lock MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 347 of 1216

ENGINE <1.8L Engine> -Front Case, Oil Pump and Silent Shaft9-63

aSocket wrench/

3EN271

MD998285R

Fasten toqether with

the timtins under cover

C

belt tensioner3ENOOWTiming marks

16. / 15. INSTALLATION OF OIL PUMP GEARS(1) Align the timing mark on the drive gear with that on

driven gear and install them into front case.

(2) Apply amplely engine oil to the gears.

3EN046

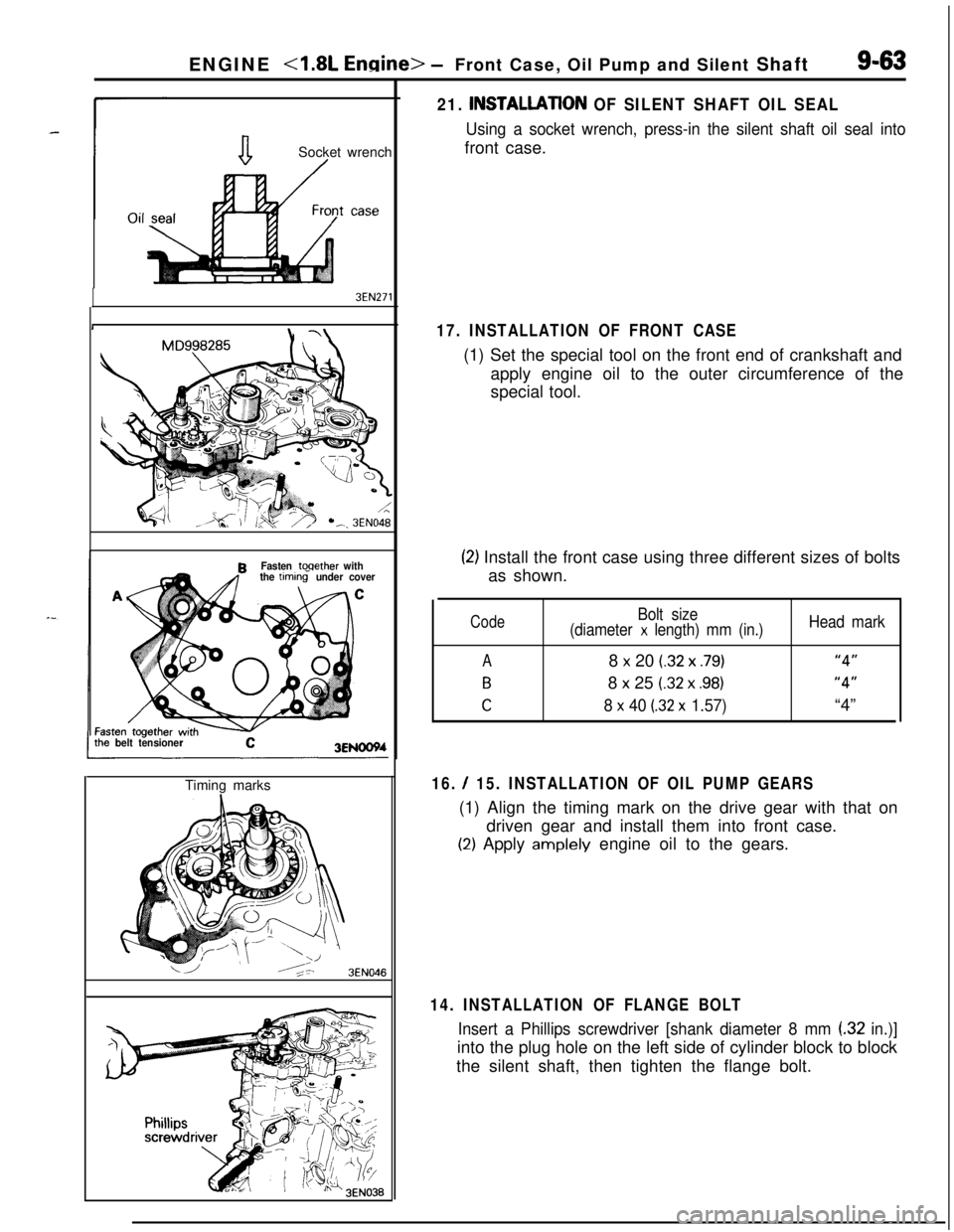

21. INSTALLATlON OF SILENT SHAFT OIL SEAL

Using a socket wrench, press-in the silent shaft oil seal intofront case.

17. INSTALLATION OF FRONT CASE(1) Set the special tool on the front end of crankshaft and

apply engine oil to the outer circumference of the

special tool.

(2) Install the front case using three different sizes of bolts

as shown.

Code

A

B

C

Bolt size

(diameter x length) mm (in.)8

x 20 (.32 x .79)8

x 25 (.32 x .98)

8 x 40 (32 x 1.57)

Head mark

“4”

“4”“4”

14. INSTALLATION OF FLANGE BOLT

Insert a Phillips screwdriver [shank diameter 8 mm (32 in.)]into the plug hole on the left side of cylinder block to block

the silent shaft, then tighten the flange bolt.

