MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 851 of 1146

i

LSTEERING

- Power Steering Gear Box37A-23

13R054f

_ Needlebearing

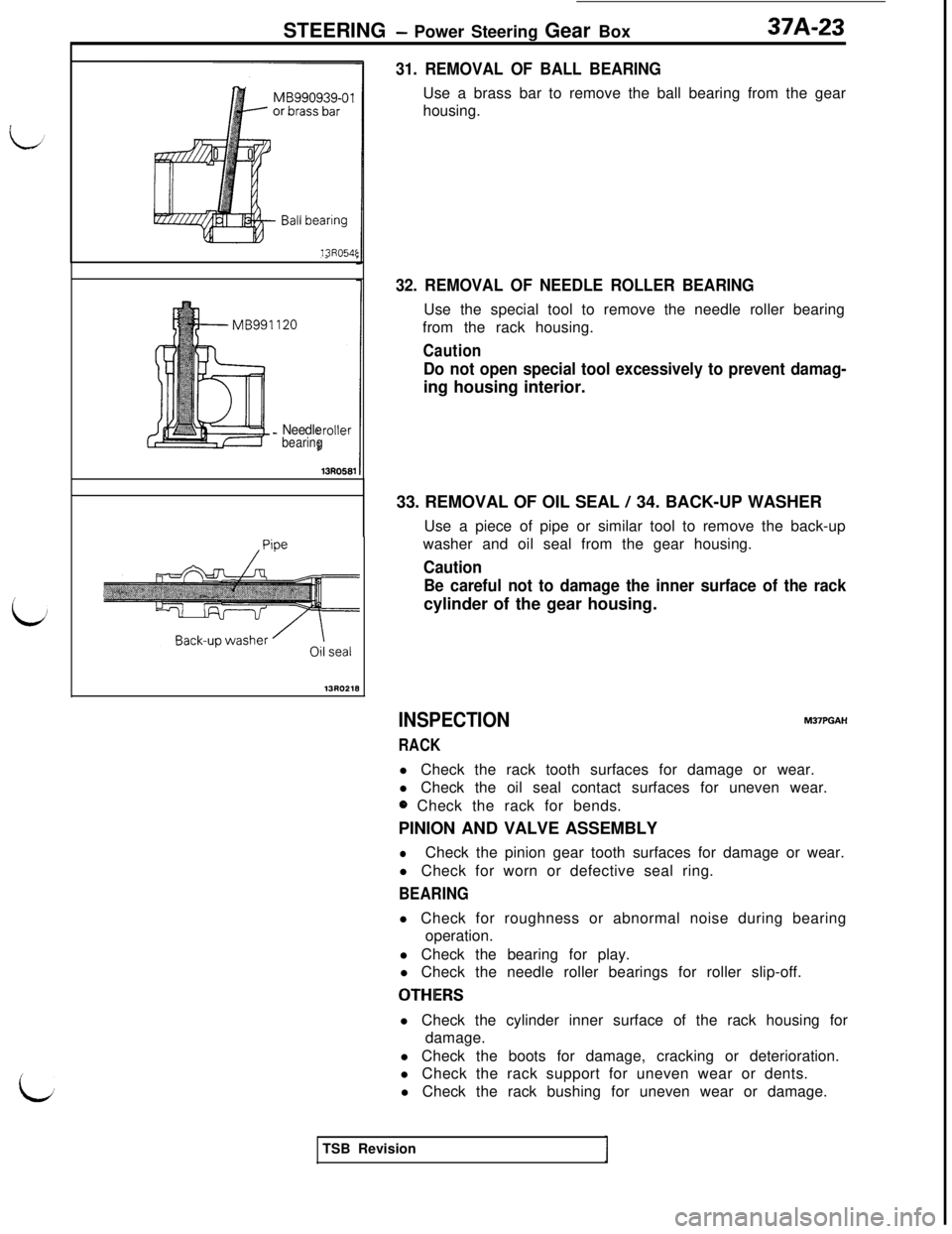

31. REMOVAL OF BALL BEARINGUse a brass bar to remove the ball bearing from the gear

housing.

32. REMOVAL OF NEEDLE ROLLER BEARINGUse the special tool to remove the needle roller bearing

from the rack housing.

Caution

Do not open special tool excessively to prevent damag-ing housing interior.

33. REMOVAL OF OIL SEAL

/ 34. BACK-UP WASHER

Use a piece of pipe or similar tool to remove the back-up

washer and oil seal from the gear housing.

Caution

Be careful not to damage the inner surface of the rackcylinder of the gear housing.

INSPECTION

RACK

M37PGAHl Check the rack tooth surfaces for damage or wear.

l Check the oil seal contact surfaces for uneven wear.

0 Check the rack for bends.

PINION AND VALVE ASSEMBLY

lCheck the pinion gear tooth surfaces for damage or wear.

l Check for worn or defective seal ring.

BEARINGl Check for roughness or abnormal noise during bearing

operation.

l Check the bearing for play.

l Check the needle roller bearings for roller slip-off.

OTHIERSl Check the cylinder inner surface of the rack housing for

damage.

l Check the boots for damage, cracking or deterioration.

l Check the rack support for uneven wear or dents.

l Check the rack bushing for uneven wear or damage.

