air condition MITSUBISHI ECLIPSE 1991 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1166 of 1216

24-22 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures(9) Charge through the suction side of the system by slowly

opening the suction manifold valve. Adjust the valve as

necessary so charging pressure does not exceed 345

kPa 6(50 psi). Maintain the temperature of the water in the pan w’

by adding warm water as necessary.

Note the weight of water added, to ensure accuracy when

determining amount of refrigerant added to system.

(lO)When specified refrigerant charge Max. 925

g (32 oz.) has

entered the system, close the gauge set manifold valves,

refrigerant manifold valves, and

reconnnect wiring. Each

can contains 397

g (14 oz.) of R-l 2. Use 2 l/2 cans.

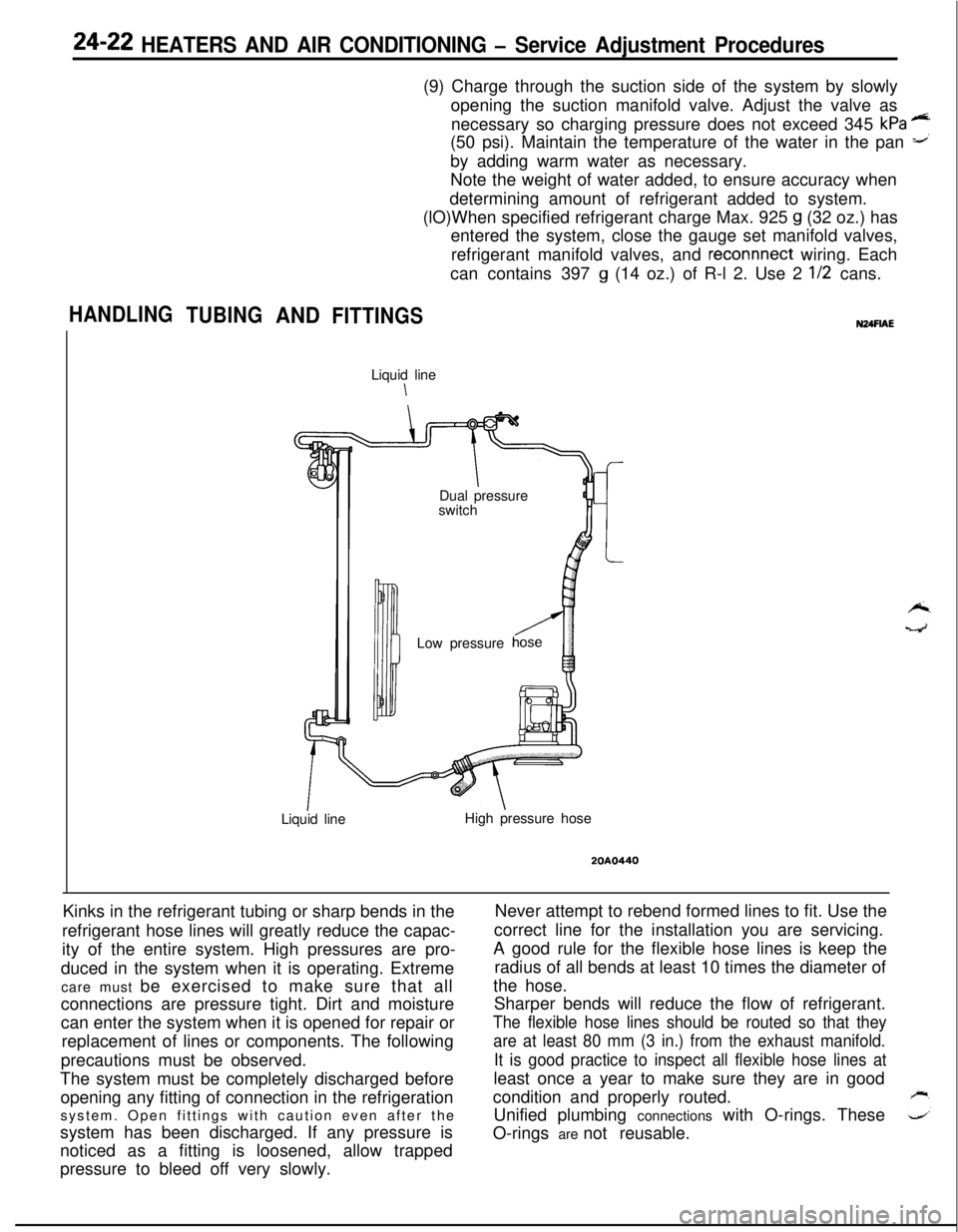

HANDLING

TUBINGANDFITTINGSLiquid line

\

IDual pressure

switch

Low pressure

Liquid lineHigh pressure hose

20A0440Kinks in the refrigerant tubing or sharp bends in the

refrigerant hose lines will greatly reduce the capac-

ity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all

connections are pressure tight. Dirt and moisture

can enter the system when it is opened for repair or

replacement of lines or components. The following

precautions must be observed.

The system must be completely discharged before

opening any fitting of connection in the refrigeration

system. Open fittings with caution even after the

system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trapped

pressure to bleed off very slowly.Never attempt to rebend formed lines to fit. Use the

correct line for the installation you are servicing.

A good rule for the flexible hose lines is keep the

radius of all bends at least 10 times the diameter of

the hose.

Sharper bends will reduce the flow of refrigerant.

The flexible hose lines should be routed so that they

are at least 80 mm (3 in.) from the exhaust manifold.

It is good practice to inspect all flexible hose lines atleast once a year to make sure they are in good

condition and properly routed.

Unified plumbing connections with O-rings. These

O-rings are not reusable.