Page 348 of 1216

9-64ENGINE 4.8L Engine> -Front Case, Oil Pump and Silent Shaft

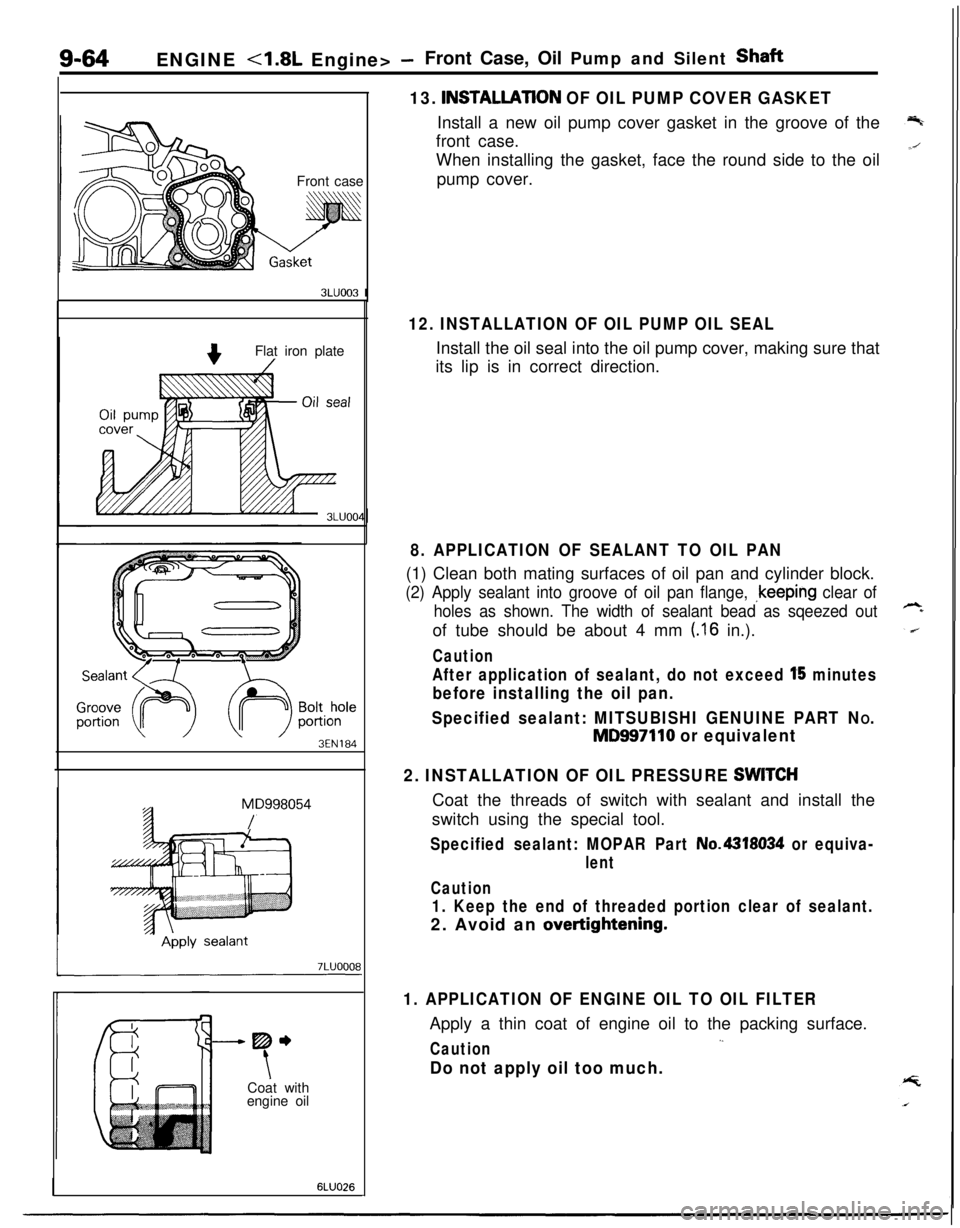

13.

INSTALLATlON OF OIL PUMP COVER GASKETInstall a new oil pump cover gasket in the groove of the

front case.

Front caseWhen installing the gasket, face the round side to the oil

pump cover.

3LUOO3 I

Flat iron plate

3EN184

MD998054

/

-----me

tCoat with

engine oil

6LUO26

12. INSTALLATION OF OIL PUMP OIL SEALInstall the oil seal into the oil pump cover, making sure that

its lip is in correct direction.

8. APPLICATION OF SEALANT TO OIL PAN(1) Clean both mating surfaces of oil pan and cylinder block.

(2) Apply sealant into groove of oil pan flange, ~keeping clear of

holes as shown. The width of sealant bead as sqeezed outof tube should be about 4 mm

(.I6 in.).

Caution

After application of sealant, do not exceed l’5 minutes

before installing the oil pan.

Specified sealant: MITSUBISHI GENUINE PART N

O.

MD997110 or equivalent

2. INSTALLATION OF OIL PRESSURE

SWlTCHCoat the threads of switch with sealant and install the

switch using the special tool.

Specified sealant: MOPAR Part No.4318034 or equiva-

lent

Caution

1. Keep the end of threaded portion clear of sealant.2. Avoid an

overtightening.

1. APPLICATION OF ENGINE OIL TO OIL FILTERApply a thin coat of engine oil to the packing surface.

,.Caution

Do not apply oil too much.

