MITSUBISHI 3000GT 1991 Service Manual

3000GT 1991

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57085/w960_57085-0.png

MITSUBISHI 3000GT 1991 Service Manual

Trending: oil dipstick, wiring diagram, tow, window, mileage, hood open, light

Page 891 of 1146

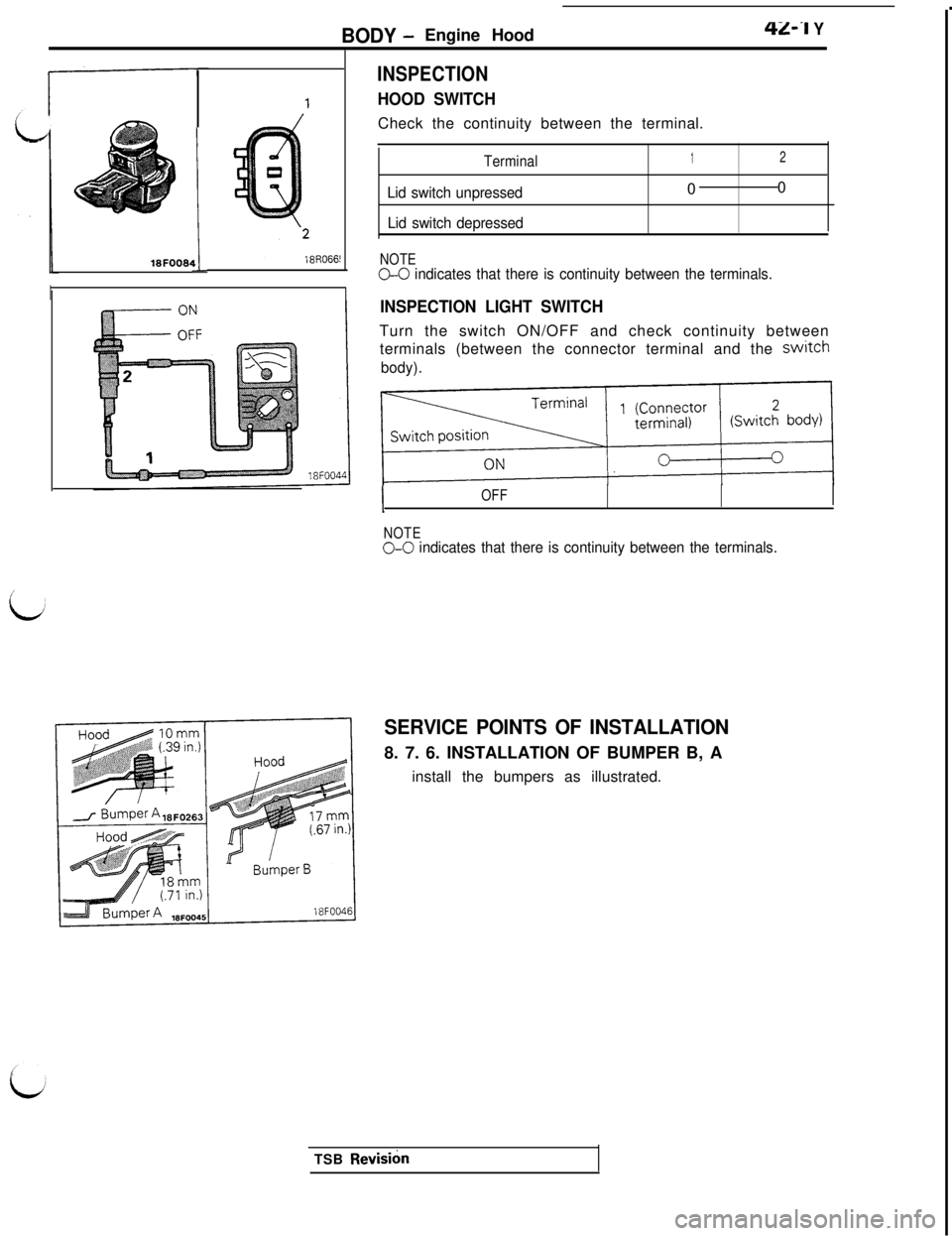

BODY -Engine Hood42-I Y18FOOW

!I

II

INSPECTION

HOOD SWITCHCheck the continuity between the terminal.

Terminal

Lid switch unpressed

Lid switch depressed

1200

NOTEG-0 indicates that there is continuity between the terminals.

INSPECTION LIGHT SWITCHTurn the switch ON/OFF and check continuity between

terminals (between the connector terminal and the

switch

body).

IOFF

NOTE

O-0 indicates that there is continuity between the terminals.

t

SERVICE POINTS OF INSTALLATION8. 7. 6. INSTALLATION OF BUMPER B, A

install the bumpers as illustrated.