Page 1167 of 1216

HEATERS AND AIR CONDITIONING - Service Adiustment Procedures 24-23

<

we2ouo2er

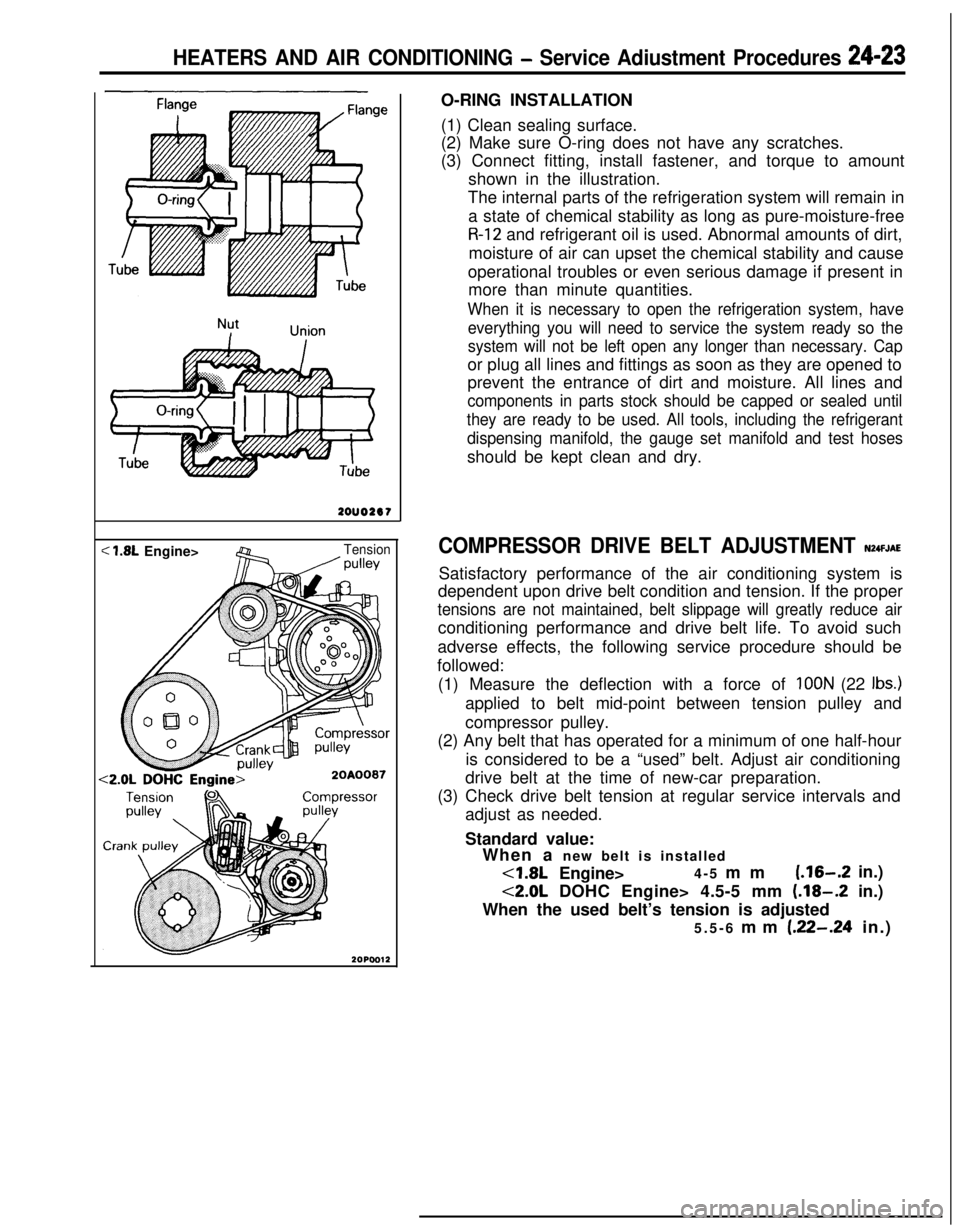

< 1.8L Engine>Tension/ wllevO-RING INSTALLATION

(1) Clean sealing surface.

(2) Make sure O-ring does not have any scratches.

(3) Connect fitting, install fastener, and torque to amount

shown in the illustration.

The internal parts of the refrigeration system will remain in

a state of chemical stability as long as pure-moisture-free

R-12 and refrigerant oil is used. Abnormal amounts of dirt,

moisture of air can upset the chemical stability and cause

operational troubles or even serious damage if present in

more than minute quantities.

When it is necessary to open the refrigeration system, have

everything you will need to service the system ready so the

system will not be left open any longer than necessary. Capor plug all lines and fittings as soon as they are opened to

prevent the entrance of dirt and moisture. All lines and

components in parts stock should be capped or sealed until

they are ready to be used. All tools, including the refrigerant

dispensing manifold, the gauge set manifold and test hosesshould be kept clean and dry.

COMPRESSOR DRIVE BELT ADJUSTMENT N24FJAESatisfactory performance of the air conditioning system is

dependent upon drive belt condition and tension. If the proper

tensions are not maintained, belt slippage will greatly reduce airconditioning performance and drive belt life. To avoid such

adverse effects, the following service procedure should be

followed:

(1) Measure the deflection with a force of

IOON (22 Ibs.)applied to belt mid-point between tension pulley and

compressor pulley.

(2) Any belt that has operated for a minimum of one half-hour

is considered to be a “used” belt. Adjust air conditioning

drive belt at the time of new-car preparation.

(3) Check drive belt tension at regular service intervals and

adjust as needed.

Standard value:

When a new belt is installed<1.8L Engine>4-5 mm

(.16-.2 in.)

<2.0L DOHC Engine> 4.5-5 mm (.18-.2 in.)

When the used belt’s tension is adjusted

5.5-6 mm

(.22-.24 in.)

Page 1168 of 1216

24-24 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

COMPRESSOR NOISENUFIABWhen investigating an air conditioning related noise, you must

first know the conditions when the noise occurs. These

conditions are: weather, vehicle speed, in gear or neutral,

engine temperature or any other special conditions.

Noises that develop during air conditioning operation can oftenbe misleading. For example: what sounds like a failed front

bearing or connecting rod, may be caused by loose bolts, nuts,mounting brackets, or a loose clutch assembly. Verify acces-

sory drive belt tension (power steering, or alternator).

Improper accessory drive belt tension can cause a misleading

noise when the compressor is engaged and little or no noise

when the compressor is disengaged.

Drive belts are speed sensitive. That is, at different engine

speeds, and depending upon belt tension, belts can develop

unusual noises that are often mistaken for mechanical prob-

lems within the compressor.

Adjustment Procedures

(1) Select a quiet area for testing. Duplicate conditions as

much as possible. Switch compressor on and off several

times to clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure),restrict air flow through condenser. Install manifold gauge

set to make sure discharge pressure doesn’t exceed 2,070

kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting

bolt, and compressor drive belt. Check to assure clutch coilis tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that cancause unusual noises.

(4) Check refrigerant charge (See “Charging the System”).

