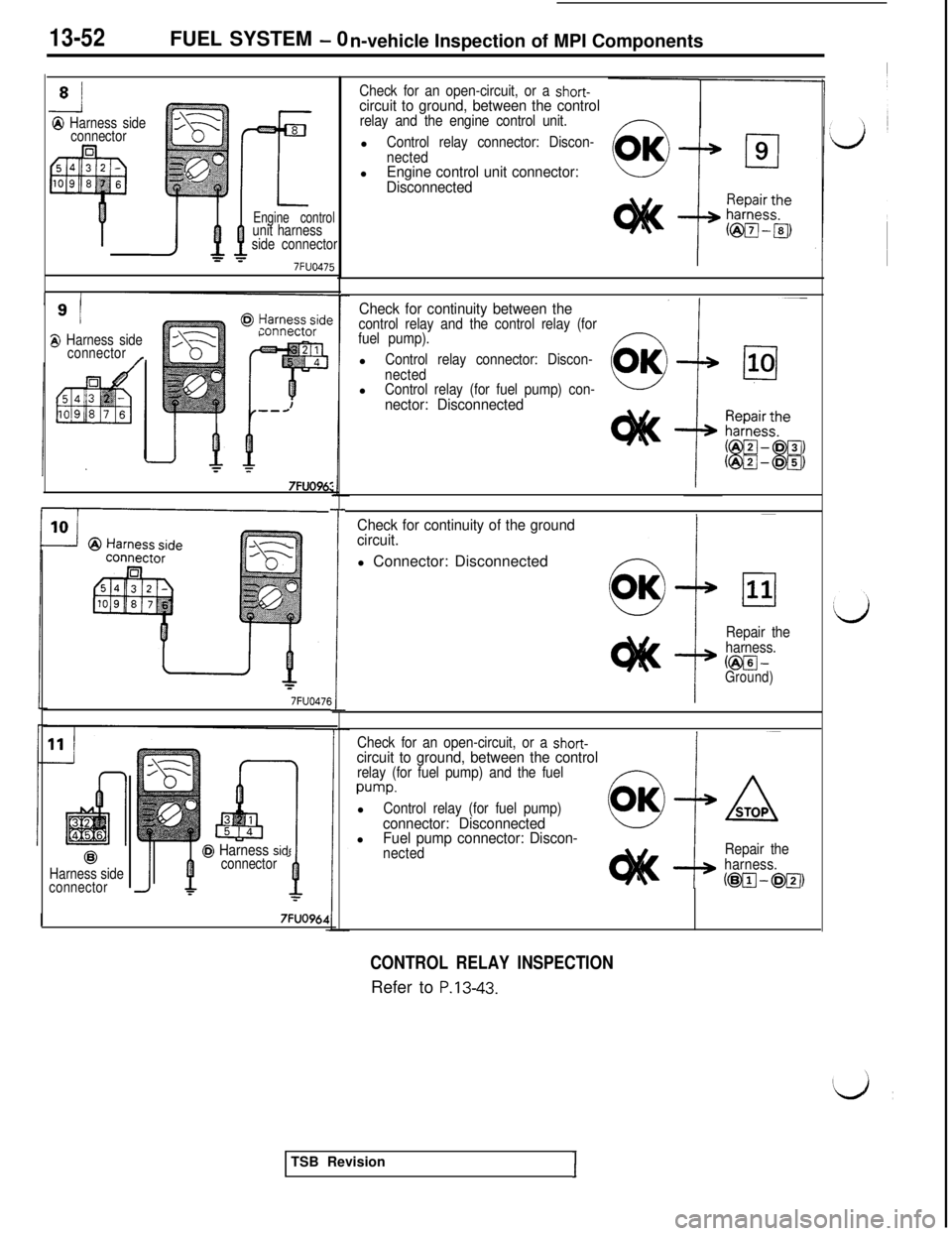

-i8

@ Harness side

connector

Check for an open-circuit, or a short-circuit to ground, between the controlrelay and the engine control unit.l

Control relay connector: Discon-

nectedl

Engine control unit connector:

Disconnected

Engine controlunit harness

side connector

7FUO475g

/Check for continuity between thecontrol relay and the control relay (for

fuel pump).l

Control relay connector: Discon-

nectedl

Control relay (for fuel pump) con-nector: Disconnected

zonnector8 Harness side

connector

/

7FUO96:

T

Check for continuity of the ground

circuit.l Connector: Disconnected

!

Repair the

harness.

@pJ-Ground)

7FUO476

Check for an open-circuit, or a short-circuit to ground, between the controlrelay (for fuel pump) and the fuel

pump.l

Control relay (for fuel pump)connector: DisconnectedlFuel pump connector: Discon-nectedRepair the

harness.

