Ignition circuit MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 793 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-92

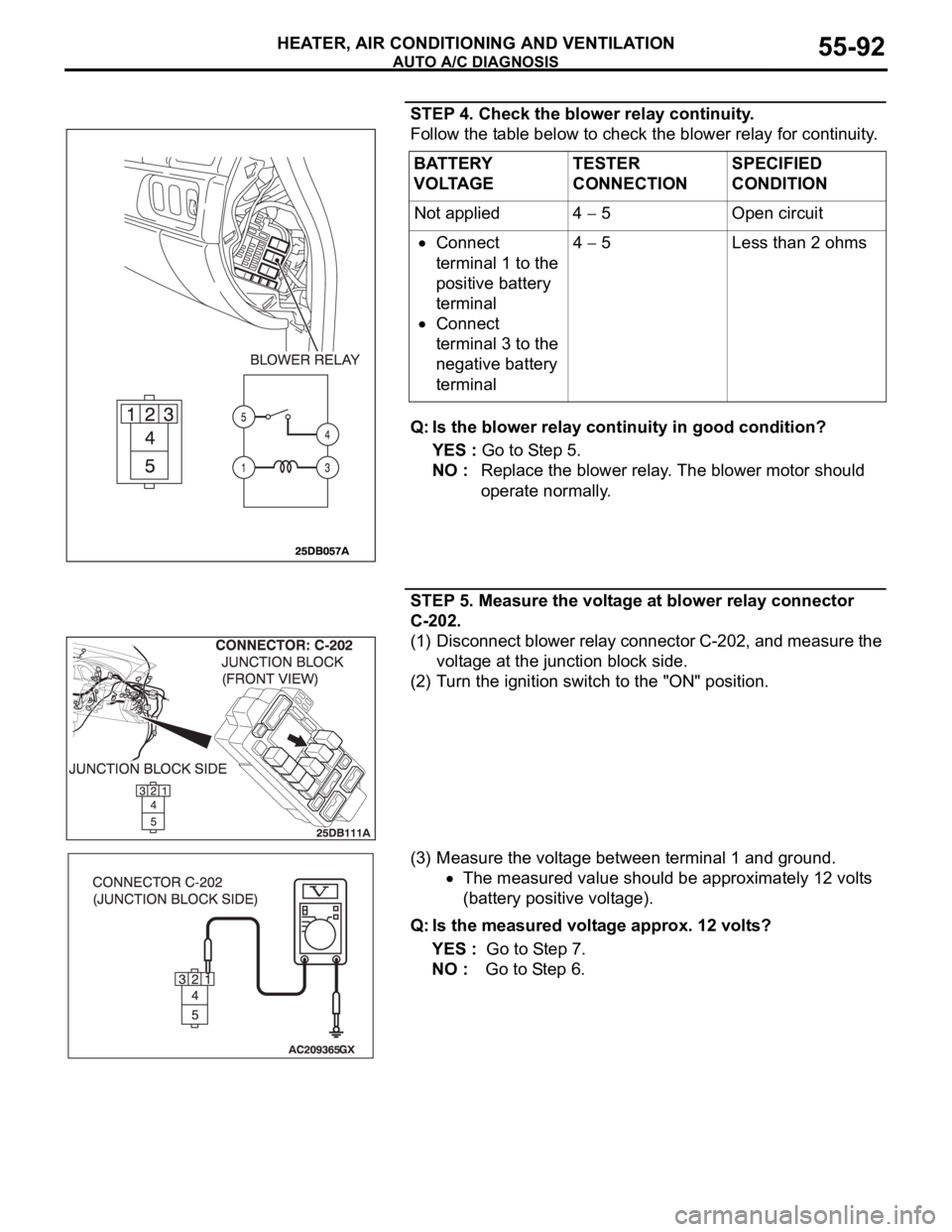

STEP 4. Check the blower relay continuity.

Follow the table below to check the blower relay for continuity.

Q: Is the blower relay continuity in good condition?

YES : Go to Step 5.

NO : Replace the blower relay. The blower motor should

operate normally.

STEP 5. Measure the voltage at blower relay connector

C-202.

(1) Disconnect blower relay connector C-202, and measure the

voltage at the junction block side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 1 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 7.