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and

retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

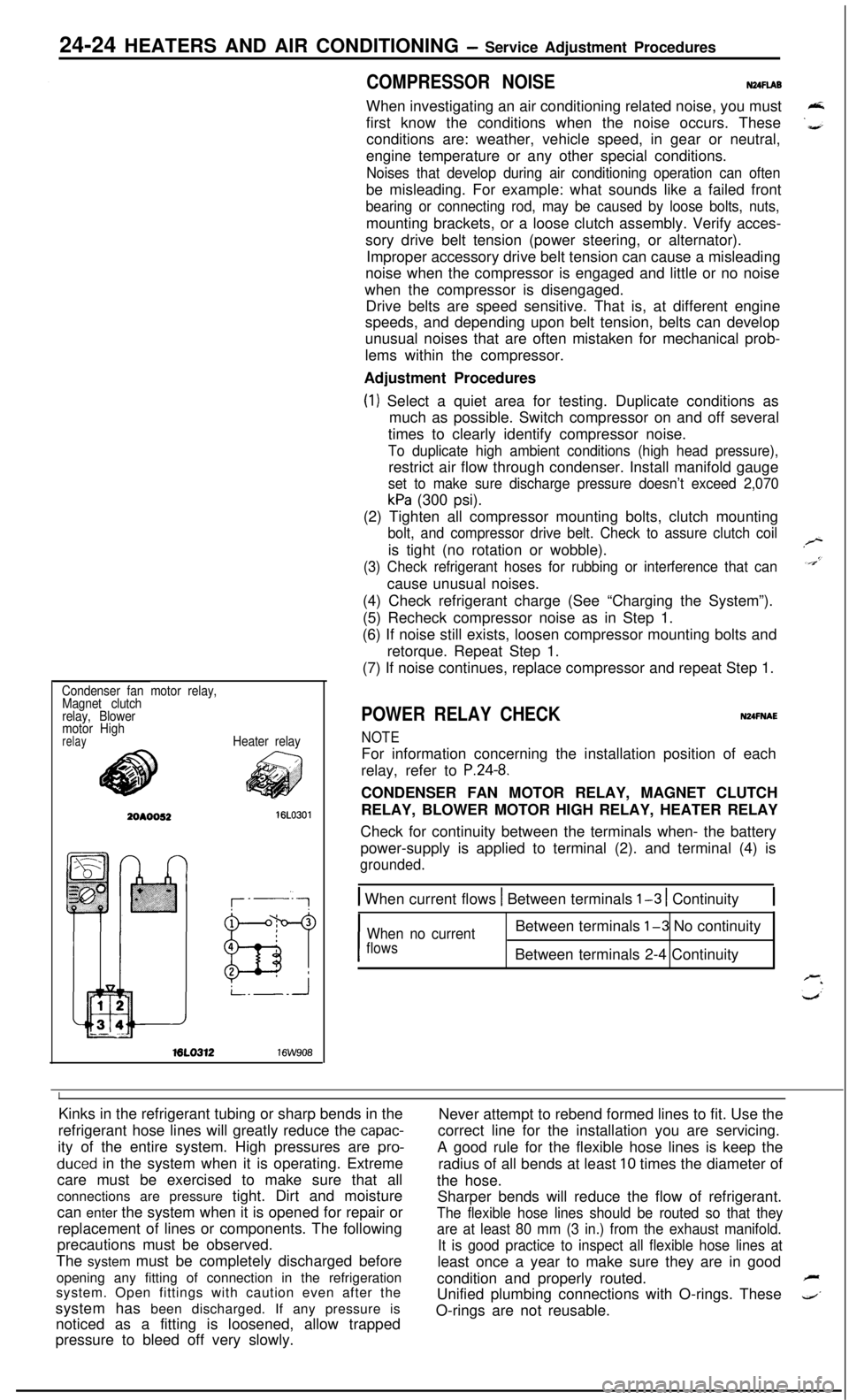

Condenser fan motor relay,

Magnet clutch

relay, Blower

motor High

relayHeater relayML0312

16W908

POWER RELAY CHECKNUFNAE

NOTEFor information concerning the installation position of each

relay, refer to

P.24-8.CONDENSER FAN MOTOR RELAY, MAGNET CLUTCH

RELAY, BLOWER MOTOR HIGH RELAY, HEATER RELAY

Check for continuity between the terminals when- the battery

power-supply is applied to terminal (2). and terminal (4) is

grounded.

1 When current flows 1 Between terminals l-3 1 Continuity1

I

When no currentBetween terminals l-3 No continuity

flowsBetween terminals 2-4 Continuity

IKinks in the refrigerant tubing or sharp bends in the

Never attempt to rebend formed lines to fit. Use the

refrigerant hose lines will greatly reduce the

capac-correct line for the installation you are servicing.

ity of the entire system. High pressures are

pro-A good rule for the flexible hose lines is keep the

duced in the system when it is operating. Extreme

radius of all bends at least 10 times the diameter of

care must be exercised to make sure that all

the hose.

connections are pressure tight. Dirt and moisture

Sharper bends will reduce the flow of refrigerant.

can enter the system when it is opened for repair or

The flexible hose lines should be routed so that theyreplacement of lines or components. The following

are at least 80 mm (3 in.) from the exhaust manifold.precautions must be observed.

It is good practice to inspect all flexible hose lines atThe system must be completely discharged before

least once a year to make sure they are in good

opening any fitting of connection in the refrigeration

condition and properly routed.

Fsystem. Open fittings with caution even after the

Unified plumbing connections with O-rings. These

4’system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trappedO-rings are not reusable.

pressure to bleed off very slowly.

