light MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1090 of 1216

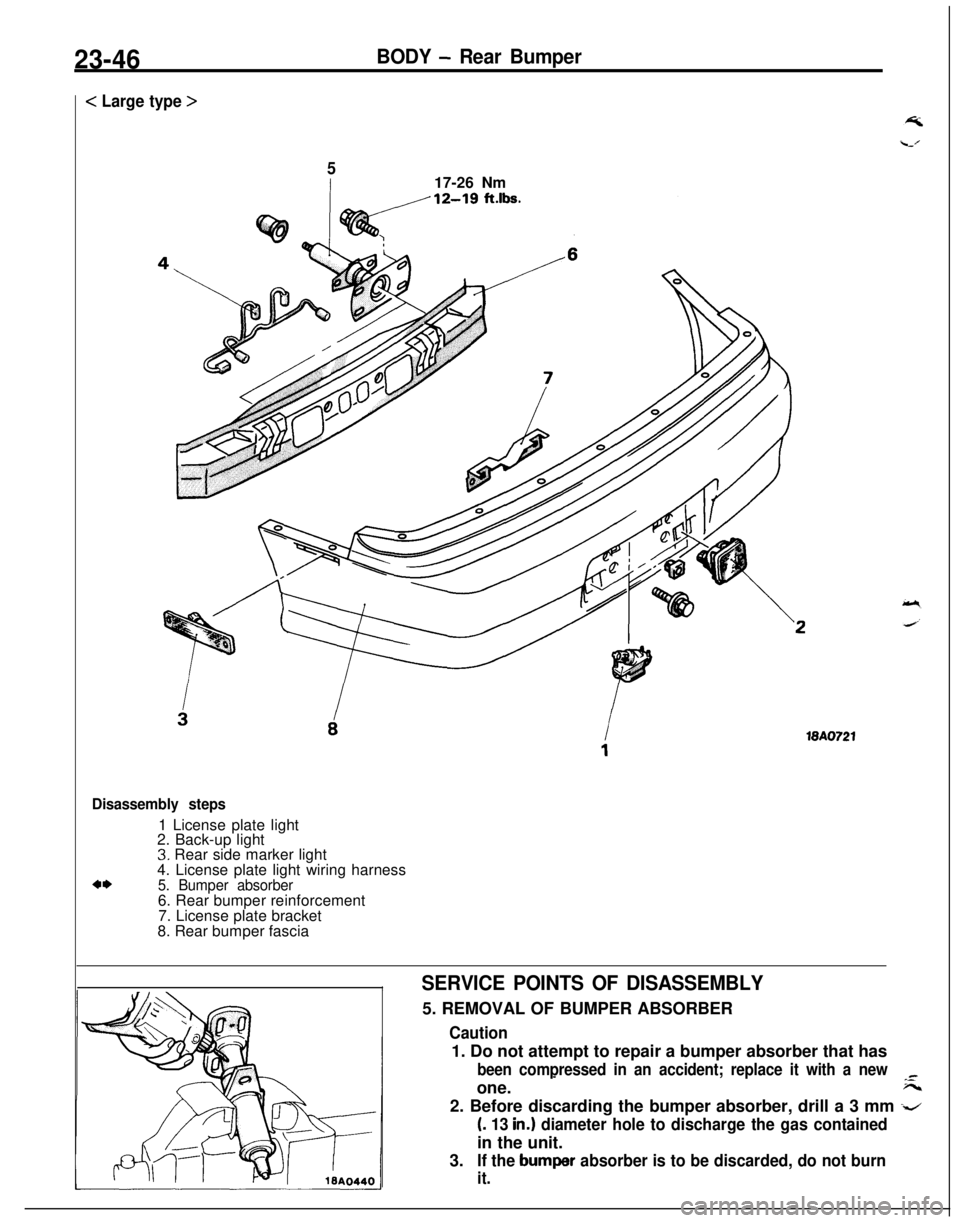

23-46BODY - Rear Bumper

< Large type >

517-26 Nm

18A0721

Disassembly steps1 License plate light

2. Back-up light

3. Rear side marker light

4. License plate light wiring harness

4*5. Bumper absorber6. Rear bumper reinforcement

7. License plate bracket

8. Rear bumper fascia

SERVICE POINTS OF DISASSEMBLY5. REMOVAL OF BUMPER ABSORBER

Caution1. Do not attempt to repair a bumper absorber that has

been compressed in an accident; replace it with a new-one.

-F--2. Before discarding the bumper absorber, drill a 3 mm

-z

(. 13 in.1 diameter hole to discharge the gas containedin the unit.

3.

If the bumper absorber is to be discarded, do not burn

it.

Page 1093 of 1216

BODY - Moulding23-493.

REMOVAL OF QUARTER WINDOW MOULDING LOWER/

4. QUARTER WINDOW MOULDING UPPER/B. QUARTERWINDOW MOULDING FRONT

Refer to

P.23-61.6. REMOVAL OF

LIFTGATE MOULDING LOWERI7. LIFT-GATE MOULDING

UPPER/8. LIFTGATE MOULDING

SIDERefer to

P.23-62.

