lock MITSUBISHI ECLIPSE 1990 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 252 of 391

.-

I

21-28AUTOMATIC TRANSAXLE - Transaxle Mechanism

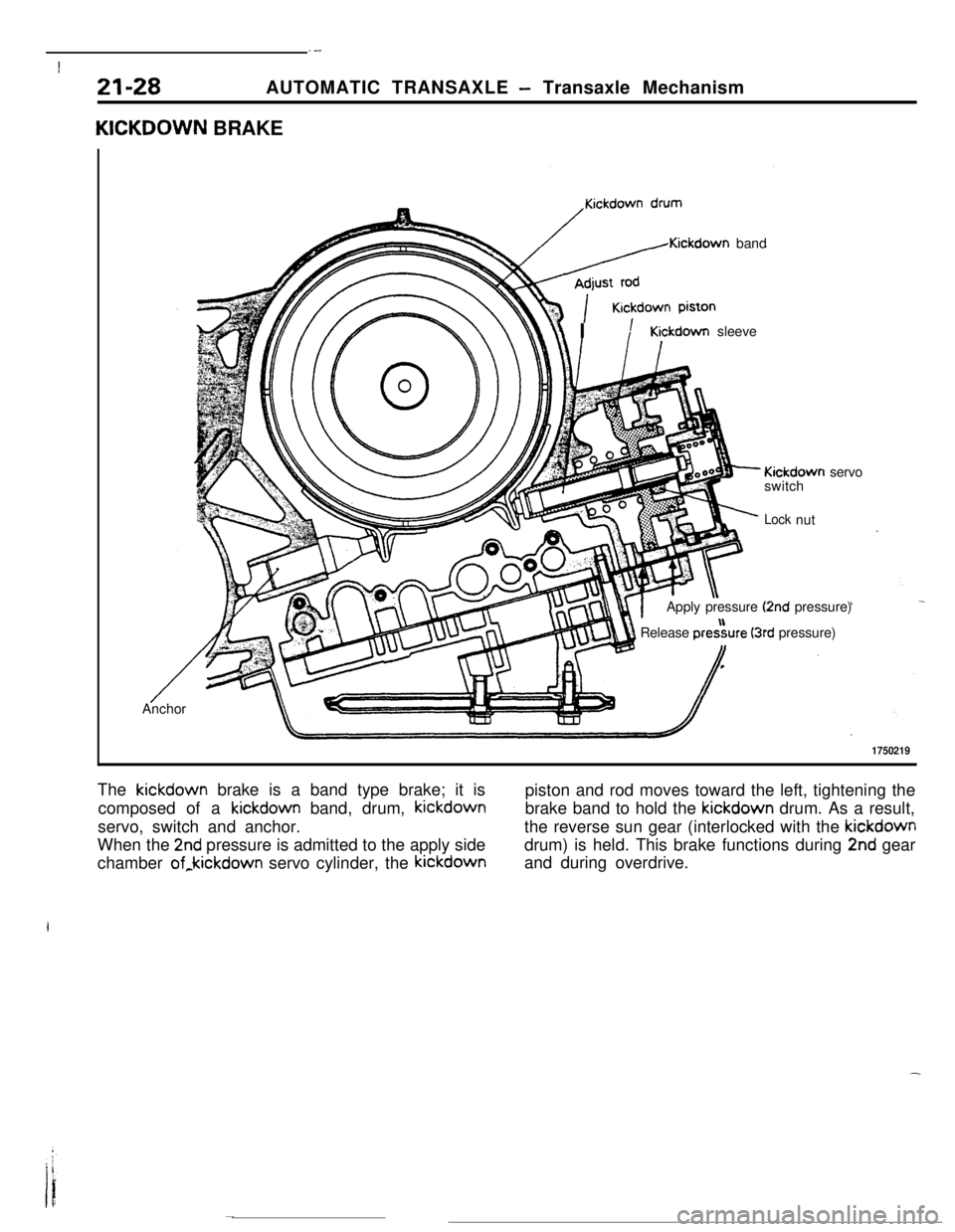

KICKDOWN BRAKE

/Kickdown band

r\\ IKickdown sleeve

- Kickdown servo

switch

;‘- Locknut

Apply pressure

(2nd pressure)

1 Release pre&re (3rd pressure)I,

/ --Anchor

1750219The kickdown brake is a band type brake; it is

piston and rod moves toward the left, tightening the

composed of a kickdown band, drum, kickdownbrake band to hold the kickdown drum. As a result,

servo, switch and anchor.the reverse sun gear (interlocked with the kickdown

When the

2nd pressure is admitted to the apply sidedrum) is held. This brake functions during 2nd gear

chamber of,kickdown servo cylinder, the kickdownand during overdrive.

Page 255 of 391

iAUTOMATIC TRANSAXLE

- Transaxle Mechanism

ONE-WAY CLUTCH

I

’

21-31

Long pinion(Planetary gear carrier)