Page 1169 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-25

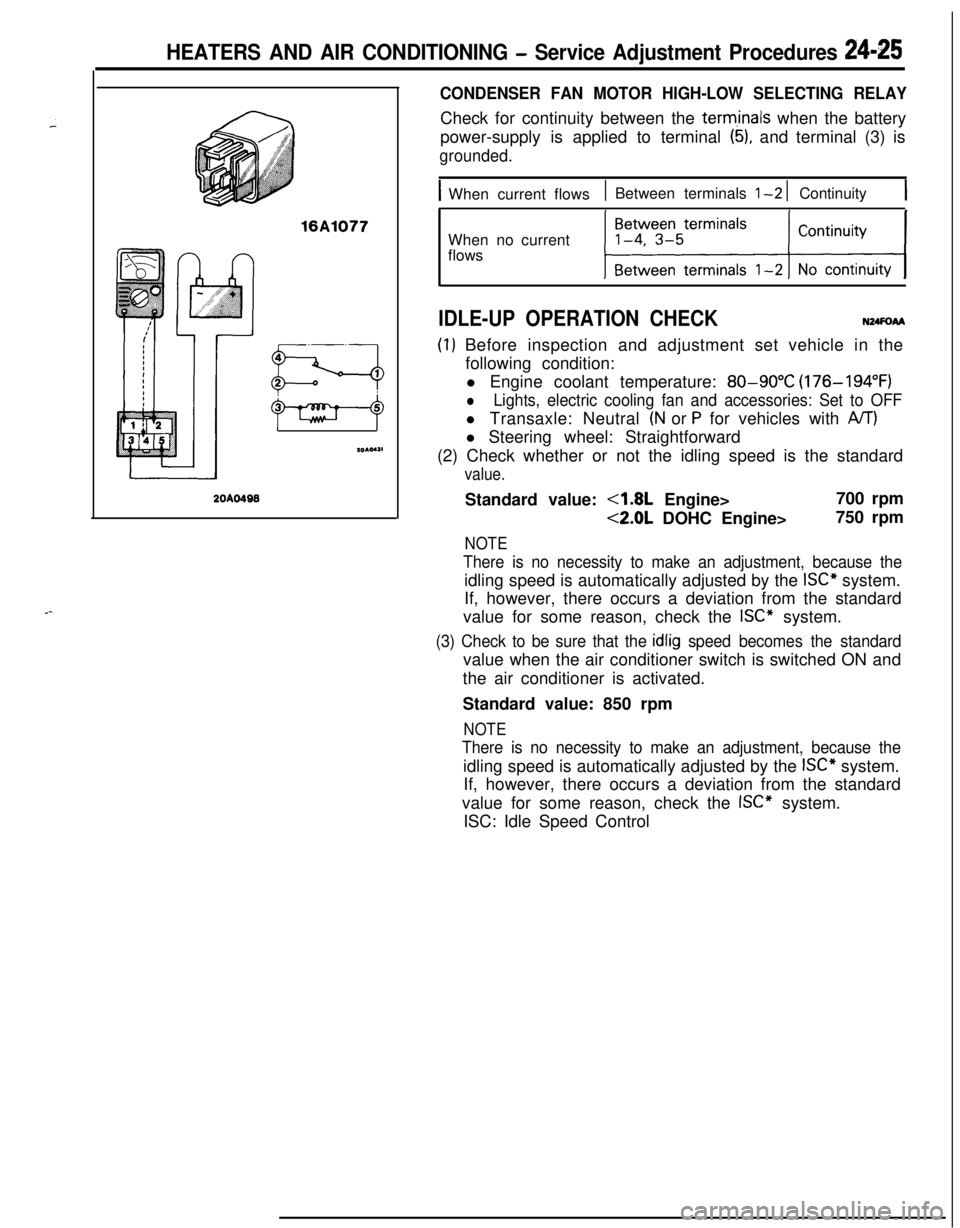

16A1077

20AO499

CONDENSER FAN MOTOR HIGH-LOW SELECTING RELAYCheck for continuity between the

term,inals when the battery

power-supply is applied to terminal

(5), and terminal (3) is

grounded.

IWhen current flows1 Between terminals l-2 1 Continuity1When no current

flows

IDLE-UP OPERATION CHECKN24FoAA

(I) Before inspection and adjustment set vehicle in the

following condition:

l Engine coolant temperature:

80-90°C (176-194°F)

lLights, electric cooling fan and accessories: Set to OFFl Transaxle: Neutral

(N or P for vehicles with A/T)l Steering wheel: Straightforward

(2) Check whether or not the idling speed is the standard

value.Standard value:

4.8L Engine>700 rpm

<2.0L DOHC Engine>750 rpm

NOTE

There is no necessity to make an adjustment, because theidling speed is automatically adjusted by the

ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the

ISC” system.

(3) Check to be sure that the idlig speed becomes the standardvalue when the air conditioner switch is switched ON and

the air conditioner is activated.

Standard value: 850 rpm

NOTE

There is no necessity to make an adjustment, because theidling speed is automatically adjusted by the

ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the

ISC” system.