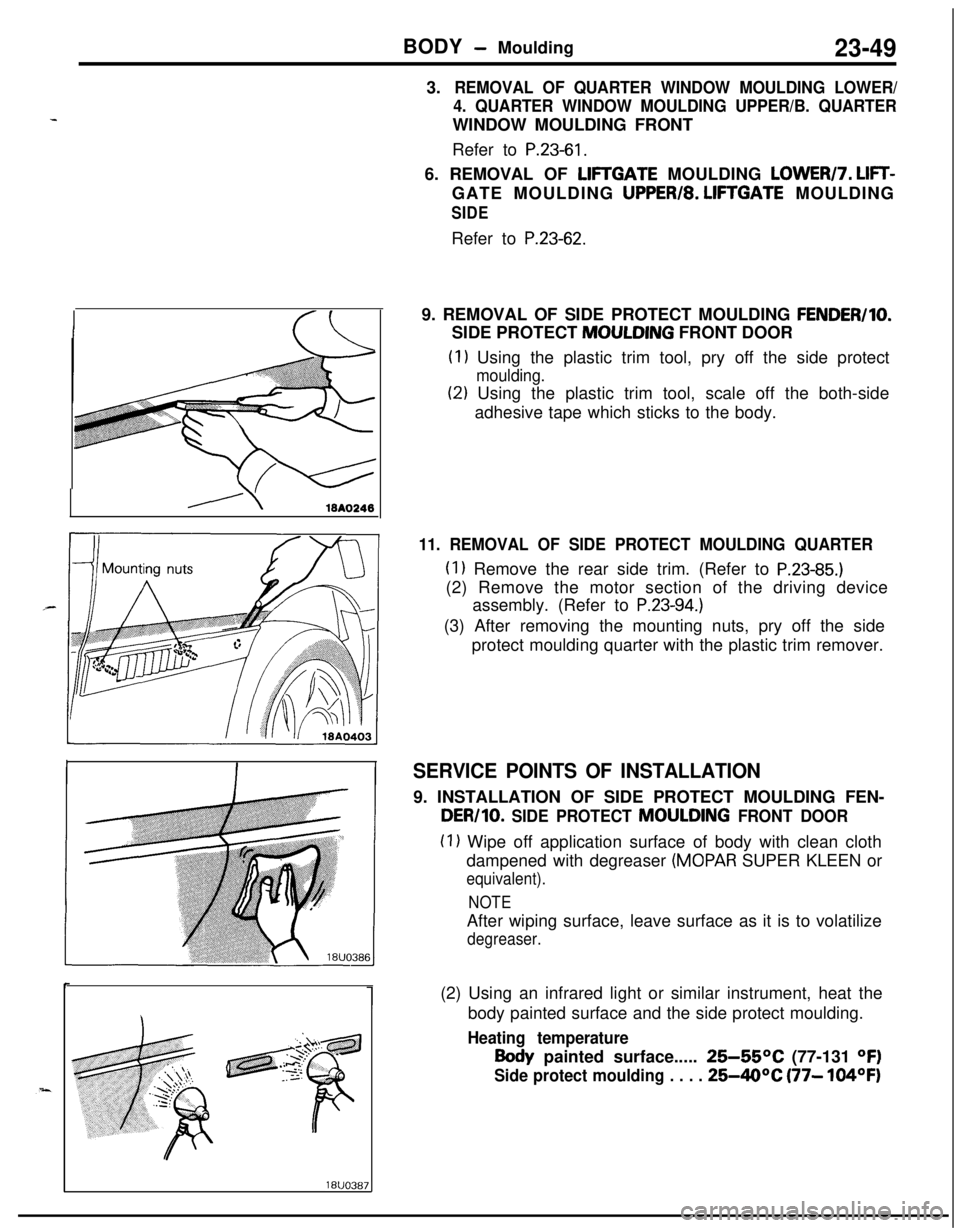

19. REMOVAL OF SIDE PROTECT MOULDING

FENDER/IO.SIDE PROTECT MOULDING FRONT DOOR

(1) Using the plastic trim tool, pry off the side protect

moulding.

(2) Using the plastic trim tool, scale off the both-side

adhesive tape which sticks to the body.

11. REMOVAL OF SIDE PROTECT MOULDING QUARTER

(1) Remove the rear side trim. (Refer to P.23-85.)(2) Remove the motor section of the driving device

assembly. (Refer to

P.23-94.)(3) After removing the mounting nuts, pry off the side

protect moulding quarter with the plastic trim remover.

SERVICE POINTS OF INSTALLATION9. INSTALLATION OF SIDE PROTECT MOULDING FEN-

DER/10. SIDE PROTECT MOULDING FRONT DOOR

(1) Wipe off application surface of body with clean cloth

dampened with degreaser

(MOPAR SUPER KLEEN or

equivalent).

NOTEAfter wiping surface, leave surface as it is to volatilize

degreaser.(2) Using an infrared light or similar instrument, heat the

body painted surface and the side protect moulding.

Heating temperature

Body painted surface..... 25-55OC (77-131 OF)

Side protect moulding . . . . 25-40°C (77- 104OF)