Page 352 of 1216

9-68ENGINE <1.8L Engine> - Piston and Connecting Rod

r-Size and maker marks

No. 1Barrel

faced

1

1 Size and maker marks

L

INo.2

ti2zza

Tapered

Barrelfaced

1 EN064

-1 No. 1 rina aarGap of

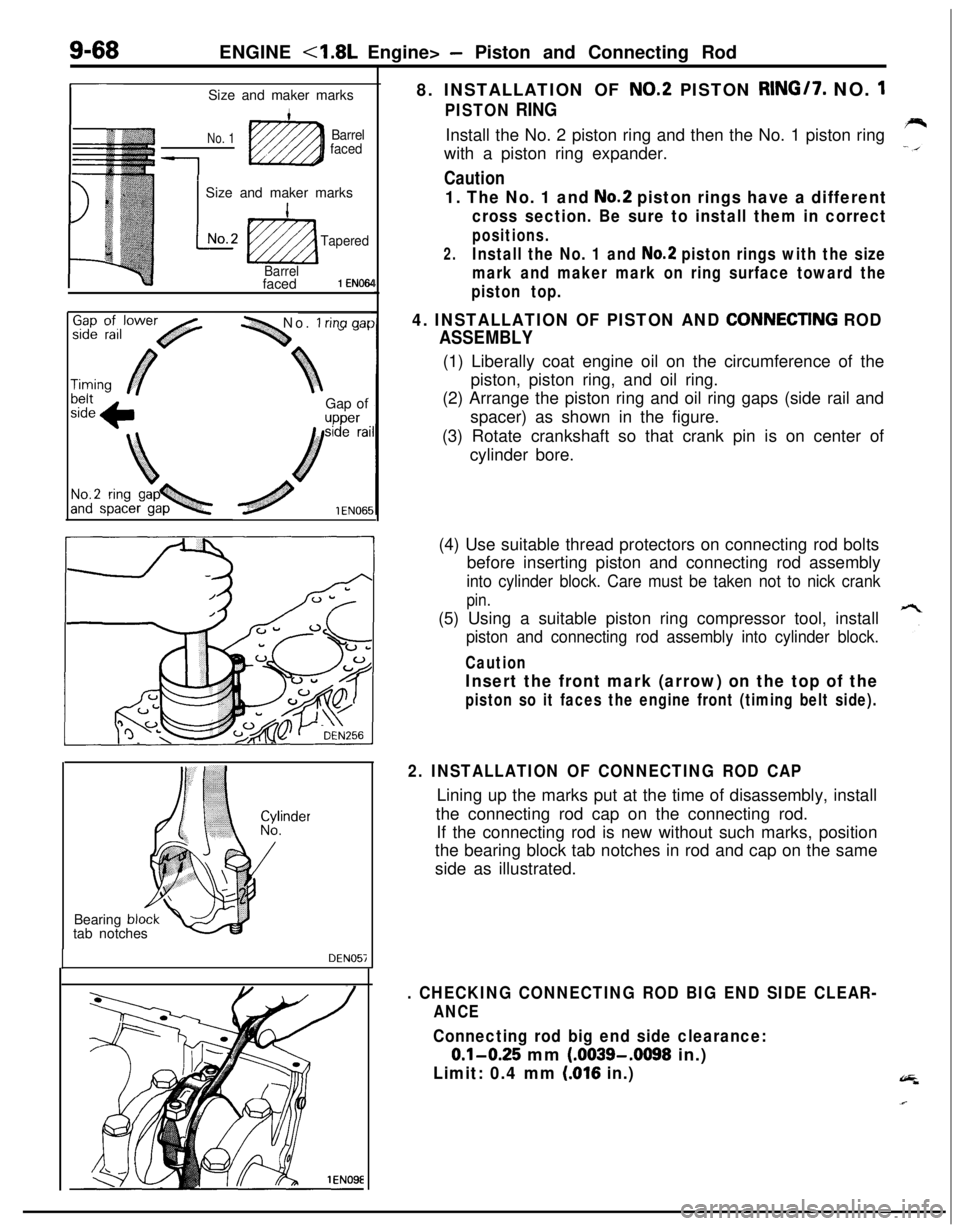

upper8. INSTALLATION OF

NO.2 PISTON RING/7. NO. 1

PISTON RINGInstall the No. 2 piston ring and then the No. 1 piston ring

with a piston ring expander.

Caution

1. The No. 1 and No.2 piston rings have a different

cross section. Be sure to install them in correct

positions.

2.Install the No. 1 and No.2 piston rings with the size

mark and maker mark on ring surface toward the

piston top.

4. INSTALLATION OF PISTON AND CONNECTlNG ROD

ASSEMBLY(1) Liberally coat engine oil on the circumference of the

piston, piston ring, and oil ring.

(2) Arrange the piston ring and oil ring gaps (side rail and

spacer) as shown in the figure.

(3) Rotate crankshaft so that crank pin is on center of

cylinder bore.

Bearing

bltab notches

DEN057(4) Use suitable thread protectors on connecting rod bolts

before inserting piston and connecting rod assembly

into cylinder block. Care must be taken not to nick crank

pin.(5) Using a suitable piston ring compressor tool, install

piston and connecting rod assembly into cylinder block.

Caution

Insert the front mark (arrow) on the top of the

piston so it faces the engine front (timing belt side).

2. INSTALLATION OF CONNECTING ROD CAPLining up the marks put at the time of disassembly, install

the connecting rod cap on the connecting rod.

If the connecting rod is new without such marks, position

the bearing block tab notches in rod and cap on the same

side as illustrated.

. CHECKING CONNECTING ROD BIG END SIDE CLEAR-

ANCE

Connecting rod big end side clearance:

0.1-0.25 mm (.0039-.0098 in.)

Limit: 0.4 mm (016 in.)

Page 355 of 1216

ENGINE - Crankshaft, Flwvheel and Drive Plate9-71

3EN30’lrrow mark toward

cap No,

I

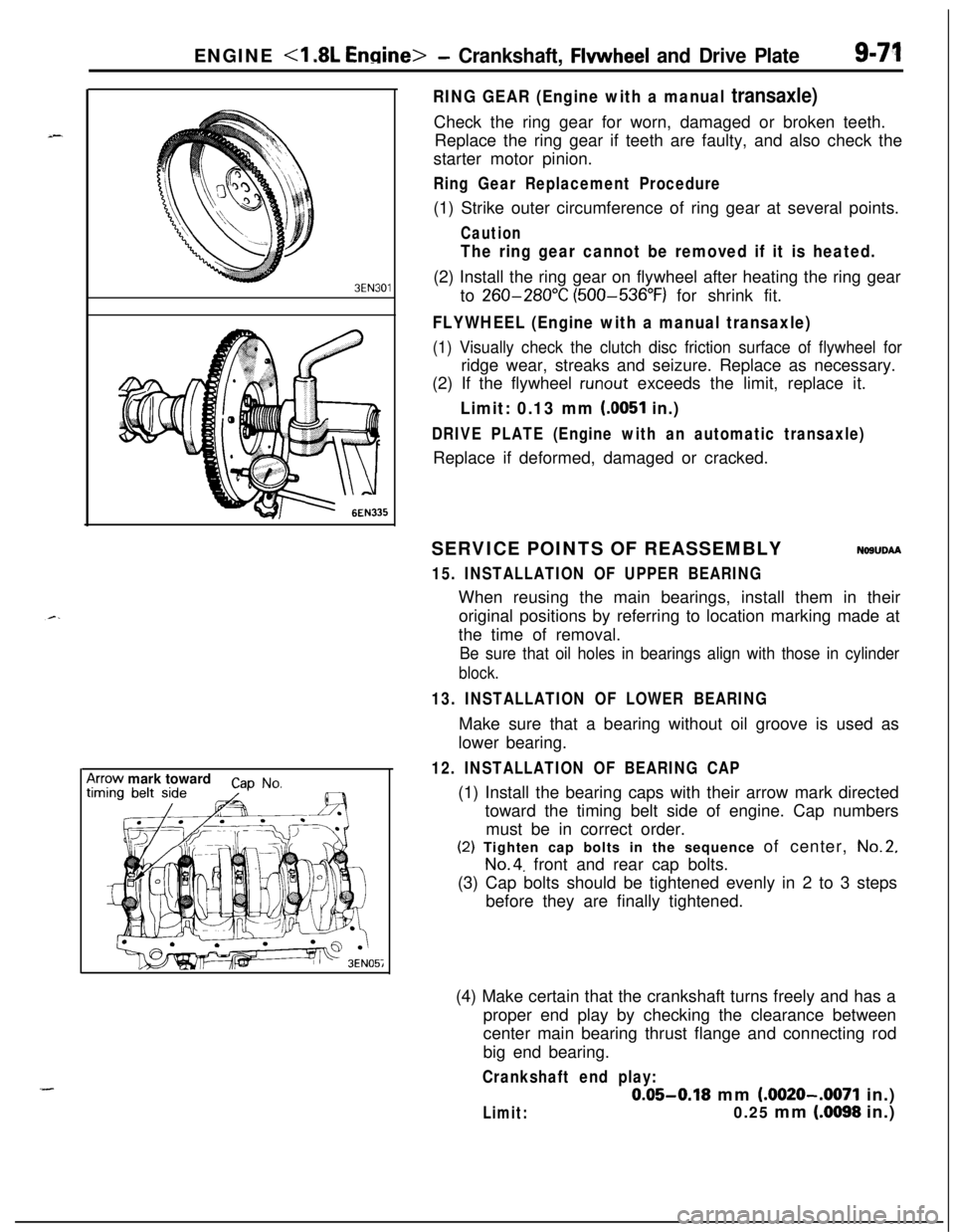

RING GEAR (Engine with a manual transaxle)Check the ring gear for worn, damaged or broken teeth.

Replace the ring gear if teeth are faulty, and also check the

starter motor pinion.