TSB

Revish

Page 892 of 1146

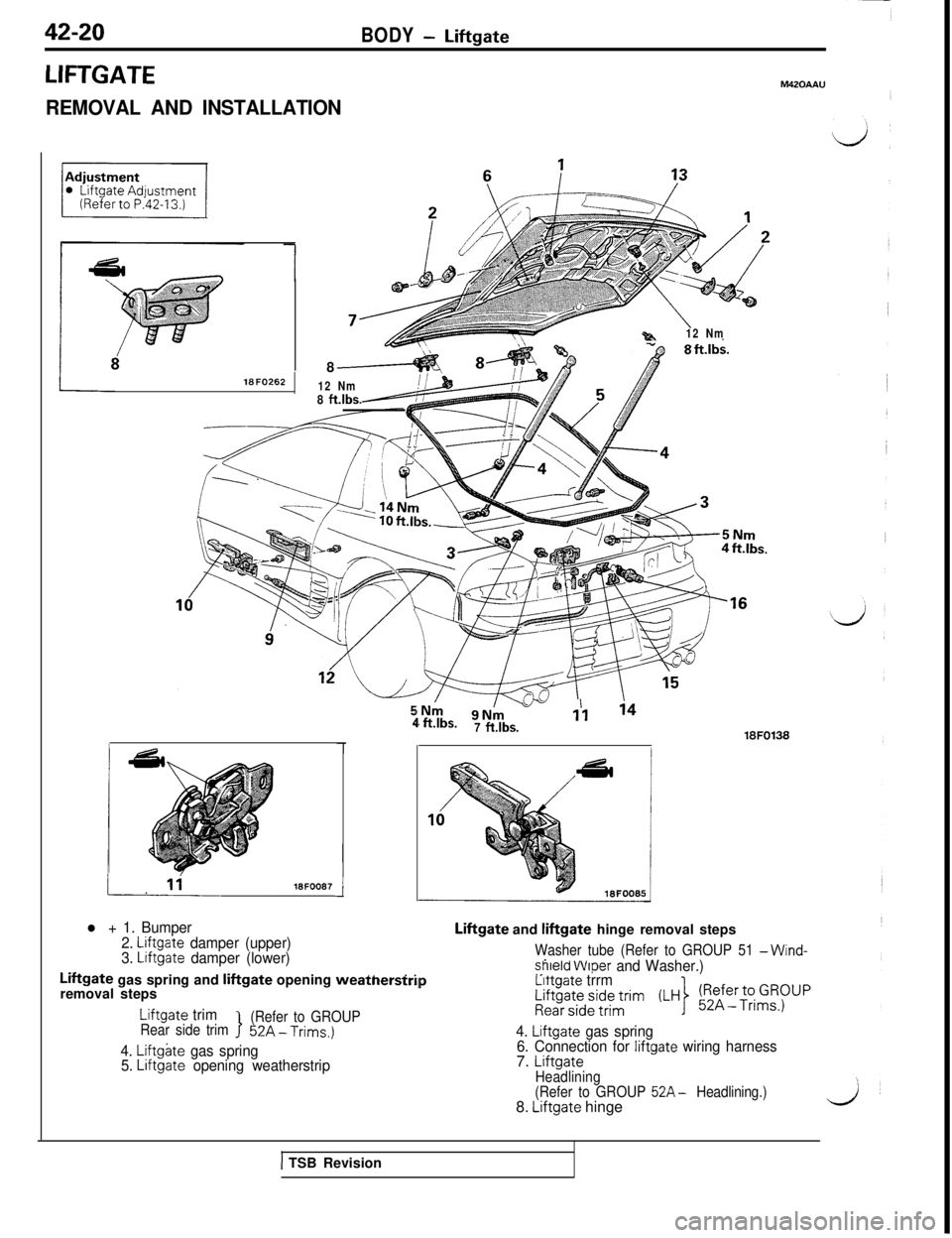

42-20BODY- Liftgate

LIFTGATEM420AAU

REMOVAL AND INSTALLATION8lSFO262

12 Nm8 ft.lbs.

%a12 Nm

18FOO87

l + 1. Bumper

2. Liftgate damper (upper)

3. Liftgate damper (lower)

1

4, ft.‘bs.1’1 ‘47 ftlbs.18FO138Liftgate and

liftgate hinge removal steps

Washer tube (Refer to GROUP 51 -Wind-

.

. .shield Wtper and Washer.). .._Liftgate gas spring and liftgate opening weatnerstrllp

removal steps

Liftgate trimRear side trim>

(Refer to GROUP52A-Trims.)