Page 1095 of 1216

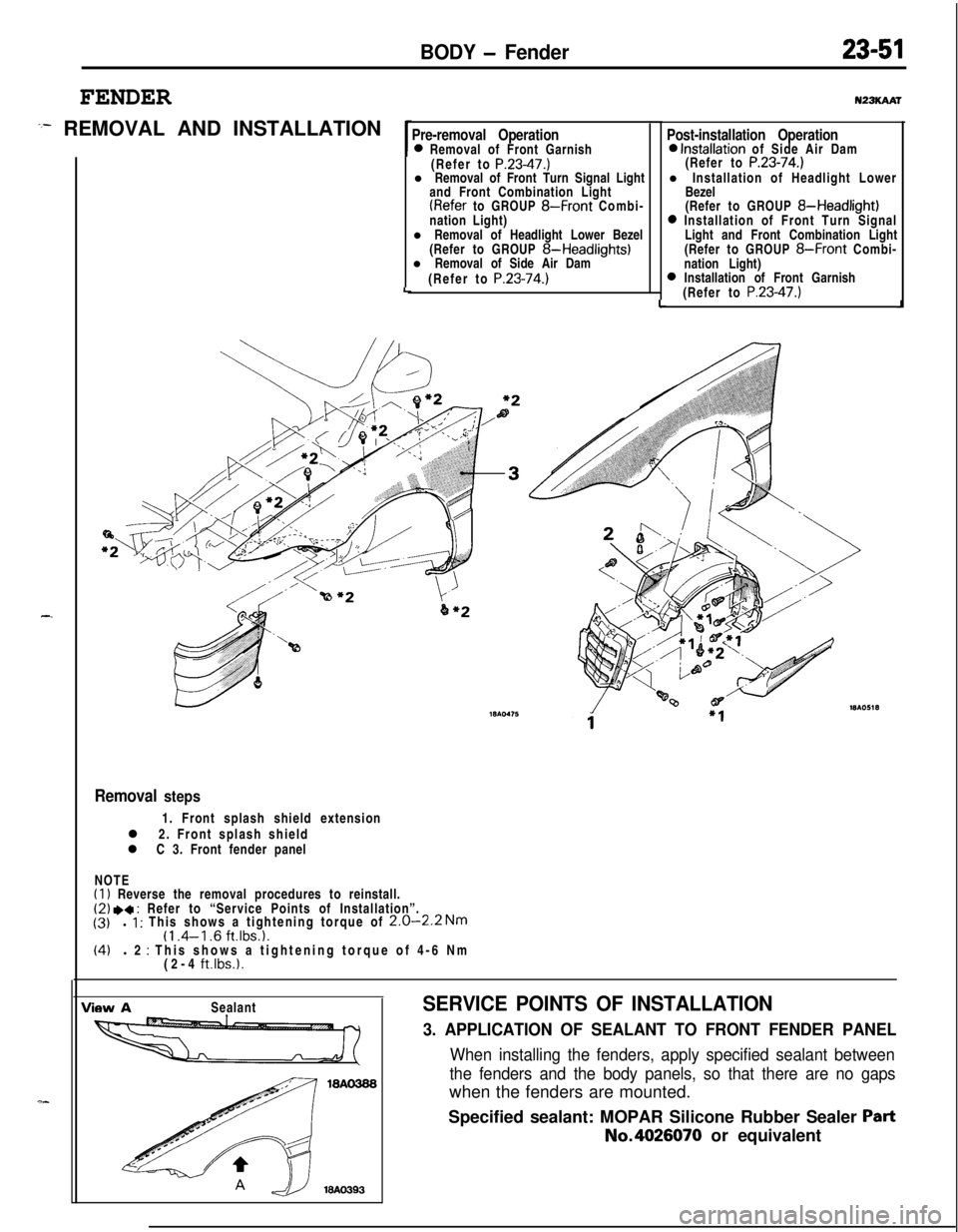

BODY - Fender

FENDER

:- REMOVAL AND INSTALLATION

-.

Pre-removal Operation0 Removal of Front Garnish

(Refer to P.23-47.)l Removal of Front Turn Signal Light

and Front Combination Light

(Refer to GROUP 8-Front Combi-

nation Light)

l Removal of Headlight Lower Bezel

(Refer to GROUP

8-Headlights)l Removal of Side Air Dam

(Refer to

P.23-74.)LLu23KAAr

Post-installation Operation0 Installation of Side Air Dam

(Refer to P.23-74.)l Installation of Headlight Lower

Bezel

(Refer to GROUP

8-Headlight)0 Installation of Front Turn Signal

Light and Front Combination Light

(Refer to GROUP

8-Front Combi-

nation Light)

0 Installation of Front Garnish

(Refer to P.23-47.)J

Removal steps1. Front splash shield extension

l 2. Front splash shield

l C 3. Front fender panel

NOTE

(1) Reverse the removal procedures to reinstall.(2) .a : Refer to “Service Points of Installation”.

(3)l 1 : This shows a tightening torque of 2.0-2.2 Nm(1 .4-l .6 ft.lbs.1.(4)l 2 : This shows a tightening torque of 4-6 Nm

(2-4 ft.lbs.1.

View ASealantSERVICE POINTS OF INSTALLATION

3. APPLICATION OF SEALANT TO FRONT FENDER PANEL

When installing the fenders, apply specified sealant between

the fenders and the body panels, so that there are no gapswhen the fenders are mounted.