TSB Revision

Page 852 of 1146

37A-24

STEERING - Power Steering Gear Box

/Oil seal

Back-up washer13A0181L

GuideNeedle roller

bearmg13R0547

MB990927-01

&

13R0378

Vent hole

SERVICE POINTS OF REASSEMBLYM37PHAW

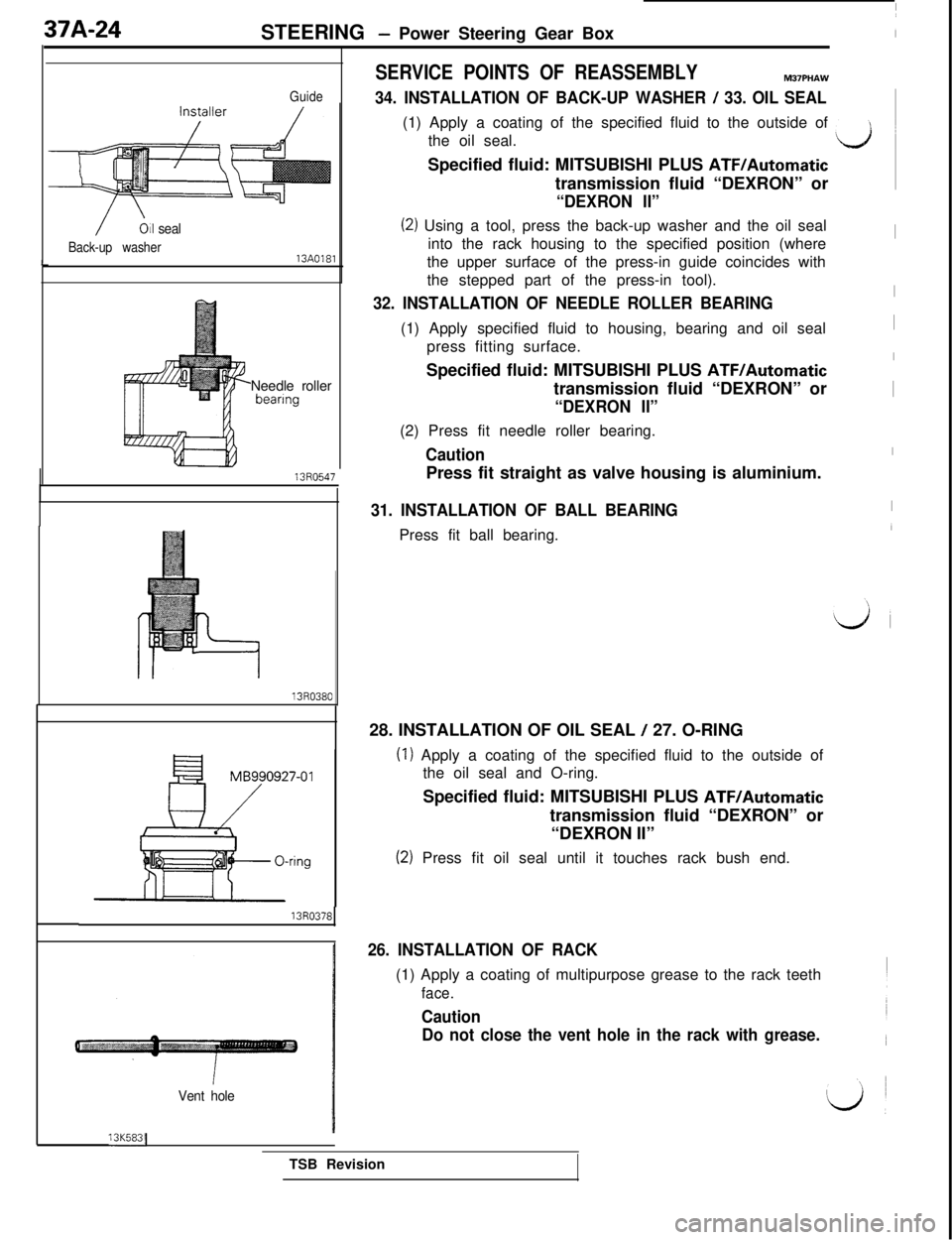

34. INSTALLATION OF BACK-UP WASHER / 33. OIL SEAL(1) Apply a coating of the specified fluid to the outside of

the oil seal.

LJSpecified fluid: MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

(2) Using a tool, press the back-up washer and the oil seal

into the rack housing to the specified position (whereIthe upper surface of the press-in guide coincides with

the stepped part of the press-in tool).

32. INSTALLATION OF NEEDLE ROLLER BEARINGI(1) Apply specified fluid to housing, bearing and oil seal

Ipress fitting surface.

ISpecified fluid: MITSUBISHI PLUS ATF/Automatictransmission fluid “DEXRON” or

I“DEXRON II”(2) Press fit needle roller bearing.

CautionIPress fit straight as valve housing is aluminium.

31. INSTALLATION OF BALL BEARINGPress fit ball bearing.

28. INSTALLATION OF OIL SEAL

/ 27. O-RING

(1) Apply a coating of the specified fluid to the outside of

the oil seal and O-ring.

Specified fluid: MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

(2) Press fit oil seal until it touches rack bush end.

26. INSTALLATION OF RACK(1) Apply a coating of multipurpose grease to the rack teeth

face.

