engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 358 of 1216

9-74ENGINE <2.0L DOHC Engine>- Service Adjustment Procedures

ENGINE <2.0L DOHC Engine>

SERVICE ADJUSTMENT PROCEDURES pi

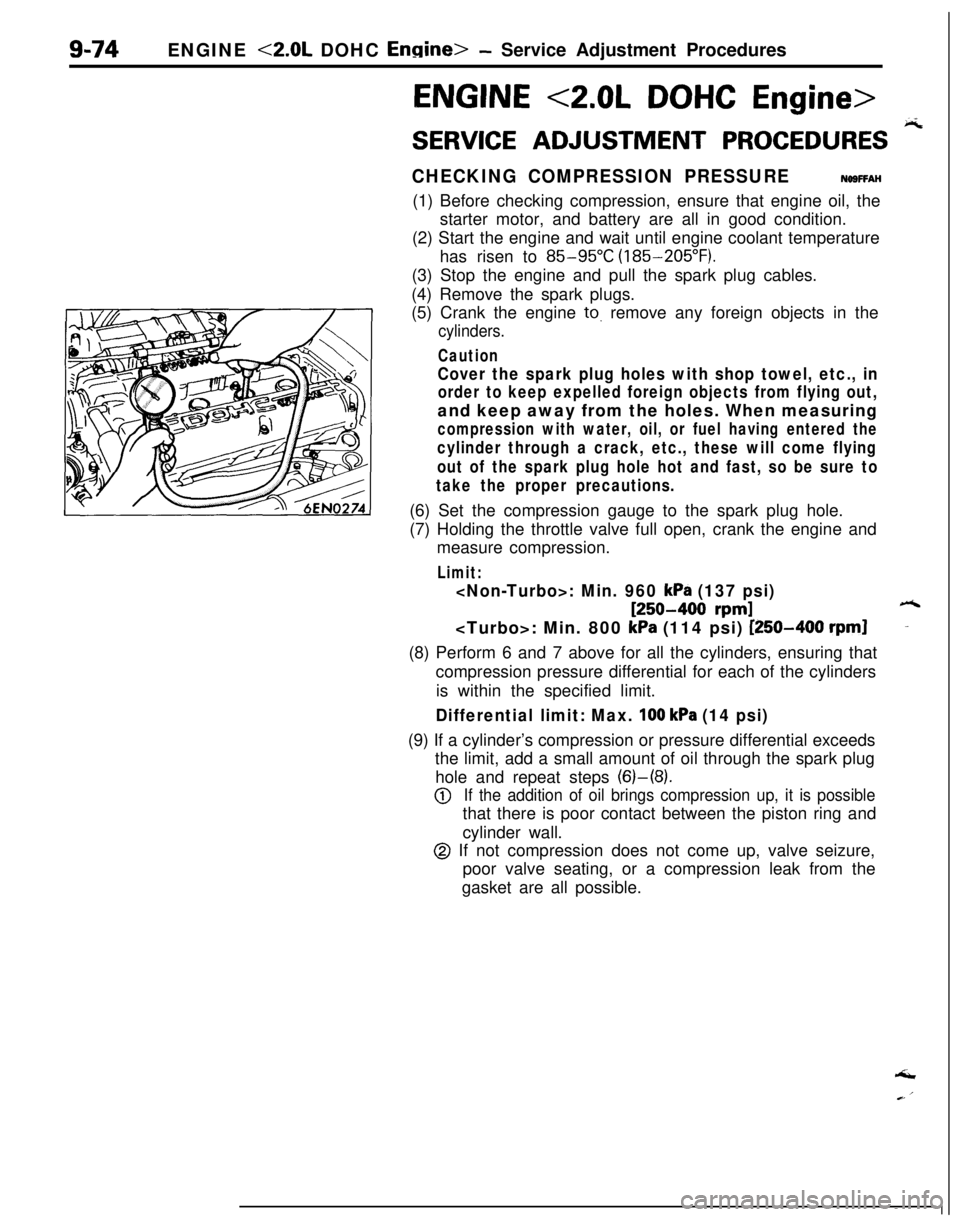

CHECKING COMPRESSION PRESSURENOSFFAH(1) Before checking compression, ensure that engine oil, the

starter motor, and battery are all in good condition.

(2) Start the engine and wait until engine coolant temperature

has risen to

85-95°C (185-205°F).