Ring Gear Replacement Procedure(1) Strike outer circumference of ring gear at several points.

Caution

The ring gear cannot be removed if it is heated.(2) Install the ring gear on flywheel after heating the ring gear

to

260-280°C (500-536°F) for shrink fit.

FLYWHEEL (Engine with a manual transaxle)

(1) Visually check the clutch disc friction surface of flywheel forridge wear, streaks and seizure. Replace as necessary.

(2) If the flywheel

runout exceeds the limit, replace it.

Limit: 0.13 mm (0051 in.)

DRIVE PLATE (Engine with an automatic transaxle)Replace if deformed, damaged or cracked.

SERVICE POINTS OF REASSEMBLY

NOSUDAA

15. INSTALLATION OF UPPER BEARINGWhen reusing the main bearings, install them in their

original positions by referring to location marking made at

the time of removal.

Be sure that oil holes in bearings align with those in cylinder

block.

13. INSTALLATION OF LOWER BEARINGMake sure that a bearing without oil groove is used as

lower bearing.

12. INSTALLATION OF BEARING CAP(1) Install the bearing caps with their arrow mark directed

toward the timing belt side of engine. Cap numbers

must be in correct order.(2) Tighten cap bolts in the sequence of center,

No.2,

No.4. front and rear cap bolts.

(3) Cap bolts should be tightened evenly in 2 to 3 steps

before they are finally tightened.

(4) Make certain that the crankshaft turns freely and has a

proper end play by checking the clearance between

center main bearing thrust flange and connecting rod

big end bearing.

Crankshaft end play:

0.05-0.18 mm (.0020-.0071 in.)

Limit:0.25 mm (.0098 in.)

Page 356 of 1216

9-72ENGINE <1.8L Engine> -Crankshaft, Flywheel and Drive Plate/Cylinder Block

PressOil seal

I

MD99801 1

/

Oil seal case1 EN06L

CYLINDER BLOCK

i//

199.

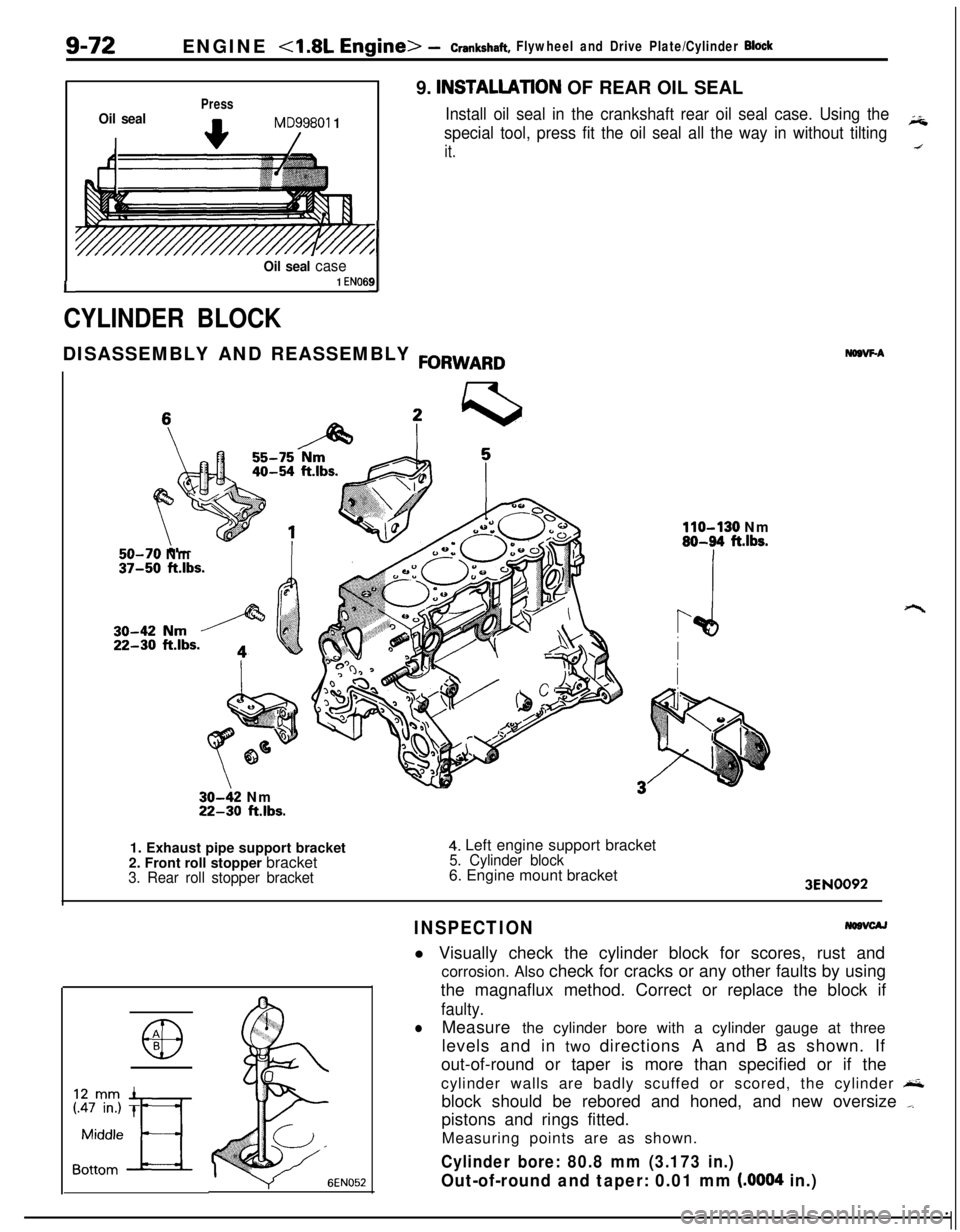

INSTALLATlON OF REAR OIL SEAL

Install oil seal in the crankshaft rear oil seal case. Using the

special tool, press fit the oil seal all the way in without tiltingiii

it.DISASSEMBLY AND REASSEMBLY

FORWARD

50-70 Nm37-50 ft.lbs.

30-42 Nm22-30 ft.lbs.

