lock MITSUBISHI ECLIPSE 1990 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 290 of 391

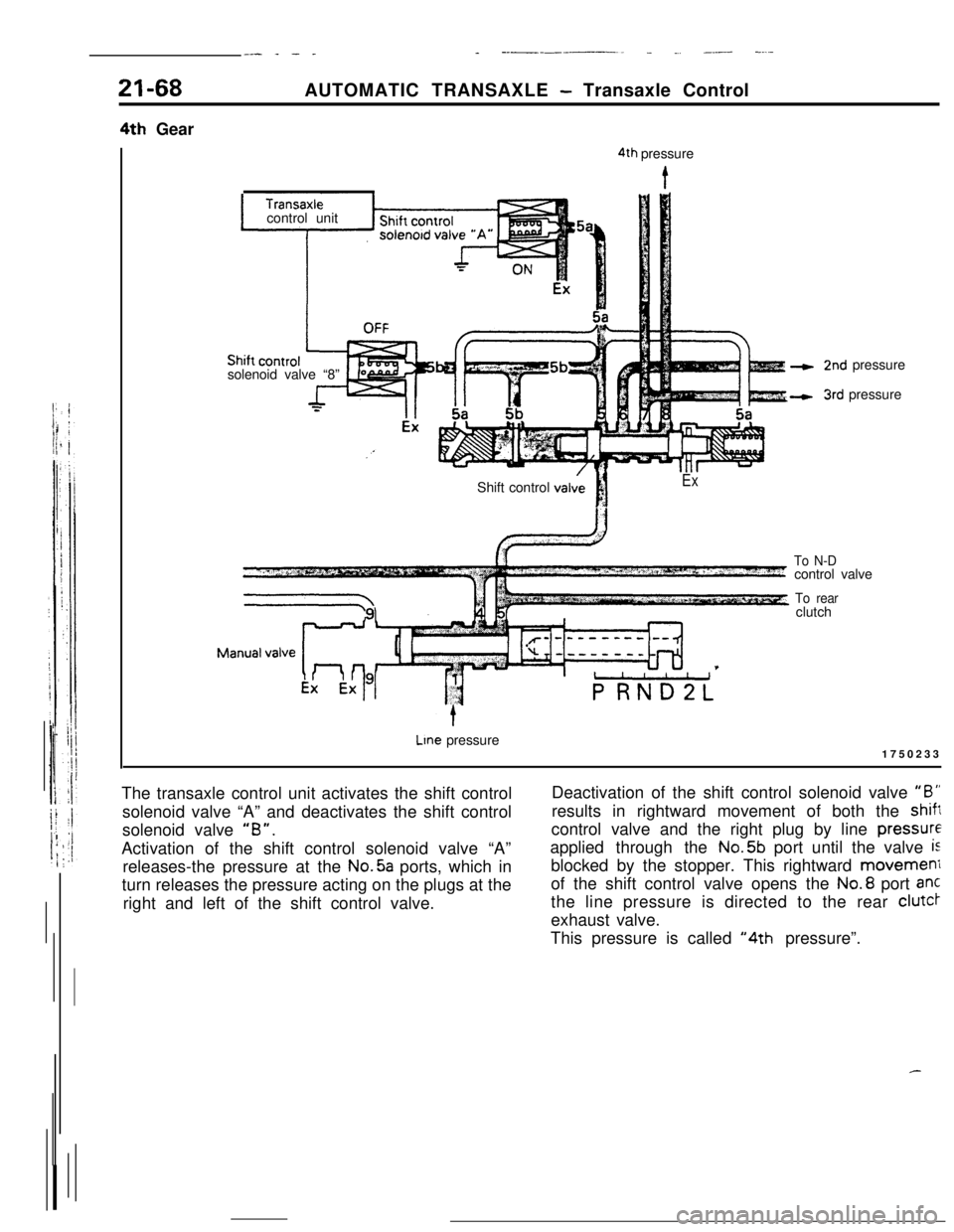

__- _ - __ ----____. _ ., _.- -....21-684th GearAUTOMATIC TRANSAXLE

- Transaxle Control

solenoid valve “8”

4th pressure

Icontrol unit

2nd pressure

3rd pressure

Shift control

valviI!

iEx

To N-Dcontrol valve

To rearclutch

Lme pressure

1750233

The transaxle control unit activates the shift control

solenoid valve “A” and deactivates the shift control

solenoid valve

“B”.Activation of the shift control solenoid valve “A”

releases-the pressure at the No.5a ports, which in

turn releases the pressure acting on the plugs at the

right and left of the shift control valve.Deactivation of the shift control solenoid valve

“B”results in rightward movement of both the

shiftcontrol valve and the right plug by line

pressureapplied through the No.5b port until the valve

isblocked by the stopper. This rightward movemeni

of the shift control valve opens the No.8 port ant

the line pressure is directed to the rear clutcr

exhaust valve.

This pressure is called

“4th pressure”.

