air condition MITSUBISHI ECLIPSE 1991 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1156 of 1216

24-12 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

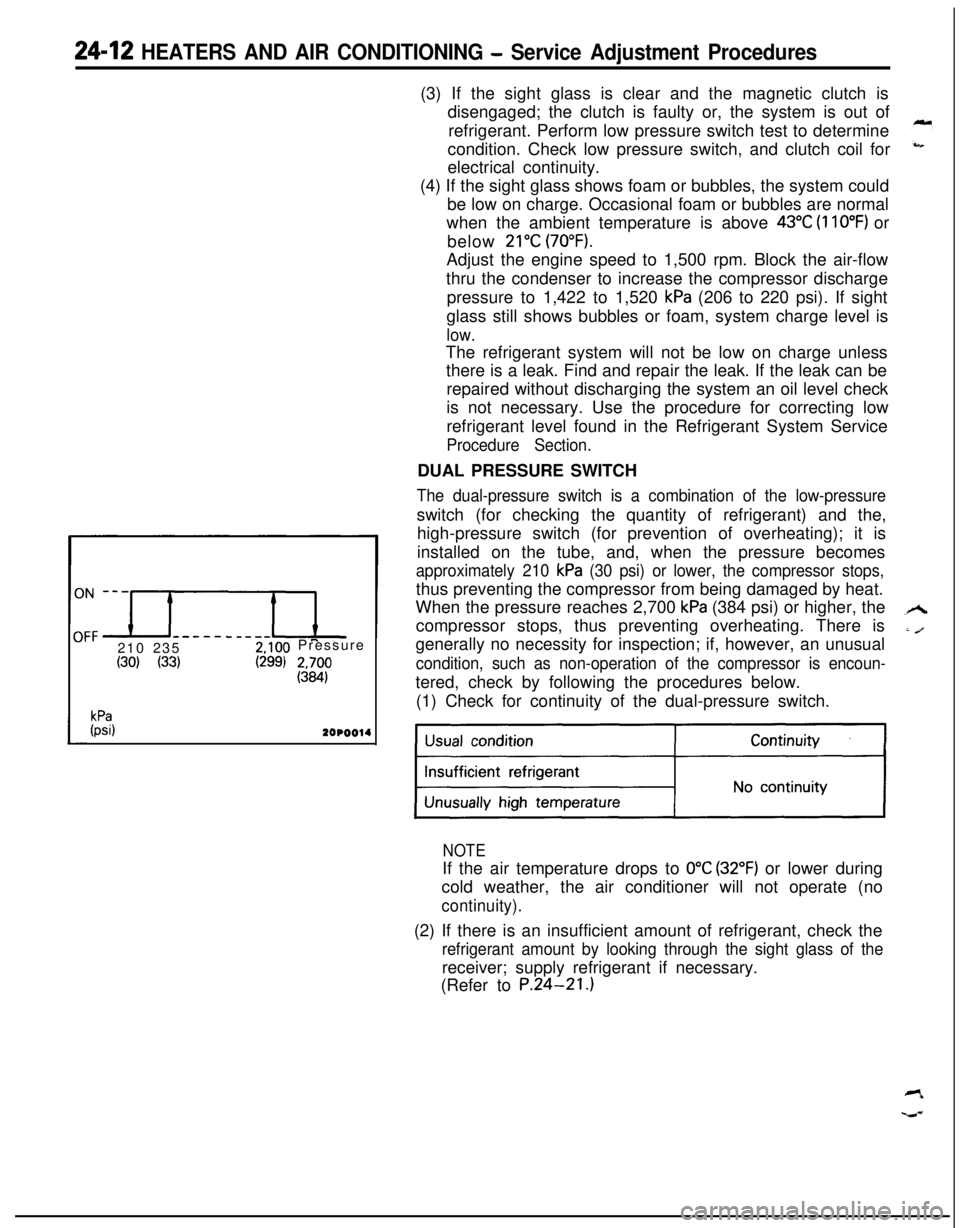

------__--210 2352,100 Pressure

(30) (33)(299) 2&

kPa(psi)2OPOO14(3) If the sight glass is clear and the magnetic clutch is

disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine

condition. Check low pressure switch, and clutch coil for

electrical continuity.

(4) If the sight glass shows foam or bubbles, the system could

be low on charge. Occasional foam or bubbles are normal

when the ambient temperature is above

43°C (110°F) or

below

21°C (70°F).Adjust the engine speed to 1,500 rpm. Block the air-flow

thru the condenser to increase the compressor discharge

pressure to 1,422 to 1,520

kPa (206 to 220 psi). If sight

glass still shows bubbles or foam, system charge level is

low.The refrigerant system will not be low on charge unless

there is a leak. Find and repair the leak. If the leak can be

repaired without discharging the system an oil level check

is not necessary. Use the procedure for correcting low

refrigerant level found in the Refrigerant System Service

Procedure Section.DUAL PRESSURE SWITCH

The dual-pressure switch is a combination of the low-pressureswitch (for checking the quantity of refrigerant) and the,

high-pressure switch (for prevention of overheating); it is

installed on the tube, and, when the pressure becomes

approximately 210 kPa (30 psi) or lower, the compressor stops,thus preventing the compressor from being damaged by heat.

When the pressure reaches 2,700

kPa (384 psi) or higher, the

compressor stops, thus preventing overheating. There is

generally no necessity for inspection; if, however, an unusual

condition, such as non-operation of the compressor is encoun-tered, check by following the procedures below.

(1) Check for continuity of the dual-pressure switch.

NOTEIf the air temperature drops to

0°C (32°F) or lower during

cold weather, the air conditioner will not operate (no

continuity).(2) If there is an insufficient amount of refrigerant, check the

refrigerant amount by looking through the sight glass of thereceiver; supply refrigerant if necessary.

(Refer to P.24-21.)

