MITSUBISHI 380 2005 Manual PDF

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 71 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-71

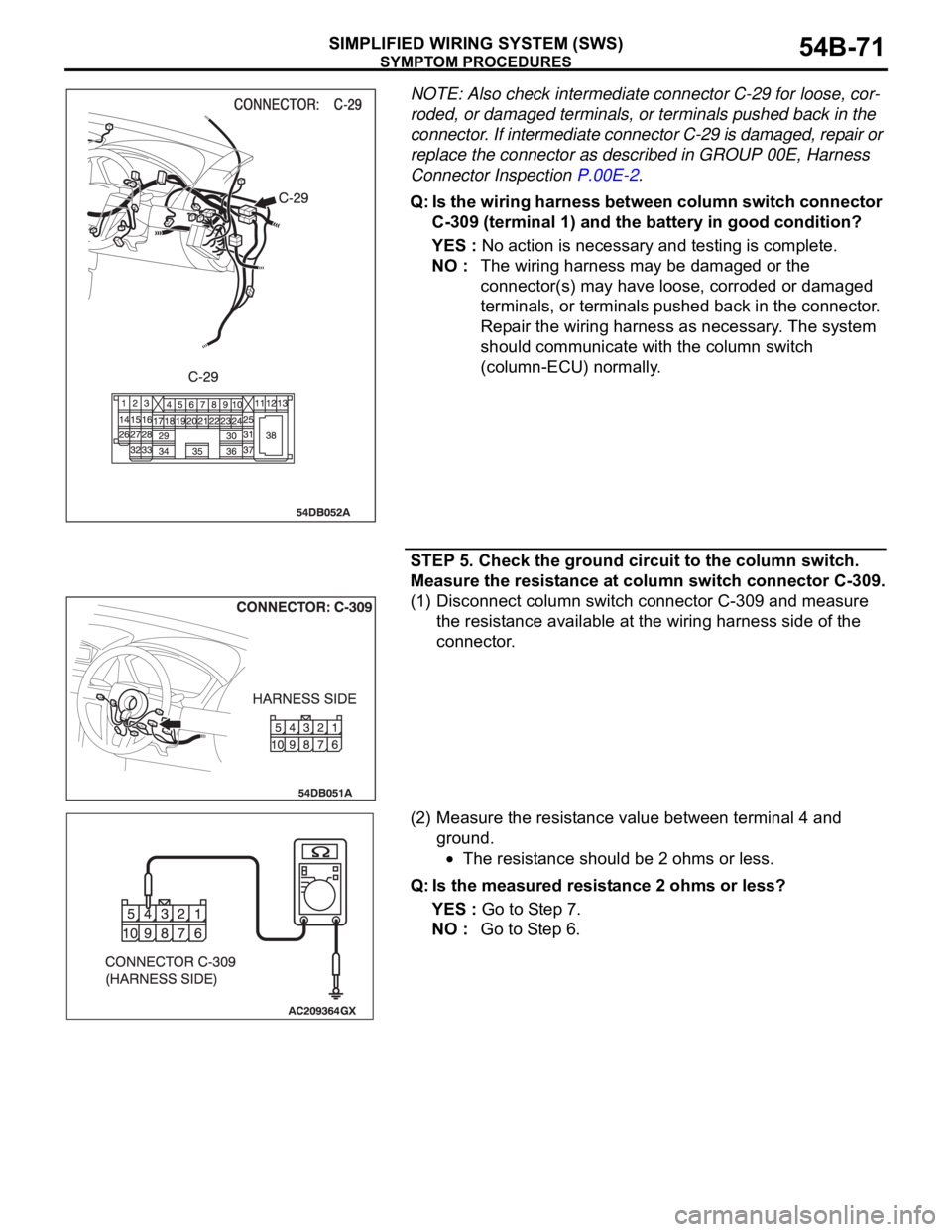

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between column switch connector

C-309 (terminal 1) and the battery in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the column switch

(column-ECU) normally.