CarrierInput

output

Held

stationary

sun gear

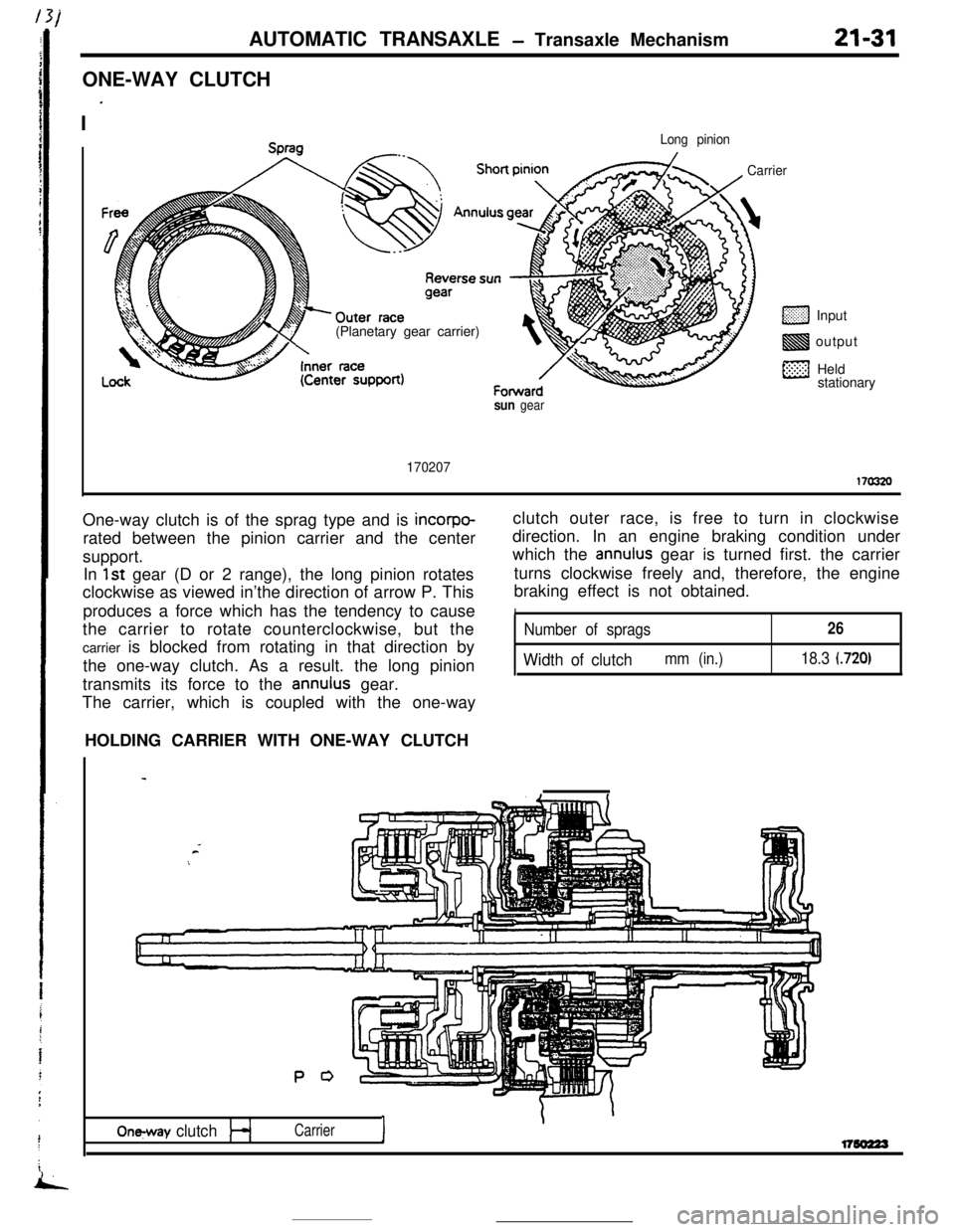

170207170320One-way clutch is of the sprag type and is

incorpo-rated between the pinion carrier and the center

support.

In

1st gear (D or 2 range), the long pinion rotates

clockwise as viewed in’the direction of arrow P. This

produces a force which has the tendency to cause

the carrier to rotate counterclockwise, but the

carrier is blocked from rotating in that direction by

the one-way clutch. As a result. the long pinion

transmits its force to the

annulus gear.

The carrier, which is coupled with the one-wayclutch outer race, is free to turn in clockwise

direction. In an engine braking condition under

which the

annulus gear is turned first. the carrier

turns clockwise freely and, therefore, the engine

braking effect is not obtained.