(@@-@lTJ)

@I Harness sidtconnector@Harness side

connector

I7FUO964

CONTROL RELAY INSPECTIONRefer to

P.13-43.TSB Revision

1

Page 159 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-53

7FU104:

Fuel pump /resistor

///I/ \\/7FU1041

7FU1043

I-TSB I

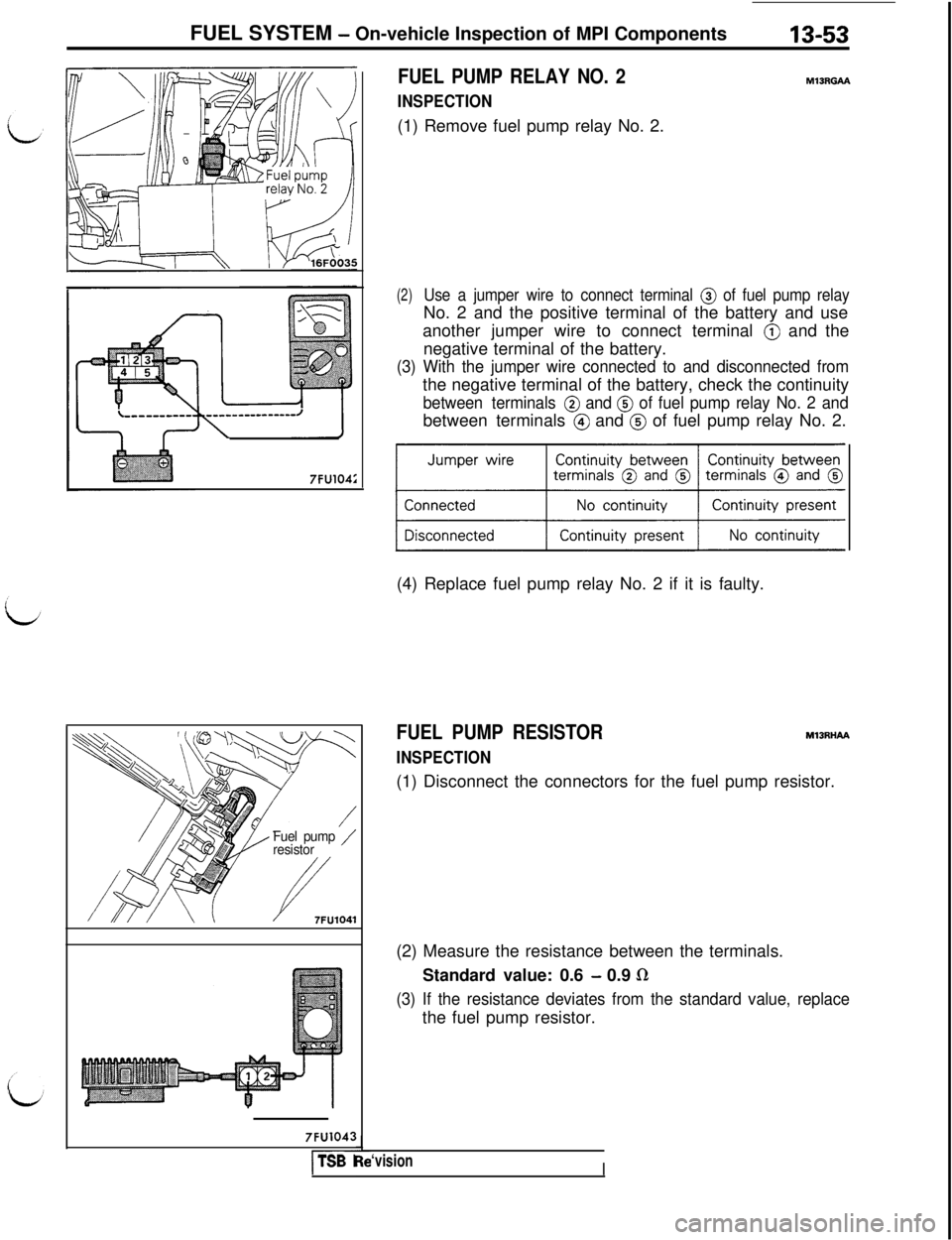

FUEL PUMP RELAY NO. 2

INSPECTION(1) Remove fuel pump relay No. 2.

M13RGAh

(2)Use a jumper wire to connect terminal @ of fuel pump relayNo. 2 and the positive terminal of the battery and use

another jumper wire to connect terminal

@ and the

negative terminal of the battery.

(3) With the jumper wire connected to and disconnected fromthe negative terminal of the battery, check the continuity

between terminals @ and @ of fuel pump relay No. 2 andbetween terminals

@ and @ of fuel pump relay No. 2.

(4) Replace fuel pump relay No. 2 if it is faulty.

FUEL PUMP RESISTOR

INSPECTION

MlBRHAA(1) Disconnect the connectors for the fuel pump resistor.

(2) Measure the resistance between the terminals.

Standard value: 0.6

- 0.9 LR

(3) If the resistance deviates from the standard value, replacethe fuel pump resistor.

