relay MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 233 of 1146

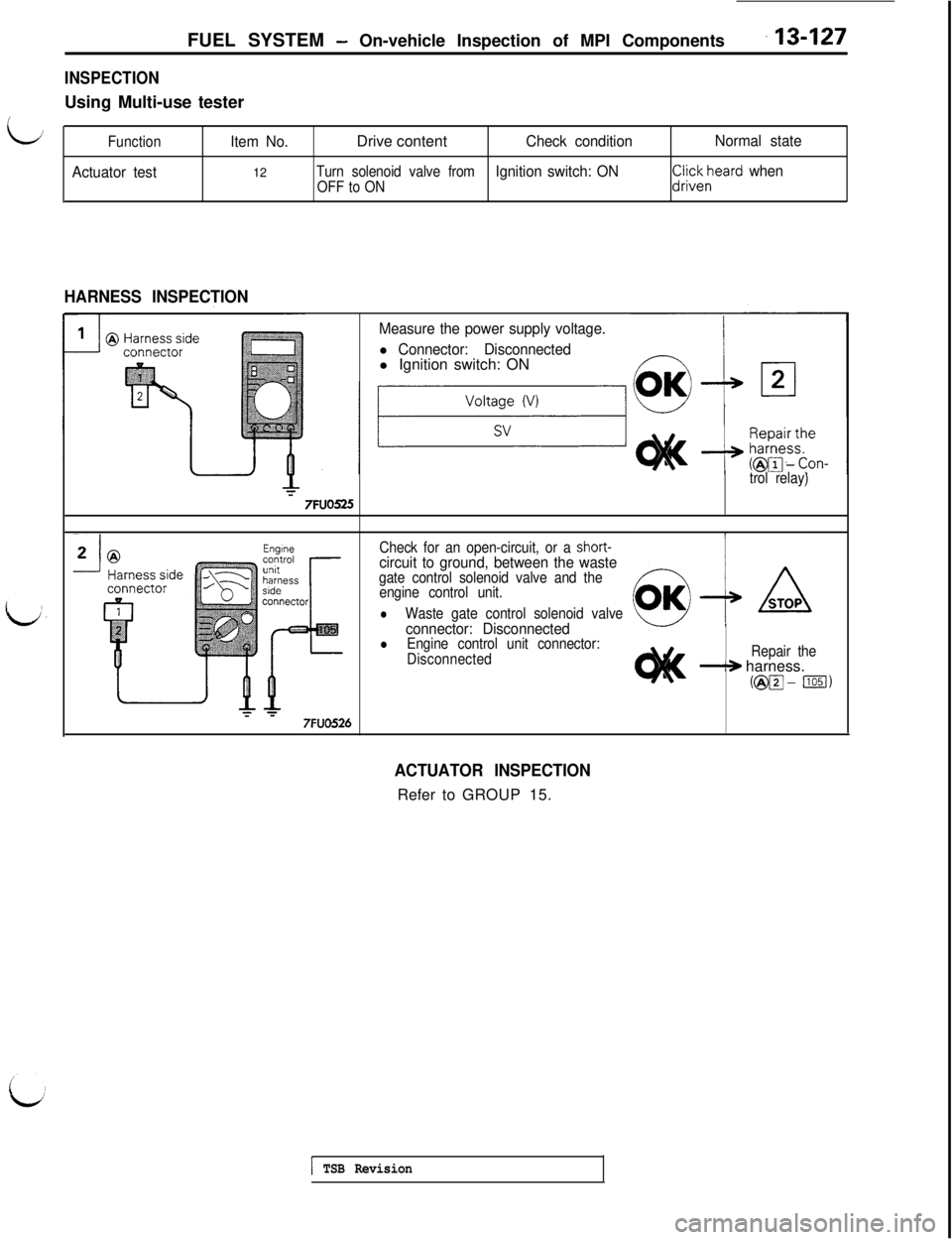

FUEL SYSTEM - On-vehicle Inspection of MPI Components'13-127

INSPECTIONUsing Multi-use tester

LFunctionItem No.Drive contentCheck conditionNormal state

Actuator test12

Turn solenoid valve fromIgnition switch: ONOFF to ON

CliZli~,“eard when

HARNESS INSPECTION

Measure the power supply voltage.

l Connector: Disconnectedl Ignition switch: ON

trol relay)

7FUO525

Check for an open-circuit, or a short-circuit to ground, between the wastegate control solenoid valve and the

engine control unit.

lWaste gate control solenoid valveconnector: DisconnectedlEngine control unit connector:

DisconnectedRepair the

-+ harness.

(@m- ml)

7FUO526

ACTUATOR INSPECTIONRefer to GROUP 15.

