MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 141 of 1216

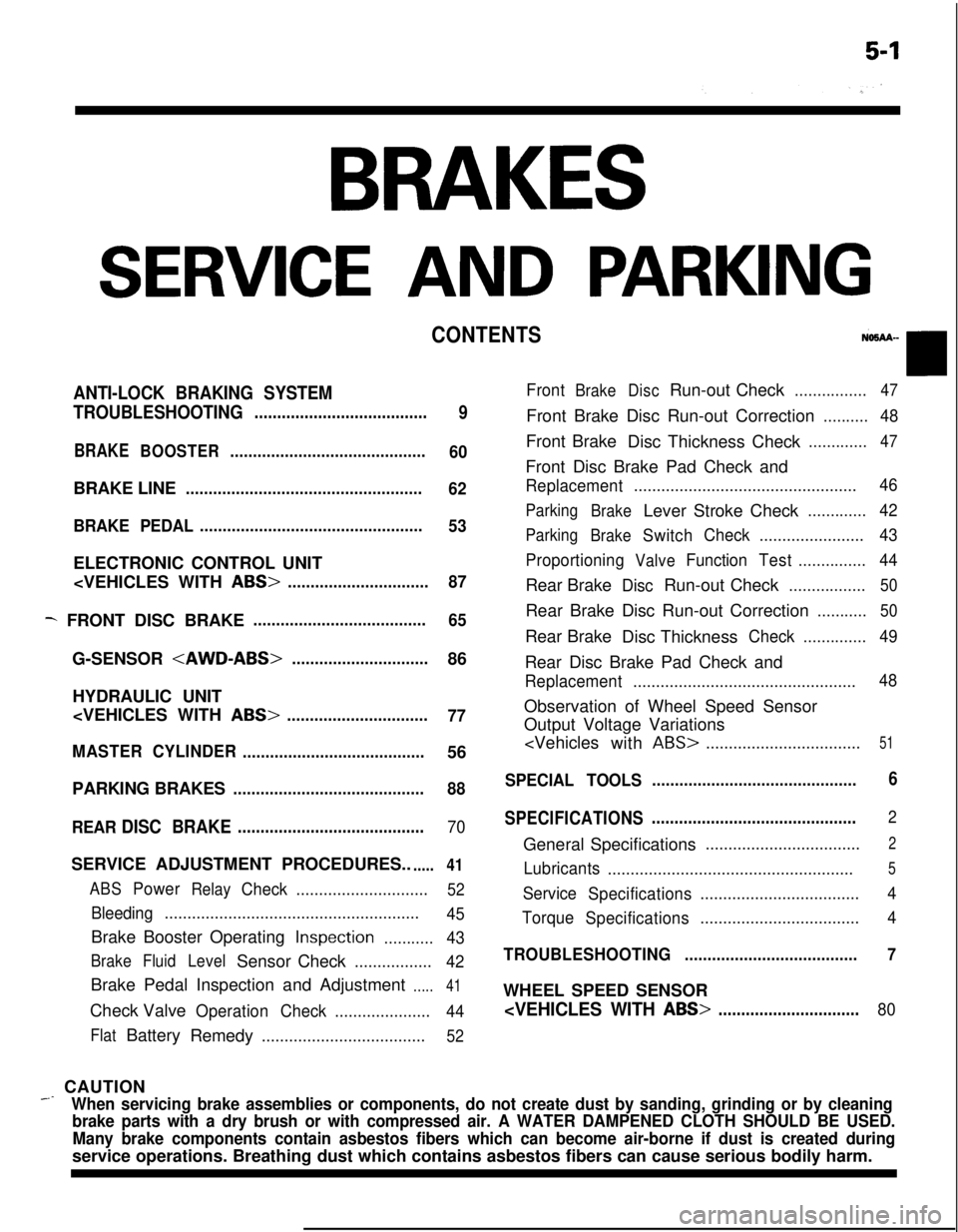

BRAKES

SERVICE AND PARKING

CONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING

......................................

9

BRAKEBOOSTER...........................................

60BRAKE LINE

....................................................

62

BRAKE PEDAL.................................................

53ELECTRONIC CONTROL UNIT

- FRONT DISC BRAKE......................................

65G-SENSOR

HYDRAULIC UNIT

77

MASTERCYLINDER

........................................56

PARKING BRAKES

..........................................88

REAR

DISC BRAKE.........................................70SERVICE ADJUSTMENT PROCEDURES..

.....41

ABSPowerRelayCheck.............................52

Bleeding........................................................

45Brake Booster Operating

Inspection...........43

BrakeFluidLevelSensor Check.................

42Brake Pedal Inspection and Adjustment

.....41Check Valve

OperationCheck.....................

44

FlatBattery

Remedy....................................52

FrontBrakeDiscRun-out Check................47Front Brake Disc Run-out Correction

..........48Front Brake

Disc Thickness Check

.............47Front Disc Brake Pad Check and

Replacement.................................................46

Parking

BrakeLever Stroke Check.............42

Parking

BrakeSwitchCheck.......................43

Proportioning

ValveFunctionTest...............44Rear Brake

DiscRun-out Check.................50Rear Brake Disc Run-out Correction

...........50Rear Brake

Disc Thickness

Check..............49Rear Disc Brake Pad Check and

Replacement.................................................48Observation of Wheel Speed Sensor

Output Voltage Variations

ABS>..................................51

SPECIAL TOOLS.............................................6

SPECIFICATIONS.............................................