‘visionI

Page 160 of 1146

FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

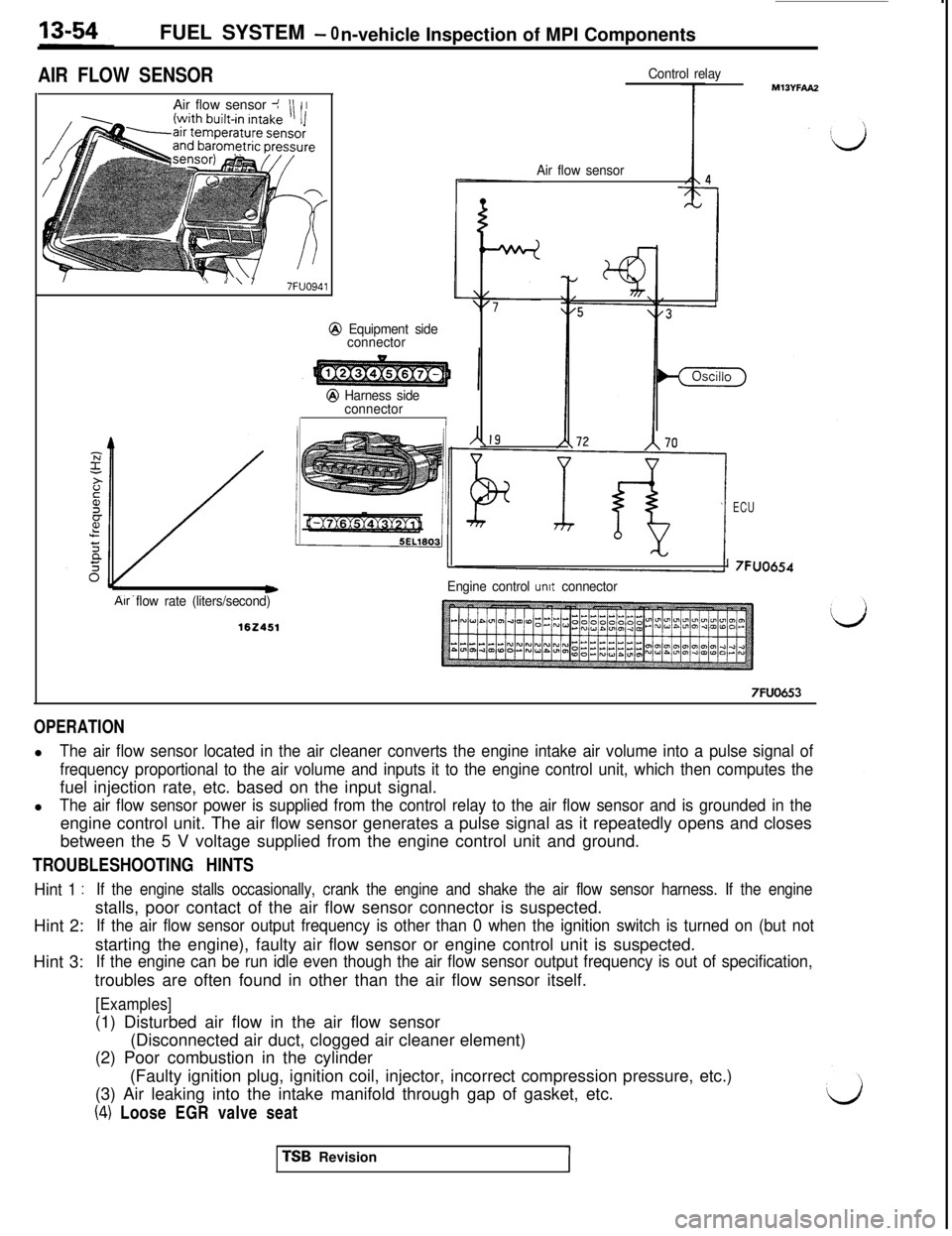

AIR FLOW SENSORAir flow sensor J

III I

\I\Y7FUO941

@ Equipment side

connector

Air flow rate (liters/second)

@ Harness side

connector

I

Control relay

I

Air flow sensor

ECU

’ 7FUO654

Engine control

unit connector

7FUO653

OPERATIONl

The air flow sensor located in the air cleaner converts the engine intake air volume into a pulse signal of

frequency proportional to the air volume and inputs it to the engine control unit, which then computes thefuel injection rate, etc. based on the input signal.

l

The air flow sensor power is supplied from the control relay to the air flow sensor and is grounded in theengine control unit. The air flow sensor generates a pulse signal as it repeatedly opens and closes

between the 5 V voltage supplied from the engine control unit and ground.

TROUBLESHOOTING HINTS

Hint 1 :If the engine stalls occasionally, crank the engine and shake the air flow sensor harness. If the engineHint 2:stalls, poor contact of the air flow sensor connector is suspected.

If the air flow sensor output frequency is other than 0 when the ignition switch is turned on (but notHint 3:starting the engine), faulty air flow sensor or engine control unit is suspected.

If the engine can be run idle even though the air flow sensor output frequency is out of specification,troubles are often found in other than the air flow sensor itself.

