MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 931 of 1146

BODY - Central Door Locking System

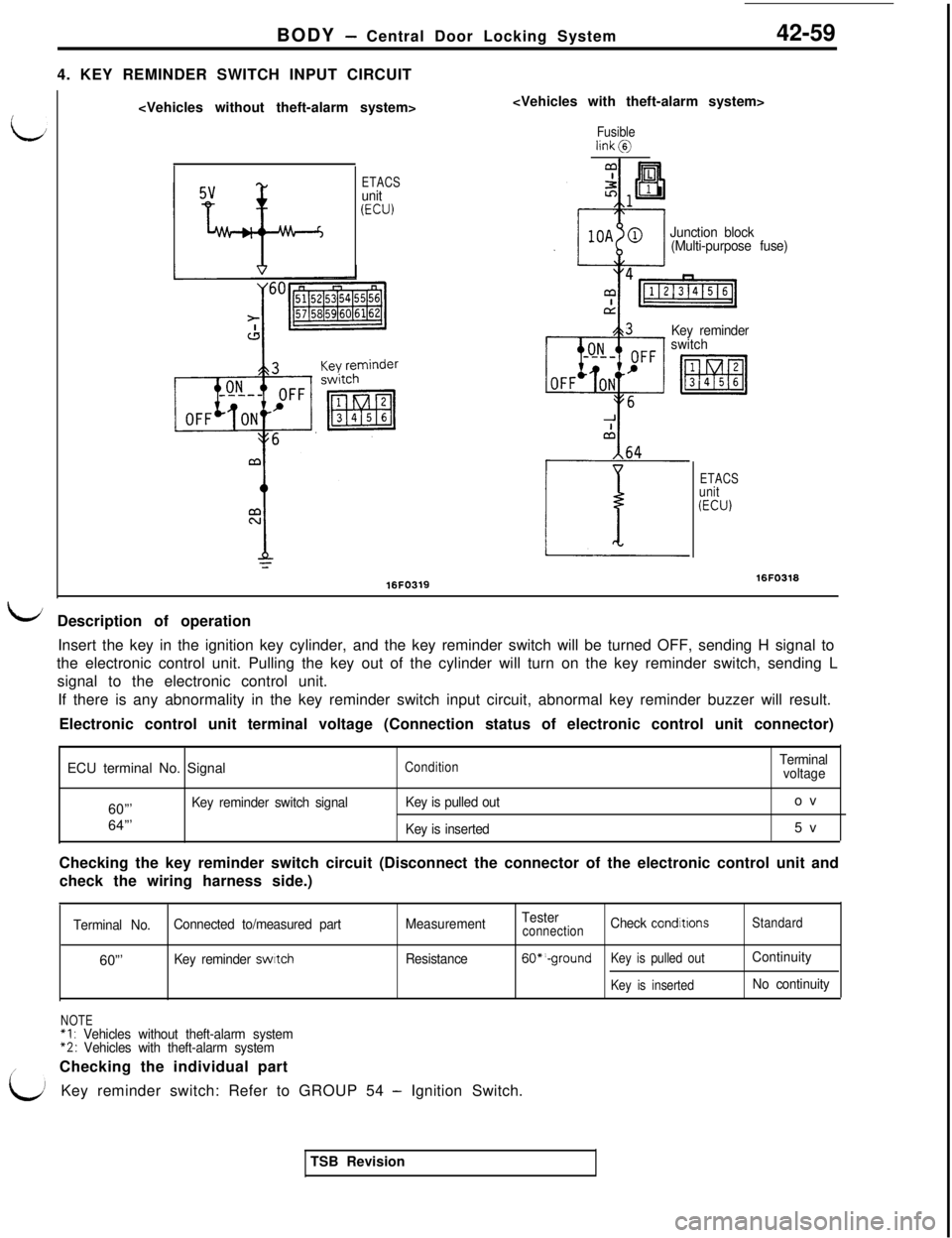

4. KEY REMINDER SWITCH INPUT CIRCUIT42-59

Fusiblelink@

ETACSunit(ECU)

16FO319

Junction block

(Multi-purpose fuse)

Key reminder

switch

ETACSunit(ECU)

16FO318

bDescription of operation

Insert the key in the ignition key cylinder, and the key reminder switch will be turned OFF, sending H signal to

the electronic control unit. Pulling the key out of the cylinder will turn on the key reminder switch, sending L

signal to the electronic control unit.

If there is any abnormality in the key reminder switch input circuit, abnormal key reminder buzzer will result.

Electronic control unit terminal voltage (Connection status of electronic control unit connector)

ECU terminal No. Signal

ConditionTerminal

voltage60”’

Key reminder switch signalKey is pulled outov

64”’

Key is inserted5v

Checking the key reminder switch circuit (Disconnect the connector of the electronic control unit and

check the wiring harness side.)

