MITSUBISHI DIAMANTE 1900 Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 361 of 408

BRAKES 9-25

Diagnostic inspection item Diagnostic content

trouble

code No.

11 Right front wheel speed sensor

12 Left front wheel speed sensor Open circuit

13 Right rear wheel speed sensor

14 Left rear wheel speed sensor

Abnormal output signal

Abnormal battery posi-

tive voltage 15 Wheel speed sensor system

16 Power supply system

r 21

I Right front wheel speed sensor 1 Excessive gap

22 I Left front wheel speed sensor or short circuit

23 Right rear wheel speed sensor

24 Left rear wheel speed sensor

36 Stop light switch system Open circuit or ON mal-

function

Right front solenoid valve system

I 5’ I Valve relay system 1 Valve relay OFF failure

I 53 1 Motor relay or motor system Motor relay OFF failure

and motor drive failure

63 ABS-ECU Malfunction in ABS-

ECU (program maze,

etc.)

I

!

Detection

conditions

B ’

A, B

A, B

A, B

A, 8

B

A, B

Detection conditions

A: During system check immediately after starting

B: When driving

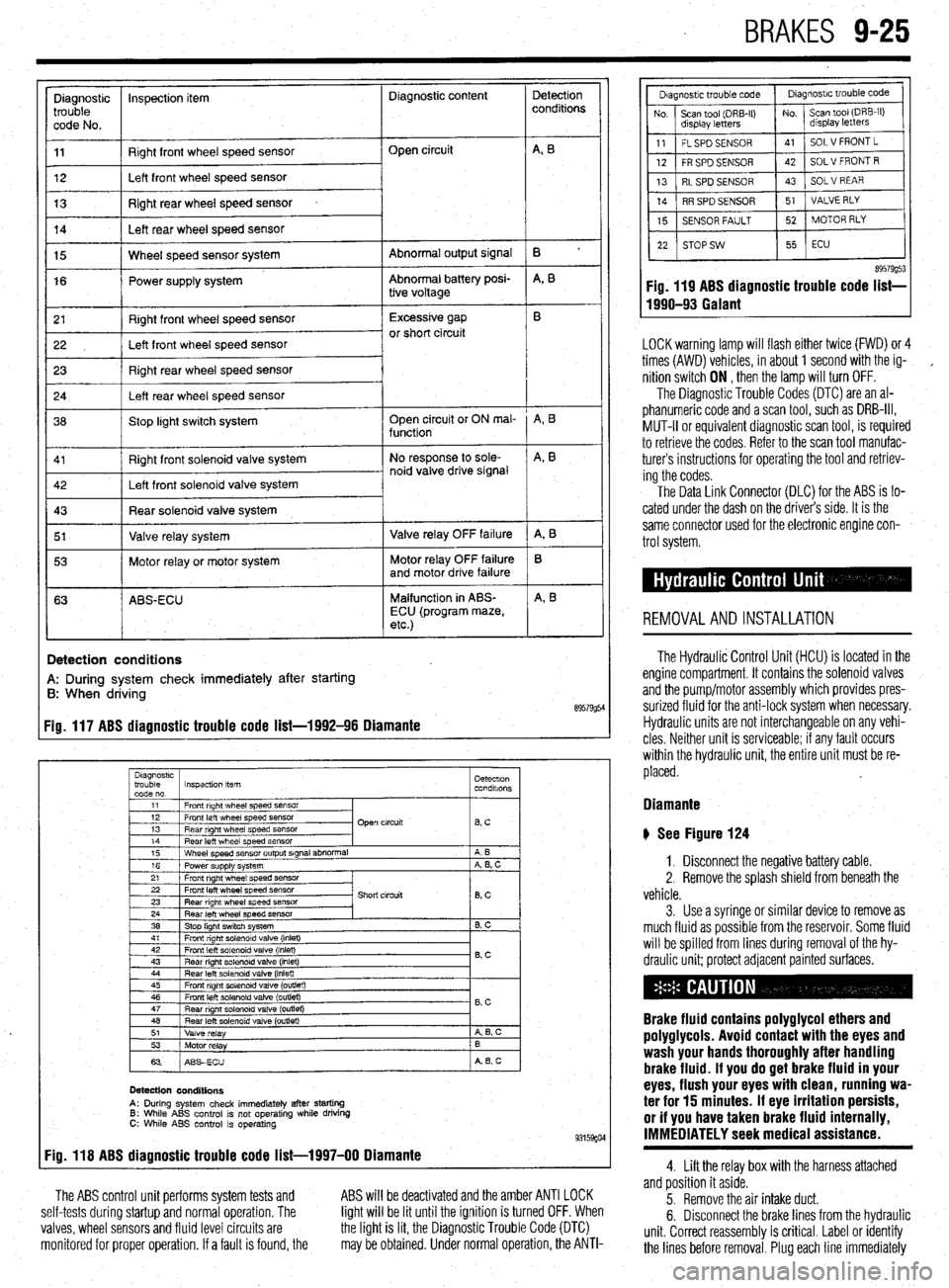

89579954 Fig. 117 ABS diagnostic trouble code list-1992-96 Diamante

Diagnostrc

trouble Inspection item Detectron

code no. condalons

1

11 1 Front right wheel speed SensOr

I

I I

12 1 Front left wheel speed sensor

13 1 Rear right wheel speed sensor Open circuit

lBsC I

14

Rear left wheel speed sensor

15 Wheel speed sensor output signal abnormal

16 Power supply system

21 Front right wheel speed sensor A B

A, B, C

22 Front left wheel speed sensor

23 Rear right wheel speed sensor

24 Rear left wheel speed sensor

38 Stop light switch system Short circuit

8, c

B. C

41 1 Front right solenoid valve (inlet)

I I

42

Front left solenoid valve (inlet)

43 Rear right solenord valve (inlet) 0.c

44 Rear left solenoid valve (inlet)

45 Front right solenoid valve (outlet)

46 Front left solenoid valve (outlet)

47

Rear nght solenoid valve (outret) - B,C

48 Rear left solenoid valve (outlet)

51

Valve relay A 6, c

53

Motor relay B

63 ABSECU A B, c

Detection conditions

A: During system check immediately after starting 6: While ABS control is not operating while driving C: While ABS control is operating 93159go4 Fig. 118 ABS diagnostic trouble code list-1997-00 Diamante

The ABS control unit performs system tests and

self-tests during startup and normal operation. The

valves, wheel sensors and fluid level circuits are

monitored for proper operation. If a fault is found, the ABS will be deactivated and the amber ANTI LOCK

light will be lit until the ignition is turned OFF. When

the light is lit, the Diagnostic Trouble Code (DTC)

may be obtained. Under normal operation, the ANTI-

89579g53 Fig. 119 ABS diagnostic trouble code list-

1990-93 Galant

LOCK warning lamp will flash either twice (FWD) or 4

times (AWD) vehicles, in about 1 second with the ig-

,

nition switch ON , then the lamp will turn OFF.

The Diagnostic Trouble Codes (DTC) are an al-

phanumeric code and a scan tool, such as DRB-III,

MUT-II or equivalent diagnostic scan tool, is required

to retrieve the codes. Refer to the scan tool manufac-

turers instructions for operating the tool and retriev-

ing the codes.

The Data Link Connector (DLC) for the ABS is lo-

cated under the dash on the driver’s side. It is the

same connector used for the electronic engine con-

trol system.

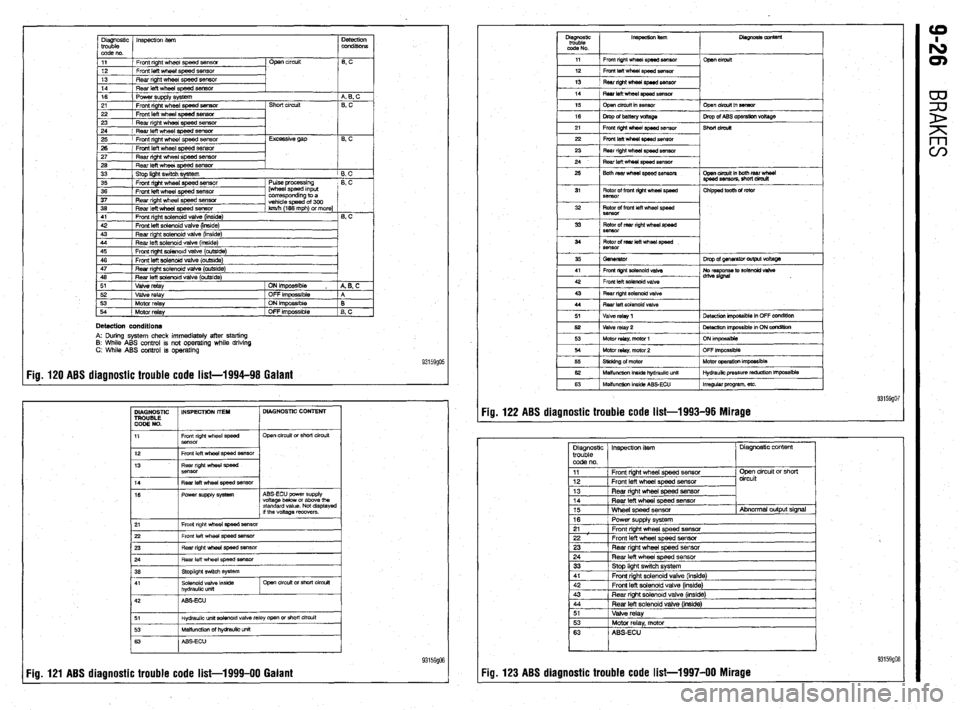

REMOVALANDINSTALLATION

The Hydraulic Control Unit (HCU) is located in the

engine compartment. It contains the solenoid valves

and the pump/motor assembly which provides pres-

surized fluid for the anti-lock system when necessary.