Caution

Do not close the vent hole in the rack with grease.13K583(

TSB Revision

Page 853 of 1146

STEERING - Power Steering Gear Box37A-25

Back-up washer1360147

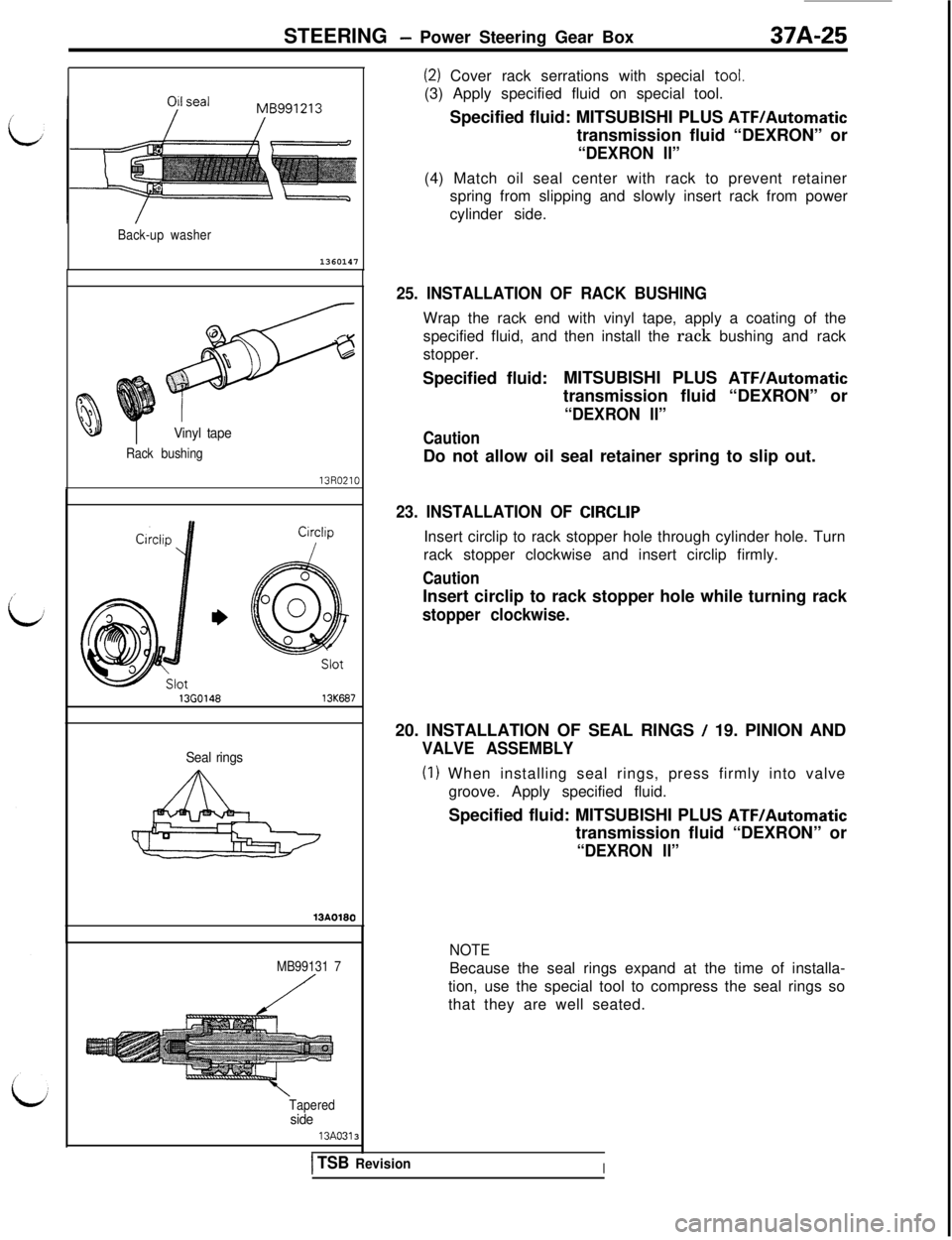

(2) Cover rack serrations with special tool.

(3) Apply specified fluid on special tool.

Specified fluid: MITSUBISHI PLUS

ATFIAutomatictransmission fluid “DEXRON” or

“DEXRON II”(4) Match oil seal center with rack to prevent retainer

spring from slipping and slowly insert rack from power

cylinder side.

Vinyl tape

Rack bushing

136014613K687

Seal rings

MB99131 7

Tapered

side13A0313

25. INSTALLATION OF RACK BUSHINGWrap the rack end with vinyl tape, apply a coating of the

specified fluid, and then install the rack bushing and rack

stopper.

Specified fluid:MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

CautionDo not allow oil seal retainer spring to slip out.

23. INSTALLATION OF CIRCLIPInsert circlip to rack stopper hole through cylinder hole. Turn

rack stopper clockwise and insert circlip firmly.

CautionInsert circlip to rack stopper hole while turning rack

stopper clockwise.20. INSTALLATION OF SEAL RINGS

/ 19. PINION AND

VALVE ASSEMBLY

(I) When installing seal rings, press firmly into valve

groove. Apply specified fluid.

Specified fluid: MITSUBISHI PLUS

ATF/Automatictransmission fluid “DEXRON” or

“DEXRON II”

NOTEBecause the seal rings expand at the time of installa-

tion, use the special tool to compress the seal rings so

that they are well seated.

ITSB RevisionI

Page 854 of 1146

37A-26

STEERING - Power Steerina Gear Box

Apply grease

Approx. 1 mm

l-(Approx. .040 in.)

