check engine MITSUBISHI ECLIPSE 1991 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 390 of 1216

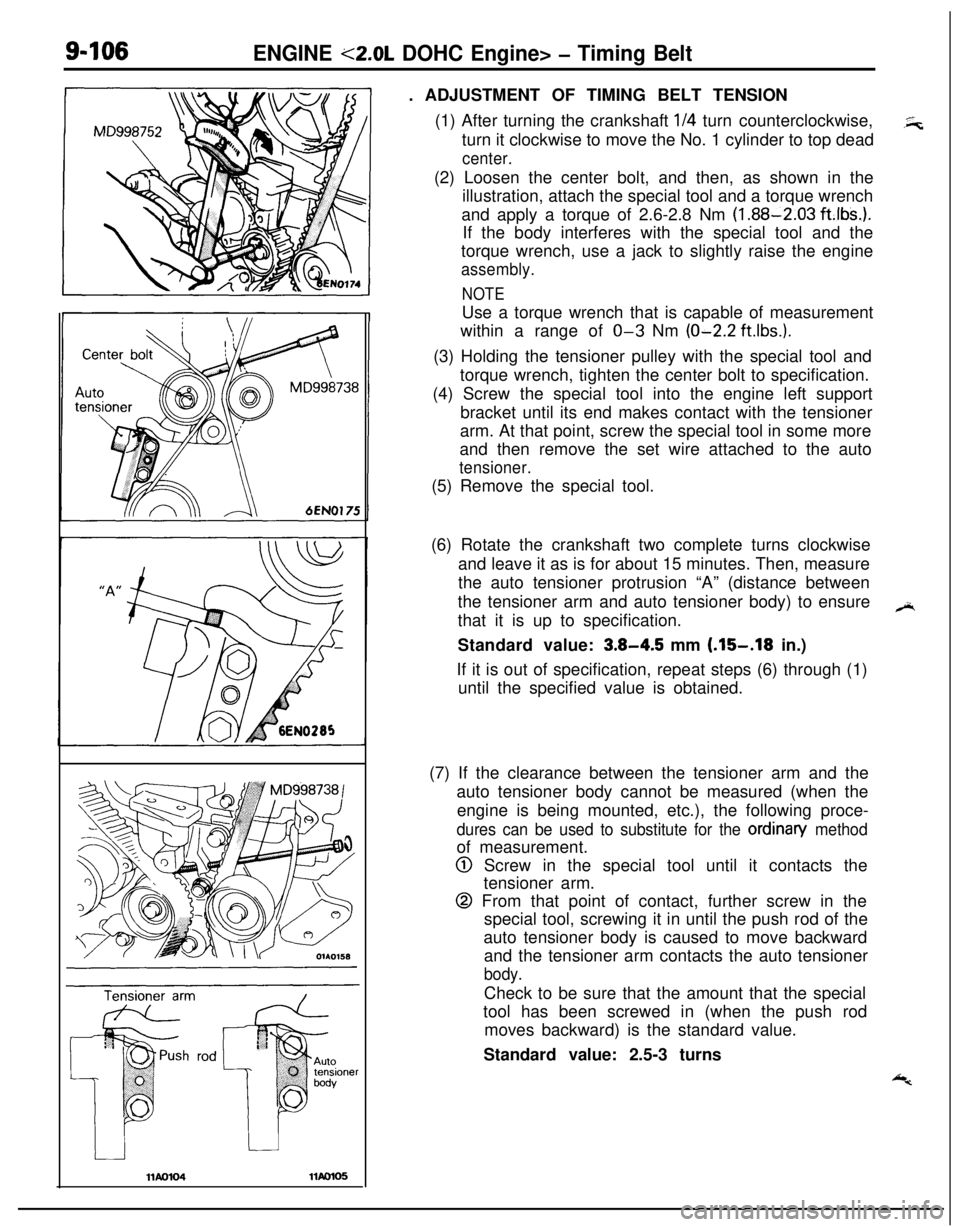

9-106ENGINE <2.0L DOHC Engine> - Timing Belt. ADJUSTMENT OF TIMING BELT TENSION

(1) After turning the crankshaft

l/4 turn counterclockwise,.5;;turn it clockwise to move the No. 1 cylinder to top dead

center.(2) Loosen the center bolt, and then, as shown in the

illustration, attach the special tool and a torque wrench

and apply a torque of 2.6-2.8 Nm

(1.88-2.03 ft.lbs.).If the body interferes with the special tool and the

torque wrench, use a jack to slightly raise the engine

assembly.

NOTEUse a torque wrench that is capable of measurement

within a range of

O-3 Nm (O-2.2 ft.lbs.).(3) Holding the tensioner pulley with the special tool and

torque wrench, tighten the center bolt to specification.

(4) Screw the special tool into the engine left support

bracket until its end makes contact with the tensioner

arm. At that point, screw the special tool in some more

and then remove the set wire attached to the auto

tensioner.(5) Remove the special tool.

(6) Rotate the crankshaft two complete turns clockwise

and leave it as is for about 15 minutes. Then, measure

the auto tensioner protrusion “A” (distance between

the tensioner arm and auto tensioner body) to ensure,.+

that it is up to specification.

Standard value:

3.8-4.5 mm (.15-.18 in.)

If it is out of specification, repeat steps (6) through (1)

until the specified value is obtained.

(7) If the clearance between the tensioner arm and the

auto tensioner body cannot be measured (when the

engine is being mounted, etc.), the following proce-

dures can be used to substitute for the ordinan/ methodof measurement.

@ Screw in the special tool until it contacts the

tensioner arm.

@ From that point of contact, further screw in the

special tool, screwing it in until the push rod of the

auto tensioner body is caused to move backward

and the tensioner arm contacts the auto tensioner

body.Check to be sure that the amount that the special

tool has been screwed in (when the push rod

moves backward) is the standard value.

