light MITSUBISHI ECLIPSE 1991 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 623 of 1216

REAR SUSPENSION

Inut

-

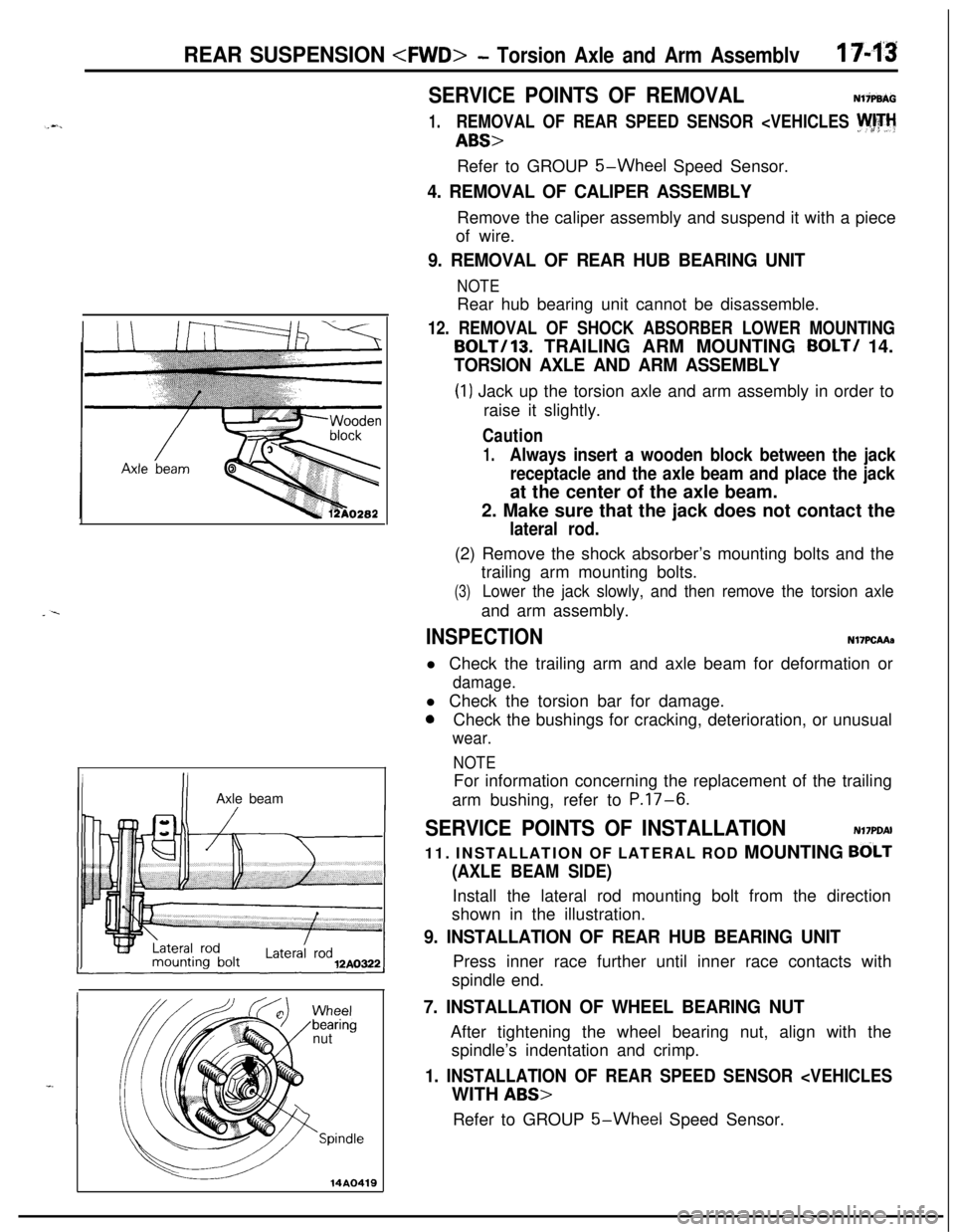

-Spindle

14AO419

SERVICE POINTS OF REMOVALNliP9AG

1.REMOVAL OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

4. REMOVAL OF CALIPER ASSEMBLYRemove the caliper assembly and suspend it with a piece

of wire.

9. REMOVAL OF REAR HUB BEARING UNIT

NOTERear hub bearing unit cannot be disassemble.

12. REMOVAL OF SHOCK ABSORBER LOWER MOUNTING

BOLT/lB. TRAILING ARM MOUNTING BOLT/ 14.

TORSION AXLE AND ARM ASSEMBLY

(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackat the center of the axle beam.

2. Make sure that the jack does not contact the

lateral rod.(2) Remove the shock absorber’s mounting bolts and the

trailing arm mounting bolts.

(3)Lower the jack slowly, and then remove the torsion axleand arm assembly.

INSPECTIONN17PCAAa

l Check the trailing arm and axle beam for deformation or

damage.l Check the torsion bar for damage.

0Check the bushings for cracking, deterioration, or unusual

wear.

NOTEFor information concerning the replacement of the trailing

arm bushing, refer to

P.17-6.

SERVICE POINTS OF INSTALLATIONN17PDAI

11. INSTALLATION OF LATERAL ROD MOUNTING

BdLT

(AXLE BEAM SIDE)Install the lateral rod mounting bolt from the direction

shown in the illustration.

9. INSTALLATION OF REAR HUB BEARING UNITPress inner race further until inner race contacts with

spindle end.

7. INSTALLATION OF WHEEL BEARING NUTAfter tightening the wheel bearing nut, align with the

spindle’s indentation and crimp.