Terminal No.Connected to/measured partMeasurementTesterconnectionCheck conditronsStandard60”’

Key reminder swatchResistance60*‘-groundKey is pulled outContinuity

Key is insertedNo continuity

NOTE“I : Vehicles without theft-alarm system*2: Vehicles with theft-alarm system

/Checking the individual part

’Key reminder switch: Refer to GROUP 54 - Ignition Switch.

TSB Revision

Page 932 of 1146

42-60

BODY - Central Door Locking System

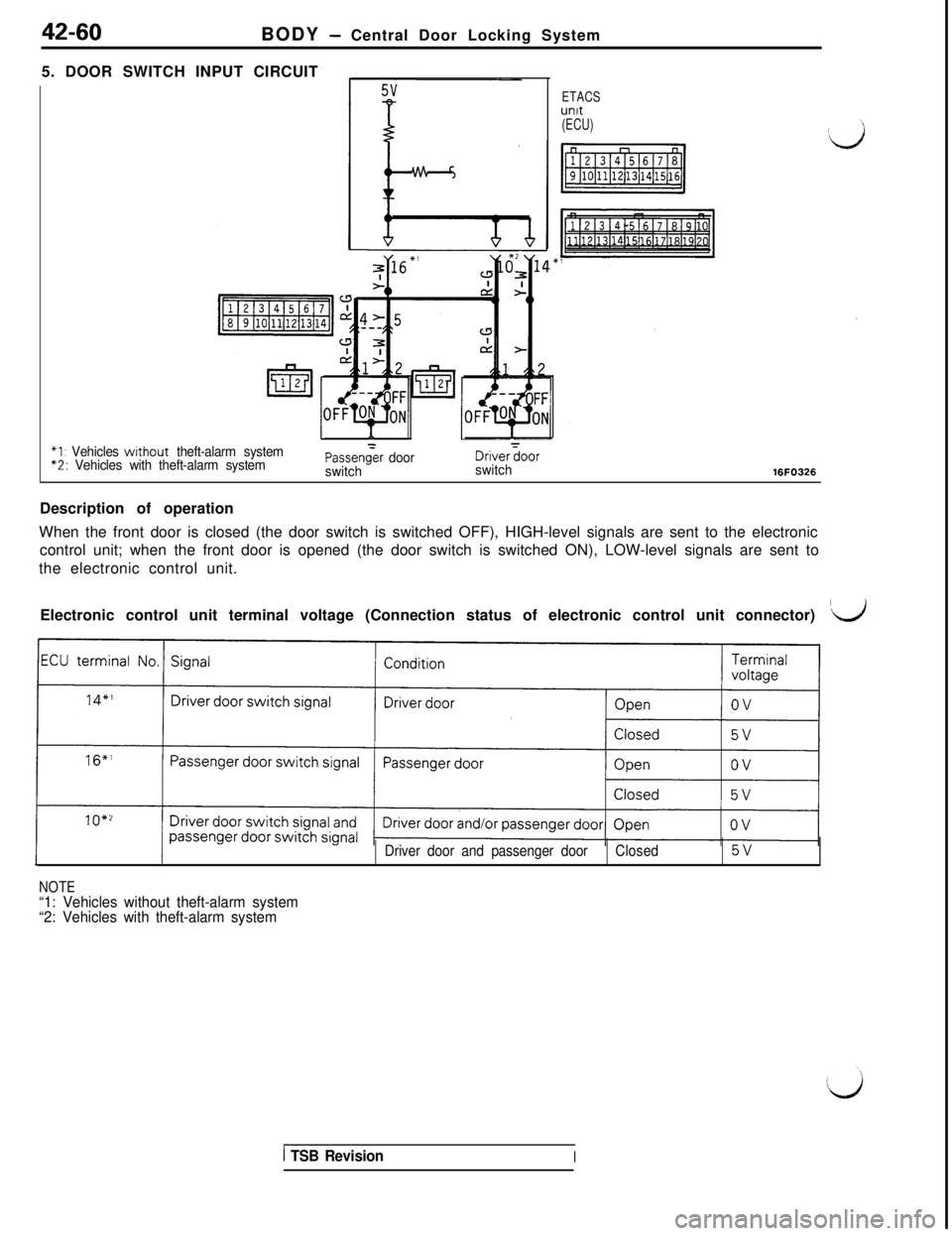

5. DOOR SWITCH INPUT CIRCUIT

ETACSunit(ECU)

*1 : Vehicles without theft-alarm system*2: Vehicles with theft-alarm systemPassen&r door

switchDrivergoorswitch16FO326Description of operation

When the front door is closed (the door switch is switched OFF), HIGH-level signals are sent to the electronic

control unit; when the front door is opened (the door switch is switched ON), LOW-level signals are sent to

the electronic control unit.