1 TSB Revision

Page 239 of 1146

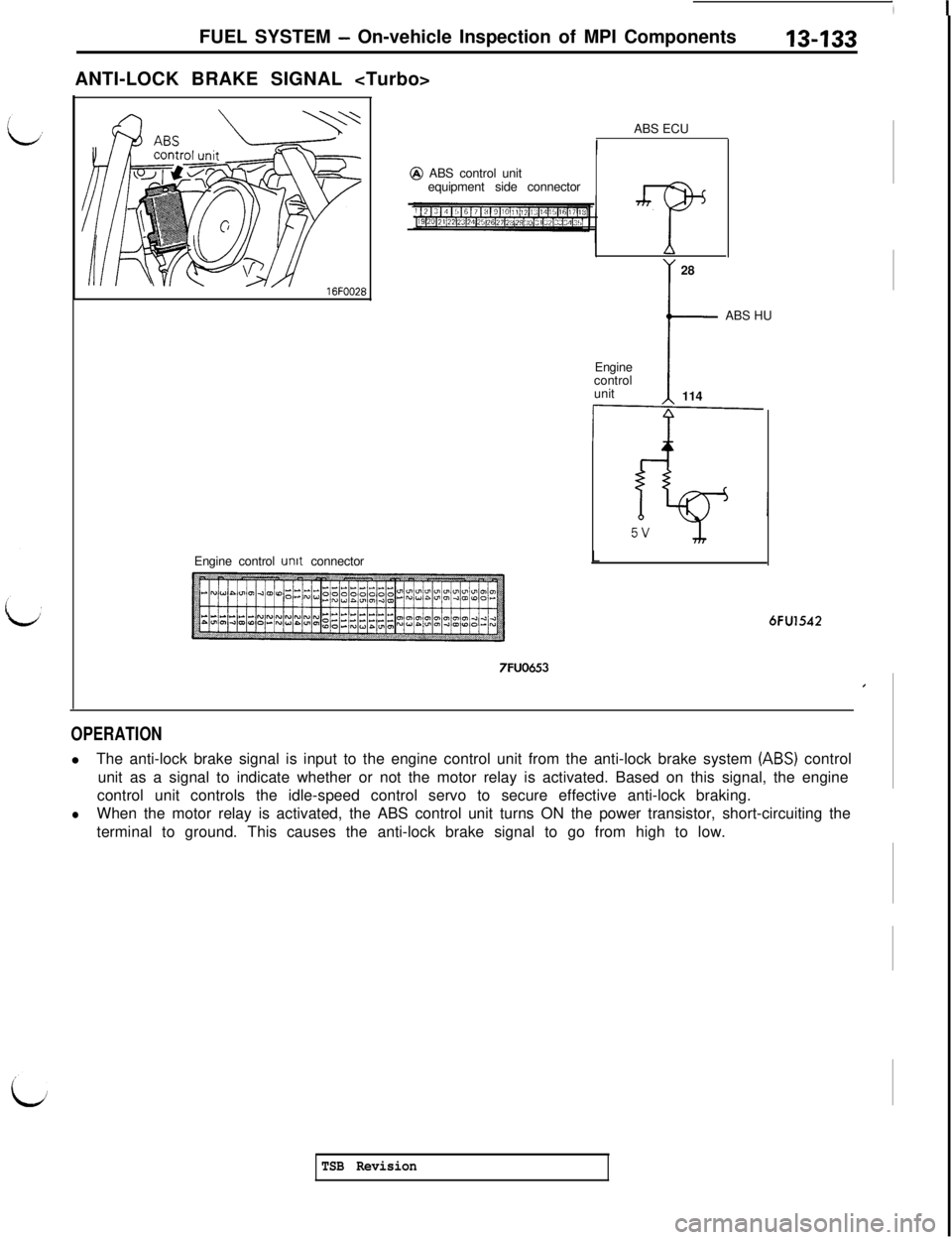

FUEL SYSTEM - On-vehicle Inspection of MPI Components

ANTI-LOCK BRAKE SIGNAL

Engine control

unit connectorABS ECU@ ABS control unit

equipment side connector

A28

tABS HU

Engine

control

unit

114

/L6FU1542

7FUO653,

OPERATIONlThe anti-lock brake signal is input to the engine control unit from the anti-lock brake system

(ABS) control

unit as a signal to indicate whether or not the motor relay is activated. Based on this signal, the engine

control unit controls the idle-speed control servo to secure effective anti-lock braking.

lWhen the motor relay is activated, the ABS control unit turns ON the power transistor, short-circuiting the

terminal to ground. This causes the anti-lock brake signal to go from high to low.

TSB Revision

Page 269 of 1146

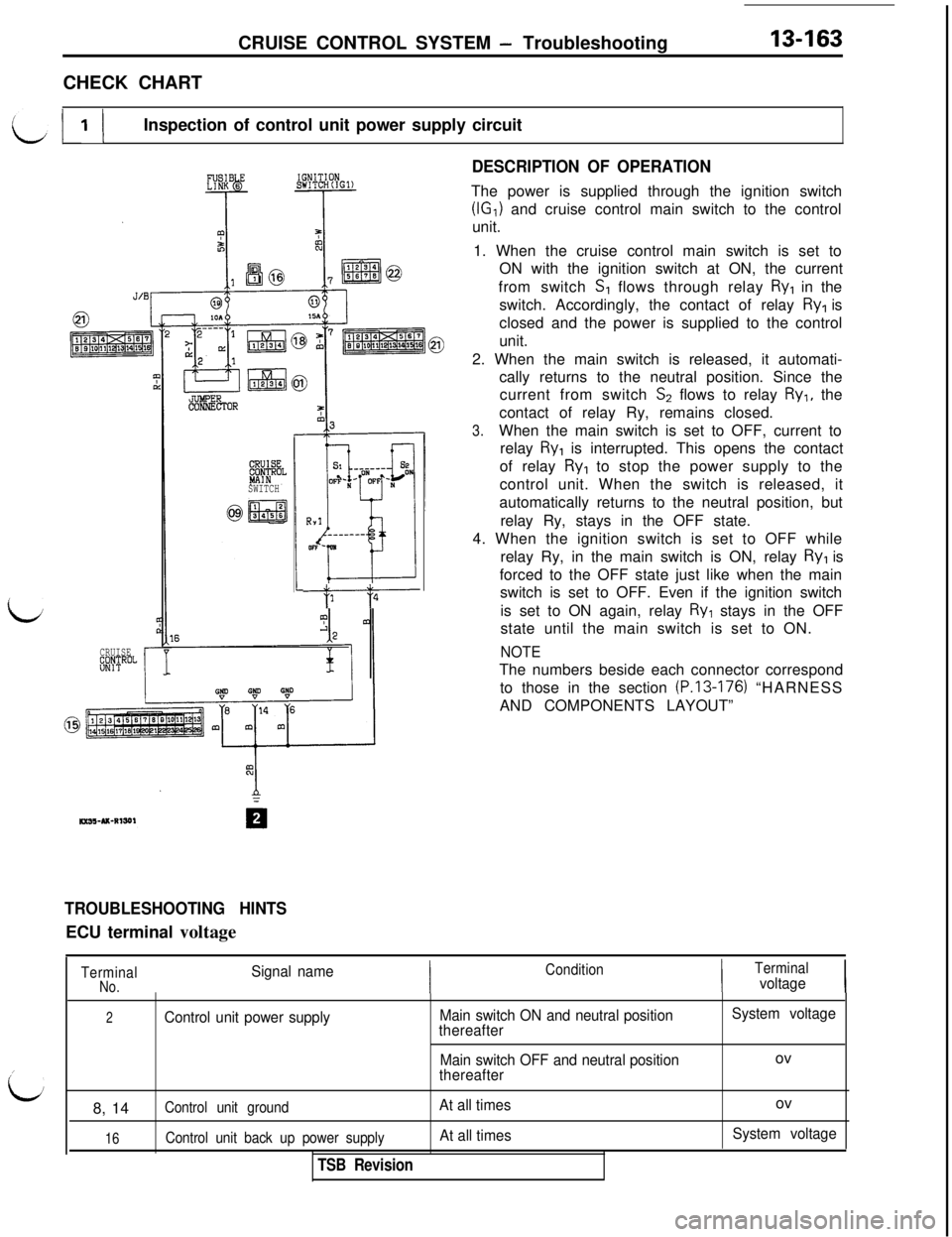

CRUISE CONTROL SYSTEM - Troubleshooting13-163CHECK CHART

it l/Inspection of control unit power supply circuit

L;

,/

id

CRUISE#fi$ROL

0

SWITCH

“71

TROUBLESHOOTING HINTSECU terminal voltage

DESCRIPTION OF OPERATIONThe power is supplied through the ignition switch

(IG,) and cruise control main switch to the control

unit.