NO : Go to Step 6. BATTERY

VOLTAGETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect

terminal 1 to the

positive battery

terminal

Connect

terminal 3 to the

negative battery

terminal4

5 Less than 2 ohms

Page 805 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-104

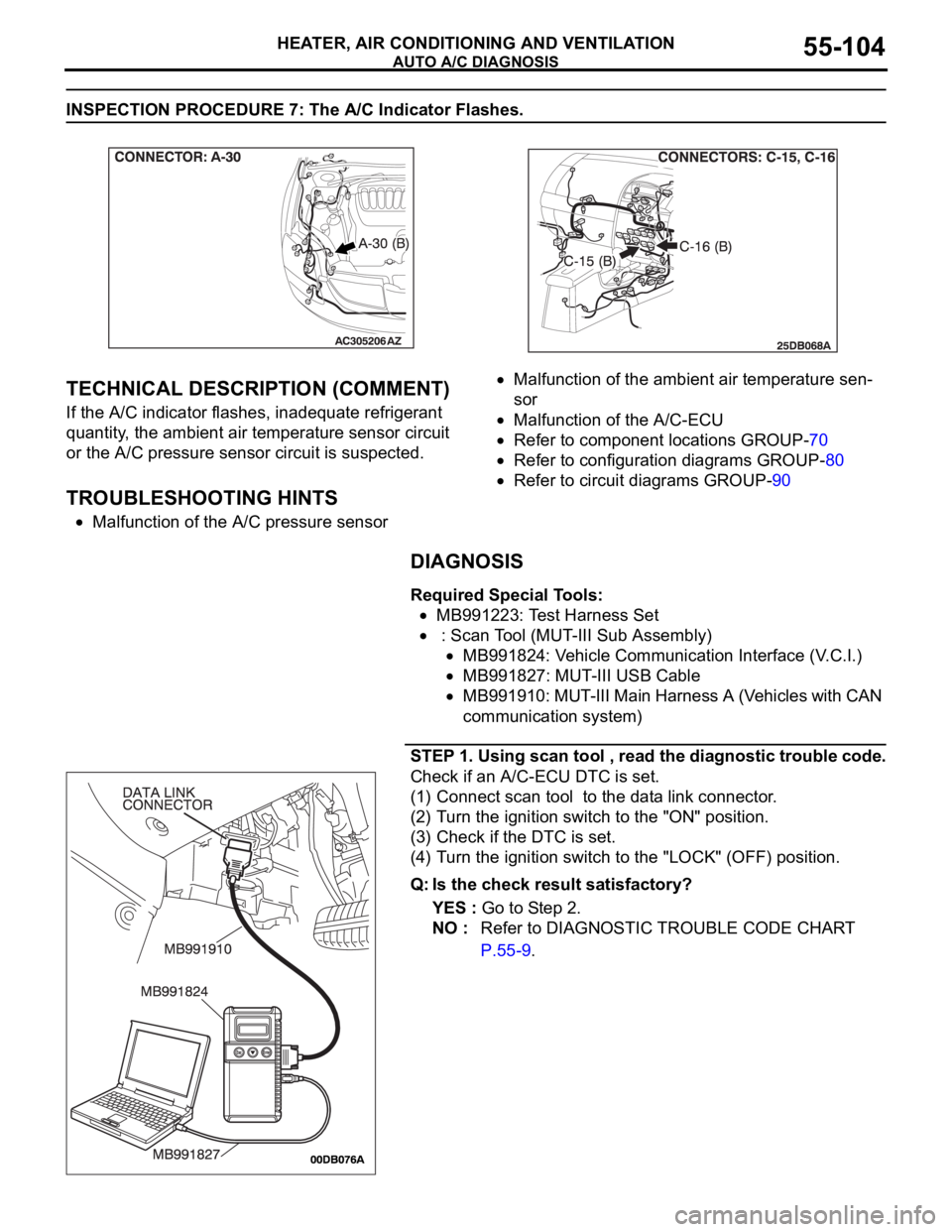

INSPECTION PROCEDURE 7: The A/C Indicator Flashes.

.

TECHNICAL DESCRIPTION (COMMENT)

If the A/C indicator flashes, inadequate refrigerant

quantity, the ambient air temperature sensor circuit

or the A/C pressure sensor circuit is suspected.

.

TROUBLESHOOTING HINTS

Malfunction of the A/C pressure sensor

Malfunction of the ambient air temperature sen-

sor

Malfunction of the A/C-ECU

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90

DIAGNOSIS

Required Special Tools:

MB991223: Test Harness Set

: Scan Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (Vehicles with CAN

communication system)

STEP 1. Using scan tool , read the diagnostic trouble code.

Check if an A/C-ECU DTC is set.

(1) Connect scan tool to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Check if the DTC is set.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the check result satisfactory?

YES : Go to Step 2.

NO : Refer to DIAGNOSTIC TROUBLE CODE CHART

P.55-9.