1. INSTALLATION OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

Page 633 of 1216

REAR SUSPENSION

14AO520

12AOlOQ

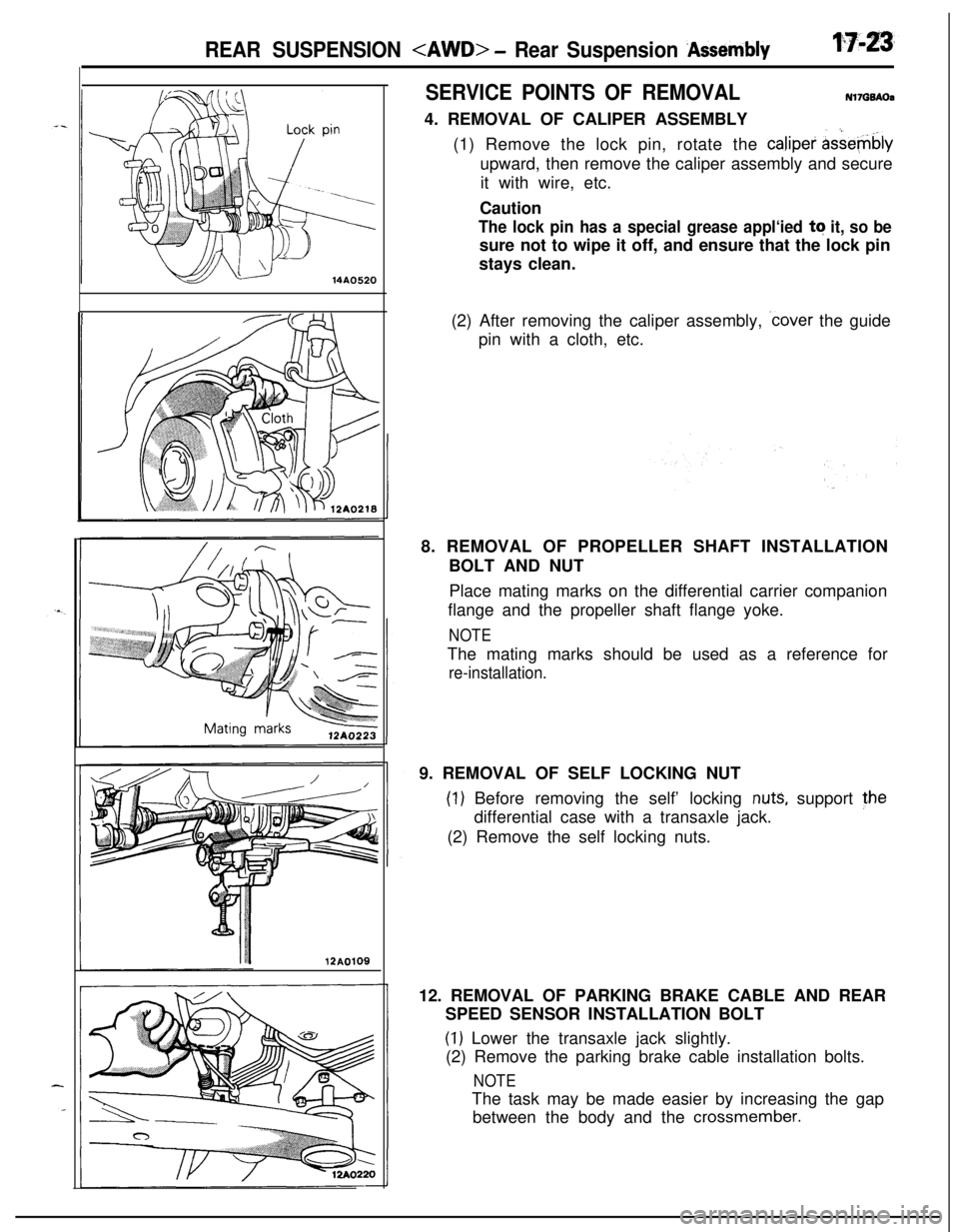

SERVICE POINTS OF REMOVALN17GQAOa4. REMOVAL OF CALIPER ASSEMBLY

(1) Remove the lock pin, rotate the calipei

&&e-@blyupward, then remove the caliper assembly and secure

it with wire, etc.

Caution

The lock pin has a special grease appl‘ied tq it, so besure not to wipe it off, and ensure that the lock pin

stays clean.

(2) After removing the caliper assembly,

.cover the guide

pin with a cloth, etc.

8. REMOVAL OF PROPELLER SHAFT INSTALLATION

BOLT AND NUT

Place mating marks on the differential carrier companion

flange and the propeller shaft flange yoke.

NOTEThe mating marks should be used as a reference for

re-installation.9. REMOVAL OF SELF LOCKING NUT

(1) Before removing the self’ locking nuts, support the

differential case with a transaxle jack.

(2) Remove the self locking nuts.

12. REMOVAL OF PARKING BRAKE CABLE AND REAR

SPEED SENSOR INSTALLATION BOLT

(1) Lower the transaxle jack slightly.

(2) Remove the parking brake cable installation bolts.

NOTEThe task may be made easier by increasing the gap

between the body and the

crossmember.