Standard value: 2.5-3 turns

Page 394 of 1216

9-110ENGINE <2.0L DOHC Engine> - Camshaft and Rocker Arm

I

I6EN0183

I6EN0184

I

I6EN0185

,I

+Front of engine (Timing belt side)

WIB’ S’it

’ Intake side

camshaft

6E NO289Cap number

Symbolidentifying

intake or

exhaust6EN6464

I

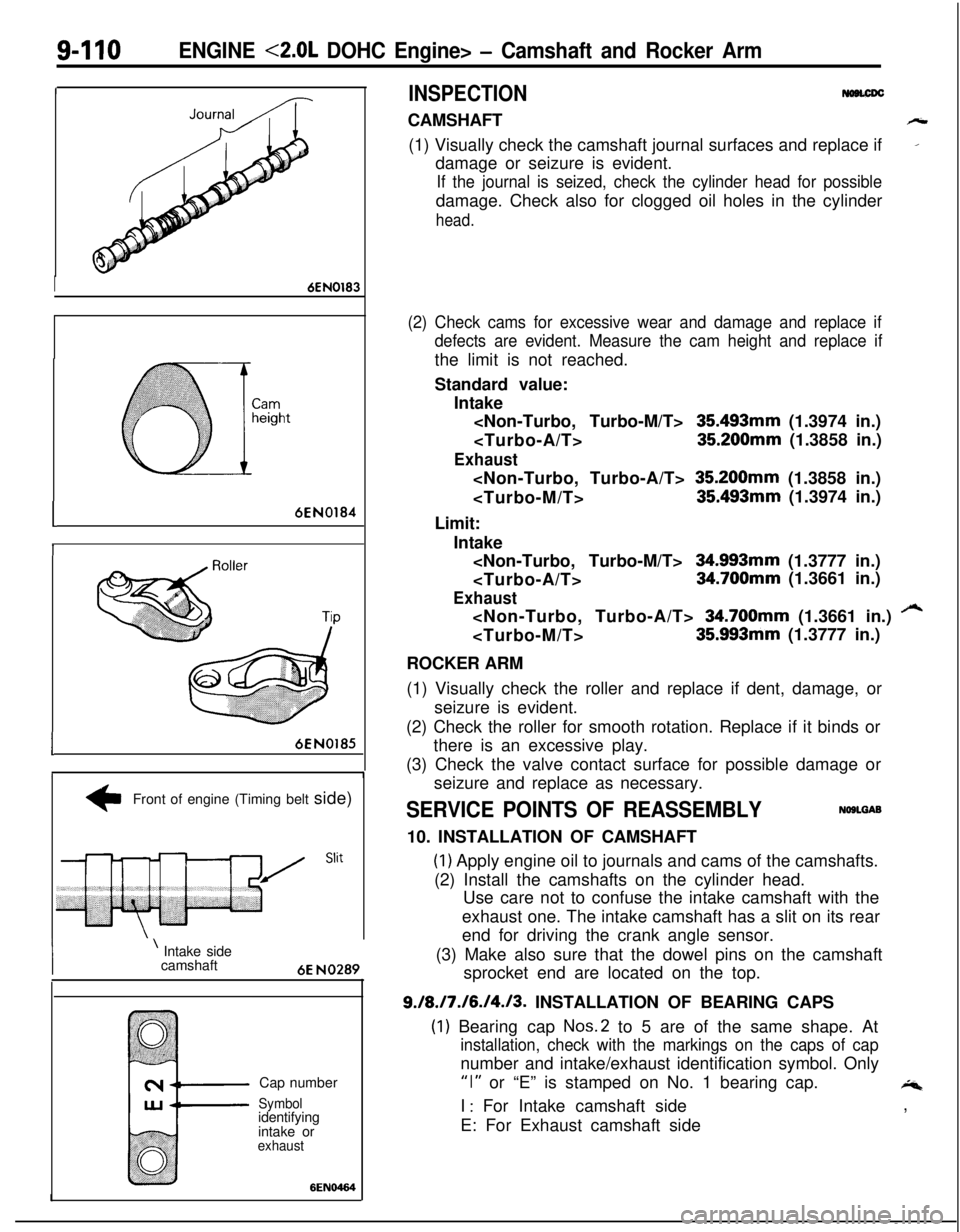

INSPECTIONCAMSHAFT

h(1) Visually check the camshaft journal surfaces and replace if

_damage or seizure is evident.

If the journal is seized, check the cylinder head for possibledamage. Check also for clogged oil holes in the cylinder

head.

(2) Check cams for excessive wear and damage and replace if

defects are evident. Measure the cam height and replace ifthe limit is not reached.

Standard value:

Intake

35493mm (1.3974 in.)

Exhaust

Limit:

Intake

Exhaust

/“4

ROCKER ARM

(1) Visually check the roller and replace if dent, damage, or

seizure is evident.

(2) Check the roller for smooth rotation. Replace if it binds or

there is an excessive play.

(3) Check the valve contact surface for possible damage or

seizure and replace as necessary.

SERVICE POINTS OF REASSEMBLYNOSLGAB10. INSTALLATION OF CAMSHAFT

(1) Apply engine oil to journals and cams of the camshafts.

(2) Install the camshafts on the cylinder head.

Use care not to confuse the intake camshaft with the

exhaust one. The intake camshaft has a slit on its rear

end for driving the crank angle sensor.

(3) Make also sure that the dowel pins on the camshaft

sprocket end are located on the top.