Electronic control unit terminal voltage (Connection status of electronic control unit connector)

’d

NOTE

Driver door and passenger doorClosed5v

“1: Vehicles without theft-alarm system

“2: Vehicles with theft-alarm system

1 TSB RevisionI

Page 933 of 1146

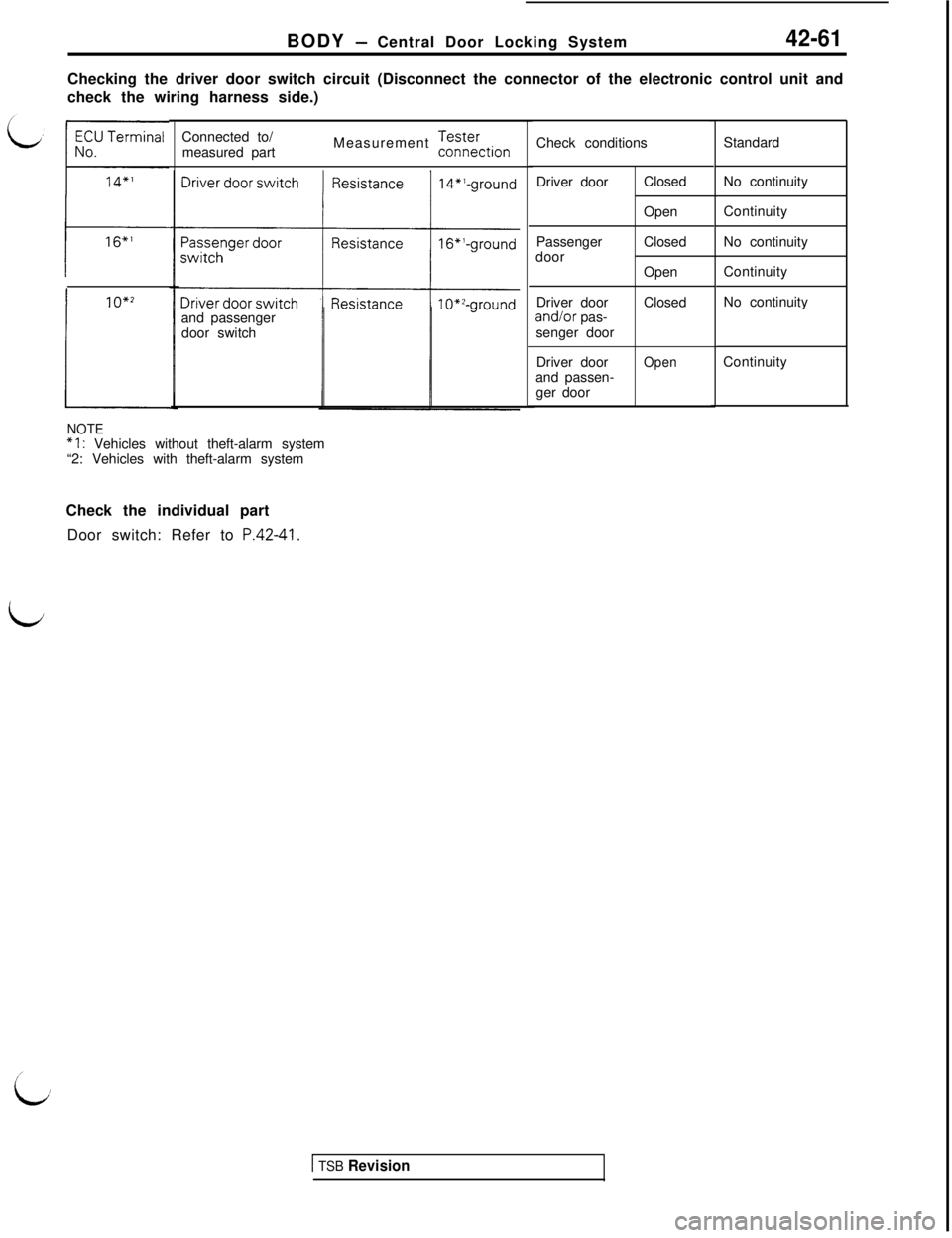

BODY - Central Door Locking System42-61Checking the driver door switch circuit (Disconnect the connector of the electronic control unit and

check the wiring harness side.)

and passenger

door switch

1O*2

i

NOTE“I : Vehicles without theft-alarm system

“2: Vehicles with theft-alarm systemConnected to/

measured partMeasurement -ff~~e~rionCheck conditionsStandard

Driver doorClosed

Open

Passenger

doorClosed

Open

Driver doorClosedand/or pas-

senger doorNo continuity

Continuity

No continuity

Continuity

No continuity

Driver door

Openand passen-

ger doorContinuity

Check the individual part

Door switch: Refer to

P.42-41.