Hydraulic units are not interchangeable on any vehi-

cles Neither unit is serviceable; if any fault occurs

within the hydraulic unit, the entire unit must be re-

placed.

Diamante

b See Figure 124

1. Disconnect the negative battery cable.

2. Remove the splash shield from beneath the

vehicle.

3. Use a syringe or similar device to remove as

much fluid as possible from the reservoir. Some fluid

will be spilled from lines during removal of the hy-

draulic unit; protect adjacent painted surfaces.

Brake fluid contains polyglycol ethers and

poly9lycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brake fluid. If you do 9et brake fluid in your

eyes, flush your eyes with clean, running wa-

ter for 15 minutes. If eye irritation persists,

or if you have taken brake fluid internally,

IMMEDIATELY seek medical assistance.

4. Lift the relay box with the harness attached

and position it aside.

5. Remove the air intake duct.

6. Disconnect the brake lines from the hydraulic

unit. Correct reassembly is critical. Label or identify

the lines before removal. Plug each line immediately

Page 362 of 408

Diagnostic InspeclM item

trouble

code no. Detection

conditions

11 Front right wheel speed sensor

12 Front left wheel speed sensor

13 Rear right wheel speed sensor Open circuit

6 c

14

Rear left wheel speed sensor

16

Power supply system

21 Front right wheel speed sensor

22 Front left wheel speed sensor Short circuit 4 0. C

0, c

23

Rear right wheel speed sensof

24 Rear left wheel speed sensor

25 Front right wheel speed sensor

26 Front left wheel speed sensor Excessive gap

B, c

27 / Rear right wheel speed sensor

26 1 Rear left wheel speed sew

33

Stop light switch system

35 Front right wheel speed sensor

36 Front left wheel speed sensor

37 Rear right wheel speed sensor Pulse orocessina

pheei speed in&t

corresponding to a

vehicle speed of 300

46 Rear left solenoid valve (outside)

51

Valve relay

52 Vti relay

53

Motor relay

54

Motor relay ON impossible ,

A B. C

OFF impossrble

A

ON impossible

B

OFF impossible

B, c

Detection conditions A: During system check immediately after starting

8: While ABS control is not operating while driving

C: While ABS control is operating

Fig. 120 ABS diagnostic trouble code list-1994-98 Galant 93159go5

DIAGNOSTIC INSPECTION IT’EH DIAGNOSTIC CONTENT

TROUBLE

CODE NO.

11 Front right wheel speed

Sensor Open circuit or short circuit

12

13 Front left wheel speed sensor

Rear right wheel speed

SBnsor

14

16 Fear left wheel speed ssnsor

Power supply system ABS-ECU power supply

voltage below or above the

standard value. Not displayed

if the voltage recovers.

21 Front right wheel speed sensor

22 Front left wheel speed sensor

23 Rear right whesl sped sensor

~

Hydraulic unit aolenoid valve relay open or short circuit

93159906

Fig. 121 ABS diagnostic trouble code list-1999-00 Galant Fig. 122 ABS diagnostic trouble code list-1993-96 Mirage

Page 363 of 408

BRAKES 9-27

93159g17

Fig. 124 HCU mounting-Diamante

after removal. It will be necessary to hold the relay

box aside to allow wrench access.

7. Detach the wiring harness connections at the

hydraulic unit.

8. Disconnect the hydraulic unit ground strap

from the chassis.

9. Remove the 3 bolts holding the hydraulic unit

bracket. Remove the unit and the bracket.

*The hydraulic unit is heavy; use care when

removing it. The unit must remain in the up-

right position at all times and be protected

from impact and shock.

IO. Set the unit upright, supported by blocks on

the workbench. The hydraulic unit must not be tilted

or turned upside down. No component of the hy-

draulic unit should be loosened or disassembled.

11. Loosen the nut holding the bracket to the hy-

draulic unit and remove the bracket.

12. Disconnect the external ground wire from the

bracket.

To install: 13. Install the bracket if removed.

14. Connect the ground wire to the bracket.

15. Install the hydraulic unit into the vehicle,

keeping it upright at all times.

16. Install the retaining nuts and tighten.

17. Connect the hydraulic unit wiring harness.

18. Connect each brake line loosely to the correct

port and double check the placement. Tighten each

line to 11 ft. Ibs. (15 Nm).

19. Fill the reservoir to the MAX line with brake

fluid.

20. Bleed the master cylinder, then bleed the

brake lines.

21. Secure the relay box in position and install

the air duct.

22. Install the splash shield.

Galant and Mirage

ti See Figures 125 and 126

1. Use a syringe or similar device to remove as

much fluid as possible from the reservoir. Some fluid

will be spilled from lines during removal of the hy-

draulic unit; protect adjacent painted surfaces.

Brake fluid contains polyglycol ethers and

polyglycols. Avoid contact with the eyes and

wash your hands thoroughly after handling

brake fluid. If you do get brake fluid in your

eyes, flush your eyes with clean, running wa-

ter for 15 minutes. If eye irritation persists,

1. Bracket

2. Air conditioning relay box

3. Oil reservoir

4. Motor relay

5. Valve relay

6. Brake pipe

7. Hydraulic unit

8. Hydraulic unit bracket

Fig. 125 HCU mounting-Mirage

or if you have taken brake fluid internally,

17. Fill the reservoir to the MAX line with brake IMMEDIATELY seek medical assistance. fluid.

2. Remove the splash shield from the left front

wheel house or fender area.

3. Remove the coolant reserve tank.

4. Remove the coolant reservoir bracket.

5. Remove the dust shield from below the hy-

draulic unit.

6. Disconnect the

brake hoses and lines from

the hydraulic unit. Correct reassembly is critical. La-

bel or identify the lines before removal. Plug each

line and each port immediately after removal.

7. Remove the cover from the relay box. Dis-

connect the electrical harness to the hydraulic unit.

8. Remove the bolts holding the 3 mounting

brackets to the vehicle; remove the unit downward

and out of the vehicle. 18. Bleed the brake system.

19. Install the dust shield and the coolant reserve

tank with its bracket.

20. Install the fender splash shield.

21. Check ABS system function by turning the ig-

nition ON and observing the dashboard warning

lamp. Test drive the vehicle and confirm system op-

eration.