Page 304 of 391

21-82AUTOMATIC TRANSAXLE - Transaxle Control

valve

A

2nd3rdpressure pressure175011:To shift

control

valve#3

land

2nd3rdpressure pressure

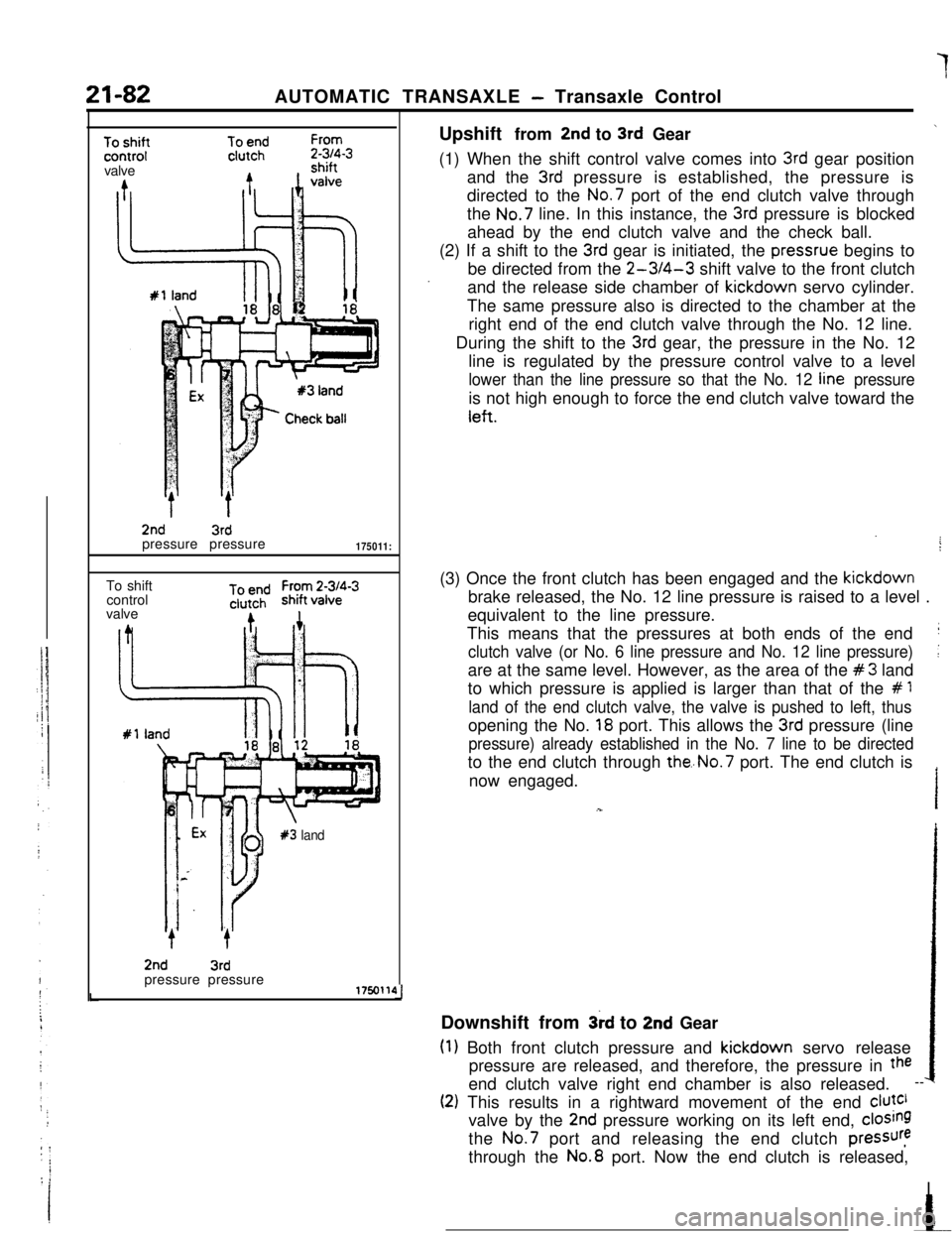

175011~LlUpshift from

2nd to 3rd Gear\(1) When the shift control valve comes into

3rd gear position

and the

3rd pressure is established, the pressure is

directed to the No.7 port of the end clutch valve through

the No.7 line. In this instance, the

3rd pressure is blocked

ahead by the end clutch valve and the check ball.

(2) If a shift to the

3rd gear is initiated, the pressrue begins to

be directed from the

2-3/4-3 shift valve to the front clutch

and the release side chamber of kickdown servo cylinder.

The same pressure also is directed to the chamber at the

right end of the end clutch valve through the No. 12 line.

During the shift to the

3rd gear, the pressure in the No. 12

line is regulated by the pressure control valve to a level

lower than the line pressure so that the No. 12 line pressureis not high enough to force the end clutch valve toward the

left.(3) Once the front clutch has been engaged and the kickdown

brake released, the No. 12 line pressure is raised to a level .

equivalent to the line pressure.

This means that the pressures at both ends of the end

j

clutch valve (or No. 6 line pressure and No. 12 line pressure)[are at the same level. However, as the area of the

#3 land

to which pressure is applied is larger than that of the

# 1

land of the end clutch valve, the valve is pushed to left, thusopening the No.

18 port. This allows the 3rd pressure (line

pressure) already established in the No. 7 line to be directedto the end clutch through

the..No.7 port. The end clutch is

now engaged.

Downshift from

3rd to 2nd Gear

(1) Both front clutch pressure and kickdown servo release

pressure are released, and therefore, the pressure in

theend clutch valve right end chamber is also released.

--

(2) This results in a rightward movement of the end clutclvalve by the

2nd pressure working on its left end, closingthe

No.7 port and releasing the end clutch pressurethrough the No.8 port. Now the end clutch is released,