Page 1157 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 249*I3

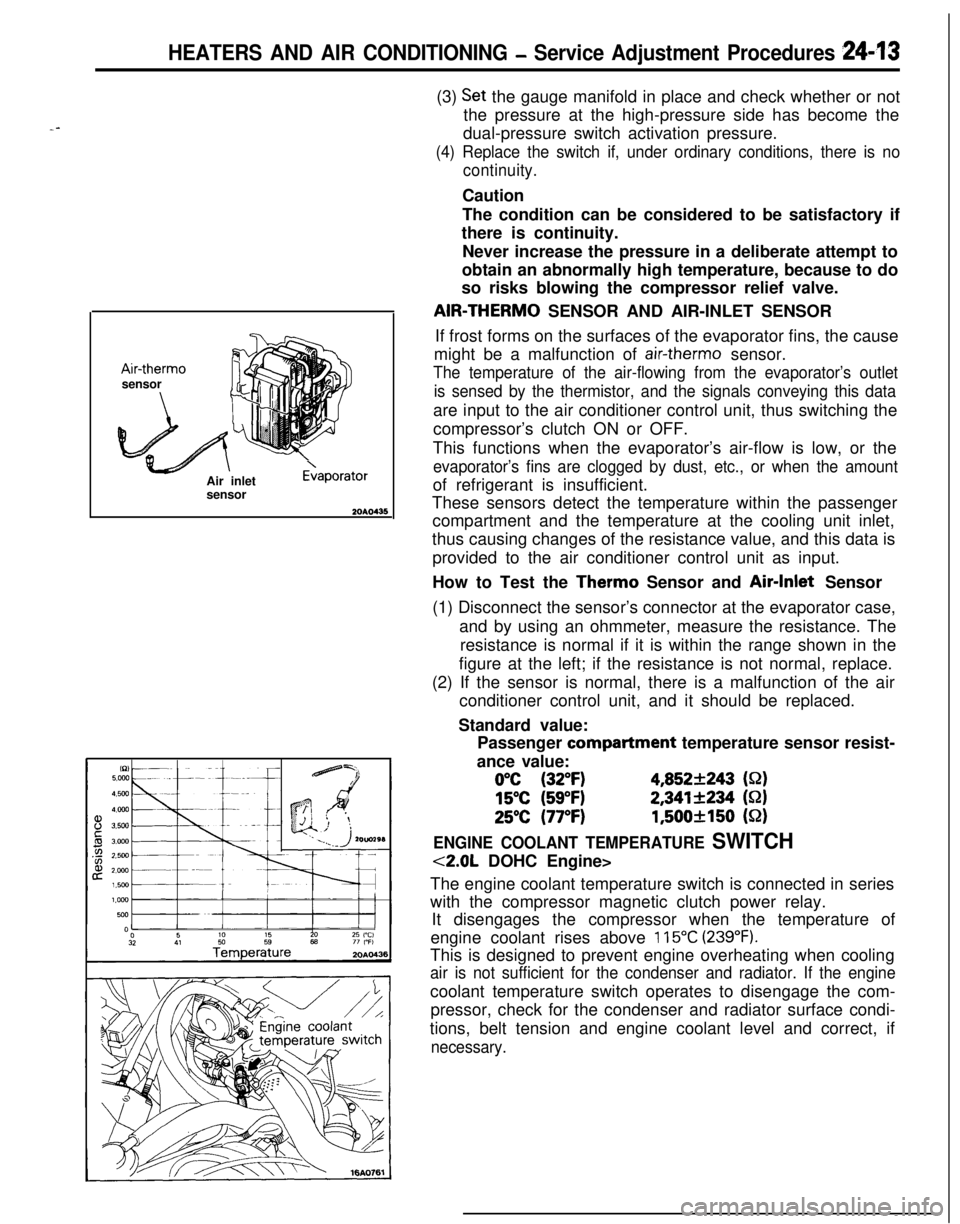

--Air-therm0

sensor

Air inlet

sensor

E>aporator(3)

Set the gauge manifold in place and check whether or not

the pressure at the high-pressure side has become the

dual-pressure switch activation pressure.

(4) Replace the switch if, under ordinary conditions, there is no

continuity.Caution

The condition can be considered to be satisfactory if

there is continuity.

Never increase the pressure in a deliberate attempt to

obtain an abnormally high temperature, because to do

so risks blowing the compressor relief valve.AIR-THERM0 SENSOR AND AIR-INLET SENSOR

If frost forms on the surfaces of the evaporator fins, the cause

might be a malfunction of

air-therm0 sensor.

The temperature of the air-flowing from the evaporator’s outlet

is sensed by the thermistor, and the signals conveying this dataare input to the air conditioner control unit, thus switching the

compressor’s clutch ON or OFF.

This functions when the evaporator’s air-flow is low, or the

evaporator’s fins are clogged by dust, etc., or when the amountof refrigerant is insufficient.

These sensors detect the temperature within the passenger

compartment and the temperature at the cooling unit inlet,

thus causing changes of the resistance value, and this data is

provided to the air conditioner control unit as input.

How to Test the Therm0 Sensor and Air-Inlet Sensor

(1) Disconnect the sensor’s connector at the evaporator case,

and by using an ohmmeter, measure the resistance. The

resistance is normal if it is within the range shown in the

figure at the left; if the resistance is not normal, replace.

(2) If the sensor is normal, there is a malfunction of the air

conditioner control unit, and it should be replaced.

Standard value:

Passenger compartment temperature sensor resist-

ance value:

0°C (32°F)4,852+243 (S-2)

15°C (59°F)2,341+234 (S-2)

25°C (77°F)1,500+150 (52)

ENGINE COOLANT TEMPERATURE SWITCH

<2.0L DOHC Engine>

The engine coolant temperature switch is connected in series

with the compressor magnetic clutch power relay.

It disengages the compressor when the temperature of

engine coolant rises above

115°C (239°F).This is designed to prevent engine overheating when cooling

air is not sufficient for the condenser and radiator. If the enginecoolant temperature switch operates to disengage the com-

pressor, check for the condenser and radiator surface condi-

tions, belt tension and engine coolant level and correct, if

necessary.