[Examples](1) Disturbed air flow in the air flow sensor

(Disconnected air duct, clogged air cleaner element)

(2) Poor combustion in the cylinder

(Faulty ignition plug, ignition coil, injector, incorrect compression pressure, etc.)

(3) Air leaking into the intake manifold through gap of gasket, etc.

(4) Loose EGR valve seatTSB Revision

Page 162 of 1146

13-56FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

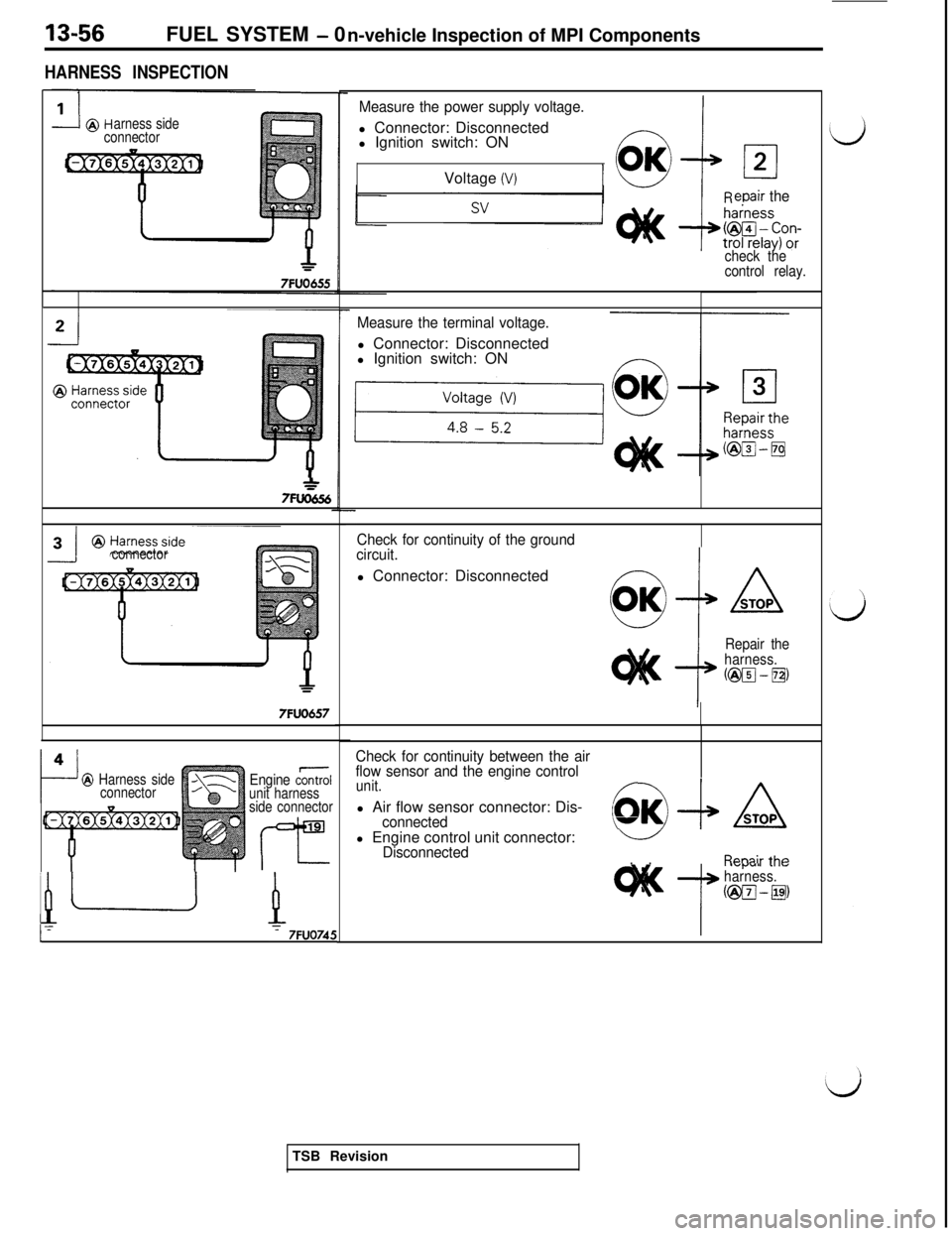

HARNESS INSPECTION

--barness side

connector

*7FUO656

connector

7FUO6574

?

@ Harness sideEngine c&lconnector

unit harness

side connector

I -

1

m

!h 4.7Fuo745u

Measure the power supply voltage.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)

eoair the

check the

control relay.

Measure the terminal voltage.l Connector: Disconnected

l Ignition switch: ON

Check for continuity of the ground

circuit.l Connector: Disconnected

Repair the

harness.

@El - I@)

Check for continuity between the air

flow sensor and the engine control

unit.l Air flow sensor connector: Dis-f

connected10l Engine control unit connector:

‘L-/Disconnected. .Rr.annir th(

t

I ‘“yu’3harness.