2General Specifications

..................................2

Lubricants

......................................................5

Service

Specifications...................................4

Torque

Specifications...................................4

TROUBLESHOOTING......................................7WHEEL SPEED SENSOR

_ CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake parts with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many brake components contain asbestos fibers which can become air-borne if dust is created duringservice operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

Page 142 of 1216

5-2BRAKES - SDecifications

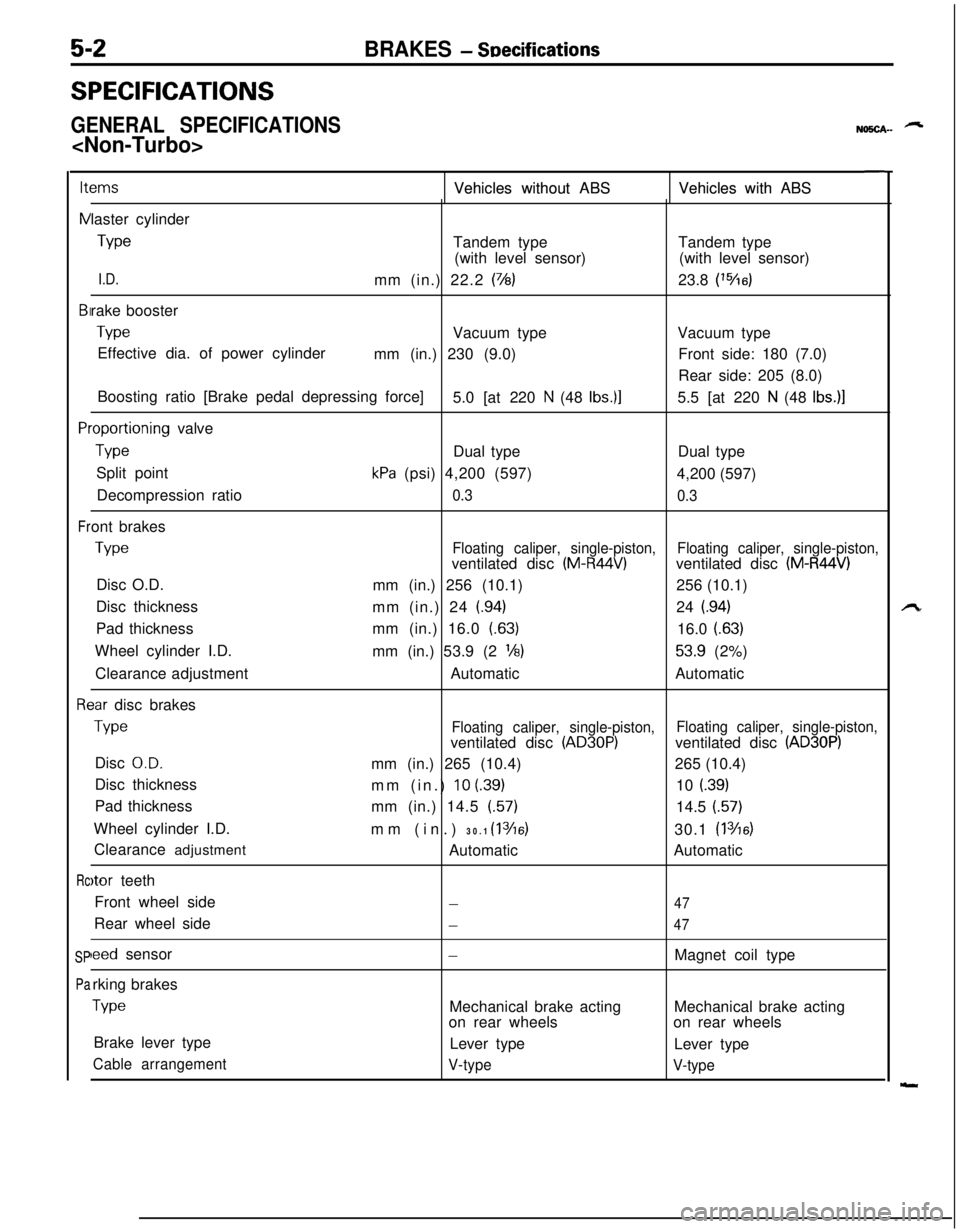

SPECIFICATIONS

GENERAL SPECIFICATIONS

NO!iCA-- -

ItemsItems

NNVehicles without ABS Vehicles without ABSVehicles with ABS Vehicles with ABS

BIBI

PlPl

Fr Frlaster cylinder

TypeTandem typeTandem type

(with level sensor)(with level sensor)

I.D.mm (in.) 22.2 (7/8)23.8 (‘%6)rake booster

TypeVacuum typeVacuum type

Effective dia. of power cylinder

mm (in.) 230 (9.0)Front side: 180 (7.0)

Rear side: 205 (8.0)

Boosting ratio [Brake pedal depressing force]

5.0 [at 220

N (48 Ibs.)]5.5 [at 220 N (48 Ibs.)]

.oportioning valve

TypeDual typeDual type

Split point

kPa (psi) 4,200 (597)

4,200 (597)

Decompression ratio

0.3

0.3ont brakes

TypeFloating caliper, single-piston,ventilated disc (M-R44V)Floating caliper, single-piston,ventilated disc (M-R44V)Disc O.D.

mm (in.) 256 (10.1)256 (10.1)

Disc thickness

mm (in.) 24

(.94)24 (.94)Pad thicknessmm (in.) 16.0 (63)

16.0

(.63)Wheel cylinder I.D.

mm (in.) 53.9 (2

l/8)53.9 (2%)

Clearance adjustmentAutomaticAutomatic

3ar disc brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (AD30P)ventilated disc (AD30P)Disc

O.D.mm (in.) 265 (10.4)265 (10.4)

Disc thickness

mm (in.)

10 (39)10 i.39)Pad thickness

mm (in.) 14.5 (57)

14.5 (57)

Wheel cylinder I.D.