Page 1158 of 1216

24-14 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

-Discharge

w-w

SuctiongaugeDischalgauge

2OUO306

SuctiongaugeDischargegauge

2OUO307--

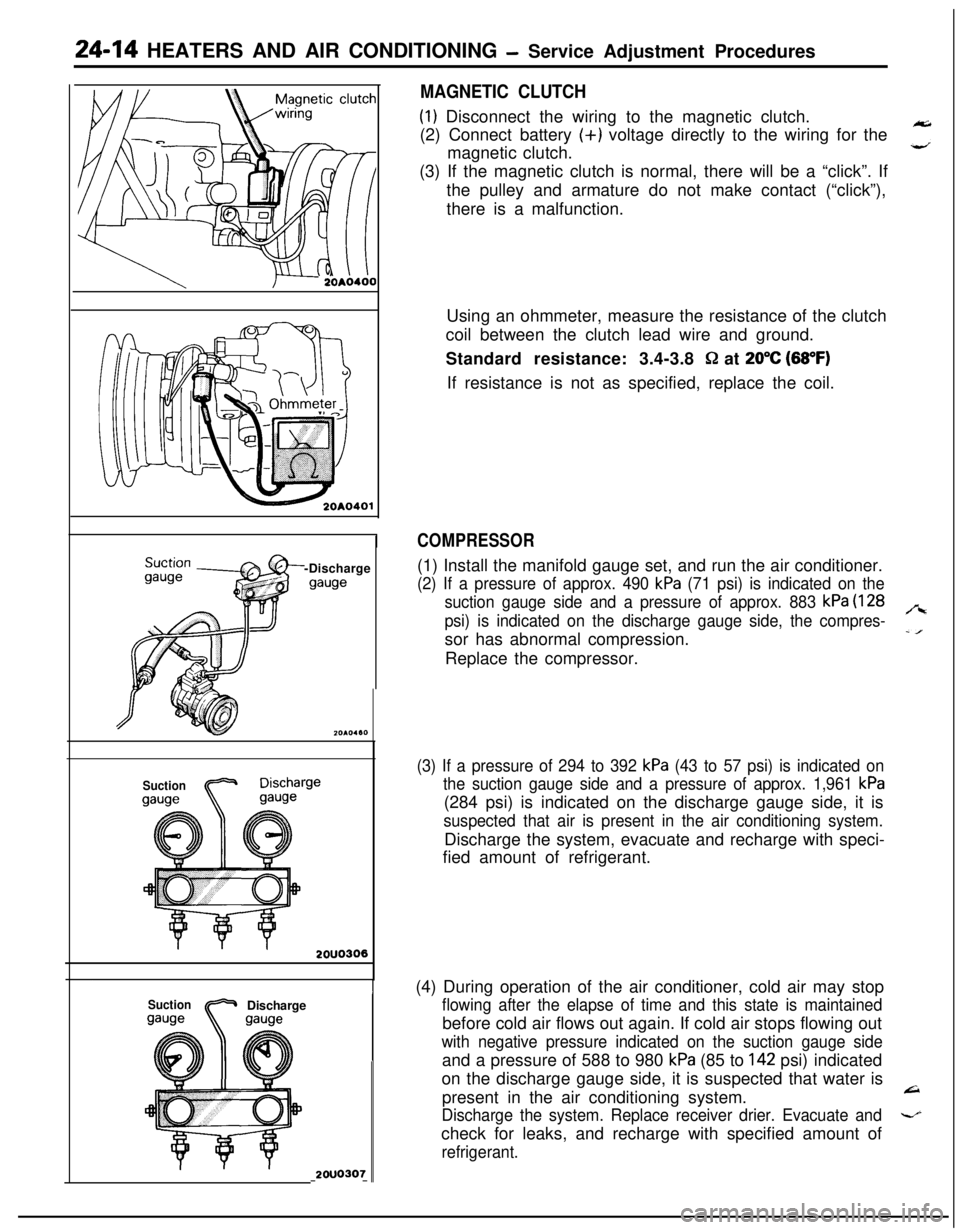

MAGNETIC CLUTCH(I) Disconnect the wiring to the magnetic clutch.

(2) Connect battery (+) voltage directly to the wiring for the

magnetic clutch.

,”(3) If the magnetic clutch is normal, there will be a “click”. If

the pulley and armature do not make contact (“click”),

there is a malfunction.

Using an ohmmeter, measure the resistance of the clutch

coil between the clutch lead wire and ground.

Standard resistance: 3.4-3.8

Q at 20°C (88°F)If resistance is not as specified, replace the coil.

COMPRESSOR(1) Install the manifold gauge set, and run the air conditioner.

(2) If a pressure of approx. 490 kPa (71 psi) is indicated on the

suction gauge side and a pressure of approx. 883

kPa (128

psi) is indicated on the discharge gauge side, the compres-

,“ssor has abnormal compression.

-IReplace the compressor.

(3) If a pressure of 294 to 392 kPa (43 to 57 psi) is indicated on

the suction gauge side and a pressure of approx. 1,961

kPa(284 psi) is indicated on the discharge gauge side, it is

suspected that air is present in the air conditioning system.Discharge the system, evacuate and recharge with speci-

fied amount of refrigerant.

(4) During operation of the air conditioner, cold air may stop

flowing after the elapse of time and this state is maintainedbefore cold air flows out again. If cold air stops flowing out

with negative pressure indicated on the suction gauge sideand a pressure of 588 to 980

kPa (85 to 142 psi) indicated

on the discharge gauge side, it is suspected that water is

present in the air conditioning system.

L=I

Discharge the system. Replace receiver drier. Evacuate and-check for leaks, and recharge with specified amount of

refrigerant.