(3) Stop the engine and pull the spark plug cables.

(4) Remove the spark plugs.

(5) Crank the engine

to. remove any foreign objects in the

cylinders.

Caution

Cover the spark plug holes with shop towel, etc., in

order to keep expelled foreign objects from flying out,and keep away from the holes. When measuring

compression with water, oil, or fuel having entered the

cylinder through a crack, etc., these will come flying

out of the spark plug hole hot and fast, so be sure to

take the proper precautions.(6) Set the compression gauge to the spark plug hole.

(7) Holding the throttle valve full open, crank the engine and

measure compression.

Limit:

[250-400 rpm]6

kPa (114 psi) [250-400 rpml-(8) Perform 6 and 7 above for all the cylinders, ensuring that

compression pressure differential for each of the cylinders

is within the specified limit.

Differential limit: Max. 100 kPa (14 psi)(9) If a cylinder’s compression or pressure differential exceeds

the limit, add a small amount of oil through the spark plug

hole and repeat steps (6)-(8).

@If the addition of oil brings compression up, it is possiblethat there is poor contact between the piston ring and

cylinder wall.

@ If not compression does not come up, valve seizure,

poor valve seating, or a compression leak from the

gasket are all possible.‘I

Page 359 of 1216

_-

a--ENGINE

<2.0L DOHC Engine> -Service Adjustment Procedures9-75

JMANIFOLD VACUUM INSPECTION

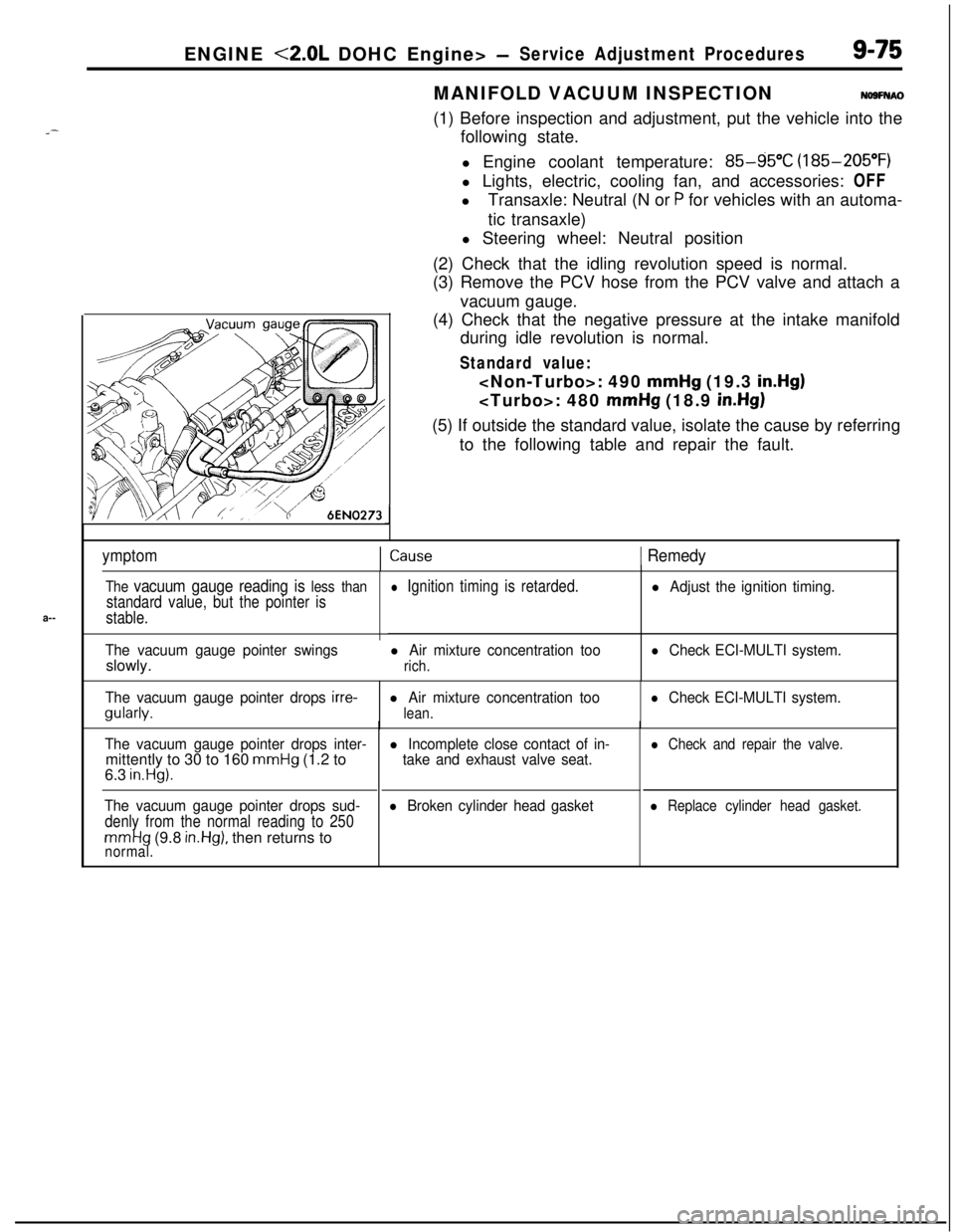

NO9FNAO(1) Before inspection and adjustment, put the vehicle into the

following state.

l Engine coolant temperature:

85-g5”C (185-205°F)

l Lights, electric, cooling fan, and accessories: OFF

lTransaxle: Neutral (N or

P for vehicles with an automa-

tic transaxle)

l Steering wheel: Neutral position

(2) Check that the idling revolution speed is normal.

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value:

mmHg (19.3 in.Hg)

mmHg (18.9 in.Hg)(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

ymptomICause1 Remedy

The vacuum gauge reading is less than

standard value, but the pointer is

stable.

The vacuum gauge pointer swingsslowly.

l Ignition timing is retarded.

l Air mixture concentration too

rich.

l Adjust the ignition timing.

l Check ECI-MULTI system.

The vacuum gauge pointer drops

irre-gularly.l Air mixture concentration too

lean.

l Check ECI-MULTI system.

The vacuum gauge pointer drops inter-mittently to 30 to 160

mmHg (1.2 to

6.3 in.Hg).

The vacuum gauge pointer drops sud-

denly from the normal reading to 250

mmHg (9.8 in.Hg), then returns tonormal.

l Incomplete close contact of in-

take and exhaust valve seat.

l Broken cylinder head gasket

l Check and repair the valve.

l Replace cylinder head gasket.

Page 360 of 1216

9-76ENGINE <2.0L DOHC Engine> -Service Adjustment Procedures

LASH ADJUSTERS CHECKNOBFEABalIf an abnormal noise is heard from the lash adjusters check as

follows.

(1) After warming up the engine, stop it.

(2) While installed to the cylinder head, press the part of rockerarm that contacts the lash adjuster. The part pressed will

feel very hard if the lash adjuster condition is normal.

(3) If, when pressed, it easily descends all the way downward,

replace the lash adjuster.

(4) If there is a spongy feeling when pressed, air is probably

mixed in, and so the cause should be investigated. The

cause is probably an insufficient amount of engine oil, or

damage to the oil screen and/or screen gasket.

(5) After finding the cause and taking the appropriate step

(adding oil or repair), warm up the engine and drive at low

speed for a short time. Then, after stopping the engine andwaiting a few minutes, drive again at low speed. Repeat

this procedure a few times to bleed out the air from the oil.