TSB Revision

Page 176 of 1146

FUEL SYSTEM - 0n-vehicleInspection of MPI Components

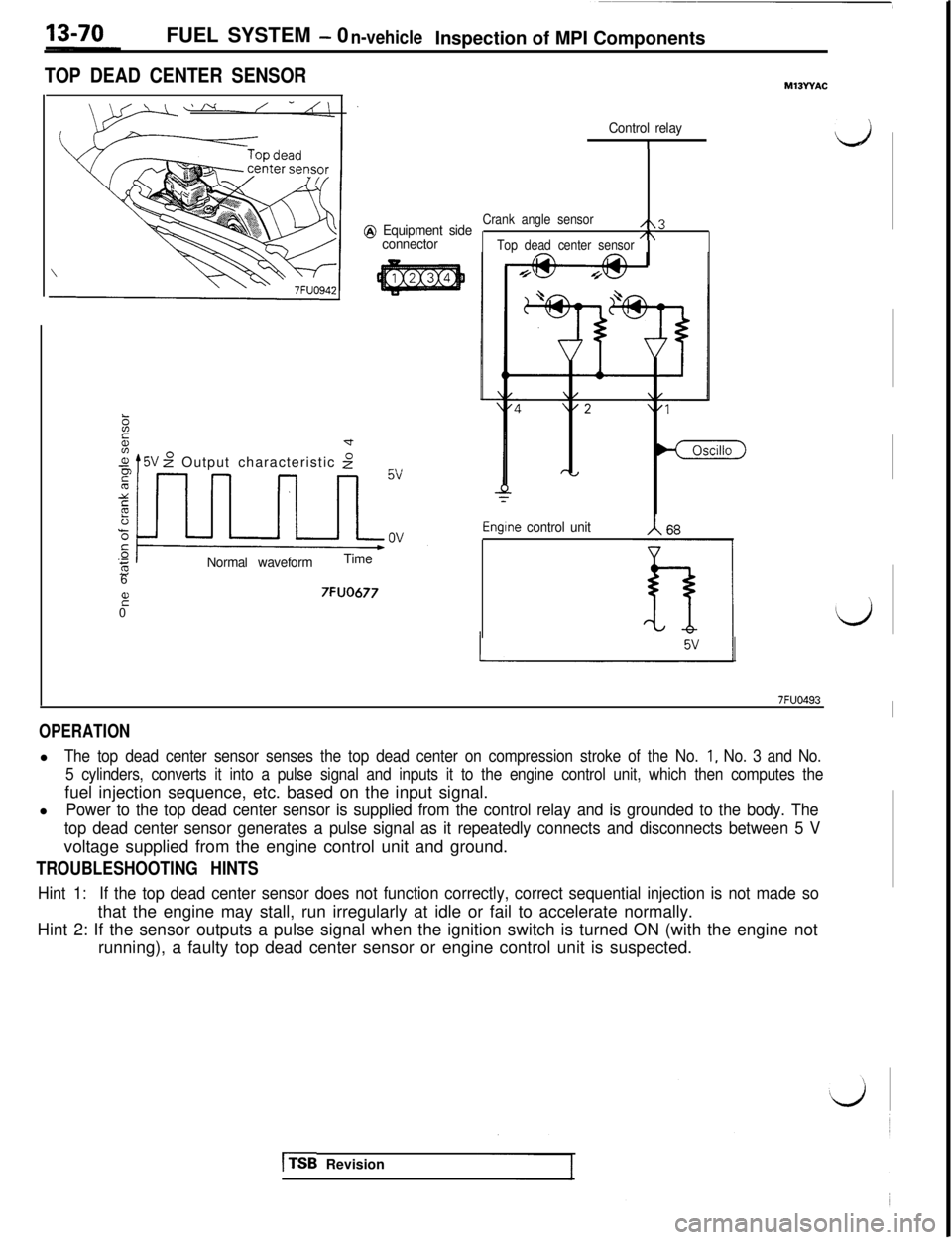

TOP DEAD CENTER SENSOR

Control relay

1d

@ Equipment side

connector

zd

.+$ t5V z” Output characteristic 2r~,

Normal waveformTime6

it07FUO677

Crank angle sensor/\3

Top dead center sensor/\

Engtne control unit

d

7FUO493I

OPERATIONl

The top dead center sensor senses the top dead center on compression stroke of the No. 1, No. 3 and No.

5 cylinders, converts it into a pulse signal and inputs it to the engine control unit, which then computes thefuel injection sequence, etc. based on the input signal.

l

Power to the top dead center sensor is supplied from the control relay and is grounded to the body. The

top dead center sensor generates a pulse signal as it repeatedly connects and disconnects between 5 Vvoltage supplied from the engine control unit and ground.

TROUBLESHOOTING HINTS

Hint 1:If the top dead center sensor does not function correctly, correct sequential injection is not made sothat the engine may stall, run irregularly at idle or fail to accelerate normally.

Hint 2: If the sensor outputs a pulse signal when the ignition switch is turned ON (with the engine not

running), a faulty top dead center sensor or engine control unit is suspected.