4. Liftgate gas spring

5. Liftgate opening weatherstrip

Lrttgate trrmi$ftft;e$d;nm (LH) !!-!-~~~G$)upi

4. Liftgate gas spring

6. Connection for liftgate wiring harness7. LiftgateHeadlining

(Refer to GROUP 52A- Headlining.)8. Liftgate hinge

1 TSB Revision

Page 893 of 1146

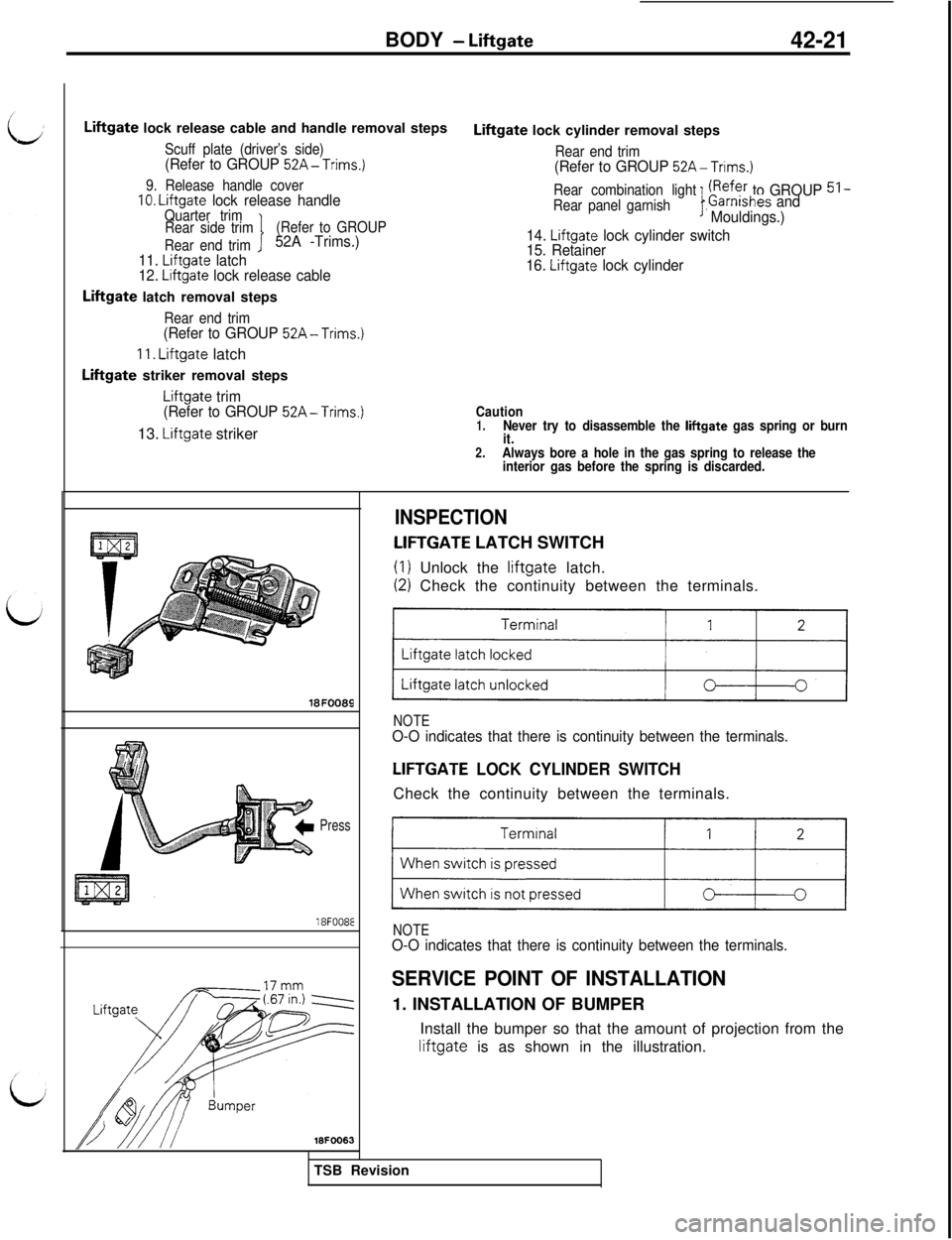

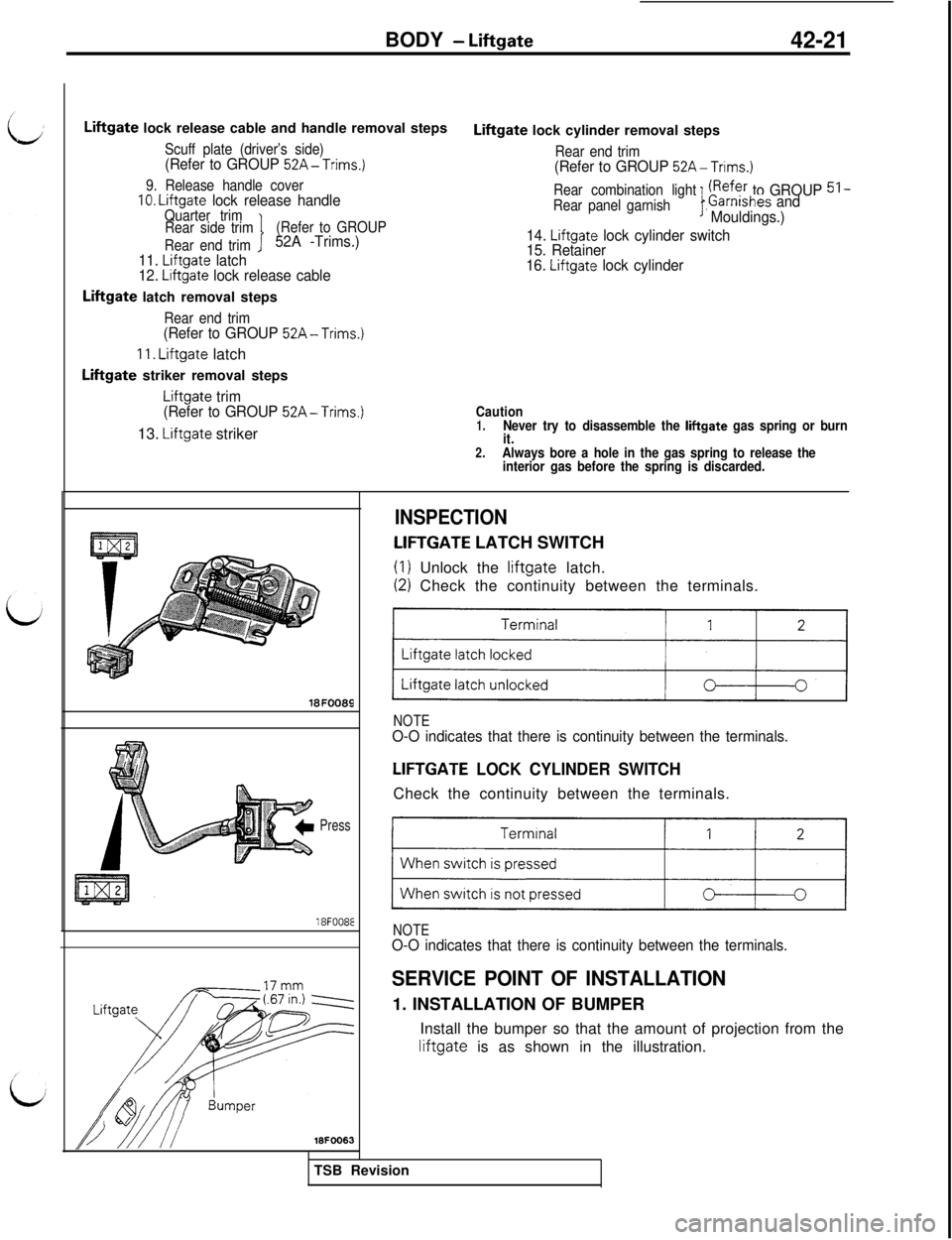

BODY - Liftgate42-21

Liftgate lock release cable and handle removal steps

Scuff plate (driver’s side)(Refer to GROUP 52A-Trims.)

9. Release handle cover10. Liftgate lock release handleQuarter trim

Rear side trim(Refer to GROUP

Rear end trim

I52A -Trims.)

11.

Liftgate latch

12. Liftgate lock release cable

Liftgate latch removal steps

Rear end trim(Refer to GROUP 52A-Trims.)

11. Liftgate latch

Liftgate striker removal steps

Liftgate trim

(Refer to GROUP 52A-Trims.)13.

Liftgate strikerLiftgate lock cylinder removal steps

Rear end trim(Refer to GROUP 52A-Trims.)

Rear combination light

I

fRefer to GROUP 51 -Rear panel garnish,Garnishes and

Mouldings.)

14.

Liftgate lock cylinder switch

15. Retainer

16.

Liftgate lock cylinder

Caution1.Never try to disassemble the liftgate gas spring or burn

it.

2.Always bore a hole in the gas spring to release the

interior gas before the spring is discarded.

18FOO89

Press

18F008E

18FOO63

INSPECTION

LIFTGATE LATCH SWITCH

(I) Unlock the liftgate latch.

(2) Check the continuity between the terminals.

)I

NOTEO-O indicates that there is continuity between the terminals.

LIFTGATE LOCK CYLINDER SWITCHCheck the continuity between the terminals.

11

NOTEO-O indicates that there is continuity between the terminals.

SERVICE POINT OF INSTALLATION1. INSTALLATION OF BUMPER

Install the bumper so that the amount of projection from theliftgate is as shown in the illustration.