Tool

13POO76

End plug

Sealant

13K130

’ IEnd plug

r=13K132

MB991 006-01

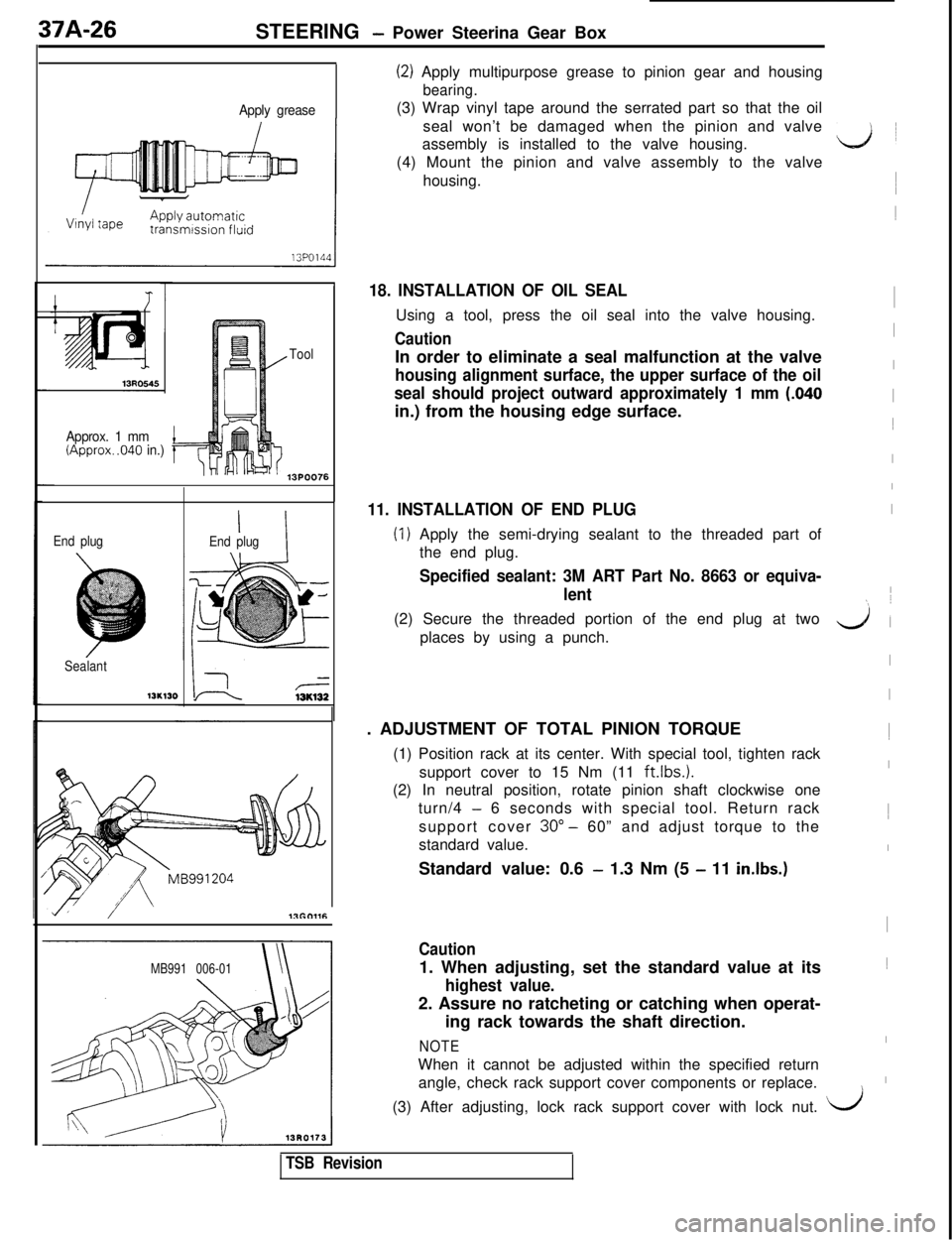

(2) Apply multipurpose grease to pinion gear and housing

bearing.(3) Wrap vinyl tape around the serrated part so that the oil

seal won’t be damaged when the pinion and valve

assembly is installed to the valve housing.

(4) Mount the pinion and valve assembly to the valve

housing.

18. INSTALLATION OF OIL SEALUsing a tool, press the oil seal into the valve housing.

CautionIn order to eliminate a seal malfunction at the valve

housing alignment surface, the upper surface of the oil

seal should project outward approximately 1 mm

(.040in.) from the housing edge surface.

11. INSTALLATION OF END PLUG

(1) Apply the semi-drying sealant to the threaded part of

the end plug.

Specified sealant: 3M ART Part No. 8663 or equiva-

lent(2) Secure the threaded portion of the end plug at two

places by using a punch.

. ADJUSTMENT OF TOTAL PINION TORQUE

(1) Position rack at its center. With special tool, tighten rack

support cover to 15 Nm (11

ft.lbs.1.(2) In neutral position, rotate pinion shaft clockwise one

turn/4

- 6 seconds with special tool. Return rack

support cover 30”

- 60” and adjust torque to the

standard value.

Standard value: 0.6

- 1.3 Nm (5 - 11 in.lbs.)

Caution1. When adjusting, set the standard value at its

highest value.2. Assure no ratcheting or catching when operat-

ing rack towards the shaft direction.

NOTEWhen it cannot be adjusted within the specified return

angle, check rack support cover components or replace.

ii1

I1

I

I

I

I1

I

I

I

I

yl (

I

I1

I1

I

I1

I

I\(3) After adjusting, lock rack support cover with lock nut.

i/

TSB Revision

Page 855 of 1146

STEERING - Power Steering Gear Box3/A-Z/

13A0175

LipMB990776-01

Sealant

I3Y56413AO259

190.6 -192.6mm(7:504 - 7.583in.)

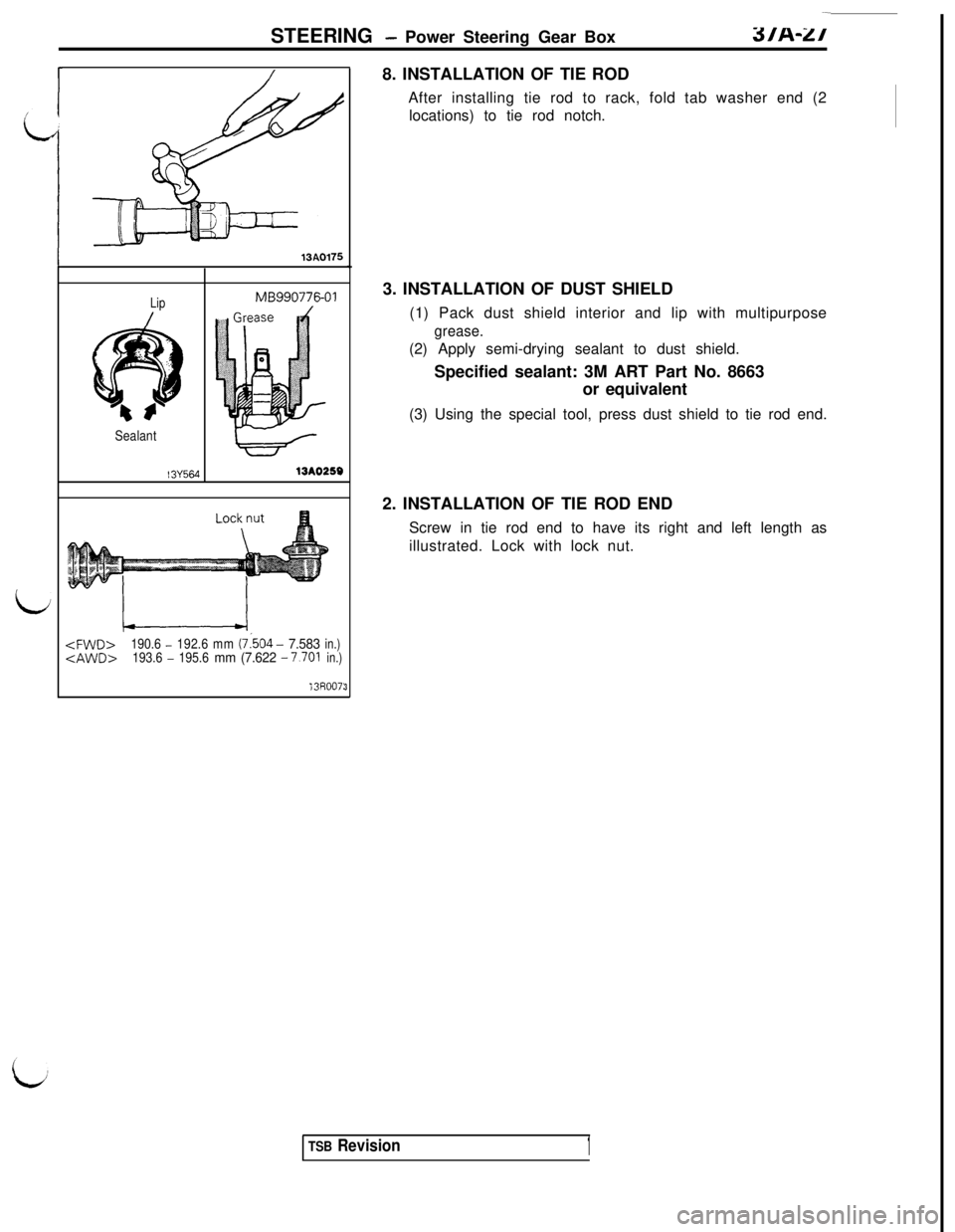

13R007:38. INSTALLATION OF TIE ROD

After installing tie rod to rack, fold tab washer end (2

locations) to tie rod notch.