Specified sealant: MOPAR Silicone Rubber Sealer

PartNo.4026070 or equivalent

Page 1097 of 1216

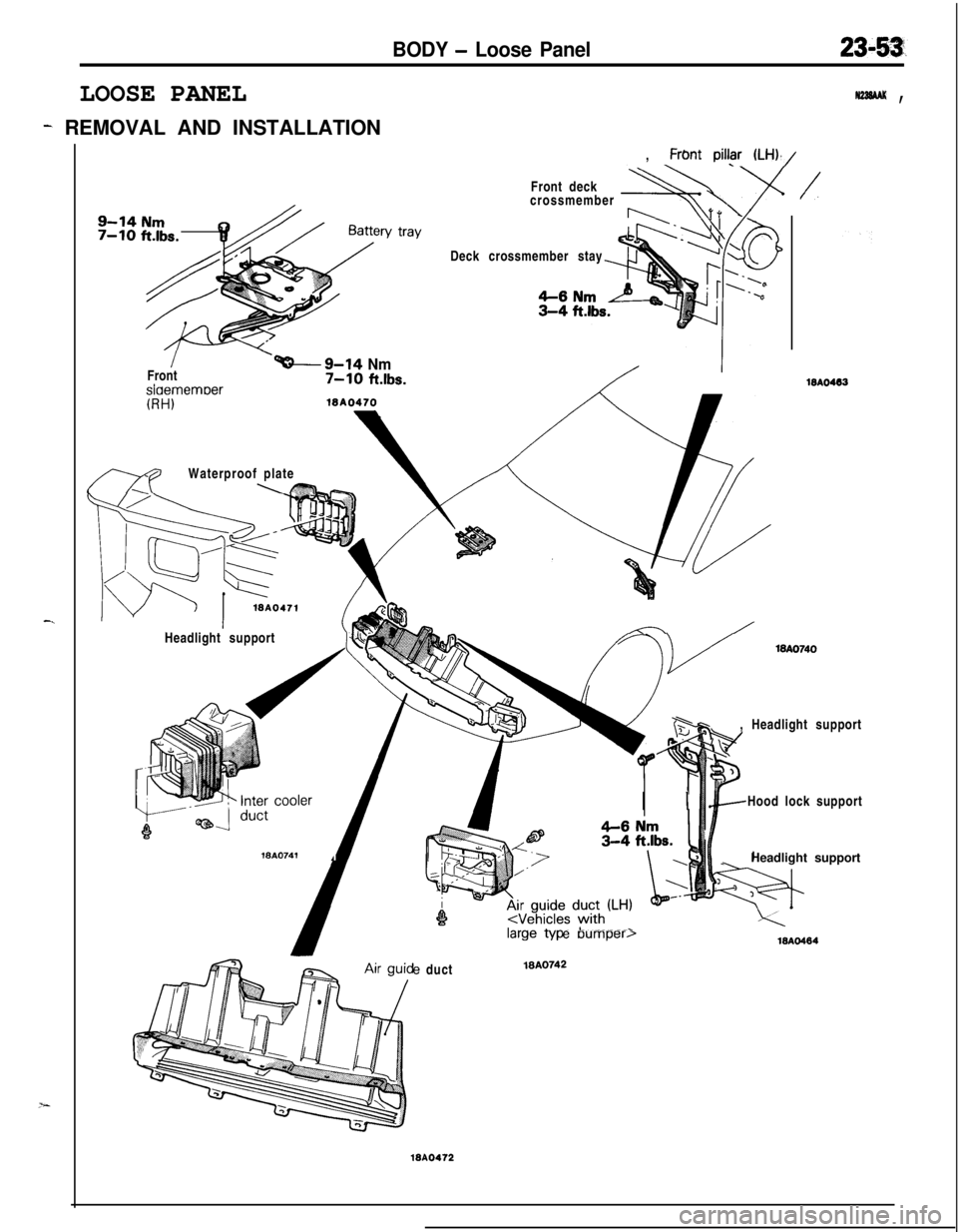

BODY - Loose Panel

LOOSE PANEL

- REMOVAL AND INSTALLATION

, Frbnt

piI@ (LH),/

N22SAAK ,

-.

v trayFront deck

crossmember

+ADeck crossmember stay

/Front

I

‘-9-14 Nm7-10 ftlbs.slaememoer

mWaterproof plate\K?%--

(RH)