Page 646 of 1216

17-36REAR SUSPENSION

/12AOllO

\.1210111

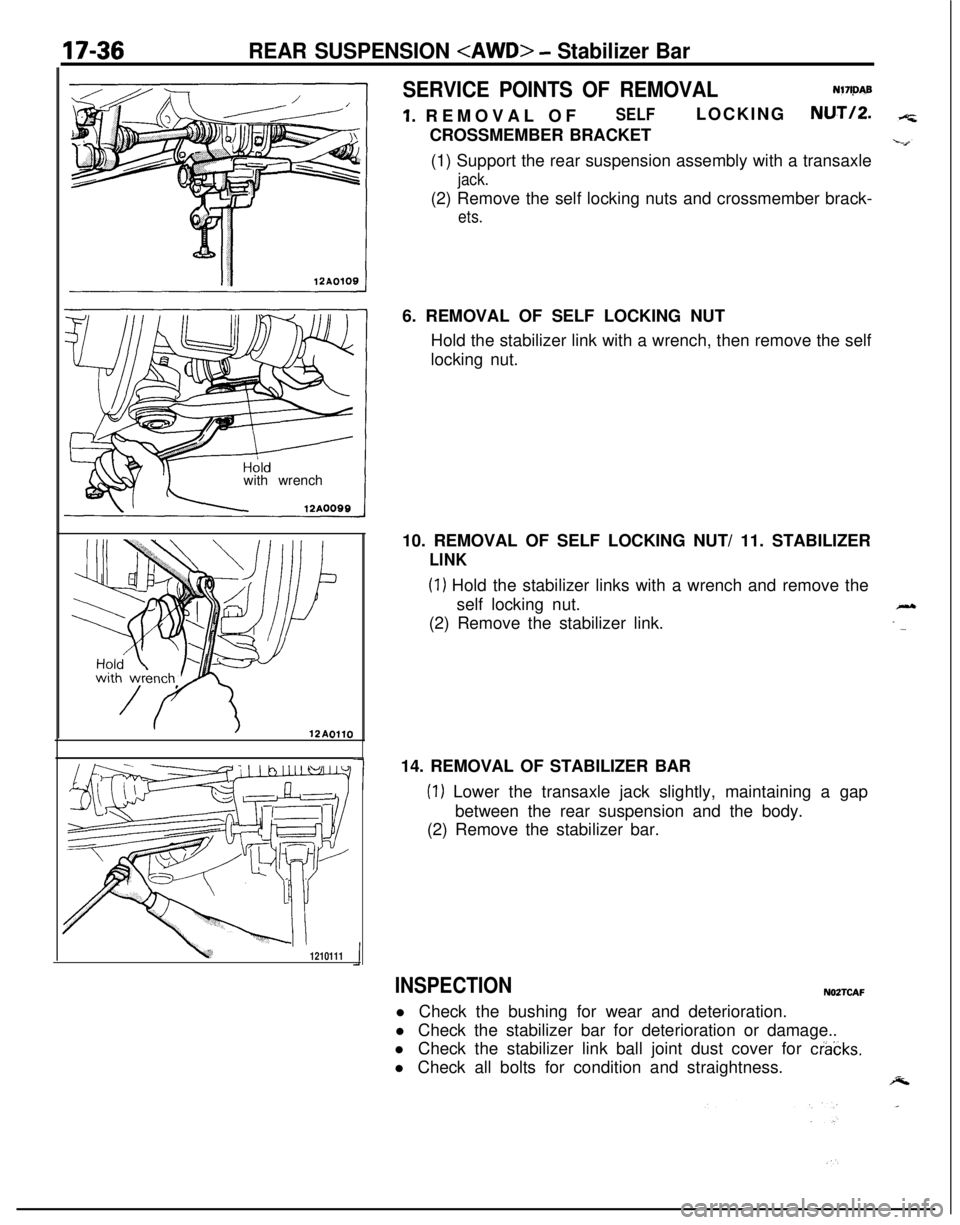

SERVICE POINTS OF REMOVALNl7ljMB

1. REMOVAL OFSELFLOCKINGNUT/P.CROSSMEMBER BRACKET

(1) Support the rear suspension assembly with a transaxle

jack.(2) Remove the self locking nuts and crossmember brack-

ets.6. REMOVAL OF SELF LOCKING NUT

Hold the stabilizer link with a wrench, then remove the self

locking nut.

10. REMOVAL OF SELF LOCKING NUT/ 11. STABILIZER

LINK

(1) Hold the stabilizer links with a wrench and remove the

self locking nut.

(2) Remove the stabilizer link.

14. REMOVAL OF STABILIZER BAR

(1) Lower the transaxle jack slightly, maintaining a gap

between the rear suspension and the body.

(2) Remove the stabilizer bar.7

INSPECTIONNOZTCAFl Check the bushing for wear and deterioration.

l Check the stabilizer bar for deterioration or damage..

l Check the stabilizer link ball joint dust cover for

cracks.l Check all bolts for condition and straightness.

Page 655 of 1216

STEERING - Special Tools/Service Adjustment Procedures

ToolNumberName1 UseI

MB991213Rack installer ’Rack installation:,.I/ ._i’, ‘,‘#

MB991317Seal ring installerCompression of the seal rings afterreplacement of the pinion seal rings13A0282

,

SERVICE ADJUSTMENT PROCEDURiS

< MANUAL STEERING >

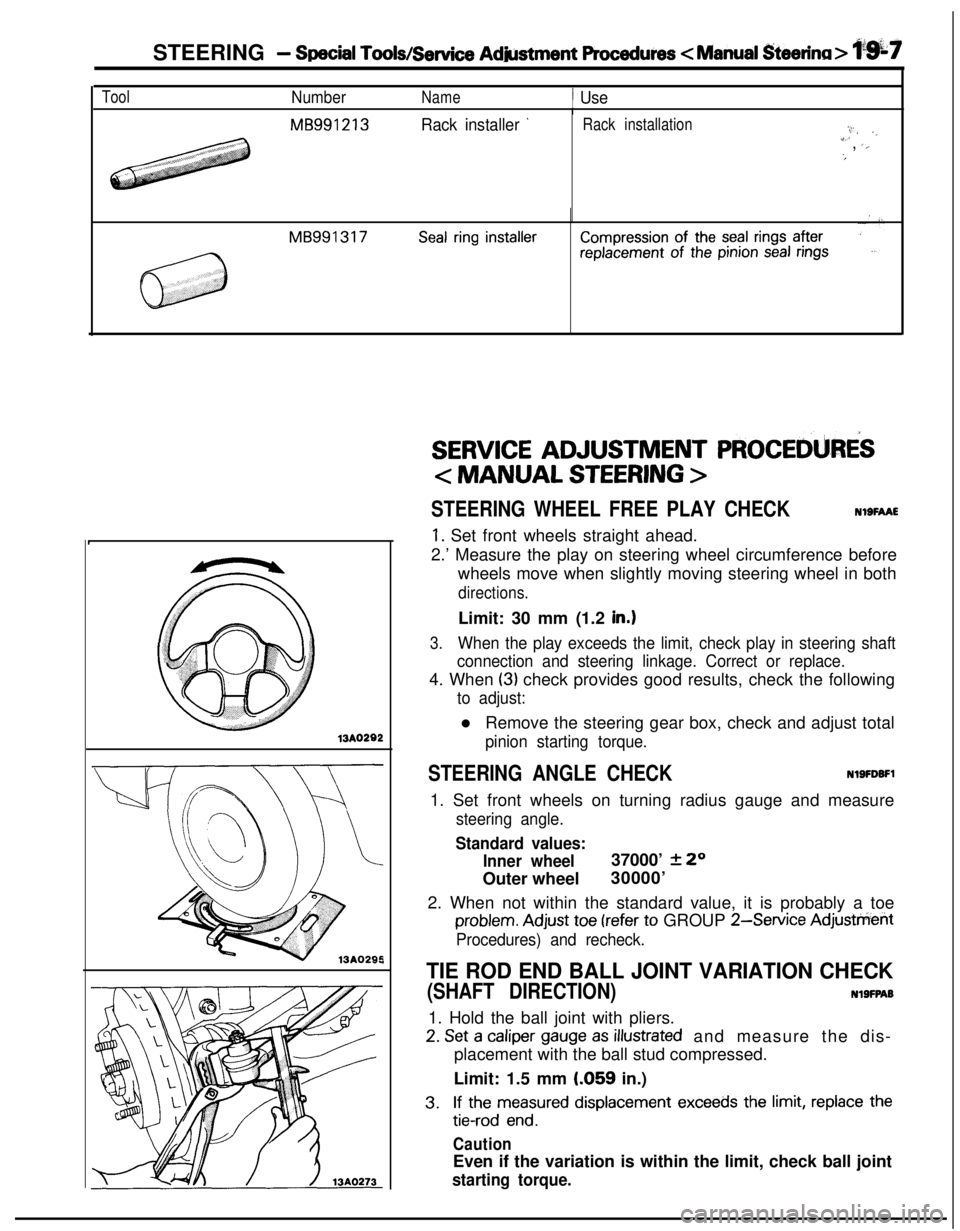

STEERING WHEEL FREE PLAY CHECKNOSFAAE

1. Set front wheels straight ahead.

2.’ Measure the play on steering wheel circumference before

wheels move when slightly moving steering wheel in both

directions.Limit: 30 mm (1.2

in.1

3.When the play exceeds the limit, check play in steering shaft

connection and steering linkage. Correct or replace.4. When

(3) check provides good results, check the following

to adjust:l Remove the steering gear box, check and adjust total

pinion starting torque.