9./8./7./6./4./3. INSTALLATION OF BEARING CAPS

(1) Bearing cap Nos.2 to 5 are of the same shape. At

installation, check with the markings on the caps of capnumber and intake/exhaust identification symbol. Only

“I” or “E” is stamped on No. 1 bearing cap.4I

: For Intake camshaft side

E: For Exhaust camshaft side,

Page 395 of 1216

ENGINE <2.0L DOHC Engine> - Camshaft and Rocker Arm9-111_ Front of engine (Timing belt side)

0 Co@

6EN0192

MD998306Oil seal

-

Y-II6ENI01946EN030’

1(2) Tighten the bearing caps in the order shown two to

three times by torquing progressively.

Tighten to specification in the final sequence.

(3) Check to be sure that the rocker arm is correctly placedon the lash adjuster and valve stem end.

5. INSTALLATION OF CAMSHAFT OIL SEAL

(1) Install the special tool, Guide, on the camshaft.

(2) Apply oil to the oil seal and insert the seal along the

Guide until it contacts the cylinder head.

(3) Using the special tool, Installer, press-fit the oil seal intothe cylinder head.

2. INSTALLATION OF CAMSHAFT SPROCKET

Using a wrench hold the camshaft at its hexagon (betweenthe

No.2 and No.3 journals) and tighten the bolt to

specification.Caution

Locking the camshaft sprocket with a tool damages the

sprocket.1. INSTALLATION OF CRANK ANGLE SENSOR

(1) Locate the dowel pin on the sprocket side of the intake

camshaft at top.

(2) Align the punch mark on the crank angle sensor housingwith the notch in plate.

NOTE

The crank angle sensor can be installed even when thepunch mark is positioned opposite the notch; however,

the position results in incorrect fuel injection and

ignition timings.

(3) Install the crank angle sensor on the cylinder head.

Page 397 of 1216

ENGINE <2.0L DOHC Engine> - Cylinder Head and Valve9-l 13

.

.

a Front of engine (Timing belt side)

6EN0211

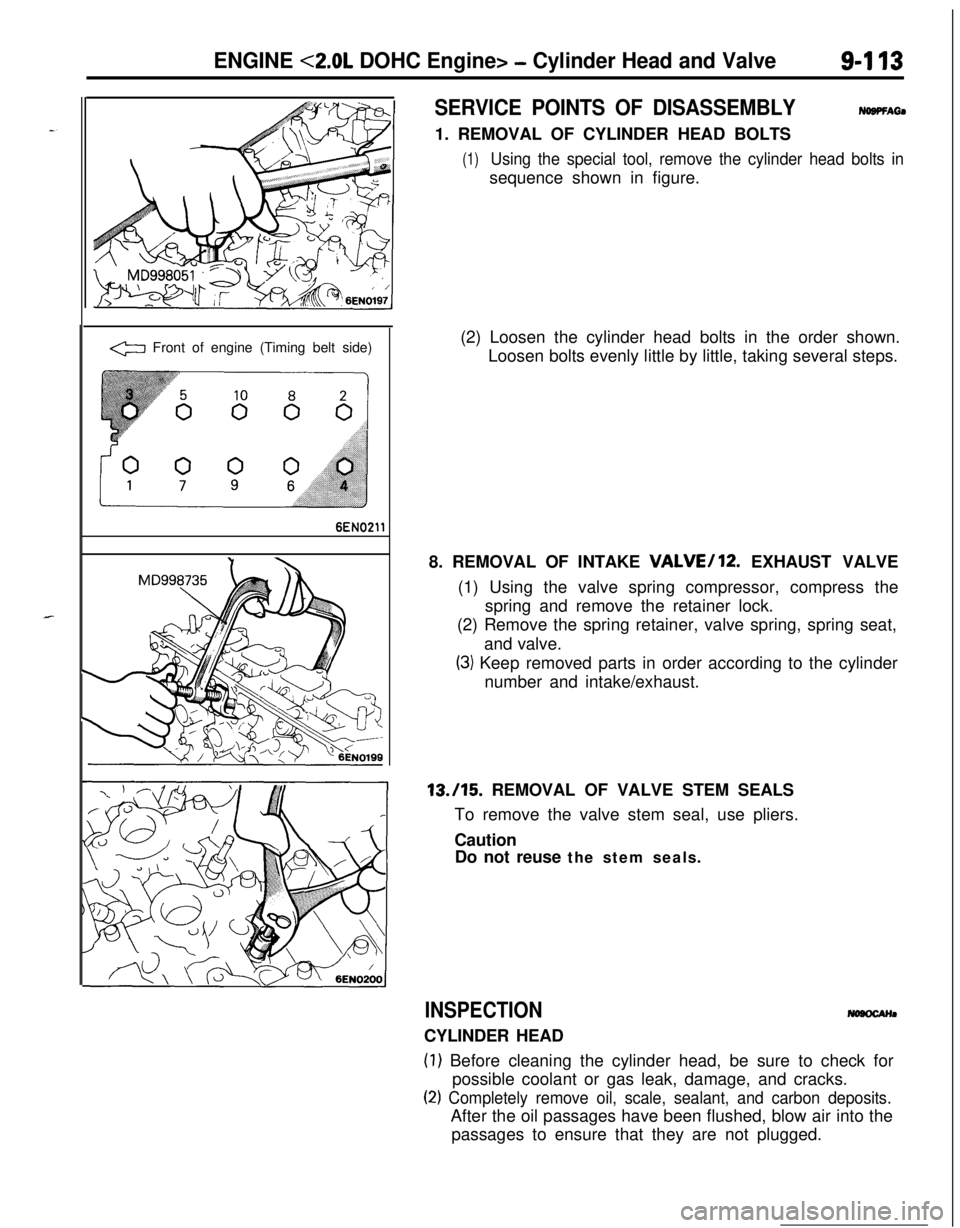

SERVICE POINTS OF DISASSEMBLYNOBPFAti1. REMOVAL OF CYLINDER HEAD BOLTS

(1)Using the special tool, remove the cylinder head bolts insequence shown in figure.