Page 1159 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-15

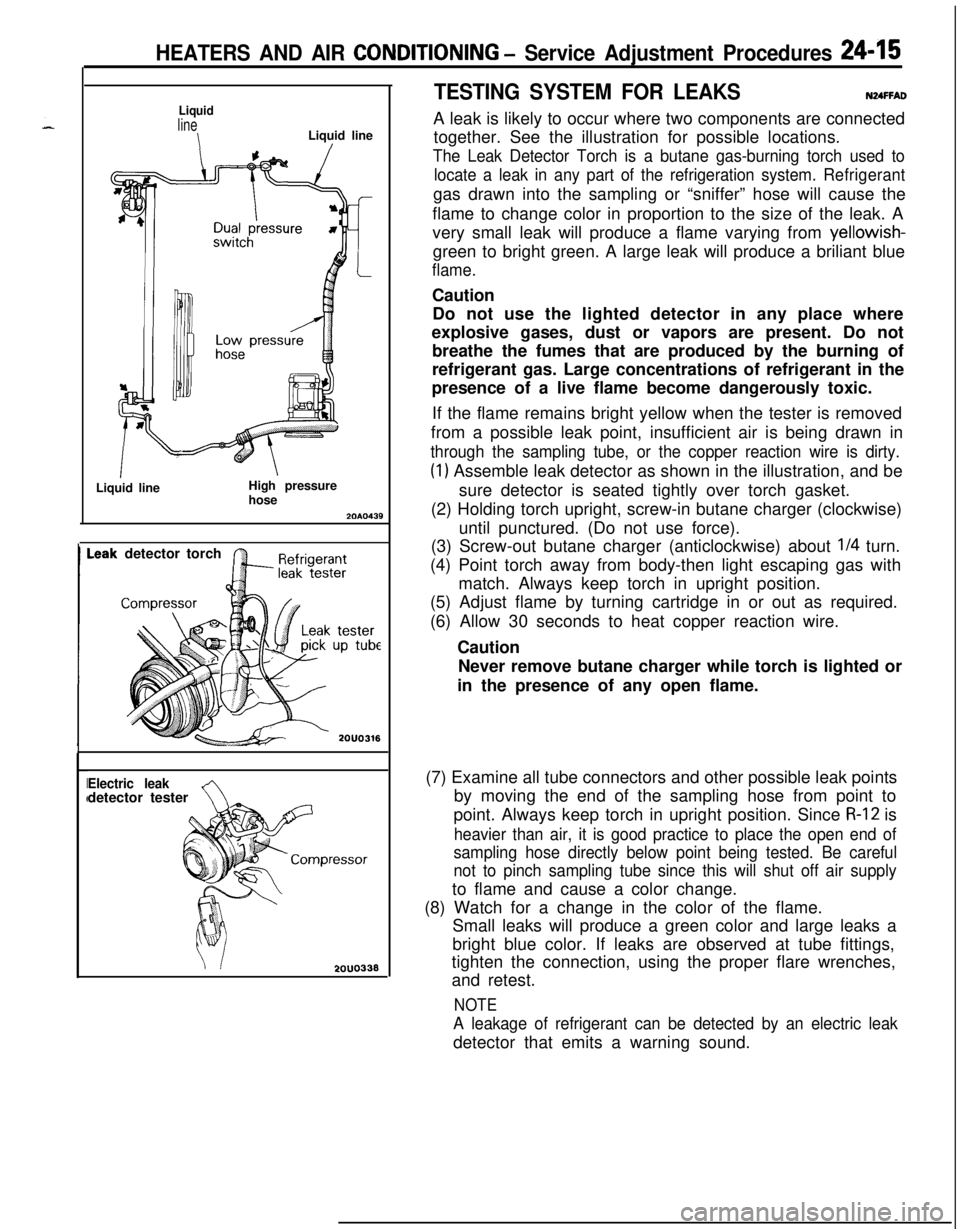

Liquid

line

\Liquid lineI

ILiquid lineHigh pressure

hose2010439

detector torch

Electric leakAdetector tester

2OUO338

TESTING SYSTEM FOR LEAKSNUFFADA leak is likely to occur where two components are connected

together. See the illustration for possible locations.

The Leak Detector Torch is a butane gas-burning torch used to

locate a leak in any part of the refrigeration system.Refrigerantgas drawn into the sampling or “sniffer” hose will cause the

flame to change color in proportion to the size of the leak. A

very small leak will produce a flame varying from yellowish-

green to bright green. A large leak will produce a briliant blue

flame.Caution

Do not use the lighted detector in any place where

explosive gases, dust or vapors are present. Do not

breathe the fumes that are produced by the burning of

refrigerant gas. Large concentrations of refrigerant in the

presence of a live flame become dangerously toxic.

If the flame remains bright yellow when the tester is removed

from a possible leak point, insufficient air is being drawn in

through the sampling tube, or the copper reaction wire is dirty.

(1) Assemble leak detector as shown in the illustration, and be

sure detector is seated tightly over torch gasket.

(2) Holding torch upright, screw-in butane charger (clockwise)

until punctured. (Do not use force).

(3) Screw-out butane charger (anticlockwise) about

l/4 turn.

(4) Point torch away from body-then light escaping gas with

match. Always keep torch in upright position.

(5) Adjust flame by turning cartridge in or out as required.

(6) Allow 30 seconds to heat copper reaction wire.

Caution

Never remove butane charger while torch is lighted or

in the presence of any open flame.

(7) Examine all tube connectors and other possible leak points

by moving the end of the sampling hose from point to

point. Always keep torch in upright position. Since

R-12 is

heavier than air, it is good practice to place the open end of

sampling hose directly below point being tested. Be careful

not to pinch sampling tube since this will shut off air supplyto flame and cause a color change.

(8) Watch for a change in the color of the flame.

Small leaks will produce a green color and large leaks a

bright blue color. If leaks are observed at tube fittings,

tighten the connection, using the proper flare wrenches,

and retest.

NOTE

A leakage of refrigerant can be detected by an electric leakdetector that emits a warning sound.

Page 1160 of 1216

24-16 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

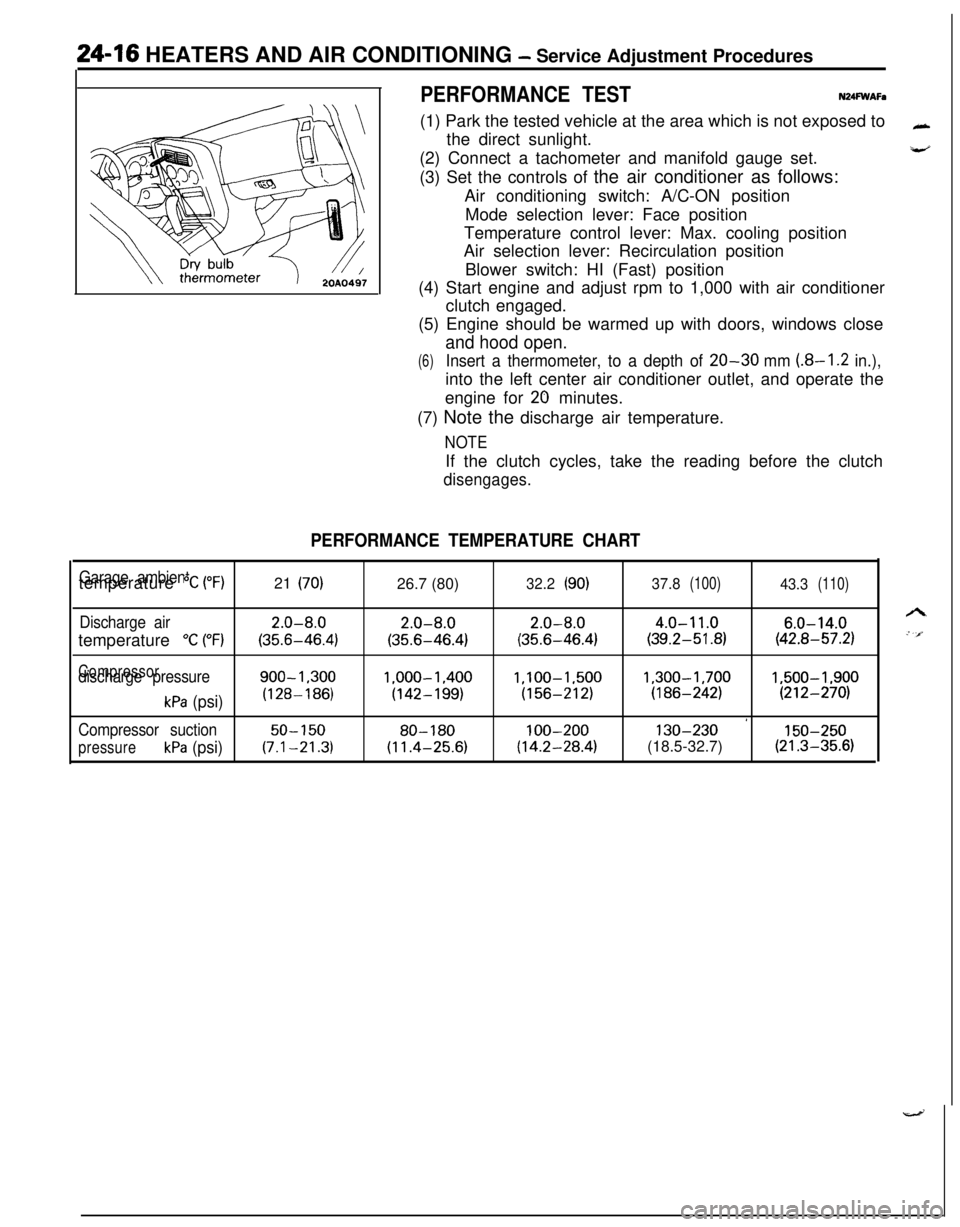

PERFORMANCE TESTN24FWAFa(1) Park the tested vehicle at the area which is not exposed to

the direct sunlight.