Page 907 of 1500

HOW TO DIAGNOSE

GENERAL

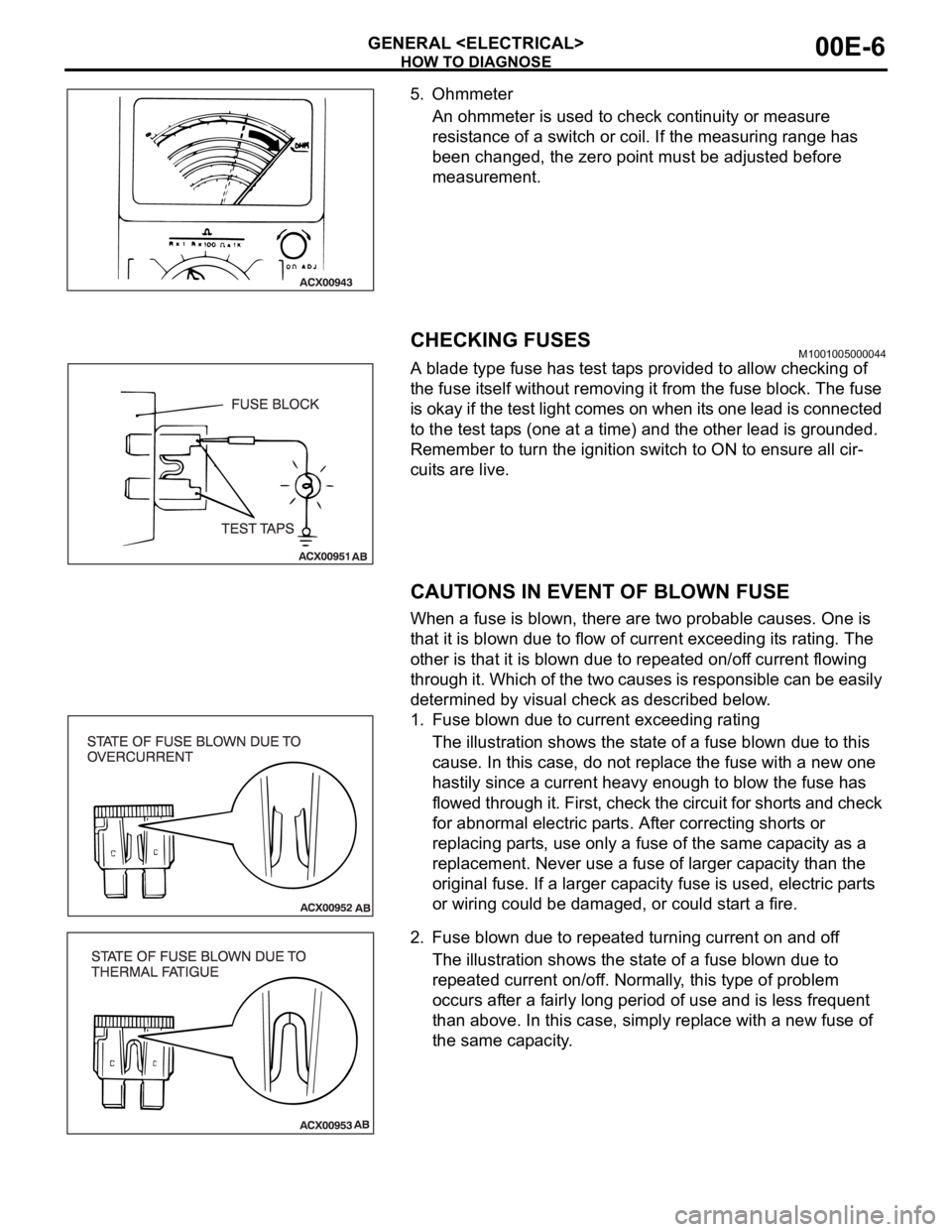

5. Ohmmeter

An ohmmeter is used to check continuity or measure

resistance of a switch or coil. If the measuring range has

been changed, the zero point must be adjusted before

measurement.

CHECKING FUSESM1001005000044

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The fuse

is okay if the test light comes on when its one lead is connected

to the test taps (one at a time) and the other lead is grounded.

Remember to turn the ignition switch to ON to ensure all cir-

cuits are live.

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes. One is

that it is blown due to flow of current exceeding its rating. The

other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

1. Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorts and check

for abnormal electric parts. After correcting shorts or

replacing parts, use only a fuse of the same capacity as a

replacement. Never use a fuse of larger capacity than the

original fuse. If a larger capacity fuse is used, electric parts

or wiring could be damaged, or could start a fire.

2. Fuse blown due to repeated turning current on and off

The illustration shows the state of a fuse blown due to

repeated current on/off. Normally, this type of problem

occurs after a fairly long period of use and is less frequent

than above. In this case, simply replace with a new fuse of

the same capacity.

Page 980 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

CHARGING SYSTEM DIAGNOSISM1161000700427

TROUBLESHOOTING HINTS

Alternator malfunction light dose not go on when the ignition

switch is turned to ON, before the engine starts.

Check the bulb.

Alternator malfunction light dose not switch off after the engine

starts.

Check the IC voltage regulator inside the

alternatoralternator.

Discharged or overcharged battery.

Check the IC voltage regulator inside the alternator.

The alternator malfunction light illuminates dimly.

Check the diode (inside the combination meter) for a

short-circuit.

TROUBLESHOOTING GUIDE

The charging system troubleshooting guide is shown in the fol-

lowing steps.

STEP 1.

Q: Is the battery in good condition? (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

YES : Go to Step 2.

NO : Charge or replace the battery.

STEP 2.

Q: Is the alternator drive belt in good condition? (Refer to

GROUP 00, General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

YES : Go to Step 3.

NO : Adjust the belt tension or replace the belt.

STEP 3.

Q: Does the alternator malfunction light come on when the

ignition switch is turned on?

YES : Go to Step 4.

NO :

Check the ignition switch. (Refer to GROUP 54A,

Chassis Electrical

Ignition Switch Ignition

Switch

Inspection P.54A-44.)

Check for burnt-out alternator malfunction light.

Check the alternator. (Refer to Charging System

Alternator Assembly

Inspection P.16-17.)

Check the alternator malfunction light-related

circuits.

Page 986 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-9

Required Special Tool:

: Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

This test determines whether the alternator outputs

normal current. For best results, use a charging sys-

tem tester. If not available, follow the steps below.

Battery posts, terminals and related acces-

sories contain lead and lead compounds.

WASH HANDS AFTER HANDLING.

1. Before the test, always be sure to check the

following.

Alternator installation

Battery (Refer to GROUP 54A, Chassis Electrical

Battery On-vehicle Service Battery Check

P.54A-5.)

NOTE: The battery to be used should be slightly

discharged. The load in a fully-charged battery

will be insufficient and the test may not be able to

be carried out correctly.