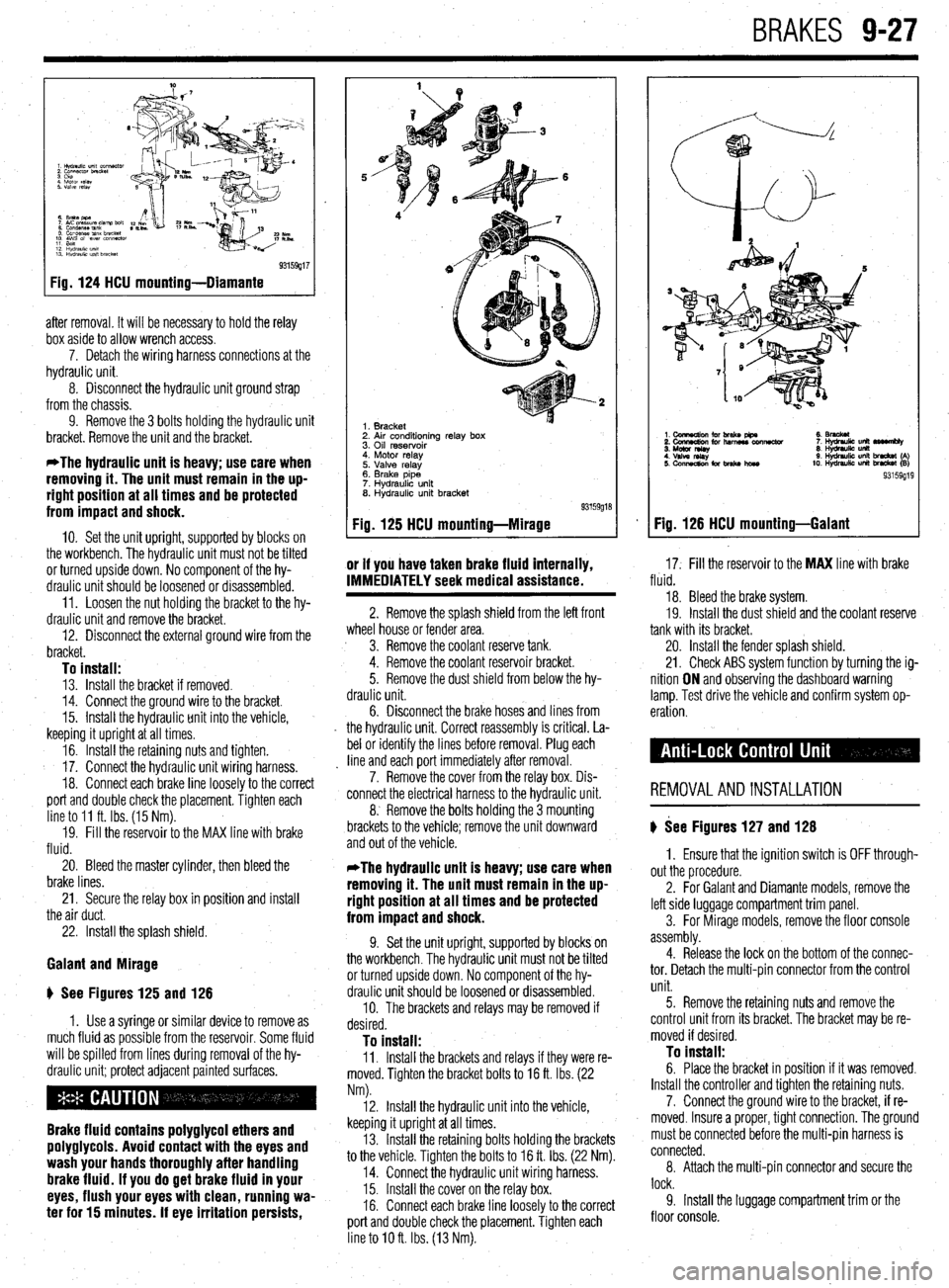

REMOVALANDINSTALLATION

) See Figures 127 and 128

*The hydraulic unit is heavy; use care when

removing it. The unit must remain in the up-

right position at all times and be protected

from impact and shock.

9. Set the unit upright, supported by blocks on

the workbench. The hydraulic unit must not be tilted

or turned upside down. No component of the hy-

draulic unit should be loosened or disassembled.

10. The brackets and relays may be removed if

desired.

To install: 11. Install the brackets and relays if they were re-

moved. Tighten the bracket bolts to 16 ft. Ibs. (22

Nm). 1. Ensure that the ignition switch is OFF through-

out the procedure.

2. For Galant and Diamante models, remove the

left side luggage compartment trim panel.

3. For Mirage models, remove the floor console

assembly.

4. Release the lock on the bottom of the connec-

tor. Detach the multi-pin connector from the control

unit.

12. Install the hydraulic unit into the vehicle,

keeping it upright at all times.

13. Install the retaining bolts holding the brackets

to the vehicle. Tighten the bolts to 16 ft. Ibs. (22 Nm).

14. Connect the hydraulic unit wiring harness.

15. Install the cover on the relay box.

16. Connect each brake line loosely to the correct

port and double check the placement. Tighten each

line to IO ft. Ibs. (13 Nm). 5. Remove the retaining nuts and remove the

control unit from its bracket. The bracket may be re-

moved if desired. To install: 6. Place the bracket in position if it was removed.

Install the controller and tighten the retaining nuts.

7. Connect the ground wire to the bracket, if re-

moved. Insure a proper, tight connection. The ground

must be connected before the multi-pin harness is

connected.

8. Attach the multi-pin connector and secure the

lock.

9. Install the luggage compartment trim or the

floor console.

Fig. 126 HCU mounting-Galant

Page 364 of 408

9-28 BRAKES

1. Electronic control una

2. Bracket 93159912 Fig. 127 Anti-lock control unit mounting-

Fig. 128 Anti-lock control unit mounting-

Mirage

Galant and Diamante

REMOVAL&INSTALLATION

Mirage

FRONT

I) See Figure 129

1, Disconnect the negative battery cable.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

2. Raise and safely support the vehicle.

3. Remove the splash shield.

4. Detach the speed sensor connector.

5. Remove the clips holding the sensor harness.

6. Remove the speed sensor from the bracket.

To install: 7. Install the speed sensor to the bracket and

secure with mounting bolt.

8. Install the clips holding the sensor harness.

9. Attach the speed sensor connector.

IO. Connect the negative battery cable.

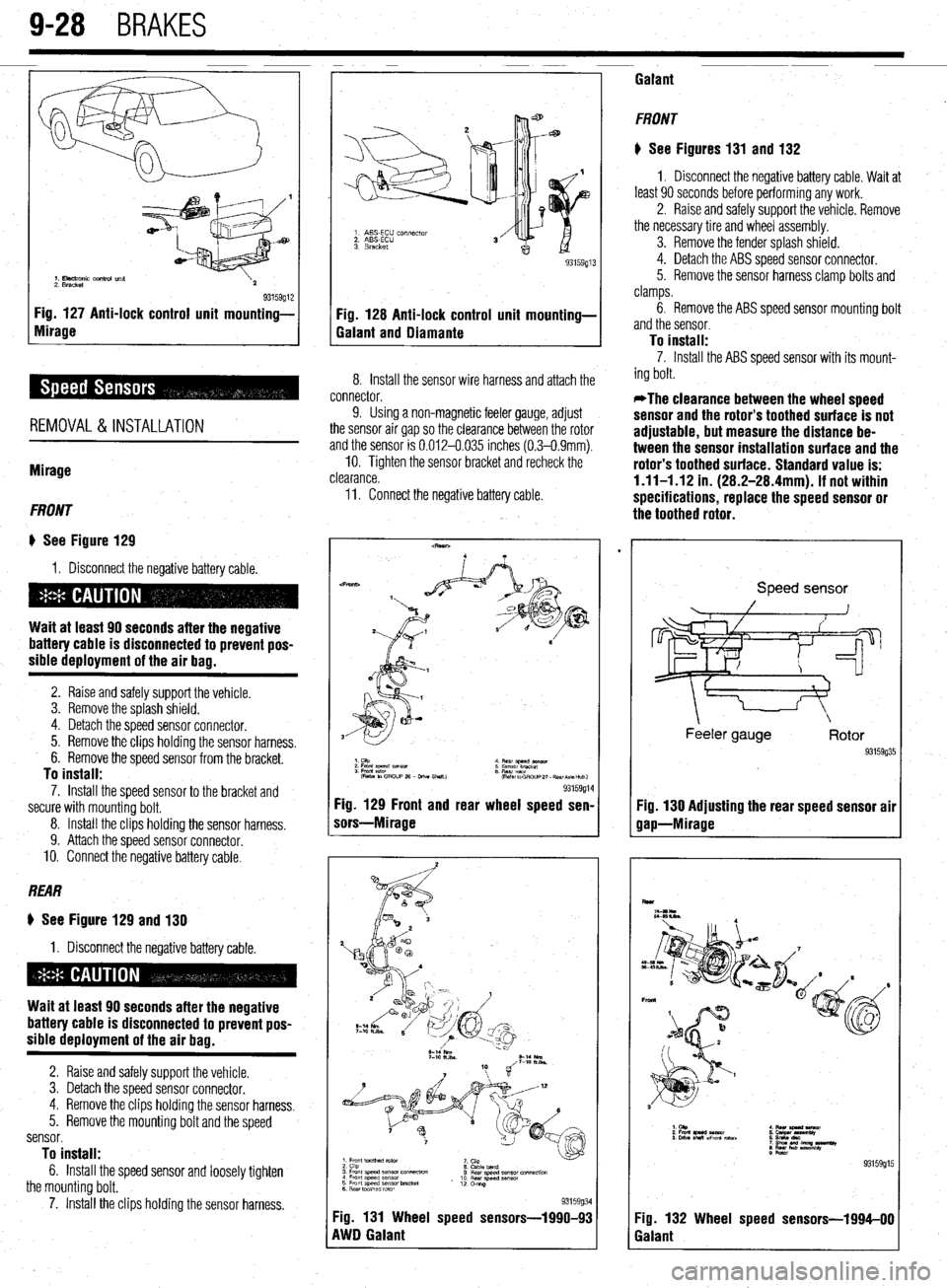

REAR

8 See Figure 129 and 130

1. Disconnect the negative battery cable.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

2. Raise and safely support the vehicle.

3. Detach the speed sensor connector.

4. Remove the clips holding the sensor harness.

5. Remove the mounting bolt and the speed

sensor.