(2) Connect a tachometer and manifold gauge set.

(3) Set the controls of the air conditioner as follows:

Air conditioning switch: A/C-ON position

Mode selection lever: Face position

Temperature control lever: Max. cooling position

Air selection lever: Recirculation position

Blower switch: HI (Fast) position

(4) Start engine and adjust rpm to 1,000 with air conditioner

clutch engaged.

(5) Engine should be warmed up with doors, windows close

and hood open.

(6)Insert a thermometer, to a depth of 20-30 mm (8-I .2 in.),into the left center air conditioner outlet, and operate the

engine for

20 minutes.

(7) Note the discharge air temperature.

NOTEIf the clutch cycles, take the reading before the clutch

disengages.

PERFORMANCE TEMPERATURE CHART

Garage ambienttemperature “C (“F)21 (70)26.7 (80)32.2(90)37.8(100)43.3(110)

Discharge air2.0-8.02.0-8.02.0-8.04.0-11.06.0-14.0temperature

“C (“F)(35.6-46.4)(35.6-46.4)(35.6-46.4)(39.2-51.8)(42.8-57.2)

Compressordischarge pressure900-1.3001.000-1.400l,lOO-1,5001,300-1,7001,500-1,900

kPa (psi)(128-186)(142-199)(156-212)(186-242)(212-270)

’Compressor suction50-15080-180100-200130-230150-250

pressurekPa (psi)(7.1-21.3)(11.4-25.6)(14.2-28.4)(18.5-32.7)(21.3-35.6)

Page 1161 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-Q

ilectric leakletector tester

2OUO333

40°C(I 04°F)20A0463

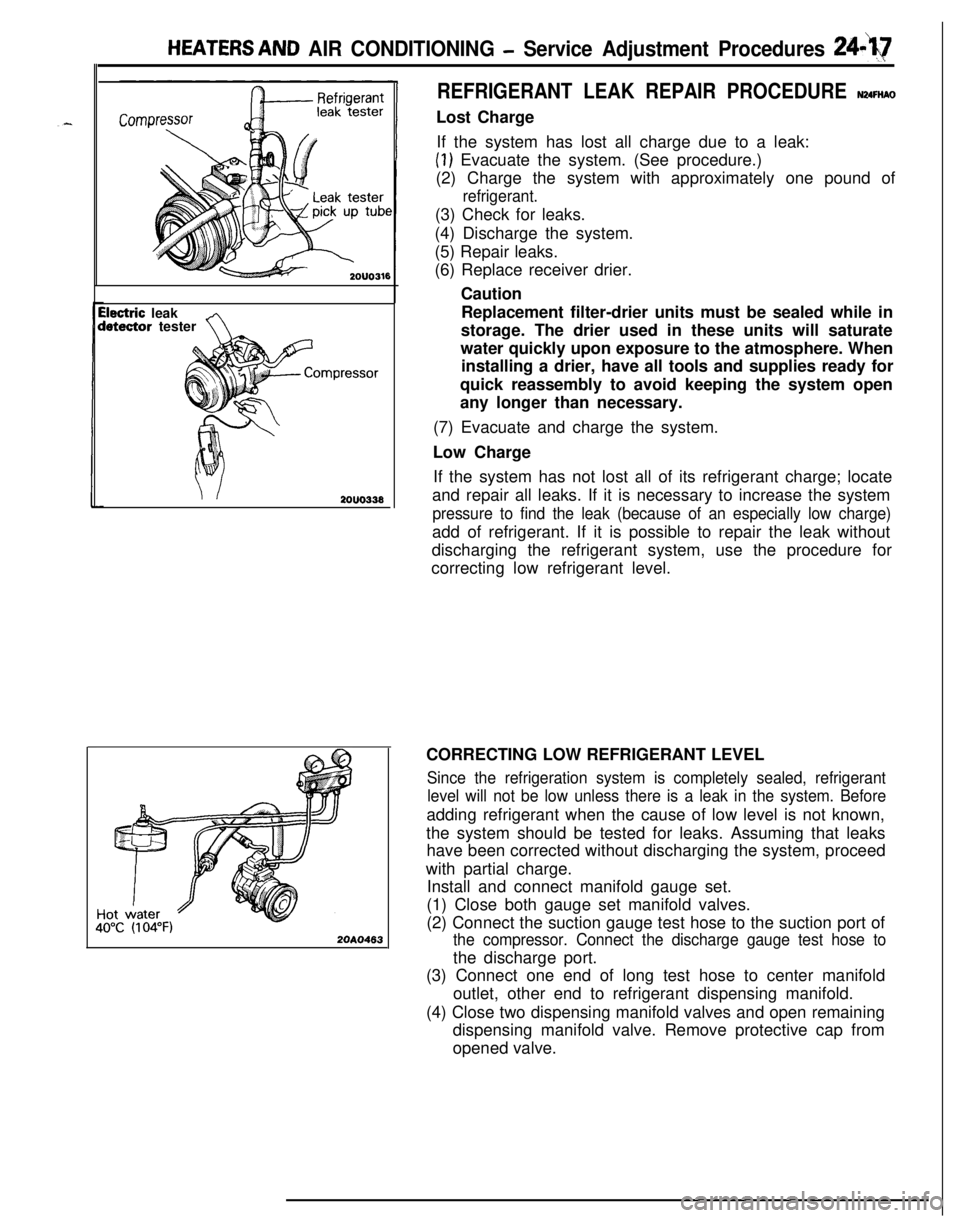

REFRIGERANT LEAK REPAIR PROCEDURE N24FtiAOLost Charge

If the system has lost all charge due to a leak:

(1) Evacuate the system. (See procedure.)

(2) Charge the system with approximately one pound of

refrigerant.(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Replacement filter-drier units must be sealed while in

storage. The drier used in these units will saturate

water quickly upon exposure to the atmosphere. When

installing a drier, have all tools and supplies ready for

quick reassembly to avoid keeping the system open

any longer than necessary.

(7) Evacuate and charge the system.

Low Charge

If the system has not lost all of its refrigerant charge; locate

and repair all leaks. If it is necessary to increase the system

pressure to find the leak (because of an especially low charge)add of refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the procedure for

correcting low refrigerant level.