I

Page 337 of 391

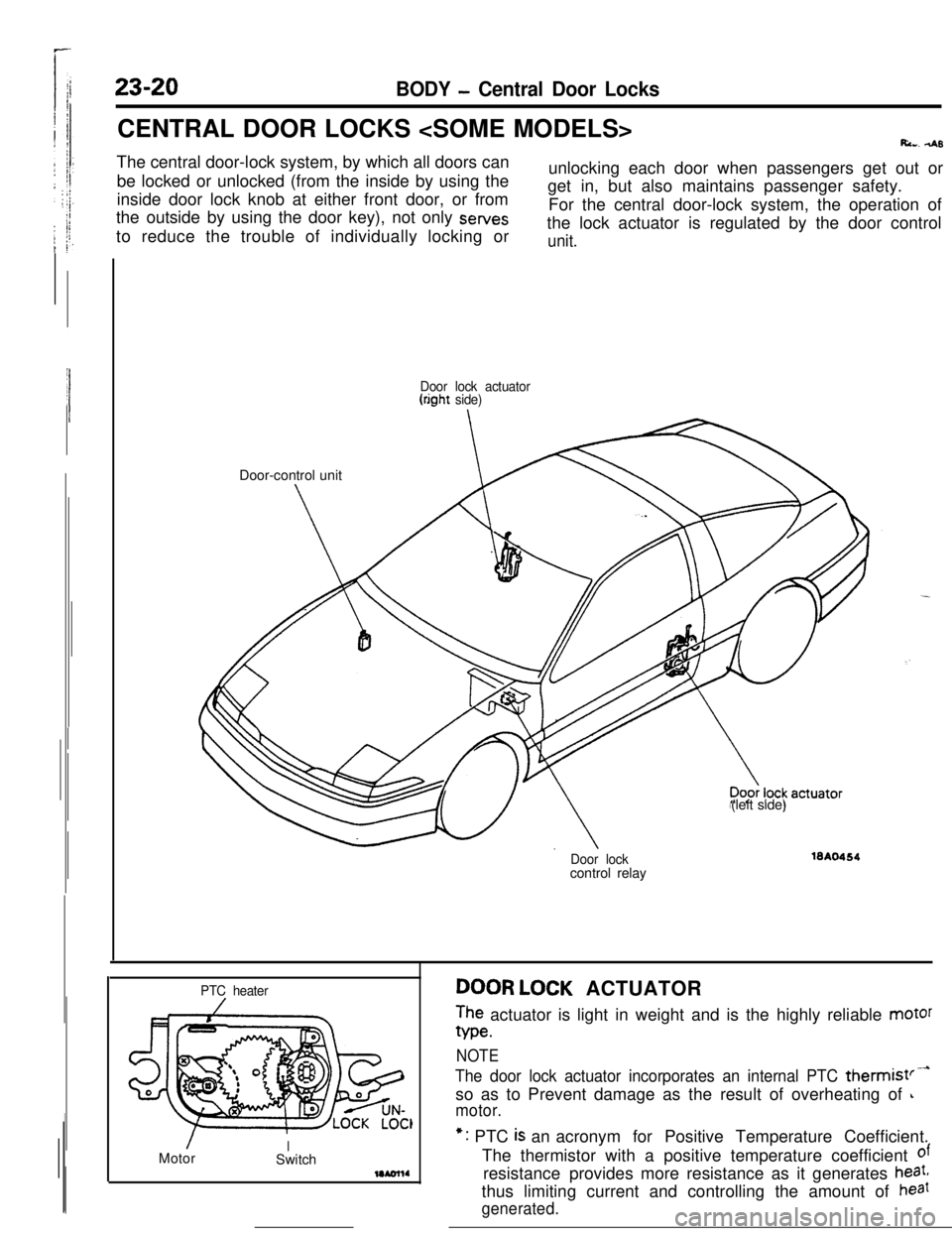

23-20BODY - Central Door LocksCENTRAL DOOR LOCKS

Ri... 4sThe central door-lock system, by which all doors can

be locked or unlocked (from the inside by using the

inside door lock knob at either front door, or from

the outside by using the door key), not only sewes

to reduce the trouble of individually locking orunlocking each door when passengers get out or

get in, but also maintains passenger safety.

For the central door-lock system, the operation of

the lock actuator is regulated by the door control

unit.

Door lock actuator(right side)Door-control unit

(left side)

Door lockcontrol relay16A0464

PTC heater

/MotorISwitchDOOR LOCK ACTUATOR

The actuator is light in weight and is the highly reliable motor

We.

NOTE

The door lock actuator incorporates an internal PTC thermist’-so as to Prevent damage as the result of overheating of

L

motor.*: PTC

is an acronym for Positive Temperature Coefficient.

The thermistor with a positive temperature coefficient

ofresistance provides more resistance as it generates

heat,thus limiting current and controlling the amount of

haat

generated.

Page 338 of 391

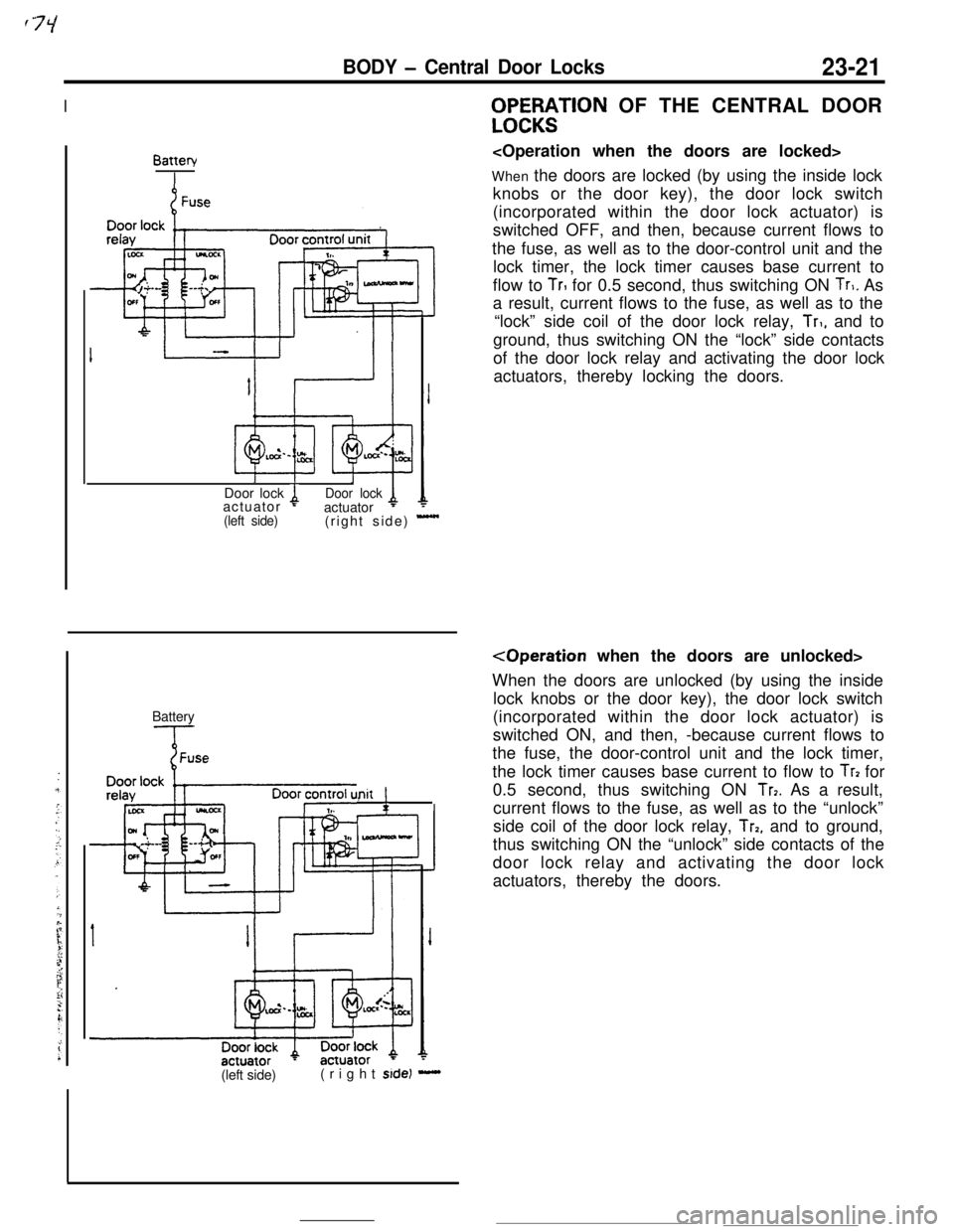

BODY - Central Door Locks23-21

IBattery

1IJDoor lock 4Door lockactuator t(left side)actuator

(right side) -Battery

Init !,WF%;$TlON OF THE CENTRAL DOOR

When the doors are locked (by using the inside lock

knobs or the door key), the door lock switch

(incorporated within the door lock actuator) is

switched OFF, and then, because current flows to

the fuse, as well as to the door-control unit and the

lock timer, the lock timer causes base current to

flow to

TrI for 0.5 second, thus switching ON Tr,. As

a result, current flows to the fuse, as well as to the

“lock” side coil of the door lock relay,

Tr,, and to

ground, thus switching ON the “lock” side contacts

of the door lock relay and activating the door lock

actuators, thereby locking the doors.