To install: 6. Install the speed sensor and loosely tighten

the mounting bolt,

7. Install the clips holding the sensor harness.

1. ABS-ECU ccr~nector

2. ABSECU

3. Bracket

8. Install the sensor wire harness and attach the

connector,

9. Using a non-magnetic feeler gauge, adjust

the sensor air gap so the clearance between the rotor

and the sensor is 0.012-0.035 inches (0.3-0.9mm).

IO. Tighten the sensor bracket and recheck the

clearance.

11. Connect the negative battery cable.

Fig. 129 Front and rear wheel speed sen-

sors-Mirage

1

3. Front speed sensor connwxwn

4 Fmnt sweed sensor

5 Front speed sensor bracket

6 Rear toothed rotor 8 Cabletand

8 Rear speed sensor connection

10 Rear speed sensx

12 omg

93159934 Fig. 131 Wheel speed sensors-1990-93

RWD Galant Galant

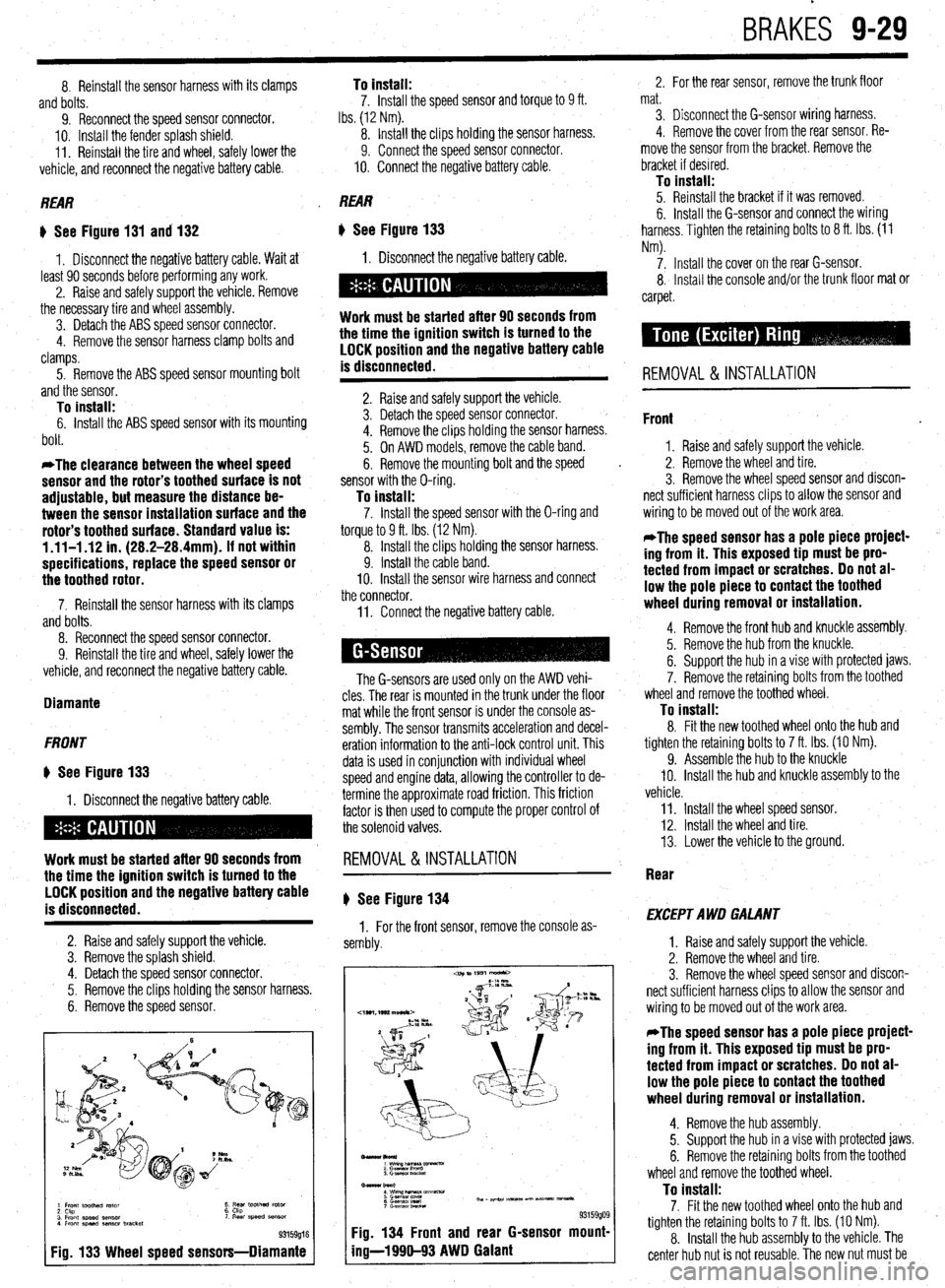

FRONT

# See Figures 131 and 132

1. Disconnect the negative battery cable. Wait at

least 90 seconds before performing any work.

2. Raise and safely support the vehicle. Remove

the necessary tire and wheel assembly.

3. Remove the fender splash shield.

4. Detach the ABS speed sensor connector.

5. Remove the sensor harness clamp bolts and

clamps.

6. Remove the ABS speed sensor mounting bolt

and the sensor.

To install: 7. Install the ABS speed sensor with its mount-

ing bolt.

*The clearance between the wheel speed

sensor and the rotor’s toothed surface is not

adjustable, but measure the distance be-

tween the sensor installation surface and the

rotor’s toothed surface. Standard value is:

1.11-1 .I2 in. (28.2-28.4mm). If not within

specifications, replace the speed sensor or

the toothed rotor.

Speed sensor

Feeler gauge

93159g35

Fig. 130 Adjusting the rear speed sensor air

gap-Mirage

6

Fig. 132 Wheel speed sensors-1994-00

Galant

Page 365 of 408

BRAKES 9-29

8. Reinstall the sensor harness with its clamps

and bolts.

9. Reconnect the speed sensor connector.

IO. Install the fender splash shield.

11. Reinstall the tire and wheel, safely lower the

vehicle, and reconnect the negative battery cable. To install: 7. Install the speed sensor and torque to 9 ft.

Ibs. (12 Nm).

8. Install the clips holding the sensor harness.

9. Connect the speed sensor connector.

IO. Connect the negative battery cable.

REAR REAR

) See Figure 131 and 132

1. Disconnect the negative battery cable. Wait at

least 90 seconds before performing any work.

2. Raise and safely support the vehicle. Remove

the necessary tire and wheel assembly.

3. Detach the ABS speed sensor connector.

4. Remove the sensor harness clamp bolts and

clamps.

I) See Figure 133

1. Disconnect the negative battery cable.

5. Remove the ABS speed sensor mounting bolt

and the sensor.

Work must be started after 90 seconds from

the time the ignition switch is turned to the

LOCK position and the negative battery cable

is disconnected.

To install:

6. Install the ABS speed sensor with its mounting

bolt.

*The clearance between the wheel speed

sensor and the rotor’s toothed surface is not

adjustable, but measure the distance be-

tween the sensor installation surface and the

rotor’s toothed surface. Standard value is:

1.11-l .I2 in. (28.2-28.4mm). If not within

specifications, replace the speed sensor or

the toothed rotor.

2. Raise and safely support the vehicle.

3. Detach the speed sensor connector.

4. Remove the clips holding the sensor harness.

5. On AWD models, remove the cable band.

6. Remove the mounting bolt and the speed

sensor with the O-ring.

To install: 7. Install the speed sensor with the O-ring and

torque to 9 ft. Ibs. (12 Nm).

8. Install the clips holding the sensor harness.

9. Install the cable band.

10. Install the sensor wire harness and connect

the connector.

7. Reinstall the sensor harness with its clamps

and bolts.

8. Reconnect the speed sensor connector.

9. Reinstall the tire and wheel, safely lower the

vehicle, and reconnect the negative battery cable.

Diamante

FRONT

* See Figure 133

1. Disconnect the negative battery cable.

Work must be started after 90 seconds from

the time the ignition switch is turned to the

LOCK position and the negative battery cable

is disconnected.

2. Raise and safely support the vehicle.

3. Remove the splash shield.

4. Detach the speed sensor connector.

5. Remove the clips holding the sensor harness.

6. Remove the speed sensor.

1 Front toothed rotor

2 Ckp

3 Front speed sensor

4 Front speed aenmr bracket t ;5’ toothed rotor ‘I Rear speed SB"SO,

93159016

Fig. 133 Wheel speed sensors-Diamante

11. Connect the negative battery cable.

The G-sensors are used only on the AWD vehi-

cles. The rear is mounted in the trunk under the floor

mat while the front sensor is under the console as-

sembly. The sensor transmits acceleration and decel-

eration information to the anti-lock control unit. This

data is used in conjunction with individual wheel

speed and engine data, allowing the controller to de-

termine the approximate road friction. This friction

factor is then used to compute the proper control of

the solenoid valves.