Alternator drive belt tension (Refer to GROUP 00,

General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

Fusible link

Abnormal noise from the alternator while the

engine is running.

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

Never use clips to connect the wire. Loose

connections (for example, using clips) will

lead to a serious accident because of high

current.

4. Connect a clamp-type DC test ammeter with a

range of 0

120 A to the alternator "B" terminal

output wire.

5. Connect a voltmeter with a range of 0

20 V

between the alternator "B" terminal and ground.

(Connect the positive lead of the voltmeter to the

"B" terminal, and then connect the negative lead

of the voltmeter to ground.)

6. Connect the negative battery cable.

7. Connect an engine tachometer or diagnostic tool.

8. Leave the hood open.9. Check to be sure that the reading on the voltmeter

is equal to the battery positive voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "B" terminal and the battery positive

terminal or malfunctioning voltmeter.

10.After turning on the headlights, start the engine.

NOTE: Because the current from the battery will

soon drop after the engine is started, step 11

should be carried out as quickly as possible in

order to obtain the maximum current output value.

11.Immediately after setting the headlights to high

beam and turning the heater blower switch to the

highest position, increase the engine speed to

2,500 r/min and read the maximum current output

value displayed on the ammeter.

Limit value: 70 % of nominal current output

NOTE: For the nominal current output, refer to the

Alternator Specifications.

NOTE: The current output value will depend on

the electrical load and the temperature of the

alternator body.

NOTE: If the electrical load is small while testing,

the specified level of current may not be output

even though the alternator is normal. In such

cases, increase the electrical load by leaving the

headlights turned on for some time to discharge

the battery or by using the lighting system in

another vehicle, and then test again.

NOTE: The specified level of current also may not

be output if the temperature of the alternator body

or the ambient temperature is too high. In such

cases, cool the alternator and then test again.

12.The reading on the ammeter should be above the

limit value. If the reading is below the limit value

and the alternator output wire is normal, remove

the alternator from the engine and check the

alternator.

13.Run the engine at idle speed after the test.

14.Turn the ignition switch to the "LOCK" (OFF)

position.

15.Disconnect the engine tachometer or diagnostic

tool.

16.Disconnect the negative battery cable.

17.Disconnect the ammeter and voltmeter .

18.Connect the negative battery cable.

19.Run the engine for 10 minutes at an idle.