INumber of sprags26

Width of clutchmm (in.)18.3 (720)HOLDING CARRIER WITH ONE-WAY CLUTCH

P 0

On-y clutchI

\Carrierl7so223

Page 257 of 391

AUTOMATIC TRANSAXLE - Transaxle Mechanism21-33

POWER FLOW

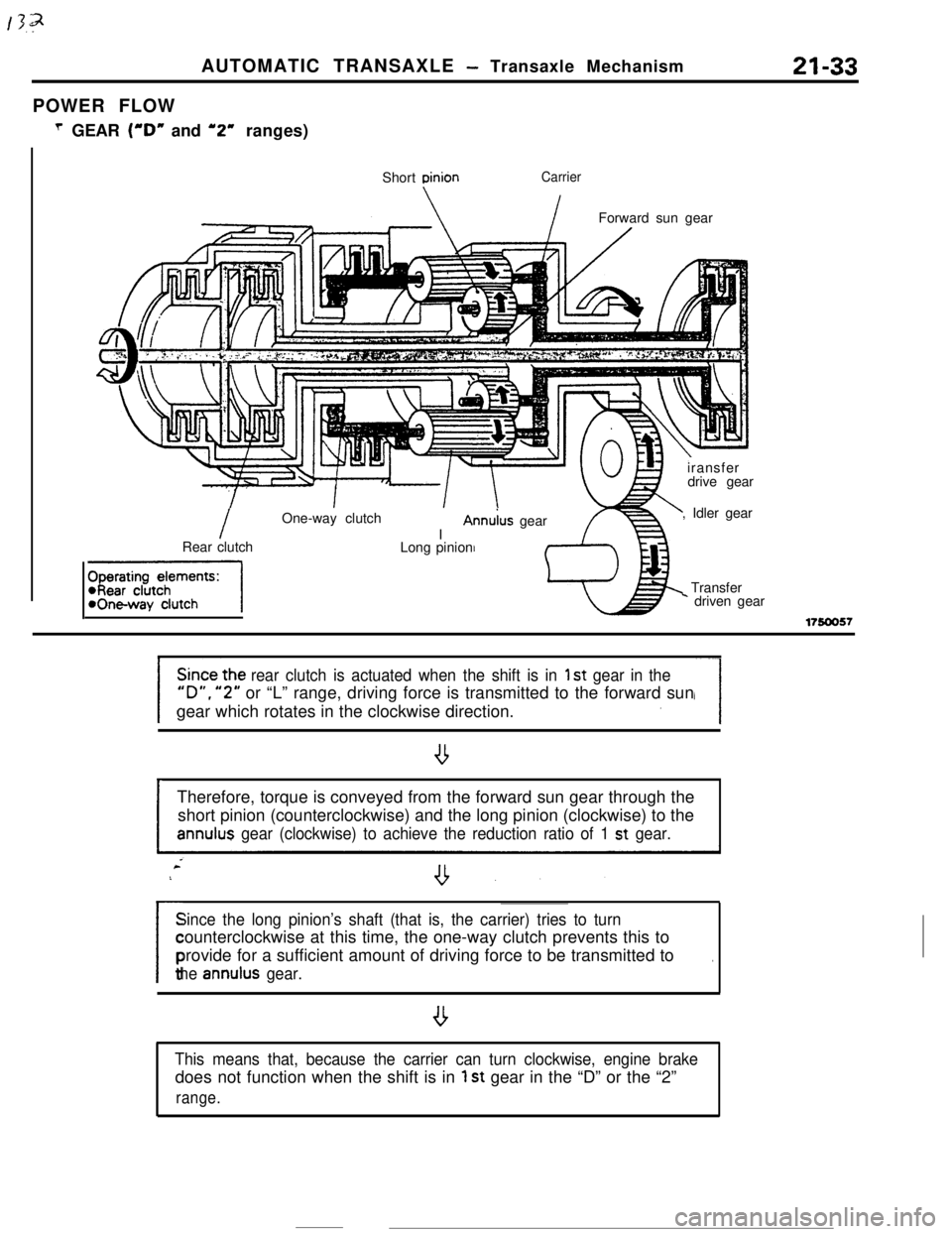

T GEAR (“D” and ‘2” ranges)

Short

DinionCarrier

IForward sun gear

IOne-way clutch

IAnn&s gear

Rear clutch

-1Long pinioniransfer

drive gear

, Idler gear

Transfer* driven gear

17!50057

rear clutch is actuated when the shift is in 1 st gear in the

“D”. “2” or “L” range, driving force is transmitted to the forward sun

gear which rotates in the clockwise direction.

ITherefore, torque is conveyed from the forward sun gear through the

short pinion (counterclockwise) and the long pinion (clockwise) to theannulus gear (clockwise) to achieve the reduction ratio of 1 st gear.

Since the long pinion’s shaft (that is, the carrier) tries to turn

/counterclockwise at this time, the one-way clutch prevents this to

provide for a sufficient amount of driving force to be transmitted to

.

the annulus gear.

,

This means that, because the carrier can turn clockwise, engine brakedoes not function when the shift is in

1 st gear in the “D” or the “2”

range.

Page 259 of 391

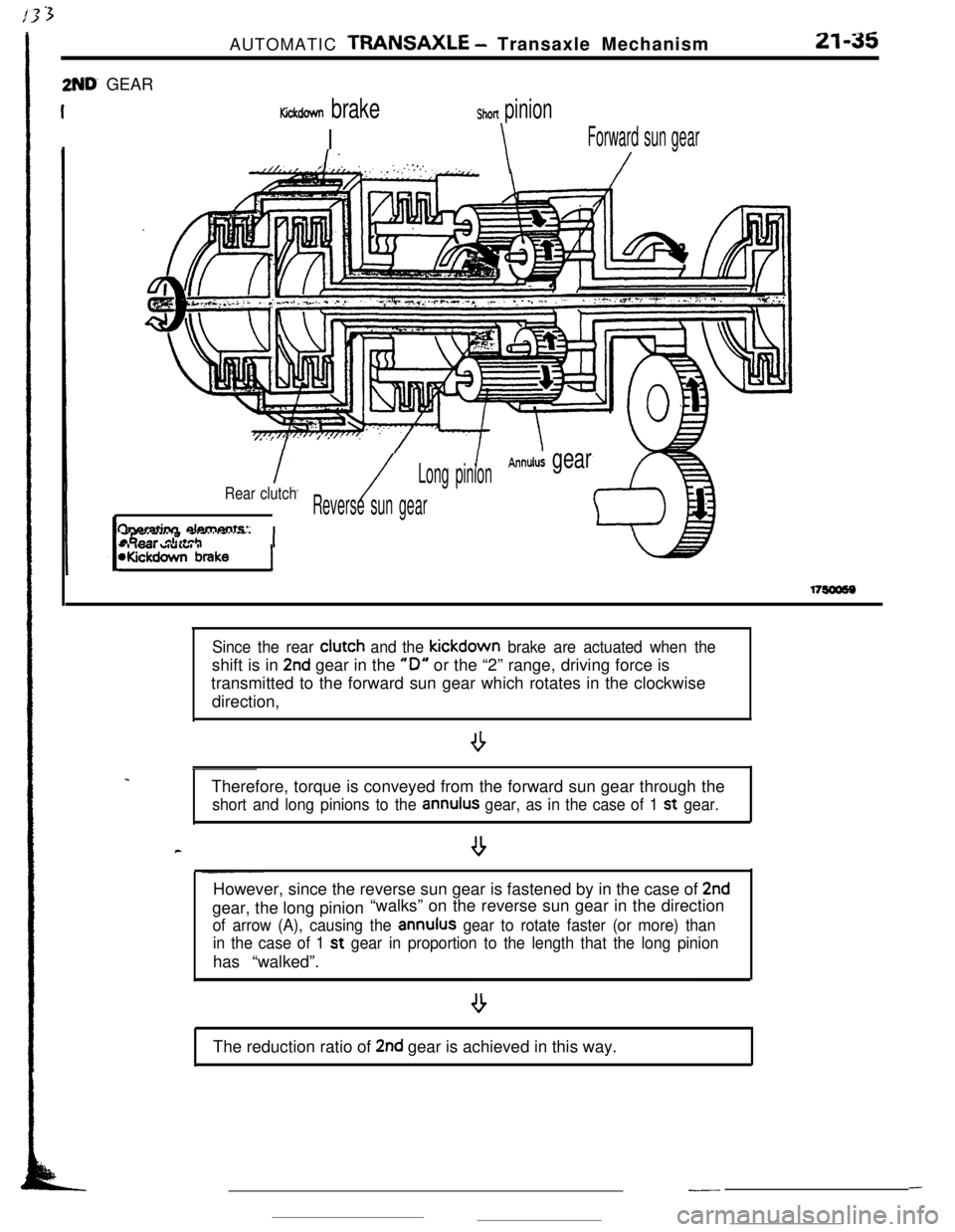

2ND’ GEARAUTOMATIC

TRANSAXLE - Transaxle Mechanism21-35

Kickdown brake

I

Shon pinion

\Forward sun gear

1.//LT.//. , ,’ .‘,,i.:,;:.:‘.,.‘,\/

/

Annulus gearLong pinion

Rear clutch/Reverse sun gear

fharatinn damants:

-, IWI WUIUI IWickdown brakeI

.

c

Since the rear clutch and the kickdown brake are actuated when theshift is in

2nd gear in the “0” or the “2” range, driving force is

transmitted to the forward sun gear which rotates in the clockwise

direction,

Therefore, torque is conveyed from the forward sun gear through the

short and long pinions to the annulus gear, as in the case of 1 st gear.