REMOVAL&INSTALLATION

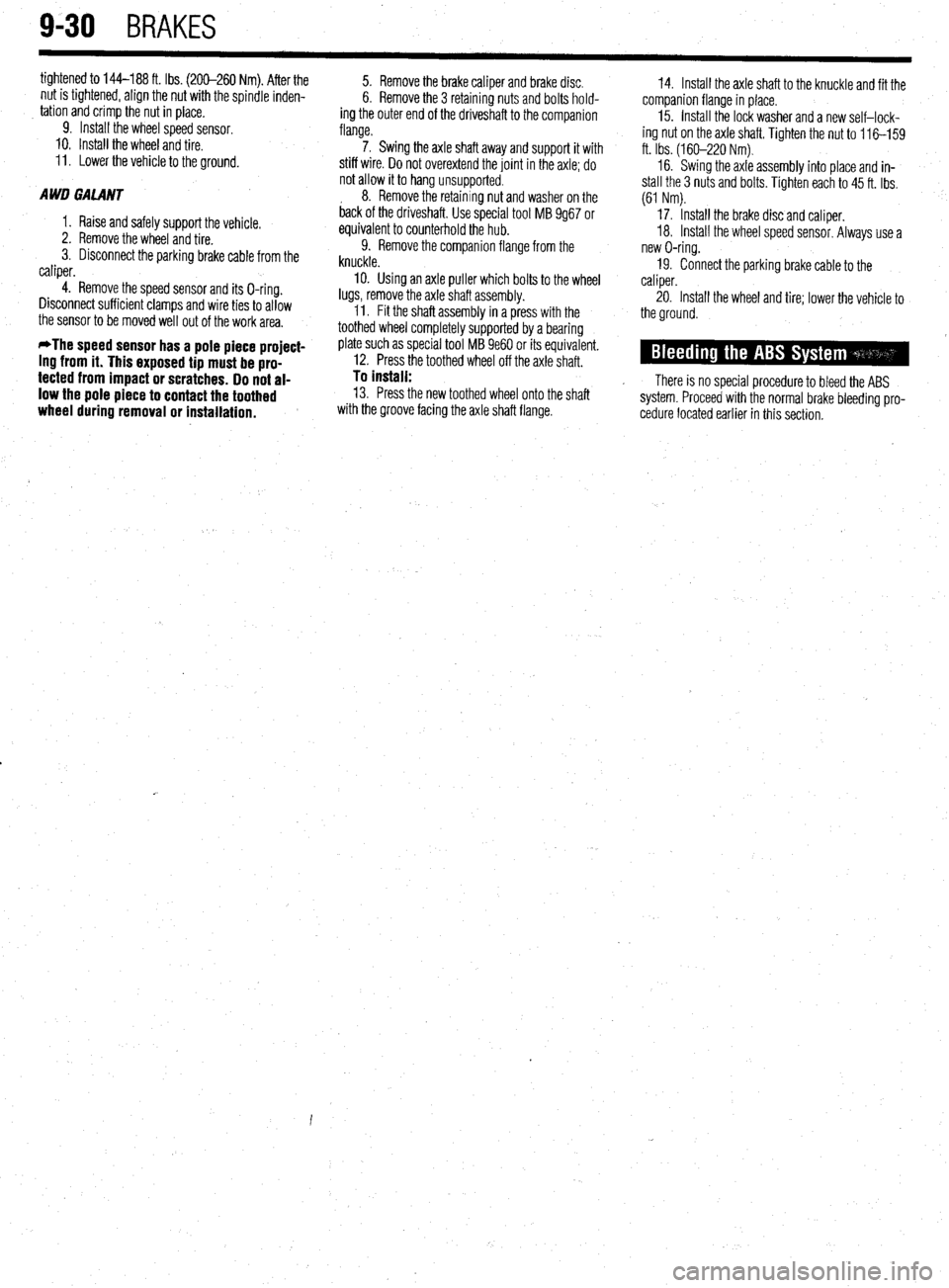

# See Figure 134

1. For the front sensor, remove the console as-

sembly.

-lkol*)

1 wimp--vx

2 Gasnan I‘m”0

3. Gmwor LmcM

Bmar burl

: wwzh&T&m~mm-

6 G.smsol Ired Th, - ape.24 m-5 un Nt- vmsa*.

7 c-.elwnbRcta

93159909 Fig. 134 Front and rear G-sensor mount-

ing-l 990-93 AWD Galant

2. For the rear sensor, remove the trunk floor

mat.

3. Disconnect the G-sensor wiring harness.

4. Remove the cover from the rear sensor. Re-

move the sensor from the bracket. Remove the

bracket if desired.

To install: 5. Reinstall the bracket if it was removed.

6. Install the G-sensor and connect the wiring

harness. Tighten the retaining bolts to 8 ft. Ibs. (11

Nm).

7. Install the cover on the rear G-sensor.

8, Install the console and/or the trunk floor mat or

carpet.

REMOVAL & INSTALLATION

Front

1. Raise and safely support the vehicle.

2. Remove the wheel and tire.

3. Remove the wheel speed sensor and discon-

nect sufficient harness clips to allow the sensor and

wiring to be moved out of the work area.

*The speed sensor has a pole piece project-

ing from it. This exposed tip must be pro-

tected from impact or scratches. Do not al-

low the pole piece to contact the toothed

wheel during removal or installation.

4. Remove the front hub and knuckle assembly.

5. Remove the hub from the knuckle.

6. Support the hub in a vise with protected jaws.

7. Remove the retaining bolts from the toothed

wheel and remove the toothed wheel.

To install: 8. Fit the new toothed wheel onto the hub and

tighten the retaining bolts to 7 ft. Ibs. (10 Nm).

9. Assemble the hub to the knuckle

IO. Install the hub and knuckle assembly to the

vehicle.

11. Install the wheel speed sensor.

12. Install the wheel and tire.

13. Lower the vehicle to the ground.

Rear

EXCEPT AWD GALANT

1. Raise and safely support the vehicle.

2. Remove the wheel and tire.

3. Remove the wheel speed sensor and discon-

nect sufficient harness clips to allow the sensor and

wiring to be moved out of the work area.

*The speed sensor has a pole piece project-

ing from it. This exposed tip must be pro-

tected from impact or scratches. Do not al-

low the pole piece to contact the toothed

wheel during removal or installation.

4. Remove the hub assembly.

5. Support the hub in a vise with protected jaws.

6. Remove the retaining bolts from the toothed

wheel and remove the toothed wheel.

To install: 7. Fit the new toothed wheel onto the hub and

tighten the retaining bolts to 7 ft. Ibs. (10 Nm).

8. Install the hub assembly to the vehicle. The

center hub nut is not reusable. The new nut must be

Page 366 of 408

9-30 BRAKES

tightened to 144-188 ft. Ibs. (200-260 Nm). After the

nut is tightened, align the nut with the spindle inden-

tation and crimp the nut in place.

9. Install the wheel speed sensor.

10. Install the wheel and tire.

11. Lower the vehicle to the ground.

AWD GALANT

1. Raise and safely support the vehicle.

2. Remove the wheel and tire.

3. Disconnect the parking brake cable from the

caliper.

4. Remove the speed sensor and its O-ring.

Disconnect sufficient clamps and wire ties to allow

the sensor to be moved well out of the work area.

*The speed sensor has a pole piece project-

ing from it. This exposed tip must be pro-

tected from impact or scratches. Do not al-

low the pole piece to contact the toothed

wheel during removal or installatlon.

5. Remove the brake caliper and brake disc.

6. Remove the 3 retaining nuts and bolts hold-

ing the outer end of the driveshaft to the companion

flange.

7. Swing the axle shaft away and support it with

stiff wire. Do not overextend the joint in the axle; do

not allow it to hang unsupported.

, 8. Remove the retaining nut and washer on the

back of the driveshaft. Use special tool MB 9967 or

equivalent to counterhold the hub.

9. Remove the companion flange from the

knuckle.

IO. Using an axle puller which bolts to the wheel

lugs, remove the axle shaft assembly.

11. Fit the shaft assembly in a press with the

toothed wheel completely supported by a bearing

plate such as special tool MB 9e60 or its equivalent.

12. Press the toothed wheel off the axle shaft.

To install: 13. Press the new toothed wheel onto the shaft

with the groove facing the axle shaft flange. 14. Install the axle shaft to the knuckle and fit the

companion flange in place.

15. Install the lock washer and a new self-lock-

ing nut on the axle shaft. Tighten the nut to 116-159

ft. Ibs. (160-220 Nm).

16. Swing the axle assembly into place and in-

stall the 3 nuts and bolts. Tighten each to 45 ft. Ibs.

(61 Nm).

17. Install the brake disc and caliper.

18. Install the wheel speed sensor. Always use a

new O-ring.

19. Connect the parking brake cable to the

caliper.

20. Install the wheel and tire; lower the vehicle to

the ground.

There is no special procedure to bleed the ABS

system. Proceed with the normal brake bleeding pro-

cedure located earlier in this section.