Page 987 of 1500

CHARGING SYSTEM

ENGINE ELECTRICAL16-10

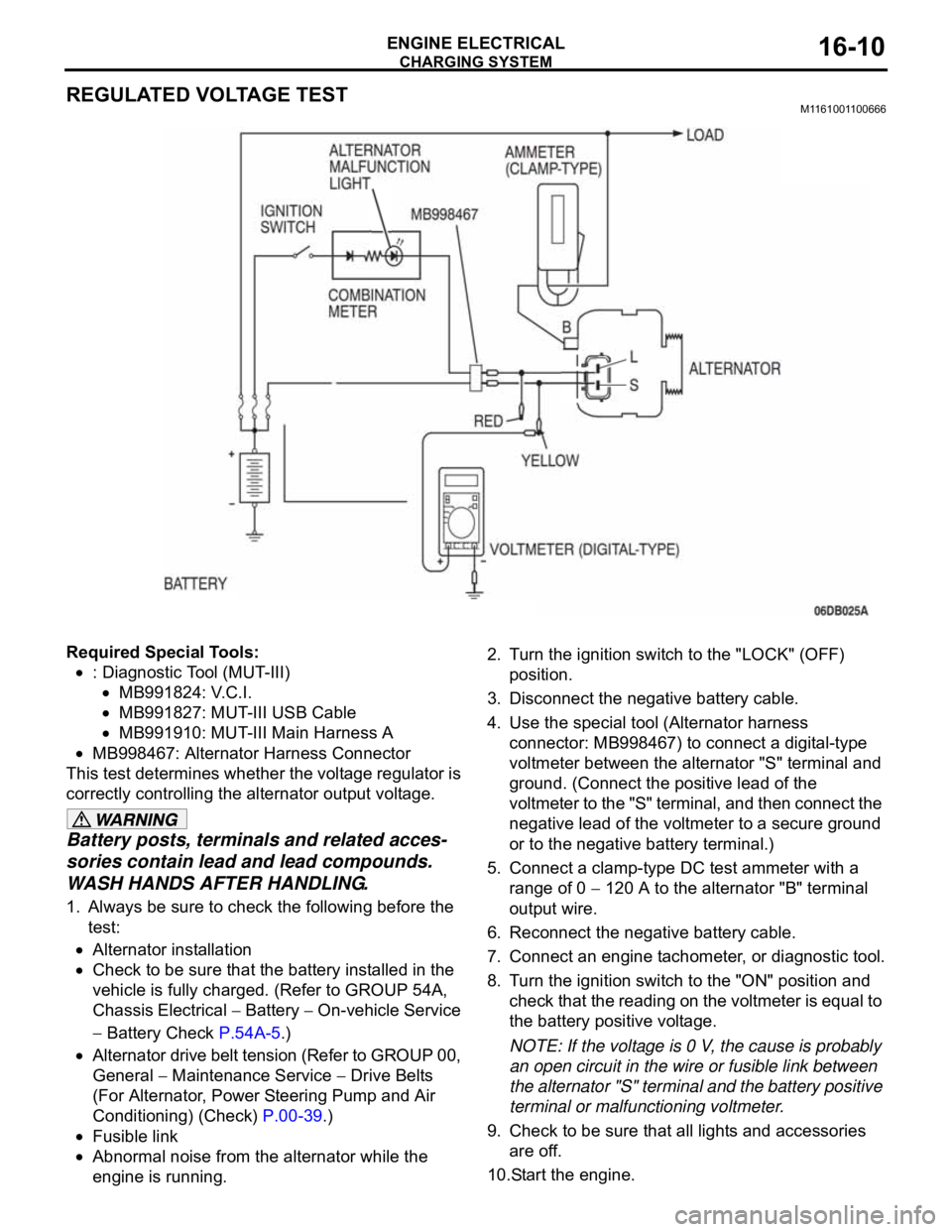

REGULATED VOLTAGE TESTM1161001100666

Required Special Tools:

: Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

MB998467: Alternator Harness Connector

This test determines whether the voltage regulator is

correctly controlling the alternator output voltage.

Battery posts, terminals and related acces-

sories contain lead and lead compounds.

WASH HANDS AFTER HANDLING.

1. Always be sure to check the following before the

test:

Alternator installation

Check to be sure that the battery installed in the

vehicle is fully charged. (Refer to GROUP 54A,

Chassis Electrical

Battery On-vehicle Service

Battery Check P.54A-5.)

Alternator drive belt tension (Refer to GROUP 00,

General

Maintenance Service Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check) P.00-39.)

Fusible link

Abnormal noise from the alternator while the

engine is running.2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Use the special tool (Alternator harness

connector: MB998467) to connect a digital-type

voltmeter between the alternator "S" terminal and

ground. (Connect the positive lead of the

voltmeter to the "S" terminal, and then connect the

negative lead of the voltmeter to a secure ground

or to the negative battery terminal.)

5. Connect a clamp-type DC test ammeter with a

range of 0

120 A to the alternator "B" terminal

output wire.

6. Reconnect the negative battery cable.

7. Connect an engine tachometer, or diagnostic tool.

8. Turn the ignition switch to the "ON" position and

check that the reading on the voltmeter is equal to

the battery positive voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "S" terminal and the battery positive

terminal or malfunctioning voltmeter.

9. Check to be sure that all lights and accessories

are off.

10.Start the engine.

Page 1008 of 1500

IGNITION SYSTEM

ENGINE ELECTRICAL16-31

ON-VEHICLE SERVICE

KNOCK CONTROL SYSTEM CHECKM1163001800081

Check the knock sensor circuit if diagnostic trouble code, No.

P0325 is shown.

Refer to GROUP 13B, Multiport Fuel Injection (MPI)

Multiport

Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Pro-

cedures

DTC P0325 : Knock Sensor Circuit 13A-346.

IGNITION COIL CHECK M1163001200380

Check by the following procedure, and replace the coil if there

is a malfunction.

.

PRIMARY COIL AND IGNITION POWER

TRANSISTOR CONTINUITY CHECK

NOTE: No test can be performed on the Primary side of coil.

.

SECONDARY COIL CHECK

NOTE: It is impossible to check the secondary coil through the

continuity check as a diode is integrated in the secondary coil

circuit of this ignition coil. Accordingly, check the secondary coil

in the following procedure.

1. Disconnect the ignition coil connector.

2. Remove the ignition coil and install a new spark plug to the

ignition coil.

3. Connect the ignition coil connector.

4. Disable vehicle fuel pump by removing fuel pump relay or

disconnecting fuel pump connector D-18 (under rear seat).

5. Ground the side electrode of the spark plug and crank the

engine.

6. Check that spark is produced between the electrodes of the

spark plug.

7. If no spark is produced, replace the ignition coil with a new

one and recheck.

8. If spark is produced with the new ignition coil, replace the

old one as it is faulty. If no spark is produced again, the

ignition circuit is suspected as faulty. Check the ignition

circuit.