3. INSTALLATION OF DUST SHIELD

(1) Pack dust shield interior and lip with multipurpose

grease.(2) Apply semi-drying sealant to dust shield.

Specified sealant: 3M ART Part No. 8663

or equivalent

(3) Using the special tool, press dust shield to tie rod end.

2. INSTALLATION OF TIE ROD END

Screw in tie rod end to have its right and left length as

illustrated. Lock with lock nut.

TSB Revision1

Page 856 of 1146

37A-28

STEERING - Power Steering Oil Pump

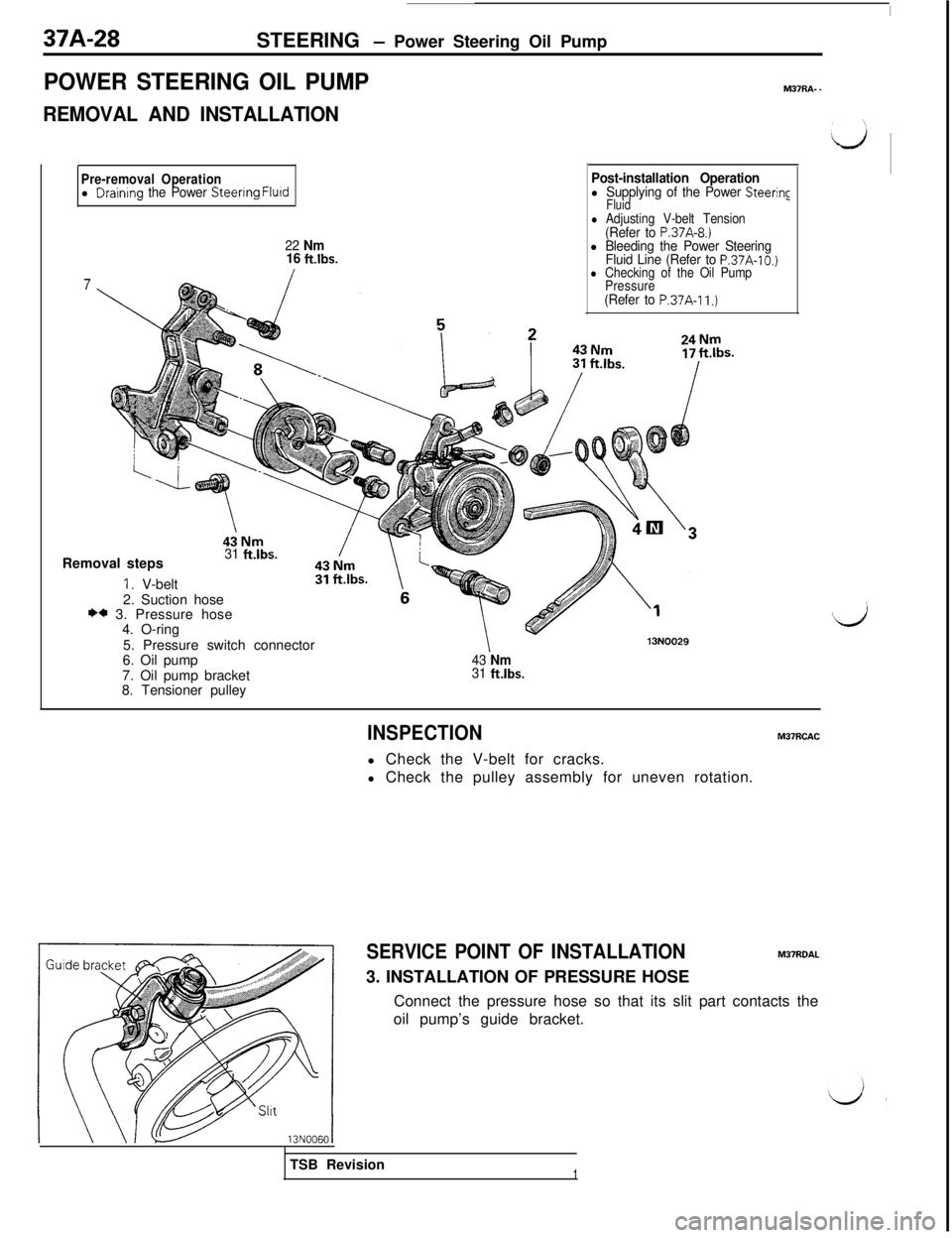

POWER STEERING OIL PUMP

REMOVAL AND INSTALLATION

I

M37RA-.

Pre-removal Operationl Draintng the Power Steenng Flurd

22 Nm

16 ft.lbs.

7

Post-installation Operationl Supplying of the Power Steering

Fluid

l Adjusting V-belt Tension(Refer to P.37A-8.)l Bleeding the Power Steering

Fluid Line (Refer to P.37A-10.)l Checking of the Oil Pump

Pressure

(Refer to P.37A-11.)Removal steps

31 ft.lbs.

1. V-belt

2. Suction hose

** 3. Pressure hose

4. O-ring

5. Pressure switch connector

6. Oil pump

7. Oil pump bracket

8. Tensioner pulley

43 Nm31 fklbs.

13N0029

Ij

INSPECTIONM37RCACl Check the V-belt for cracks.

l Check the pulley assembly for uneven rotation.

SERVICE POINT OF INSTALLATIONM37ROAL3. INSTALLATION OF PRESSURE HOSE

Connect the pressure hose so that its slit part contacts the

oil pump’s guide bracket.