Page 367 of 408

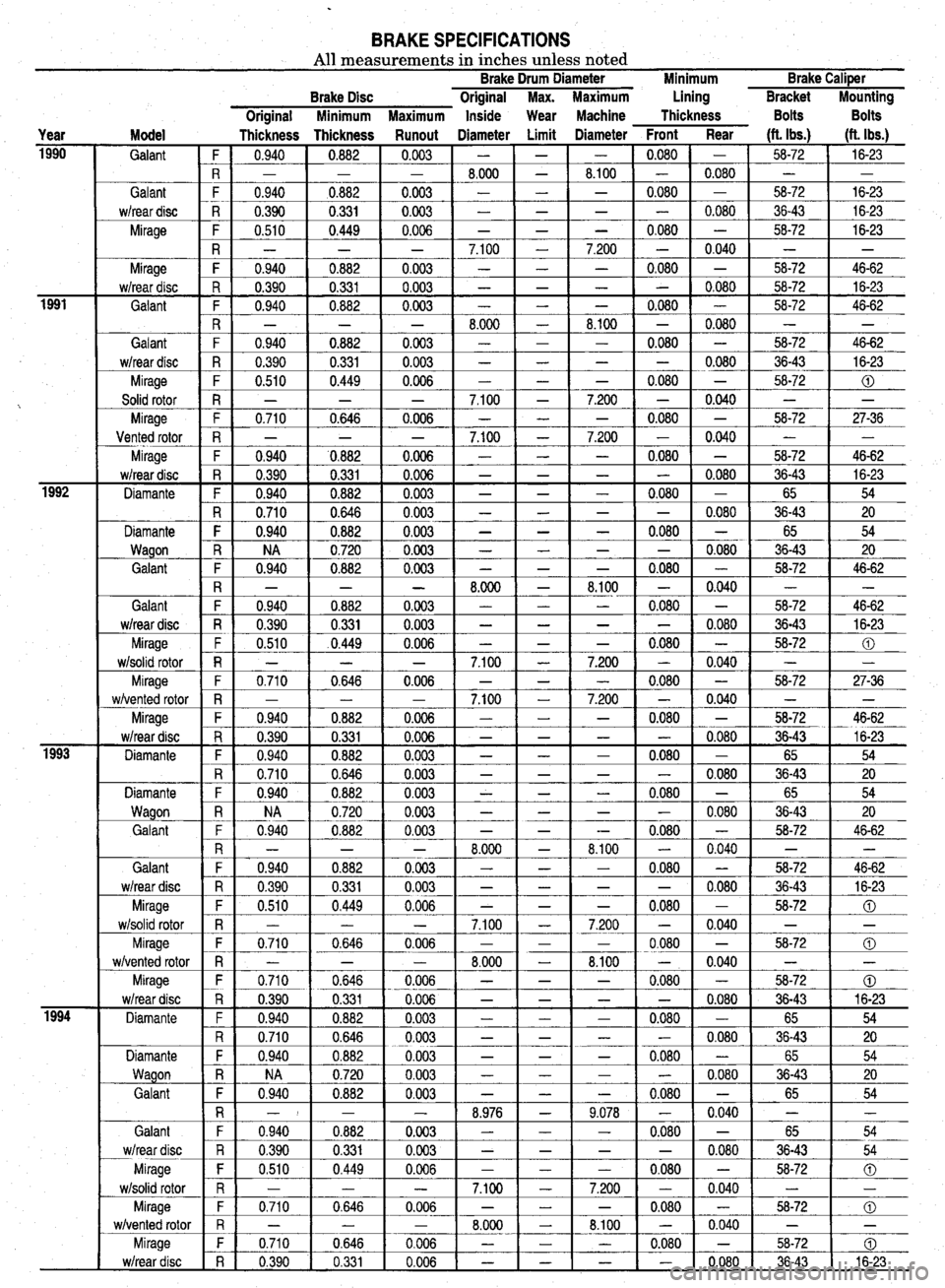

BRAKE SPECIFICATIONS All measurements in inches unless noted Brake Drum Diameter Minimum Brake CaliPer

Year Model

1990

Galant ~

Galant

w/rear disc

Mirage

1991

:

iiz- Mirage

w/rear disc

Galant

Galant

w/rear disc

Mirage

Solid rotor

Mirage

Vented rotor

Mirage

w/rear disc

Diamante

Diamante

Wagon

Galant

1993 Galant

w/rear disc

Mirage

w/solid rotor

Mirage

w/vented rotor

Mirage

w/rear disc

Diamante

Diamante

Wagon

Galant

im- Galant

w/rear disc

Mirage

w/solid rotor

Mirage

w/vented rotor

Mirage

w/rear disc

Diamante

Diamante

Wagon

Galant

Galant

w/rear disc

Mirage

w/solid rotor

Mirage

w/vented rotor

Mirage

w/rear disc Brake Disc Original Max. Maximum Lining Bracket

Miunting

Original Minimum Maximum Inside Wear Machine Thickness Bolts Bolts

Thickness Thickness Runout Diameter Limit Diameter Front Rear (ft. Ibs.)

(ft. Ibs.)