id

1 TSB Revision

Page 934 of 1146

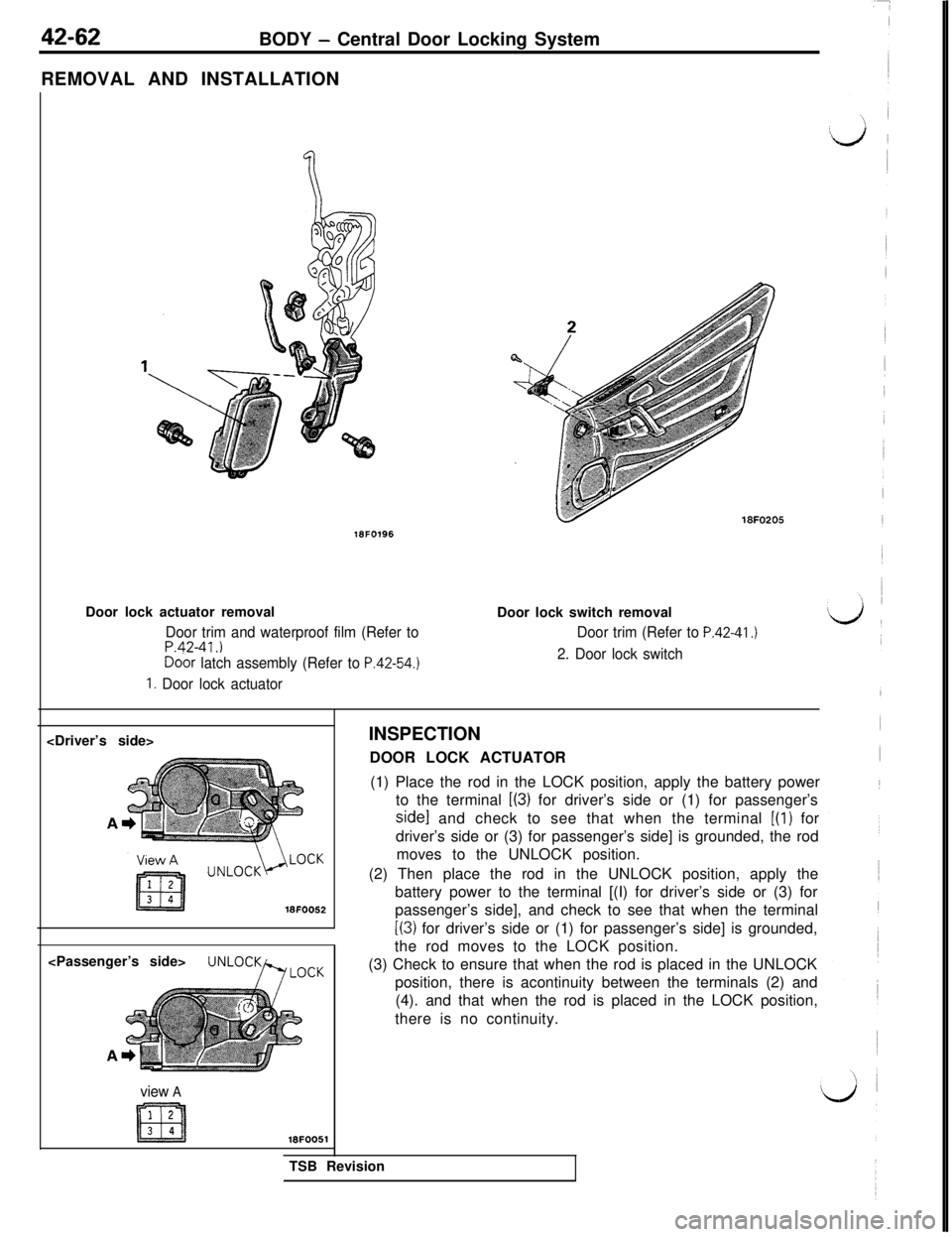

42-62BODY - Central Door Locking System

REMOVAL AND INSTALLATION16FO196

Door lock actuator removal

Door trim and waterproof film (Refer toP.42-41.)Do&

latch assembly (Refer to P.42-54.)

1. Door lock actuator

18FO205Door lock switch removal

Door trim (Refer to P.42-41.)

2. Door lock switch

view A16FOO51INSPECTION

DOOR LOCK ACTUATOR

(1) Place the rod in the LOCK position, apply the battery power

to the terminal

L(3) for driver’s side or (1) for passenger’s

side1 and check to see that when the terminal [(l) for

driver’s side or (3) for passenger’s side] is grounded, the rod

moves to the UNLOCK position.

(2) Then place the rod in the UNLOCK position, apply the

battery power to the terminal [(I) for driver’s side or (3) for

passenger’s side], and check to see that when the terminal

[(3) for driver’s side or (1) for passenger’s side] is grounded,

the rod moves to the LOCK position.

(3) Check to ensure that when the rod is placed in the UNLOCK

position, there is acontinuity between the terminals (2) and

(4). and that when the rod is placed in the LOCK position,

there is no continuity.