(2) Loosen the cylinder head bolts in the order shown.

Loosen bolts evenly little by little, taking several steps.

8. REMOVAL OF INTAKE

VALVE/12. EXHAUST VALVE

(1) Using the valve spring compressor, compress the

spring and remove the retainer lock.

(2) Remove the spring retainer, valve spring, spring seat,

and valve.

(3) Keep removed parts in order according to the cylinder

number and intake/exhaust.13./15. REMOVAL OF VALVE STEM SEALS

To remove the valve stem seal, use pliers.

Caution

Do not reuse the stem seals.

INSPECTIONCYLINDER HEAD

(1) Before cleaning the cylinder head, be sure to check for

possible coolant or gas leak, damage, and cracks.

(2) Completely remove oil, scale, sealant, and carbon deposits.After the oil passages have been flushed, blow air into the

passages to ensure that they are not plugged.

Page 398 of 1216

9-114ENGINE <2.0L DOHC Engine> - Cylinder Head and Valve

Ridgewear

1 EN034Contact with

valve seat

(to be at center

6EN020

I

Freeheight

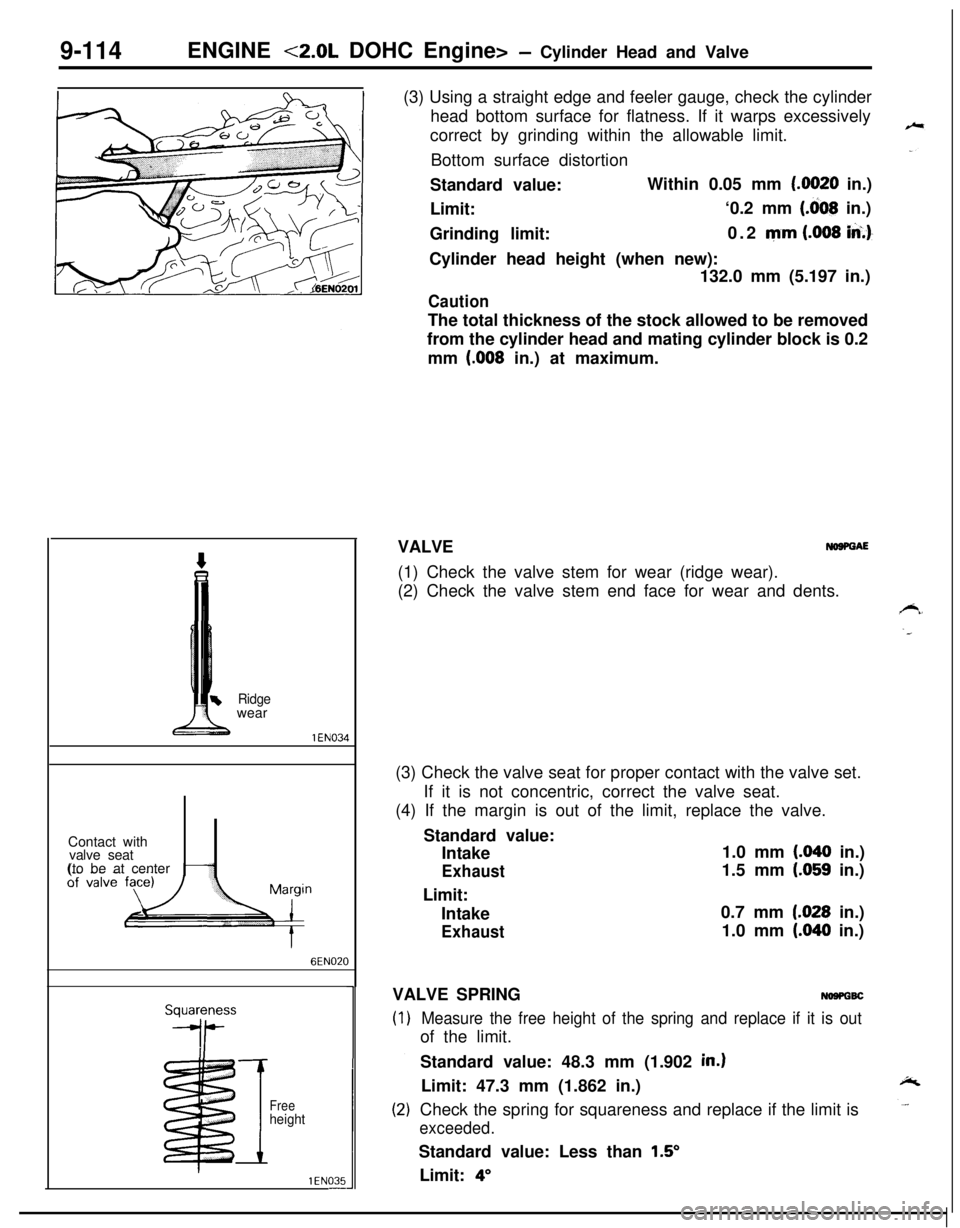

1 EN035-(3) Using a straight edge and feeler gauge, check the cylinder

head bottom surface for flatness. If it warps excessively

correct by grinding within the allowable limit.

Bottom surface distortion

Standard value:Within 0.05 mm

(.0020 in.)

Limit:‘0.2 mm

(.dO8 in.)

Grinding limit:0.2 mm

(.008 iA.)-Cylinder head height (when new):

132.0 mm (5.197 in.)

CautionThe total thickness of the stock allowed to be removed

from the cylinder head and mating cylinder block is 0.2

mm

(.008 in.) at maximum.

VALVE

NOSPGAE(1) Check the valve stem for wear (ridge wear).

(2) Check the valve stem end face for wear and dents.