WA0471Headlight supportWA.0741

,

/

WA0463, Headlight support

/-c---x/

I IHood lock support

_Headlight supporte duct

MA0742

WA0472

e Dumper,18AO484

Page 1118 of 1216

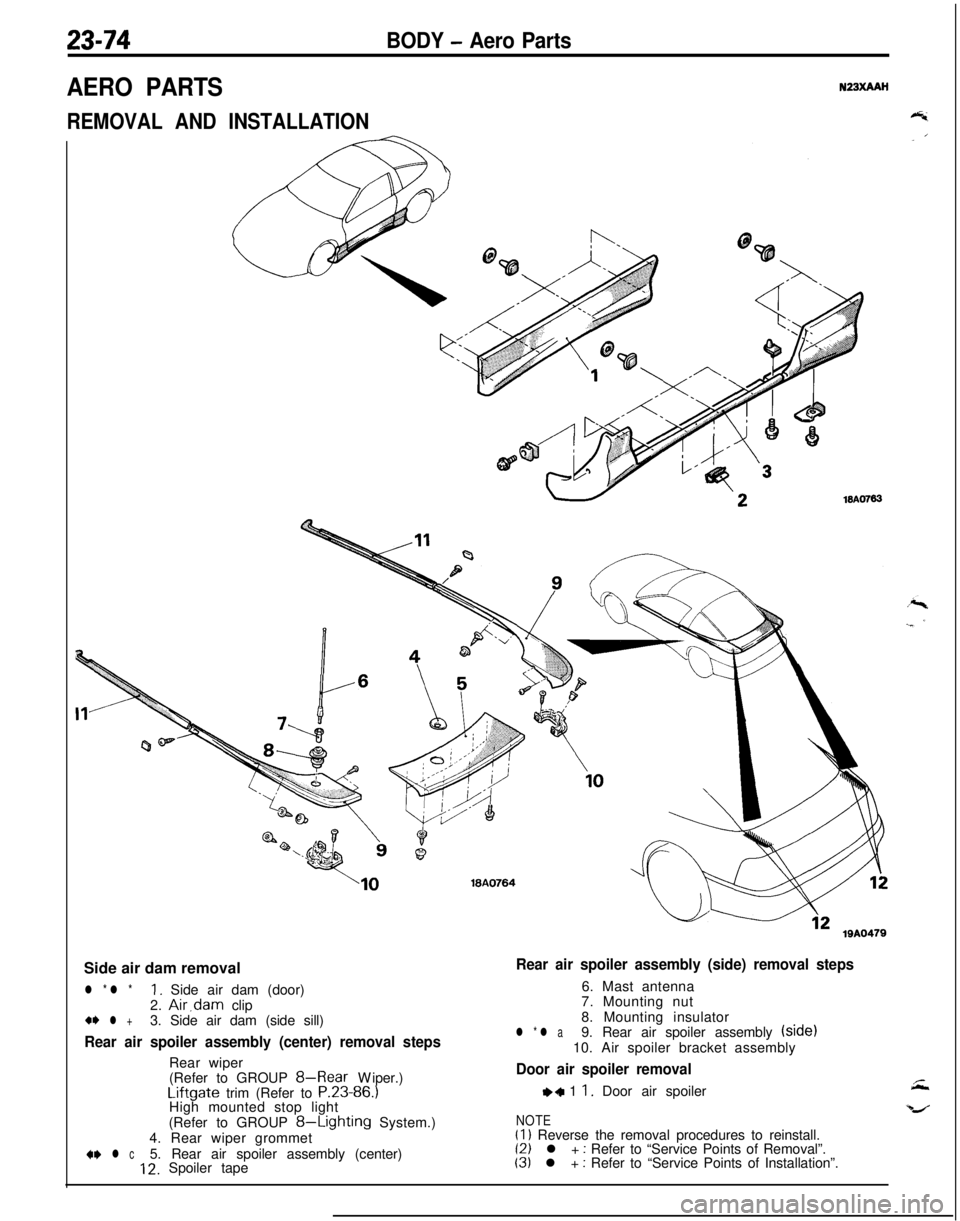

23-74BODY - Aero Parts

AERO PARTSN23XAAH

REMOVAL AND INSTALLATION

WA076318A0764

lQA0479Side air dam removal

l * l *1. Side air dam (door)

2. Air,dam clip+* l +3. Side air dam (side sill)

Rear air spoiler assembly (center) removal stepsRear wiper

(Refer to GROUP

8-Rear Wiper.)Liftgate trim (Refer to P.23-86.)

High mounted stop light

(Refer to GROUP

8-Lighting System.)

4. Rear wiper grommet

+w l c5. Rear air spoiler assembly (center)12. Spoiler tape

Rear air spoiler assembly (side) removal steps6. Mast antenna

7. Mounting nut

8. Mounting insulator

l * l a9. Rear air spoiler assembly (side)

10. Air spoiler bracket assembly

Door air spoiler removal

,+ 1 1. Door air spoiler

NOTE(1) Reverse the removal procedures to reinstall.(2) l + : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.