CORRECTING LOW REFRIGERANT LEVEL

Since the refrigeration system is completely sealed, refrigerant

level will not be low unless there is a leak in the system. Beforeadding refrigerant when the cause of low level is not known,

the system should be tested for leaks. Assuming that leaks

have been corrected without discharging the system, proceed

with partial charge.

Install and connect manifold gauge set.

(1) Close both gauge set manifold valves.

(2) Connect the suction gauge test hose to the suction port of

the compressor. Connect the discharge gauge test hose tothe discharge port.

(3) Connect one end of long test hose to center manifold

outlet, other end to refrigerant dispensing manifold.

(4) Close two dispensing manifold valves and open remaining

dispensing manifold valve. Remove protective cap from

opened valve.

Page 1162 of 1216

24-18 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

(5) Screw a can of R-12 to the opened manifold valve. Be sure

gasket is in place and in good condition. Tighten refrigerantcan and manifold locking nut to insure a good seal. Do not

overtighten 8 to

11 Nm (6 to 8 ft.lbs.) is sufficient if gasket

is in good condition.

(6) Turn manifold valve (above the refrigerant can) completely

clockwise to puncture the can. This closes the valve and

seals the refrigerant in the can.

Caution

Never heat small cans of refrigerant over

40°C (104°F)as they may explode.

(7) Place the refrigerant in a large pan of water heated to 52°C

(104°F). Place pan of water containing the refrigerant can

on an accurate scale so the amount of refrigerant added

can be weighed. Open the refrigerant manifold valve.

(8) Purge all air from test hoses. Air in the system will be

trapped in the condenser causing abnormally high dis-

charge pressures and interfering with condensing of the

refrigerant.(9) Slightly loosen both test hoses at the gauge set manifold.

Tighten the hoses as soon as the air is purged.

(10)Slightly loosen charging hose connection at gauge set

manifold. This will purge air from the charging hose.

Tighten connection as soon as air is purged.

(I l)With vehicle windows open and hood up, operate engine at1,500 rpm and jump the low pressure switch terminals

located on the receiver drier so the clutch will remain

engaged.

(12)Place air conditioner control on air conditioner and place theblower switch on high.

(13)lf necessary, block the condenser to maintain a discharge

pressure of 1,422 to 1,520

kPa (206 to 220 psi). System

must be charged through the evaporator suction service

ports as follows:

(a) Slowly open the suction service gauge valve.

Meter flow of refrigerant by adjusting, the suciton

service gauge valve so that pressure registered at the

suction service gauge does not exceed 345 kPa (50 psi).Keep refrigerant container upright.

(b) Add refrigerant gas until there is no foam visible at the

sight glass.

Add an additional

170 g (6 oz.)

(c) Close the suction gauge valve.

CautionToo much refrigerant in the system can cause

abnormally high discharge pressures. Care must beused so that the exact recommended amount or

refrigerant is added after foam clears in the sight

glass.(d) Close dispensing manifold valve. Remove test hoses

and adapters from the service ports of compressor,

install protective caps at service ports and reconnect

wiring.(e) Check system performance.

(P.24- 16.)

e

. i”

A

i-4

Page 1163 of 1216

-.

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 241$19Oil collector can

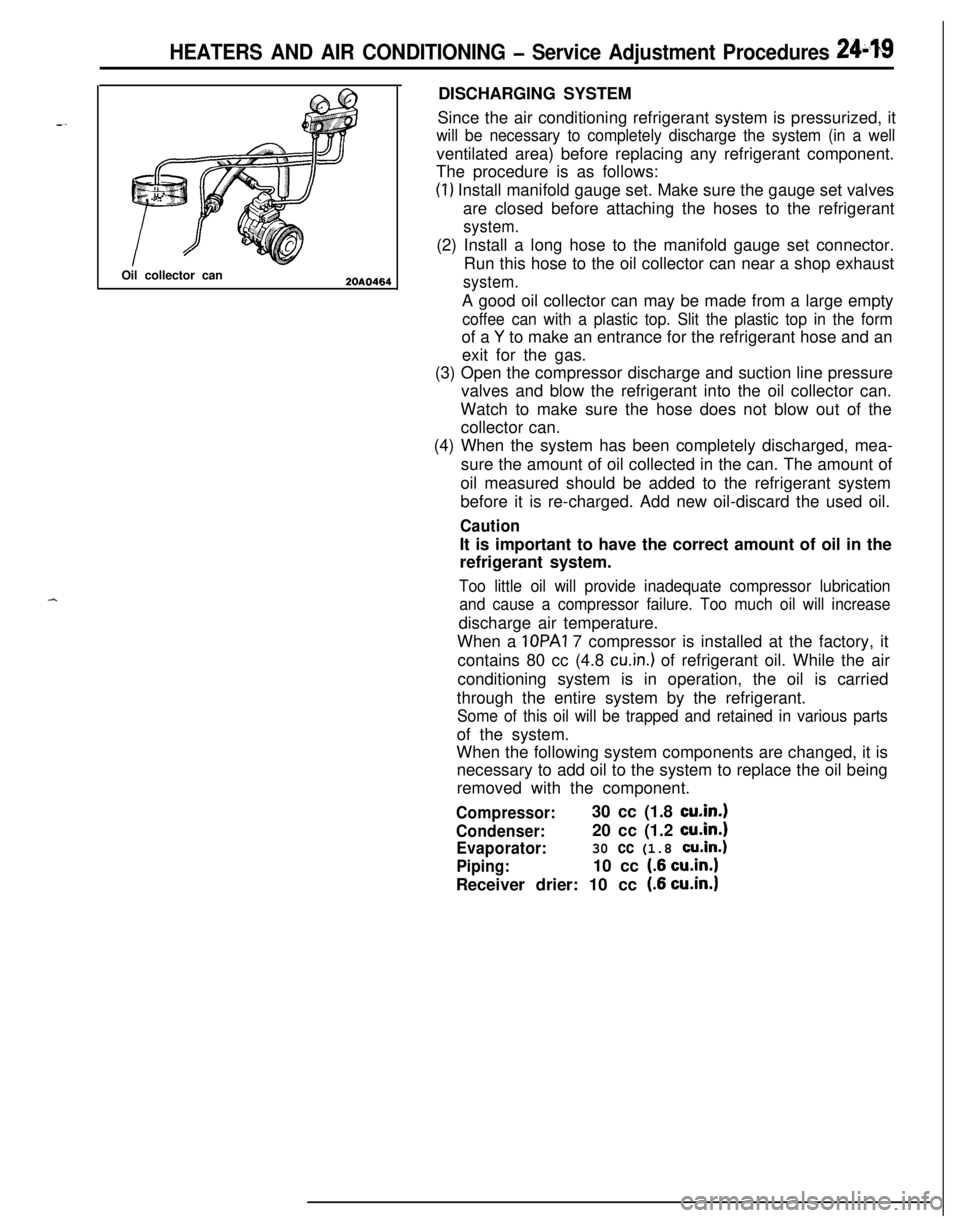

2OAO464DISCHARGING SYSTEM

Since the air conditioning refrigerant system is pressurized, it

will be necessary to completely discharge the system (in a wellventilated area) before replacing any refrigerant component.