Page 1009 of 1500

IGNITION SYSTEM

ENGINE ELECTRICAL16-32

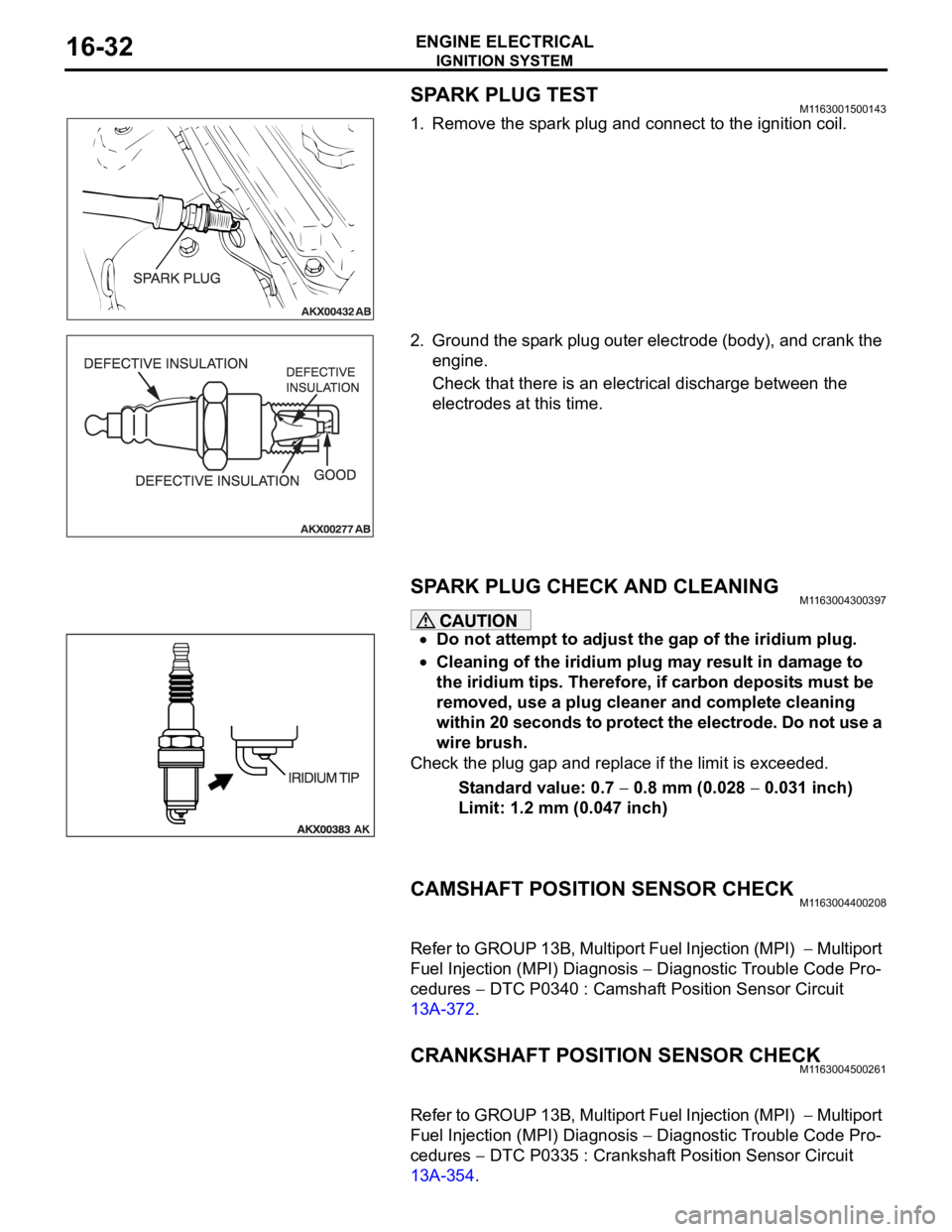

SPARK PLUG TESTM1163001500143

1. Remove the spark plug and connect to the ignition coil.

2. Ground the spark plug outer electrode (body), and crank the

engine.

Check that there is an electrical discharge between the

electrodes at this time.

SPARK PLUG CHECK AND CLEANING M1163004300397

Do not attempt to adjust the gap of the iridium plug.

Cleaning of the iridium plug may result in damage to

the iridium tips. Therefore, if carbon deposits must be

removed, use a plug cleaner and complete cleaning

within 20 seconds to protect the electrode. Do not use a

wire brush.

Check the plug gap and replace if the limit is exceeded.

Standard value: 0.7

0.8 mm (0.028 0.031 inch)

Limit: 1.2 mm (0.047 inch)

CAMSHAFT POSITION SENSOR CHECKM1163004400208

Refer to GROUP 13B, Multiport Fuel Injection (MPI) Multiport

Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Pro-

cedures

DTC P0340 : Camshaft Position Sensor Circuit

13A-372.

CRANKSHAFT POSITION SENSOR CHECKM1163004500261

Refer to GROUP 13B, Multiport Fuel Injection (MPI) Multiport

Fuel Injection (MPI) Diagnosis

Diagnostic Trouble Code Pro-

cedures

DTC P0335 : Crankshaft Position Sensor Circuit

13A-354.

Page 1143 of 1500

SUNROOF ASSEMBLY

BODY42-76

SUNROOF TIMER FUNCTION CHECKM1426004300100

Keep the door closed, turn OFF the ignition switch and check to

see if the sunroof can be operated for 30 seconds after that. If

not, perform troubleshooting (Refer to GROUP 54B, SWS

Diagnosis P.54B-57).