Page 361 of 1216

ENGINE <2.0L DOHC Engine> - Engine Mounting

ENGINE MOUNTING

- REMOVAL AND INSTALLATION

9-77

NOBGA-B

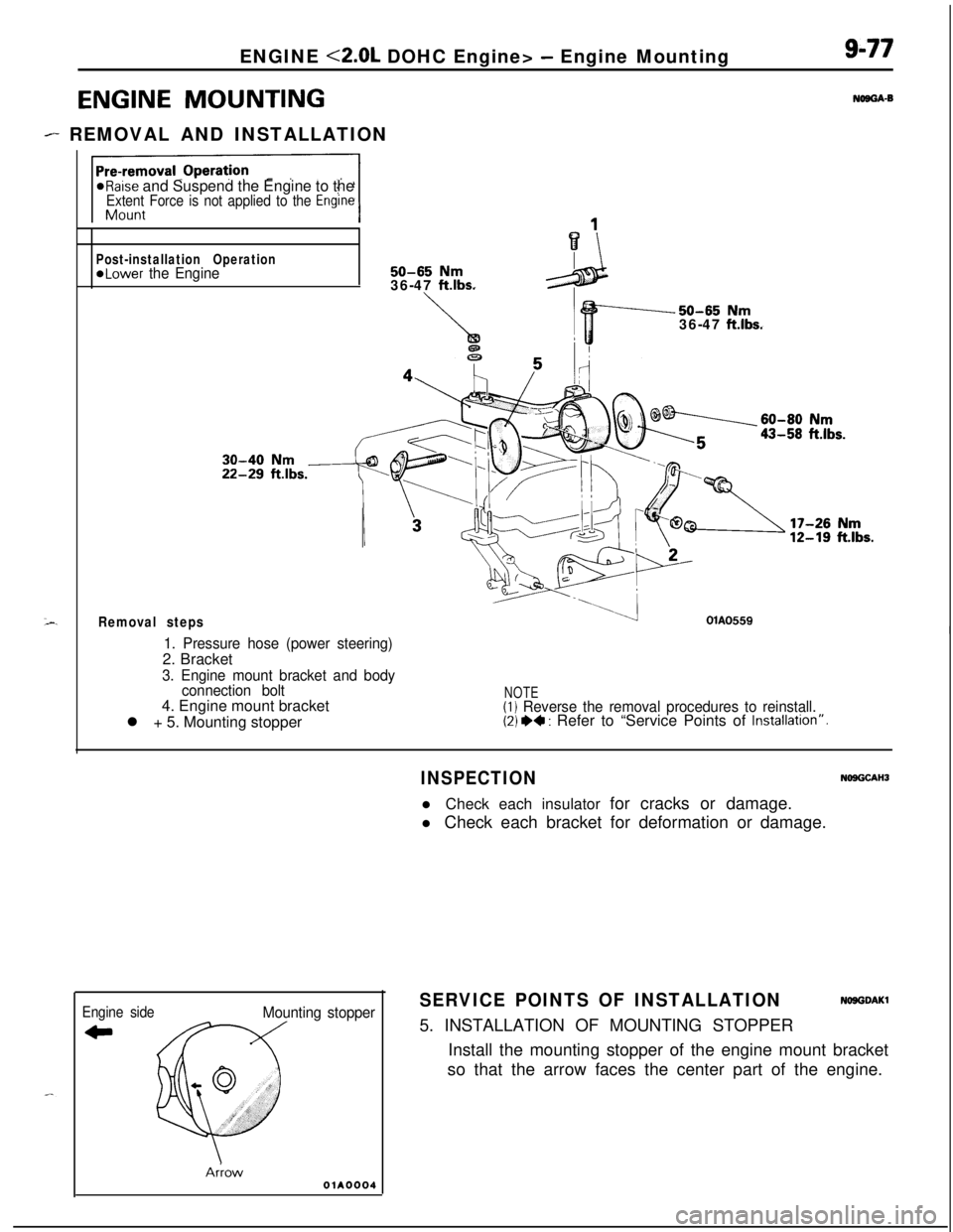

*Raise and Suspend the Engine to theExtent Force is not applied to the Engine

Post-installation Operation@Lower the Engine50-65 Nm36-47 ftlbs.

Removal steps

50-65 Nm36-47 ftlbs.

OlAO559I1. Pressure hose (power steering)2. Bracket

3. Engine mount bracket and body

connection bolt4. Engine mount bracket

l + 5. Mounting stopper

NOTE(1) Reverse the removal procedures to reinstall.(2) *+ : Refer to “Service Points of Installatron”.

Engine side

CI

Mounting stopper

AnowOlA0004

INSPECTIONNOSGCAHJl Check each insulator for cracks or damage.

l Check each bracket for deformation or damage.

SERVICE POINTS OF INSTALLATIONNOSGDAKl5. INSTALLATION OF MOUNTING STOPPER

Install the mounting stopper of the engine mount bracket

so that the arrow faces the center part of the engine.