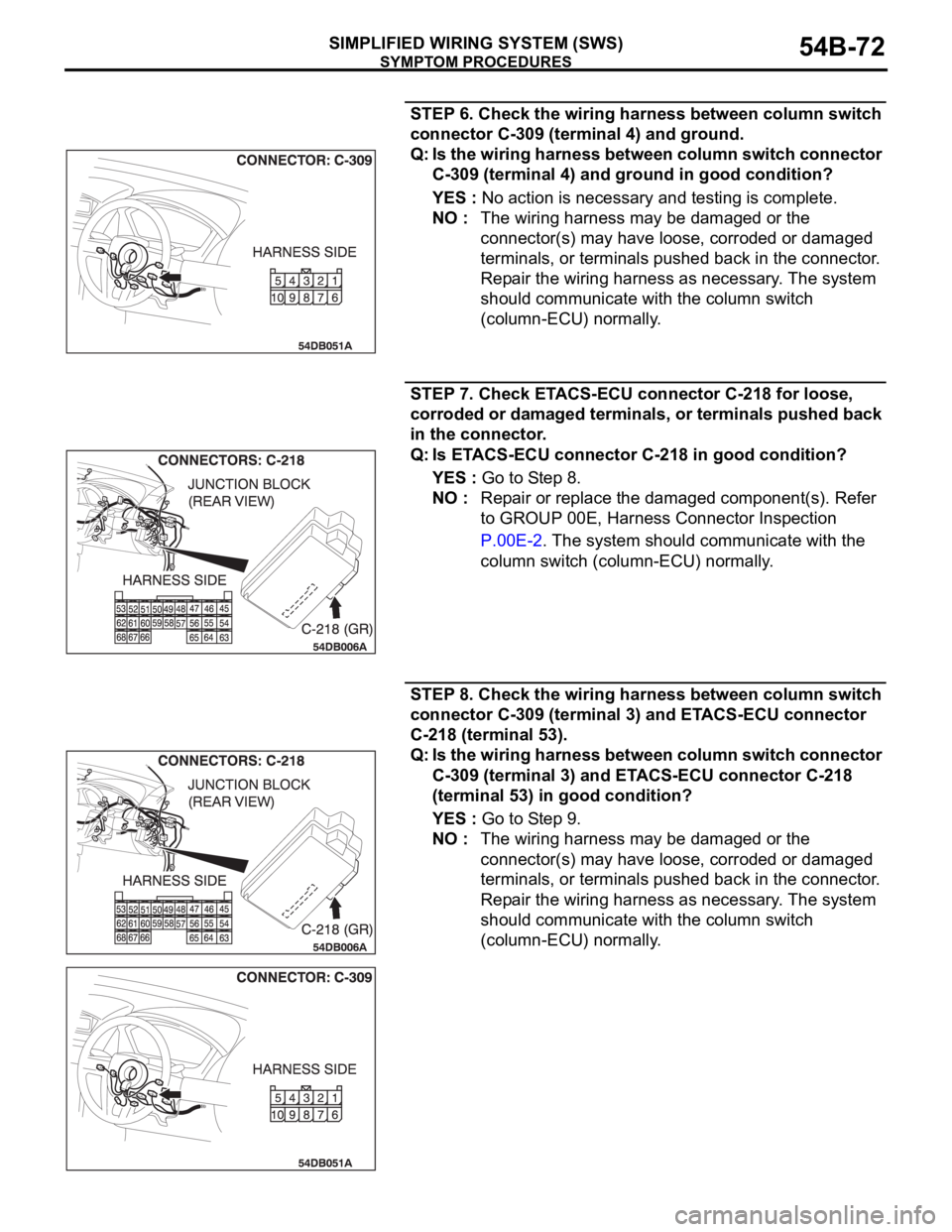

STEP 5. Check the ground circuit to the column switch.

Measure the resistance at column switch connector C-309.

(1) Disconnect column switch connector C-309 and measure

the resistance available at the wiring harness side of the

connector.

(2) Measure the resistance value between terminal 4 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 7.

NO : Go to Step 6.