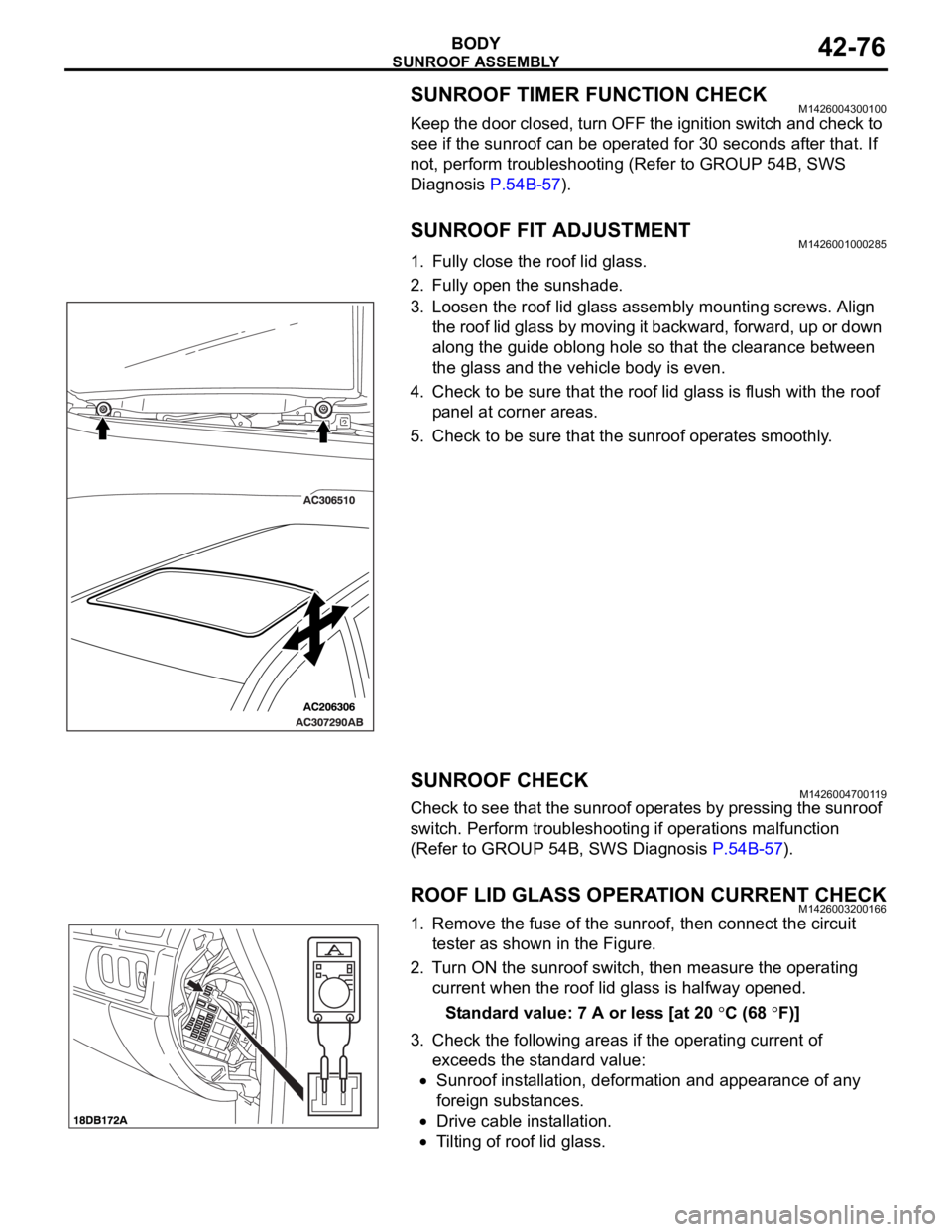

SUNROOF FIT ADJUSTMENTM1426001000285

1. Fully close the roof lid glass.

2. Fully open the sunshade.

3. Loosen the roof lid glass assembly mounting screws. Align

the roof lid glass by moving it backward, forward, up or down

along the guide oblong hole so that the clearance between

the glass and the vehicle body is even.

4. Check to be sure that the roof lid glass is flush with the roof

panel at corner areas.

5. Check to be sure that the sunroof operates smoothly.

SUNROOF CHECKM1426004700119

Check to see that the sunroof operates by pressing the sunroof

switch. Perform troubleshooting if operations malfunction

(Refer to GROUP 54B, SWS Diagnosis P.54B-57).