NDBVF-A

110-130 Nm80-94 ft.lbs.1. Exhaust pipe support bracket

2. Front roll stopper bracket

3. Rear roll stopper bracket

4. Left engine support bracket5. Cylinder block6. Engine mount bracket

3EN0092

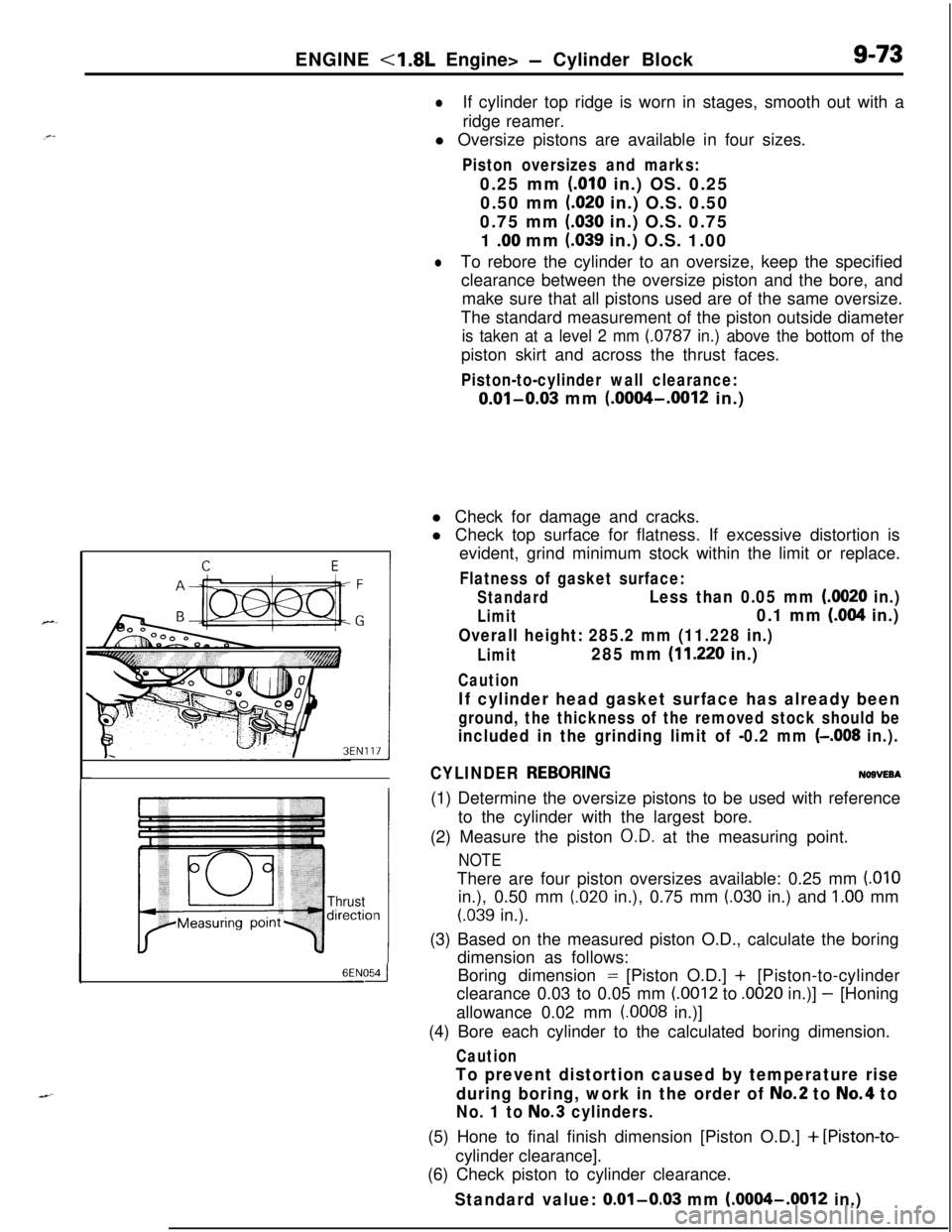

INSPECTIONl Visually check the cylinder block for scores, rust and

corrosion. Also check for cracks or any other faults by using

the magnaflux method. Correct or replace the block if

faulty.

lMeasure the cylinder bore with a cylinder gauge at three

levels and in two directions A and

B as shown. If

out-of-round or taper is more than specified or if the

cylinder walls are badly scuffed or scored, the cylinder

&block should be rebored and honed, and new oversize

_pistons and rings fitted.

Measuring points are as shown.

Cylinder bore: 80.8 mm (3.173 in.)

Out-of-round and taper: 0.01 mm (.0004 in.)

Page 357 of 1216

ENGINE <1.8L Engine> - Cylinder Block9-73

lIf cylinder top ridge is worn in stages, smooth out with a

ridge reamer.

l Oversize pistons are available in four sizes.

Piston oversizes and marks:0.25 mm

(.OlO in.) OS. 0.25

0.50 mm

(.020 in.) O.S. 0.50

0.75 mm

(.030 in.) O.S. 0.75

1

.OO mm (.039 in.) O.S. 1.00

lTo rebore the cylinder to an oversize, keep the specified

clearance between the oversize piston and the bore, and

make sure that all pistons used are of the same oversize.

The standard measurement of the piston outside diameter

is taken at a level 2 mm (0787 in.) above the bottom of thepiston skirt and across the thrust faces.

Piston-to-cylinder wall clearance:

0.01-0.03 mm (.0004-.0012 in.)

Thrustdirectiol

6ENOdl Check for damage and cracks.

l Check top surface for flatness. If excessive distortion is

evident, grind minimum stock within the limit or replace.

Flatness of gasket surface:

StandardLess than 0.05 mm (0020 in.)

Limit0.1 mm (.004 in.)

Overall height: 285.2 mm (11.228 in.)

Limit285 mm (11.220 in.)

Caution

If cylinder head gasket surface has already been

ground, the thickness of the removed stock should be

included in the grinding limit of -0.2 mm (-.008 in.).

CYLINDER

REBORINGNOBVEBA(1) Determine the oversize pistons to be used with reference

to the cylinder with the largest bore.

(2) Measure the piston

O.D. at the measuring point.

NOTEThere are four piston oversizes available: 0.25 mm

(.OlOin.), 0.50 mm

(.020 in.), 0.75 mm (.030 in.) and 1.00 mm

(.039 in.).

(3) Based on the measured piston O.D., calculate the boring

dimension as follows:

Boring dimension = [Piston O.D.] + [Piston-to-cylinder

clearance 0.03 to 0.05 mm

(.0012 to .0020 in.)] - [Honing

allowance 0.02 mm

(.0008 in.)]

(4) Bore each cylinder to the calculated boring dimension.

Caution

To prevent distortion caused by temperature rise

during boring, work in the order of

No.2 to No.4 to

No. 1 to No.3 cylinders.(5) Hone to final finish dimension [Piston O.D.]

+ [Piston-to-cylinder clearance].

(6) Check piston to cylinder clearance.

Standard value: 0.01-0.03 mm (.0004-.0012 in.)