mm (in.) 30.1

(1 3/16)30.1 (1 346)Clearance adjustment

AutomaticAutomatic

)tor teeth

Front wheel side

-47Rear wheel side

-47

leed sensor-Magnet coil type

rking brakes

TypeMechanical brake actingMechanical brake acting

on rear wheelson rear wheels

Brake lever type

Lever type

Lever type

Cable arrangement

V-type

V-type

Rc Rc

SP SP

Pa Pa

Page 143 of 1216

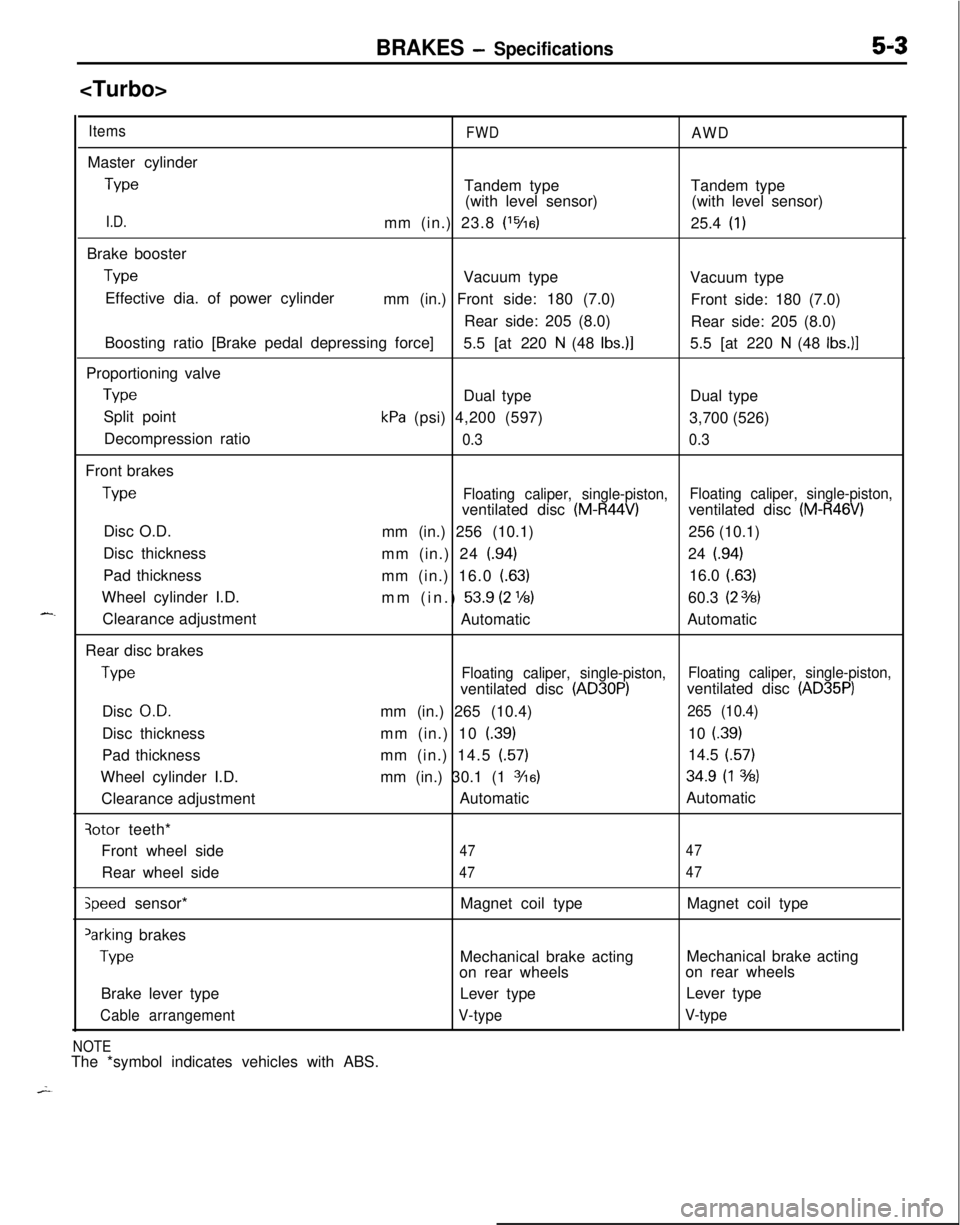

BRAKES - Specifications5-3

ItemsFWDAWDMaster cylinder

TypeTandem type

(with level sensor)Tandem type

(with level sensor)

I.D.mm (in.) 23.8 (‘%a)25.4 (1)Brake booster

TypeVacuum type

Vacuum type

Effective dia. of power cylinder

mm (in.) Front side: 180 (7.0)

Front side: 180 (7.0)

Rear side: 205 (8.0)

Rear side: 205 (8.0)

Boosting ratio [Brake pedal depressing force]

5.5 [at 220

N (48 Ibs.)]5.5 [at 220 N (48 Ibs.)]Proportioning valve

TypeDual typeDual type

Split point

kPa (psi) 4,200 (597)

3,700 (526)

Decompression ratio

0.30.3Front brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (M-R44V)ventilated disc (M-R46V)Disc O.D.

mm (in.) 256 (10.1)256 (10.1)

Disc thickness

mm (in.) 24

(.94)24 (.94)Pad thickness

mm (in.) 16.0

(.63)16.0 (.63)Wheel cylinder I.D.

mm (in.)

53.9 (2 ‘16)60.3 (23%3)Clearance adjustment

AutomaticAutomatic

Rear disc brakes

TypeFloating caliper, single-piston,Floating caliper, single-piston,ventilated disc (AD30P)ventilated disc (AD35P)Disc

O.D.mm (in.) 265 (10.4)265 (10.4)Disc thicknessmm (in.) 10

(.39)10 f.39)Pad thicknessmm (in.) 14.5

(.57)14.5 (.57)Wheel cylinder I.D.mm (in.) 30.1 (1

3/16)34.9 (1 3h)Clearance adjustmentAutomaticAutomatic

qotor teeth*

Front wheel side

4747Rear wheel side

4747

speed sensor*Magnet coil typeMagnet coil type‘arking brakes

TypeMechanical brake actingMechanical brake acting

on rear wheelson rear wheels

Brake lever typeLever typeLever type

Cable arrangementV-typeV-type

NOTEThe *symbol indicates vehicles with ABS.