1. When the cruise control main switch is set to

ON with the ignition switch at ON, the current

from switch

S, flows through relay Ry, in the

switch. Accordingly, the contact of relay

Ry, is

closed and the power is supplied to the control

unit.

2. When the main switch is released, it automati-

cally returns to the neutral position. Since the

current from switch

S2 flows to relay Ry,, the

contact of relay Ry, remains closed.

3.When the main switch is set to OFF, current to

relay

Ry, is interrupted. This opens the contact

of relay

Ry, to stop the power supply to the

control unit. When the switch is released, it

automatically returns to the neutral position, but

relay Ry, stays in the OFF state.

4. When the ignition switch is set to OFF while

relay Ry, in the main switch is ON, relay

Ry, is

forced to the OFF state just like when the main

switch is set to OFF. Even if the ignition switch

is set to ON again, relay

Ry, stays in the OFF

state until the main switch is set to ON.

NOTEThe numbers beside each connector correspond

to those in the section

(P.13-176) “HARNESS

AND COMPONENTS LAYOUT”

TerminalNo.Signal nameCondition

I

TerminalvoltageI

2Control unit power supplyMain switch ON and neutral positionSystem voltage

thereafter

Main switch OFF and neutral positionov

thereafter8, 14

Control unit groundAt all timesov

16Control unit back up power supplyAt all timesSystem voltage

TSB Revision

Page 297 of 1146

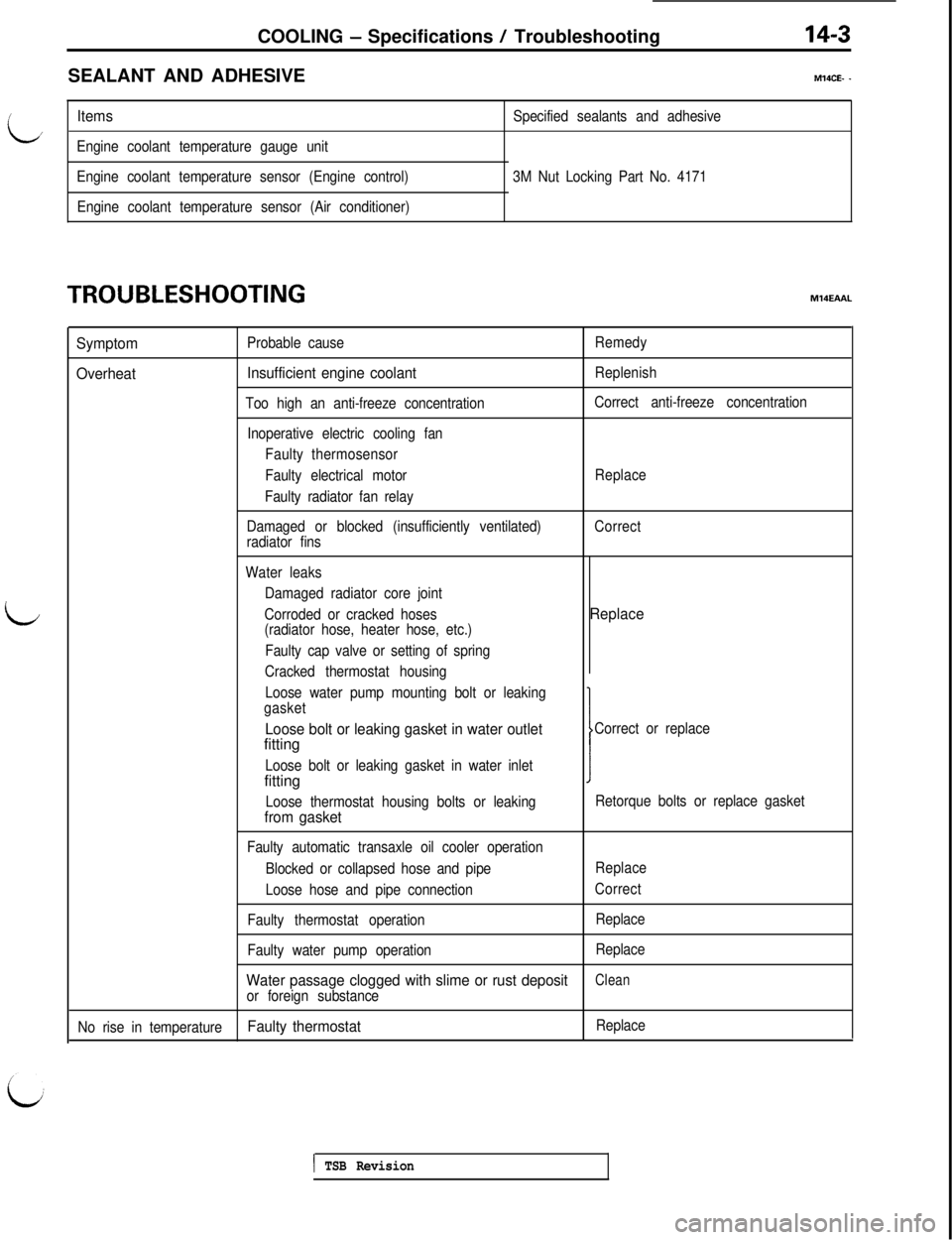

COOLING - Specifications / Troubleshooting

SEALANT AND ADHESIVE14-3

MMCE- -

/

id

ItemsSpecified sealants and adhesive/

Engine coolant temperature gauge unit

Engine coolant temperature sensor (Engine control)

Engine coolant temperature sensor (Air conditioner)3M Nut Locking Part No. 4171

TROUBLESHOOTING

L

MllEAAL

Symptom

OverheatProbable cause

Insufficient engine coolant

Too high an anti-freeze concentration

Inoperative electric cooling fan

Faulty thermosensor

Faulty electrical motor

Faulty radiator fan relayRemedy

Replenish

Correct anti-freeze concentration

Replace

Damaged or blocked (insufficiently ventilated)

radiator finsCorrect

Water leaks

Damaged radiator core joint

Corroded or cracked hoses

(radiator hose, heater hose, etc.)