TSB Revision

Page 935 of 1146

BODY - Central Door Lockina Svstem42-63

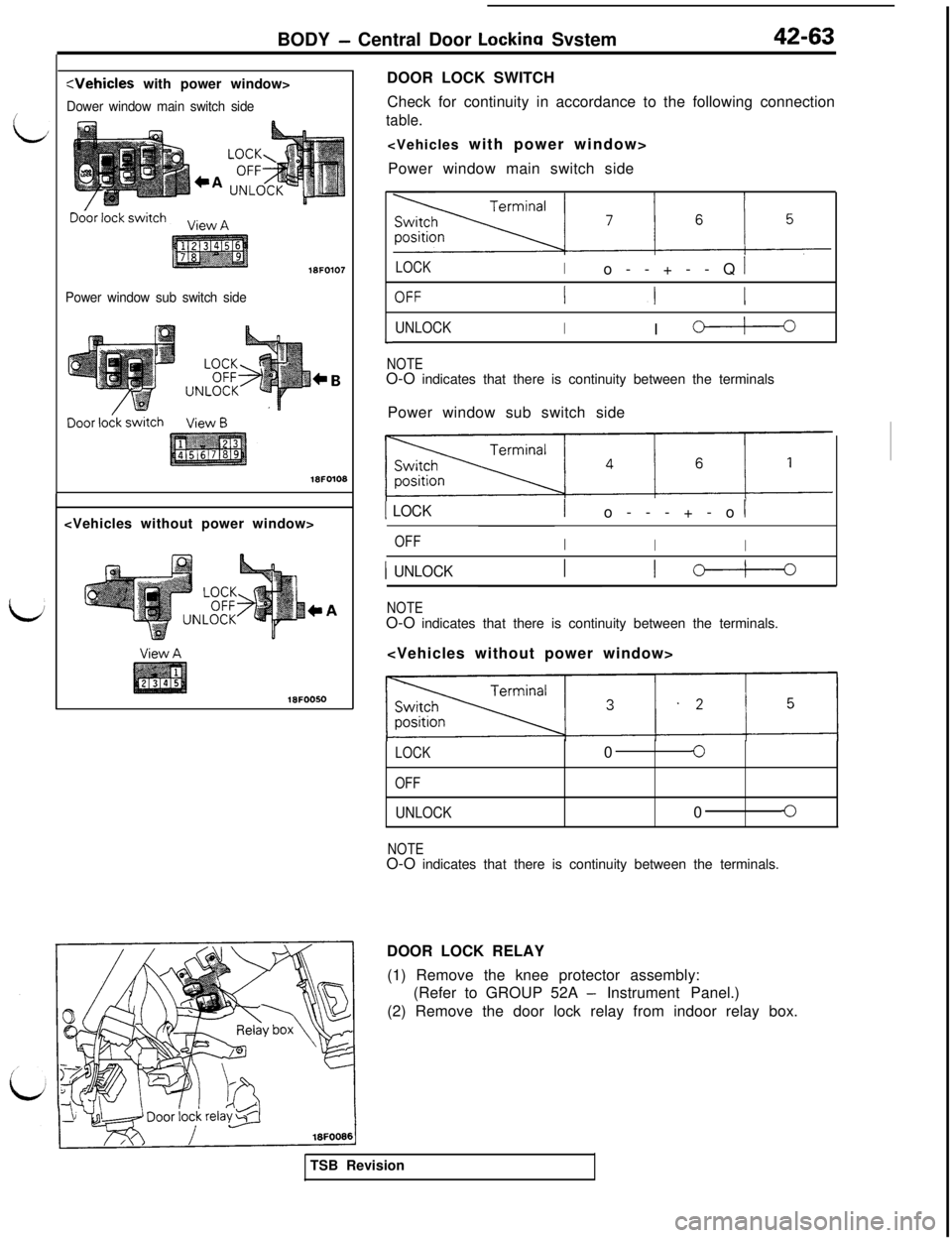

:Vehicles with power window>

Dower window main switch side

Power window sub switch side

18FO107

Check for continuity in accordance to the following connection

table.

Power window main switch side

LOCKIo--+--Q I

UNLOCKII c-+---oL

NOTEO-O indicates that there is continuity between the terminals

Power window sub switch side

1 LOCKIo---+-o I

OFFII

I

1 UNLOCKI c--+--

NOTEO-O indicates that there is continuity between the terminals.

LOCK00

OFF

UNLOCK00

NOTEO-O indicates that there is continuity between the terminals.

DOOR LOCK RELAY

(1) Remove the knee protector assembly:

(Refer to GROUP 52A

- Instrument Panel.)

(2) Remove the door lock relay from indoor relay box.