Page 144 of 1216

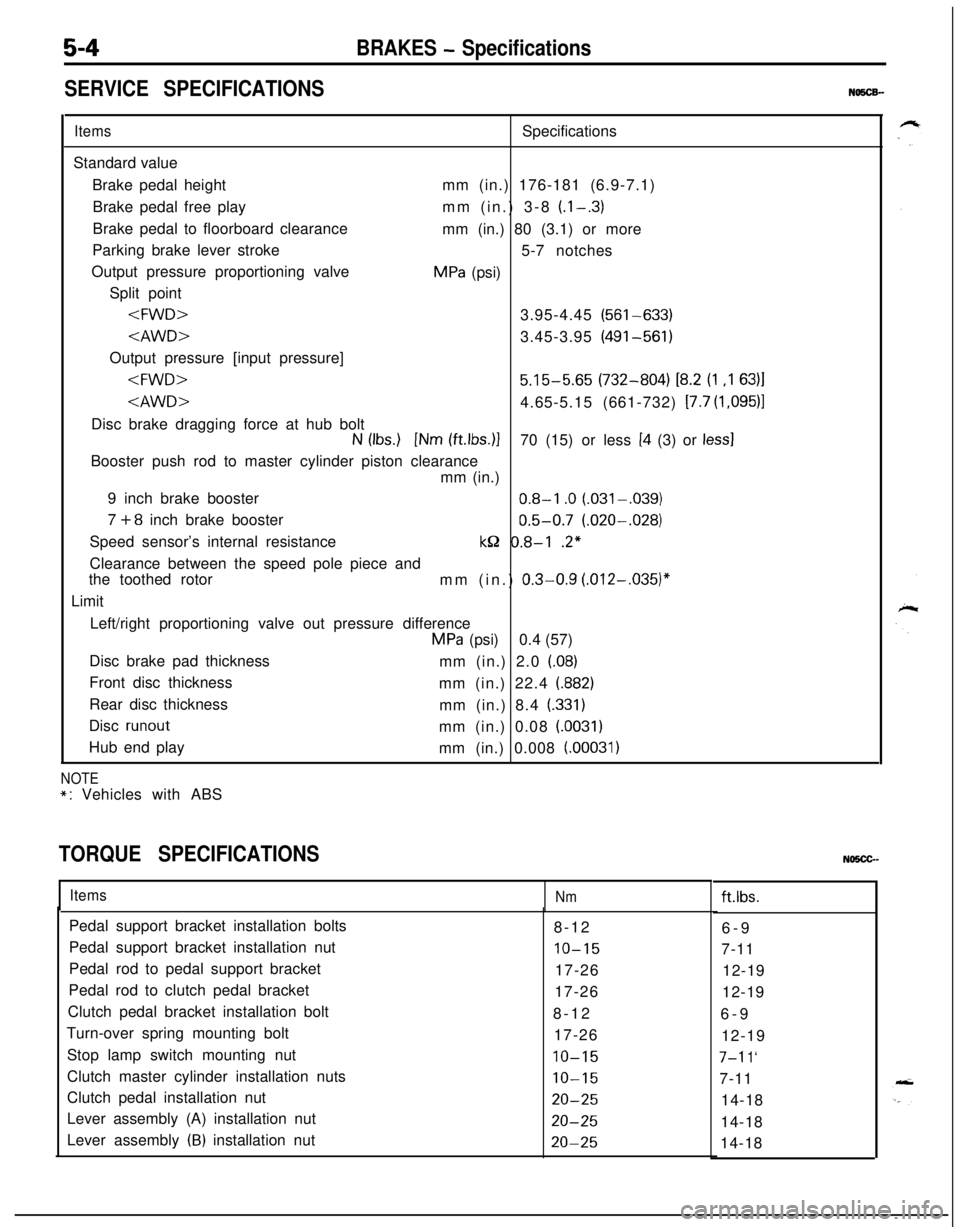

5-4BRAKES - Specifications

SERVICE SPECIFICATIONS

NO5CB-

ItemsSpecifications

Standard value

Brake pedal heightmm (in.) 176-181 (6.9-7.1)

Brake pedal free playmm (in.) 3-8

(l-.3)Brake pedal to floorboard clearance

mm (in.) 80 (3.1) or more

Parking brake lever stroke

5-7 notches

Output pressure proportioning valve

MPa (psi)

Split point

Output pressure [input pressure]

N (Ibs.) [Nm (ftlbs.)]70 (15) or less [4 (3) or less1Booster push rod to master cylinder piston clearance

mm (in.)

9 inch brake booster

0.8-l .O (.031-,039)

7

+8 inch brake booster0.5-0.7 (.020-.028)

Speed sensor’s internal resistance

kQ 0.8-l .2*

Clearance between the speed pole piece and

the toothed rotor

mm (in.)

0.3-0.9 (.012-,035)”Limit

Left/right proportioning valve out pressure difference

MPa (psi)0.4 (57)

Disc brake pad thickness

mm (in.) 2.0 (08)

Front disc thickness

mm (in.) 22.4 (882)

Rear disc thickness

mm (in.) 8.4

(.331)Disc

runoutmm (in.) 0.08 (.0031)Hub end play

mm (in.) 0.008

(.00031)

NOTE

*: Vehicles with ABS

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Pedal support bracket installation bolts