Page 1120 of 1216

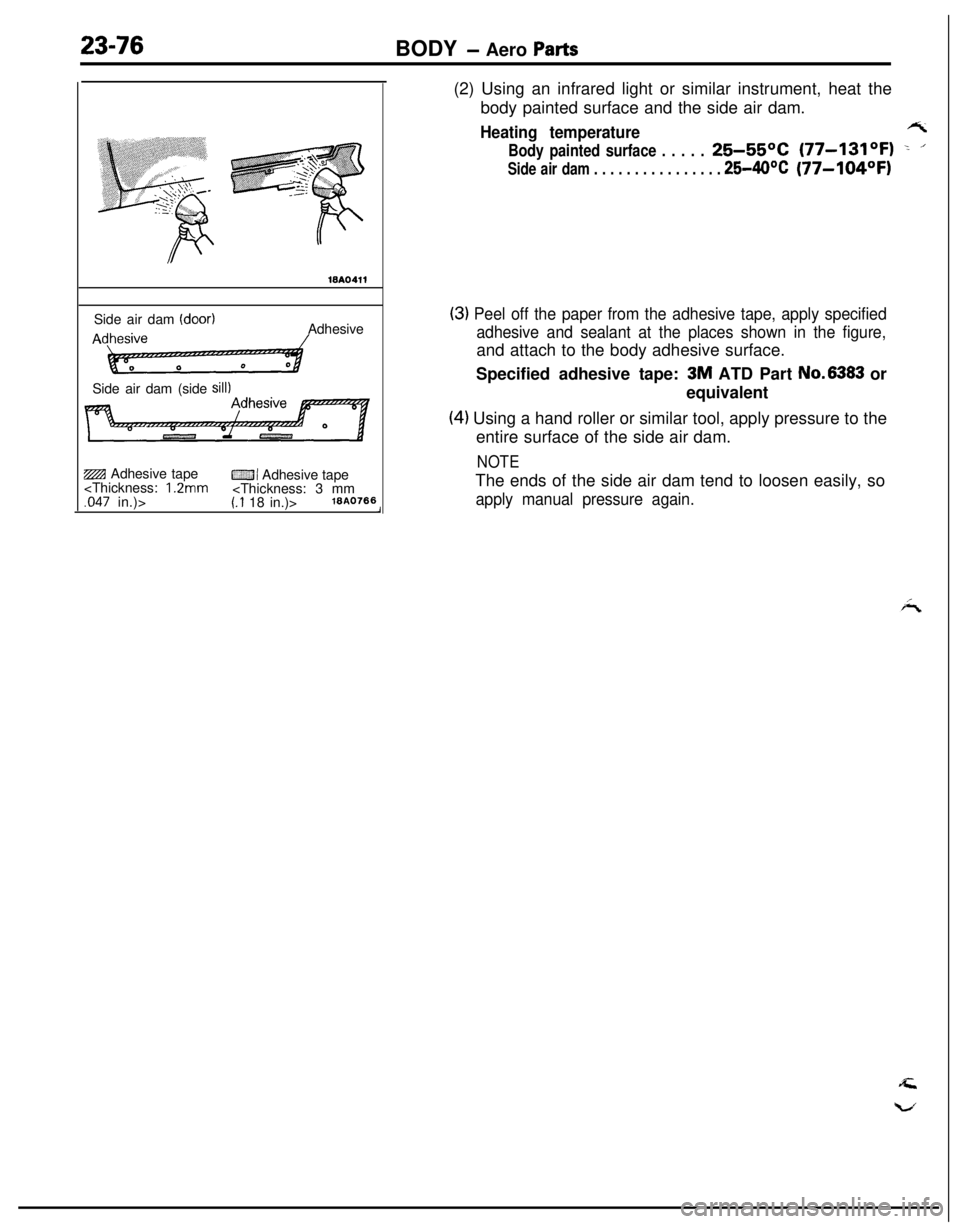

23-76BODY - Aero Parts

WA0411Side air dam

(door)AAdhesive

Side air dam (side

sill)ZBI Adhesive tape

CZJI Adhesive tape

body painted surface and the side air dam.

Heating temperaturert

Body painted surface . . . . .25-55OC (77-131OF) -. ’

Side air dam . . . . . . . . . . . . . . . . 25-40°C(77-104OFI

(3) Peel off the paper from the adhesive tape, apply specified

adhesive and sealant at the places shown in the figure,and attach to the body adhesive surface.

Specified adhesive tape:

3M ATD Part No.6383 or

equivalent

(4) Using a hand roller or similar tool, apply pressure to the

entire surface of the side air dam.

NOTEThe ends of the side air dam tend to loosen easily, so

apply manual pressure again.

Page 1125 of 1216

BODY - Instrument Panel23-81

SECT. A-A

Flat-tip

( - ) screwdriver19A0274

1910267

SERVICE POINTS OF REMOVAL

10. REMOVAL OF CENTER AIR OUTLET ASSEMBLY

Removing the paw1 of the center air outlet assembly with aflat-tip

( - 1 screwdriver,remove the center air outlet

assembly with the plastic trim tool.

16. REMOVAL OF SPEEDOMETER CABLE ADAPTER

(1) Disconnect the speedometer cable at the transaxle endof the cable.

(2) Pull the speedometer cable slightly toward the vehicle

interior, release the lock by turning the adapter to the leftor right, and then remove the adapter.

Page 1126 of 1216

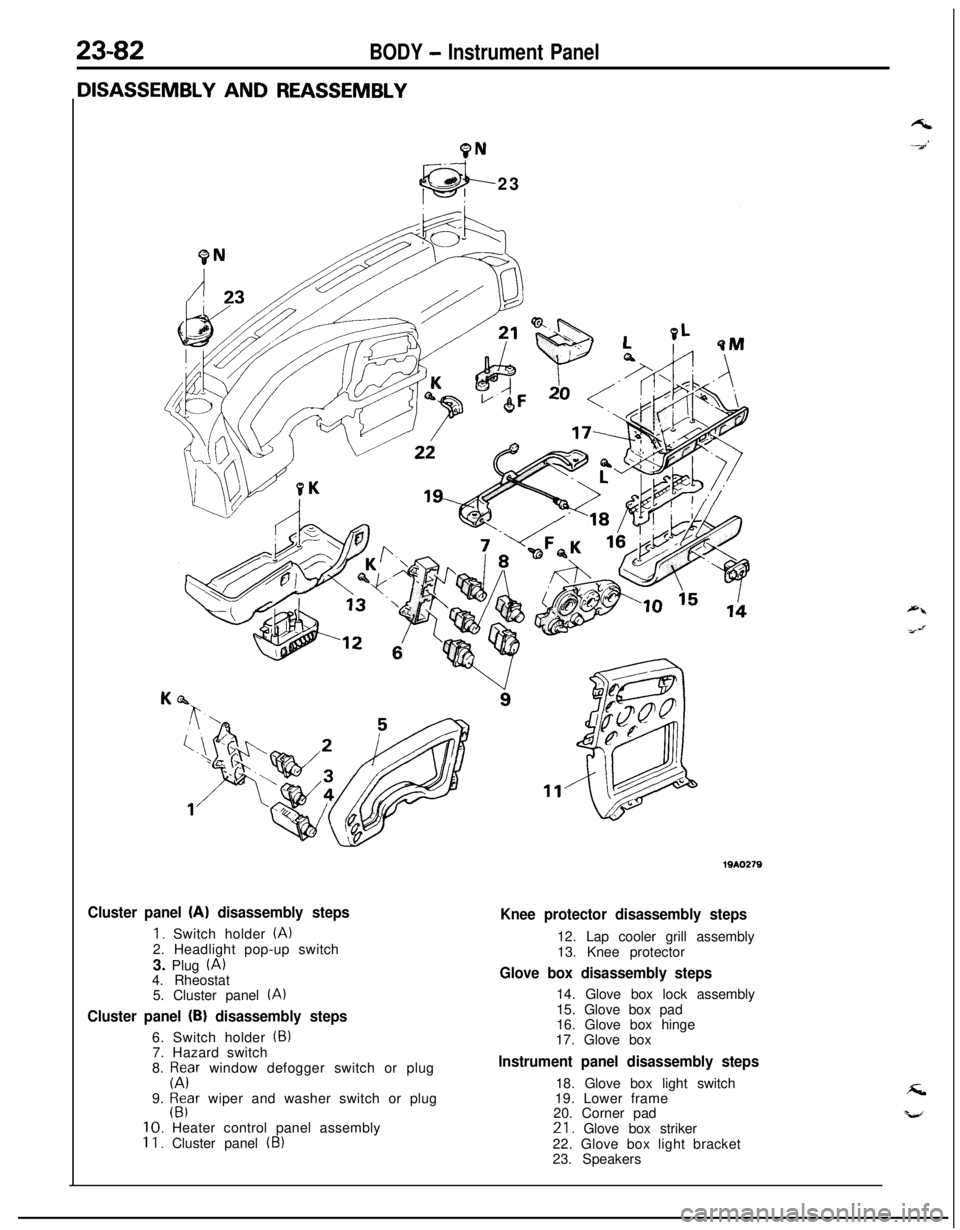

23-82BODY - Instrument Panel

9N23

Cluster panel (A) disassembly steps

1. Switch holder (A)2. Headlight pop-up switch

3. Plug

(A)4. Rheostat

5. Cluster panel

(A)

Cluster panel (B) disassembly steps6. Switch holder

(5)7. Hazard switch

8.

p;Fr window defogger switch or plug

9.