TSB Revision

Page 936 of 1146

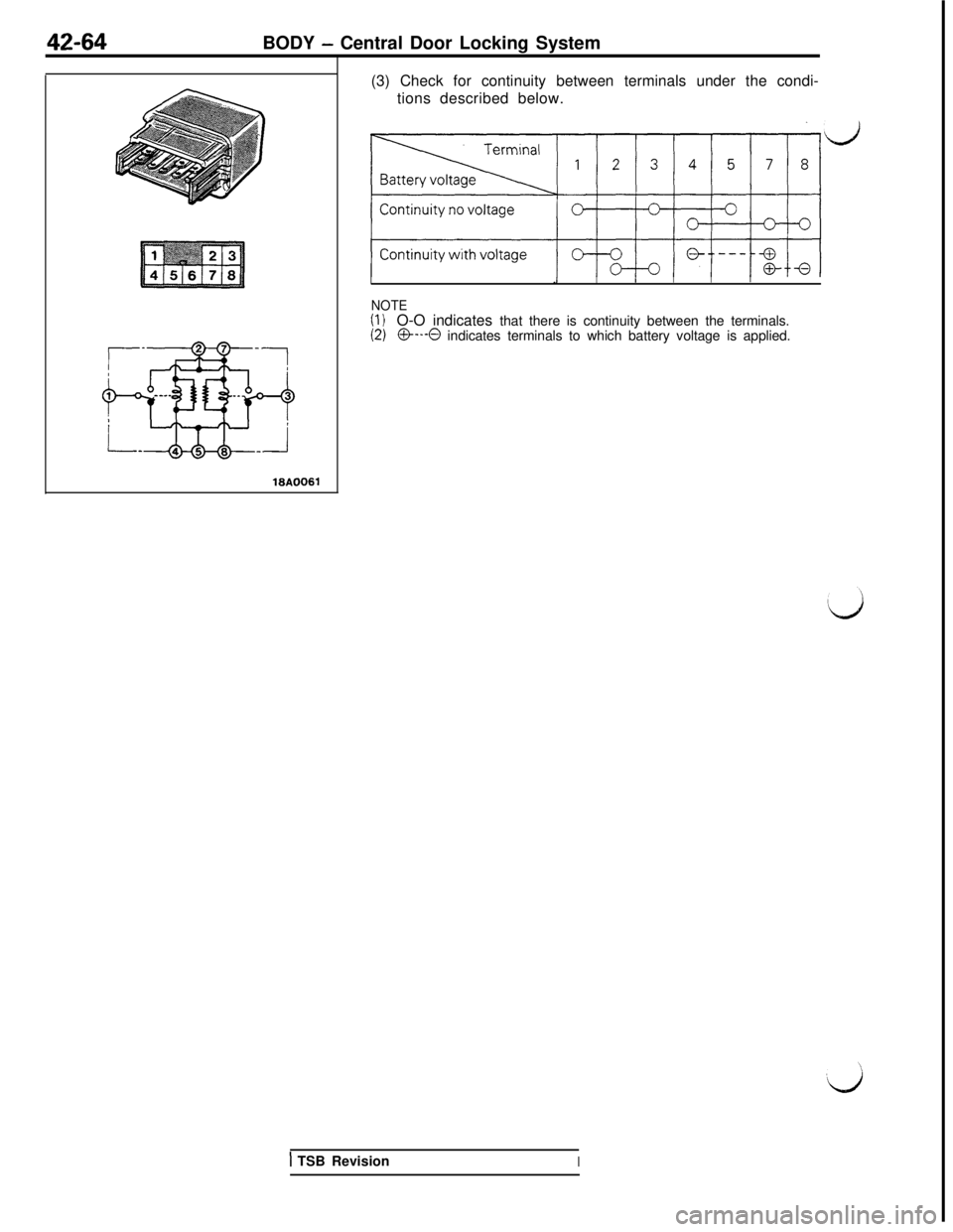

42-64BODY - Central Door Locking System

(3) Check for continuity between terminals under the condi-

tions described below.

I.IIIIII

NOTE(I )O-O indicates that there is continuity between the terminals.(2)O---O indicates terminals to which battery voltage is applied.