--However, since the reverse sun gear is fastened by in the case of

2ndgear, the long pinion“walks” on the reverse sun gear in the direction

of arrow (A), causing the annulus gear to rotate faster (or more) than

in the case of 1 st

gear in proportion to the length that the long pinionhas “walked”.

The reduction ratio of

2nd gear is achieved in this way.

---

Page 260 of 391

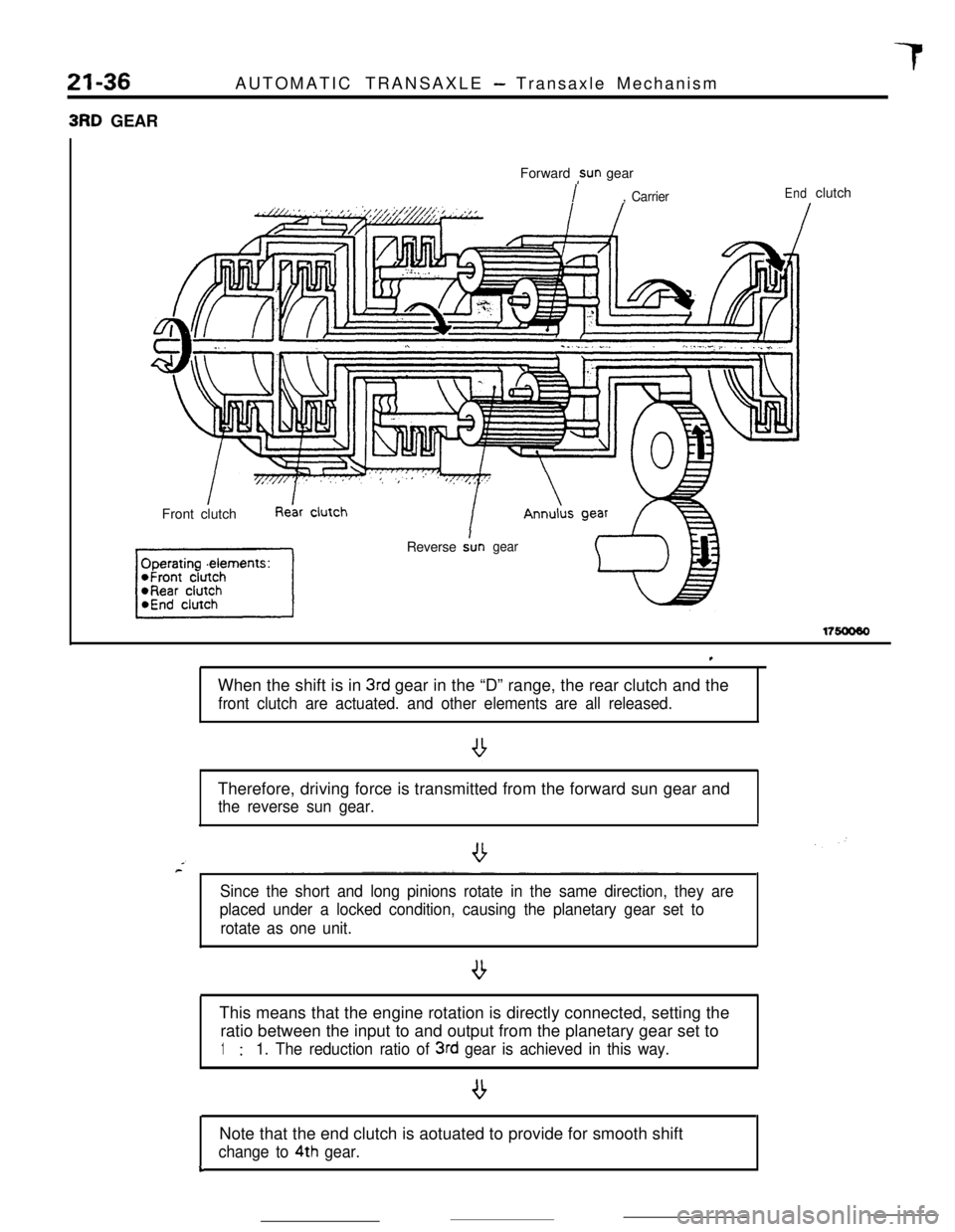

21-36AUTOMATIC TRANSAXLE - Transaxle Mechanism3RD GEAR

Forward

,sun gear

I, CarrierEndclutch

Front clutch

Reverse

Angear

17soo60

,When the shift is in

3rd gear in the “D” range, the rear clutch and the

front clutch are actuated. and other elements are all released.Therefore, driving force is transmitted from the forward sun gear and

the reverse sun gear.

Since the short and long pinions rotate in the same direction, they are

placed under a locked condition, causing the planetary gear set to

rotate as one unit.

lThis means that the engine rotation is directly connected, setting the

ratio between the input to and output from the planetary gear set to

1:1. The reduction ratio of 3rd gear is achieved in this way.Note that the end clutch is aotuated to provide for smooth shift