STEERING ANGLE CHECKNlSFDBFl1. Set front wheels on turning radius gauge and measure

steering angle.

Standard values:

Inner wheel37000’

2 20

Outer wheel30000’

2. When not within the standard value, it is probably a toe

problem. Adjust toe (refer to GROUP 2-Service Adjusttierit

Procedures) and recheck.

TIE ROD END BALL JOINT VARIATION CHECK

(SHAFT DIRECTION)NlSFPAB1. Hold the ball joint with pliers.

2. Set a caliper gauge as illustrated and measure the dis-

placement with the ball stud compressed.

Limit: 1.5 mm

LO59 in.)

3.If the measured displacement exceeds the limit, replace the

tie-rod end.

CautionEven if the variation is within the limit, check ball joint

starting torque.

Page 658 of 1216

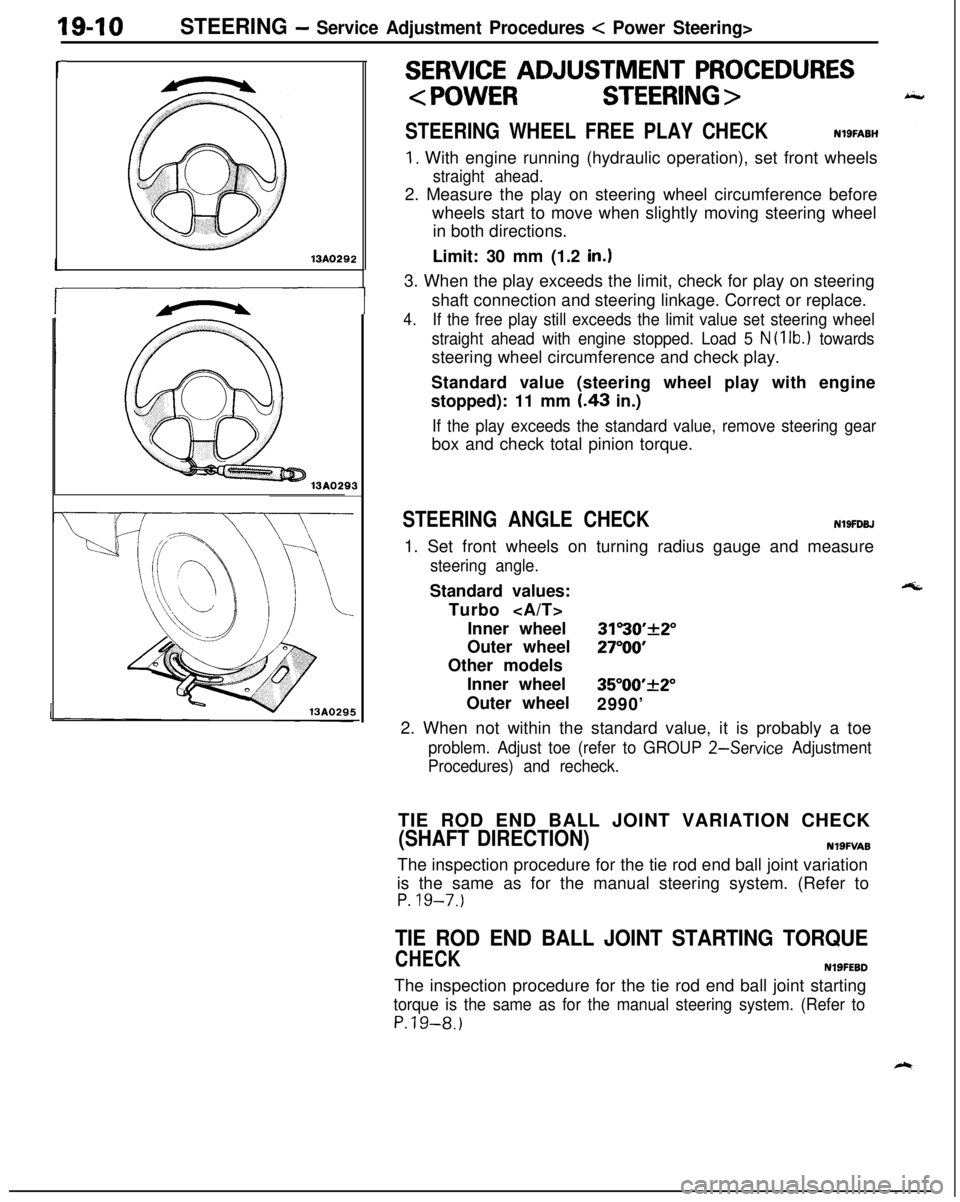

19-10STEERING - Service Adjustment Procedures c Power Steering>

r13A029213A0293

r

1

i

SERVICE ADJUSTMENT PROCEDURES

STEERING WHEEL FREE PLAY CHECKNlSFABH

1. With engine running (hydraulic operation), set front wheels

straight ahead.2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm (1.2

in.13. When the play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4.If the free play still exceeds the limit value set steering wheel

straight ahead with engine stopped. Load 5

N (1 lb.1 towardssteering wheel circumference and check play.

Standard value (steering wheel play with engine

stopped): 11 mm

I.43 in.)

If the play exceeds the standard value, remove steering gearbox and check total pinion torque.

STEERING ANGLE CHECKN19FDBJ1. Set front wheels on turning radius gauge and measure

steering angle.Standard values:

Turbo

Inner wheel

31”30’+2”Outer wheel

27”OOOther models

Inner wheel

35”00’_+2”Outer wheel

2990’

2. When not within the standard value, it is probably a toe

problem. Adjust toe (refer to GROUP 2-Service Adjustment

Procedures) and recheck.TIE ROD END BALL JOINT VARIATION CHECK

(SHAFT DIRECTION)N19FVA8The inspection procedure for the tie rod end ball joint variation

is the same as for the manual steering system. (Refer to

P. 19-7.)

TIE ROD END BALL JOINT STARTING TORQUE

CHECKNlSFEBDThe inspection procedure for the tie rod end ball joint starting

torque is the same as for the manual steering system. (Refer to

P.19-8.)