Faulty cap valve or setting of spring

Cracked thermostat housing

Loose water pump mounting bolt or leaking

gasket

Replace

Loose bolt or leaking gasket in water outlet

I

Correct or replacefitting

Loose bolt or leaking gasket in water inletfitting

Loose thermostat housing bolts or leakingfrom gasket

Retorque bolts or replace gasket

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipeReplace

Loose hose and pipe connectionCorrect

Faulty thermostat operationReplace

Faulty water pump operationReplace

Water passage clogged with slime or rust depositClean

or foreign substance

No rise in temperature

Faulty thermostatReplace

( TSB Revision

Page 299 of 1146

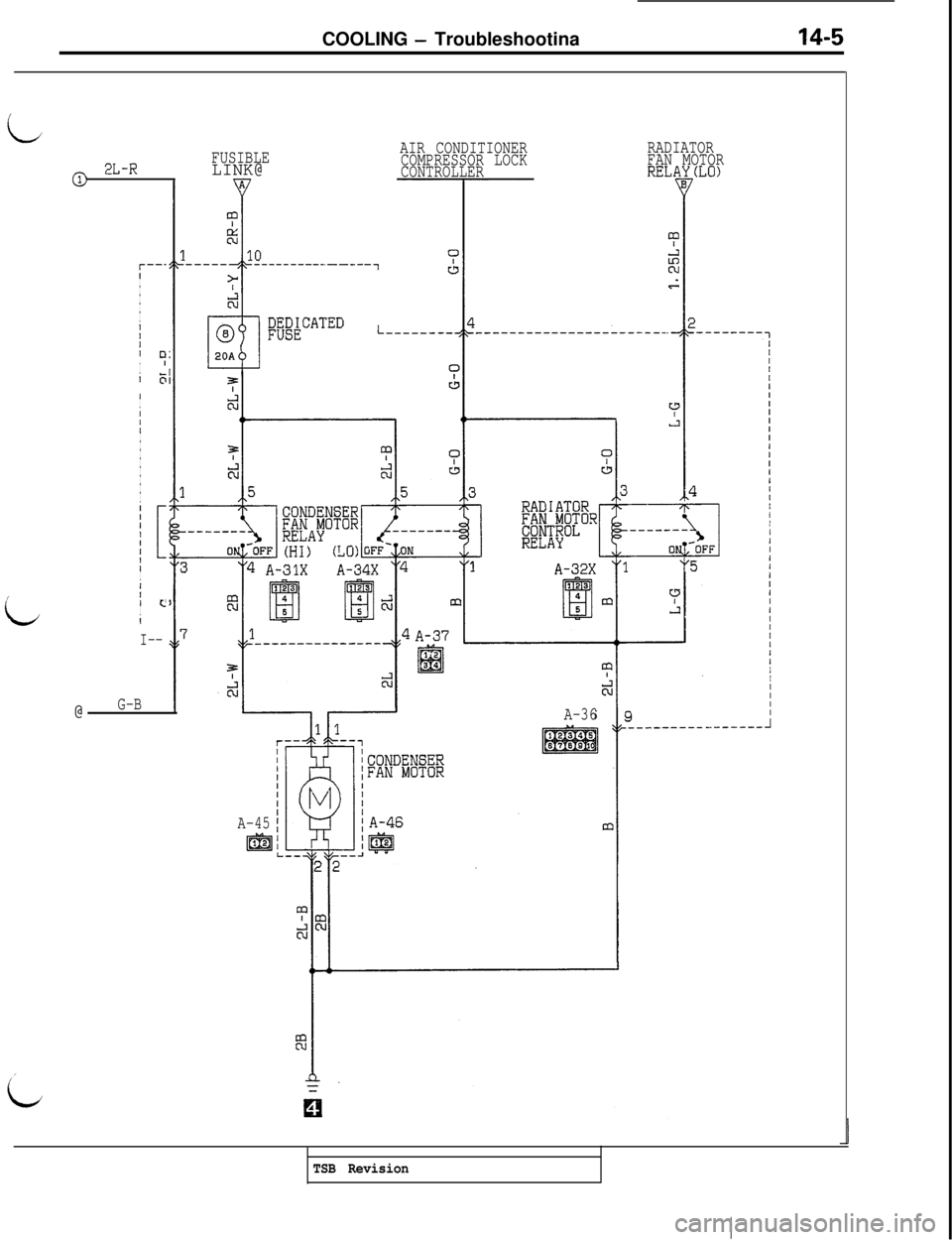

COOLING - Troubleshootina14-5

i

L

@2L-R

:---I

I

I

I

I

III1 nI

I

1 6IIIII

I

I

I

I

I

I

I

I

ii

II

! cI1

I--@

G-B

FUSIBLELINK@

_------ __._ -_--

L-

AIR CONDITIONER

COMPRESSOR LOCK

CONTROLLERRADIATOR

FAN MOTOR

RELAYCLO)