The procedure is as follows:

(1) Install manifold gauge set. Make sure the gauge set valves

are closed before attaching the hoses to the refrigerant

system.(2) Install a long hose to the manifold gauge set connector.

Run this hose to the oil collector can near a shop exhaust

system.A good oil collector can may be made from a large empty

coffee can with a plastic top. Slit the plastic top in the formof a

Y to make an entrance for the refrigerant hose and an

exit for the gas.

(3) Open the compressor discharge and suction line pressure

valves and blow the refrigerant into the oil collector can.

Watch to make sure the hose does not blow out of the

collector can.

(4) When the system has been completely discharged, mea-

sure the amount of oil collected in the can. The amount of

oil measured should be added to the refrigerant system

before it is re-charged. Add new oil-discard the used oil.

CautionIt is important to have the correct amount of oil in the

refrigerant system.

Too little oil will provide inadequate compressor lubrication

and cause a compressor failure. Too much oil will increasedischarge air temperature.

When a IOPAI 7 compressor is installed at the factory, it

contains 80 cc (4.8

cu.in.) of refrigerant oil. While the air

conditioning system is in operation, the oil is carried

through the entire system by the refrigerant.

Some of this oil will be trapped and retained in various partsof the system.

When the following system components are changed, it is

necessary to add oil to the system to replace the oil being

removed with the component.

Compressor:30 cc (1.8 cu.in.1

Condenser:20 cc (1.2 cu.in.1

Evaporator:30 cc (1.8 cu.in.)

Piping:10 cc (.6 cu.in.1Receiver drier: 10 cc

(.6 cu.in.1

Page 1164 of 1216

24-20 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

20A0465

20A0466

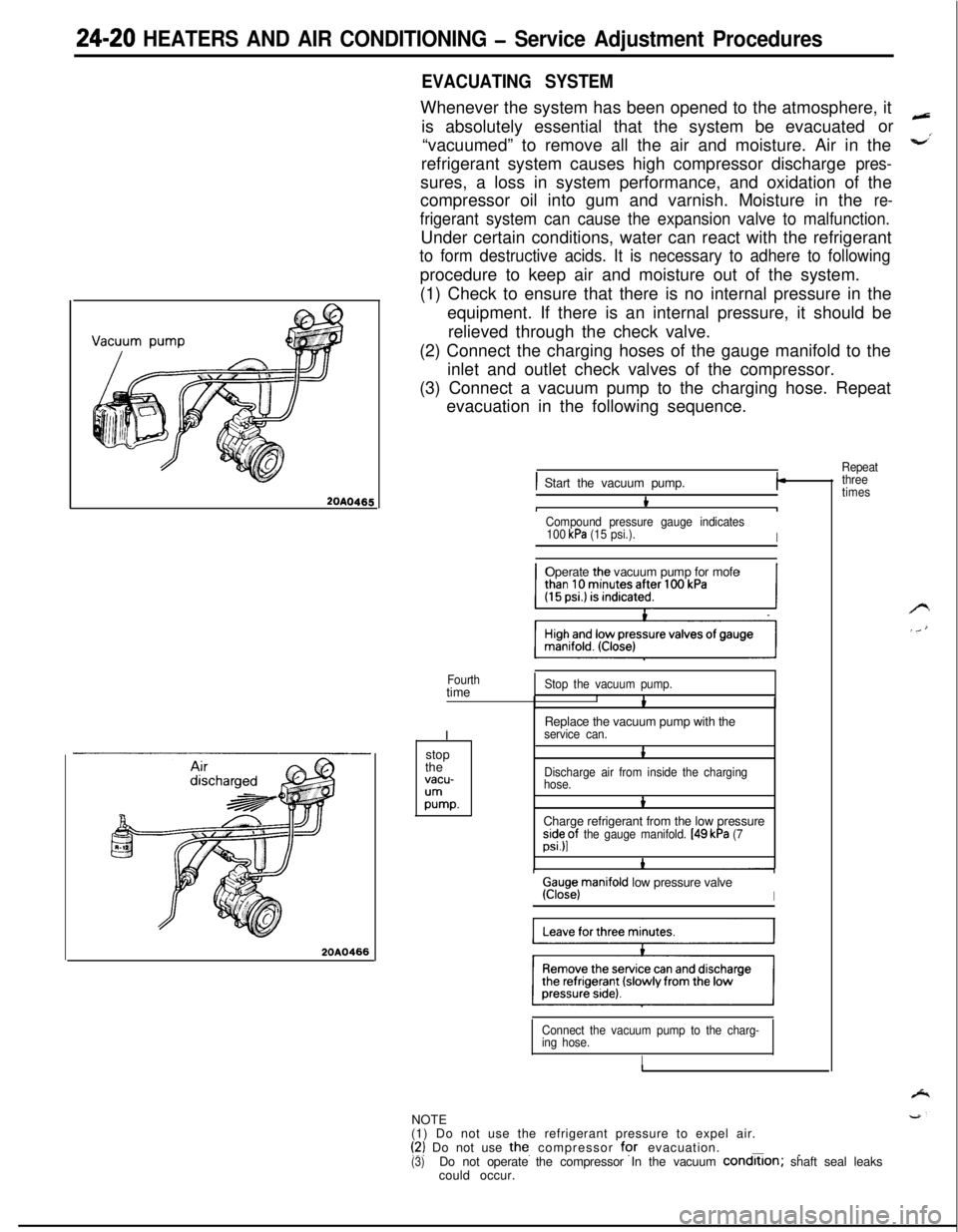

EVACUATING SYSTEMWhenever the system has been opened to the atmosphere, it

is absolutely essential that the system be evacuatedor

“vacuumed” to remove all the air and moisture. Air in the

refrigerant system causes high compressor discharge

pres-sures, a loss in system performance, and oxidation of the

compressor oil into gum and varnish. Moisture in the

re-

frigerant system can cause the expansion valve to malfunction.Under certain conditions, water can react with the refrigerant

to form destructive acids. It is necessary to adhere to followingprocedure to keep air and moisture out of the system.

(1) Check to ensure that there is no internal pressure in the

equipment. If there is an internal pressure, it should be

relieved through the check valve.

(2) Connect the charging hoses of the gauge manifold to the

inlet and outlet check valves of the compressor.

(3) Connect a vacuum pump to the charging hose. Repeat

evacuation in the following sequence.

