lock MITSUBISHI ECLIPSE 1990 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 181 of 391

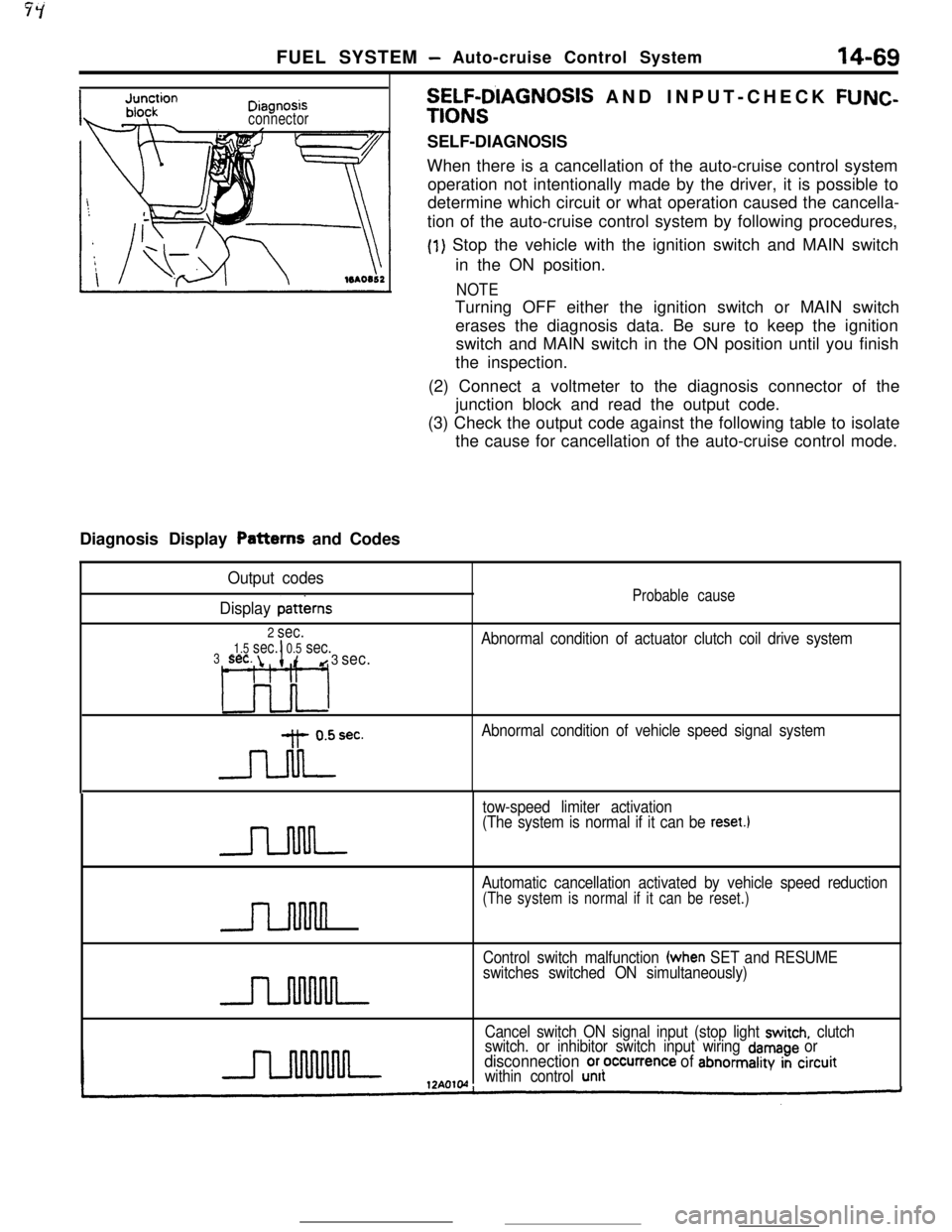

FUEL SYSTEM- Auto-cruise Control System14-69

ni2nnncisv,“y’I”“.-

connectorDiagnosis Display Patterns and Codes

SELF-D’IAGNOSIS AND INPUT-CHECK FUNC-

TIONSSELF-DIAGNOSIS

When there is a cancellation of the auto-cruise control system

operation not intentionally made by the driver, it is possible to

determine which circuit or what operation caused the cancella-

tion of the auto-cruise control system by following procedures,

(1) Stop the vehicle with the ignition switch and MAIN switch

in the ON position.

NOTETurning OFF either the ignition switch or MAIN switch

erases the diagnosis data. Be sure to keep the ignition

switch and MAIN switch in the ON position until you finish

the inspection.

(2) Connect a voltmeter to the diagnosis connector of the

junction block and read the output code.

(3) Check the output code against the following table to isolate

the cause for cancellation of the auto-cruise control mode.

Output codes

Display

patterns

2 sec.

1.5 sec.I0.5 sec.3sec. id 3 sec.

L3o-l

-Jdrec.

Probable cause

Abnormal condition of actuator clutch coil drive system

Abnormal condition of vehicle speed signal system

tow-speed limiter activation

(The system is normal if it can be

reset.1

n

Automatic cancellation activated by vehicle speed reduction

(The system is normal if it can be reset.)

Control switch malfunction (when SET and RESUME

switches switched ON simultaneously)

Cancel switch ON signal input (stop light

switch, clutch

switch. or inhibitor switch input wiring damage ordisconnection or,occurrence of abnormality in circuitwithin control unit