[TSB Revision

Page 177 of 1146

iFUEL SYSTEM

- On-vehicle Inspection of MPI Components

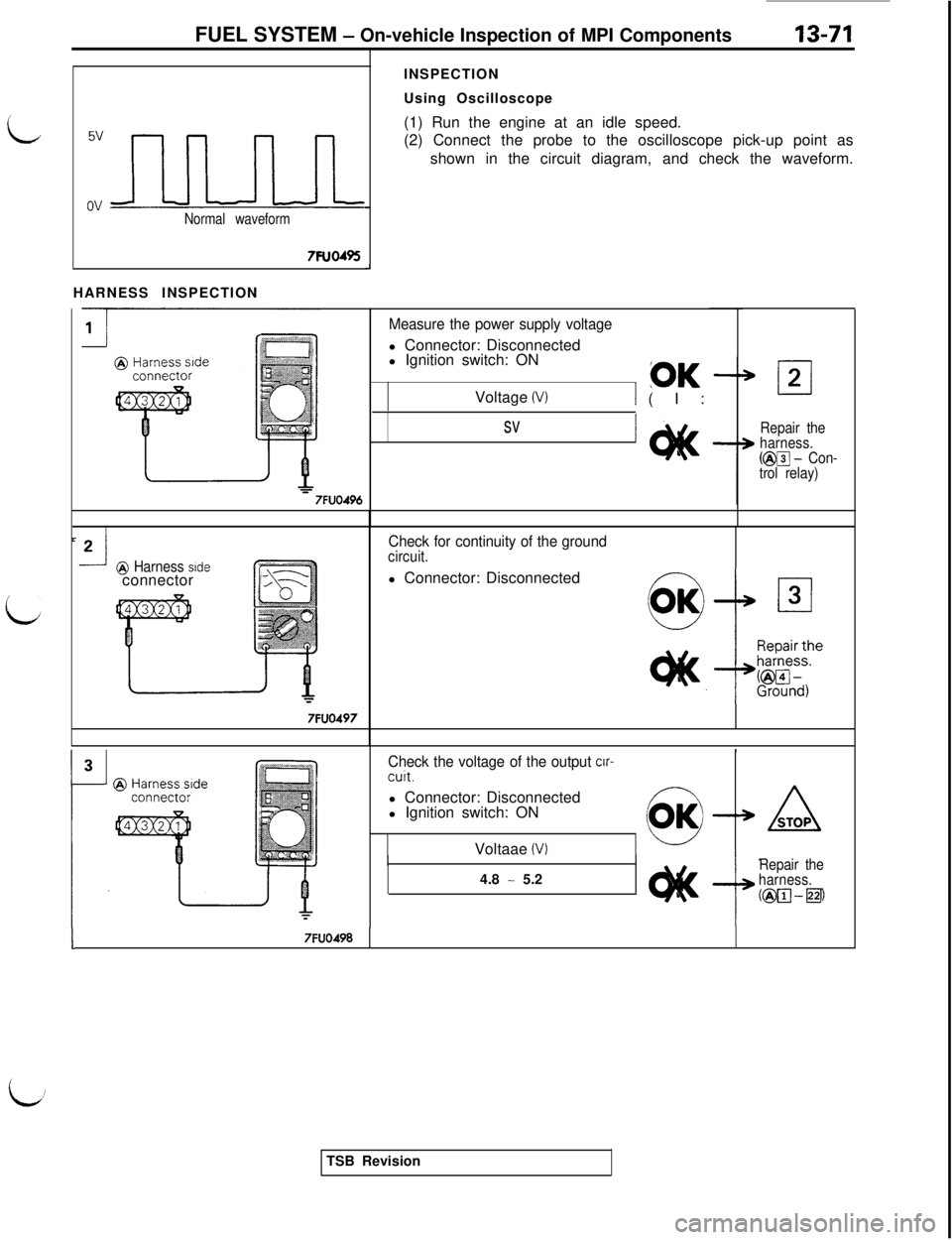

INSPECTION

Using Oscilloscope13-71

::Normal waveform(1) Run the engine at an idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

7Fuo495HARNESS INSPECTION

= 7FUO496r

i2

@ Harness sideconnectorF

7FUO497

J

Measure the power supply voltagel Connector: Disconnected

l Ignition switch: ON

Voltage

(VI, OK(I:

sv

ib

02

Repair the

harness.

(@m - Con-

trol relay)

ICheck for continuity of the groundcircuit.l Connector: Disconnected

3

~,

Check the voltage of the output err-cuit.l Connector: Disconnected

l Ignition switch: ON

Voltaae

(V)4.8

- 5.2Repair the

harness.