Page 690 of 1216

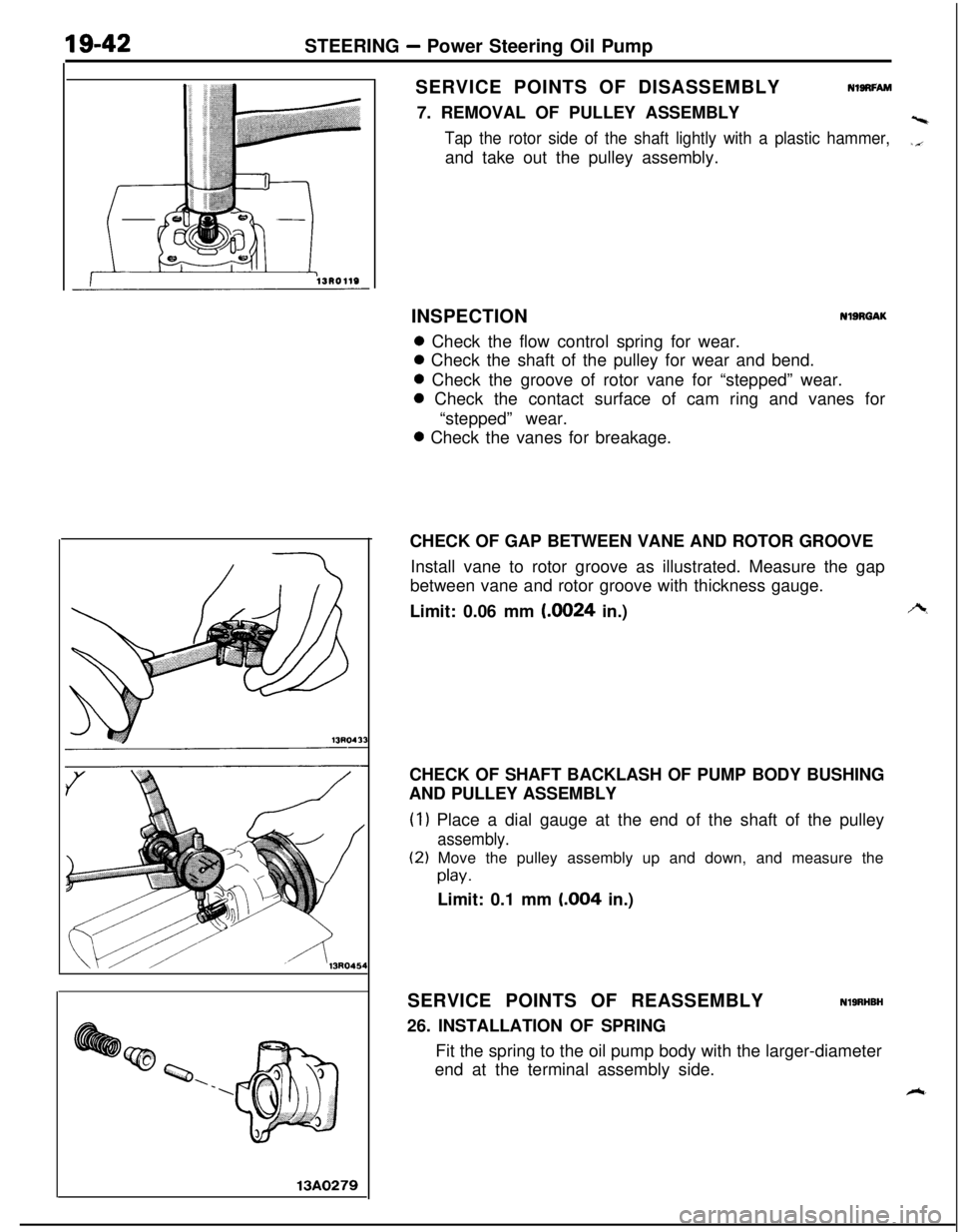

19-42STEERING - Power Steering Oil Pump

13A0279SERVICE POINTS OF DISASSEMBLY

NleRFAM7. REMOVAL OF PULLEY ASSEMBLY

%

Tap the rotor side of the shaft lightly with a plastic hammer,,,~and take out the pulley assembly.

INSPECTION

NlSRGAK0 Check the flow control spring for wear.0 Check the shaft of the pulley for wear and bend.0 Check the groove of rotor vane for “stepped” wear.0 Check the contact surface of cam ring and vanes for

“stepped” wear.0 Check the vanes for breakage.

CHECK OF GAP BETWEEN VANE AND ROTOR GROOVE

Install vane to rotor groove as illustrated. Measure the gap

between vane and rotor groove with thickness gauge.

Limit: 0.06 mm

(.0024 in.)?ACHECK OF SHAFT BACKLASH OF PUMP BODY BUSHING

AND PULLEY ASSEMBLY

(1) Place a dial gauge at the end of the shaft of the pulley

assembly.

(2) Move the pulley assembly up and down, and measure theplay.

Limit: 0.1 mm

I.004 in.)

SERVICE POINTS OF REASSEMBLY

NlSRHBH26. INSTALLATION OF SPRING

Fit the spring to the oil pump body with the larger-diameter

end at the terminal assembly side.

A.