Page 366 of 1216

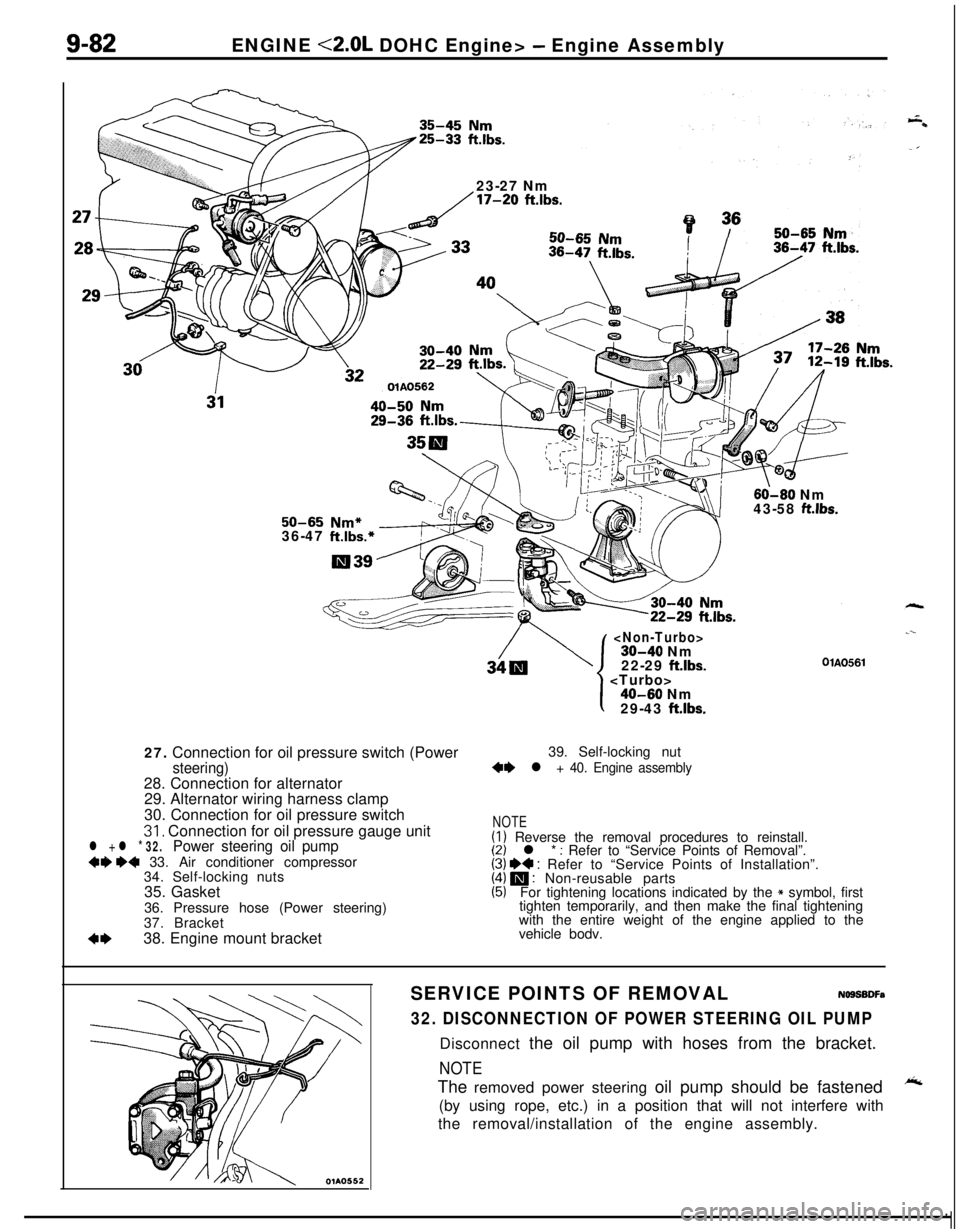

9-82ENGINE <2.0L DOHC Engine> - Engine Assembly

23-27 Nm

/17-20 ftlbs.

60-60 Nm

43-58 ft.lbs.50-65 Nm*36-47 ft.lbs.*27. Connection for oil pressure switch (Power

steering)28. Connection for alternator

29. Alternator wiring harness clamp

30. Connection for oil pressure switch

31, Connection for oil pressure gauge unitl + l * 32.Power steering oil pump+9 ~~ 33. Air conditioner compressor

34. Self-locking nuts

35. Gasket

36. Pressure hose (Power steering)

37. Bracket

4*38. Engine mount bracket

22-29 ftlbs.

.--

OlAO561

1

I40-60 Nm

29-43 ft.lbs.39. Self-locking nut

+e l + 40. Engine assembly

NOTE(I) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.(3) I)+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts(5)For tightening locations indicated by the * symbol, first

tighten temporarily, and then make the final tightening

with the entire weight of the engine applied to the

vehicle bodv.

SERVICE POINTS OF REMOVALNOSSBDFa

32. DISCONNECTION OF POWER STEERING OIL PUMPDisconnect the oil pump with hoses from the bracket.

NOTEThe removed power steering oil pump should be fastened

A(by using rope, etc.) in a position that will not interfere with

the removal/installation of the engine assembly.