1 TSB RevisionI

Page 937 of 1146

BODY - Drir, Line Weatherstrir,42-65

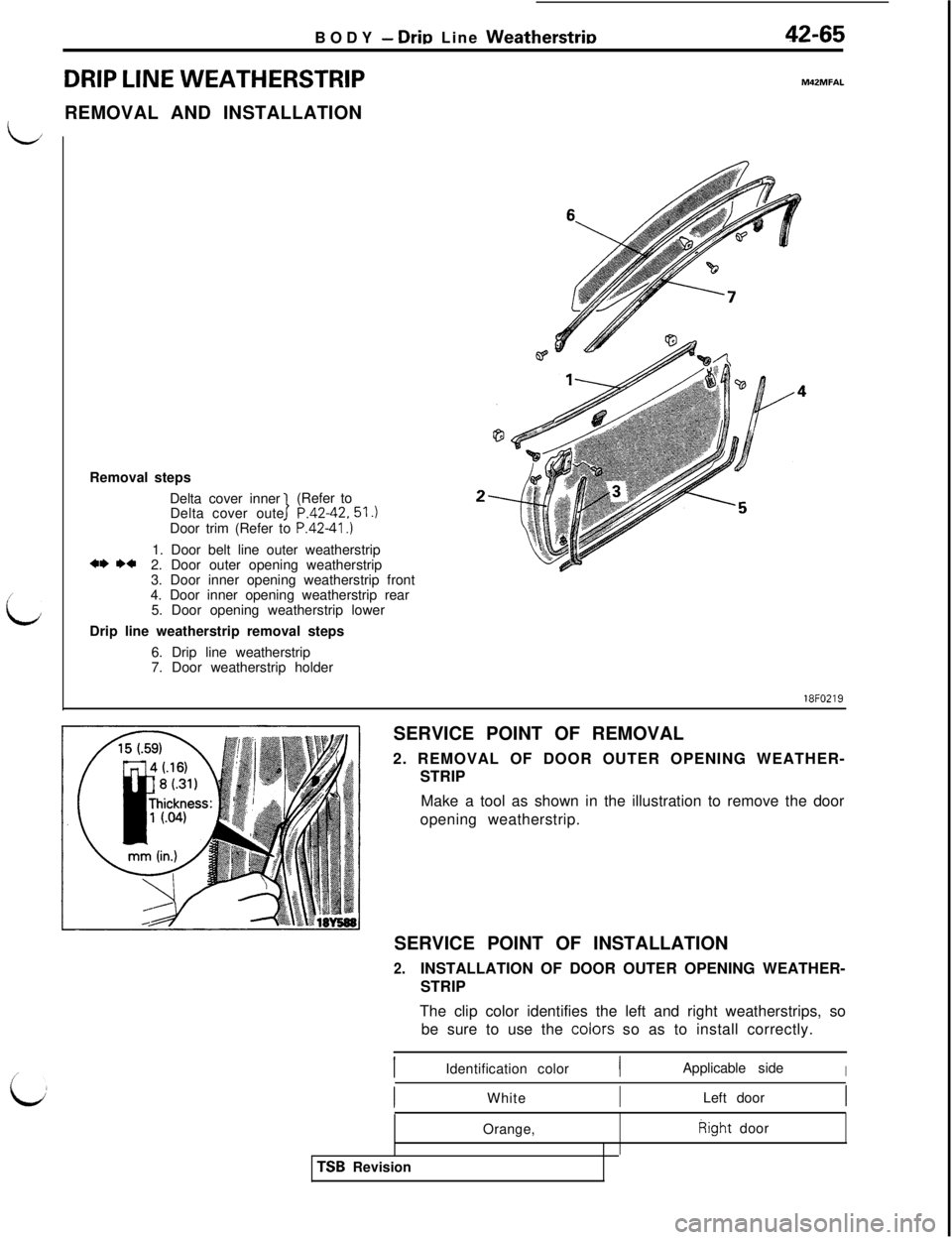

DRIP LINE WEATHERSTRIPM42MFALREMOVAL AND INSTALLATION

/

L

iRemoval steps

Delta cover inner

Delta cover outer P.42-42.51.)

1(Refer to

Door trim (Refer to P.4241.)

1. Door belt line outer weatherstrip

*I) I)+2. Door outer opening weatherstrip

3. Door inner opening weatherstrip front

4. Door inner opening weatherstrip rear

5. Door opening weatherstrip lower

Drip line weatherstrip removal steps

6. Drip line weatherstrip

7. Door weatherstrip holder

2-18FO219

SERVICE POINT OF REMOVAL

2. REMOVAL OF DOOR OUTER OPENING WEATHER-

STRIP

Make a tool as shown in the illustration to remove the door

opening weatherstrip.

SERVICE POINT OF INSTALLATION

2.INSTALLATION OF DOOR OUTER OPENING WEATHER-

STRIP

The clip color identifies the left and right weatherstrips, so

be sure to use the coiors so as to install correctly.

IIdentification colorIApplicable sideIWhiteLeft door

TSB RevisionOrange,Right door

Page 938 of 1146

Page 939 of 1146

EXTERIORCONTENTS

MSIAA- -AERO PARTS

........................................................20

SERVICE ADJUSTMENT PROCEDURES........

10DOOR MIRROR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38Inspection of Active Aero System. . . . . . . . . . . . . . . .10FRONT BUMPER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..__...............11SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..__............_._...4

GARNISHES

AND MOULDINGS . ..__............... 16

REAR BUMPER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...............2General Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2Sealants and Adhesives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3REAR WIPER AND WASHER

. . . . . . . . . . . . . . . . . . . . . . . . . . . .35Service Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5WINDSHIELD WIPER AND WASHER