Page 72 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-72

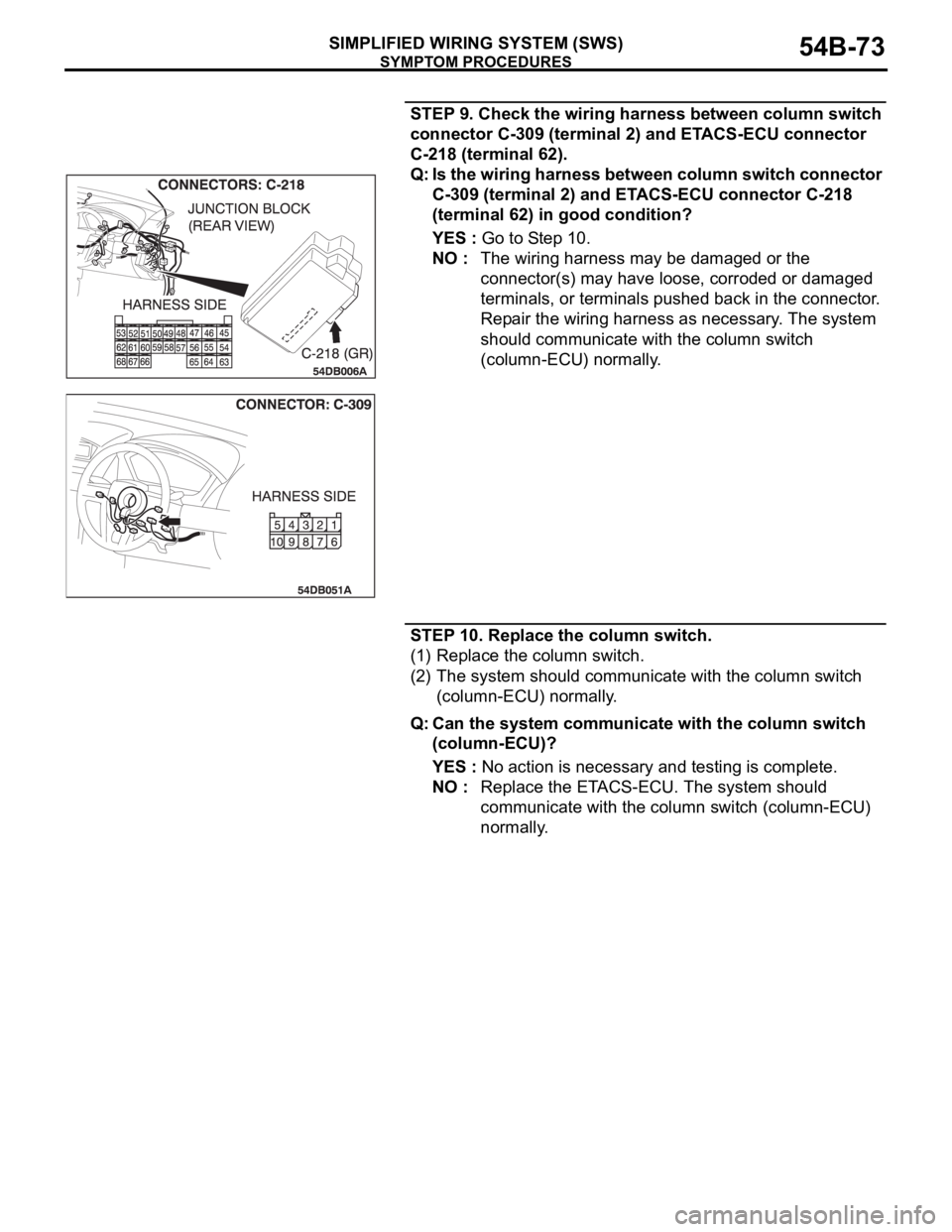

STEP 6. Check the wiring harness between column switch

connector C-309 (terminal 4) and ground.

Q: Is the wiring harness between column switch connector

C-309 (terminal 4) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the column switch

(column-ECU) normally.

STEP 7. Check ETACS-ECU connector C-218 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-218 in good condition?

YES : Go to Step 8.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The system should communicate with the

column switch (column-ECU) normally.

STEP 8. Check the wiring harness between column switch

connector C-309 (terminal 3) and ETACS-ECU connector

C-218 (terminal 53).

Q: Is the wiring harness between column switch connector

C-309 (terminal 3) and ETACS-ECU connector C-218

(terminal 53) in good condition?

YES : Go to Step 9.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the column switch

(column-ECU) normally.

Page 73 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-73

STEP 9. Check the wiring harness between column switch

connector C-309 (terminal 2) and ETACS-ECU connector

C-218 (terminal 62).

Q: Is the wiring harness between column switch connector

C-309 (terminal 2) and ETACS-ECU connector C-218

(terminal 62) in good condition?

YES : Go to Step 10.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the column switch

(column-ECU) normally.

STEP 10. Replace the column switch.

(1) Replace the column switch.

(2) The system should communicate with the column switch

(column-ECU) normally.

Q: Can the system communicate with the column switch

(column-ECU)?

YES : No action is necessary and testing is complete.

NO : Replace the ETACS-ECU. The system should

communicate with the column switch (column-ECU)

normally.