When the doors are unlocked (by using the inside

lock knobs or the door key), the door lock switch

(incorporated within the door lock actuator) is

switched ON, and then, -because current flows to

the fuse, the door-control unit and the lock timer,

the lock timer causes base current to flow to

Tr? for

0.5 second, thus switching ON

Tr7. As a result,

current flows to the fuse, as well as to the “unlock”

side coil of the door lock relay,

Trp, and to ground,

thus switching ON the “unlock” side contacts of the

door lock relay and activating the door lock

actuators, thereby the doors.

(left side)(right

side) -

Page 339 of 391

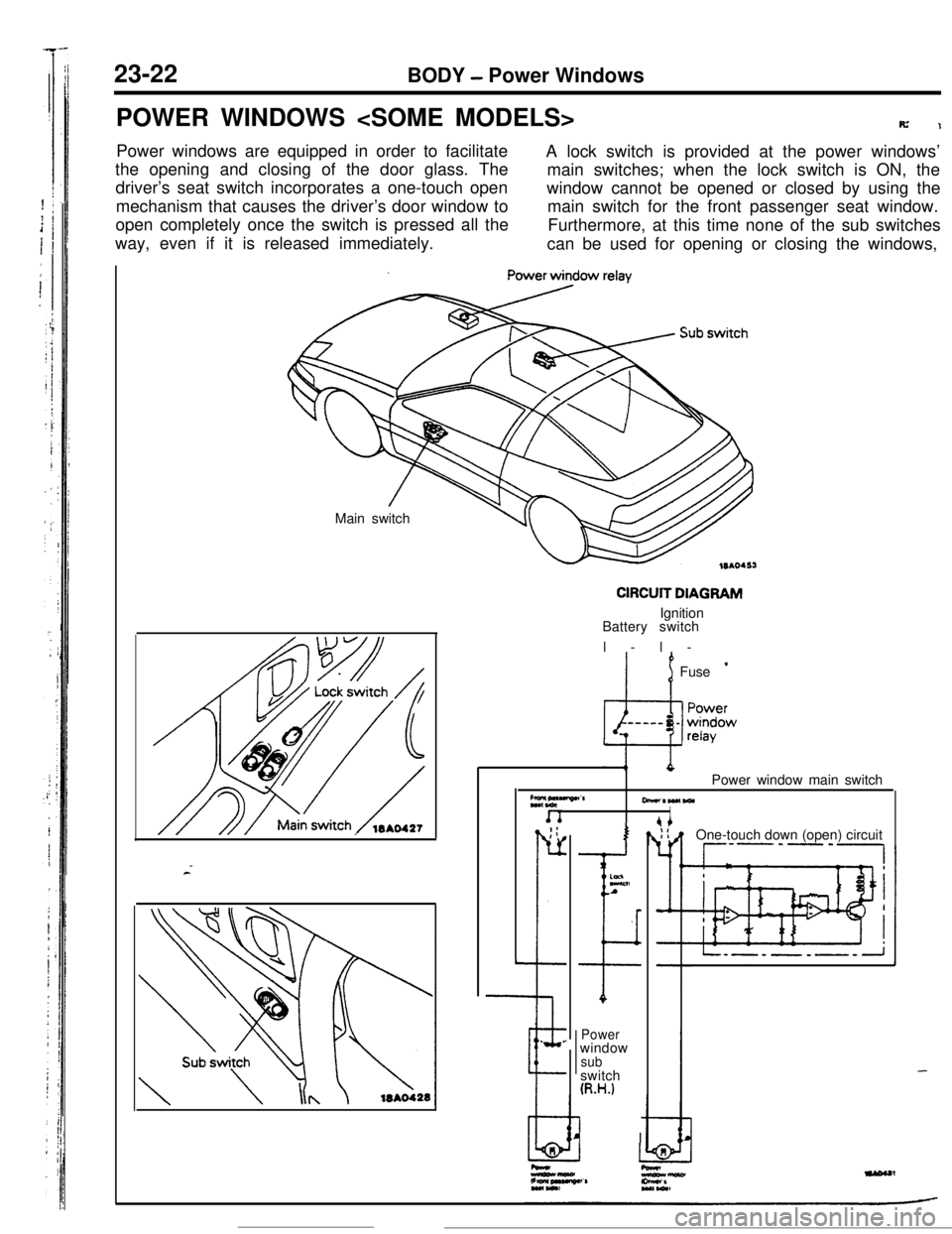

23-22BODY - Power Windows

POWER WINDOWS

R’1Power windows are equipped in order to facilitate

A lock switch is provided at the power windows’

the opening and closing of the door glass. The

main switches; when the lock switch is ON, the

driver’s seat switch incorporates a one-touch open

mechanism that causes the driver’s door window towindow cannot be opened or closed by using the

main switch for the front passenger seat window.

open completely once the switch is pressed all the

way, even if it is released immediately.Furthermore, at this time none of the sub switches

can be used for opening or closing the windows,

Main switch

CIRCUIT DIAGRAMIgnition

Battery switch

l-l-

’ 1Fuse ’

Z*,“““”CrPower window main switch

-*W(WlI. _;:

r-

L

--e.

.

I

ELnA

I

Powerwindow

subswitch

(R.H.)