Page 182 of 391

14-70

-_FUEL SYSTEM

- Auto-cruise Control System

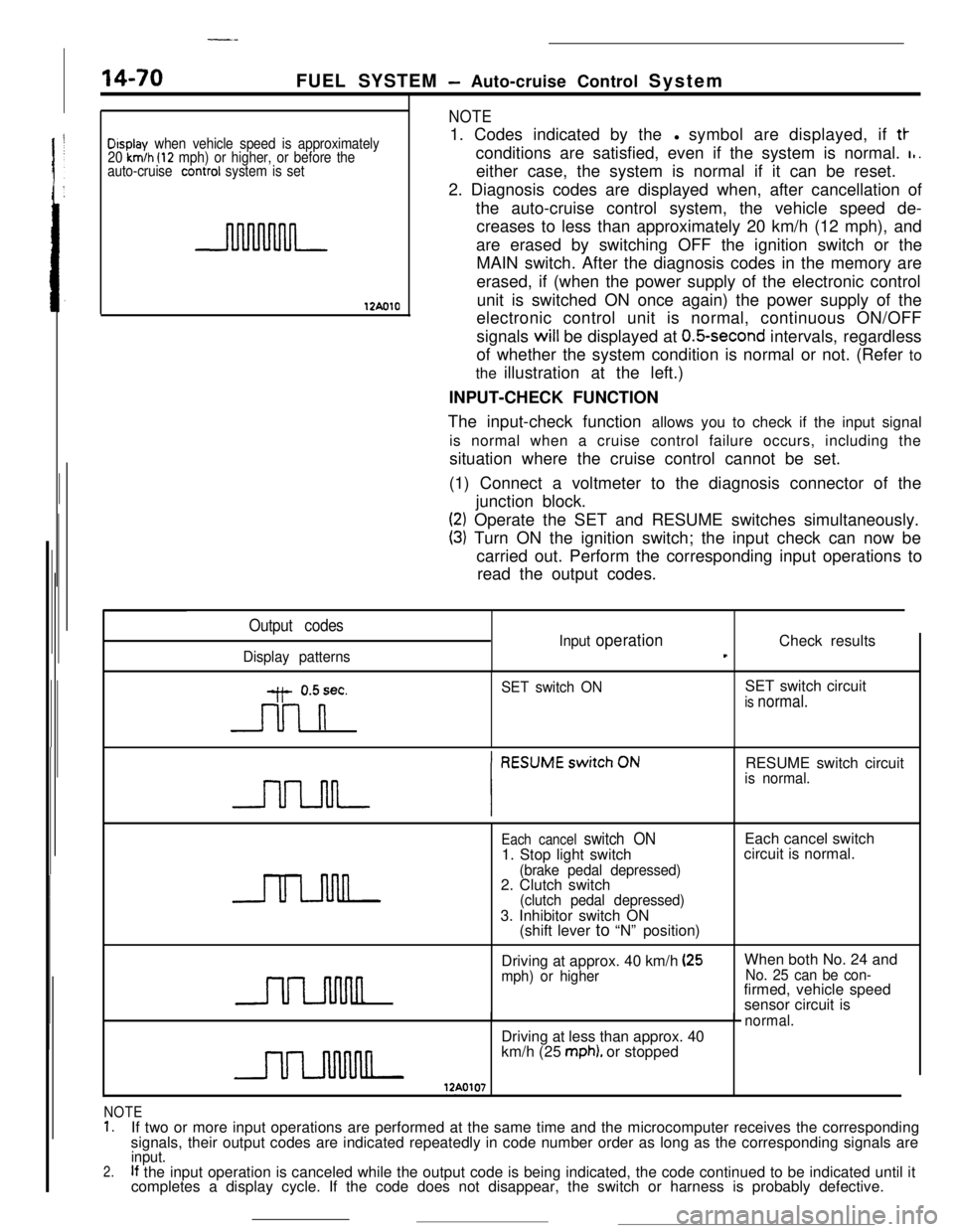

Display when vehicle speed is approximately

20 km/h (12 mph) or higher, or before the

auto-cruise conrrol system is set

12AolO

NOTE1. Codes indicated by thel symbol are displayed, if

tt-conditions are satisfied, even if the system is normal.

I,.either case, the system is normal if it can be reset.

2. Diagnosis codes are displayed when, after cancellation of

the auto-cruise control system, the vehicle speed de-

creases to less than approximately 20 km/h (12 mph), and

are erased by switching OFF the ignition switch or the

MAIN switch. After the diagnosis codes in the memory are

erased, if (when the power supply of the electronic control

unit is switched ON once again) the power supply of the

electronic control unit is normal, continuous ON/OFF

signals will be displayed at

O.&second intervals, regardless

of whether the system condition is normal or not. (Refer to

the illustration at the left.)

INPUT-CHECK FUNCTION

The input-check function allows you to check if the input signal

is normal when a cruise control failure occurs, including the

situation where the cruise control cannot be set.

(1) Connect a voltmeter to the diagnosis connector of the

junction block.

(2) Operate the SET and RESUME switches simultaneously.

(3) Turn ON the ignition switch; the input check can now be

carried out. Perform the corresponding input operations to

read the output codes.

Output codes

Display patternsInput

operationCheck resultst

y- 0.5sec.

n

SET switch ONSET switch circuitis normal.RESUME switch circuit

is normal.

Each cancel switch ON1. Stop light switch

(brake pedal depressed)2. Clutch switch

(clutch pedal depressed)3. Inhibitor switch ON

(shift lever to “N” position)Each cancel switch

circuit is normal.

Driving at approx. 40 km/h

(25mph) or higherWhen both No. 24 andNo. 25 can be con-firmed, vehicle speed

sensor circuit is

normal.Driving at less than approx. 40

km/h (25

mph). or stopped

NOTE1.If two or more input operations are performed at the same time and the microcomputer receives the corresponding

signals, their output codes are indicated repeatedly in code number order as long as the corresponding signals are

2.input.If the input operation is canceled while the output code is being indicated, the code continued to be indicated until it

completes a display cycle. If the code does not disappear, the switch or harness is probably defective.