Page 367 of 1216

r-.ENGINE <2.0L DOHC Engine>

- Engine AssemblyS-83

OlA0177

-mpp.-/- --OlA0553

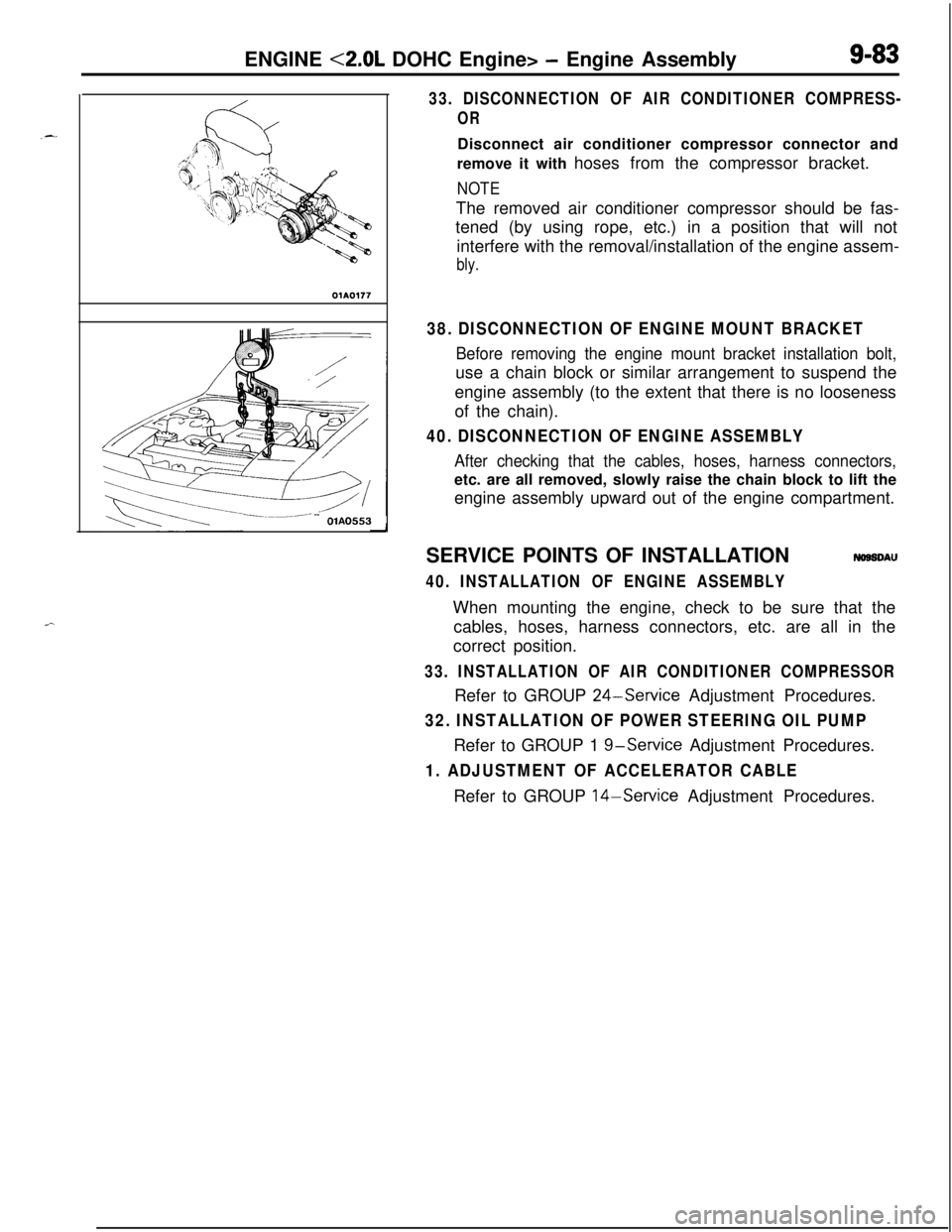

33. DISCONNECTION OF AIR CONDITIONER COMPRESS-

ORDisconnect air conditioner compressor connector and

remove it with hoses from the compressor bracket.

NOTEThe removed air conditioner compressor should be fas-

tened (by using rope, etc.) in a position that will not

interfere with the removal/installation of the engine assem-

bly.

38. DISCONNECTION OF ENGINE MOUNT BRACKET

Before removing the engine mount bracket installation bolt,use a chain block or similar arrangement to suspend the

engine assembly (to the extent that there is no looseness

of the chain).

40. DISCONNECTION OF ENGINE ASSEMBLY

After checking that the cables, hoses, harness connectors,etc. are all removed, slowly raise the chain block to lift the

engine assembly upward out of the engine compartment.

SERVICE POINTS OF INSTALLATION

NOSSDAU

40. INSTALLATION OF ENGINE ASSEMBLYWhen mounting the engine, check to be sure that the

cables, hoses, harness connectors, etc. are all in the

correct position.

33. INSTALLATION OF AIR CONDITIONER COMPRESSORRefer to GROUP

24-Service Adjustment Procedures.

32. INSTALLATION OF POWER STEERING OIL PUMPRefer to GROUP 1

g-service Adjustment Procedures.

1. ADJUSTMENT OF ACCELERATOR CABLERefer to GROUP 14-Service Adjustment Procedures.

Page 371 of 1216

ENGINE <2.0L DOHC Engine> -Camshafts and Camshaft Oil Seals/Oil Pan and Oil Screen9-87

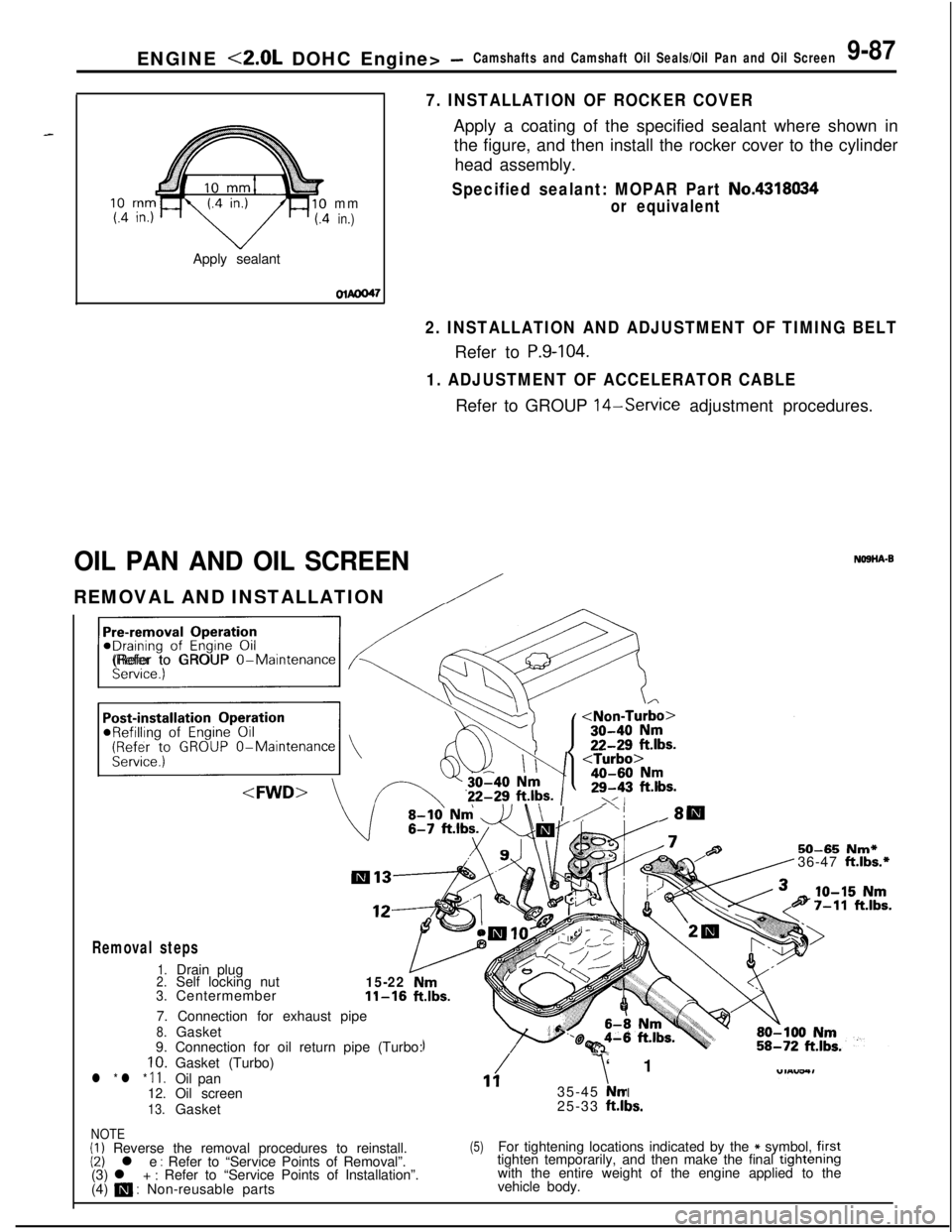

7. INSTALLATION OF ROCKER COVERApply a coating of the specified sealant where shown in

the figure, and then install the rocker cover to the cylinder

head assembly.