(@El-ED

I7FUO498

idliTSB Revision

Page 178 of 1146

13-72FUEL SYSTEM - On-vehicle Inspection of MPI Components

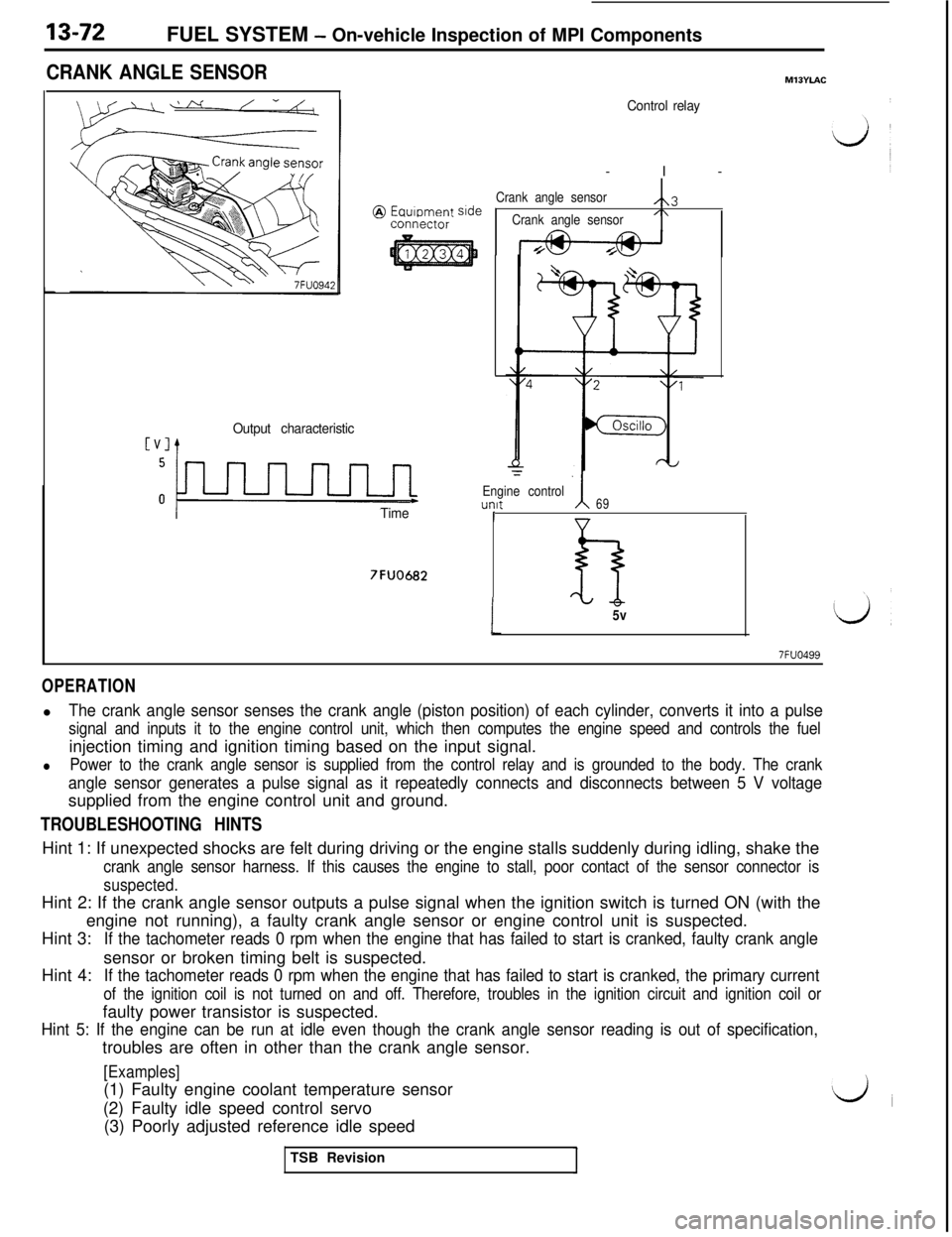

CRANK ANGLE SENSOR

co.ntiector

Output characteristic

LTime

7FUO682

MllYiAC

Control relay-I-

Crank angle sensorsideA3

Crank angle sensor/\

‘=

Engine controlunft69I

1

h5v

7FUO499

OPERATIONl

The crank angle sensor senses the crank angle (piston position) of each cylinder, converts it into a pulse

signal and inputs it to the engine control unit, which then computes the engine speed and controls the fuelinjection timing and ignition timing based on the input signal.

lPower to the crank angle sensor is supplied from the control relay and is grounded to the body. The crank

angle sensor generates a pulse signal as it repeatedly connects and disconnects between 5 V voltagesupplied from the engine control unit and ground.

TROUBLESHOOTING HINTSHint 1: If unexpected shocks are felt during driving or the engine stalls suddenly during idling, shake the

crank angle sensor harness. If this causes the engine to stall, poor contact of the sensor connector is

suspected.Hint 2: If the crank angle sensor outputs a pulse signal when the ignition switch is turned ON (with the

engine not running), a faulty crank angle sensor or engine control unit is suspected.

Hint 3:

If the tachometer reads 0 rpm when the engine that has failed to start is cranked, faulty crank angleHint 4:sensor or broken timing belt is suspected.