F 0.940

0.882 0.003 - - - 0.080 - 58-72

16-23

R - - - 8.000

- 8.100 - 0.080 - -

F 0.940

aO.882 0.003 - - - 0.080 - 58-72

16-23

R 0.390 0.331 0.003 -

- - - 0.080 36-43 16-23

F 0.510

0.449 0.006 - - - 0.080 - 58-72

16-23

R

- - - 7.100 - 7.200 - 0.040

- -

F 0.940 0.882 0.003 -

- - 0.080 - 58-72 46-62

R 0.390 0.331 0.003 -

- - - 0.080 58-72 16-23

F 0.940

0.882 0.003 - - - 0.080 - 58-72

46-62

R

_ - - 8.000 - 8.100 - 0.080

- -

F 0.940 0.882 0.003 -

- - 0.080 - 58-72 46-62

R 0.390 0.331 0.003 -

- - - 0.080 36-43 16-23

F 0.510

0.449 0.006 - - - 0.080 - 58-72

0

R - - - 7.100

- 7.200 - 0.040 - -

F 0.710 0.646 0.006 -

- - 0.080 - 58-72 27-36

R - - - 7.100

- 7.200 - 0.040 - -

F 0.940

'0.882 0.006 - - - 0.080 - 58-72

46-62

R 0.390

0.331 0.006 - - - - 0.080 36-43

16-23

F 0.940 0.882 0.003 -

- - 0.080 - 65 54

R 0.710

0.646 0.003 - - - - 0.080 36-43

20

F 0.940 0.882 0.003 -

- - 0.080 - 65 54

R

NA 0.720 0.003 - - - - 0.080

36-43 20

F 0.940 0.882 0.003 -

- - 0.080 - 58-72 46-62

R

- _ - 8.000 - 8.100 - 0.040

- -

F 0.940

0.882 0,003 - - - 0.080 -

58-72 46-62

R 0.390

0.331 0.003 - - - - 0.080

36-43 16-23

F 0.510

.0.449 0.006 - - - 0.080 -

58-72 0

R - - - 7.100

- 7.200 - 0.040 - -

F 0.710

0.646 0.006 - - - 0.080 -

58-72 27-36

R - - - 7.100

- 7.200 - 0.040 - -

F 0.940 0.882 0.006 -

- - 0.080 - 58-72 46-62

R 0.390

0.331 0.006 - - - - 0.080

36-43 16-23

F 0.940 0.882 0.003 -

- - 0.080 - 65 54

R 0.710

0.646 0.003 - - - - 0.080

36-43 20

F 0.940

0.882 0.003 - - - 0.080 -

65 54

R

NA 0.720 0.003 - - - - 0.080

36-43 20

F 0.940 0.882 0.003 -

- -- 0.080 - 58-72 46-62

R

- - - 8.000 - 8.100 - 0.040

- -

F 0.940

0.882 0.003 - - - 0.080 -

58-72 46-62

R 0.390 0.331 0.003 -

- - - 0.080 36-43 16-23

F 0.510 0.449 0.006 -

- - 0.080 - 58-72 0

R _ _ - 7.100

- 7.200 - 0.040 - -

F 0.710

0.646 0.006 - - - 0.080 -

58-72 0

R

_ - - 8.000 - 8.100 - 0.040

- -

F 0.710

0.646 0.006 - - - 0.080 -

58-72 CD

R 0.390

0.331 0.006 - - - - 0.080

36-43 16-23

F

0.940 0.882 0.003 - - - 0.080 -

65 54

R 0.710 0.646 0.003 -

- - - 0.080 36-43 20

F 0.940 0.882 0.003 -

- - 0.080 - 65 54

R

NA 0.720 0.003 - - - - 0.080

36-43 20

F 0.940 0.882 0.003 -

- - 0.080 - 65 54

R -I - - 8.976

- 9.078 - 0.040 - -

F 0.940 0.882 0.003 -

- - 0.080 - 65 54

R

0.390 0.331 0.003 - - - - 0.080

36-43 54

F 0,510 0.449 0.006 -

- - 0.080 - 58-72 0

R

_ _ - 7.100 - 7.200 - 0.040

- -

F 0.710 0.646 0.006 -

- - 0.080 - 58-72 0

R

- - - 8.000 - 8.100 - 0.040

- -

F

0.710 0.646 0.006 - - - 0.080 -

58-72 0

R 0.390 0.331 0.006 -

- - - 0.080 36-43 16-23

Page 368 of 408

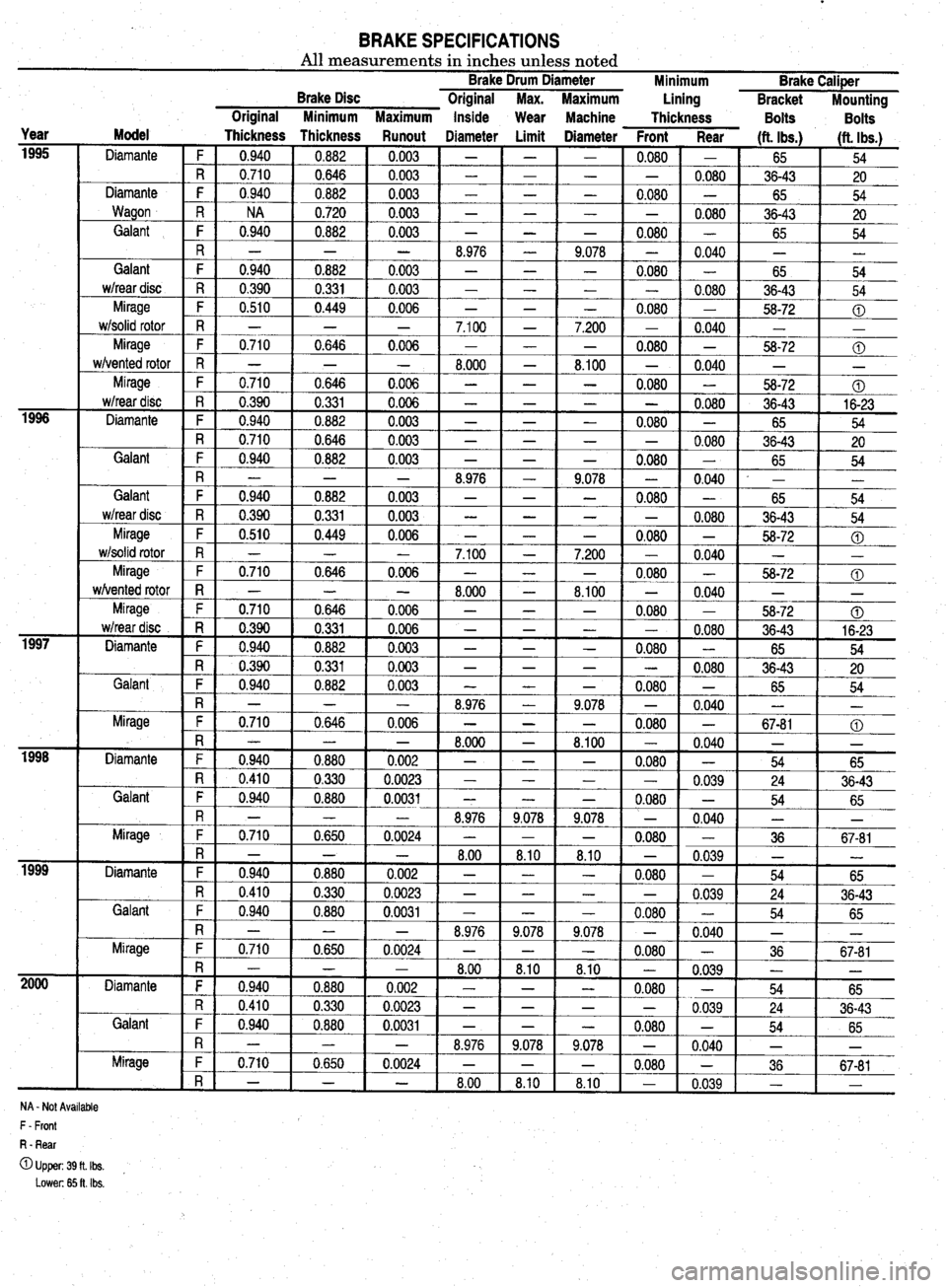

BRAKE SPECIFICATIONS All measurements in inches unless noted Brake Drum Diameter

Brake Disc Original Max. Maximum Minimum Brake Caliper

Lining

Bracket Mounting

Year

1995

1996

1997

isi-

1999

2ooo Original Minimum Maximum Inside

Wear Machine

Thickness Bolts

Bolts

Model

Thickness Thickness Runout Diameter Limit Diameter Front Rear Ht. Ibs.1

Diamante 1 (ft. Ibs.)

F 1 0.940 1 0.882 1 0.003 1 - 1 -

- 54 -

R 0.710 0.646 0.003 - -

Diamante F 0.940 0.882 0.003 - -

Wagon R NA 0.720 0.003 - -

Galant F 0.940 0.882 0.003 - - 0.080

-

0.080

-

-

0.080

-

--iizG-

-

0.040 ' I

65

36-43 20

65 54

36-43 20

65 54

- -

65 54

36-43 54

58-72 0

-

-

t- 0

-

.710 1 0.646 1 0.006 1 -

- 1 0.080 1

- 1 56-72 1 @

-

-

-

-

0.080 R - - - 8.976 -

Galant F 0.940 0.882 0.003 - -

wheardisc R 0.390 0.331 0.003 - -

Mirage F 0.510 0.449 0.006 - - 9.078

- -

0.080

- -

-

0.080

w/solid rotor

7.200

-

8.100 Mirage

w/vented rotor

Mirage

w/rear disc

Diam 1 R 1 0.390 1 0.331 1 0.006 I -

t--=-E5 1 -t-xii- 54

ante F 0.940 0.882 0.003 - - - 0.080 - 65

R 0.710 0.646 0.003 - - - - 0.080 36-43

20

Galant

Galant

wheardisc

Mirage

w/solid rotor

-

-

-

Mirage 1

wivente

d rotor -

‘ge

*disc 8.100 - 0.040 - -

- 0.080 -

58-72 0

- - 0.080 36-43 16-23 Mira - w/rear - -

Diamante F 0.940 0.882 0.003 - - - 0.080 -

65 54

R 0.390 0.331 0.003 - - - - 0.080

36-43 20

Galant F 0.940 0.882 0.003 - - -

0.l

380 - 65 54

R - - - 8.976 - 9.078 - 0.040 - -

Mirage F 0.710 0,646 0.006 - - -

0.l

380 - 67-81 0

PI

InI * n-a

- - - 1 LI.uuu 1 1 A #-A

- 8.1UU 1 - 0.040 - -

Diamante F 1 PPP- 0

t-t- R 0 ,940 0.880 0.002 - - - 0.080 - 54

65

,410 0.330 0.0023 - - - - _

0.039 24

36-43

snt 1 F I 0.940 0.880 0.0031 - - - 0.080 -

54 65 Gdi

Mirage

Diamante

Galant

R ' - _ - 8.976 9.078 9.078 -

0.040 L -

F 0.710 0.650 0.0024 - - - 0.080 - 36 67-81

R - - - 8.00 8.10 8.10 - 0.039 - -

F 0.940 0.880 0.002 - 1 - -

0.080 -

54 65

R 0

F 0

Mir;

Diamante

Galant I.410 0.330 0.0023 - -

1.940 0.880 0.0031 - -

- -

-

8.976 9.078

0.710 0.650 0.0024 - - - -

0.039

-

0.080 -

9,078 -

0.040

-

0.080 - 24

54

-

36 36-43

65

-

67-81

R - _ - 8.00 8.10 8.10 - 0.039 ii -

F 0.940 0.880 0.002 - - -

0.080 -

54 65

R 0.410 0.330 0.0023 - - - -

0.039 24 36-43

F 0.940

0.880 0.0031 - - - 0.080 - 54

65

R - - - 8.976 9.078 9.078 - 0.040 - -

we F 0.710 0.650 0.0024 - - - 0.080 - 36 Mirl _

i 1 1 1 1 1 . I 1 I I

R - - - 8.00 1 8.10 8.10 -

1 0.039

1 1 ,r -

1

NA - Not Available

F - Front

R - Rear

OUpper:39fLIbs. , Lower: 65 ft. Ibs.