TSB Revision

1

Page 857 of 1146

STEERING - Power Steering Oil Pump37A-29

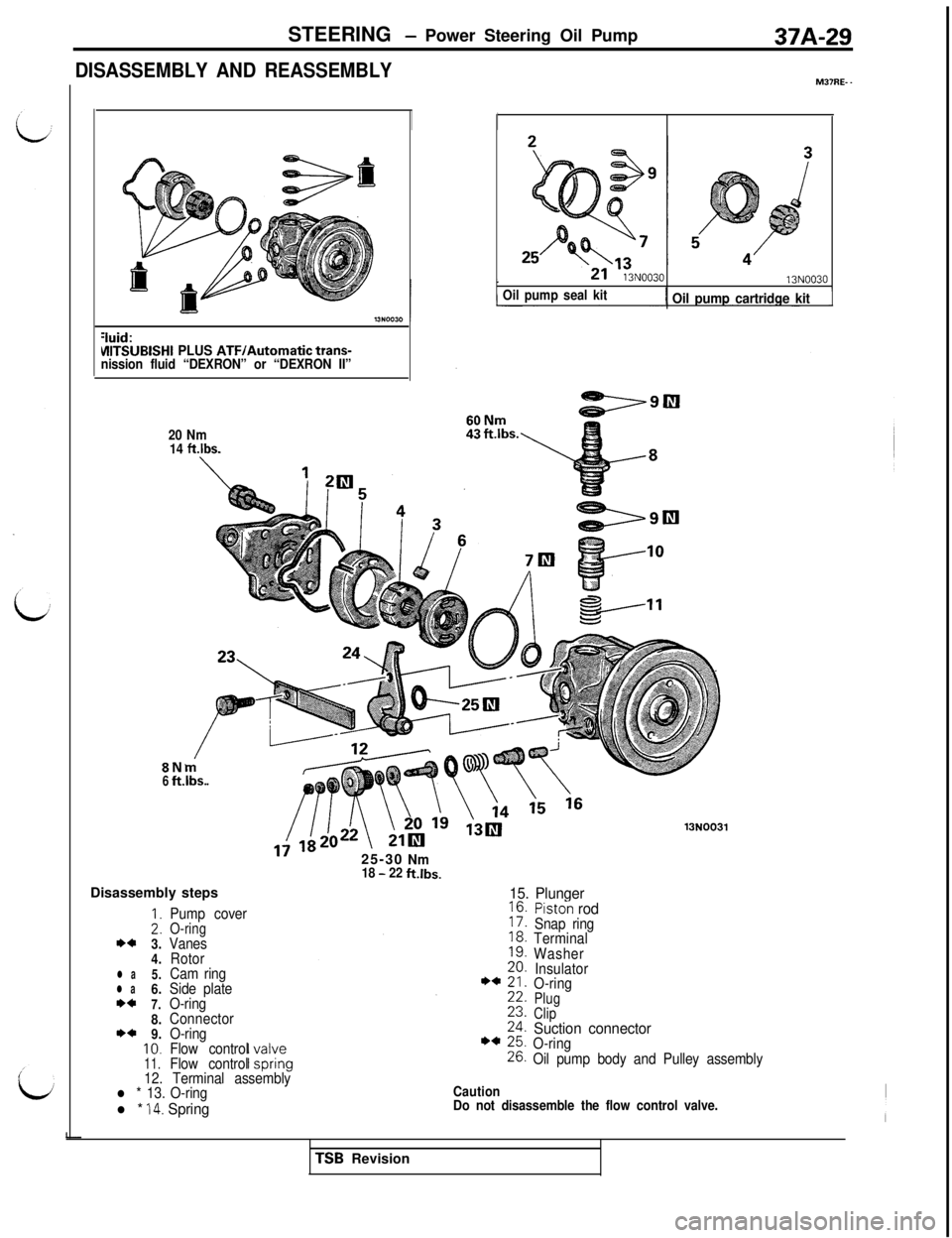

DISASSEMBLY AND REASSEMBLYMS’RE- -

:iuid:VllTSlJBlSHI PLUS ATF/Automatic trans-

nission fluid “DEXRON” or “DEXRON II”

20 Nm

14

ft.lbs.

13N0030

Oil pump seal kit1 Oil pump cartridge kit

8N6ft.lbs.

13N0031Disassembly steps25-30

Nm18 - 22ft.lbs.

15. Plunger

:I*a3.

4.

l a5.l a6.*a7.8.**9.10.

11.