8-12

6-9

Pedal support bracket installation nut

IO-157-11

Pedal rod to pedal support bracket

17-26

12-19

Pedal rod to clutch pedal bracket

17-26

12-19

Clutch pedal bracket installation bolt

8-12

6-9

Turn-over spring mounting bolt

17-26

12-19

Stop lamp switch mounting nut

IO-157-l 1‘Clutch master cylinder installation nuts

10-157-11

Clutch pedal installation nut

20-2514-18

Lever assembly (A) installation nut

20-2514-18

Lever assembly

(B) installation nut20-2514-18

Page 145 of 1216

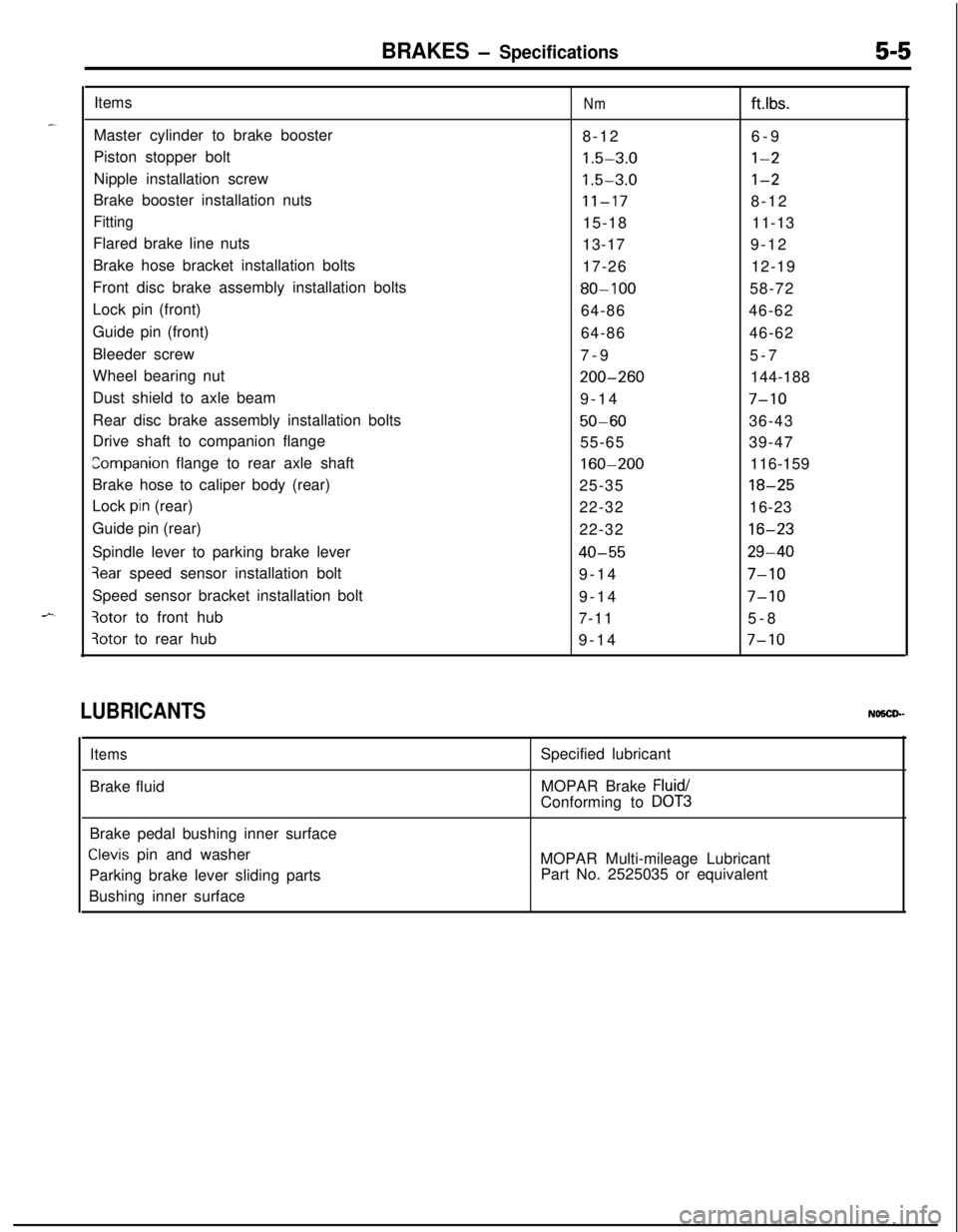

BRAKES - Specifications5-5Items

Nmftlbs.Master cylinder to brake booster

8-126-9

Piston stopper bolt

1.5-3.0l-2Nipple installation screw

1.5-3.0l-2Brake booster installation nuts

11-178-12

Fitting15-1811-13

Flared brake line nuts

13-179-12

Brake hose bracket installation bolts

17-2612-19

Front disc brake assembly installation bolts

80-10058-72

Lock pin (front)

64-8646-62

Guide pin (front)

64-8646-62

Bleeder screw

7-95-7

Wheel bearing nut

200-260144-188

Dust shield to axle beam

9-14

7-10Rear disc brake assembly installation bolts

50-6036-43

Drive shaft to companion flange

55-6539-47

companion flange to rear axle shaft160-200116-159

Brake hose to caliper body (rear)

25-35

18-25Lock

pin (rear)

22-3216-23

Guide pin (rear)

22-32

16-23Spindle lever to parking brake lever

40-5529-40

3ear speed sensor installation bolt

9-147-10Speed sensor bracket installation bolt

9-14

7-10

3otor to front hub

7-115-8

3otor to rear hub

9-147-10

LUBRICANTSNO5CP-

ItemsBrake fluidSpecified lubricant

MOPAR Brake

Fluid/Conforming to

DOT3Brake pedal bushing inner surface

Clevis pin and washer

Parking brake lever sliding parts

Bushing inner surfaceMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Page 146 of 1216