change to 4th gear.&

Page 262 of 391

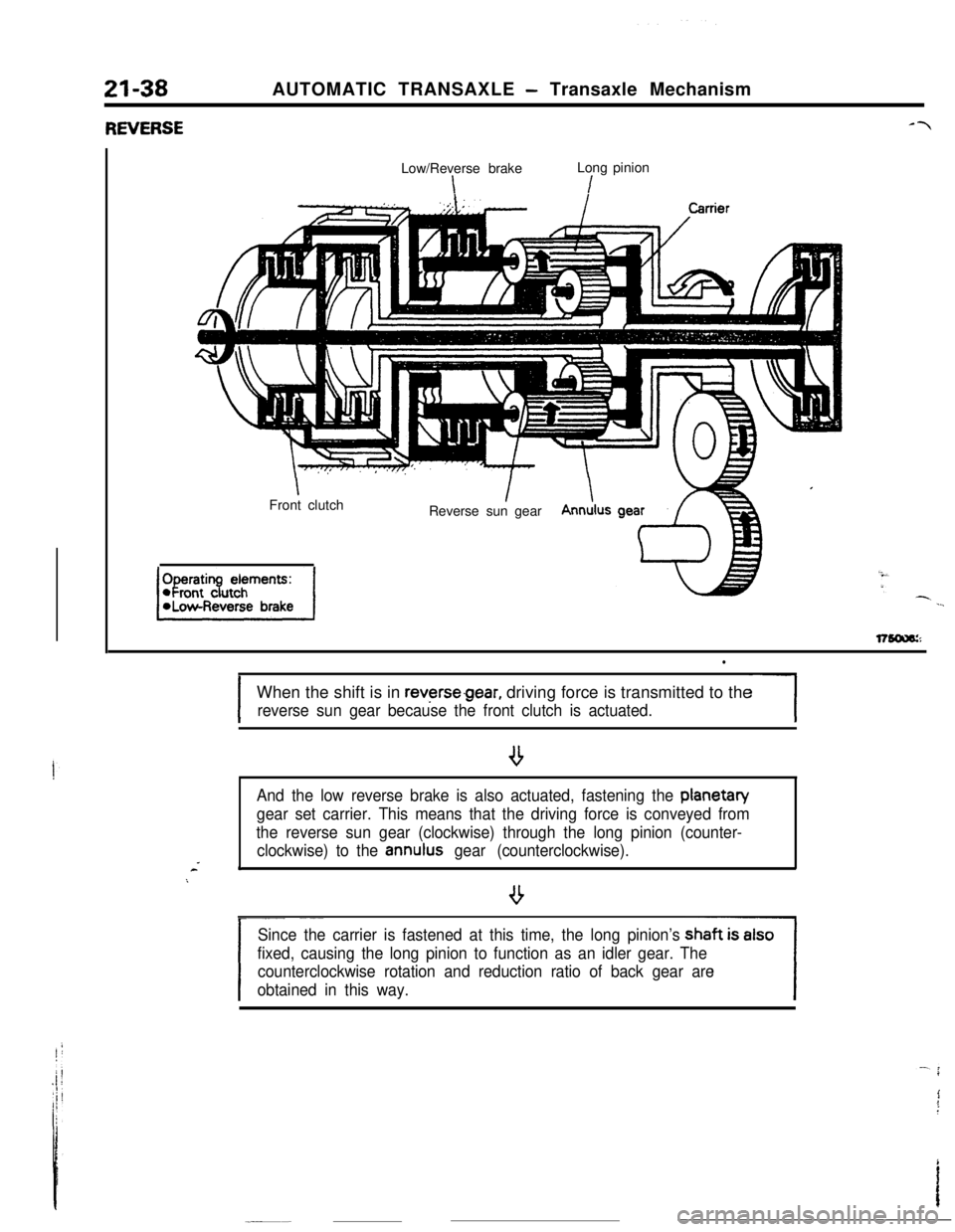

21-38RNERSEAUTOMATIC TRANSAXLE - Transaxle Mechanism

Low/Reverse brakeLong pinion

\I

IFront clutchIReverse sun gearIAnnulus

l

IWhen the shift is in

reverse.gear, driving force is transmitted to the

reverse sun gear because the front clutch is actuated.-1

And the low reverse brake is also actuated, fastening the planetan/

gear set carrier. This means that the driving force is conveyed from

the reverse sun gear (clockwise) through the long pinion (counter-

clockwise) to the

annulus gear (counterclockwise).*

/

- ~~_~

Since the carrier is fastened at this time, the long pinion’s

fixed, causing the long pinion to function as an idler gear. The

counterclockwise rotation and reduction ratio of back gear are

obtained in this way.