A-36

A-45

@!A

TSB Revision

Page 300 of 1146

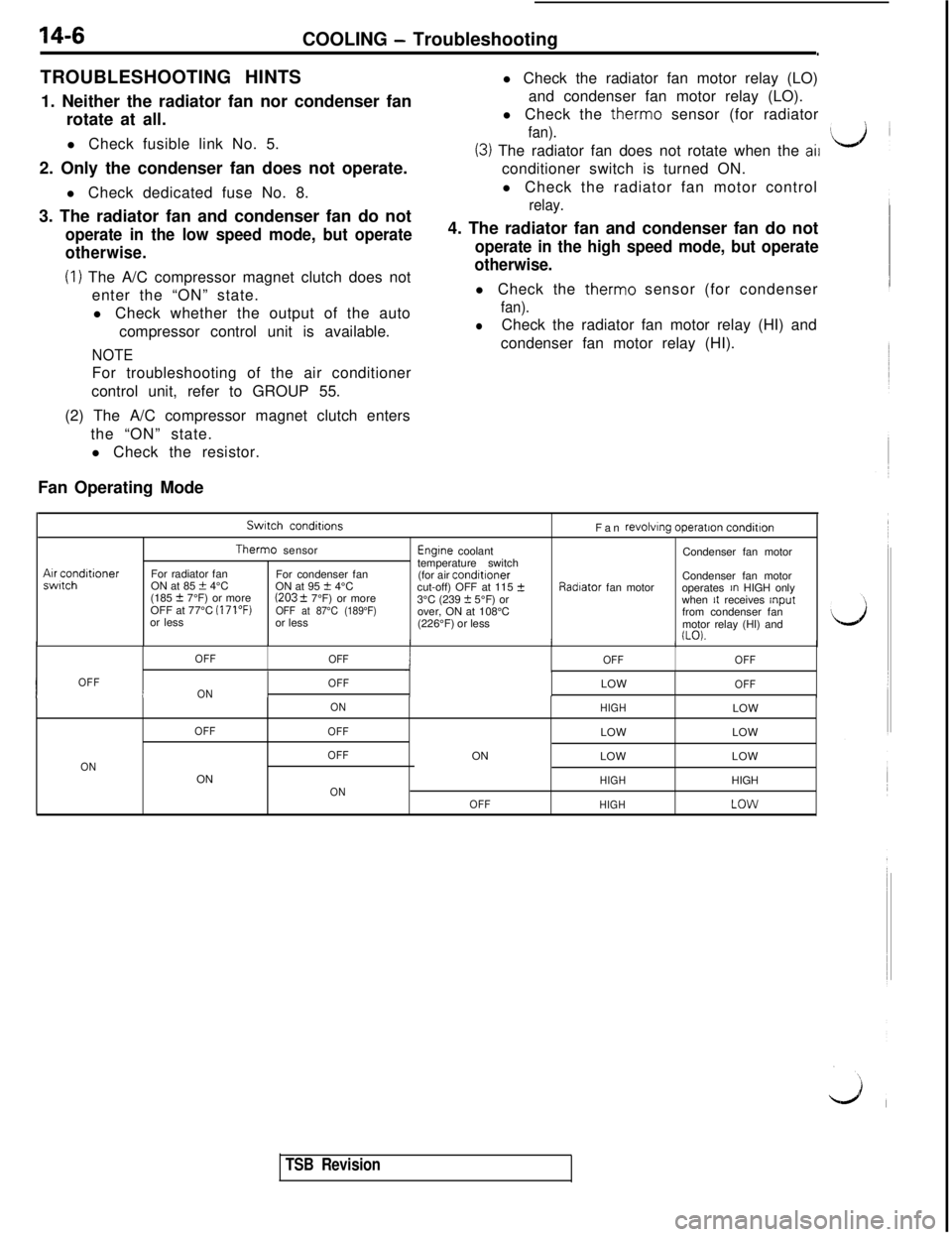

14-6COOLING - Troubleshooting.TROUBLESHOOTING HINTS

1. Neither the radiator fan nor condenser fan

rotate at all.

l Check fusible link No. 5.

2. Only the condenser fan does not operate.

l Check dedicated fuse No. 8.

3. The radiator fan and condenser fan do not

operate in the low speed mode, but operate

otherwise.

(1) The A/C compressor magnet clutch does not

enter the “ON” state.

l Check whether the output of the auto

compressor control unit is available.

NOTEFor troubleshooting of the air conditioner

control unit, refer to GROUP 55.

(2) The A/C compressor magnet clutch enters

the “ON” state.

l Check the resistor.

Fan Operating Model Check the radiator fan motor relay (LO)

and condenser fan motor relay (LO).

l Check the therm0 sensor (for radiator

fan).

(3) The radiator fan does not rotate when the ailconditioner switch is turned ON.

l Check the radiator fan motor control

relay.4. The radiator fan and condenser fan do not

operate in the high speed mode, but operate

otherwise.l Check the therm0 sensor (for condenser

fan).

lCheck the radiator fan motor relay (HI) and

condenser fan motor relay (HI).Air

conditionerswitch

Switch conditionsTherm0 sensor

For radiator fan

For condenser fan

ON at 85

k 4°C

ON at 95 t 4°C

(185 f 7°F) or more(203 + 7°F) or more

OFF at 77°C (171°F)