Page 74 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-74

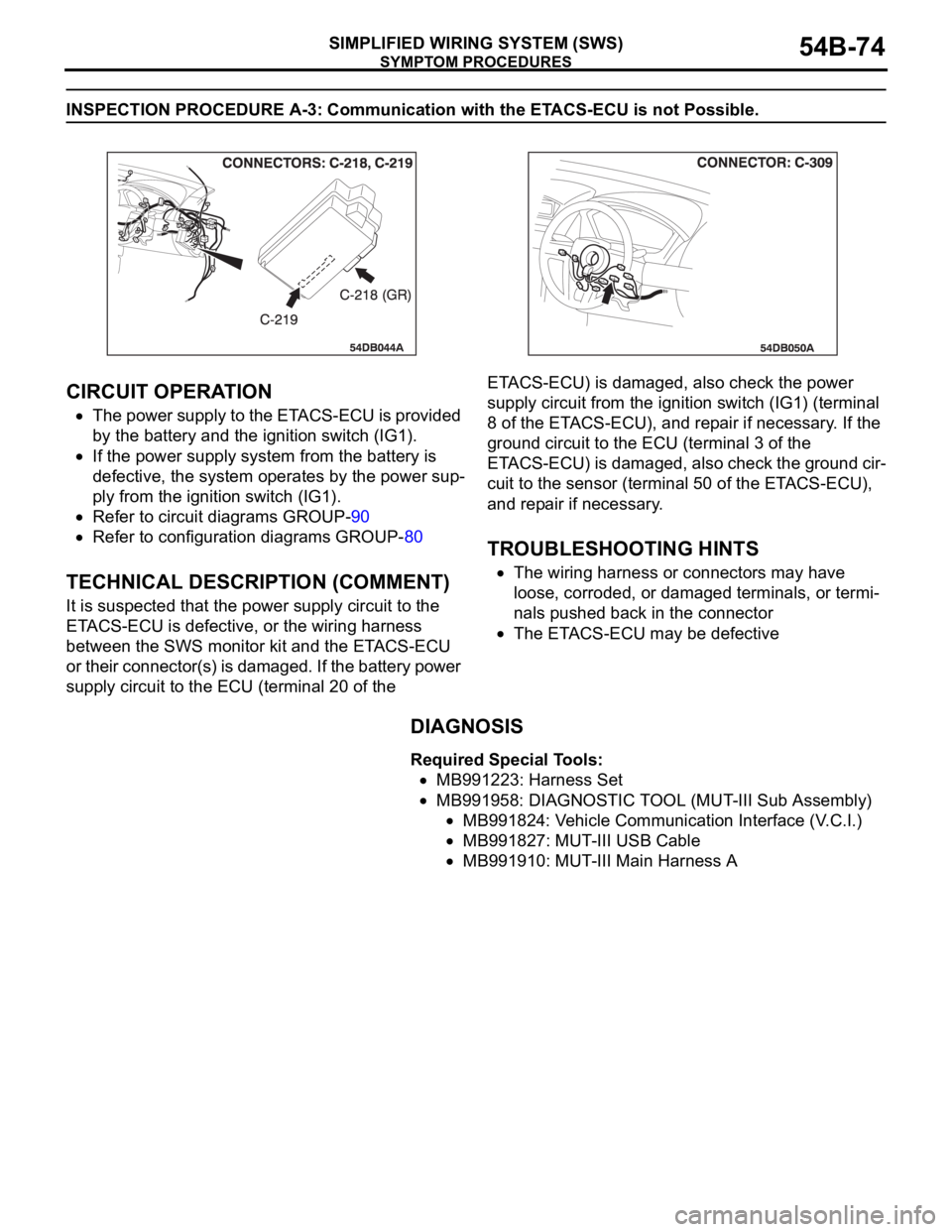

INSPECTION PROCEDURE A-3: Communication with the ETACS-ECU is not Possible.

.

CIRCUIT OPERATION

The power supply to the ETACS-ECU is provided

by the battery and the ignition switch (IG1).

If the power supply system from the battery is

defective, the system operates by the power sup-

ply from the ignition switch (IG1).

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

.

TECHNICAL DESCRIPTION (COMMENT)

It is suspected that the power supply circuit to the

ETACS-ECU is defective, or the wiring harness

between the SWS monitor kit and the ETACS-ECU

or their connector(s) is damaged. If the battery power

supply circuit to the ECU (terminal 20 of the ETACS-ECU) is damaged, also check the power

supply circuit from the ignition switch (IG1) (terminal

8 of the ETACS-ECU), and repair if necessary. If the

ground circuit to the ECU (terminal 3 of the

ETACS-ECU) is damaged, also check the ground cir-

cuit to the sensor (terminal 50 of the ETACS-ECU),

and repair if necessary.

.

TROUBLESHOOTING HINTS

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

MB991223: Harness Set

MB991958: DIAGNOSTIC TOOL (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A