Pump coverO-ringVanes

Rotor

Cam ring

Side plate

O-ring

Connector

O-ring

Flow control

Flow control

Piston rodSnap ring

Terminal

Washer

Insulator

O-ring

Plug

Clip

Suction connectorO-ring

Oil pump body and Pulley assembly

12. Terminal assembly

l * 13. O-ring

l * 14. Spring

Caution

Do not disassemble the flow control valve.TSB Revision

Page 858 of 1146

37A-30STEERING - Power Steering Oil Pump

13R0433

Connector

13K752

Terminal assembly

Side plate613N0059

Suction connector

mounting portion

of oil pump body

13K75313NOOSi

13FOO50

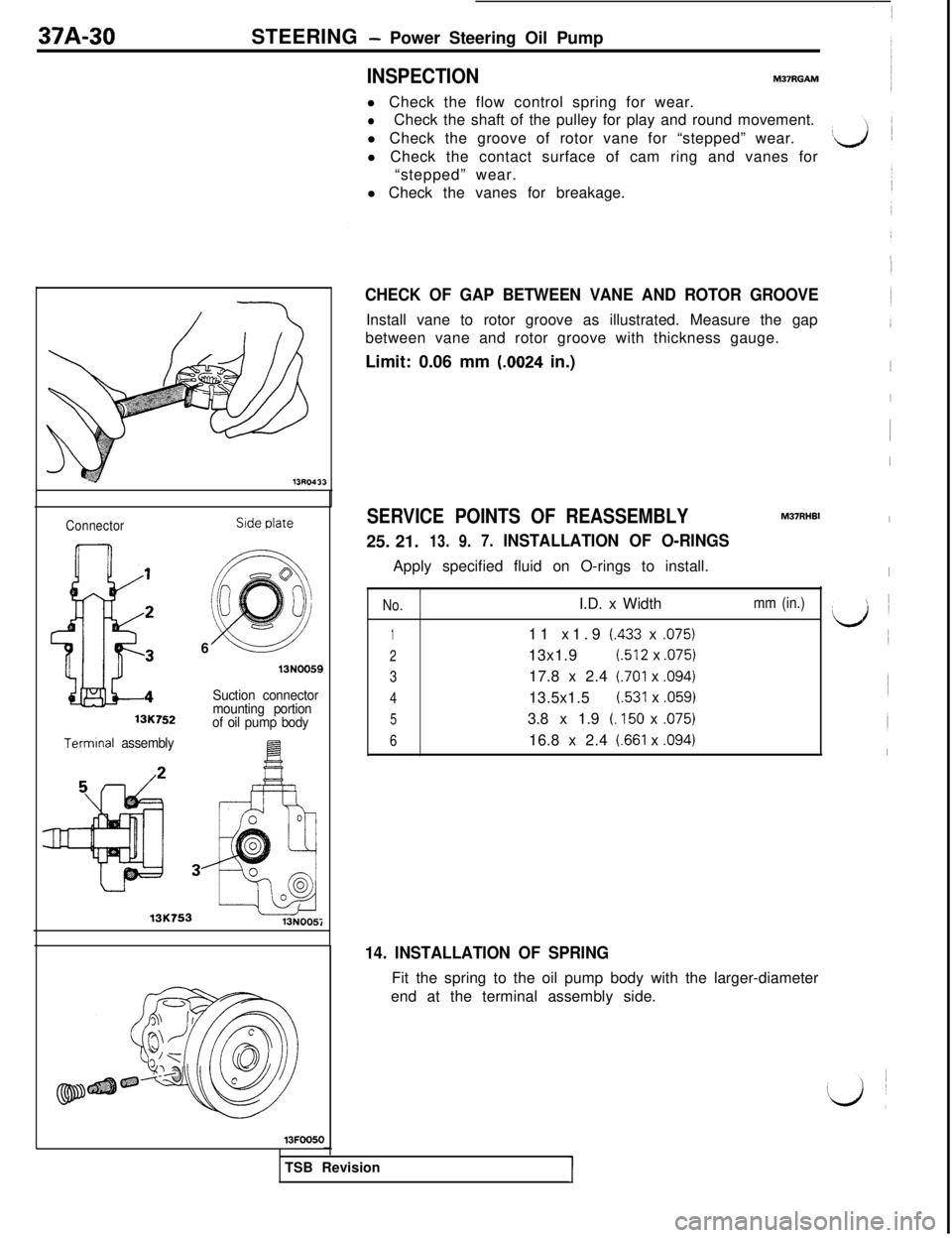

INSPECTIONM37RGAM

l Check the flow control spring for wear.

lCheck the shaft of the pulley for play and round movement.

l Check the groove of rotor vane for “stepped” wear.

l Check the contact surface of cam ring and vanes for

“stepped” wear.

l Check the vanes for breakage.

CHECK OF GAP BETWEEN VANE AND ROTOR GROOVEInstall vane to rotor groove as illustrated. Measure the gap

between vane and rotor groove with thickness gauge.

Limit: 0.06 mm

(.0024 in.)

M37RHBISERVICE POINTS OF REASSEMBLY25. 21.

13.9.7.INSTALLATION OF O-RINGSApply specified fluid on O-rings to install.

No.I.D. x Width

111 x1.9 (.433 x ,075)

213x1.9(.512 x ,075)

317.8 x 2.4

(.701 x ,094)

413.5x1.5

(.531 x .059)

53.8 x 1.9 (. 150 x ,075)

616.8 x 2.4

i.661 x ,094)

mm (in.)

I1

I

I

I

I

t i

14. INSTALLATION OF SPRINGFit the spring to the oil pump body with the larger-diameter

end at the terminal assembly side.