OFF at 87°C (189°F)or less

or lessEngine coolant

temperature switch

(for air conditioner

cut-off) OFF at 115

+3°C (239 2 5°F) or

over, ON at 108°C

(226°F) or lessFan revolving operation

conditionCondenser fan motor

Condenser fan motorRadiator fan motor

operates

In HIGH only

when it receives input

from condenser fan

motor relay (HI) and

U-0).I/I/

OFF

OFF

OFFOFF

IOFFIOFF

ONLOWOFF

ON

HIGHLOW

OFF

OFFLOWLOW

OFF

ONON

LOWLOW

ON

HIGH

ONHIGH

OFF

HIGHLOW

TSB Revision

Page 304 of 1146

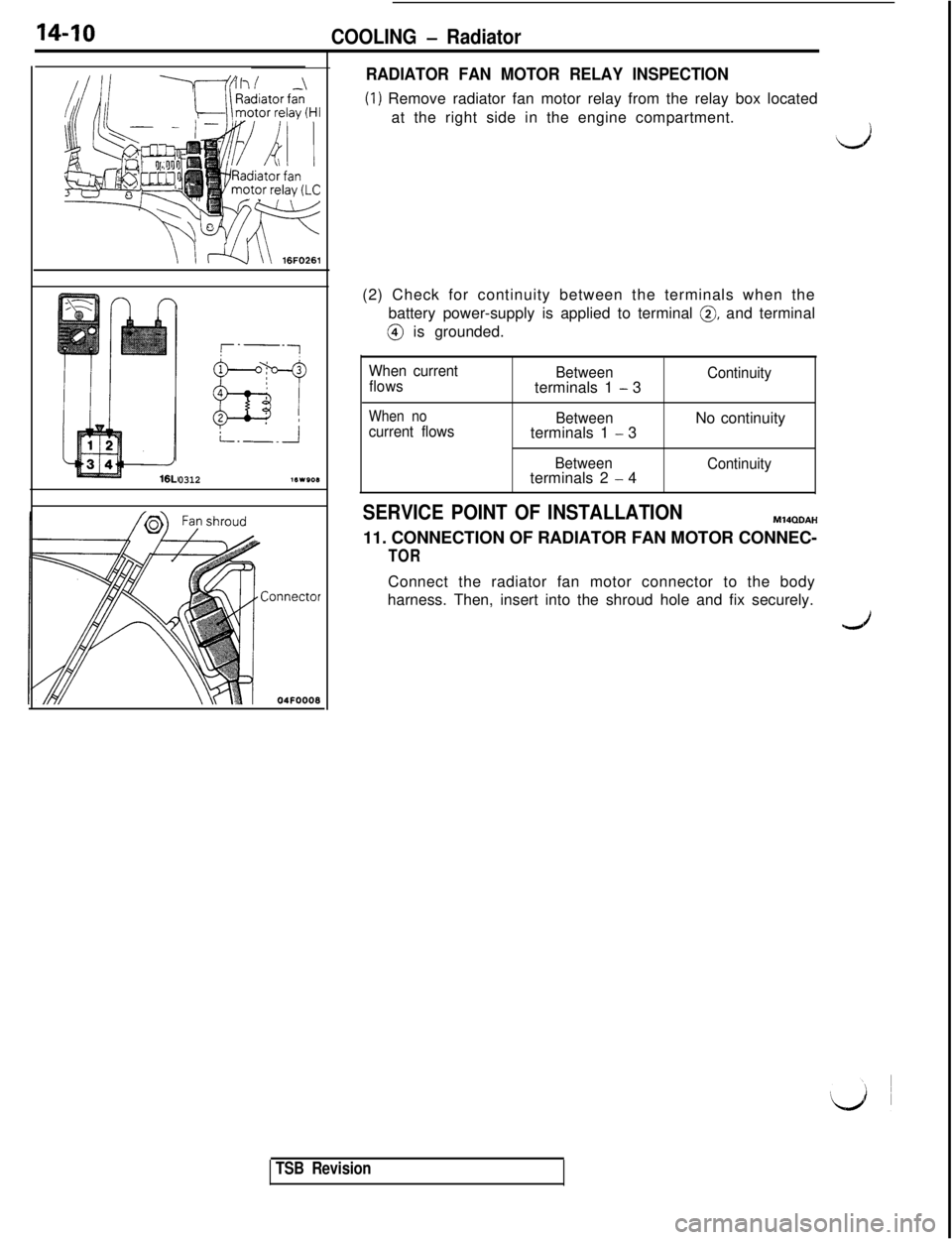

14-10COOLING - Radiator

r-----I

113

EY

4 :

2 :

i.-.-..i

0312161908

Ionnector04FOOO8

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor relay from the relay box located

at the right side in the engine compartment.

Ll(2) Check for continuity between the terminals when the

battery power-supply is applied to terminal

0, and terminal@ is grounded.

When current

flowsBetweenterminals 1

- 3Continuity

When nocurrent flowsBetweenterminals 1 - 3No continuity

Betweenterminals 2 - 4Continuity

SERVICE POINT OF INSTALLATIONM14QDAH

11. CONNECTION OF RADIATOR FAN MOTOR CONNEC-

TORConnect the radiator fan motor connector to the body

harness. Then, insert into the shroud hole and fix securely.

TSB Revision

Page 314 of 1146

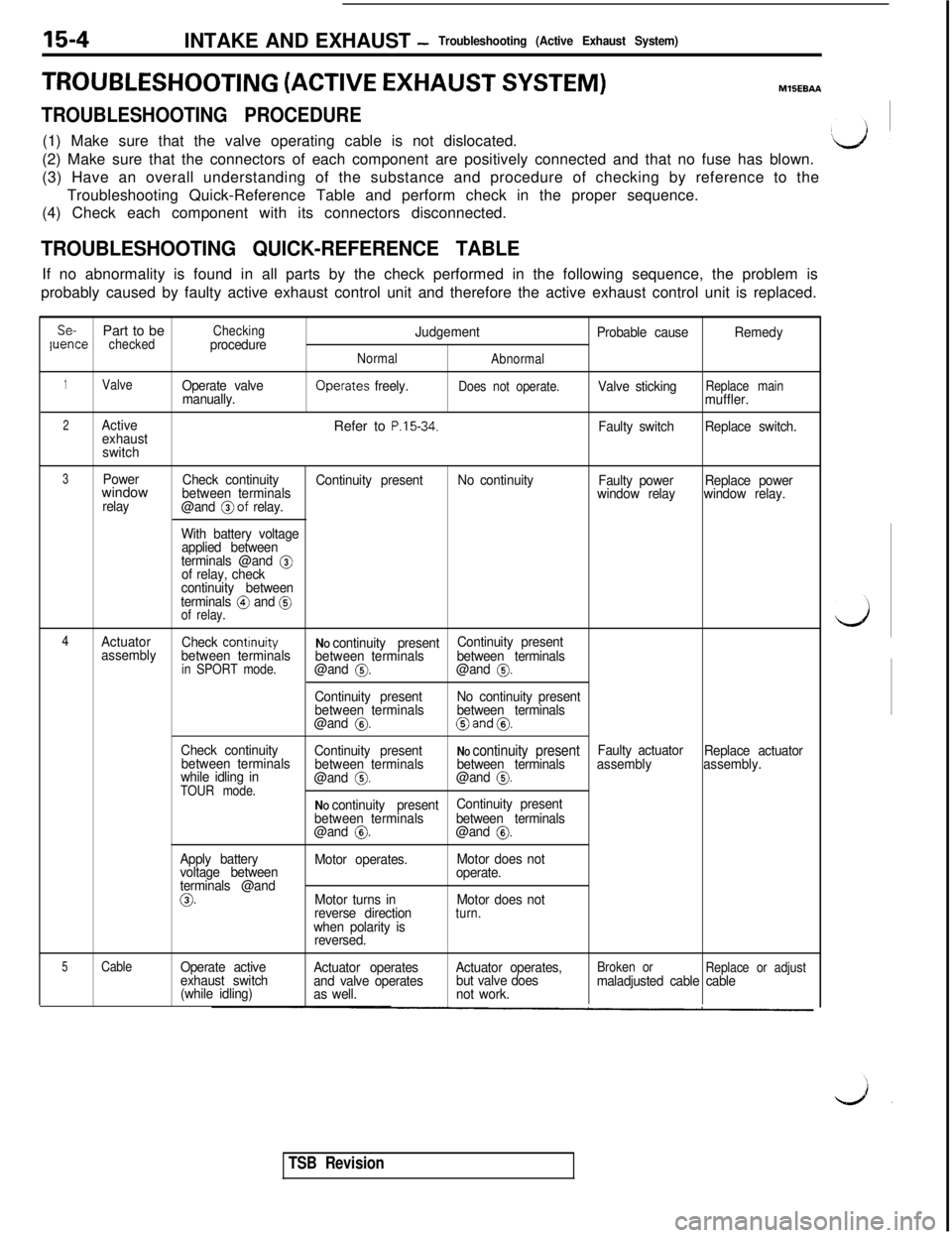

15-4INTAKE AND EXHAUST -Troubleshooting (Active Exhaust System)

TROUBLESHOOTING (ACTIVE EXHAUST SYSTEM)MlSEBAA

TROUBLESHOOTING PROCEDURE(1) Make sure that the valve operating cable is not dislocated.