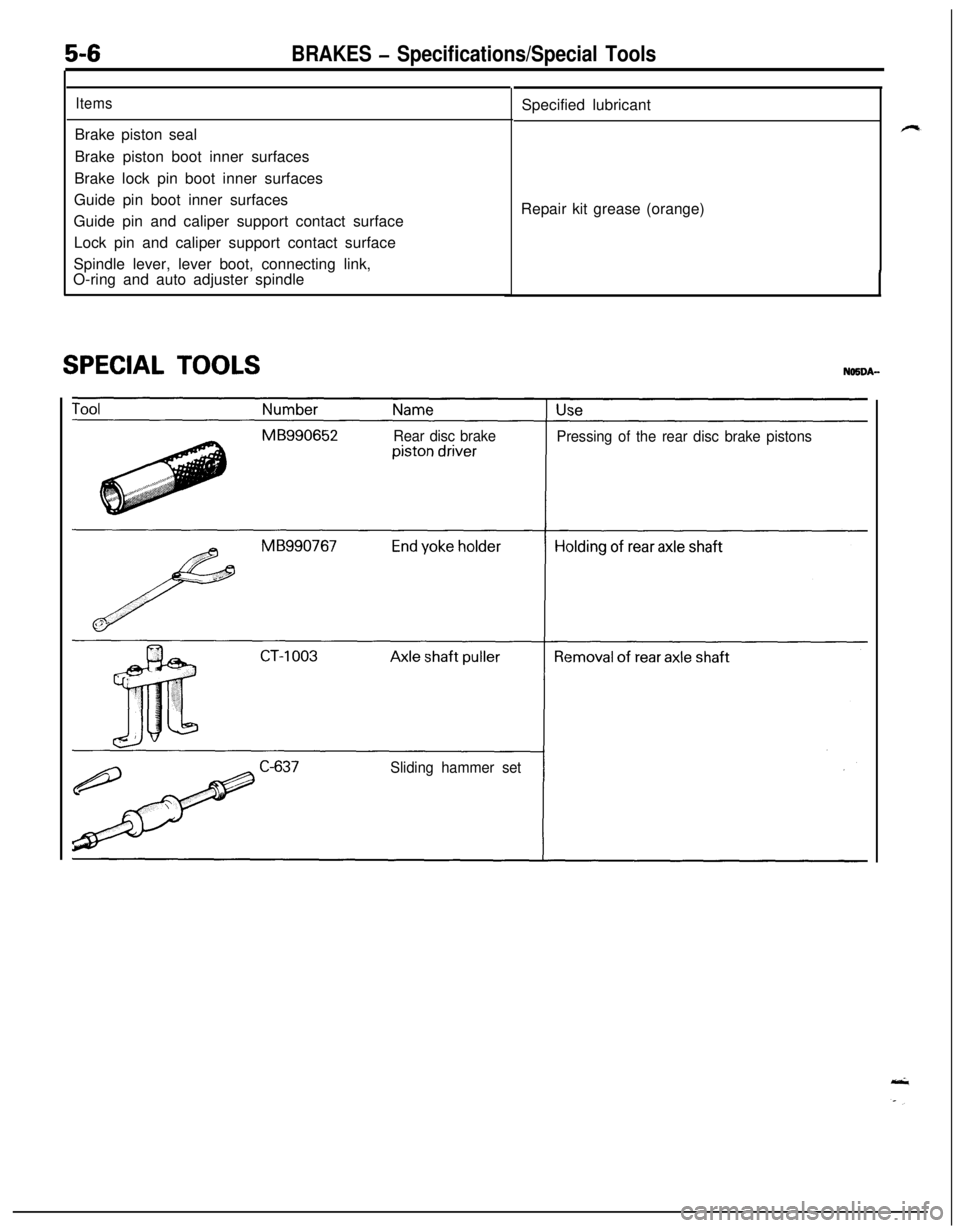

5-6BRAKES - Specifications/Special Tools

ItemsBrake piston seal

Brake piston boot inner surfaces

Brake lock pin boot inner surfaces

Guide pin boot inner surfaces

Guide pin and caliper support contact surface

Lock pin and caliper support contact surface

Spindle lever, lever boot, connecting link,

O-ring and auto adjuster spindle

SPECIAL TOOLSSpecified lubricant

Repair kit grease (orange)