(3) Check the valve seat for proper contact with the valve set.

If it is not concentric, correct the valve seat.

(4) If the margin is out of the limit, replace the valve.

Standard value:

Intake1.0 mm

(.040 in.)

Exhaust1.5 mm (.059 in.)

Limit:

Intake0.7 mm

1.028 in.)

Exhaust1.0 mm (.040 in.)

VALVE SPRING

NOSPGBC

Measure the free height of the spring and replace if it is outof the limit.

Standard value: 48.3 mm (1.902

in.)Limit: 47.3 mm (1.862 in.)

Check the spring for squareness and replace if the limit is

exceeded.Standard value: Less than

1.5’Limit:

4”

Page 401 of 1216

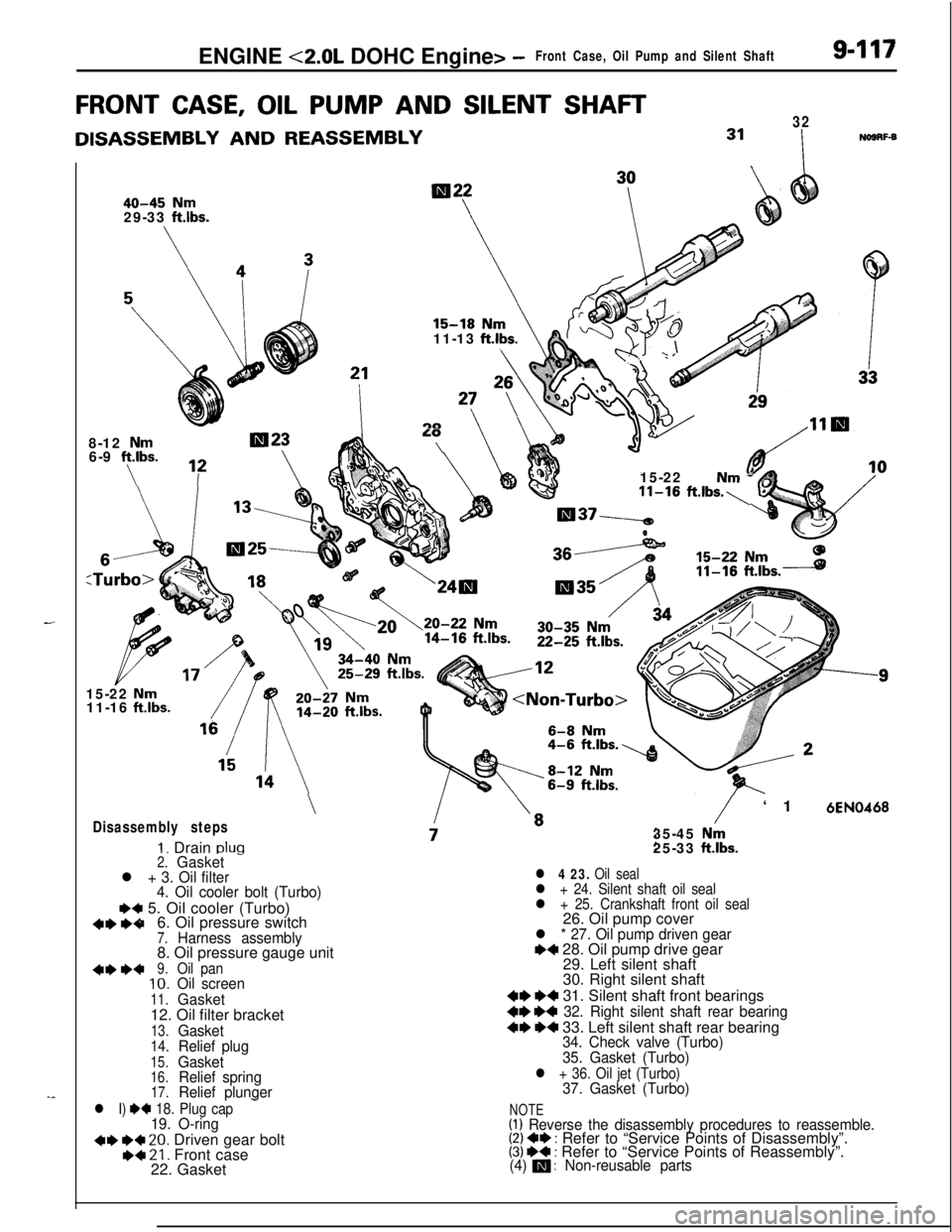

ENGINE <2.0L DOHC Engine> -Front Case, Oil Pump and Silent Shaft9-117

FRONT CASE, OIL PUMP AND SILENT SHAFT

DISASSEMBLY AND REASSEMBLY

40-45 Nm29-33 ft.lbs.

\

32

I

NOSRF-B11-13

ft.lbs.

LO8-12 Nm6-9 ft.lbs.\

\715-22 Nm -11-16 ft.lbs.,15-22

Nm11-16 ft.lbs.

Disassembly steps

I. Drain pluo

\/‘16EN046835-45

Nm25-33 ft.lbs.2.Gasket-l + 3. Oil filter

4. Oil cooler bolt (Turbo)

~~ 5. Oil cooler (Turbo)

6. Oil pressure switch

7.Harness assembly8. Oil pressure gauge unit

9.Oil pan10.Oil screen

11.Gasket12. Oil filter bracket

13.Gasket14.Relief plug

15.Gasket16.Relief spring17.Relief plunger

l 4 23. Oil seall + 24. Silent shaft oil seall + 25. Crankshaft front oil seal26. Oil pump cover

l * 27. Oil pump driven geare+ 28. Oil pump drive gear

29. Left silent shaft

30. Right silent shaft

W W 31. Silent shaft front bearings

W W 32. Right silent shaft rear bearing

~~ ~~ 33. Left silent shaft rear bearing34. Check valve (Turbo)

35. Gasket (Turbo)

l + 36. Oil jet (Turbo)37. Gasket (Turbo)

l I) W 18. Plug cap-NOTE19. O-ring(1) Reverse the disassembly procedures to reassemble.+e I)+ 20. Driven gear bolt(2) 4I) : Refer to “Service Points of Disassembly”.