Page 213 of 391

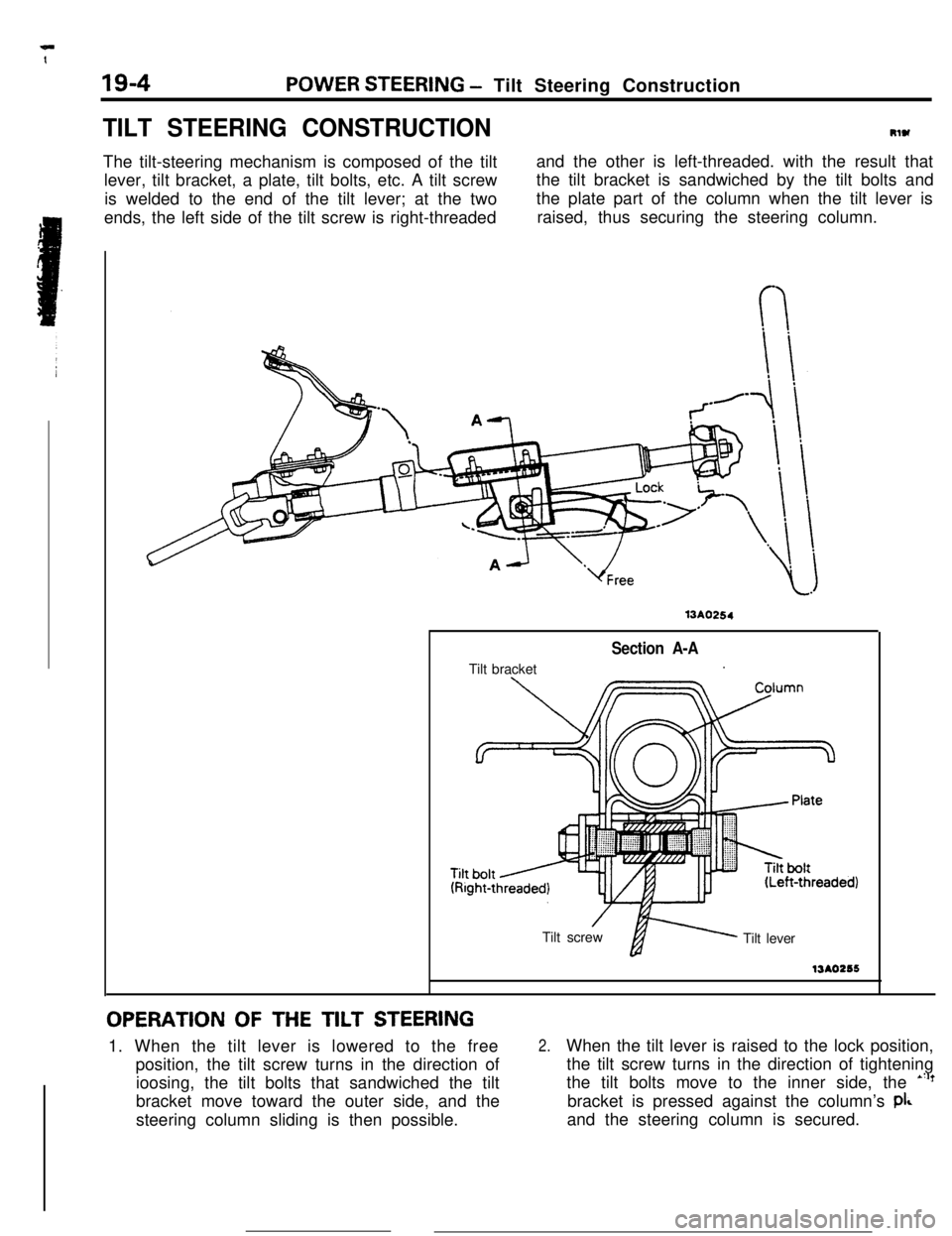

19-4POWER STEERING - Tilt Steering Construction

TILT STEERING CONSTRUCTIONRlW

The tilt-steering mechanism is composed of the tilt

lever, tilt bracket, a plate, tilt bolts, etc. A tilt screw

is welded to the end of the tilt lever; at the two

ends, the left side of the tilt screw is right-threadedand the other is left-threaded. with the result that

the tilt bracket is sandwiched by the tilt bolts and

the plate part of the column when the tilt lever is

raised, thus securing the steering column.

13A0254Tilt bracket

Section A-A.

’Tilt screwfi Tilt lever13AO256

OPERATION OF THE TILT STEERING1. When the tilt lever is lowered to the free

position, the tilt screw turns in the direction of

ioosing, the tilt bolts that sandwiched the tilt

bracket move toward the outer side, and the

steering column sliding is then possible.

2.When the tilt lever is raised to the lock position,

the tilt screw turns in the direction of tightening

the tilt bolts move to the inner side, the

*“?bracket is pressed against the column’s

pi&and the steering column is secured.