(2) Make sure that the connectors of each component are positively connected and that no fuse has blown.

(3) Have an overall understanding of the substance and procedure of checking by reference to the

Troubleshooting Quick-Reference Table and perform check in the proper sequence.

(4) Check each component with its connectors disconnected.

TROUBLESHOOTING QUICK-REFERENCE TABLEIf no abnormality is found in all parts by the check performed in the following sequence, the problem is

probably caused by faulty active exhaust control unit and therefore the active exhaust control unit is replaced.

Se-Part to becheckedCheckingprocedureJudgement

Probable causeluenceRemedy

Normal

Abnormal

1ValveOperate valve

manually.Operates freely.Does not operate.Valve stickingReplace mainmuffler.

2ActiveRefer to P.15-34.exhaustFaulty switchReplace switch.

switch

3PowerwindowCheck continuity

between terminalsContinuity presentNo continuity

Faulty power

relay

@and @of

relay.window relayReplace power

window relay.

With battery voltage

applied between

terminals @and

@of relay, check

continuity between

terminals

@ and @of relay.

4

Actuator

Check contrnuityassembly

between terminalsNO continuity present

between terminalsContinuity present

between terminals

in SPORT mode.@and 0.@and 0.

Continuity present

between terminalsNo continuity present

between terminals

@and

0.@and 0.

Check continuity

between terminalsContinuity present

between terminalsNO continuity presentbetween terminalsFaulty actuator

Replace actuator

while idling in

@and 0.@and @assemblyassembly.

TOUR mode.NO continuity present

between terminalsContinuity present

between terminals

@and

0.@and 0.

Apply battery

Motor operates.Motor does not

voltage between

terminals @andoperate.

0.Motor turns inMotor does not

reverse directionturn.when polarity is

reversed.

5CableOperate activeBroken orexhaust switchActuator operates

and valve operatesActuator operates,

but valve doesReplace or adjust

(while idling)

as well.not work.maladjusted cable cable

TSB Revision

Page 352 of 1146

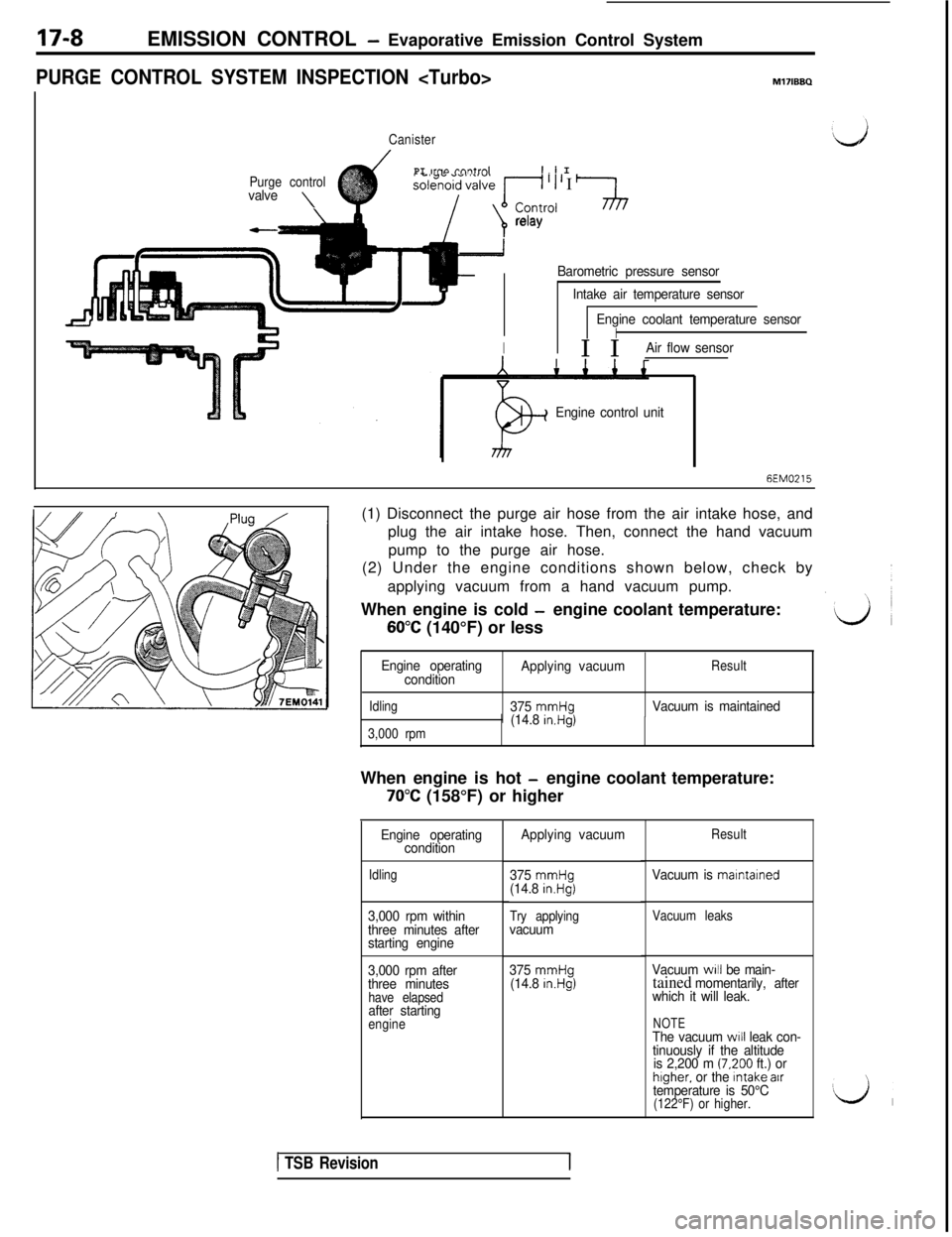

17-8EMISSION CONTROL - Evaporative Emission Control System

PURGE CONTROL SYSTEM INSPECTION

Canister

Purge control

valve\

PI IrnQ rnntrnlI.1 I

kXffo~~~~r~~ ’ I I-J

relay

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

II1 I IAir flow sensor

Engine control unit

6EM0215(1) Disconnect the purge air hose from the air intake hose, and

plug the air intake hose. Then, connect the hand vacuum

pump to the purge air hose.