I)+ 21. Front case(3) ~~ : Refer to “Service Points of Reassembly”.

22. Gasket(4) m : Non-reusable parts

Page 403 of 1216

ENGINE <2.0L DOHC Engine>- Front Case, Oil Puma and Silent Shaft9419

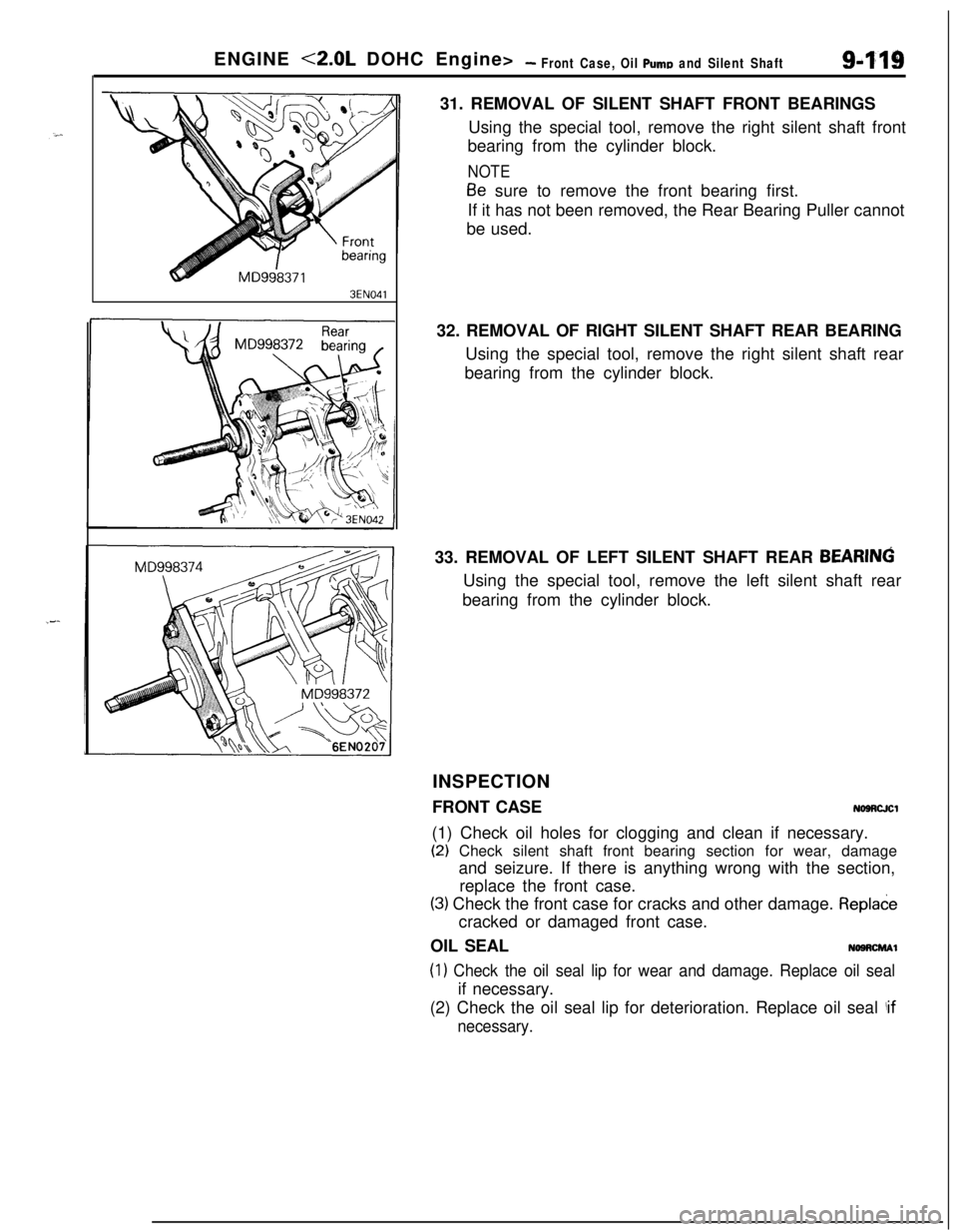

3EN04131. REMOVAL OF SILENT SHAFT FRONT BEARINGS

Using the special tool, remove the right silent shaft front

bearing from the cylinder block.

NOTE

Be sure to remove the front bearing first.

If it has not been removed, the Rear Bearing Puller cannot

be used.

32. REMOVAL OF RIGHT SILENT SHAFT REAR BEARING

Using the special tool, remove the right silent shaft rear

bearing from the cylinder block.

33. REMOVAL OF LEFT SILENT SHAFT REAR

BEARINGUsing the special tool, remove the left silent shaft rear

bearing from the cylinder block.

INSPECTION

FRONT CASE

NOSRCJCl(1) Check oil holes for clogging and clean if necessary.

(2) Check silent shaft front bearing section for wear, damage

and seizure. If there is anything wrong with the section,

replace the front case.

(3) Check the front case for cracks and other damage. Repladecracked or damaged front case.

OIL SEAL

NOSRCMAl

(1) Check the oil seal lip for wear and damage. Replace oil sealif necessary.

(2) Check the oil seal lip for deterioration. Replace oil seal

!if

necessary.