Page 234 of 391

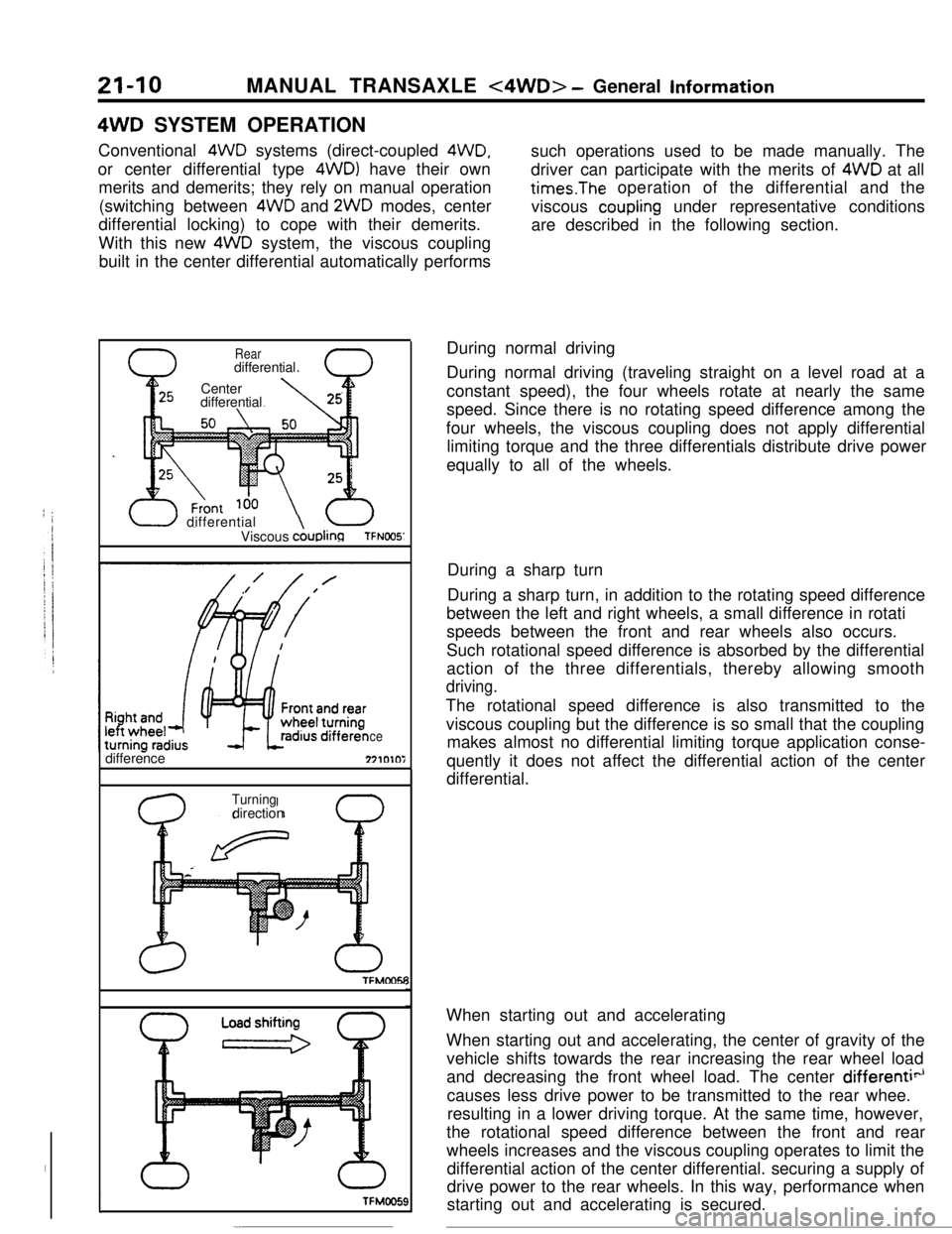

21-10MANUAL TRANSAXLE <4WD> - General Information4WD SYSTEM OPERATION

Conventional 4WD systems (direct-coupled

4WD,or center differential type 4WDl have their own

merits and demerits; they rely on manual operation

(switching between 4WD and 2WD modes, center

differential locking) to cope with their demerits.

With this new 4WD system, the viscous coupling

built in the center differential automatically performssuch operations used to be made manually. The

driver can participate with the merits of 4WD at alltimes.The operation of the differential and the

viscous

coupling under representative conditions

are described in the following section.

I

Reardifferential

Center

differential

U differential

Viscous AuDk?TFNOO5’difference

ce271010i

TFMMYTFMMY

0

Turningdirection

ITFMOO!X

-.During normal driving

During normal driving (traveling straight on a level road at a

constant speed), the four wheels rotate at nearly the same

speed. Since there is no rotating speed difference among the

four wheels, the viscous coupling does not apply differential

limiting torque and the three differentials distribute drive power

equally to all of the wheels.

During a sharp turn

During a sharp turn, in addition to the rotating speed difference

between the left and right wheels, a small difference in rotati

speeds between the front and rear wheels also occurs.

Such rotational speed difference is absorbed by the differential

action of the three differentials, thereby allowing smooth

driving.The rotational speed difference is also transmitted to the

viscous coupling but the difference is so small that the coupling

makes almost no differential limiting torque application conse-

quently it does not affect the differential action of the center

differential.

When starting out and accelerating

When starting out and accelerating, the center of gravity of the

vehicle shifts towards the rear increasing the rear wheel load

and decreasing the front wheel load. The center

differenti”causes less drive power to be transmitted to the rear whee.

resulting in a lower driving torque. At the same time, however,

the rotational speed difference between the front and rear

wheels increases and the viscous coupling operates to limit the

differential action of the center differential. securing a supply of

drive power to the rear wheels. In this way, performance when

starting out and accelerating is secured.

Page 242 of 391

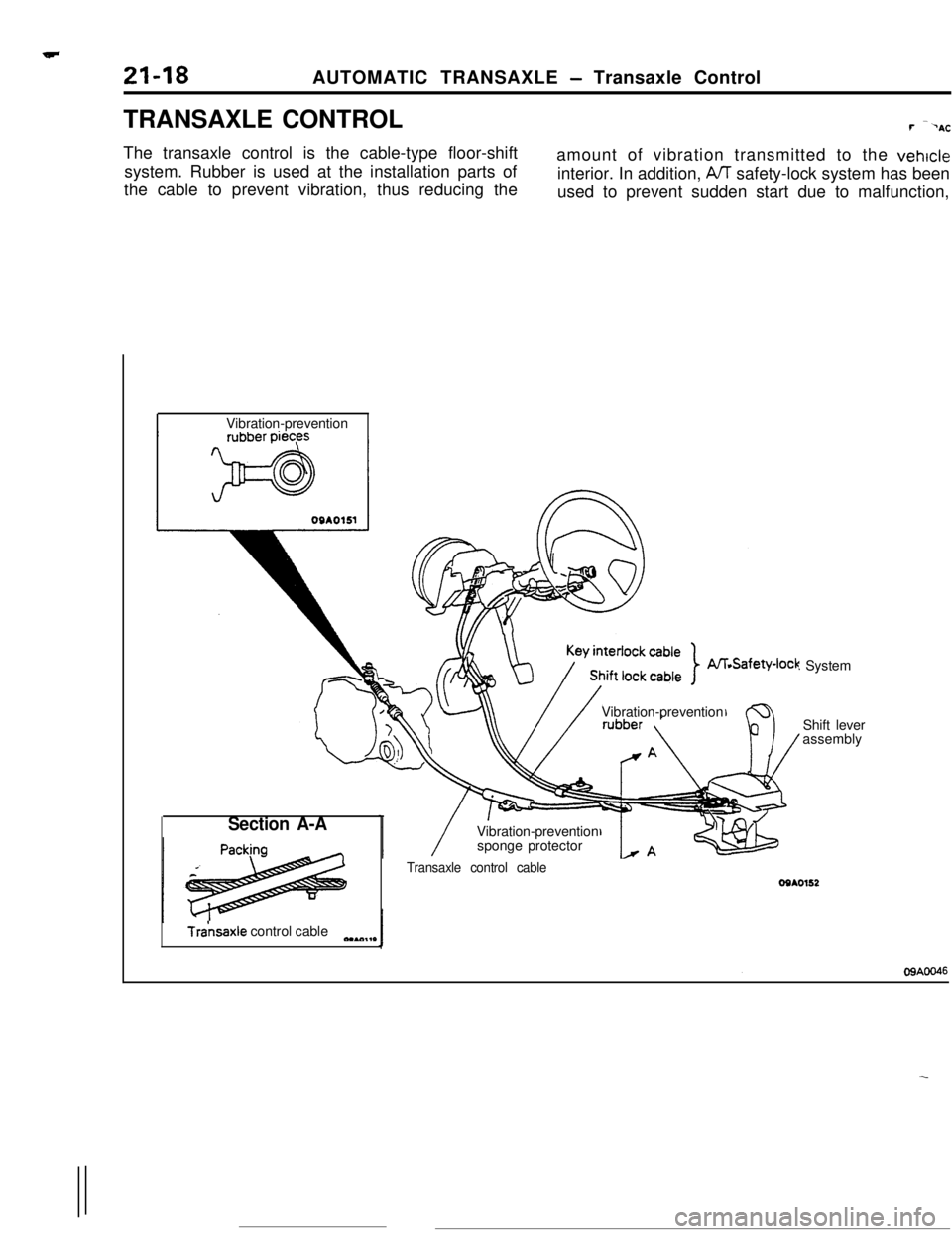

21-18AUTOMATIC TRANSAXLE - Transaxle Control

TRANSAXLE CONTROLr---AC

The transaxle control is the cable-type floor-shift

system. Rubber is used at the installation parts of

the cable to prevent vibration, thus reducing theamount of vibration transmitted to the