ISC: Idle Speed Control

Page 1170 of 1216

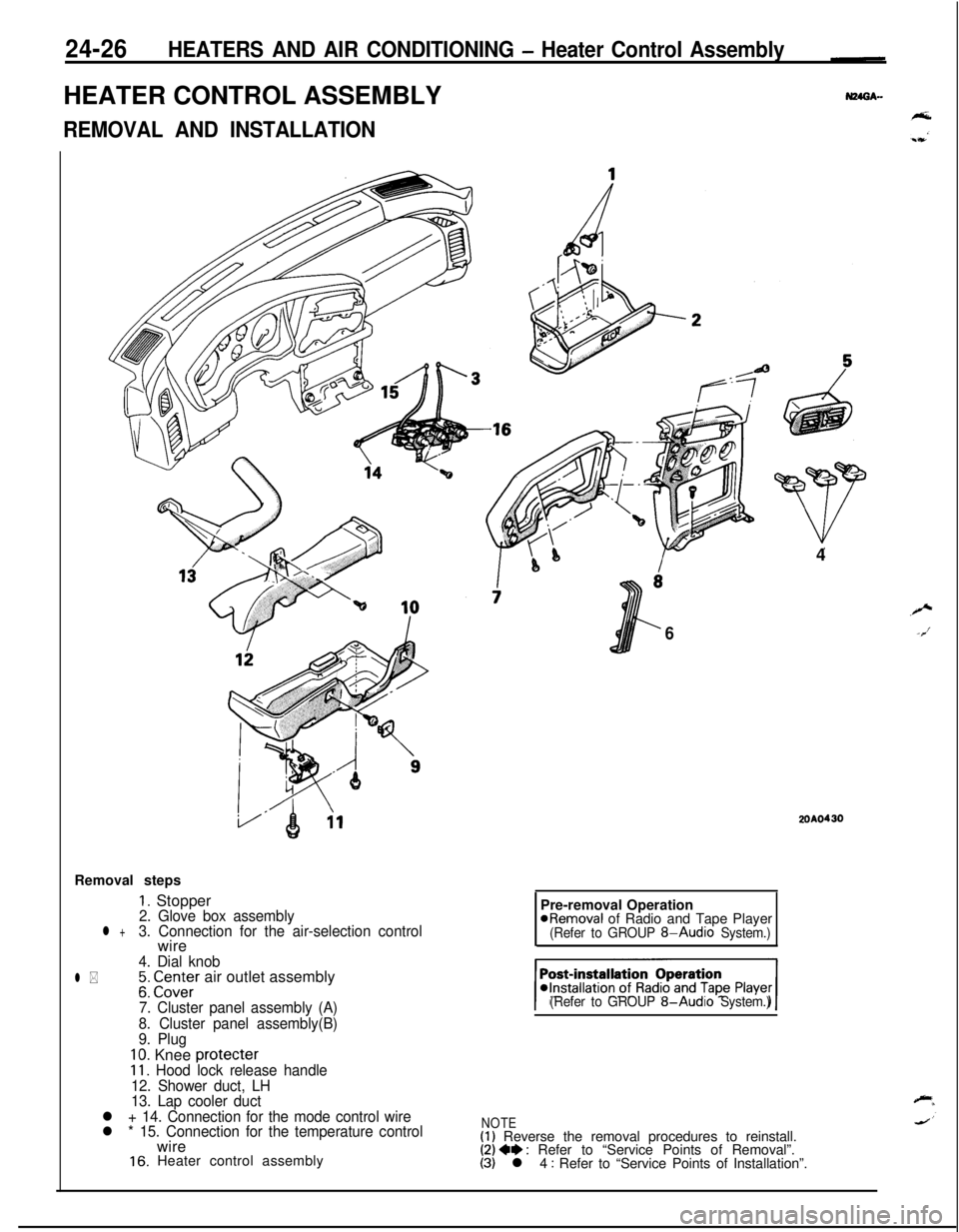

24-26HEATERS AND AIR CONDITIONING - Heater Control AssemblyHEATER CONTROL ASSEMBLY

REMOVAL AND INSTALLATIONRemoval steps

1. Stopper2. Glove box assemblyl +3. Connection for the air-selection controlwire

4. Dial knob

l *;: CI.Z;Er air outlet assembly

7. Cluster panel assembly (A)

8. Cluster panel assembly(B)

9. Plug

10. Knee protecter11. Hood lock release handle

12. Shower duct, LH

13. Lap cooler duct

l + 14. Connection for the mode control wire

l * 15. Connection for the temperature controlwire

16. Heater control assembly4

6

2OAO430Pre-removal Operation

@Removal of Radio and Tape Player(Refer to GROUP 8-Audio System.)

(Refer to GROUP

8-Audio System.)

NOTE(1) Reverse the removal procedures to reinstall.(2) 4e : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.

Page 1171 of 1216

HEATERS AND AIR CONDITIONING - Heater Control Assembly24-27

lQA0274

20A0408

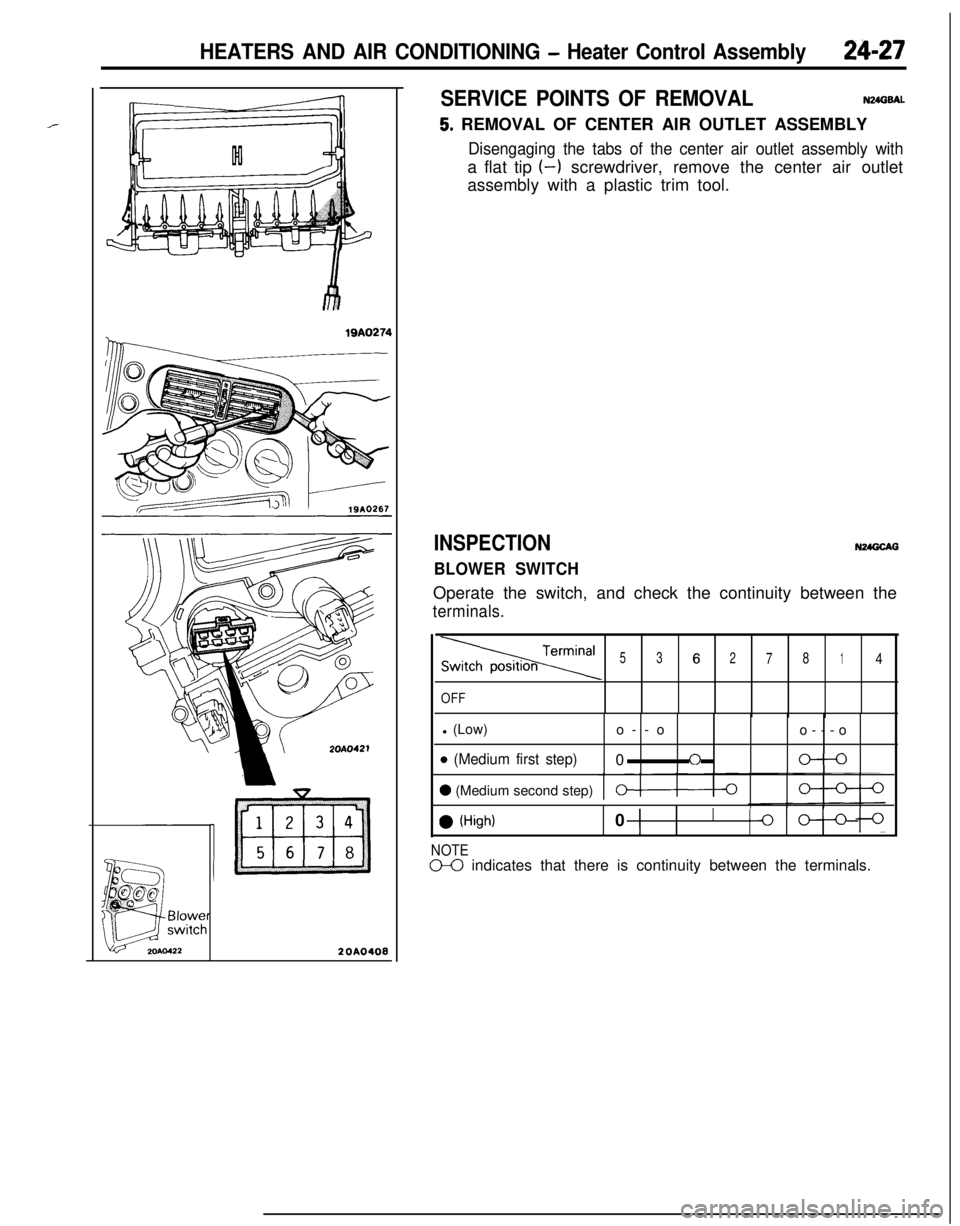

SERVICE POINTS OF REMOVALN24GBAL

5. REMOVAL OF CENTER AIR OUTLET ASSEMBLY

Disengaging the tabs of the center air outlet assembly witha flat tip (-1 screwdriver, remove the center air outlet

assembly with a plastic trim tool.

INSPECTION

BLOWER SWITCHN24GCAG

Operate the switch, and check the continuity between the

terminals.

Termina’53627814

OFFl (Low)

o--o

o---o

o (Medium first step)0f-le-0

0 (Medium second step)0-0

0 (High)0 1I

Ilo oln

NOTED0 indicates that there is continuity between the terminals.