Page 404 of 1216

9-120ENGINE <2.0L DOHC Engine>- Front Case, Oil Pump and Silent Shaft

7LUOoo6

Fine

7LUOOO76LUO12OIL PRESSURE SWITCH

-1

(1) Connect a tester (ohm range) between the terminal and thebody and check for conductivity. If there is no conductivity,

replace the switch.

(2) Next insert a very fine wedge through the oil hole, pushing

it slightly. There should be no conductivity (resistance

should be infinite). If there is conductivity even when

wedge is pushed, replace the switch.

(3) Or, if there is no conductivity when a 50

kPa (71 psi)

pressure is placed through the oil hole, the switch is

operating properly. Check at this time to see that there is

no air pressure leakage. If there is air pressure leakage, thediaphragm is broken, and the switch should be replaced.

OIL COOLER BYPASS VALVE (Turbo)

NaacNA

(1) Make sure that the valve moves smoothly.

(2) Ensure that the dimension

L measures the standard value

under normal temperature and humidity.

Dimension

L: 34.5 mm (1.358 in.)

(3) The dimension must be the standard value when measuredafter the valve has been dipped in

100°C (212°F) oil.

Dimension

L: 40 mm (1.57 in.) or more

OIL PUMP

NOBRCGG(1) Assemble the oil pump gear to the front case and rotate it

to ensure smooth rotation with no looseness.

(2) Ensure that there is no ridge wear on the contact surface

between the front case and the gear surface of the oil

pump cover.

(3) With the drive and driven gears installed into the front case.Standard value:

Drive gear

0.16-0.21 mm (.0063-.0083 in.)

Driven gear

0.13-0.18 mm (.0051-.0071 in.)

Limit:

Drive gear0.25 mm

(.0098 in.)

Driven gear0.25 mm

(4098 in.)

k

Page 405 of 1216

ENGINE <2.0L DOHC Engine>- Front Case, Oil Pump and Silent Shaft9-121

II6LUOO13~DEN662

Engine oil

bOil jet

Check valve assembly

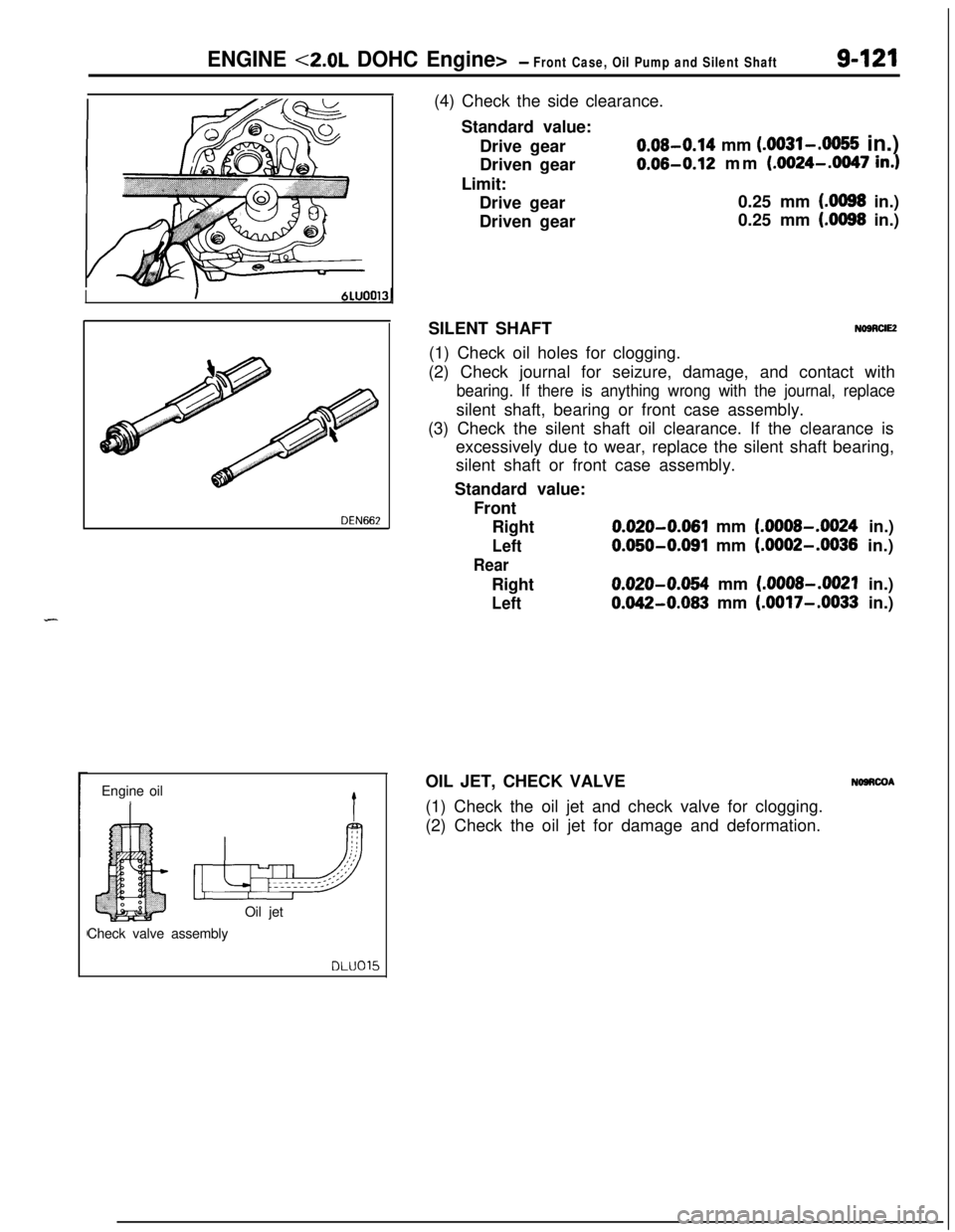

DLU015(4) Check the side clearance.