If the tachometer reads 0 rpm when the engine that has failed to start is cranked, the primary current

of the ignition coil is not turned on and off. Therefore, troubles in the ignition circuit and ignition coil orfaulty power transistor is suspected.

Hint 5: If the engine can be run at idle even though the crank angle sensor reading is out of specification,troubles are often in other than the crank angle sensor.

[Examples](1) Faulty engine coolant temperature sensor

(2) Faulty idle speed control servo

(3) Poorly adjusted reference idle speed

TSB Revision

Page 180 of 1146

13-74FUEL SYSTEM - 0n-vehicle Inspection of MPI Components

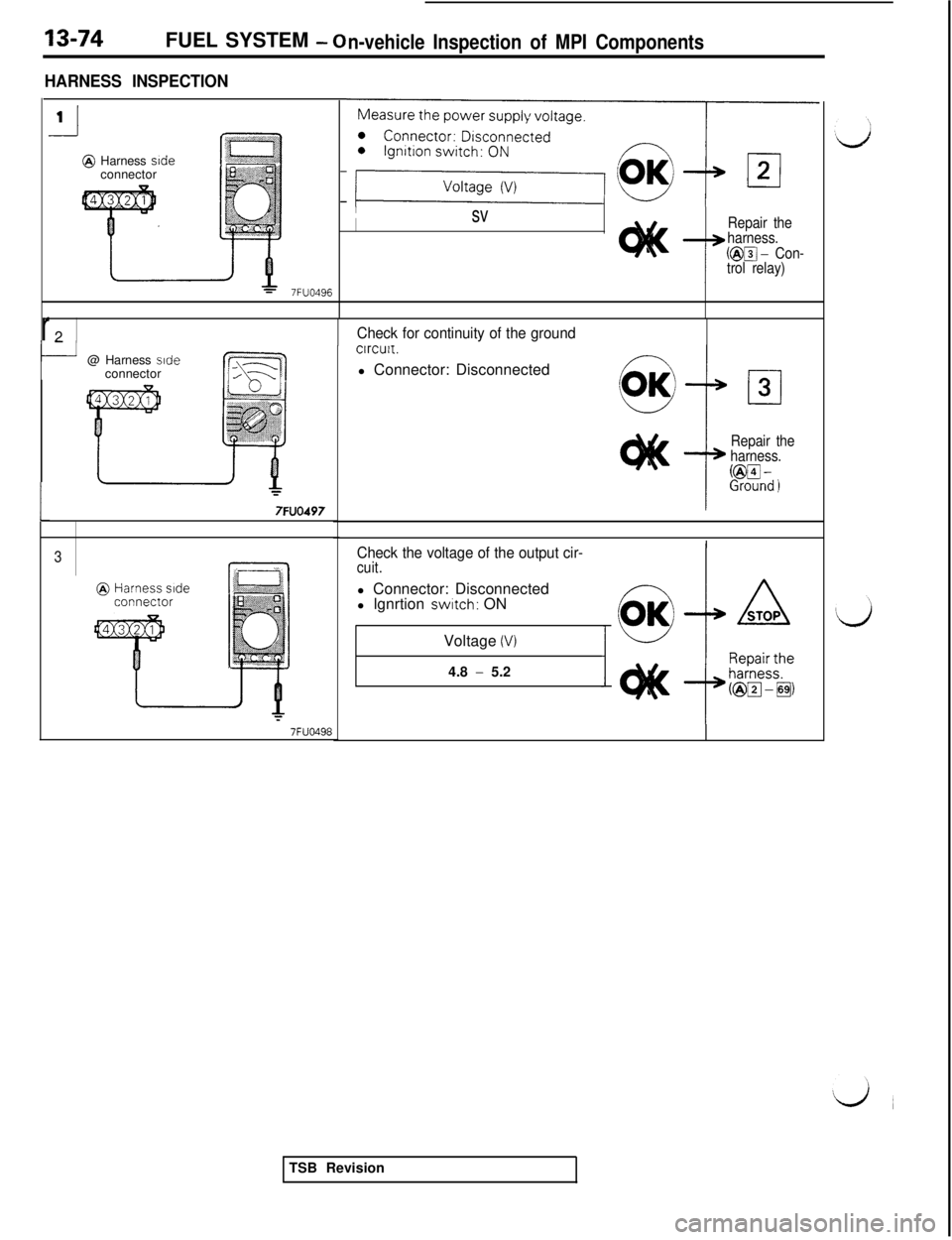

HARNESS INSPECTION

J1@ Harness side

connector

1

7FUO496

Measure the power supply voltage.

IsvRepair the

harness.

(@I@ - Con-

trol relay)

r2

t-@ Harness side

connector

Check for continuity of the groundcbrcux.l Connector: Disconnected

7FUO497

3

‘L‘7FUO498

El3

Repair the

harness.

!?.!!ni )

Check the voltage of the output cir-cuit.l Connector: Disconnected

l lgnrtion switch: ON

Voltage

(VI4.8

- 5.2

TSB Revision