Page 695 of 1216

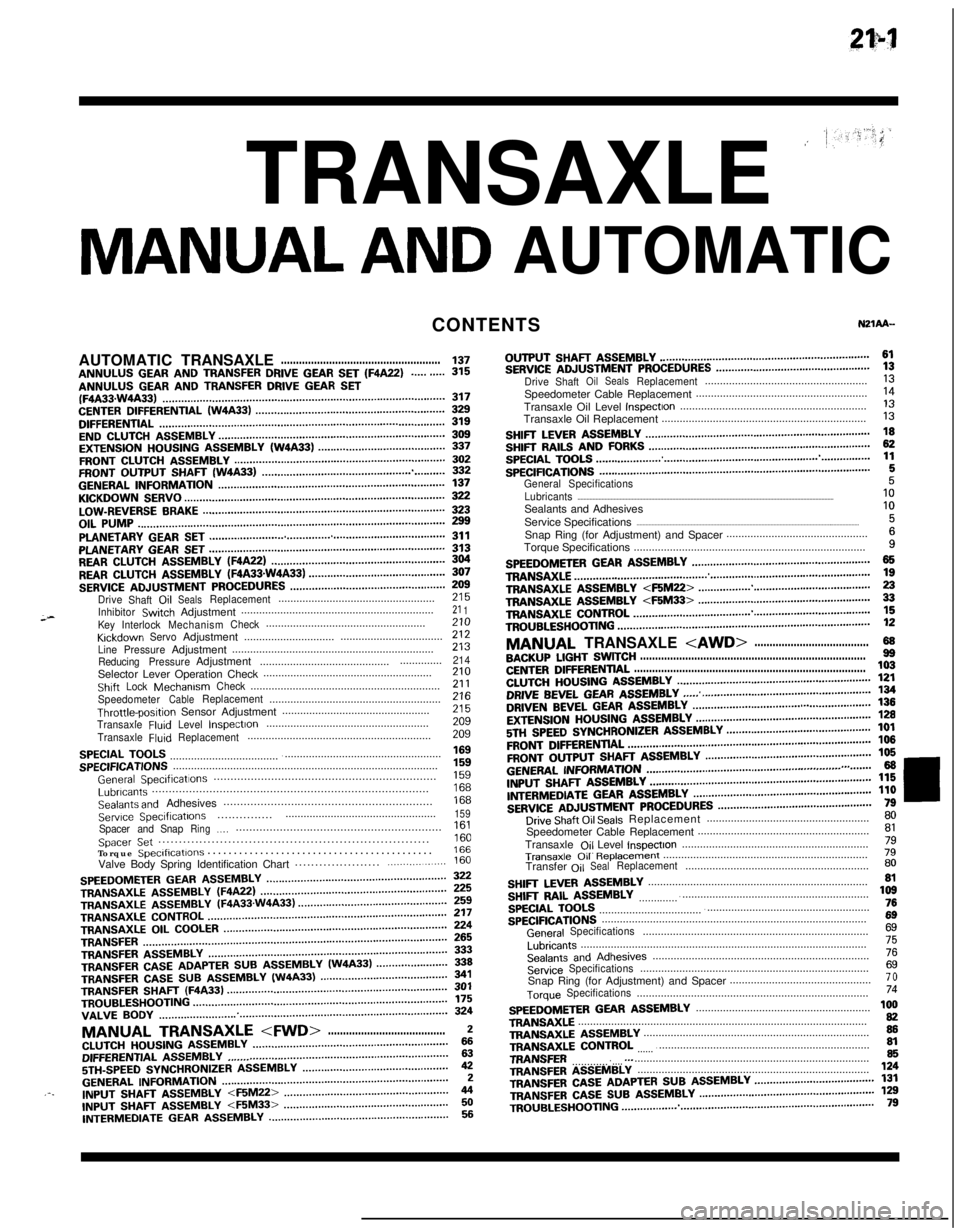

TRANSAXLE ’

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;

Page 703 of 1216

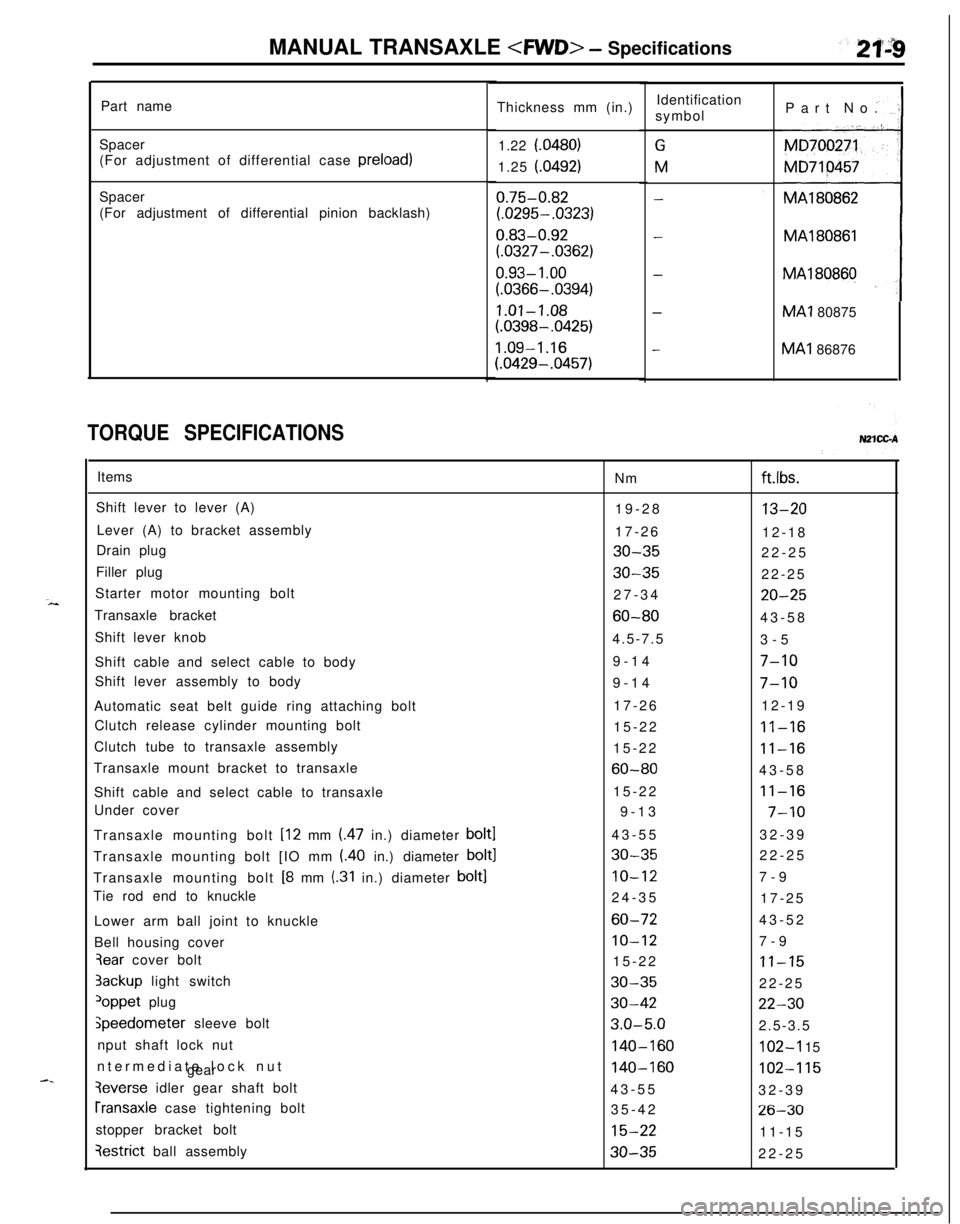

MANUAL TRANSAXLE

Part name

Spacer

(For adjustment of differential case preload)

Spacer

(For adjustment of differential pinion backlash)

TORQUE SPECIFICATIONSThickness mm (in.)