Page 264 of 391

21-40AUTOMATIC TRANSAXLE - Transaxle Mechanism

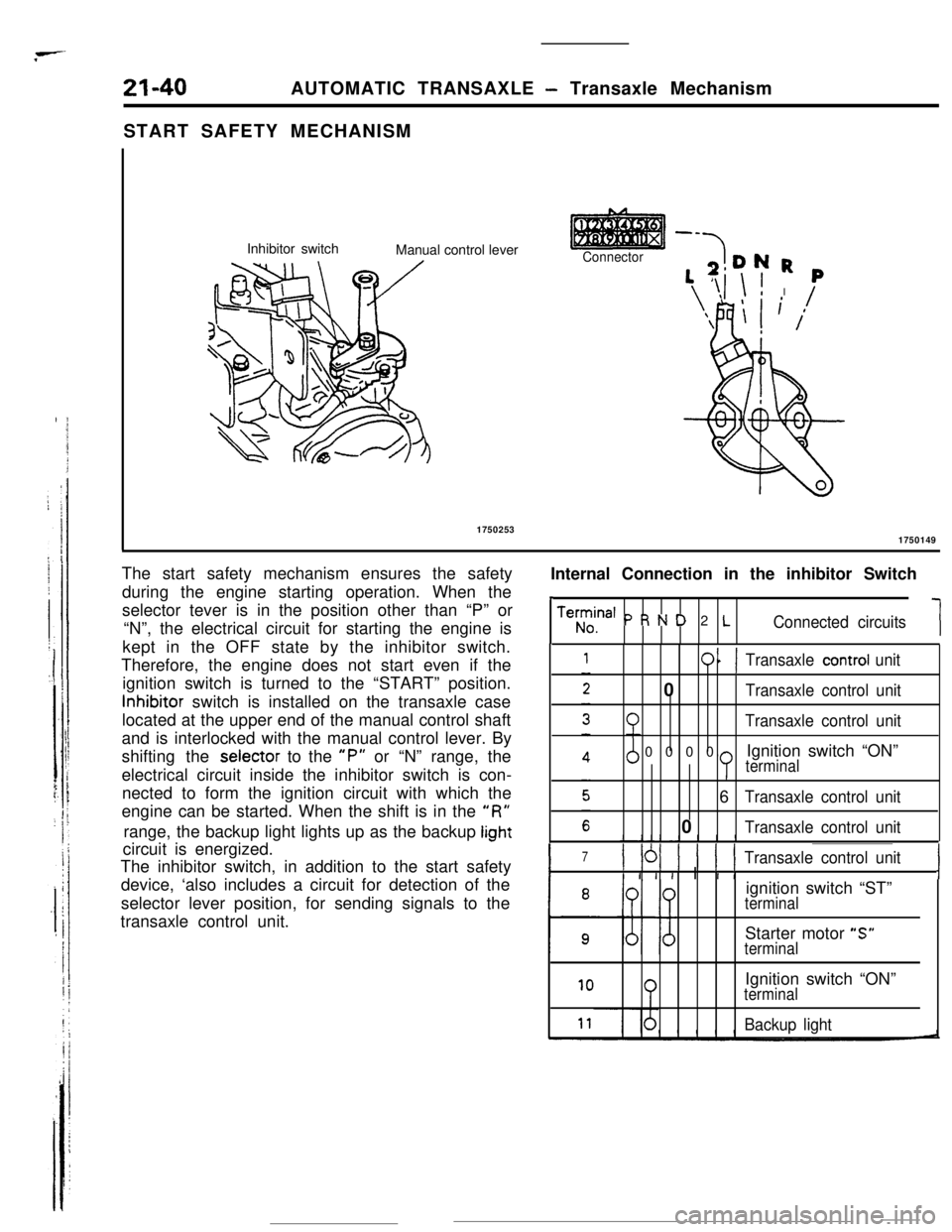

START SAFETY MECHANISM

Inhibitor switch

Manual control lever

--

Connector-7DN R

‘,T,i \ ! I

‘\FlI

\ L

,p

( /1750253

1750149

Internal Connection in the inhibitor Switch

,

Teh;ina’ P R N D 2 LConnected circuits1 The start safety mechanism ensures the safety

during the engine starting operation. When the

selector tever is in the position other than “P” or

“N”, the electrical circuit for starting the engine is

kept in the OFF state by the inhibitor switch.

Therefore, the engine does not start even if the

ignition switch is turned to the “START” position.Inhibitor switch is installed on the transaxle case

located at the upper end of the manual control shaft

and is interlocked with the manual control lever. By

shifting the selector to the

“P” or “N” range, the

electrical circuit inside the inhibitor switch is con-

nected to form the ignition circuit with which the

engine can be started. When the shift is in the

“R”range, the backup light lights up as the backup

lightcircuit is energized.

The inhibitor switch, in addition to the start safety

device, ‘also includes a circuit for detection of the

selector lever position, for sending signals to the

transaxle control unit.

011Transaxle control unit0

Transaxle control unit

Transaxle control unit0000Ignition switch “ON”

terminal6

Transaxle control unit0

Transaxle control unit

I

7) 161 ) 1 ( 1Transaxle control unit

I I I I I I IIignition switch “ST”

terminalStarter motor “S”

terminal

10Ignition switch “ON”terminal

Backup light

Page 275 of 391

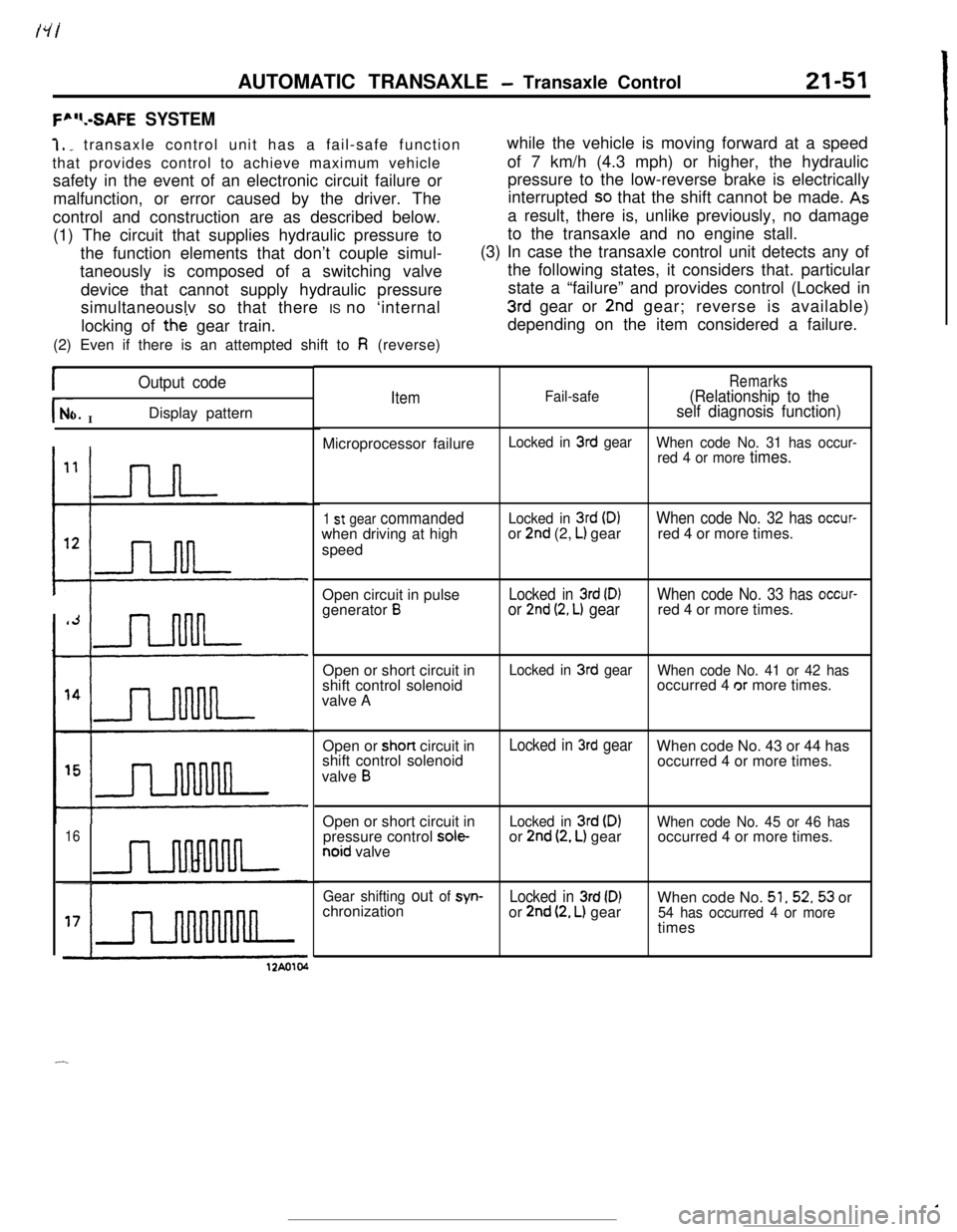

AUTOMATIC TRANSAXLE - Transaxle Control21-51

F”“.-SAFE SYSTEM7,

_ transaxle control unit has a fail-safe function

that provides control to achieve maximum vehicle

safety in the event of an electronic circuit failure or

malfunction, or error caused by the driver. The

control and construction are as described below.