TSB Revision

I

Page 859 of 1146

STEERING - Power Steering Oil Pump37A-31 1

Dowel pin

131025i

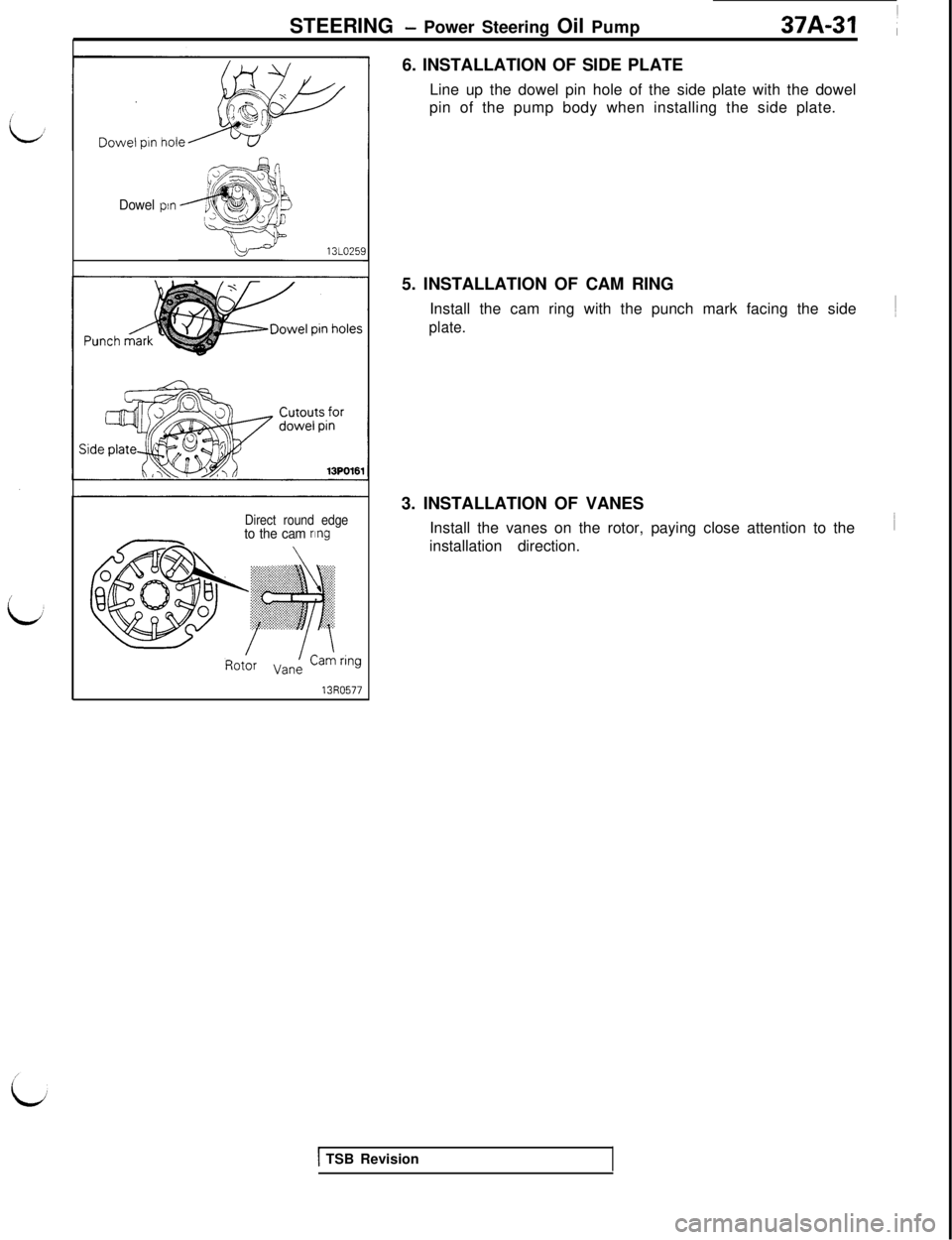

Direct round edgeto the cam nng6. INSTALLATION OF SIDE PLATE

Line up the dowel pin hole of the side plate with the dowel

pin of the pump body when installing the side plate.

5. INSTALLATION OF CAM RING

Install the cam ring with the punch mark facing the side

plate.3. INSTALLATION OF VANES

Install the vanes on the rotor, paying close attention to the

installation direction.

1 TSB Revision

Page 860 of 1146

37A-32STEERING - Power Steering Hoses

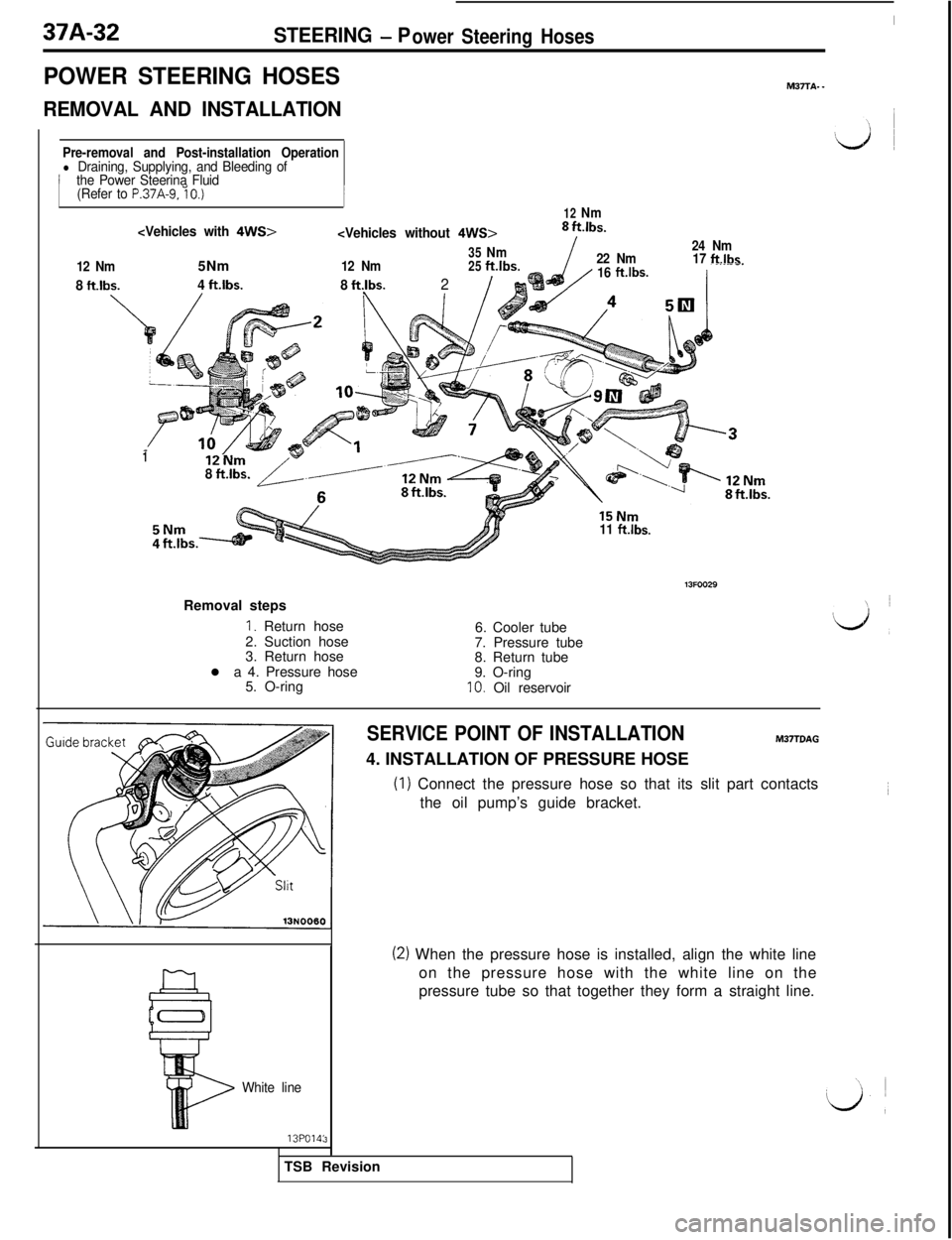

POWER STEERING HOSES

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Il Draining, Supplying, and Bleeding of

the Power Steerina Fluid

(Refer to

P.37A-9,‘iO.)

12 Nm5Nm

8 ftlbs.4 ftlbs.

I12Nm

35Nm

12 Nm25ft.lbs.

8 ftlbs.2

I24 Nm

22 Nm17 f-tlbsad/16 ft.lbs.

11 klbs.

112/Nm8 ftlbs.M37TA.

_Removal steps

I. Return hose

2. Suction hose

3. Return hose

l a 4. Pressure hose

5. O-ring6. Cooler tube

7. Pressure tube

8. Return tube

9. O-ring

IO. Oil reservoir

3

White line

13po14:

SERVICE POINT OF INSTALLATIONM3TTDAG

4. INSTALLATION OF PRESSURE HOSE

(1) Connect the pressure hose so that its slit part contacts

the oil pump’s guide bracket.

(2) When the pressure hose is installed, align the white line

on the pressure hose with the white line on the

pressure tube so that together they form a straight line.

TSB Revision