I IOne-touch down (open) circuit

--P’-‘-,

-

Page 348 of 391

BODY - Seat Belts

._-- -

23-31

Shoulder beltI

Lapbelt

IGlove box pad toasty

Knee protector

Guide rail\Fasten switch

\

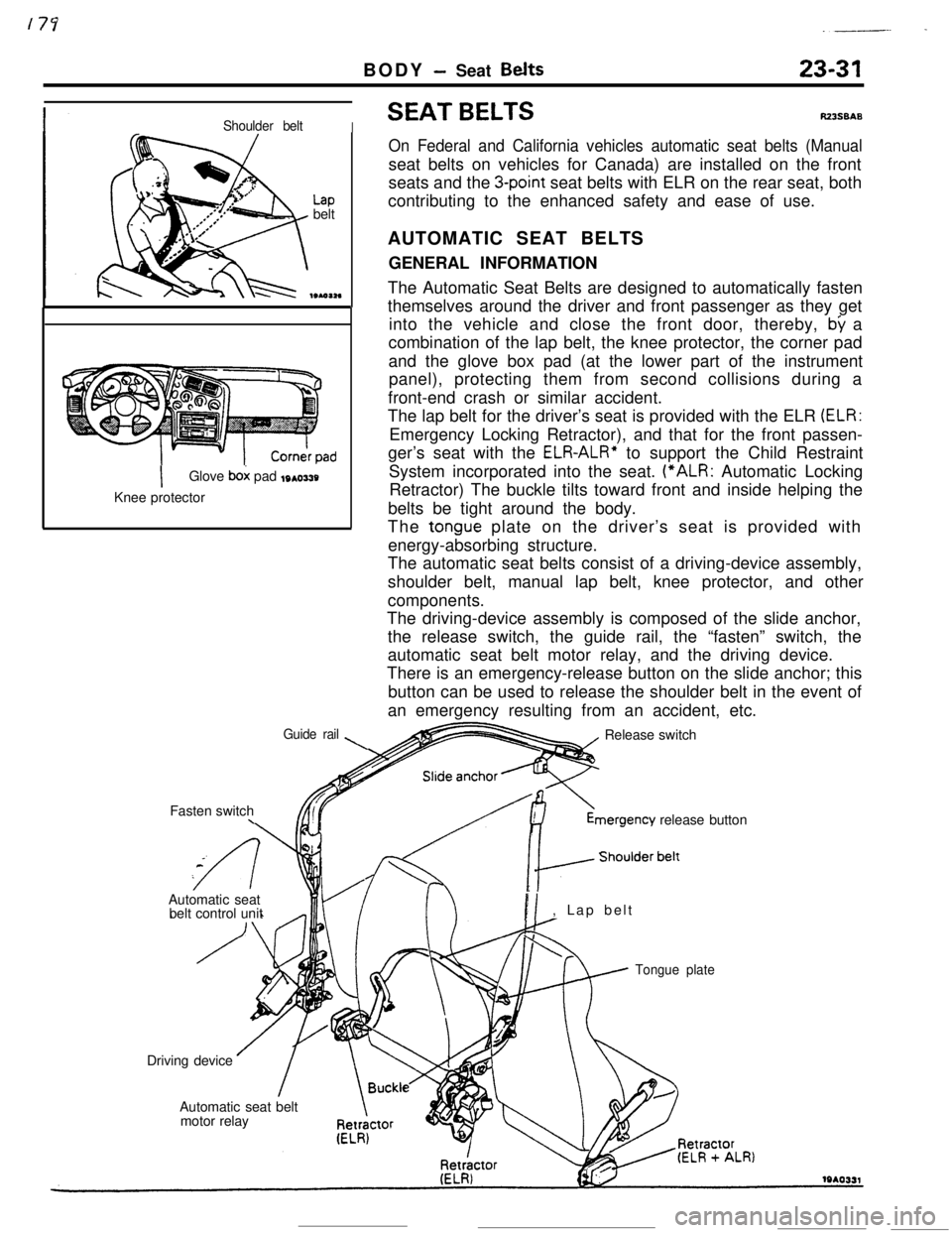

SEAT BELTSRZ3SBAS

On Federal and California vehicles automatic seat belts (Manualseat belts on vehicles for Canada) are installed on the front

seats and the

3-point seat belts with ELR on the rear seat, both

contributing to the enhanced safety and ease of use.

AUTOMATIC SEAT BELTS

GENERAL INFORMATION

The Automatic Seat Belts are designed to automatically fasten

themselves around the driver and front passenger as they get

into the vehicle and close the front door, thereby,

by a

combination of the lap belt, the knee protector, the corner pad

and the glove box pad (at the lower part of the instrument

panel), protecting them from second collisions during a

front-end crash or similar accident.

The lap belt for the driver’s seat is provided with the ELR

(ELR:Emergency Locking Retractor), and that for the front passen-

ger’s seat with the

ELR-ALR” to support the Child Restraint

System incorporated into the seat. (“ALR: Automatic Locking

Retractor) The buckle tilts toward front and inside helping the

belts be tight around the body.

The

tongue plate on the driver’s seat is provided with

energy-absorbing structure.

The automatic seat belts consist of a driving-device assembly,

shoulder belt, manual lap belt, knee protector, and other

components.

The driving-device assembly is composed of the slide anchor,

the release switch, the guide rail, the “fasten” switch, the

automatic seat belt motor relay, and the driving device.

There is an emergency-release button on the slide anchor; this

button can be used to release the shoulder belt in the event of

an emergency resulting from an accident, etc.

Release switchmergency

release button

Automatic seat

belt control unit

PI, Lap belt

Tongue plateDriving device

Automatic seat belt

motor relay

Page 349 of 391

23-32BODY - Seat Belts

OPERATION OF AUTOMATIC SEAT BELTS

The operation of the Automatic Seat Belts is as follows.

(1) The belts fasten itself around the occupant when the front

door is closed with the ignition switch in the “ON” position.

(2) The belts release itself from the occupant when the front

door is opened with the ignition switch in the

*“ON” or

“LOCK” or “ACC” position.

(3) The belts cease to fasten itself around the occupant if the

ignition switch is turned to “LOCK” or “ACC” or when the

front door is opened during the belt motion.

(4) The belts for the driver’s and front passenger’s seats

operate independently of each other.

Lever springStopper, Rod A

Sub paw1

Gear B

Rod B19po37:

Sub’pawlIWO374

IStopperGear AI

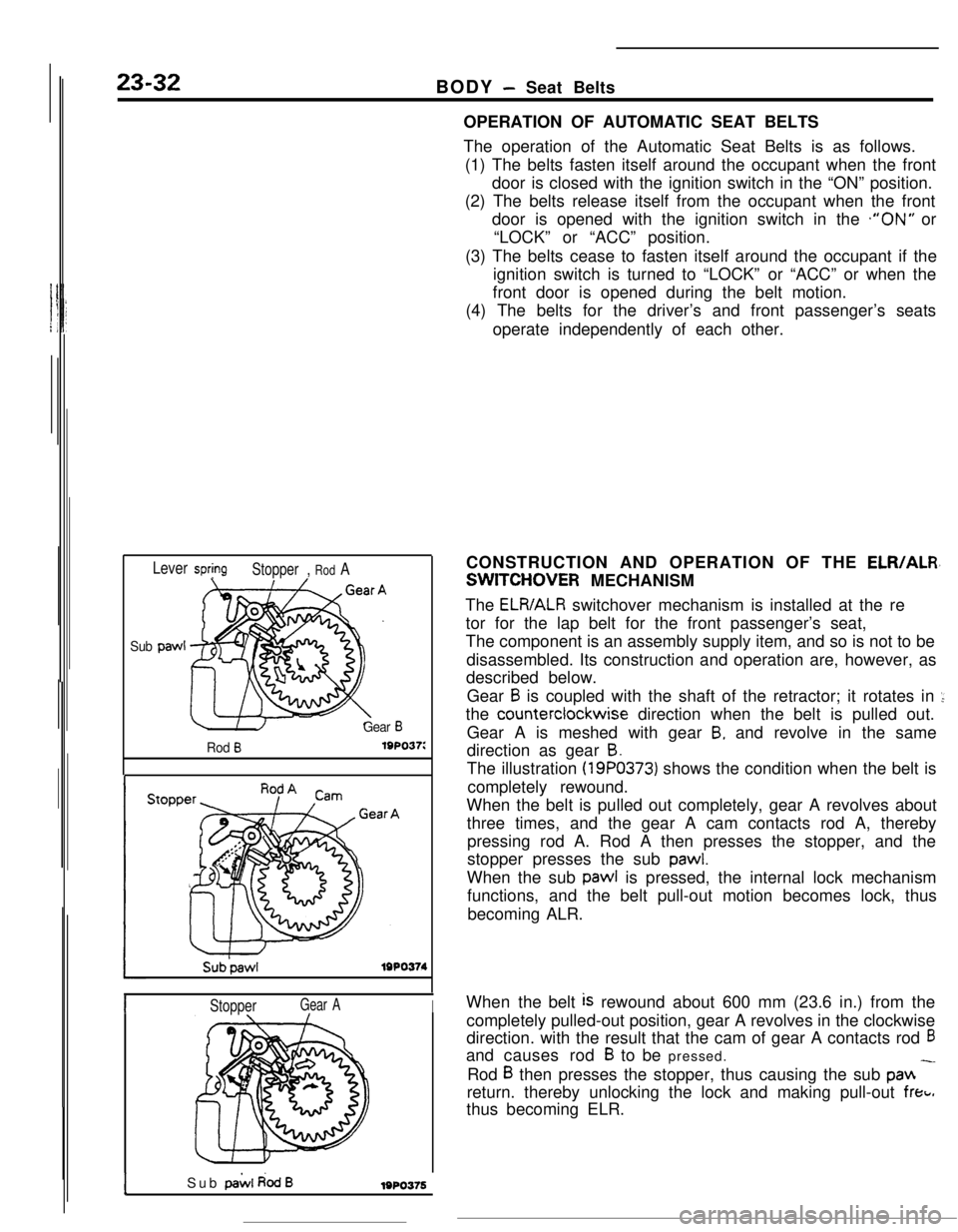

ISub pai.4 dodB1980376CONSTRUCTION AND OPERATION OF THE

ELR/ALR,

SWITCHOVER MECHANISM

The

ELR/ALR switchover mechanism is installed at the re

tor for the lap belt for the front passenger’s seat,

The component is an assembly supply item, and so is not to be

disassembled. Its construction and operation are, however, as

described below.

Gear

B is coupled with the shaft of the retractor; it rotates in ::the counterclockwise direction when the belt is pulled out.

Gear A is meshed with gear

B, and revolve in the same

direction as gear

B.The illustration

(19PO373) shows the condition when the belt is

completely rewound.

When the belt is pulled out completely, gear A revolves about

three times, and the gear A cam contacts rod A, thereby

pressing rod A. Rod A then presses the stopper, and the

stopper presses the sub

pawl.When the sub pawl is pressed, the internal lock mechanism

functions, and the belt pull-out motion becomes lock, thus

becoming ALR.

When the belt

is rewound about 600 mm (23.6 in.) from the

completely pulled-out position, gear A revolves in the clockwise

direction. with the result that the cam of gear A contacts rod

6and causes rod

B to be pressed.

Rod

B then presses the stopper, thus causing the sub pan -return. thereby unlocking the lock and making pull-out

freti.thus becoming ELR.