TSB Revision

Page 894 of 1146

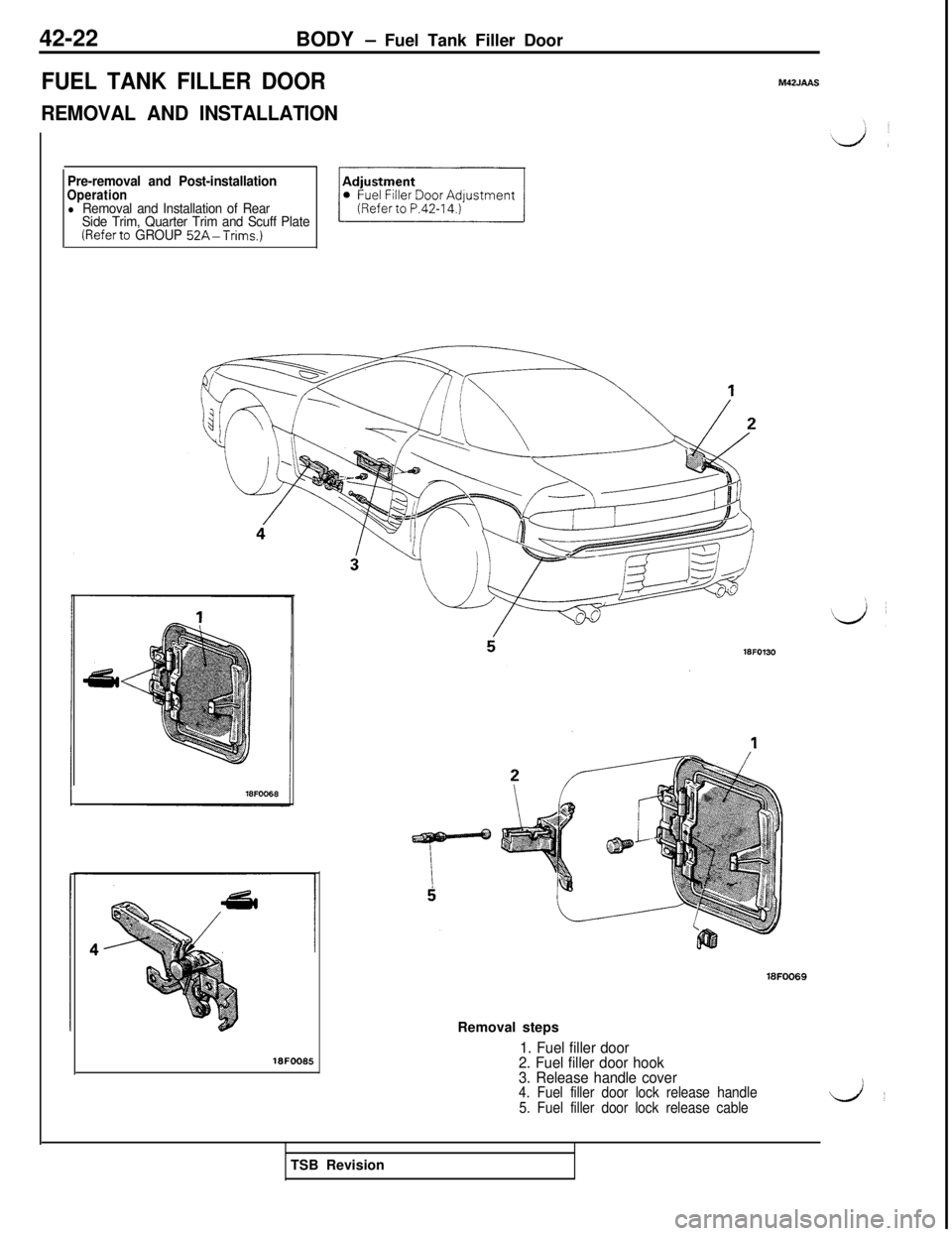

42-22BODY - Fuel Tank Filler Door

FUEL TANK FILLER DOOR

REMOVAL AND INSTALLATION

M42JAAS

Pre-removal and Post-installationOperationl Removal and Installation of Rear

Side Trim, Quarter Trim and Scuff Plate

(Referto GROUP 52A-Trims.)

18FOO86

18FOO69Removal steps

1. Fuel filler door

2. Fuel filler door hook

3. Release handle cover

4. Fuel filler door lock release handle

5. Fuel filler door lock release cableLA’TSB Revision

Page 895 of 1146

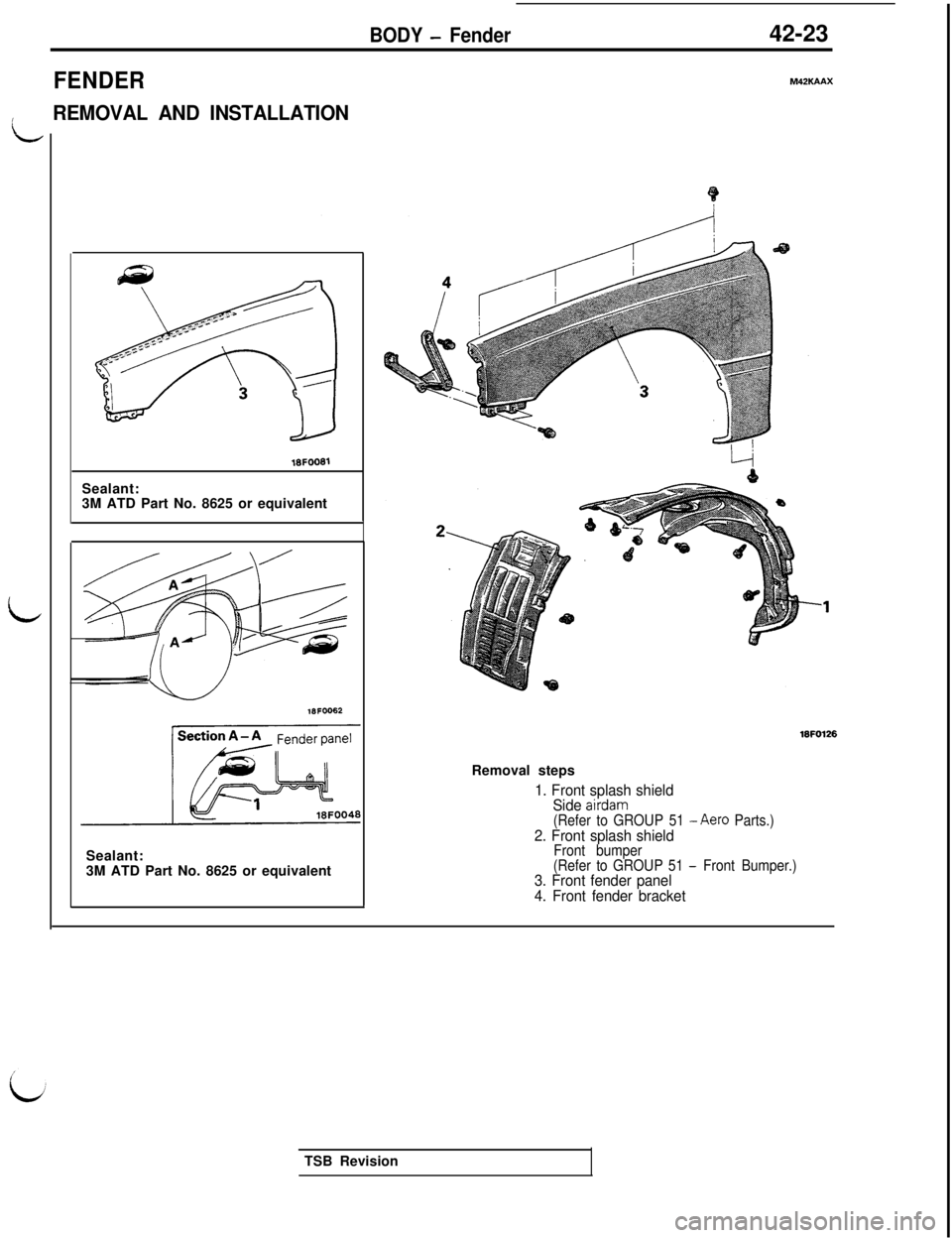

BODY - Fender42-23

FENDER

L

REMOVAL AND INSTALLATIONSealant:

16FOO613M ATD Part No. 8625 or equivalent

18FOO62Sealant:

3M ATD Part No. 8625 or equivalent

M42KAAX

16FO126Removal steps

1. Front splash shield

Side airdam(Refer to GROUP 51 -Aero Parts.)2. Front splash shieldFront bumper

(Refer to GROUP 51 - Front Bumper.)3. Front fender panel

4. Front fender bracketTSB Revision

Page 896 of 1146

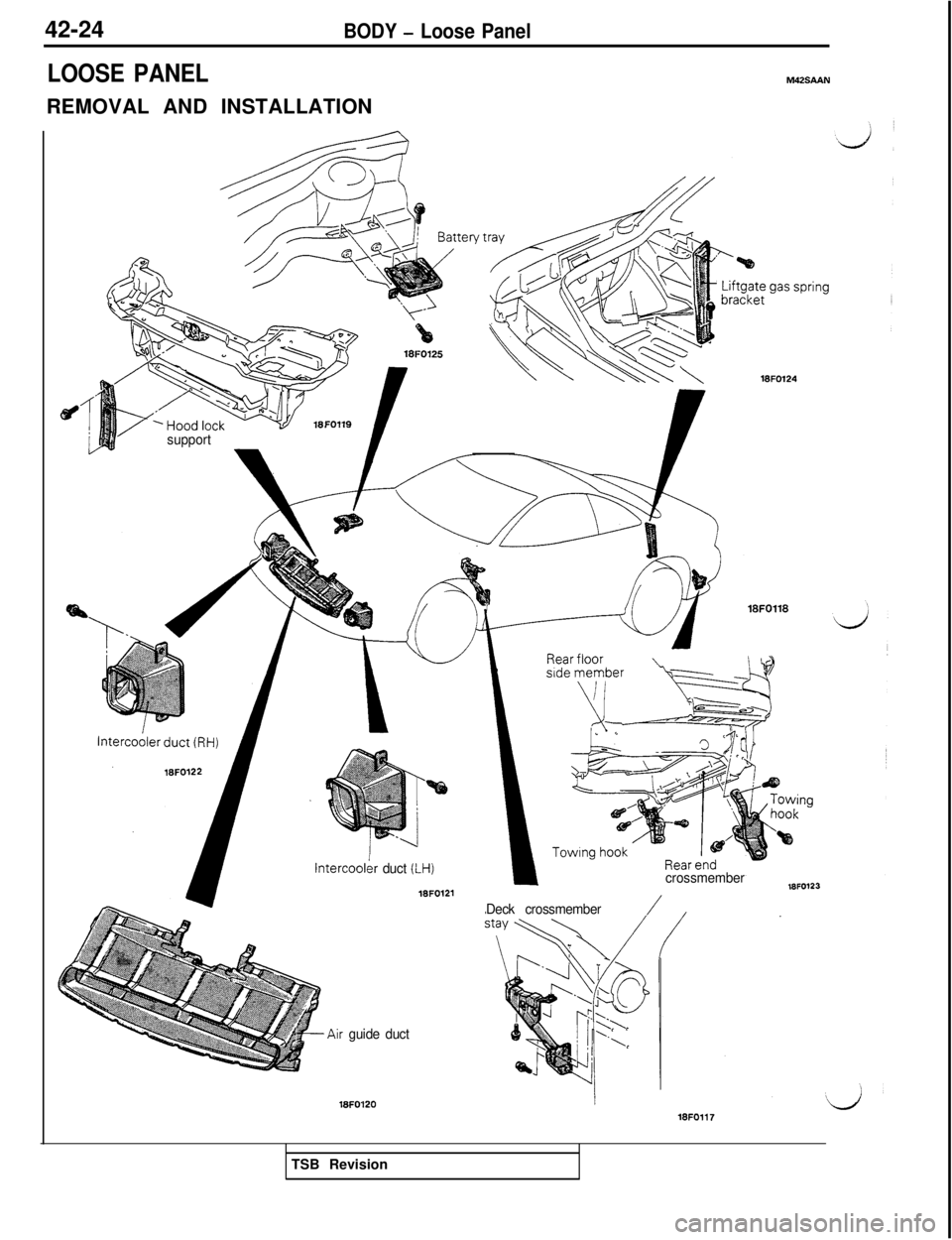

42-24BODY - Loose Panel

LOOSE PANELREMOVAL AND INSTALLATIONM42SAAN

FOllQ

support

lntercoolkr duct (1-H)