vehicleinterior. In addition,

A/T safety-lock system has been

used to prevent sudden start due to malfunction,

Vibration-prevention

Vibration-prevention

Vibration-prevention

sponge protector

Section A-A

Tra’nsaxle control cableeaAc.,,*

: System

Shift lever

assembly

Transaxle control cableOSAO152

Page 243 of 391

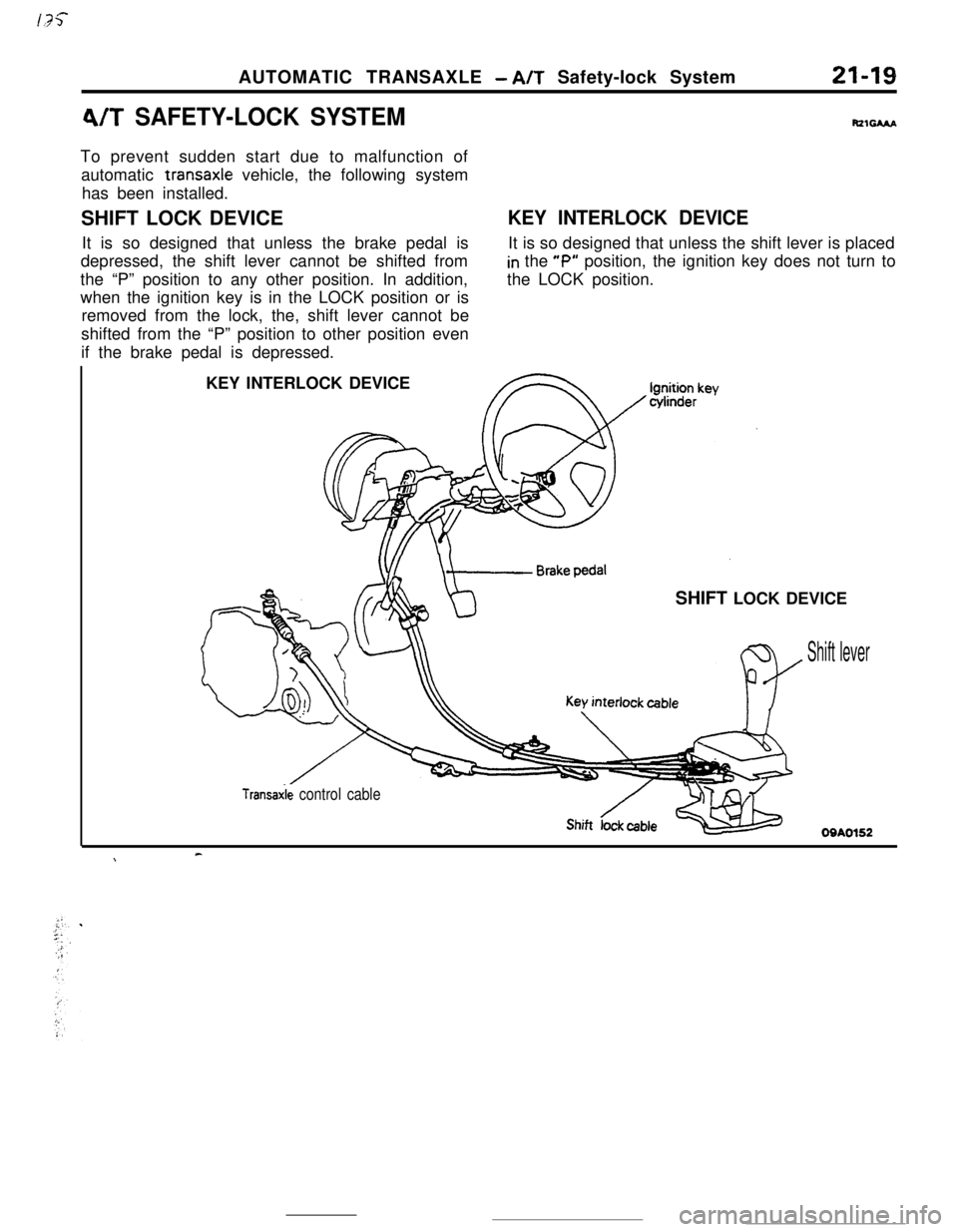

AUTOMATIC TRANSAXLE - A/T Safety-lock System21-19

4/T SAFETY-LOCK SYSTEMRzsAAaTo prevent sudden start due to malfunction of

automatic transaxle vehicle, the following system

has been installed.

SHIFT LOCK DEVICE

It is so designed that unless the brake pedal is

depressed, the shift lever cannot be shifted from

the “P” position to any other position. In addition,

when the ignition key is in the LOCK position or is

removed from the lock, the, shift lever cannot be

shifted from the “P” position to other position even

if the brake pedal is depressed.

KEY INTERLOCK DEVICEIt is so designed that unless the shift lever is placed

in the “P” position, the ignition key does not turn to

the LOCK position.