Page 369 of 408

EXTERIOR IO-2

DOORS IO-2

REMOVAL&INSTALLATION IO-2

HOOD IO-2

REMOVAL&INSTALLATION IO-2

ALIGNMENT IO-3

HATCH IO-3

REMOVAL & INSTALLATION IO-3

ALIGNMENT IO-3

TAILGATE IO-3

REMOVAL & INSTALLATION IO-3

ALIGNMENT IO-3

TRUNK LID IO-3

REMOVAL &INSTALLATION IO-3

ALIGNMENT IO-3

OUTSIDE MIRRORS IO-3

REMOVAL &INSTALLATION IO-3

ANTENNA IO-4

REPLACEMENT IO-4

FENDERS IO-4

REMOVAL & INSTALLATION IO-4

INTERIOR 1

O-6 INSTRUMENTPANEL IO-6

REMOVAL & INSTALLATION IO-6

FLOOR CONSOLE IO-6

REMOVAL & INSTALLATION IO-6

DOOR PANELS IO-7

REMOVAL & INSTALLATION IO-7

DOORHANDLE/LATCHASSEMBLY IO-IO

REMOVAL &INSTALLATION IO-IO

DOOR LOCKCYLINDER IO-IO

REMOVAL &INSTALLATION IO-IO

HATCH/TAILGATE/TRUNKLID LOCK

CYLINDER IO-IO

REMOVAL &INSTALLATION IO-IO

TAILGATE/HATCH HANDLE IO-IO

REMOVAL &INSTALLATION IO-IO

DOORGLASSANDREGULATOR IO-IO

REMOVAL&INSTALLATION IO-IO

ELECTRIC WINDOW MOTOR IO-IO

REMOVAL &INSTALLATION IO-IO

INSIDE REAR VIEW MIRROR IO-IO

REPLACEMENT IO-IO

SEATS IO-IO

REMOVAL & INSTALLATION IO-IO

POWERSEATMOTOR IO-11

REMOVAL &INSTALLATION IO-11

SPECIFICATIONS CHART

TORQUE SPECIFICATIONS IO-14

4

Page 370 of 408

IO-2 BODYANDTRIM

6. Remove the hinge bolts and remove the door

assembly.

REMOVAL &INSTALLATION To install:

7. Position the door into place and finger

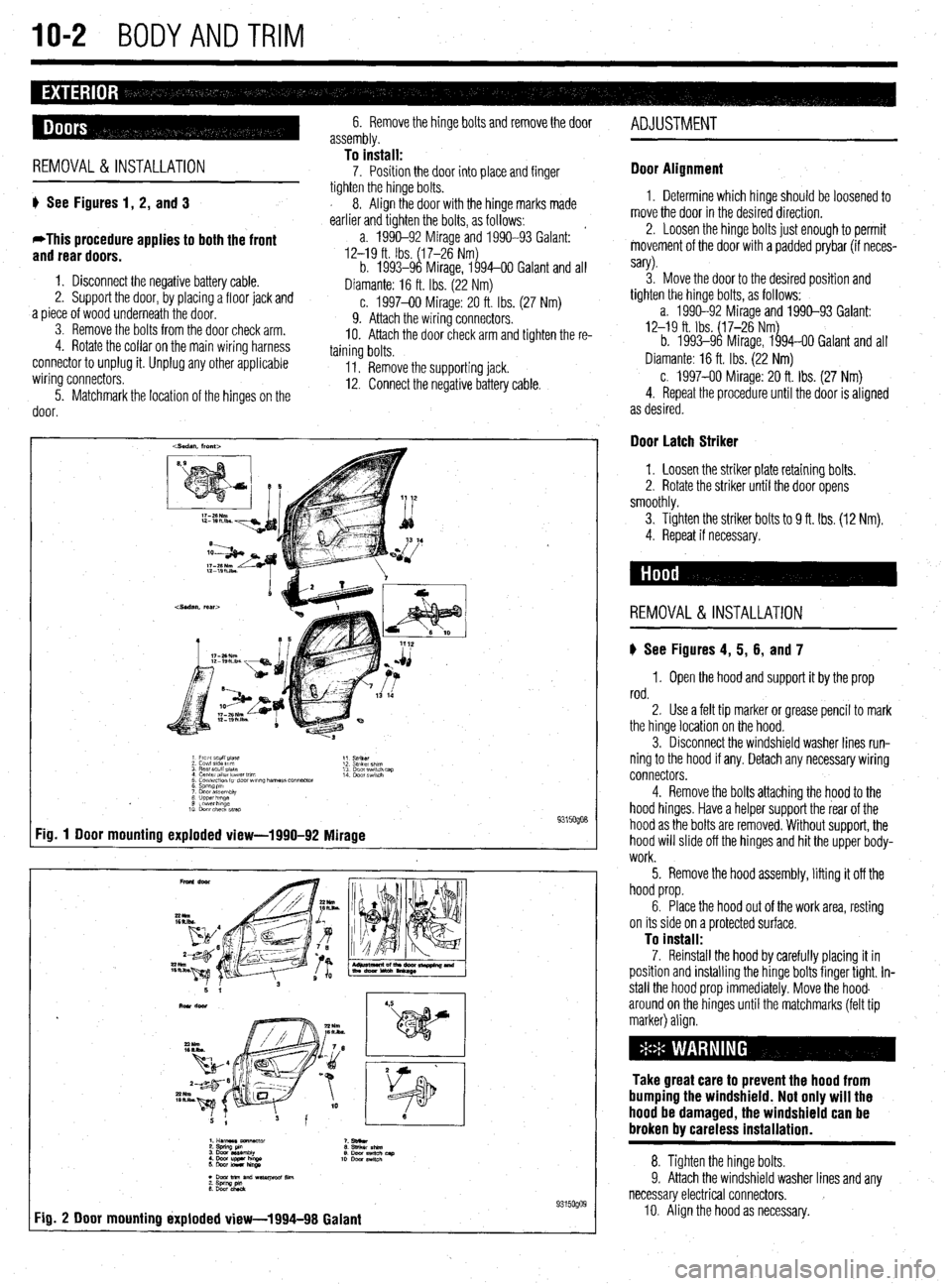

ti See Figures 1, 2, and 3

*This procedure applies to both the front

and rear doors.

1. Disconnect the negative battery cable.

2. Support the door, by placing a floor jack and

.a piece of wood underneath the door.

3. Remove the bolts from the door check arm.

4. Rotate the collar on the main wiring harness

connector to unplug it. Unplug any other applicable

wiring connectors.

5. Matchmark the location of the hinges on the

door. tighten the hinge bolts.

s 8. Align the door with the hinge marks made

earlier and tighten the bolts, as follows:

’

a. 1990-92 Mirage and 1990-93 Galant:

12-19 ft. Ibs. (6l7,26 Nm&

b. 1993-9 Mirage, 1 94-00 Galant and all

Diamante: 16 ft. Ibs. (22 Nm)

c. 1997-00 Mirage: 20 ft. Ibs. (27 Nm)

9. Attach the wiring connectors.

IO. Attach the door check arm and tighten the re-

taining bolts.

II. Remove the supporting jack.

12. Connect the negative battery cable.

Fig. 1 Door mounting exploded view-1990-92

Mirage 9315oQo8

9315oQog 1

Fig. 2 Door mounting ixploded view-1994-98 Galanf ADJUSTMENT

Door Alignment

1. Determine which hinge should be loosened to

move the door in the desired direction.

2. Loosen the hinge bolts just enough to permit

movement of the door with a padded prybar (if neces-

sary).

3. Move the door to the desired position and

tighten the hinge bolts, as follows:

a. 1990-92 Mirage and 1990-93 Galant:

12-19 ft. Ibs. ($7-26 Nmg

b. 1993-9 Mirage, 1 94-00 Galant and all

Diamante: 16 ft. Ibs. (22 Nm)

c. 1997-00 Mirage: 20 ft. Ibs. (27 Nm)

4. Repeat the procedure until the door is aligned

as desired.

Door Latch Striker

1. Loosen the striker plate retaining bolts.

2. Rotate the striker until the door opens

smoothly.

3. Tighten the striker

bolts to 9 ft. Ibs. (12 Nm).

4. Repeat if necessary.

REMOVAL & INSTALLATION

ti See Figures 4, 5, 6, and 7

1, Open the hood and support it by the prop

rod.

2. Use a felt tip marker or grease pencil to mark

the hinge location on the hood.

3. Disconnect the windshield washer lines run-

ning to the hood if any. Detach any necessary wiring

connectors.

4. Remove the bolts attaching the hood to the

hood hinges. Have a helper support the rear of the

hood as the bolts are removed. Without support, the

hood will slide off the hinges and hit the upper body-

work.

5. Remove the hood assembly, lifting it off the

hood prop.

6. Place the hood out of the work area, resting

on its side on a protected surface.

To install: 7. Reinstall the hood by carefully placing it in

position and instaliing the hinge bolts finger tight. In-

stall the hood prop immediately. Move the hood.

around on the hinges until the matchmarks (felt tip

marker) align.

Take great care to prevent the hood from

bumping the windshield. Not only will the

hood be damaged, the windshield can be

broken by careless installation.

8. Tighten the hinge bolts.

9. Attach the windshield washer lines and any

necessary electrical connectors. )

IO. Align the hood as necessary.