(1) The circuit that supplies hydraulic pressure to

the function elements that don’t couple simul-

taneously is composed of a switching valve

device that cannot supply hydraulic pressure

simultaneouslv so that there IS no ‘internal

locking of the gear train.

(2) Even if there is an attempted shift to

Fi (reverse)while the vehicle is moving forward at a speed

of 7 km/h (4.3 mph) or higher, the hydraulic

pressure to the low-reverse brake is electrically

interrupted

SO that the shift cannot be made. Asa result, there is, unlike previously, no damage

to the transaxle and no engine stall.

(3) In case the transaxle control unit detects any of

the following states, it considers that. particular

state a “failure” and provides control (Locked in

3rd gear or 2nd gear; reverse is available)

depending on the item considered a failure.

IOutput code

r- INo.Display pattern

16

ItemFail-safeRemarks(Relationship to the

self diagnosis function)Microprocessor failure

Locked in 3rd gear

When code No. 31 has occur-

red 4 or more

times.

1 st gear commandedwhen driving at high

speedLocked in 3rd (D)or 2nd (2, L) gearWhen code No. 32 has occur-red 4 or more times.

Open circuit in pulse

generator

BLocked in 3rd (D)or 2nd (2, L) gearWhen code No. 33 has occur-red 4 or more times.

Open or short circuit in

shift control solenoid

valve A

Locked in 3rd gear

When code No. 41 or 42 hasoccurred 4 or more times.

Open or short circuit in

shift control solenoid

valve

B

Locked in 3rd gearWhen code No. 43 or 44 has

occurred 4 or more times.

Open or short circuit in

pressure control

sole-noid valve

Locked in 3rd (DIor 2nd (2, L) gearWhen code No. 45 or 46 hasoccurred 4 or more times.

Gear shifting out of syn-Locked in 3rd (D)When code No. 51,52,53 or

chronization

or 2nd (2, L) gear54 has occurred 4 or moretimes

12Ao104

-

Page 276 of 391

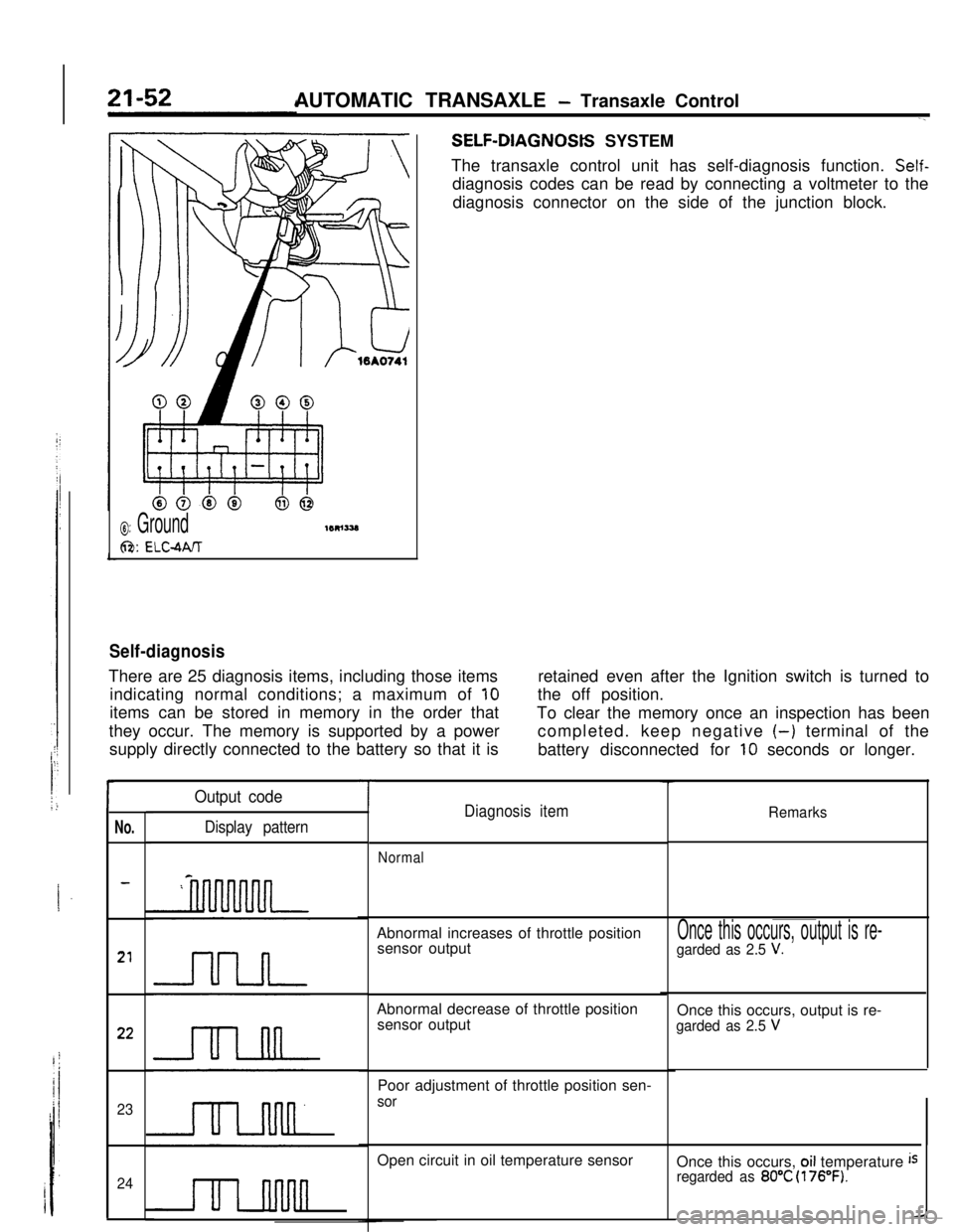

AUTOMATIC TRANSAXLE - Transaxle ControlSELF-DIAGNOStS SYSTEM

The transaxle control unit has self-diagnosis function.