Repeat

) Start the vacuum pump.I-

bIICompound pressure gauge indicates

100 kPa (15 psi.).IOperate the vacuum pump for mofe

Fourthtime

IStop the vacuum pump.IbReplace the vacuum pump with the

service can.stop

the

vacu-

;Ummp.

1

Discharge air from inside the charging

hose.

bCharge refrigerant from the low pressure

;s”;pf the gauge manifold. [49 kPa (7

Ga;iejmanifold low pressure valveI

Connect the vacuum pump to the charg-

ing hose.

INOTE

(1) Do not use the refrigerant pressure to expel air.

(‘2) Do not use the. compressor for evacuation.___(3)Do not operate the compressor In the vacuum condrtlon; shaft seal leaks

could occur.

three

times

Page 1165 of 1216

i

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-21Hot water40°C (104°F)

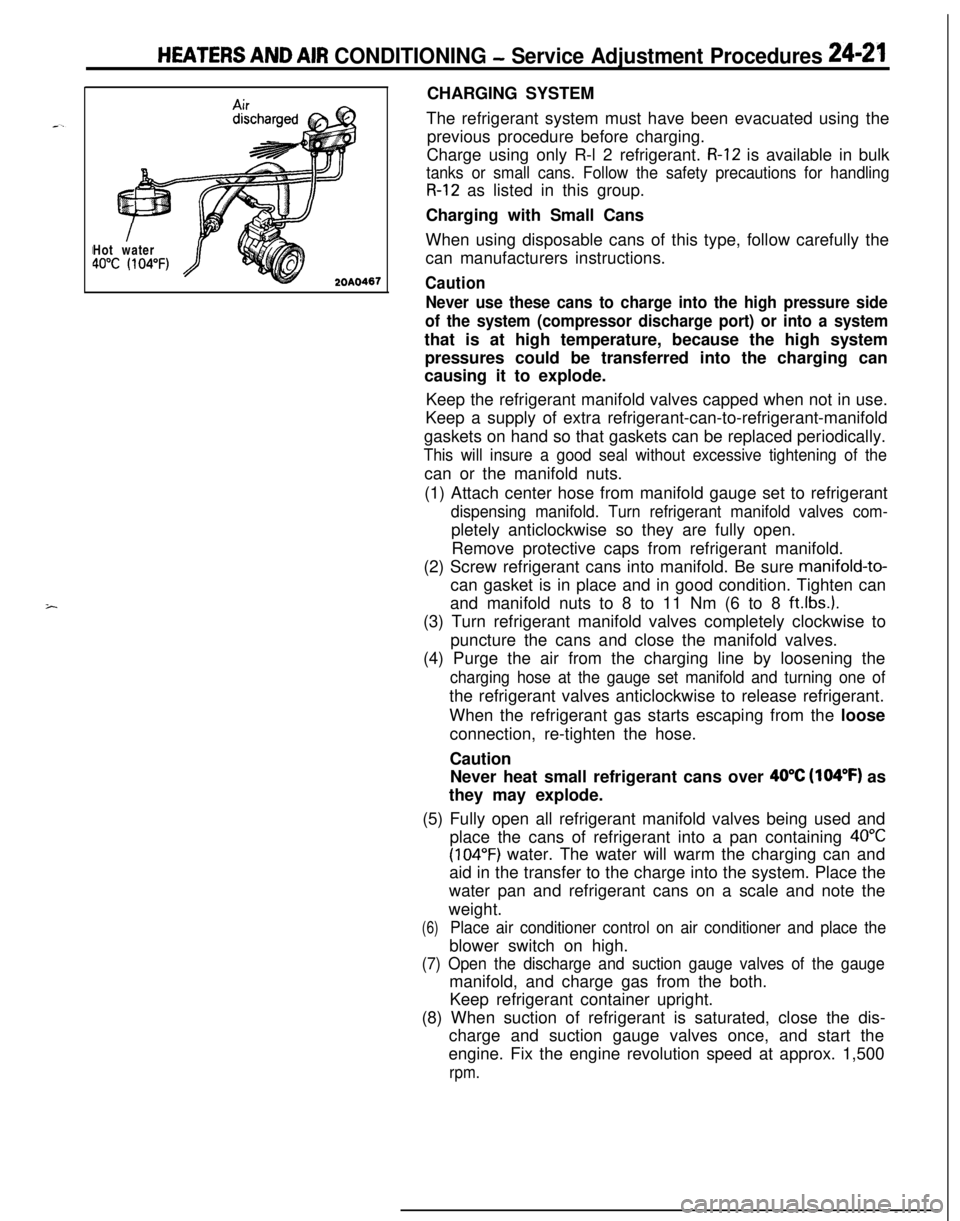

1467CHARGING SYSTEM

The refrigerant system must have been evacuated using the

previous procedure before charging.

Charge using only R-l 2 refrigerant.

R-12 is available in bulk

tanks or small cans. Follow the safety precautions for handling

R-12 as listed in this group.

Charging with Small Cans

When using disposable cans of this type, follow carefully the

can manufacturers instructions.

Caution

Never use these cans to charge into the high pressure side

of the system (compressor discharge port) or into a systemthat is at high temperature, because the high system

pressures could be transferred into the charging can

causing it to explode.

Keep the refrigerant manifold valves capped when not in use.

Keep a supply of extra refrigerant-can-to-refrigerant-manifold

gaskets on hand so that gaskets can be replaced periodically.

This will insure a good seal without excessive tightening of thecan or the manifold nuts.

(1) Attach center hose from manifold gauge set to refrigerant

dispensing manifold. Turn refrigerant manifold valves com-pletely anticlockwise so they are fully open.

Remove protective caps from refrigerant manifold.

(2) Screw refrigerant cans into manifold. Be sure

manifold-to-can gasket is in place and in good condition. Tighten can

and manifold nuts to 8 to 11 Nm (6 to 8

ft.lbs.).(3) Turn refrigerant manifold valves completely clockwise to

puncture the cans and close the manifold valves.

(4) Purge the air from the charging line by loosening the

charging hose at the gauge set manifold and turning one ofthe refrigerant valves anticlockwise to release refrigerant.

When the refrigerant gas starts escaping from the loose

connection, re-tighten the hose.

Caution

Never heat small refrigerant cans over

40°C (104°F) as

they may explode.

(5) Fully open all refrigerant manifold valves being used and

place the cans of refrigerant into a pan containing

40°C

(104°F) water. The water will warm the charging can and

aid in the transfer to the charge into the system. Place the

water pan and refrigerant cans on a scale and note the

weight.

(6)Place air conditioner control on air conditioner and place theblower switch on high.

(7) Open the discharge and suction gauge valves of the gaugemanifold, and charge gas from the both.

Keep refrigerant container upright.

(8) When suction of refrigerant is saturated, close the dis-

charge and suction gauge valves once, and start the

engine. Fix the engine revolution speed at approx. 1,500

rpm.