Apply sealant

mmin.)

Specified sealant: MOPAR Part No.4318034

or equivalent

olmO47

2. INSTALLATION AND ADJUSTMENT OF TIMING BELTRefer to

P.9-104.

1. ADJUSTMENT OF ACCELERATOR CABLERefer to GROUP 14-Service adjustment procedures.

OIL PAN AND OIL SCREENNO9HA-BREMOVAL AND INSTALLATION

/

/j<&(Refer to GROUP O-Maintenance

\ I/“!18

III13

12-

Removal steps

1.Drain plug2.Self locking nut15-22Nm3.Centermember11-16ft.lbs.7. Connection for exhaust pipe

8.Gasket

9. Connection for oil return pipe (Turbo:IO. Gasket (Turbo)

l * l * 11.Oil pan12.Oil screen

13.Gasket

50-65 Nm*36-47 ft.lbs.*

/117‘1

35-45 NmI25-33 ft.ll3s.

NOTE(I) Reverse the removal procedures to reinstall.(2) l e : Refer to “Service Points of Removal”.

(3) l + : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

(5)For tightening locations indicated by the * symbol, firsttighten temporarily, and then make the final trghtenrngwith the entire weight of the engine applied to the

vehicle body.

Page 372 of 1216

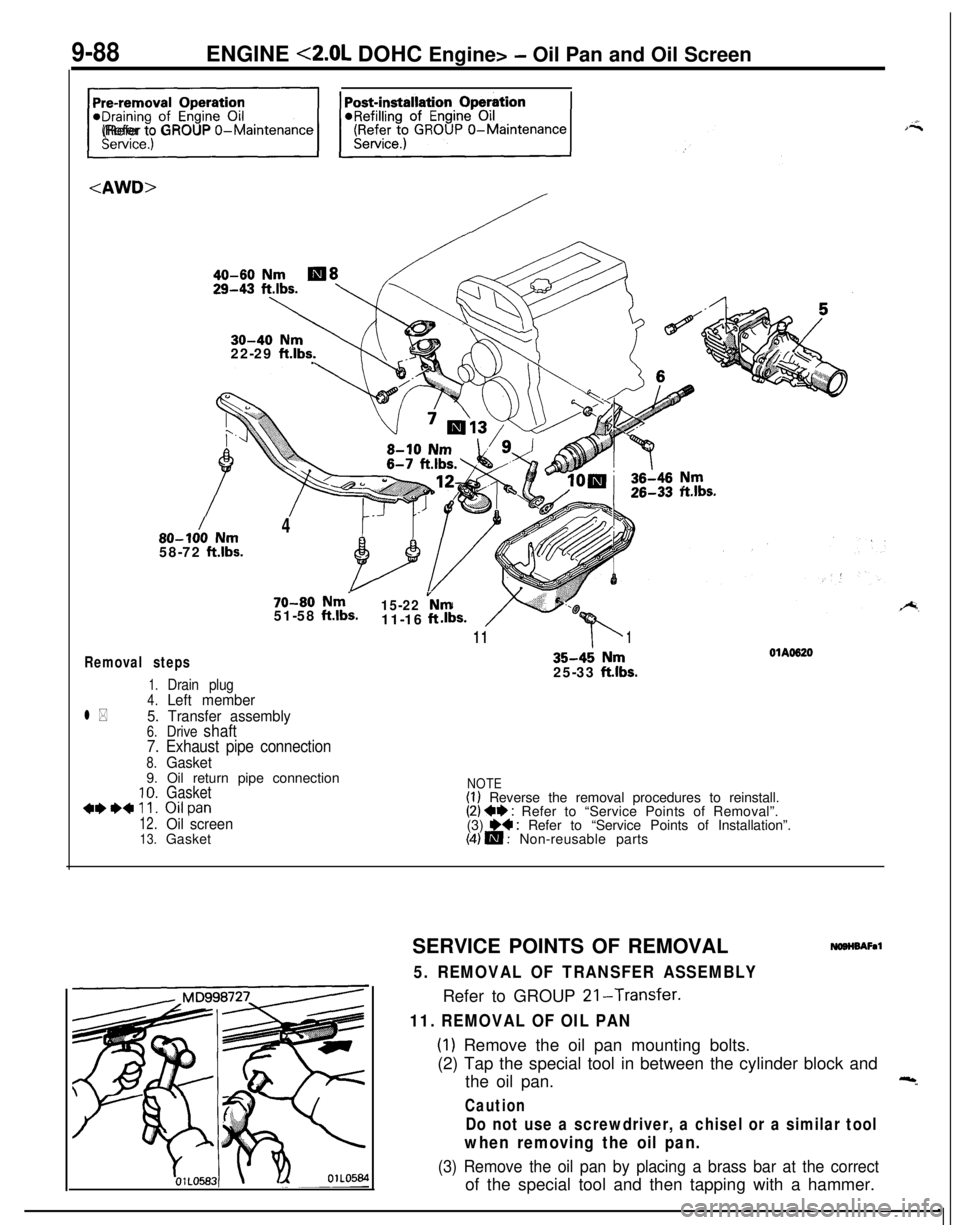

9-88ENGINE <2.0L DOHC Engine> - Oil Pan and Oil Screen

/

40-60 Nm

30-40 Nm22-29 ft.lbs..

/80-100 Nm458-72

ft.lbs.

70-80 Nm-51-58 ftlbs.15-22 vNm11-16 ft

11b1

Removal steps

1.Drain plug4.Left member

l *5. Transfer assembly6.Drive shaft

7. Exhaust pipe connection

8.Gasket9. Oil return pipe connection

10.Gasket***+ll. Oilpan

12.Oil screen13.Gasket

35-4; Nm25-33 ftlbs.

OlAO620

NOTE(I) Reverse the removal procedures to reinstall.(2) +I) : Refer to “Service Points of Removal”.

(3) H : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

SERVICE POINTS OF REMOVAL

NOBHBAFal

5. REMOVAL OF TRANSFER ASSEMBLYRefer to GROUP 21-Transfer.

11. REMOVAL OF OIL PAN

(1) Remove the oil pan mounting bolts.

(2) Tap the special tool in between the cylinder block and

the oil pan.

Caution

Do not use a screwdriver, a chisel or a similar tool

when removing the oil pan.

(3) Remove the oil pan by placing a brass bar at the correctof the special tool and then tapping with a hammer.