Self-diagnosis codes can be read by connecting a voltmeter to the

diagnosis connector on the side of the junction block.

0: Ground

6%: ELC-MIT

Self-diagnosisThere are 25 diagnosis items, including those items

indicating normal conditions; a maximum of

10items can be stored in memory in the order that

they occur. The memory is supported by a power

supply directly connected to the battery so that it isretained even after the Ignition switch is turned to

the off position.

To clear the memory once an inspection has been

completed. keep negative

(-) terminal of the

battery disconnected for

10 seconds or longer.

r

No.

23

24

Output code

Display pattern

TDiagnosis itemRemarks

NormalAbnormal increases of throttle position

sensor output

Abnormal decrease of throttle position

sensor output

Poor adjustment of throttle position sen-

sorOpen circuit in oil temperature sensor

Once this occurs, output is re-

garded as 2.5 V.Once this occurs, output is re-

garded as 2.5 VOnce this occurs,

oil temperature isregarded as 80°C (176°F).

Page 288 of 391

/

1. .)

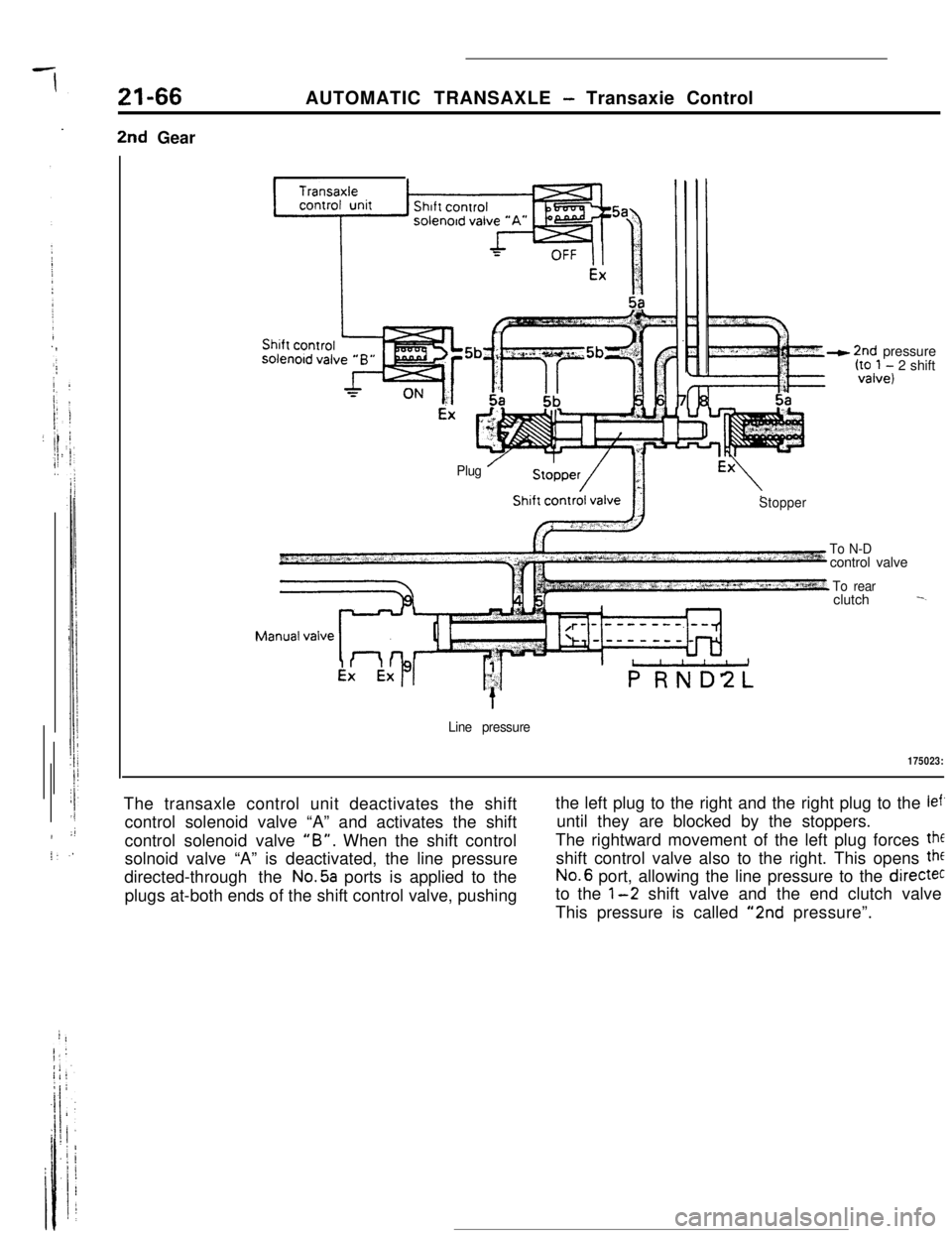

21-66

2nd GearAUTOMATIC TRANSAXLE

- Transaxie Control

Plug ’

- 2nd pressure‘:“,,tol, 2 shift

Stopper

To N-Dcontrol valve

To rearclutch -.

Line pressure

175023:The transaxle control unit deactivates the shift

control solenoid valve “A” and activates the shift

control solenoid valve

“B”. When the shift control

solnoid valve “A” is deactivated, the line pressure

directed-through the

No.5a ports is applied to the

plugs at-both ends of the shift control valve, pushingthe left plug to the right and the right plug to the

lef’until they are blocked by the stoppers.

The rightward movement of the left plug forces

theshift control valve also to the right. This opens

theNo.6 port, allowing the line pressure to the

directecto the

l-2 shift valve and the end clutch valve

This pressure is called

“2nd pressure”.