. . . . . . . . . . . .24

Page 940 of 1146

51-2

SPECIFICATIONSEXTERIOR

- Specifications

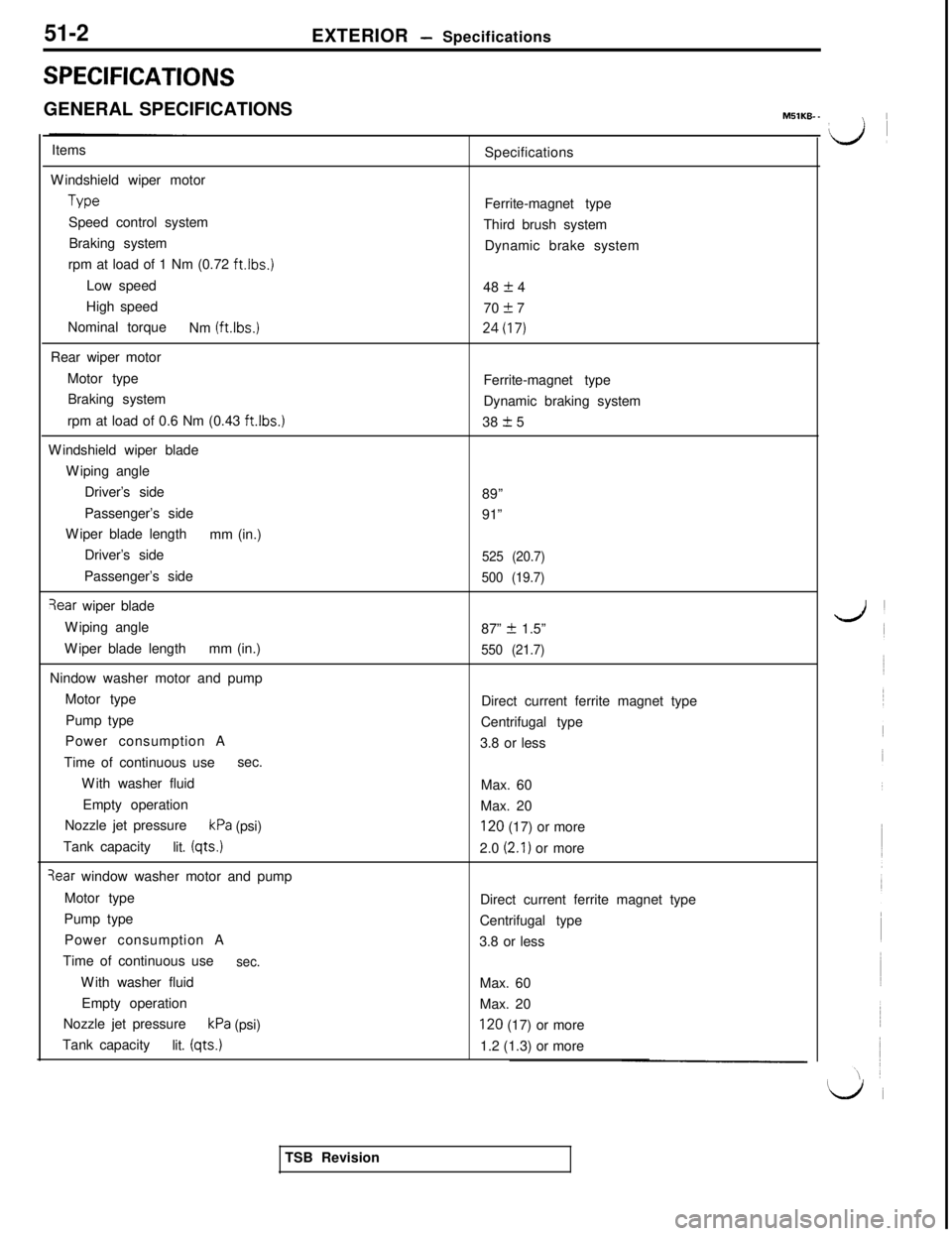

GENERAL SPECIFICATIONSMSlKB-

-\ IItems

Windshield wiper motorType

Speed control system

Braking system

rpm at load of 1 Nm (0.72

ft.lbs.)Low speed

High speed

Nominal torque

Nm (ft.lbs.)

Rear wiper motor

Motor type

Braking system

rpm at load of 0.6 Nm (0.43

ft.lbs.)Windshield wiper blade

Wiping angle

Driver’s side

Passenger’s side

Wiper blade length

mm (in.)

Driver’s side

Passenger’s side

Tear wiper blade

Wiping angle

Wiper blade lengthmm (in.)

Nindow washer motor and pump

Motor type

Pump type

Power consumption A

Time of continuous usesec.

With washer fluid

Empty operation

Nozzle jet pressure

kPa (psi)

Tank capacity

lit.

(qts.)

3ear window washer motor and pump

Motor type

Pump type

Power consumption A

Time of continuous use

sec.With washer fluid

Empty operation

Nozzle jet pressure

kPa (psi)

Tank capacity

lit. (qts.)Specifications

Ferrite-magnet type

Third brush system

Dynamic brake system

48

_+ 4

70

2 724(17)

Ferrite-magnet type

Dynamic braking system

38

+ 5

89”

91”

525 (20.7)

500 (19.7)87”

k 1.5”

550 (21.7)Direct current ferrite magnet type

Centrifugal type

3.8 or less

Max. 60

Max. 20

120 (17) or more

2.0

(2.1) or more

Direct current ferrite magnet type

Centrifugal type

3.8 or less

Max. 60

Max. 20

120 (17) or more

1.2 (1.3) or more

LJ

L/iTSB Revision