Page 75 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-75

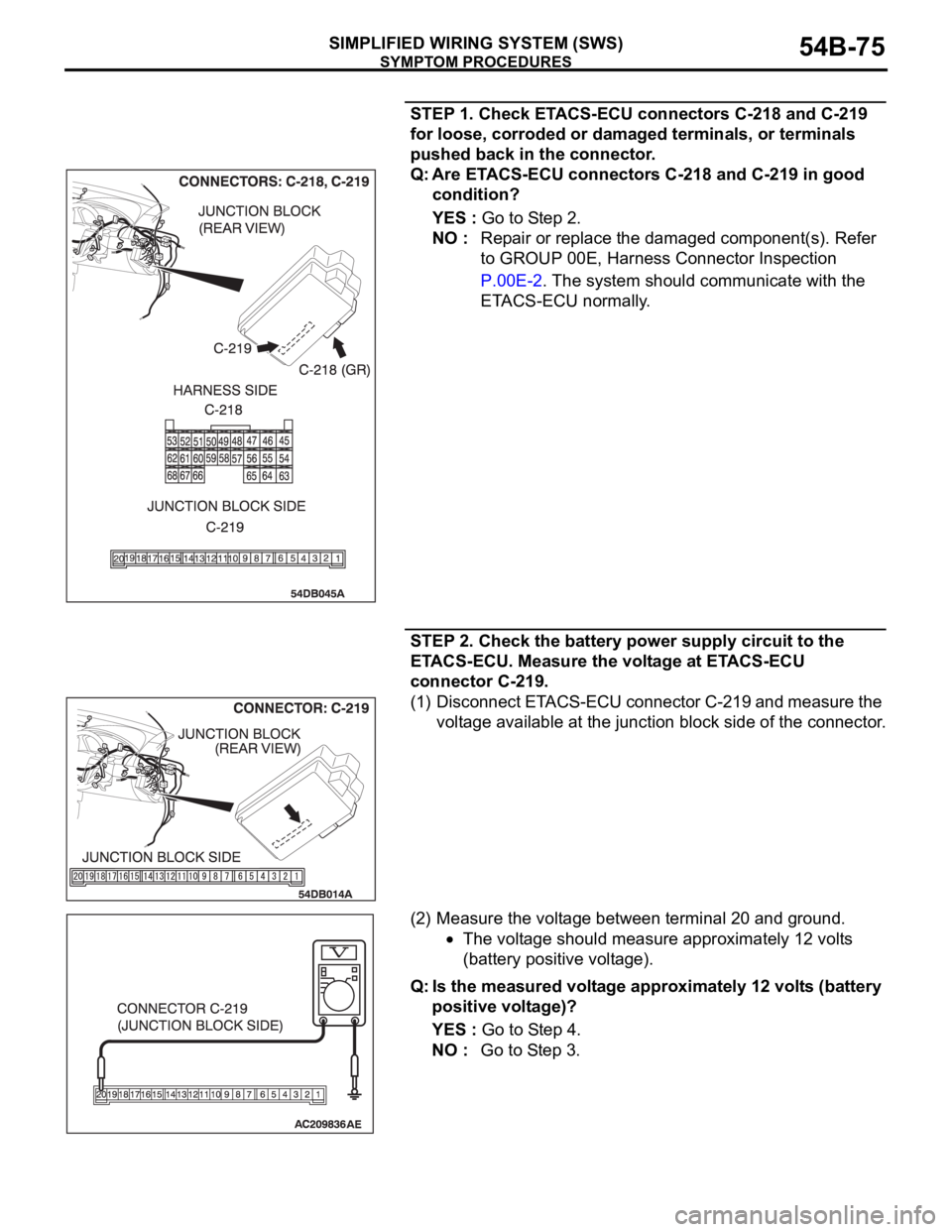

STEP 1. Check ETACS-ECU connectors C-218 and C-219

for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Are ETACS-ECU connectors C-218 and C-219 in good

condition?

YES : Go to Step 2.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The system should communicate with the

ETACS-ECU normally.

STEP 2. Check the battery power supply circuit to the

ETACS-ECU. Measure the voltage at ETACS-ECU

connector C-219.

(1) Disconnect ETACS-ECU connector C-219 and measure the

voltage available at the junction block side of the connector.

(2) Measure the voltage between terminal 20 and ground.

The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 4.

NO : Go to Step 3.