KEY INTERLOCK DEVICE

SHIFT LOCK DEVICE

Shift lever

Transaxie control cable

Shift dieOQA0152

c\

Page 244 of 391

-_ - .--.7

!21-20AUTOMATIC TRANSAXLE - A/T Safety-lock System

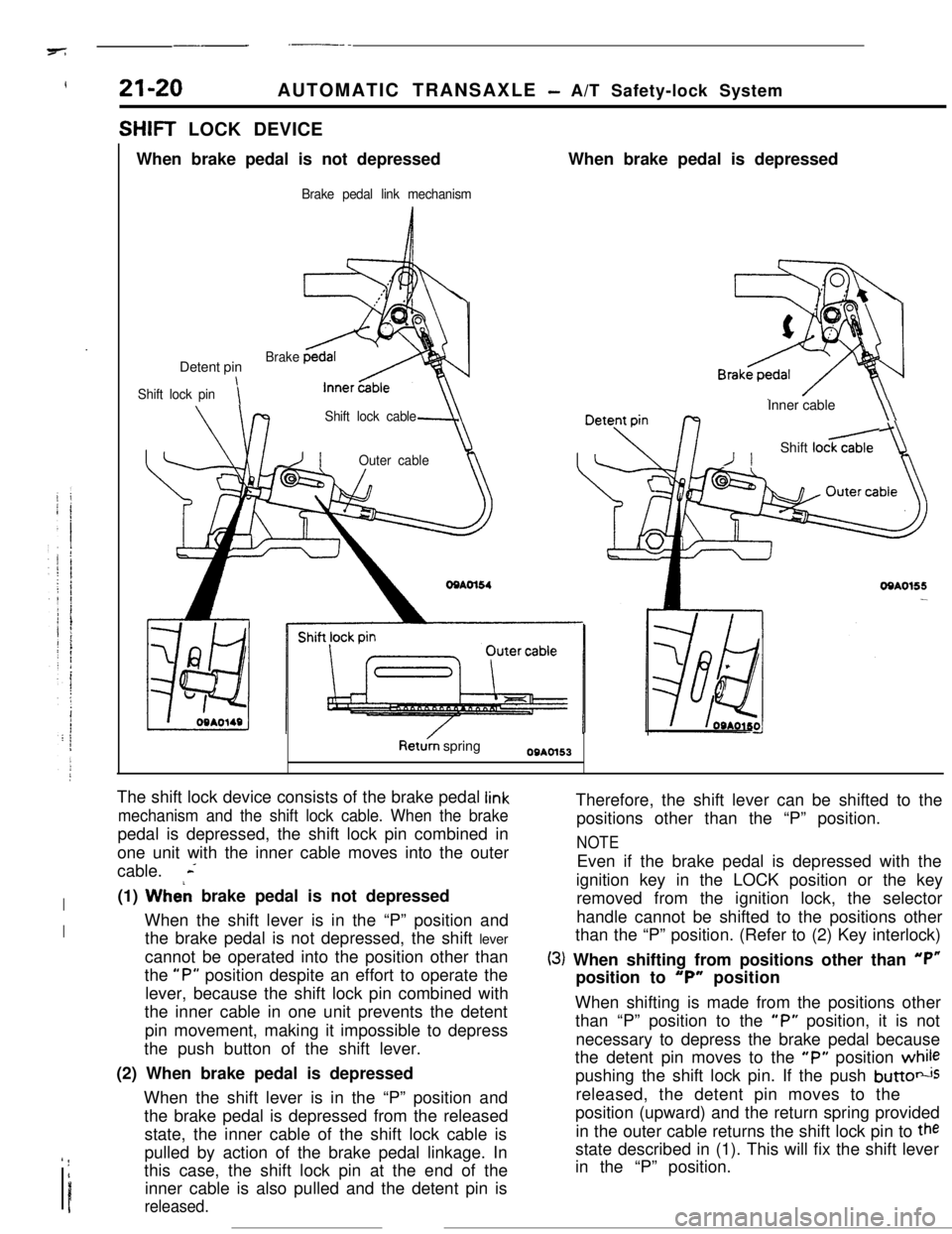

SHIFT LOCK DEVICE

When brake pedal is not depressed

Brake pedal link mechanismWhen brake pedal is depressed

Detent pin

Shift lock pini

Brake

Shift lock cable

-JIOuter cableInner cable

\\

/IShift loc&

OQAO155-

Ret& springOBAOl53

The shift lock device consists of the brake pedal

link

mechanism and the shift lock cable. When the brakepedal is depressed, the shift lock pin combined in

one unit with the inner cable moves into the outer

cable.

L

I(1) Wheh brake pedal is not depressed

IWhen the shift lever is in the “P” position and

the brake pedal is not depressed, the shift lever

cannot be operated into the position other than

the

“P” position despite an effort to operate the

lever, because the shift lock pin combined with

the inner cable in one unit prevents the detent

pin movement, making it impossible to depress

the push button of the shift lever.

(2) When brake pedal is depressed

When the shift lever is in the “P” position and

the brake pedal is depressed from the released

state, the inner cable of the shift lock cable is

’ !I

Ipulled by action of the brake pedal linkage. In

this case, the shift lock pin at the end of the

inner cable is also pulled and the detent pin isreleased.Therefore, the shift lever can be shifted to the

positions other than the “P” position.

NOTEEven if the brake pedal is depressed with the

ignition key in the LOCK position or the key

removed from the ignition lock, the selector

handle cannot be shifted to the positions other

than the “P” position. (Refer to (2) Key interlock)

(3) When shifting from positions other than “P”position to

“P” position

When shifting is made from the positions other

than “P” position to the

“P” position, it is not

necessary to depress the brake pedal because

the detent pin moves to the

“P” position whilepushing the shift lock pin. If the push

buttotisreleased, the detent pin moves to the

position (upward) and the return spring provided

in the outer cable returns the shift lock pin to

thestate described in (1). This will fix the shift lever

in the “P” position.