Standard value:

Drive gear

0.08-0.14 mm (.0031-.0055 in.)

Driven gear

0.06-0.12 mm (.0024-.0047 in.)Limit:

Drive gear0.25 mm

(.0098 in.)

Driven gear0.25 mm

(.0098 in.)

SILENT SHAFT

NOBRUE(1) Check oil holes for clogging.

(2) Check journal for seizure, damage, and contact with

bearing. If there is anything wrong with the journal, replacesilent shaft, bearing or front case assembly.

(3) Check the silent shaft oil clearance. If the clearance is

excessively due to wear, replace the silent shaft bearing,

silent shaft or front case assembly.

Standard value:

Front

Right

0.020-0.061 mm (.0008-.0024 in.)

Left0.050-0.091 mm (.0002-.0036 in.)

RearRight

0.020-0.054 mm (.0008-.0021 in.)

Left0.042-0.083 mm (.0017-.0033 in.)

OIL JET, CHECK VALVE

NOSRCOA(1) Check the oil jet and check valve for clogging.

(2) Check the oil jet for damage and deformation.

Page 406 of 1216

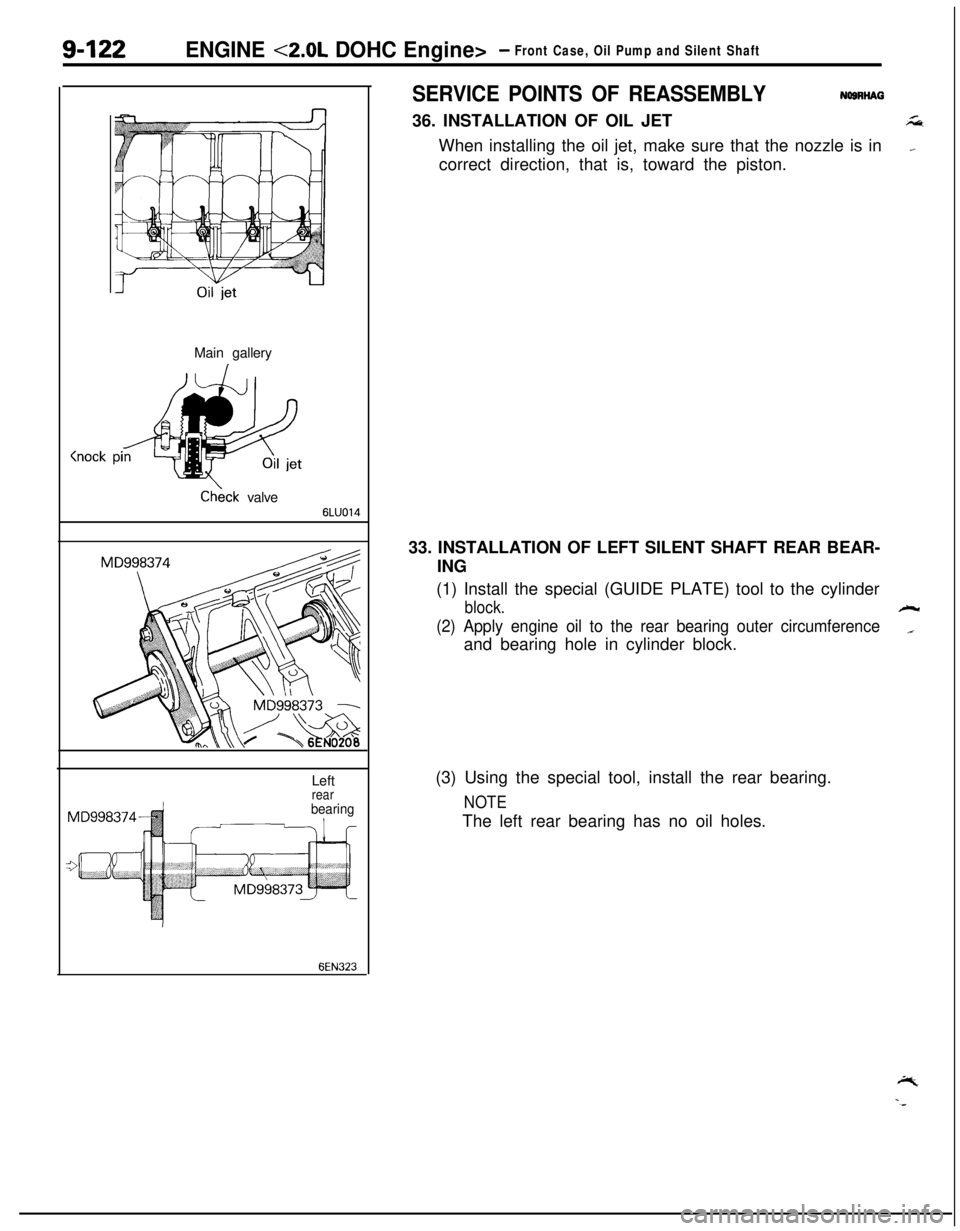

9-122ENGINE <2.0L DOHC Engine>- Front Case, Oil Pump and Silent ShaftMain gallery

rearbearing

6EN323

SERVICE POINTS OF REASSEMBLYNOSRHAG36. INSTALLATION OF OIL JET

;;;itWhen installing the oil jet, make sure that the nozzle is in

_correct direction, that is, toward the piston.

33. INSTALLATION OF LEFT SILENT SHAFT REAR BEAR-

ING

(1) Install the special (GUIDE PLATE) tool to the cylinder

block.k

(2) Apply engine oil to the rear bearing outer circumference1and bearing hole in cylinder block.

(3) Using the special tool, install the rear bearing.

NOTEThe left rear bearing has no oil holes.