16FO121

&Air guide duct

16FOl20

16FO124

Deck crossmember/

crossmember18FO123

18FOll7TSB Revision

Page 897 of 1146

BODY - Window Glass

42-25

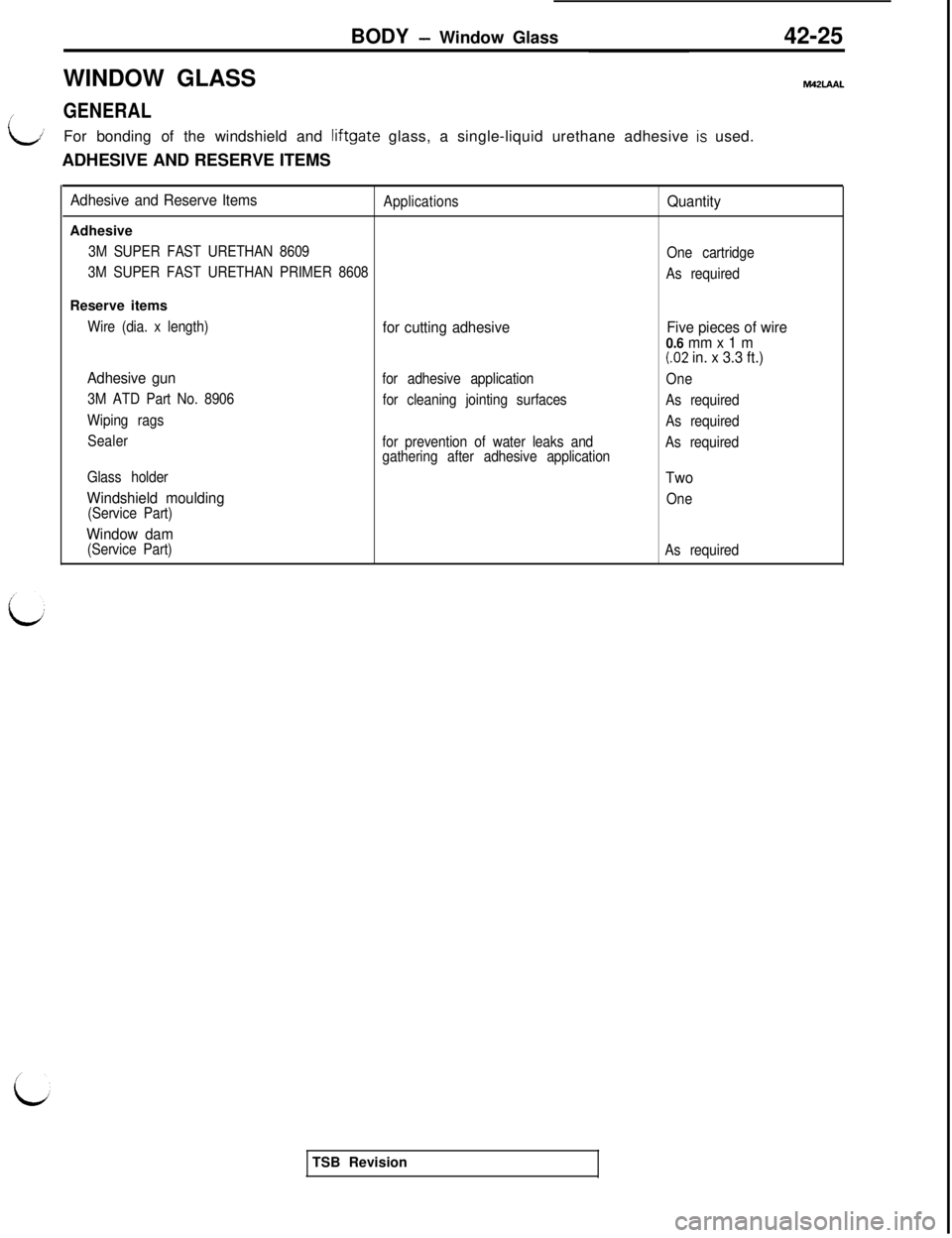

WINDOW GLASS

M42LAAL

/GENERAL

LiFor bonding of the windshield and liftgate glass, a single-liquid urethane adhesive is used.

ADHESIVE AND RESERVE ITEMS

Adhesive and Reserve ItemsApplicationsQuantityAdhesive

3M SUPER FAST URETHAN 8609

One cartridge

3M SUPER FAST URETHAN PRIMER 8608

As requiredReserve items

Wire (dia. x length)for cutting adhesiveFive pieces of wire

0.6 mm x 1 m

f.02 in. x 3.3 ft.)

Adhesive gun

for adhesive application

One

3M ATD Part No. 8906

for cleaning jointing surfaces

As required

Wiping rags

As required

Sealer

for prevention of water leaks and

gathering after adhesive applicationAs required

Glass holder

Two

Windshield moulding

One

(Service Part)

Window dam(Service Part)

As requiredTSB Revision

Page 898 of 1146

42-26

BODY - Window Glass

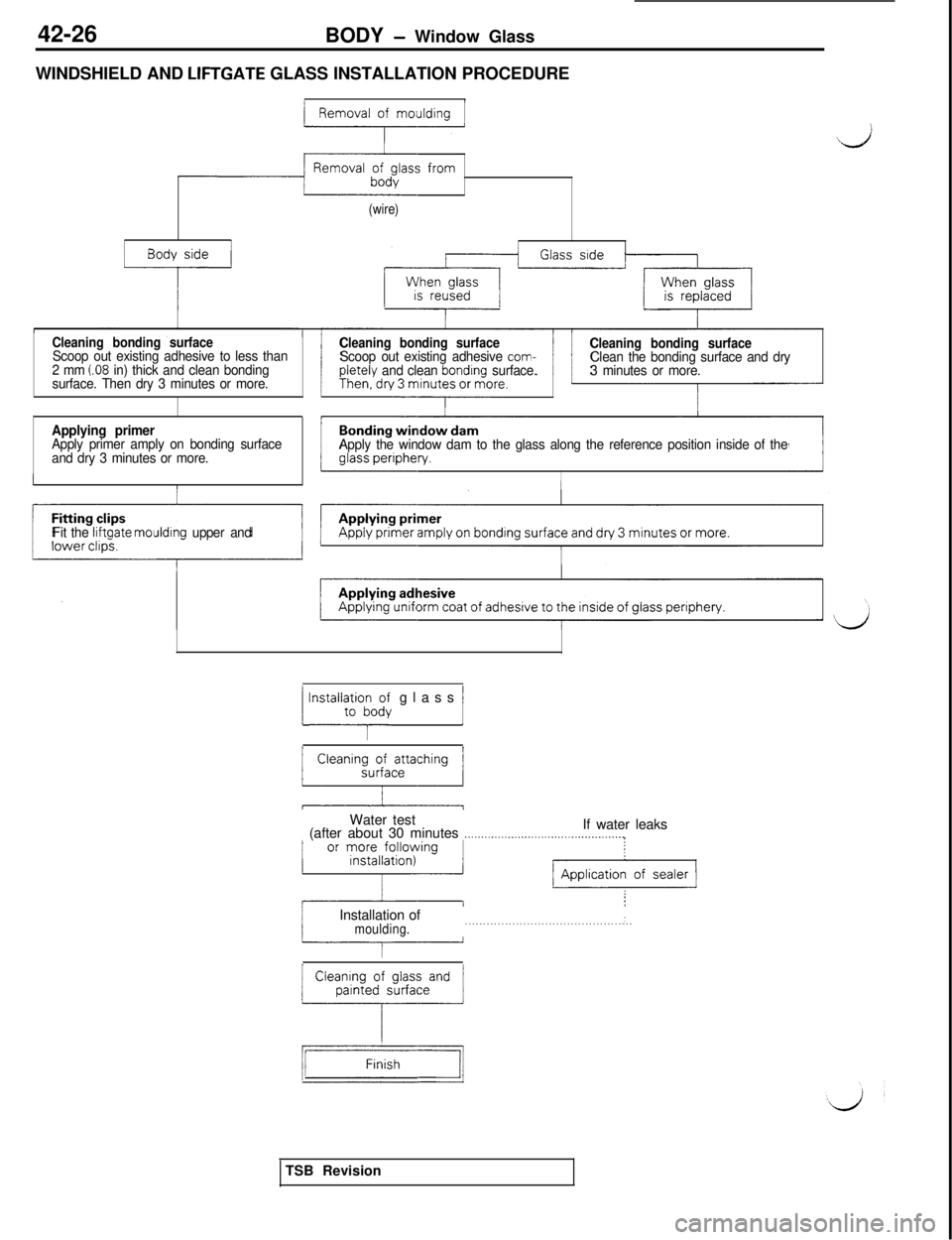

WINDSHIELD AND

LIFTGATE GLASS INSTALLATION PROCEDURE

Removal of

moutding

-4

(wire)

Body side

-i---

Cleaning bonding surfaceScoop out existing adhesive to less than

2 mm (.08 in) thick and clean bonding

surface. Then dry 3 minutes or more.

Cleaning bonding surfaceScoop out existing adhesive com-pletely and clean bondrng surface.

Cleaning bonding surfaceClean the bonding surface and dry

3 minutes or more.