Page 76 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-76

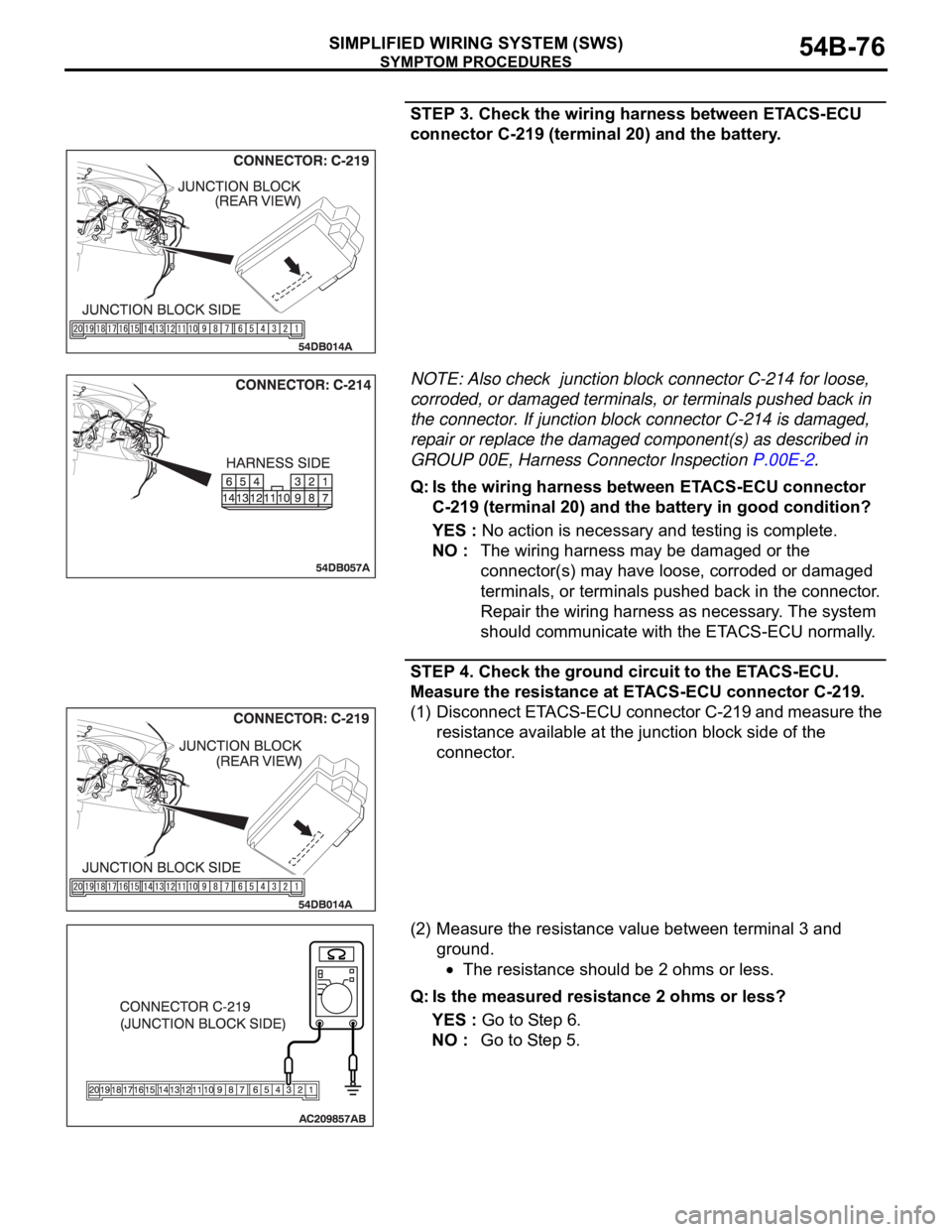

STEP 3. Check the wiring harness between ETACS-ECU

connector C-219 (terminal 20) and the battery.

NOTE: Also check junction block connector C-214 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-214 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between ETACS-ECU connector

C-219 (terminal 20) and the battery in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the ETACS-ECU normally.

STEP 4. Check the ground circuit to the ETACS-ECU.

Measure the resistance at ETACS-ECU connector C-219.

(1) Disconnect ETACS-ECU connector C-219 and measure the

resistance available at the junction block side of the

connector.

(2) Measure the resistance value between terminal 3 and

ground.

The resistance should be 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 6.

NO : Go to Step 5.

Page 77 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-77

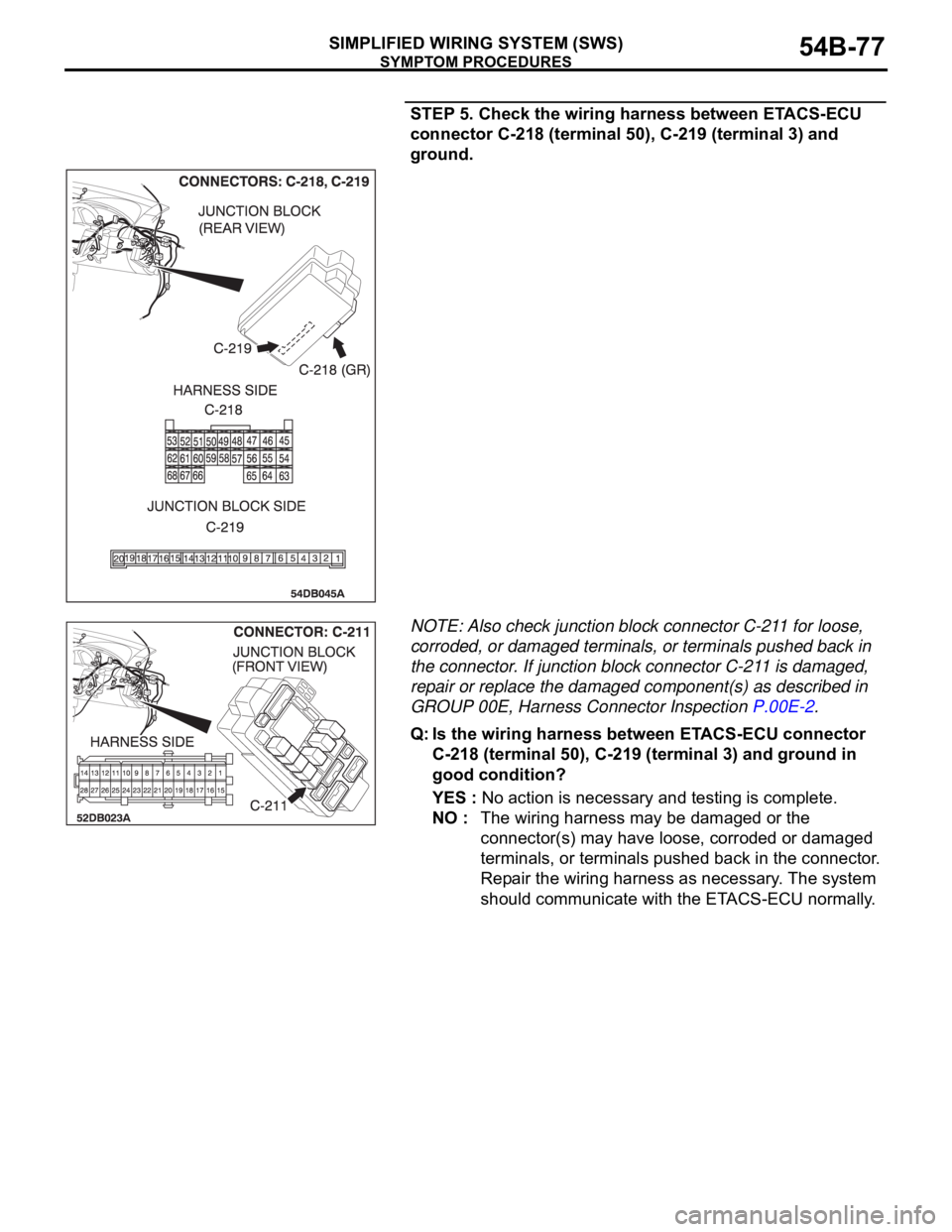

STEP 5. Check the wiring harness between ETACS-ECU

connector C-218 (terminal 50), C-219 (terminal 3) and

ground.