1.22 f.0480)

1.25 (.0492)

0.75-0.82

(.0295-.0323)

0.83-0.92

(.0327-.0362)

0.93- 1 .oo

(.0366-.0394)

1.01-1.08

(.0398-.0425)

1.09-1.16

(.0429-.0457)Identification

symbol

GM

-

-

-

-Part No.

MA180862MA1

80866MA1 80875MA1 86876

Items

Nm

Shift lever to lever (A)

19-28

Lever (A) to bracket assembly

17-26

Drain plug

30-35Filler plug

30-35Starter motor mounting bolt

27-34

Transaxle bracket

60-80Shift lever knob

4.5-7.5

Shift cable and select cable to body9-14

Shift lever assembly to body

9-14

Automatic seat belt guide ring attaching bolt17-26

Clutch release cylinder mounting bolt

15-22

Clutch tube to transaxle assembly

15-22

Transaxle mount bracket to transaxle

60-80Shift cable and select cable to transaxle15-22

Under cover

9-13

Transaxle mounting bolt [12 mm (.47 in.) diameter

bolt143-55

Transaxle mounting bolt [IO mm (.40 in.) diameter

bolt130-35Transaxle mounting bolt

[8 mm (.31 in.) diameter bolt]IO-12Tie rod end to knuckle

24-35

Lower arm ball joint to knuckle

60-72Bell housing cover

IO-123ear cover bolt

15-223ackup light switch

30-35

loppet plug30-42

jpeedometer sleeve bolt3.0-5.0nput shaft lock nut

140-160ntermediate lock nut

gear

140-160

3everse idler gear shaft bolt

43-55

rransaxle case tightening bolt

35-42

stopper bracket bolt

15-22

qestrict ball assembly30-35

ft.lbs.

13-2012-18

22-25

22-25

20-2543-58

3-5

7-10

7-1012-19

11-16

11-1643-58

11-16

7-1032-39

22-25

7-9

17-25

43-52

7-9

11-1522-25

22-302.5-3.5

102-I 15

102-11532-39

26-3011-15

22-25

Page 713 of 1216

MANUAL TRANSAXLE

TRANSAXLE

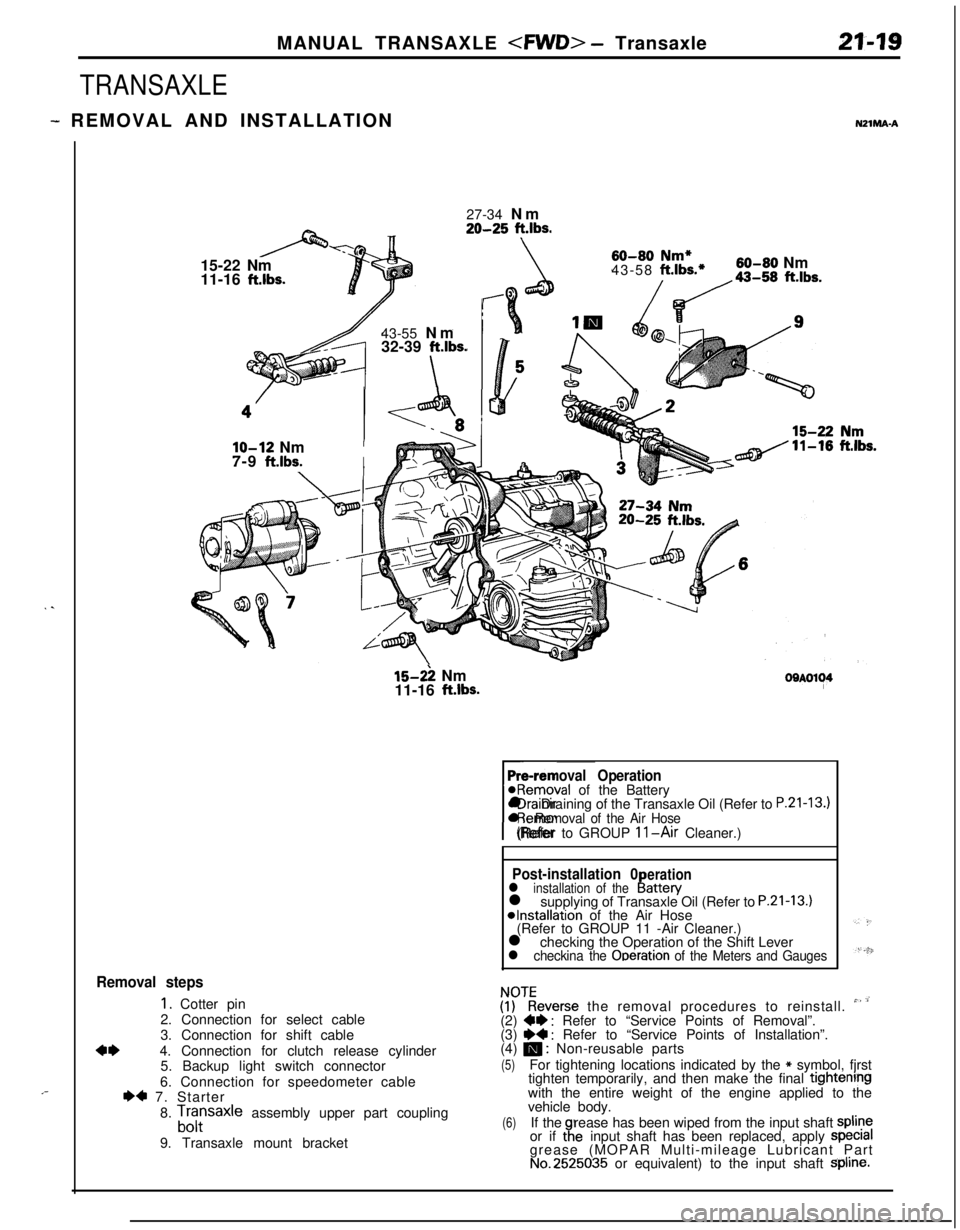

- REMOVAL AND INSTALLATIONNZlMA-A

. .

,-27-34 Nm

20-25 ft.lbs.15-22 Nm

11-16

ft.lbs.43-55 Nm

32-39

ft.lbs.