$far wiper and washer switch or plug10. Heater control panel assembly

II. Cluster panel (B)

Knee protector disassembly steps12. Lap cooler grill assembly

13. Knee protector

Glove box disassembly steps14. Glove box lock assembly

15. Glove box pad

16. Glove box hinge

17. Glove box

Instrument panel disassembly steps18. Glove box light switch

19. Lower frame

20. Corner pad21. Glove box striker

22. Glove box light bracket

23. Speakers

Page 1128 of 1216

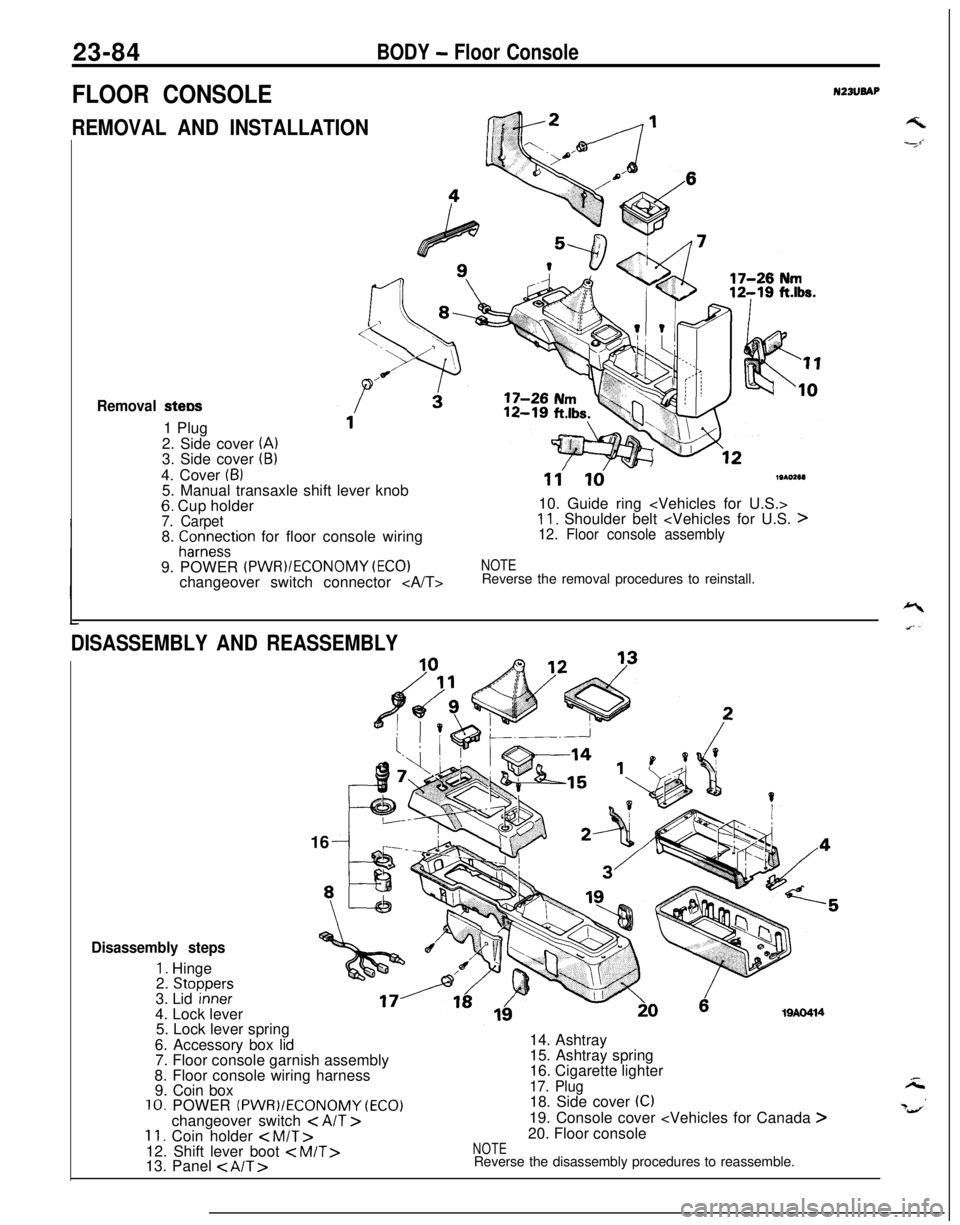

23-84BODY - Floor Console

FLOOR CONSOLEN23lJBAP

REMOVAL AND INSTALLATIONGk2 /---I

Removal stew1 Plug

2. Side cover

(A)3. Side cover (B)4. Cover

(6)5. Manual transaxle shift lever knob

6. Cup holder7. Carpet8. fCor;e~tion for floor console wiring

9. POWER

(PWR)/ECONOMY (EC01changeover switch connector

11'ld19102e1)10. Guide ring

11. Shoulder belt

NOTEReverse the removal procedures to reinstall.