Page 245 of 391

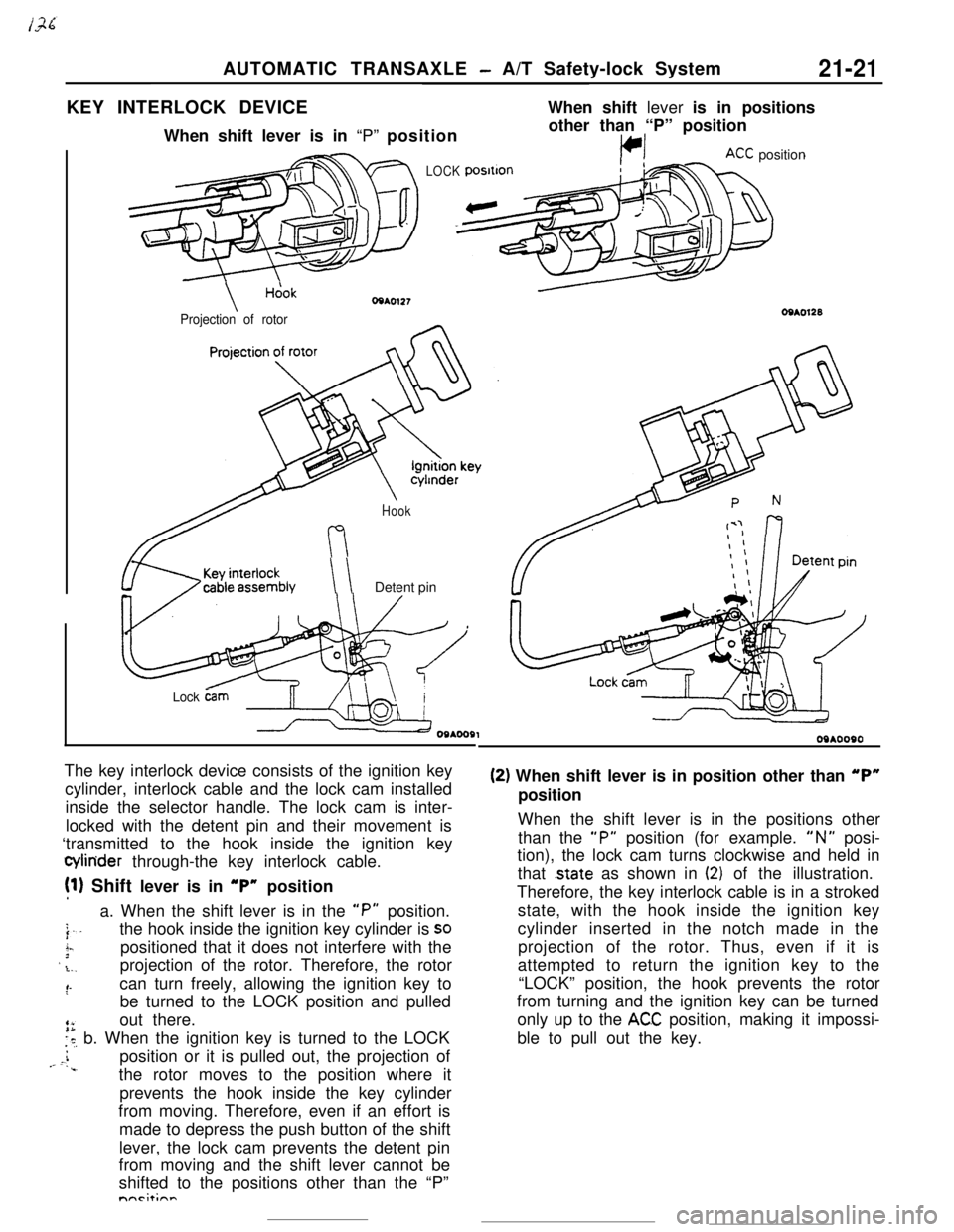

AUTOMATIC TRANSAXLE - A/T Safety-lock System21-21KEY INTERLOCK DEVICEWhen shift lever is in positions

When shift lever is in “P” position

LOCK

\Hcjok

Projection of rotorother than “P” position

KC position

Hook

\ \Detent pin

Lock &mThe key interlock device consists of the ignition key

cylinder, interlock cable and the lock cam installed

inside the selector handle. The lock cam is inter-

locked with the detent pin and their movement is

‘transmitted to the hook inside the ignition key

Q4inder through-the key interlock cable.

!l) Shift lever is in “P” position

a. When the shift lever is in the

“P” position.

j..the hook inside the ignition key cylinder is SO

i-.3positioned that it does not interfere with the’ .L.,projection of the rotor. Therefore, the rotor

:‘-can turn freely, allowing the ignition key to

be turned to the LOCK position and pulled

out there.

is, b. When the ignition key is turned to the LOCK

i,- c.position or it is pulled out, the projection of‘..the rotor moves to the position where it

prevents the hook inside the key cylinder

from moving. Therefore, even if an effort is

made to depress the push button of the shift

lever, the lock cam prevents the detent pin

from moving and the shift lever cannot be

shifted to the positions other than the “P”nnrit;nn

09*0090

(2) When shift lever is in position other than “P”position

When the shift lever is in the positions other

than the

“P” position (for example. “N” posi-

tion), the lock cam turns clockwise and held in

that

.state as shown in (2) of the illustration.

Therefore, the key interlock cable is in a stroked

state, with the hook inside the ignition key

cylinder inserted in the notch made in the

projection of the rotor. Thus, even if it is

attempted to return the ignition key to the

“LOCK” position, the hook prevents the rotor

from turning and the ignition key can be turned

only up to the

ACC position, making it impossi-

ble to pull out the key.