Applying primerApply primer amply on bonding surface

and dry 3 minutes or more.Apply the window dam to the glass along the reference position inside of the

I

Fit the liftgate mouldrng upper and

1 lnstall;rtoio~;~ glass 1Water test

If water leaks

(after about 30 minutes

_............__,,,__........,........,.....,,,..,

IInstallation ofmoulding.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~

Cleaning of glass andpainted surface

L

--ITSB Revision

Page 899 of 1146

BODY -Window Glass42-27

/

L

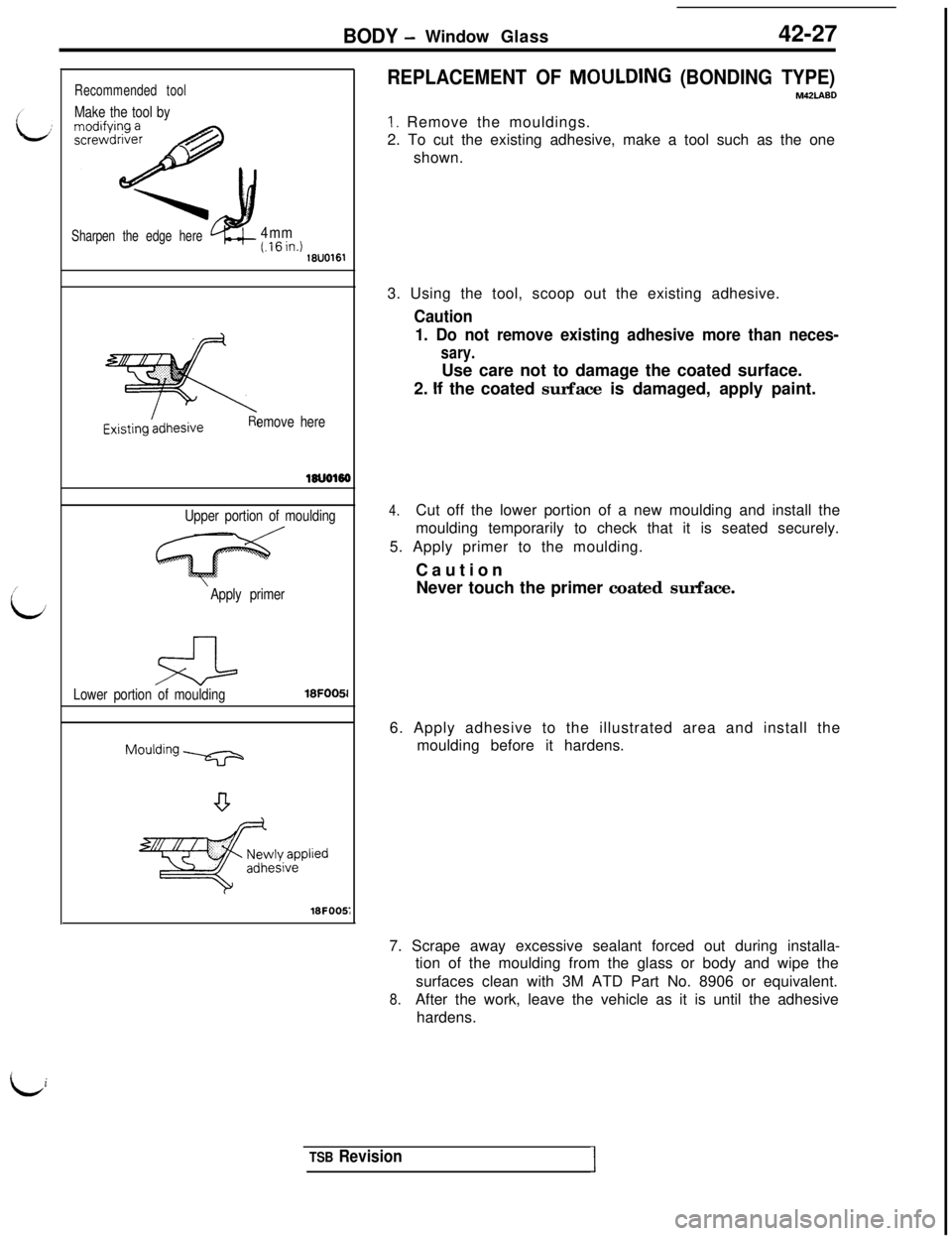

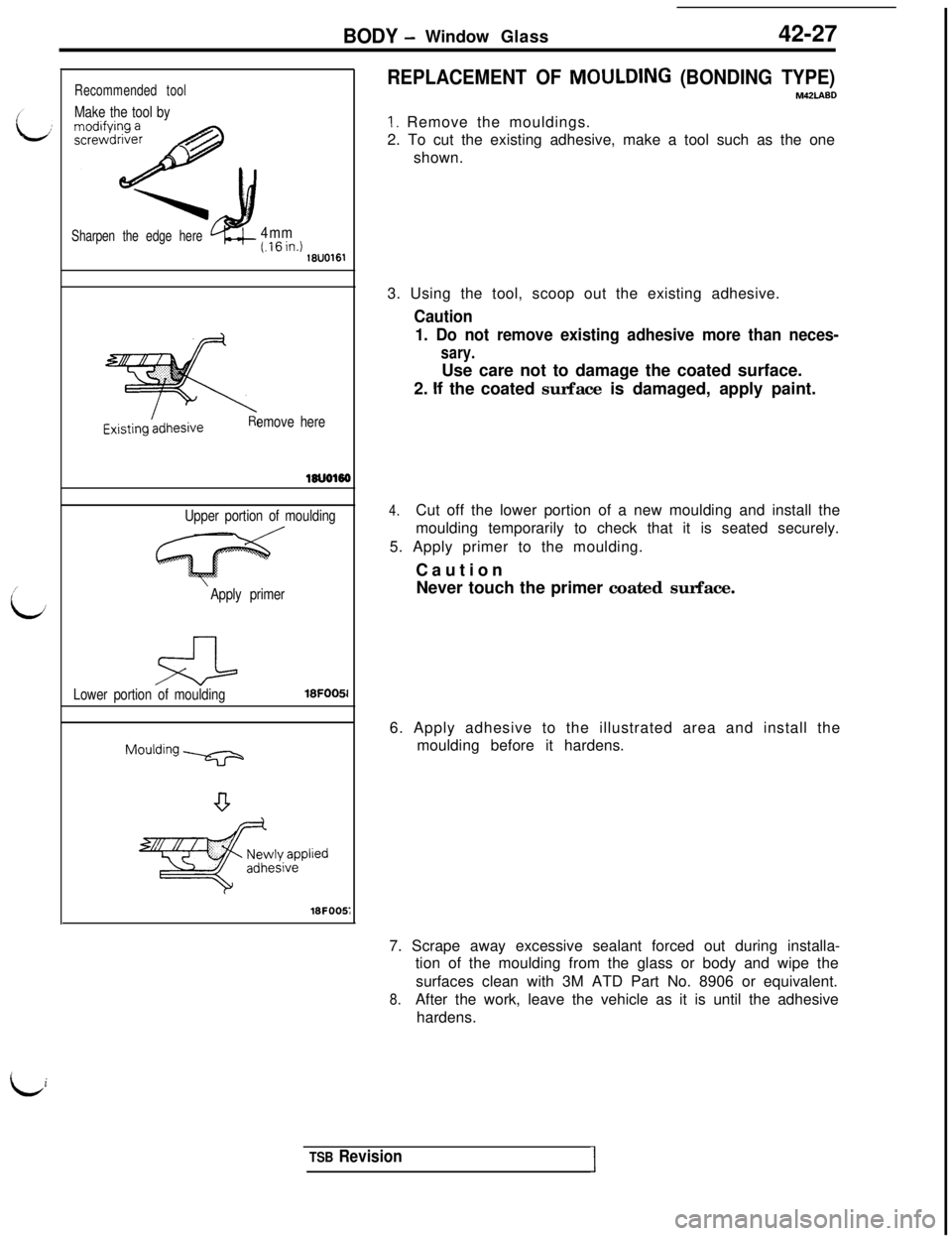

Recommended tool

Make the tool by

Sharpen the edge here4mm(.16in.)18UO161

emove here

lsuo16a/

Upper portion of moulding

Apply primer

Lower portion of moulding

Mou’ding v

18FOO51

REPLACEMENT OF MOULDING (BONDING TYPE)M42LA80

1. Remove the mouldings.

2. To cut the existing adhesive, make a tool such as the one

shown.

3. Using the tool, scoop out the existing adhesive.

Caution

1. Do not remove existing adhesive more than neces-

sary.Use care not to damage the coated surface.

2.

If the coated surface is damaged, apply paint.

4.Cut off the lower portion of a new moulding and install the

moulding temporarily to check that it is seated securely.

5. Apply primer to the moulding.

Caution