Page 351 of 391

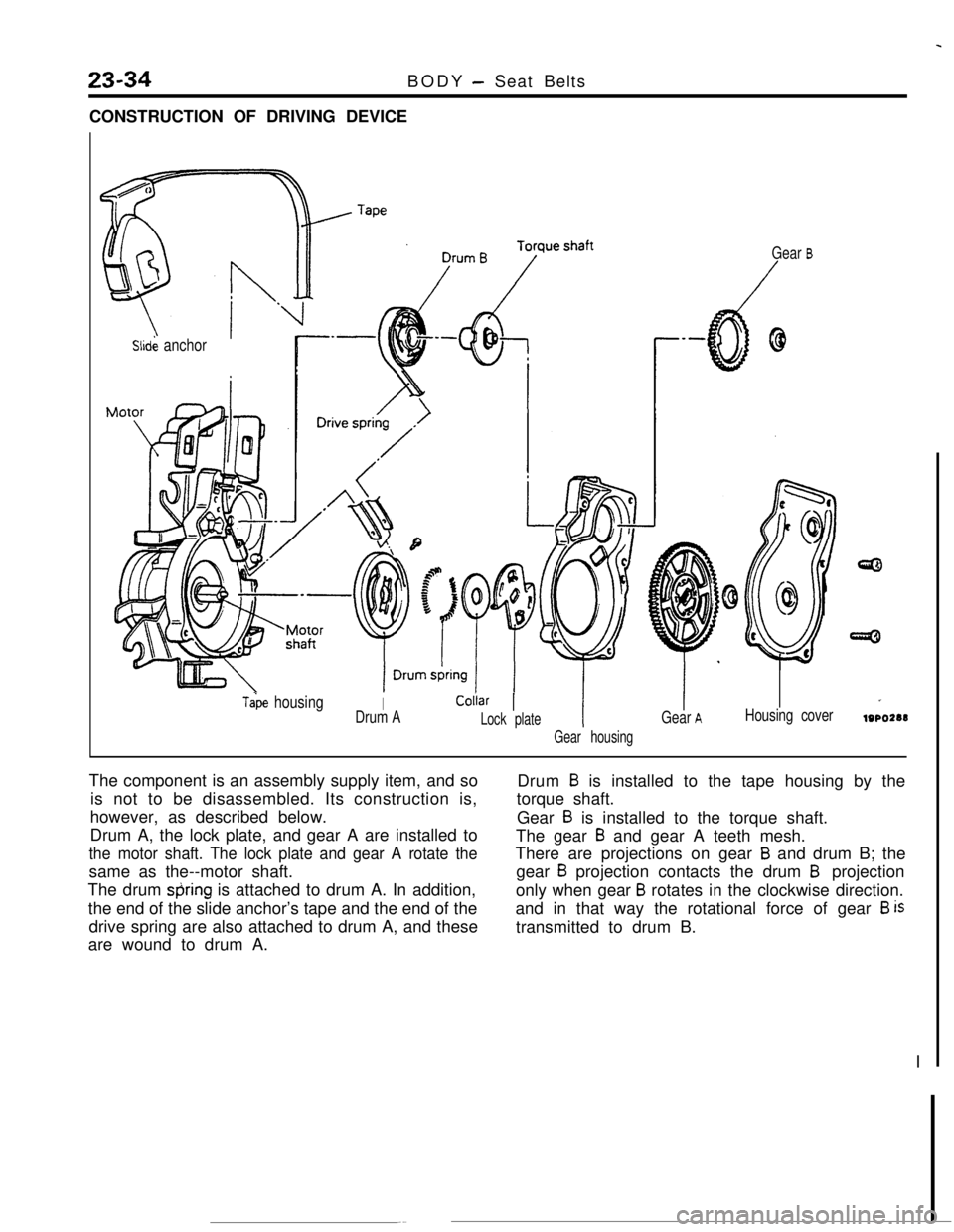

23-34BODY - Seat Belts

CONSTRUCTION OF DRIVING DEVICE

Slid& anchor

Tabe housingIColiar 1

Drum ALock plate

Gear housing

Gear B

Gear AHousing cover

I

lOPO288The component is an assembly supply item, and so

is not to be disassembled. Its construction is,

however, as described below.

Drum A, the lock plate, and gear A are installed to

the motor shaft. The lock plate and gear A rotate thesame as the--motor shaft.

The drum

&ring is attached to drum A. In addition,

the end of the slide anchor’s tape and the end of the

drive spring are also attached to drum A, and these

are wound to drum A.Drum

B is installed to the tape housing by the

torque shaft.

Gear

B is installed to the torque shaft.

The gear

B and gear A teeth mesh.

There are projections on gear

B and drum B; the

gear

B projection contacts the drum B projection

only when gear

B rotates in the clockwise direction.

and in that way the rotational force of gear

B istransmitted to drum B.

I

Page 352 of 391

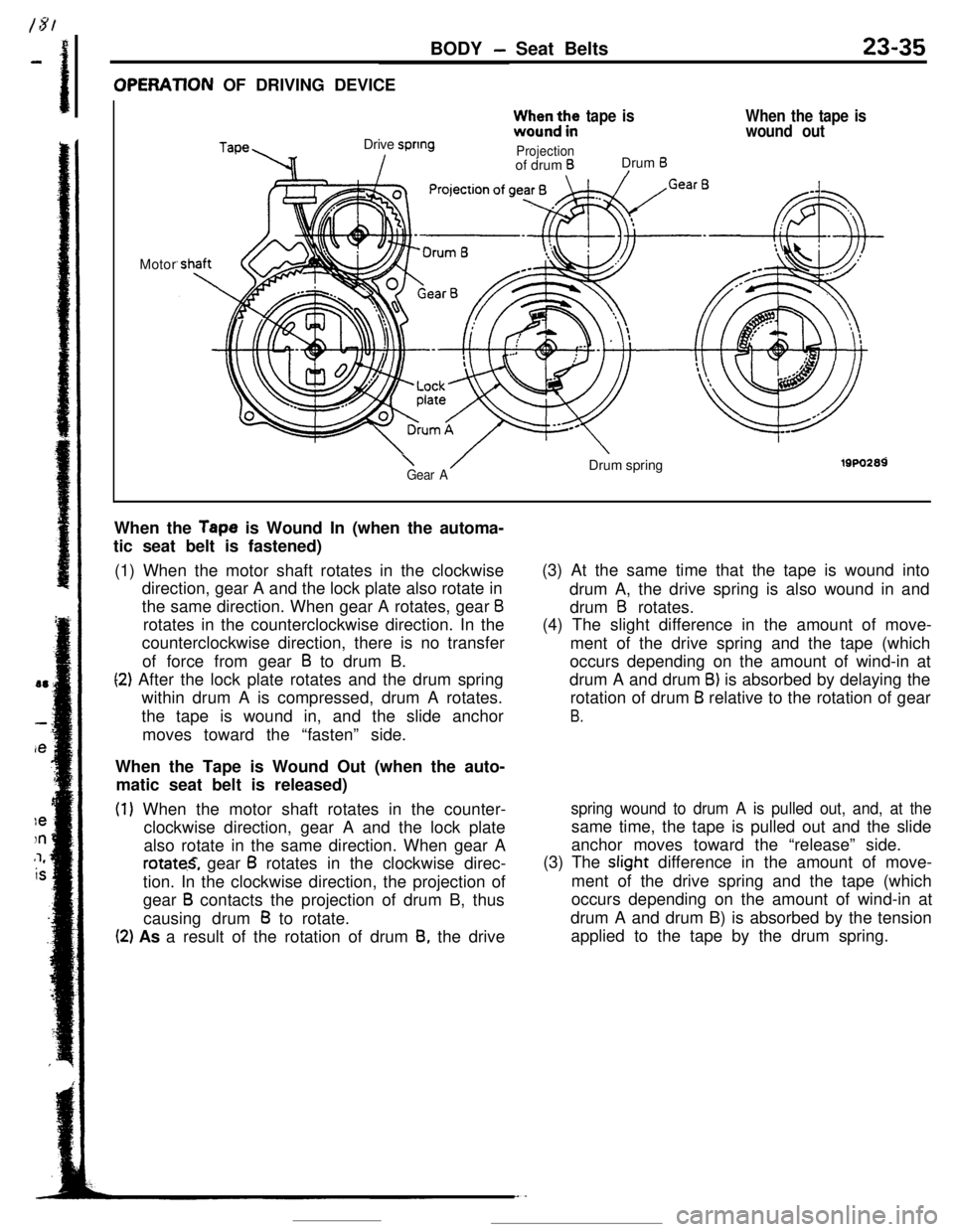

BODY - Seat Belts23-35OPERATlON OF DRIVING DEVICE

TapeDrive spring

Izz;b3;:,e

tape is

Projectionof drum BDrum B/

When the tape is

wound outMotor

\ /Gear ADrum springi9w2a9When the

Tape is Wound In (when the automa-

tic seat belt is fastened)

(1) When the motor shaft rotates in the clockwise

direction, gear A and the lock plate also rotate in

the same direction. When gear A rotates, gear

Brotates in the counterclockwise direction. In the

counterclockwise direction, there is no transfer

of force from gear

B to drum B.

(2) After the lock plate rotates and the drum spring

within drum A is compressed, drum A rotates.

the tape is wound in, and the slide anchor

moves toward the “fasten” side.

When the Tape is Wound Out (when the auto-

matic seat belt is released)

(1) When the motor shaft rotates in the counter-

clockwise direction, gear A and the lock plate

also rotate in the same direction. When gear A

rotate.S, gear B rotates in the clockwise direc-

tion. In the clockwise direction, the projection of

gear

B contacts the projection of drum B, thus

causing drum

B to rotate.