(2) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold

-engine coolant temperature:

60°C (140°F) or less

Engine operating

conditionApplying vacuumResult

Idling

375 mmHgVacuum is maintained

3,000 rpm(14.8 in.Hg)When engine is hot

-engine coolant temperature:

70°C (158°F) or higher

Engine operating

condition

Idling

3,000 rpm within

three minutes after

starting engine

3,000 rpm after

three minutes

have elapsedafter startingengine

Applying vacuum

375

mmHg(14.8 in.Hg)

Try applyingvacuum

375

mmHg(14.8 in.Hg)

Result

Vacuum is marntained

Vacuum leaks

Vacuum WIII be main-tained momentarily, after

which it will leak.

NOTEThe vacuum WIII leak con-

tinuously if the altitude

is 2,200 m

(7,200 ft.) orhrgher. or the Intake arrtemperature is 50°C(122°F) or higher.

1 TSB Revision

Page 482 of 1146

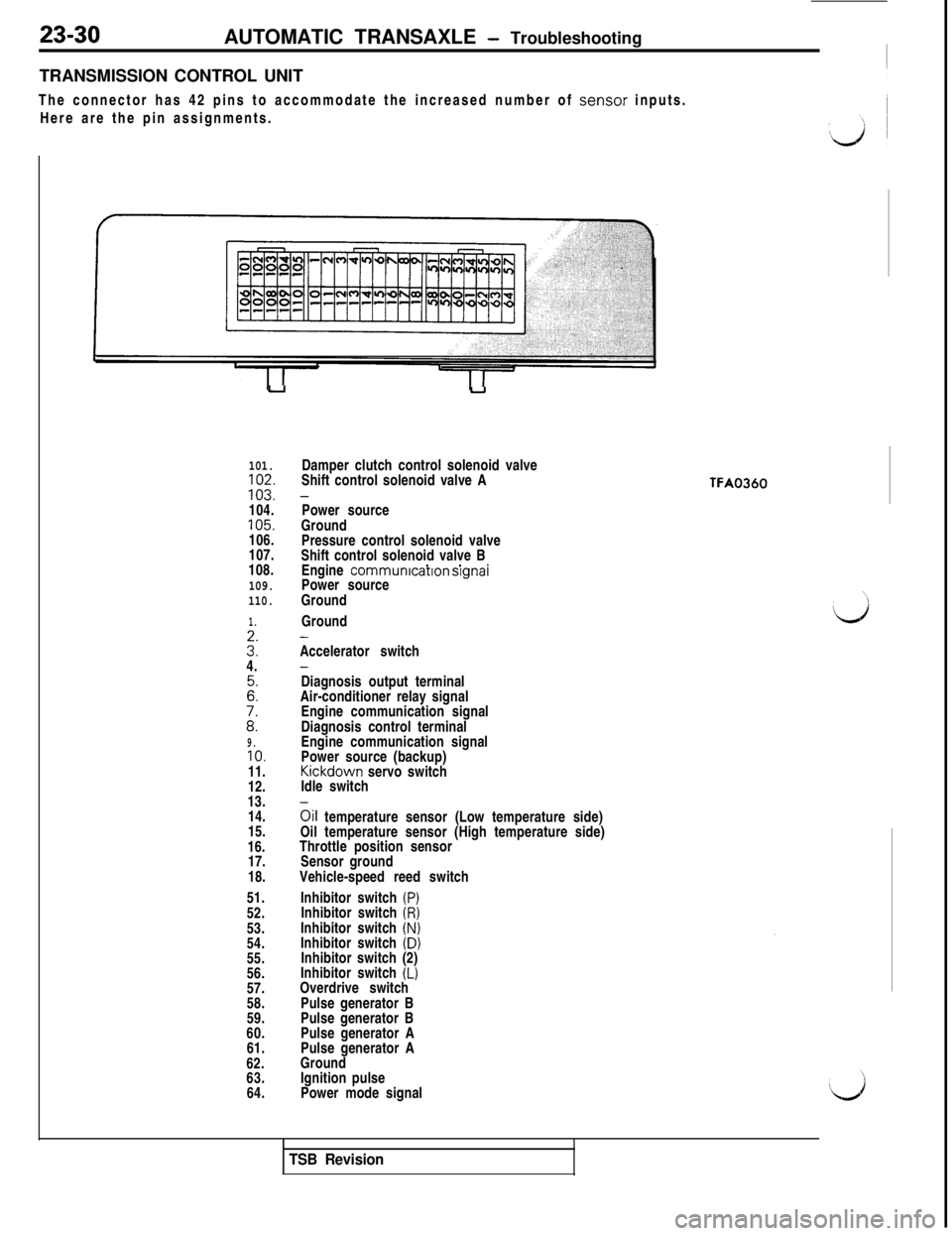

23-30AUTOMATIC TRANSAXLE - Troubleshooting

TRANSMISSION CONTROL UNIT

The connector has 42 pins to accommodate the increased number of senso.r inputs.

Here are the pin assignments.

uu

101.102.103.

104.105.

106.

107.

108.

109.

110.

1.

3':4.

Z:

i:9.10.11.

12.

13.

14.

15.

16.

17.

18.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.Damper clutch control solenoid valve

Shift control solenoid valve A

-Power source

Ground

Pressure control solenoid valve

Shift control solenoid valve B

. .

*Engine communrcatron srgnaiPower source

Ground

Ground

-Accelerator switch

-Diagnosis output terminal

Air-conditioner relay signal

Engine communication signal

Diagnosis control terminal

Engine communication signal

Power source (backup)Kickdown servo switch

Idle switch

oil temperature sensor (Low temperature side)

Oil temperature sensor (High temperature side)

Throttle position sensor

Sensor ground

Vehicle-speed reed switch

Inhibitor switch

(P)Inhibitor switch (R)Inhibitor switch (N)Inhibitor switch (D)

Inhibitor switch (2)

Inhibitor switch

(L)Overdrive switch

Pulse generator B

Pulse generator B

Pulse generator A

Pulse generator A

Ground

Ignition pulse

Power mode signal

TFA0360

TSB Revision