Page 1172 of 1216

24-28HEATERS AND AIR CONDITIONING - Heater Control Assembly

II

IT20AO409

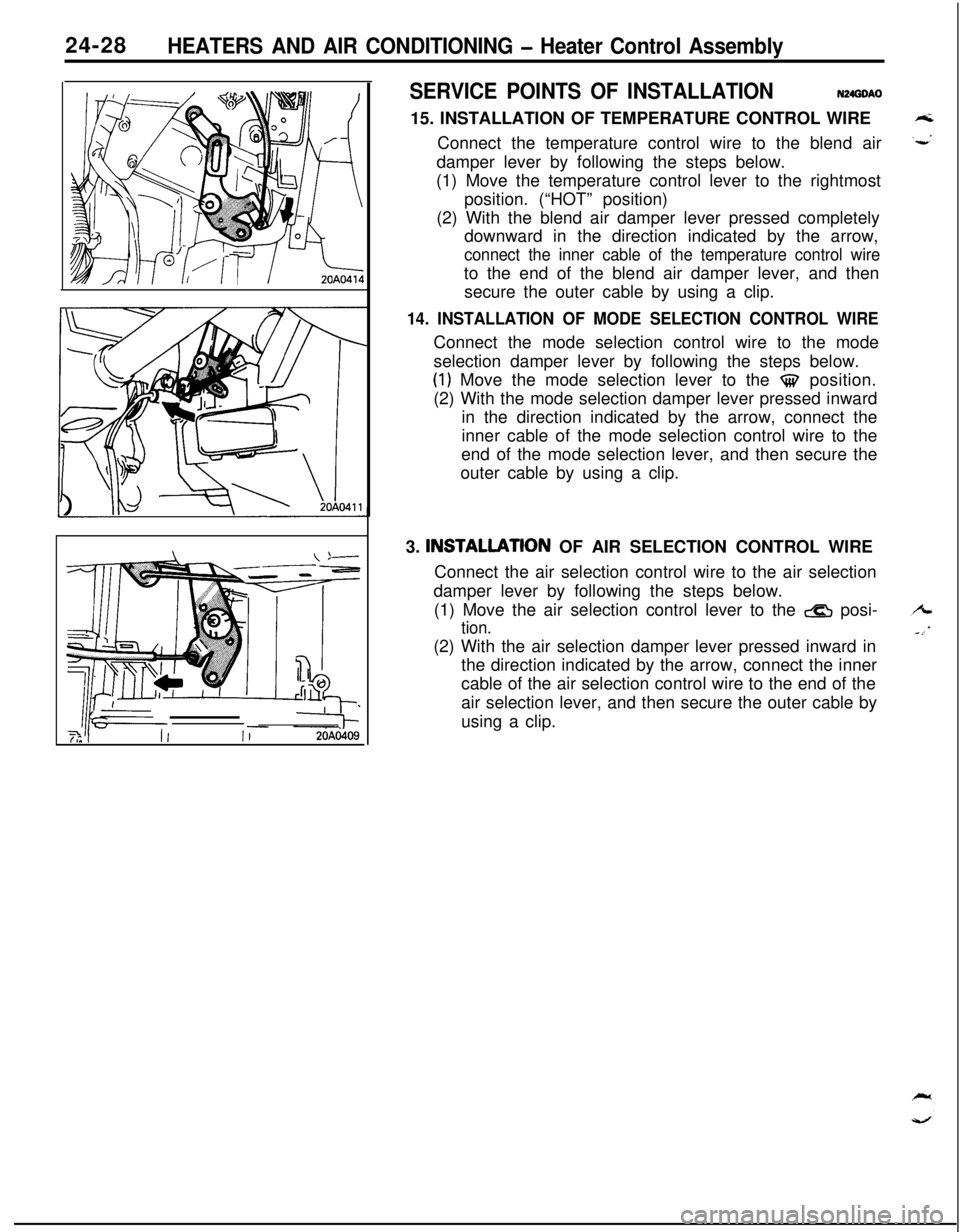

SERVICE POINTS OF INSTALLATIONN24GOAO

15. INSTALLATION OF TEMPERATURE CONTROL WIRE

Connect the temperature control wire to the blend air

damper lever by following the steps below.

(1) Move the temperature control lever to the rightmost

position. (“HOT” position)

(2) With the blend air damper lever pressed completely

downward in the direction indicated by the arrow,

connect the inner cable of the temperature control wireto the end of the blend air damper lever, and then

secure the outer cable by using a clip.

14. INSTALLATION OF MODE SELECTION CONTROL WIREConnect the mode selection control wire to the mode

selection damper lever by following the steps below.

(1) Move the mode selection lever to the $$ position.

(2) With the mode selection damper lever pressed inward

in the direction indicated by the arrow, connect the

inner cable of the mode selection control wire to the

end of the mode selection lever, and then secure the

outer cable by using a clip.

3. INSTALLATlON OF AIR SELECTION CONTROL WIRE

Connect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the

& posi-

tion.(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection lever, and then secure the outer cable by

using a clip.