Rear disc brake

Pressing of the rear disc brake pistons

Sliding hammer set

Page 147 of 1216

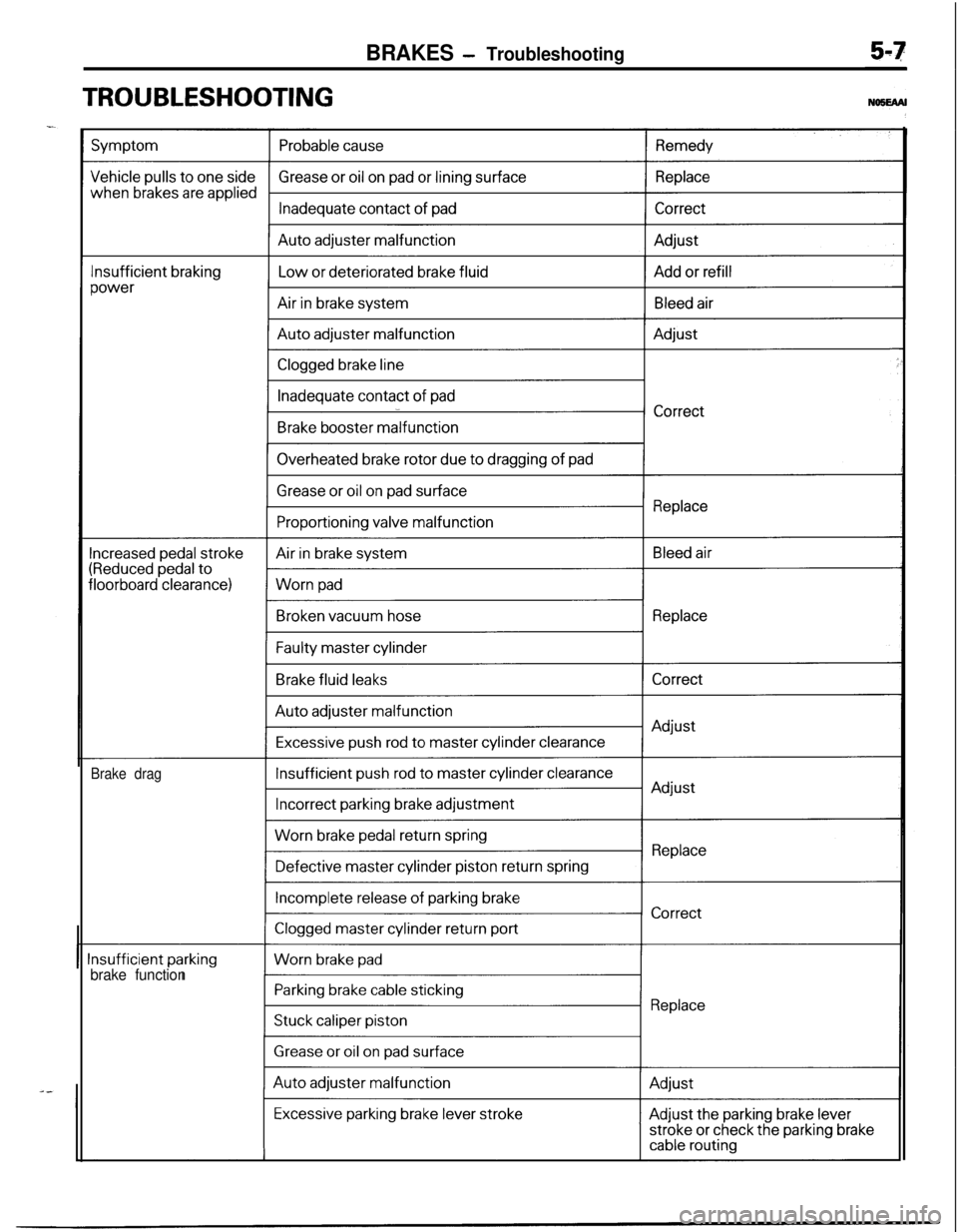

BRAKES - Troubleshooting

TROUBLESHOOTING

-

Brake drag

brake function

Page 148 of 1216

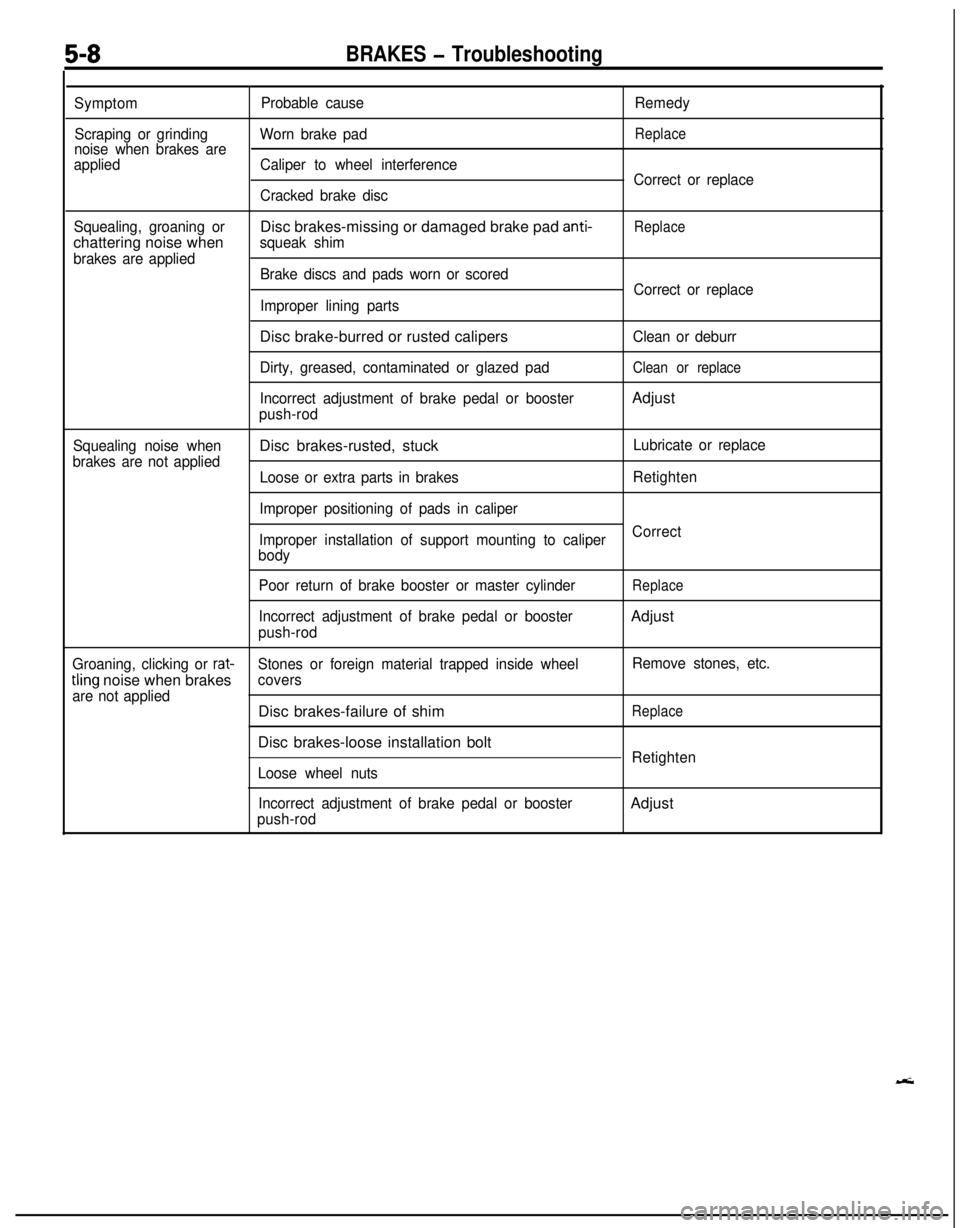

5-8BRAKES - Troubleshooting

Symptom

Scraping or grinding

noise when brakes are

appliedProbable cause

Worn brake pad

Caliper to wheel interference

Cracked brake discRemedy

Replace

Correct or replace

Squealing, groaning orchattering noise when

brakes are appliedDisc brakes-missing or damaged brake pad

anti-

squeak shimReplace

Brake discs and pads worn or scored

Improper lining partsCorrect or replaceDisc brake-burred or rusted calipers

Dirty, greased, contaminated or glazed pad

Incorrect adjustment of brake pedal or booster

push-rodClean or deburrClean or replaceAdjust

Squealing noise when

brakes are not appliedDisc brakes-rusted, stuckLubricate or replace

Loose or extra parts in brakes

Improper positioning of pads in caliperRetighten

Improper installation of support mounting to caliperCorrect

body

Poor return of brake booster or master cylinder

Incorrect adjustment of brake pedal or booster

push-rod

ReplaceAdjust

Groaning, clicking or rat-Stones or foreign material trapped inside wheelRemove stones, etc.

tling noise when brakescovers

are not appliedDisc brakes-failure of shim

ReplaceDisc brakes-loose installation bolt

Retighten

Loose wheel nuts

Incorrect adjustment of brake pedal or booster

push-rodAdjust

Page 149 of 1216

BRAKES - Anti-lock Braking System Troubleshooting5-9

ANTI-LOCK BRAKING SYSTEM

-- TROUBLESHOOTINGNO!JEBAE

PARTICULAR CHARACTERISTICS OF

THE ANTI-LOCK BRAKING SYSTEMModels equipped with the anti-lock braking system

(A.B.S.) may exhibit one or more of the following

characteristics from time to time, but none of these

is abnormal.

(1) A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.Actually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.(2) When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), a

whining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place, but this noise is simply the result

of a self-check being made of the anti-lock

braking system operation.