DISASSEMBLY AND REASSEMBLY16

19AO414

Disassembly steps

1. Hinge

2. Stoooers3. Lid ‘inneF4. Lock lever

5. Lock lever spring

6. Accessory box lid

7. Floor console garnish assembly

8. Floor console wiring harness

9. Coin box

10. POWER (PWR)/ECONOMY (ECO)changeover switch < AIT >11. Coin holder < M/T>12. Shift lever boot

15. Ashtray spring

16. Cigarette lighter

17. Plug18. Side cover (C)19. Console cover

NOTEReverse the disassembly procedures to reassemble.

Page 1130 of 1216

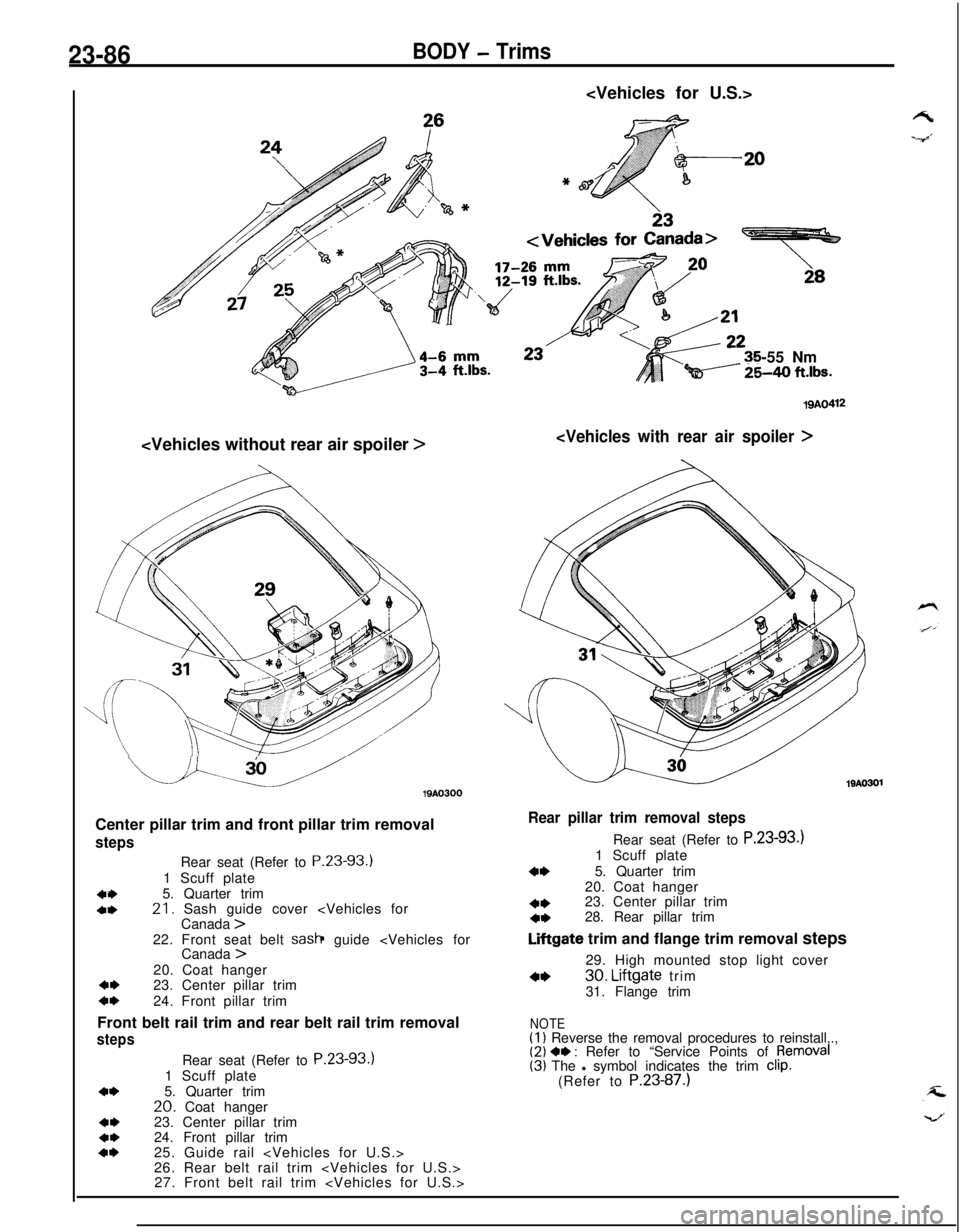

23-86BODY - Trims

-55 Nm

Qi----- %40 ft.lbs.

u.u19AO300

Center pillar trim and front pillar trim removal

steps

404,Rear seat (Refer to P.23-93.)

1 Scuff plate

5. Quarter trim21. Sash guide cover

4,23. Center pillar trimc*24. Front pillar trim

Front belt rail trim and rear belt rail trim removal

steps

4*

4,4*4*Rear seat (Refer to P.23-93.)

1 Scuff plate

5. Quarter trim

20. Coat hanger

23. Center pillar trim

24. Front pillar trim

25. Guide rail

26. Rear belt rail trim

27. Front belt rail trim

19AO412

19AO301

Rear pillar trim removal stepsRear seat (Refer to P.23-93.)

1 Scuff plate

4*5. Quarter trim

20. Coat hanger

4*23. Center pillar trim4*28. Rear pillar trim

Liftgate trim and flange trim removal steps

29. High mounted stop light cover

4*30. Liftgate trim

31. Flange trim

NOTE(1) Reverse the removal procedures to reinstall,.,(2) 4, : Refer to “Service Points of pemoval(3) The l symbol indicates the trim clip.(Refer to P.23-87.)