NOTE: Also check junction block connector C-211 for loose,

corroded, or damaged terminals, or terminals pushed back in

the connector. If junction block connector C-211 is damaged,

repair or replace the damaged component(s) as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between ETACS-ECU connector

C-218 (terminal 50), C-219 (terminal 3) and ground in

good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the ETACS-ECU normally.

Page 78 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-78

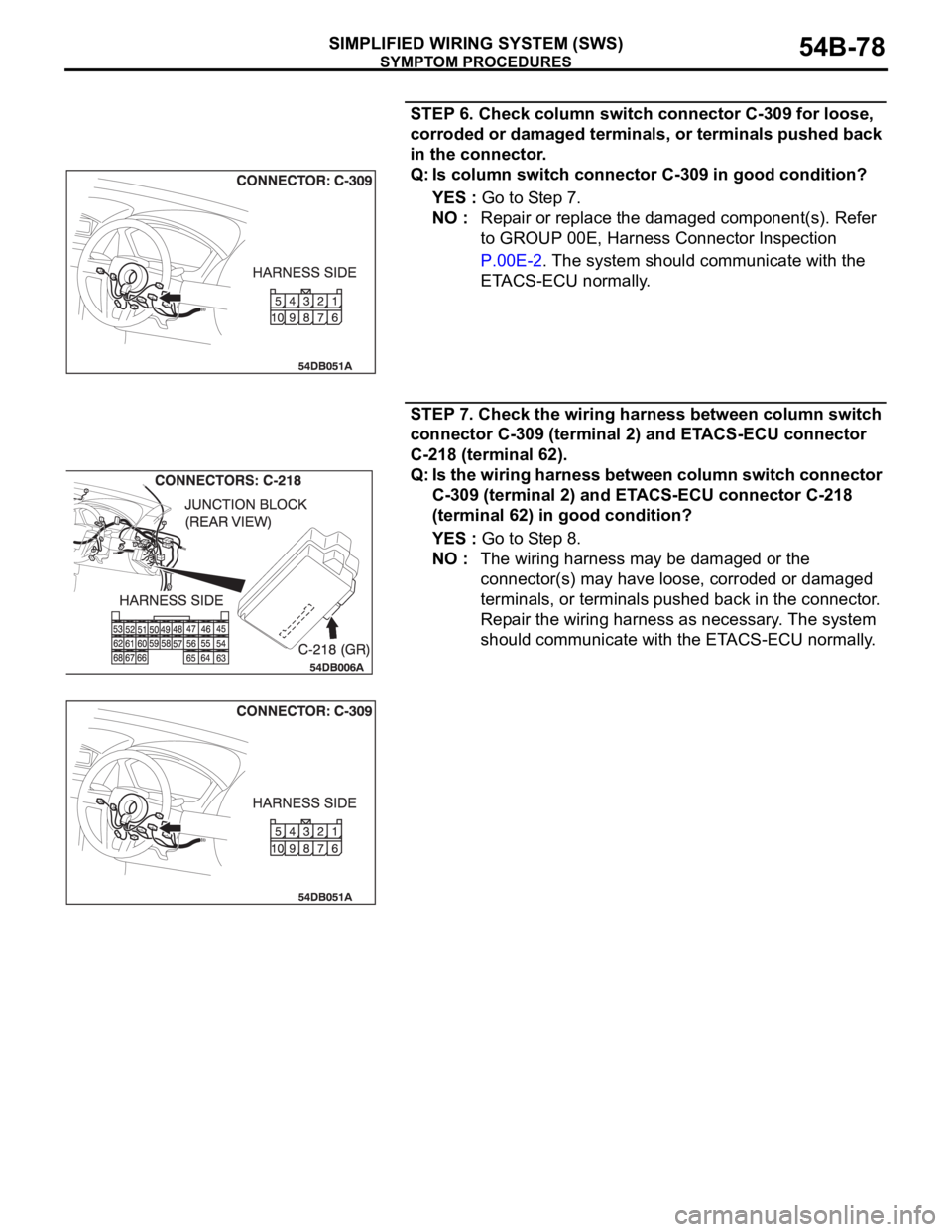

STEP 6. Check column switch connector C-309 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is column switch connector C-309 in good condition?

YES : Go to Step 7.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

P.00E-2. The system should communicate with the

ETACS-ECU normally.

STEP 7. Check the wiring harness between column switch

connector C-309 (terminal 2) and ETACS-ECU connector

C-218 (terminal 62).

Q: Is the wiring harness between column switch connector

C-309 (terminal 2) and ETACS-ECU connector C-218

(terminal 62) in good condition?

YES : Go to Step 8.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the ETACS-ECU normally.

Page 79 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-79

STEP 8. Check the wiring harness between column switch

connector C-309 (terminal 3) and ETACS-ECU connector

C-218 (terminal 53).