TROUBLESHOOTING METHODSProblems related to the anti-lock braking system

(A.B.S.) can be classified into two general categor-

ies: problems in the electrical system and those in

the hydraulic system.For problems in the electrical system, the

self-diagnosis function is built into the electronic control

unit (E.C.U.) causing the A.B.S. warning light to

illuminate as a warning to the driver.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check todetermine whether the problem is related to ordin-

ary brake components or to the components relatedto the A.B.S.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART(1) Using the flow chart, check the ABS warning

light light-up sequence and check the condition

of braking operation.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Explana-tion] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTEECU: Electronic control unit

HU: Hydraulic unit

MUT: Multi-use tester

Page 150 of 1216

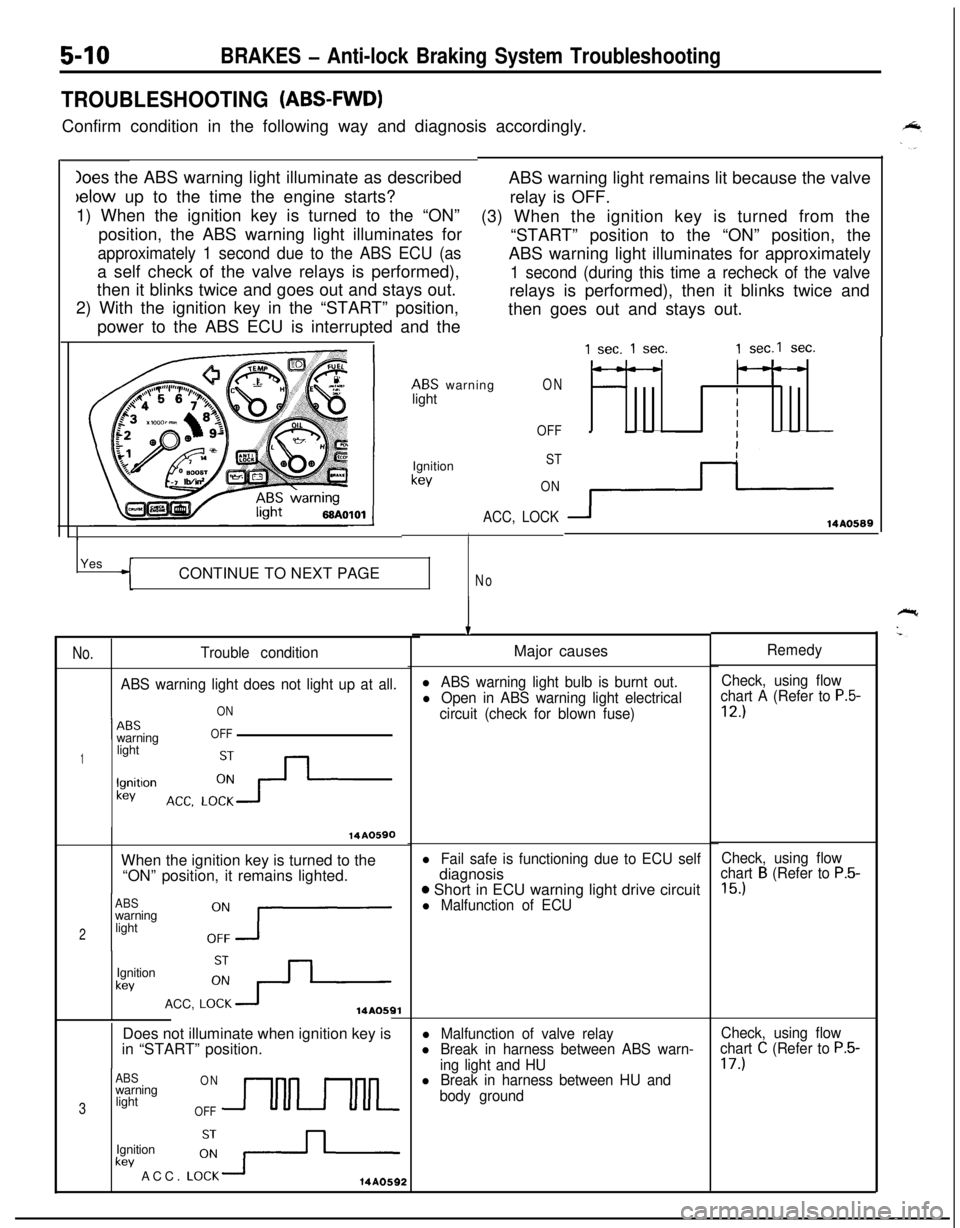

Ioes the ABS warning light illuminate as describedbelow up to the time the engine starts?

1) When the ignition key is turned to the “ON”

position, the ABS warning light illuminates for

approximately 1 second due to the ABS ECU (asa self check of the valve relays is performed),

then it blinks twice and goes out and stays out.

2) With the ignition key in the “START” position,

power to the ABS ECU is interrupted and the

5-10BRAKES - Anti-lock Braking System Troubleshooting

TROUBLESHOOTING (ABS-FWD)Confirm condition in the following way and diagnosis accordingly.

ABS warning light remains lit because the valve

relay is OFF.

(3) When the ignition key is turned from the

“START” position to the “ON” position, the

ABS warning light illuminates for approximately

1 second (during this time a recheck of the valverelays is performed), then it blinks twice and

then goes out and stays out.

ABS warning

lightON

OFF

1Ignition

kev

ST

ON

ACC, LOCK

IYes

CONTINUE TO NEXT PAGE

No

No.Trouble condition

ABS warning light does not light up at all.

ON

1 --ABSwarningOFF

1lightlgnitlon

kev

14A0590When the ignition key is turned to the

“ON” position, it remains lighted.

ABSwarning

2light

Ignition

kevACC,

LO:+14AOSQlDoes not illuminate when ignition key is

in “START” position.

ABSONwarning

3lightOFFUULkev ACC.

LO:-+-Ignition14A0592

1 sec. 1 sec.1 sec.1 sec.

---

IIII

3114AO589

IMajor causes

l ABS warning light bulb is burnt out.Check, using flow

l Open in ABS warning light electricalchart A (Refer to P.5-

circuit (check for blown fuse)12.)

l Fail safe is functioning due to ECU selfdiagnosis

o Short in ECU warning light drive circuitl Malfunction of ECU

l Malfunction of valve relayl Break in harness between ABS warn-

ing light and HU

l Break in harness between HU and

body groundRemedy

Check, using flow

chart

B (Refer to P.5-

15.)

Check, using flow

chart C (Refer to P.5-17.)