Page 1173 of 1216

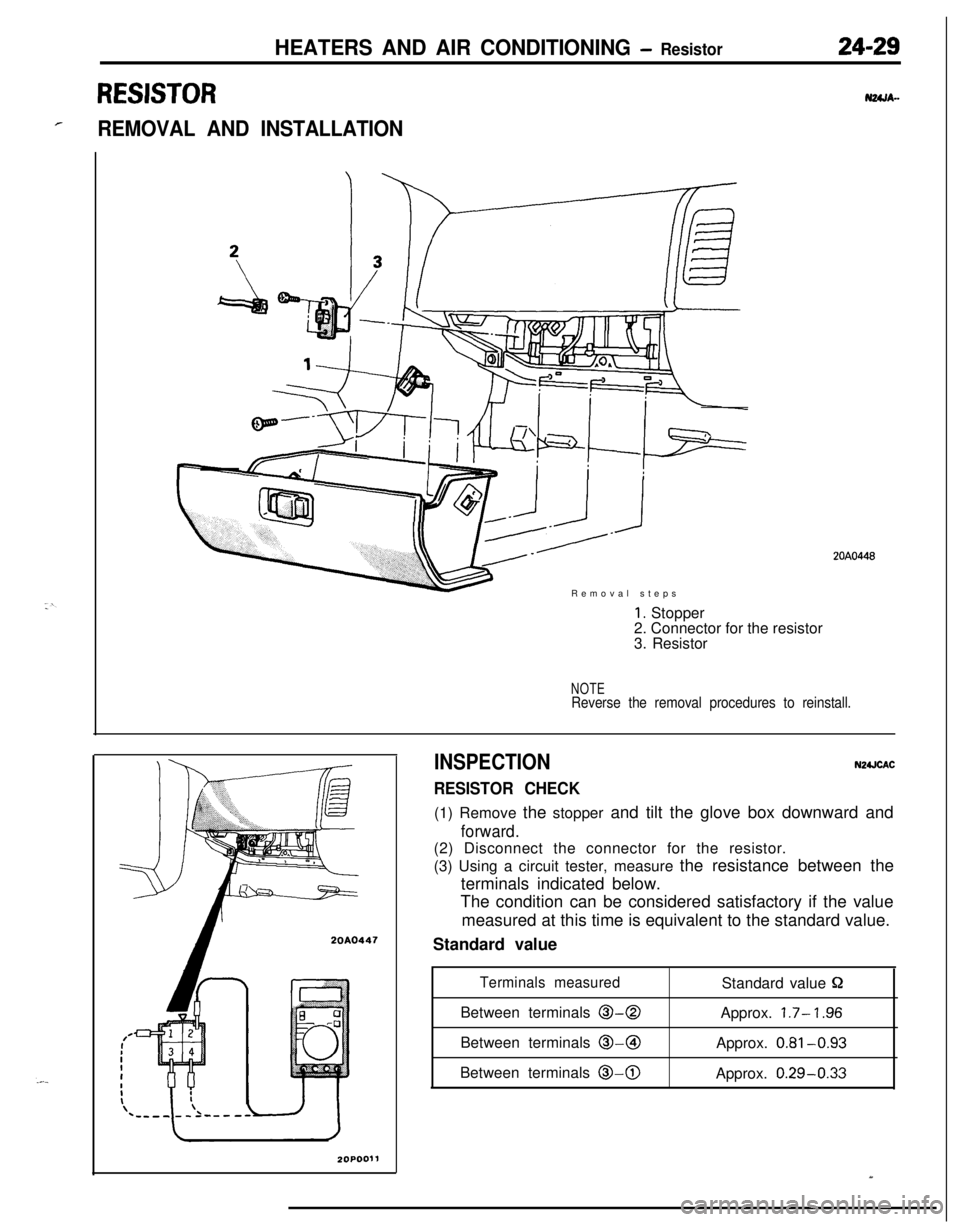

HEATERS AND AIR CONDITIONING - Resistor

RESISTOR

rREMOVAL AND INSTALLATIONRemoval steps

20A0447

1. Stopper

2. Connector for the resistor

3. Resistor

NOTEReverse the removal procedures to reinstall.

INSPECTION

RESISTOR CHECK

N2UCAC(1) Remove the stopper and tilt the glove box downward and

forward.(2) Disconnect the connector for the resistor.

(3) Using a circuit tester, measure the resistance between the

terminals indicated below.

The condition can be considered satisfactory if the value

measured at this time is equivalent to the standard value.

Standard value

Terminals measuredStandard value PBetween terminals

O-0Approx. 1.7- ‘I .96Between terminals @-@I

Approx.

0.81-0.93Between terminals

0-0Approx. 0.29-0.33

20A0448

Page 1174 of 1216

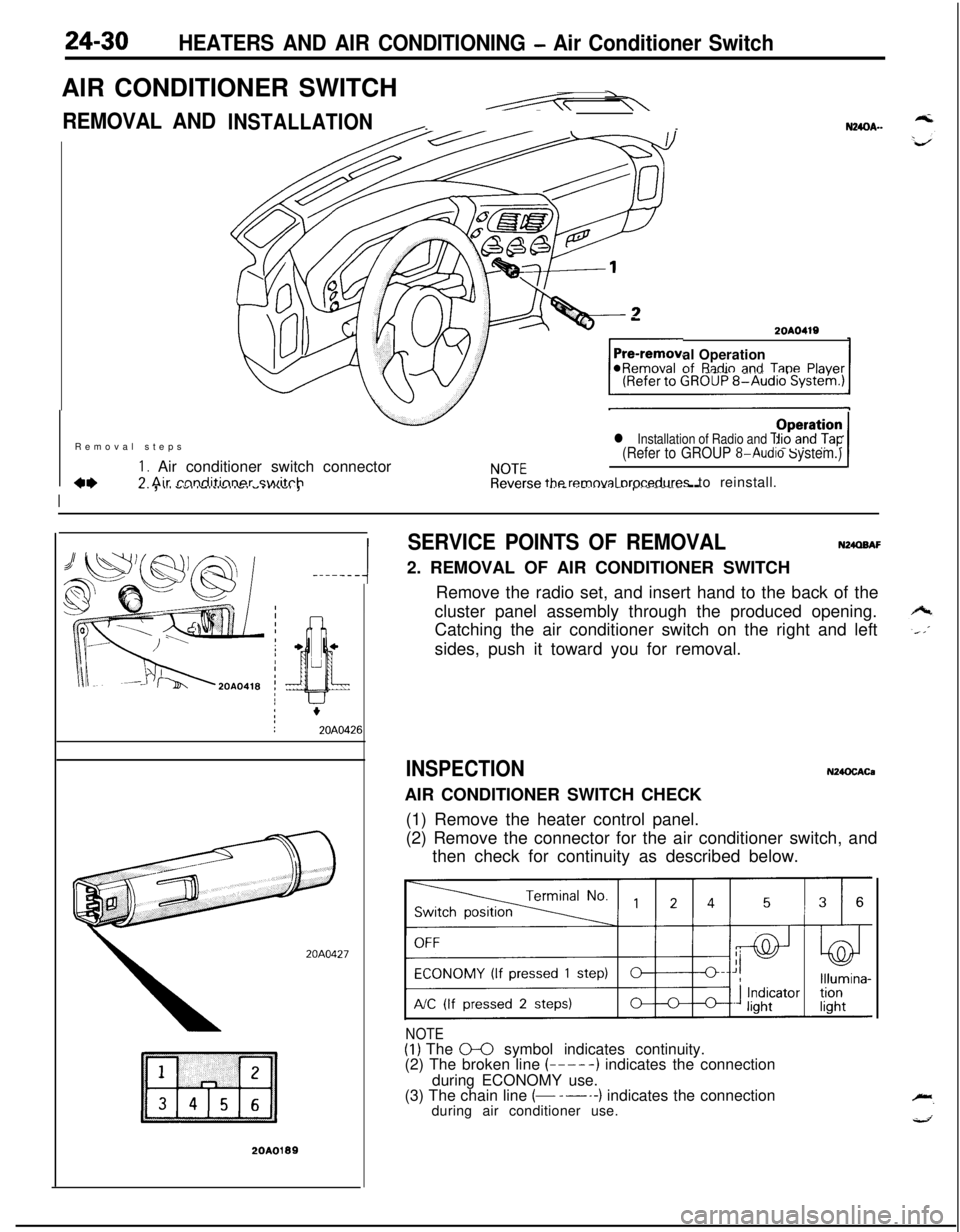

24-30HEATERS AND AIR CONDITIONING - Air Conditioner SwitchAIR CONDITIONER SWITCH

REMOVAL AND--N24OA..INSTALLATION

-2OAO419al Operationof

R;tdio and TanePlaver@Removal -..--._ _.-.-, -Removal steps

I. Air conditioner switch connectorCL7 Air rnnditinner switch

l Installation of Radio and Tape Player(Refer to GROUP 8-Audio System.)