\

60-80 Nm*43-58 ft.lbs.*60-80 Nm

/da-,, ft.lbs.

lo-12 NmI7-9

ft.lbs.I

15-2: Nm

11-16 ft.lbs.OOAOl~4

Pre-removal Operation@Removal of the Battery

rl Draining of the Transaxle Oil (Refer to

P.21-13.)l Removal of the Air Hose(Refer to GROUP 11-Air Cleaner.)

Post-installation 0erationl installation of theI!attery

l supplying of Transaxle Oil (Refer to P.21-13.)*Installation of the Air Hose

(Refer to GROUP 11 -Air Cleaner.)

l checking the Operation of the Shift Lever

l checkina the Ooeration of the Meters and Gauges

Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

4*4. Connection for clutch release cylinder

5. Backup light switch connector

6. Connection for speedometer cable

I)* 7. Starter

8.

Lfrsaxle assembly upper part coupling

9. Transaxle mount bracket

ZKeverse the removal procedures to reinstall. ” ’(2) W : Refer to “Service Points of Removal”.

(3) ~~ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

(5)For tightening locations indicated by the * symbol, fjrst

tighten temporarily, and then make the final tightenrngwith the entire weight of the engine applied to the

vehicle body.

(6)If therease has been wiped from the input shaft spline

or if taeinput shaft has been replaced, apply specralgrease (MOPAR Multi-mileage Lubricant Part

No.2525035 or equivalent) to the input shaft Spline.

Page 717 of 1216

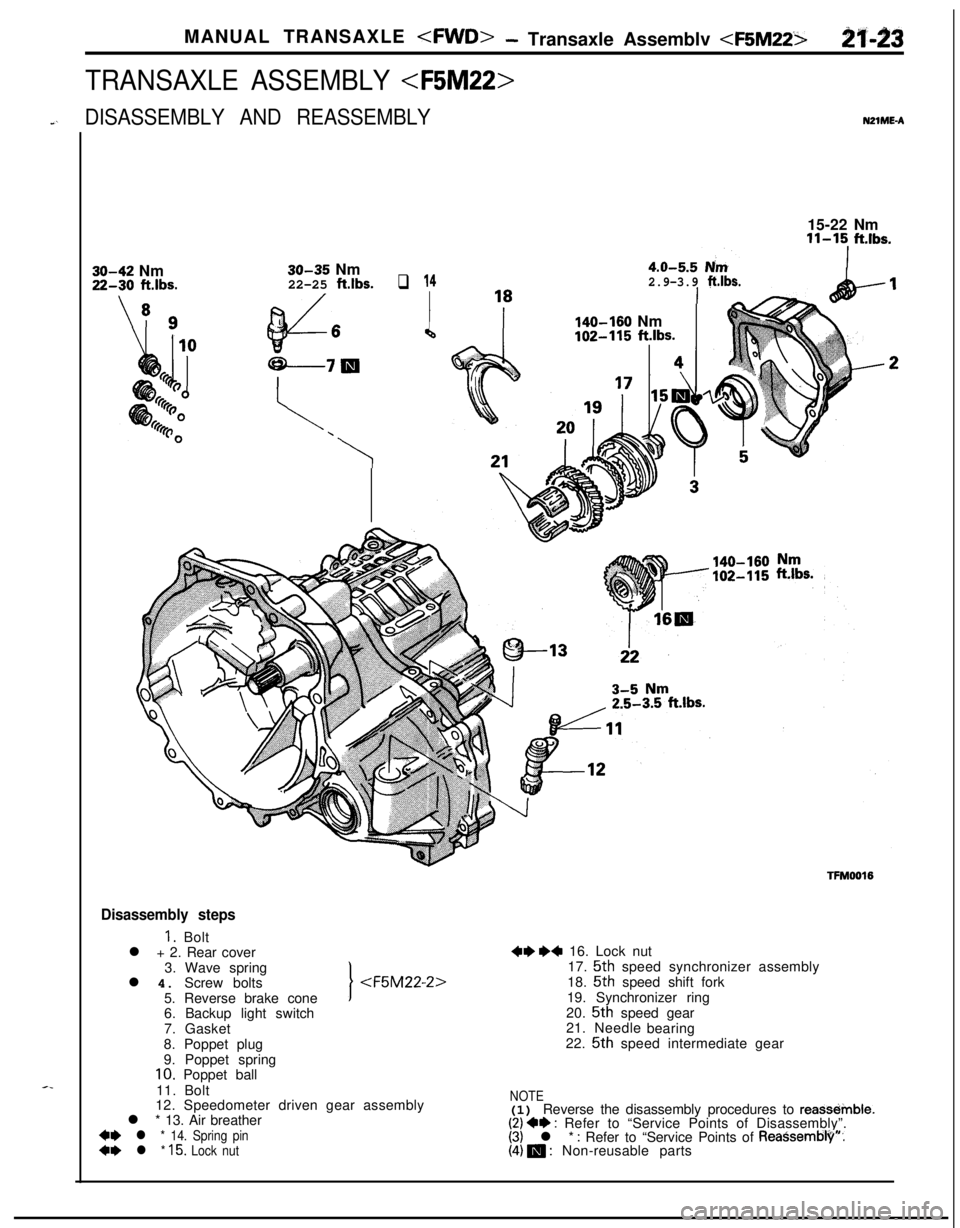

MANUAL TRANSAXLE

TRANSAXLE ASSEMBLY

.._DISASSEMBLY AND REASSEMBLYN21ME-A

__

30-42 Nm22-30 ft.lbs.30-35 Nm22-25 ftlbs.q l4

ig5 !

----7m

IQ15-22 Nm

II-15 ft.lbs.

4.0-5.5 Nm2.9-3.9 ft.lbs.1I”I

a

140-160 Nmf

102-115 ft.lbs.

Disassembly steps

1. Bolt

l + 2. Rear cover

3. Wave spring

l 4. Screw bolts

5. Reverse brake cone

6. Backup light switch

7. Gasket

9. Poppet spring

10. Poppet ball

11. Bolt

12. Speedometer driven gear assembly

l * 13. Air breather

*I) l * 14. Spring pin+I) l * 15. Lock nut

140-160102-115

TFMOOl6

+e I)+ 16. Lock nut

17. 5th speed synchronizer assembly

18. 5th speed shift fork

19. Synchronizer ring

20. 5th speed gear

21.Needle

bearing

22. 5th speed intermediate gear

NOTE(1) Reverse the disassembly procedures to reasseinble.

(2) ++ : Refer to “Service Points of Disassembly”.(3) l * : Refer to “Service Points of ReaSsembly”:(4) m : Non-reusable parts