Q: Is the wiring harness between column switch connector

C-309 (terminal 3) and ETACS-ECU connector C-218

(terminal 53) in good condition?

YES : Replace the ETACS-ECU. The system should

communicate with the ETACS-ECU normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. The system

should communicate with the ETACS-ECU normally.

Page 80 of 1500

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-80

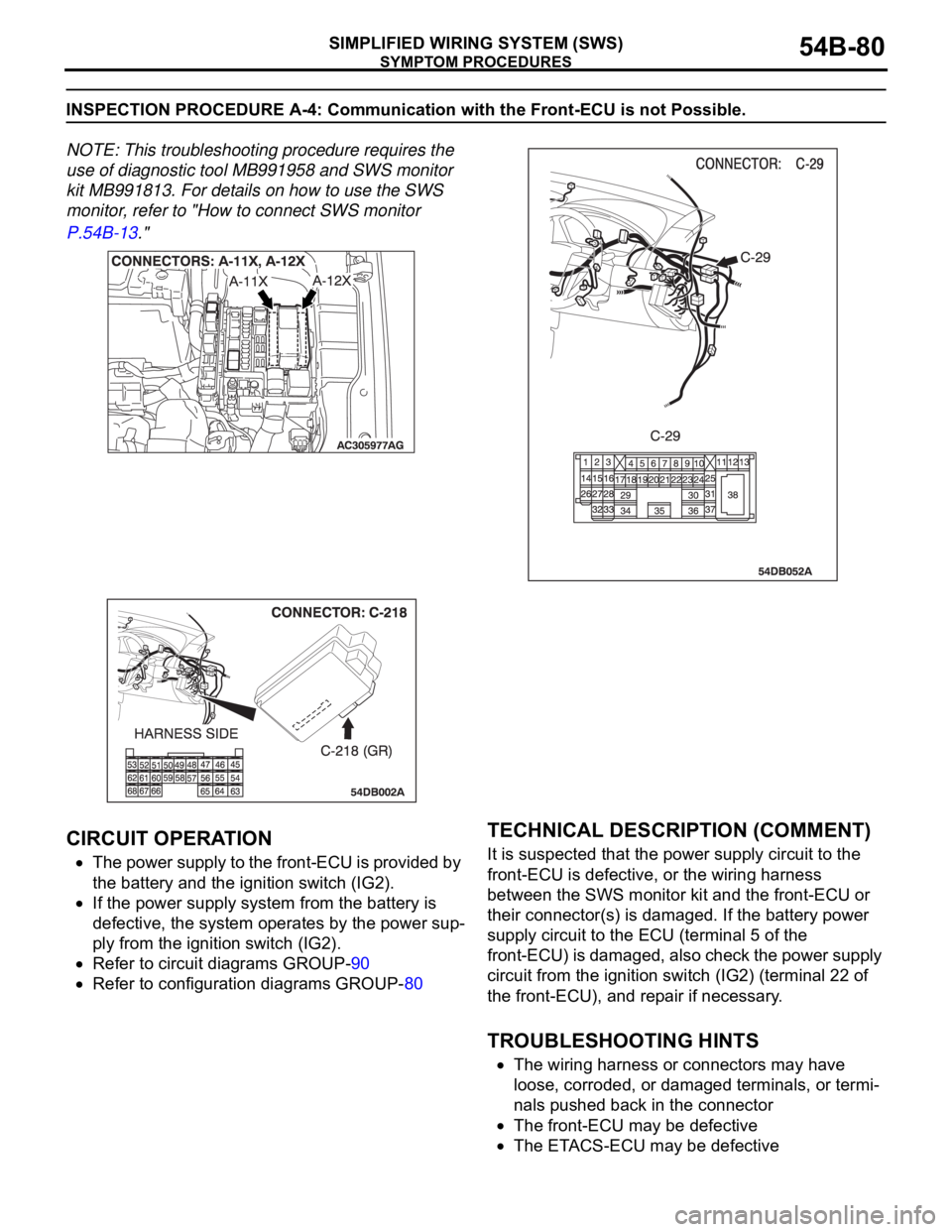

INSPECTION PROCEDURE A-4: Communication with the Front-ECU is not Possible.

NOTE: This troubleshooting procedure requires the

use of diagnostic tool MB991958 and SWS monitor

kit MB991813. For details on how to use the SWS

monitor, refer to "How to connect SWS monitor

P.54B-13."

.

CIRCUIT OPERATION

The power supply to the front-ECU is provided by

the battery and the ignition switch (IG2).

If the power supply system from the battery is

defective, the system operates by the power sup-

ply from the ignition switch (IG2).

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

.

TECHNICAL DESCRIPTION (COMMENT)

It is suspected that the power supply circuit to the

front-ECU is defective, or the wiring harness

between the SWS monitor kit and the front-ECU or

their connector(s) is damaged. If the battery power

supply circuit to the ECU (terminal 5 of the

front-ECU) is damaged, also check the power supply

circuit from the ignition switch (IG2) (terminal 22 of

the front-ECU), and repair if necessary.

.

TROUBLESHOOTING HINTS

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The front-ECU may be defective

The ETACS-ECU may be defective