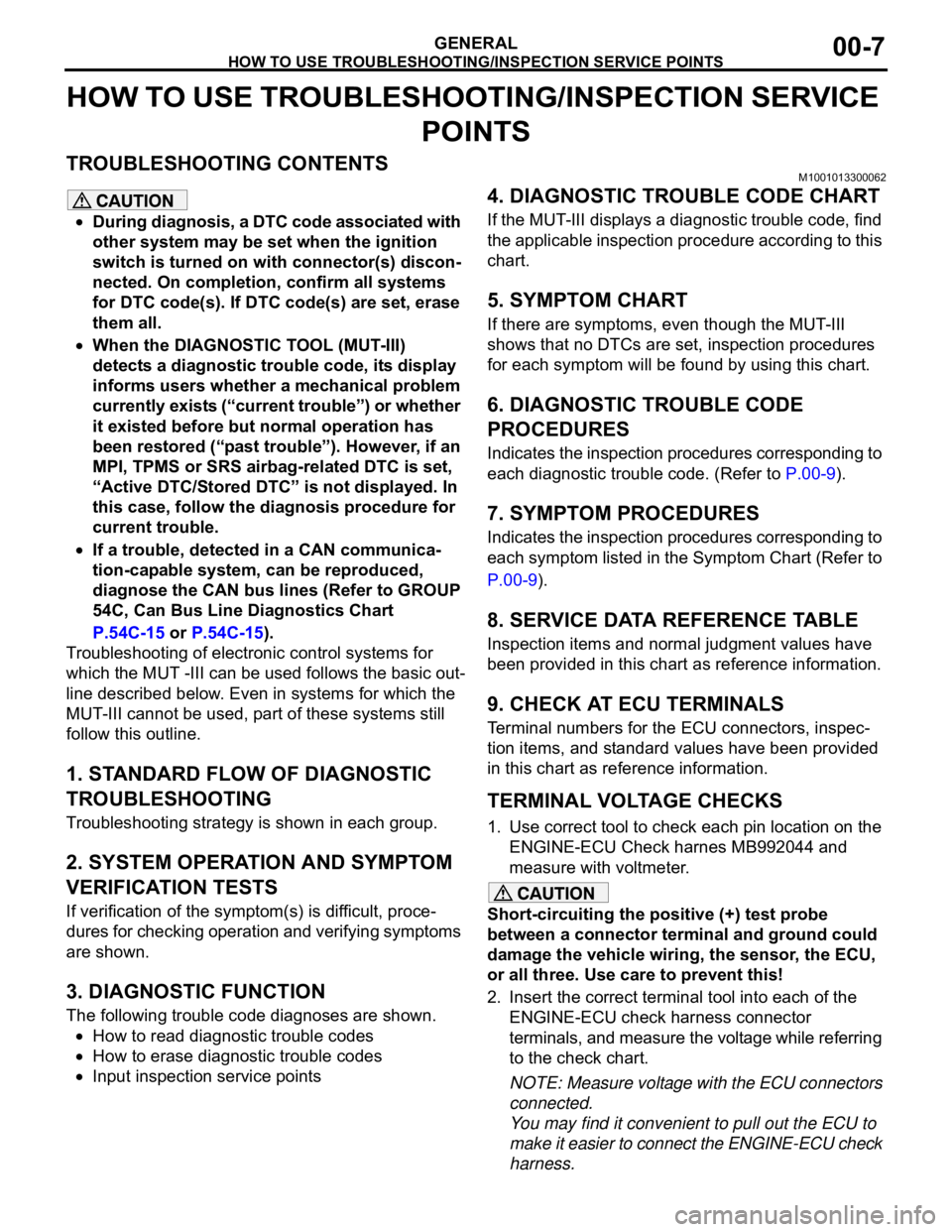

ROOF LID GLASS OPERATION CURRENT CHECKM1426003200166

1. Remove the fuse of the sunroof, then connect the circuit

tester as shown in the Figure.

2. Turn ON the sunroof switch, then measure the operating

current when the roof lid glass is halfway opened.

Standard value: 7 A or less [at 20

C (68 F)]

3. Check the following areas if the operating current of

exceeds the standard value:

Sunroof installation, deformation and appearance of any

foreign substances.

Drive cable installation.

Tilting of roof lid glass.

Page 1228 of 1500

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL00-7

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE

POINTS

TROUBLESHOOTING CONTENTSM1001013300062

During diagnosis, a DTC code associated with

other system may be set when the ignition

switch is turned on with connector(s) discon-

nected. On completion, confirm all systems

for DTC code(s). If DTC code(s) are set, erase

them all.

When the DIAGNOSTIC TOOL (MUT-III)

detects a diagnostic trouble code, its display

informs users whether a mechanical problem

currently exists (“current trouble”) or whether

it existed before but normal operation has

been restored (“past trouble”). However, if an

MPI, TPMS or SRS airbag-related DTC is set,

“Active DTC/Stored DTC” is not displayed. In

this case, follow the diagnosis procedure for

current trouble.

If a trouble, detected in a CAN communica-

tion-capable system, can be reproduced,

diagnose the CAN bus lines (Refer to GROUP

54C, Can Bus Line Diagnostics Chart

P.54C-15 or P.54C-15).

Troubleshooting of electronic control systems for

which the MUT -III can be used follows the basic out-

line described below. Even in systems for which the

MUT-III cannot be used, part of these systems still

follow this outline.

1. STANDARD FLOW OF DIAGNOSTIC

TROUBLESHOOTING

Troubleshooting strategy is shown in each group.

2. SYSTEM OPERATION AND SYMPTOM

VERIFICATION TESTS

If verification of the symptom(s) is difficult, proce-

dures for checking operation and verifying symptoms

are shown.

3. DIAGNOSTIC FUNCTION

The following trouble code diagnoses are shown.

How to read diagnostic trouble codes

How to erase diagnostic trouble codes

Input inspection service points

4. DIAGNOSTIC TROUBLE CODE CHART

If the MUT-III displays a diagnostic trouble code, find

the applicable inspection procedure according to this

chart.

5. SYMPTOM CHART

If there are symptoms, even though the MUT-III

shows that no DTCs are set, inspection procedures

for each symptom will be found by using this chart.

6. DIAGNOSTIC TROUBLE CODE

PROCEDURES

Indicates the inspection procedures corresponding to

each diagnostic trouble code. (Refer to P.00-9).

7. SYMPTOM PROCEDURES

Indicates the inspection procedures corresponding to

each symptom listed in the Symptom Chart (Refer to

P.00-9).

8. SERVICE DATA REFERENCE TABLE

Inspection items and normal judgment values have

been provided in this chart as reference information.

9. CHECK AT ECU TERMINALS

Terminal numbers for the ECU connectors, inspec-

tion items, and standard values have been provided

in this chart as reference information.

.

TERMINAL VOLTAGE CHECKS

1. Use correct tool to check each pin location on the

ENGINE-ECU Check harnes MB992044 and

measure with voltmeter.

Short-circuiting the positive (+) test probe

between a connector terminal and ground could

damage the vehicle wiring, the sensor, the ECU,

or all three. Use care to prevent this!

2. Insert the correct terminal tool into each of the

ENGINE-ECU check harness connector

terminals, and measure the voltage while referring

to the check chart.

NOTE: Measure voltage with the ECU connectors

connected.

You may find it convenient to pull out the ECU to

make it easier to connect the ENGINE-ECU check

harness.