(2) As a result of the rotation of drum 8, the drive(3) At the same time that the tape is wound into

drum A, the drive spring is also wound in and

drum

B rotates.

(4) The slight difference in the amount of move-

ment of the drive spring and the tape (which

occurs depending on the amount of wind-in at

drum A and drum

B) is absorbed by delaying the

rotation of drum

B relative to the rotation of gear

B.

spring wound to drum A is pulled out, and, at thesame time, the tape is pulled out and the slide

anchor moves toward the “release” side.

(3) The slight difference in the amount of move-

ment of the drive spring and the tape (which

occurs depending on the amount of wind-in at

drum A and drum B) is absorbed by the tension

applied to the tape by the drum spring.

Page 356 of 391

BODY - Seat Belts23-39

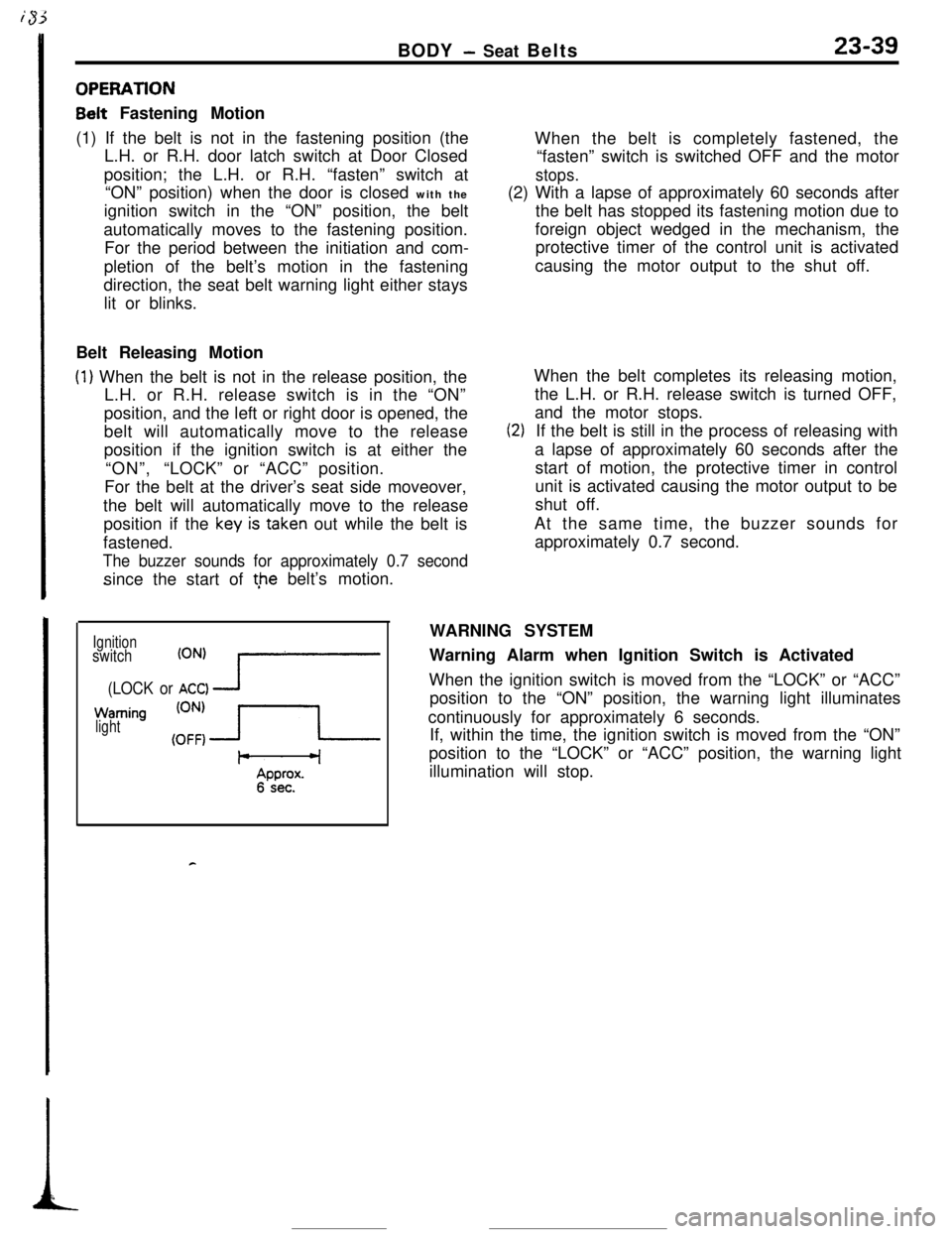

OPERATlON

Belt Fastening Motion

(1) If the belt is not in the fastening position (the

L.H. or R.H. door latch switch at Door Closed

position; the L.H. or R.H. “fasten” switch at

“ON” position) when the door is closed with the

ignition switch in the “ON” position, the belt

automatically moves to the fastening position.

For the period between the initiation and com-

pletion of the belt’s motion in the fastening

direction, the seat belt warning light either stays

lit or blinks.

Belt Releasing Motion

(1) When the belt is not in the release position, the

L.H. or R.H. release switch is in the “ON”

position, and the left or right door is opened, the

belt will automatically move to the release

position if the ignition switch is at either the

“ON”,“LOCK” or “ACC” position.

For the belt at the driver’s seat side moveover,

the belt will automatically move to the release

position if the

key is taken out while the belt is

fastened.

The buzzer sounds for approximately 0.7 secondsince the start of thebelt’s motion.When the belt is completely fastened, the

“fasten” switch is switched OFF and the motor

stops.(2) With a lapse of approximately 60 seconds after

the belt has stopped its fastening motion due to

foreign object wedged in the mechanism, the

protective timer of the control unit is activated

causing the motor output to the shut off.

When the belt completes its releasing motion,

the L.H. or R.H. release switch is turned OFF,

and the motor stops.

(2)If the belt is still in the process of releasing with

a lapse of approximately 60 seconds after the

start of motion, the protective timer in control

unit is activated causing the motor output to be

shut off.

At the same time, the buzzer sounds for

approximately 0.7 second.

Ignitionswitch

(ONI I------(LOCK or ACC) -J

Warning

light

I-6 sec. ’

cWARNING SYSTEM

Warning Alarm when Ignition Switch is Activated

When the ignition switch is moved from the “LOCK” or “ACC”

position to the “ON” position, the warning light illuminates

continuously for approximately 6 seconds.

If, within the time, the ignition switch is moved from the “ON”

position to the “LOCK” or “ACC” position, the warning light

illumination will stop.