Never touch the primer coated surface.

6. Apply adhesive to the illustrated area and install the

moulding before it hardens.

7. Scrape away excessive sealant forced out during installa-

tion of the moulding from the glass or body and wipe the

surfaces clean with 3M ATD Part No. 8906 or equivalent.

8.After the work, leave the vehicle as it is until the adhesive

hardens.

Li

TSB RevisionI

Page 900 of 1146

42-28

BODY - Windshield

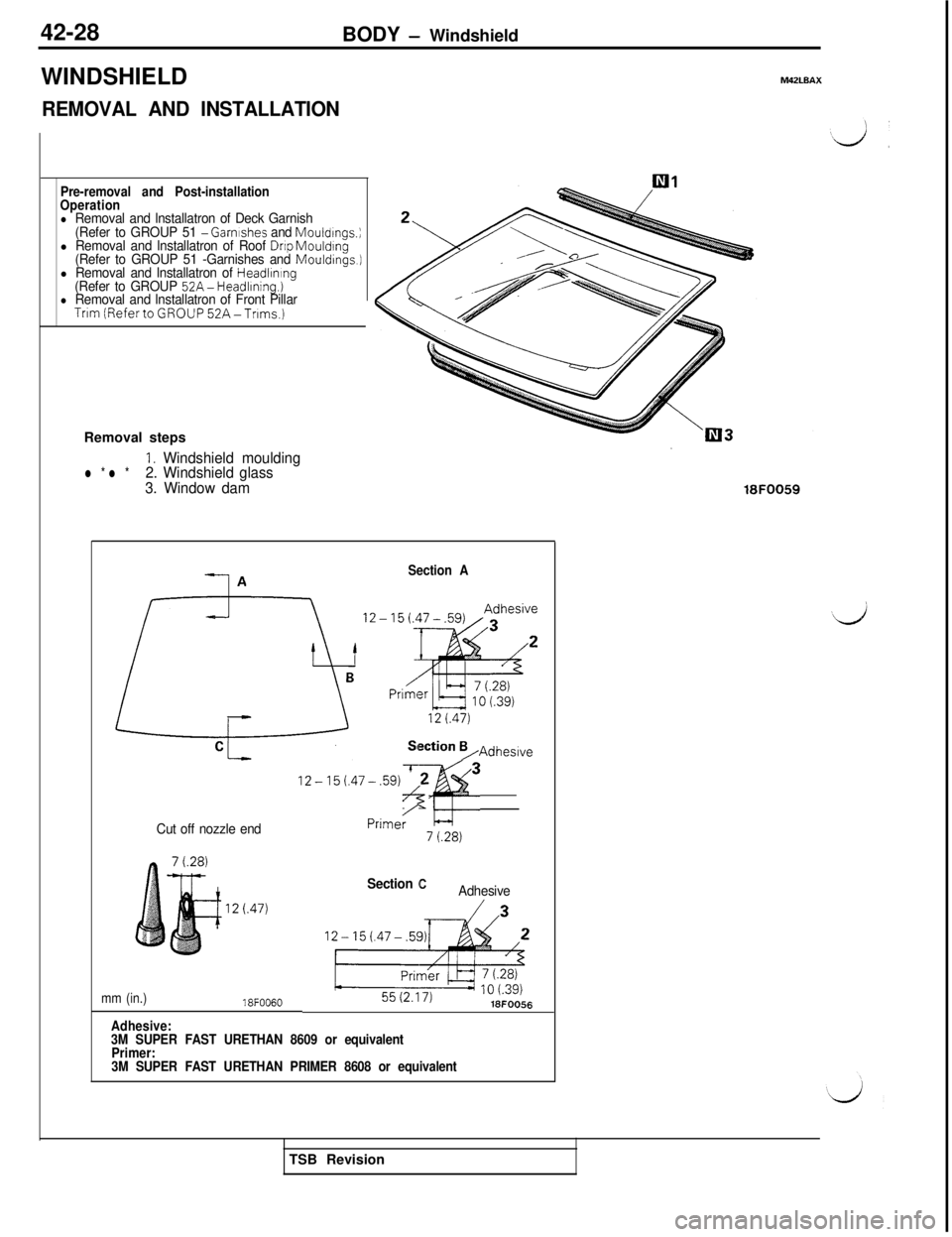

WINDSHIELD

REMOVAL AND INSTALLATION

M42LBAX

Pre-removal and Post-installation

Operation

l Removal and lnstallatron of Deck Garnish

(Refer to GROUP 51 - Garnrshes and Mouldrngs.;l Removal and lnstallatron of Roof Drop Mouldrng(Refer to GROUP 51 -Garnishes and Mouldings.]l Removal and lnstallatron of Headlrnrng(Refer to GROUP 52A- Headlrning.)l Removal and lnstallatron of Front PillarTrim (RefertoGROUP52A-Tnms.)

Removal steps

1. Windshield mouldingl * l *2. Windshield glass

3. Window dam

18FOO59

Cut off nozzle end

mm (in.)18FOO60

Section ASection =,Adheswe

12-l5..47-.59jT;F,<

/

Section CAdhesive

Adhesive:

3M SUPER FAST URETHAN 8609 or equivalent

Primer:

3M SUPER FAST URETHAN PRIMER 8608 or equivalentTSB Revision

Trending: jump start terminals, tires, mileage, oil viscosity, wiring diagram, window, remove seats