Page 246 of 391

AUTOMATIC TRANSAXLE - Torque Converter

TORQUE CONVERTER

Lock

ring

I

Damper

F

clutch-

B-.Turbine

.AA

/:ront cover

h,Impeller

AStartorWhen damper clutch is

I\When damper

aInput shaftactivated

clutch isactivated

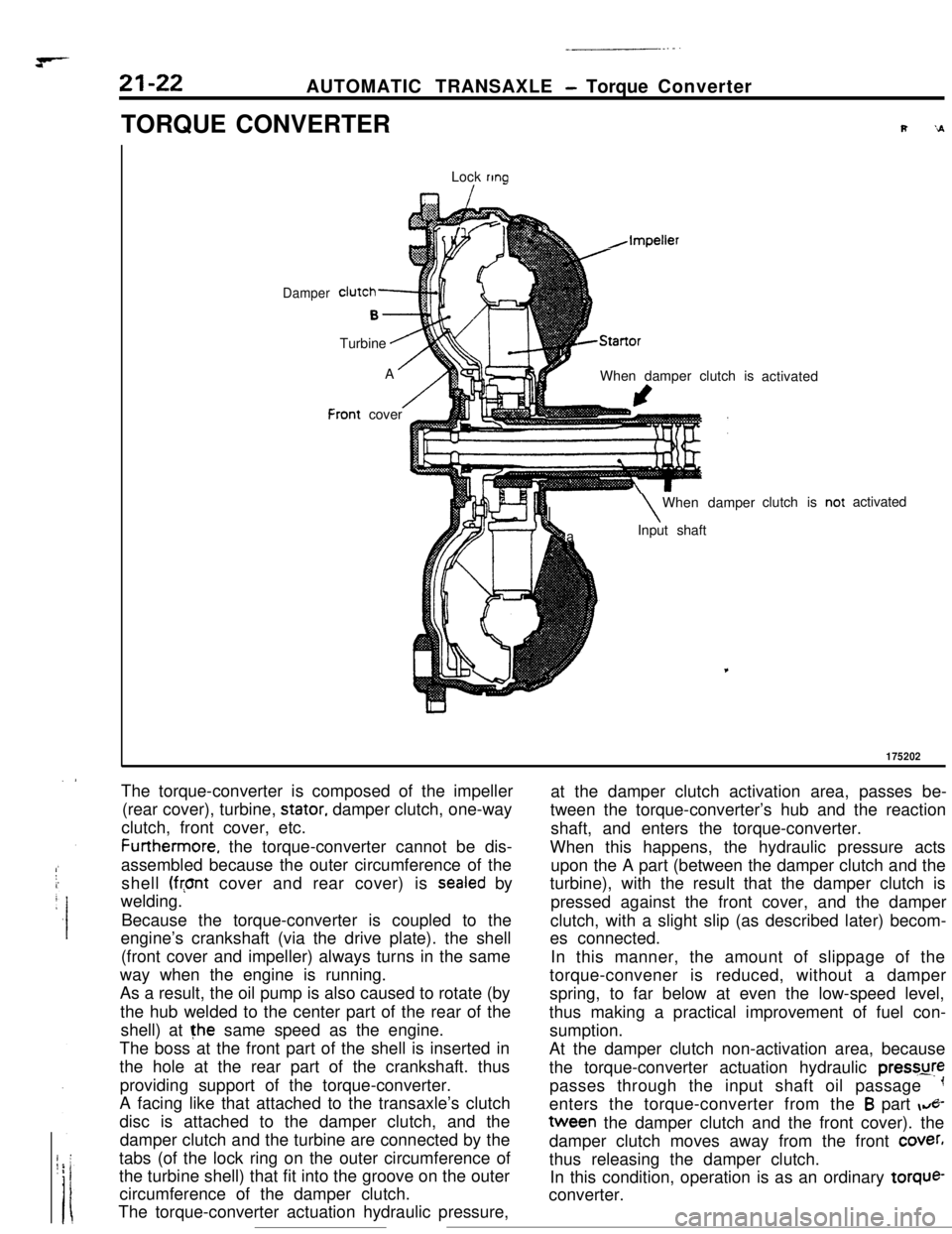

175202The torque-converter is composed of the impeller

(rear cover), turbine,

stator, damper clutch, one-way

clutch, front cover, etc.Furthermore. the torque-converter cannot be dis-

assembled because the outer circumference of the

shell

(front cover and rear cover) is sealed by

welding.

Because the torque-converter is coupled to the

engine’s crankshaft (via the drive plate). the shell

(front cover and impeller) always turns in the same

way when the engine is running.

As a result, the oil pump is also caused to rotate (by

the hub welded to the center part of the rear of the

shell) at the same speed as the engine.

The boss at the front part of the shell is inserted in

the hole at the rear part of the crankshaft. thus

providing support of the torque-converter.

A facing like that attached to the transaxle’s clutch

disc is attached to the damper clutch, and the

damper clutch and the turbine are connected by the

tabs (of the lock ring on the outer circumference of

the turbine shell) that fit into the groove on the outer

circumference of the damper clutch.

The torque-converter actuation hydraulic pressure,at the damper clutch activation area, passes be-

tween the torque-converter’s hub and the reaction

shaft, and enters the torque-converter.

When this happens, the hydraulic pressure acts

upon the A part (between the damper clutch and the

turbine), with the result that the damper clutch is

pressed against the front cover, and the damper

clutch, with a slight slip (as described later) becom-

es connected.

In this manner, the amount of slippage of the

torque-convener is reduced, without a damper

spring, to far below at even the low-speed level,

thus making a practical improvement of fuel con-

sumption.

At the damper clutch non-activation area, because

the torque-converter actuation hydraulic pressure

passes through the input shaft oil passage

-1enters the torque-converter from the

B part &-tween the damper clutch and the front cover). the

damper clutch moves away from the front

cover,thus releasing the damper clutch.

In this condition, operation is as an ordinary torque-

converter.

Page 248 of 391

21-24AUTOMATIC TRANSAXLE - Transaxle Mechanism

SELECT PATTERN

Select pattern refers to the indication of transaxle

positions to be manually selected by the driver. This

transaxie is provided with 6 positions: P-R-N-D-

2-L. The following contains the explanations of the

function of each position selected.

P-Parking

(1)

(2)

(3)

Each element does not operate at all. Therefore,the engine output is not transmitted to the

output shaft.

The output shaft is completely locked by mecha-

nical means. Therefore, the vehicle does not

move in forward or reverse direction.

The engine can be started.

R-Reverse

(1) The vehicle moves in reverse direction.

(2) The engine cannot be started.

N-Neutral

(1) The engine output is not transmitted to the

output shaft as in the case of

“P”(2) The engine can be started.

D-Drive

(1)

(2)

(3)Corresponding with the degree that the

accelerator pedal is pressed down (i.e. throttle

opening) and vehicle speed,

“D” automatically

shifts between forward 4 speeds. Note, howev-

er,’ that the forward 3 speeds are selected when

the overdrive control switch is OFF. The automa-tic shifting (up or down) is performed according

to the shift pattern shown in the illustration on

page 2

l-30.Driving-off is always performed in

1st gear.Kickdown refers to the downshift that is per-

formed if the accelerator pedal is pressed down

(4)

(5)when the vehicle is running. in

2nd. 3rd or 4t,.

gear. It is performed when the load exceeds the

downshift point.

This function

IS useful when the driver isaccelerating to pass another vehicle.

Engine brake does not function when the shift is

in

1st gear.

When the vehicle is stopped, shifting is made to

the

2nd gear to minimize creep and vibration.

Upon starting, shifting is made to

1st gear.

S-Second

(1)

(2)

(3)“2” automatically shifts between

1st and 2ndgears. This means no upshift to

3rd gear occurs.

Driving-off is always performed in

1st gear.

Downshift to

2nd or 3rd gear is performed by

selecting the“2” range while the vehicle is

running in

3,rd or 4th gear, when a speed lower

than the set value is reached.

(4)As in the case of the “D” range, engine brake

does not work when the shift is in

1st gear.

L-Lock-up

(1)

(2)

(3)While “L” (Lock-up) performs downshift from

2nd to 1st gear, it does not shift up the gear

from

1st to 2nd or 3rd. The enables what is_.called

“1st gear holding”.

Driving-off is always performed in

1st gear.

Engine brake functions in the case of this

1st

gear..By selecting the “L” range while the vehicle is

running in the

“0” or “2” range, downshift from4th to

3rd, 3rd to 2nd, or 2nd to 1st is performed

when the vehicle reaches the respective speed

prescribed for each gear.