NOTEOperation /Reverse

removal orocedures to reinstall.

I

77-. , .,a -.,a ,-,..-,.-. -.....,. ,.._._.__ _..- .-...-.-.r----- --

-----A

20A0427

20A0199

SERVICE POINTS OF REMOVALN24QBAF2. REMOVAL OF AIR CONDITIONER SWITCH

Remove the radio set, and insert hand to the back of the

cluster panel assembly through the produced opening.

Catching the air conditioner switch on the right and left

sides, push it toward you for removal.

INSPECTIONN24OCACaAIR CONDITIONER SWITCH CHECK

(1) Remove the heater control panel.

(2) Remove the connector for the air conditioner switch, and

then check for continuity as described below.

NOTE(1) The 0-0 symbol indicates continuity.

(2) The broken line (-----) indicates the connection

during ECONOMY use.

(3) The chain line

(- -----) indicates the connection

during air conditioner use.

Page 1175 of 1216

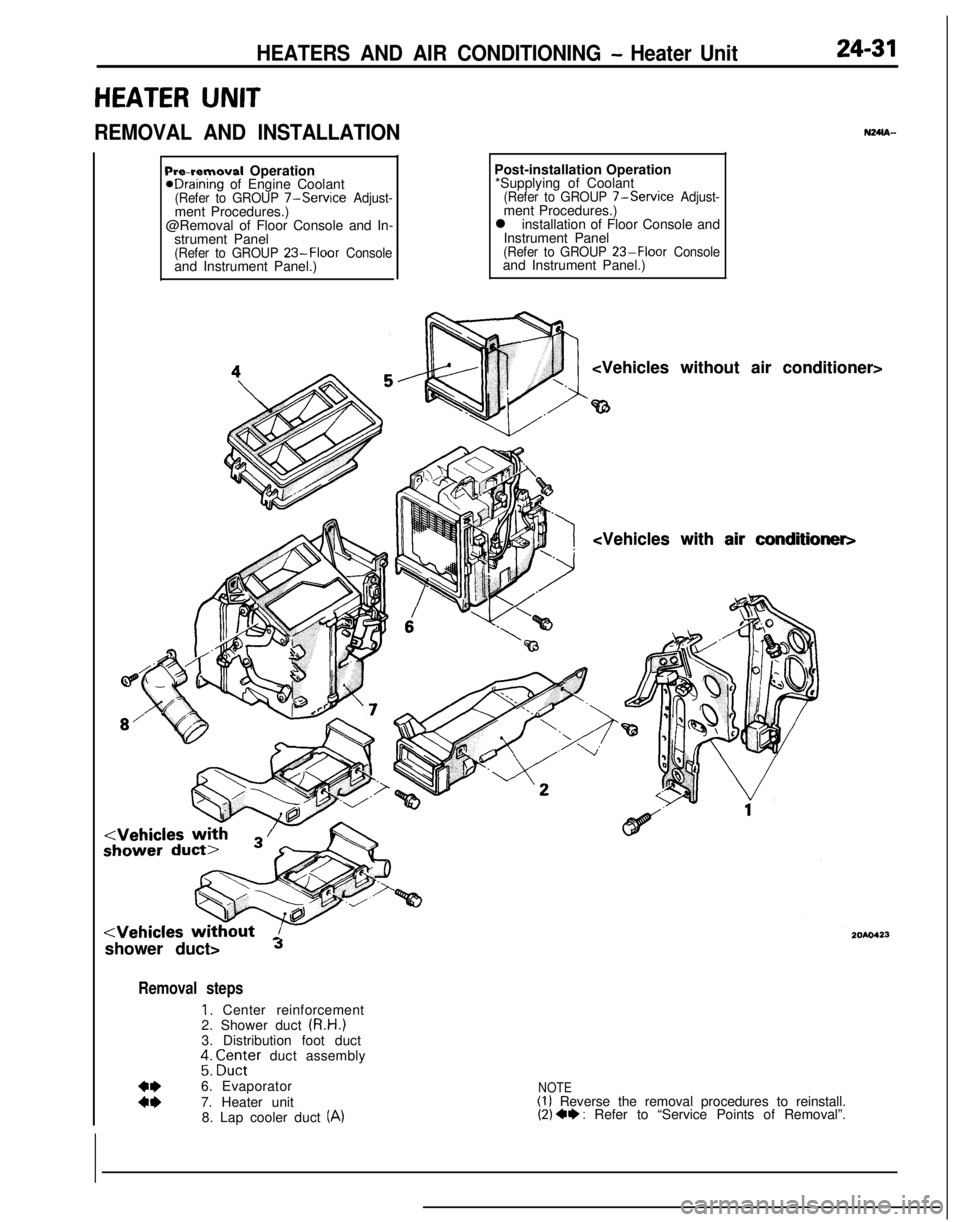

HEATERS AND AIR CONDITIONING - Heater Unit24-31

HEATER UNIT

REMOVAL AND INSTALLATIONN24m-

Pre-removal OperationeDraining of Engine Coolant(Refer to GROUP 7-Service Adjust-ment Procedures.)

@Removal of Floor Console and In-

strument Panel

(Refer to GROUP 23-Floor Consoleand Instrument Panel.)Post-installation Operation

*Supplying of Coolant

(Refer to GROUP 7-Service Adjust-ment Procedures.)

l installation of Floor Console and

Instrument Panel

(Refer to GROUP 23-Floor Consoleand Instrument Panel.)

shower duct>

Jshower duct>

Removal steps

1. Center reinforcement

2. Shower duct (R.H.)

3. Distribution foot duct

;: ;Z;;er duct assembly

:z6. Evaporator

7. Heater unit

8. Lap cooler duct (A)

NOTE(1) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.