Page 362 of 1216

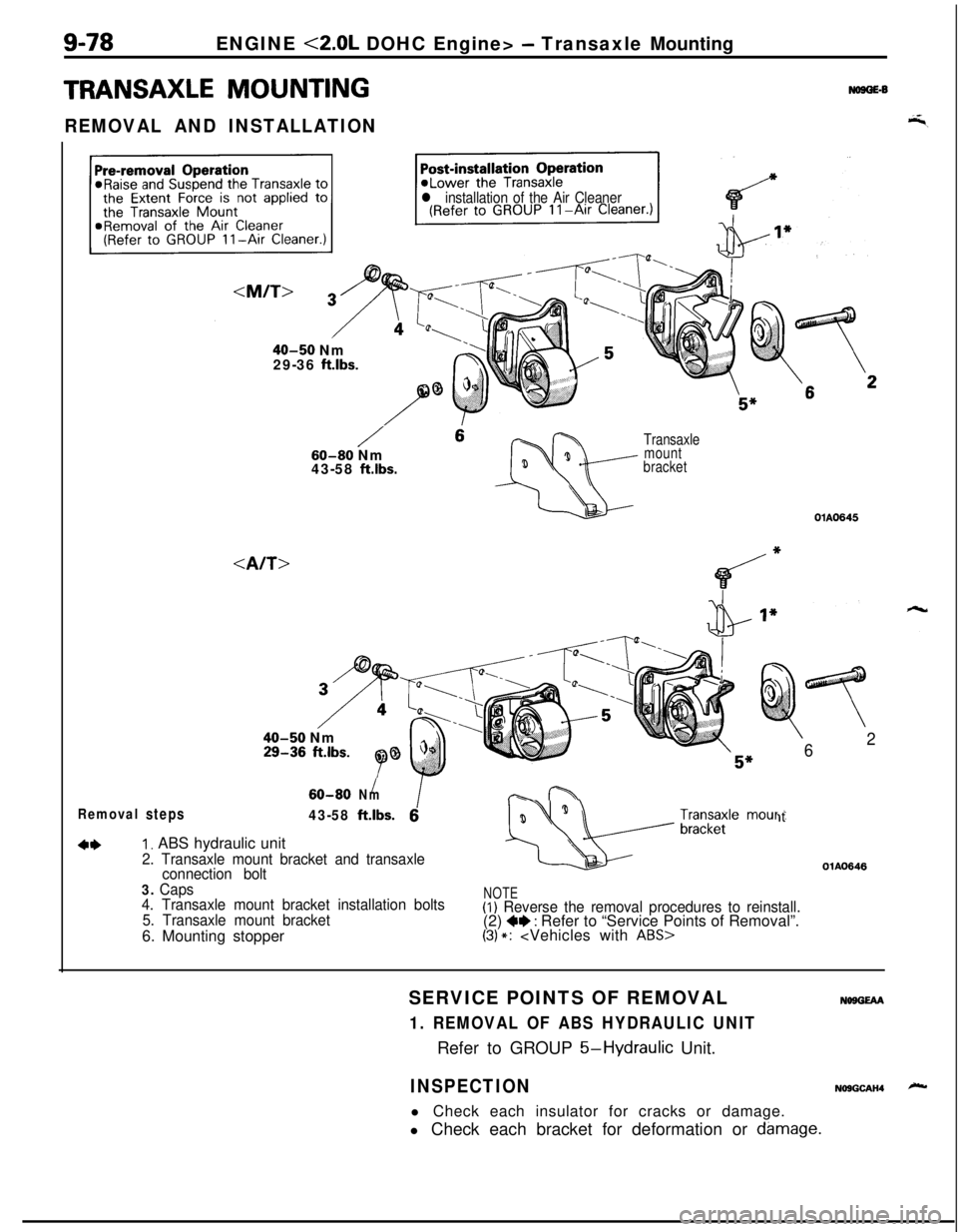

9-78ENGINE <2.0L DOHC Engine> - Transaxle Mounting

TRANSAXLE MOUNTING

REMOVAL AND INSTALLATION

No9GE-6

l installation of the Air Cleaner

40-50 Nm

29-36 ftlbs.

/ 660-80 Nm

43-58 ftlbs.

Transaxle

mount

bracketOlA0645

40-50 Nm

*

6

625”

/60-80Nm-f-h

Removalsteps43-58ftlbs.61t

4*I. ABS hydraulic unit

2. Transaxle mount bracket and transaxle

connection bolt

3. Caps

4. Transaxle mount bracket installation bolts

5. Transaxle mount bracket6. Mounting stopperNOTE(I) Reverse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Removal”.(3) *:

1. REMOVAL OF ABS HYDRAULIC UNITRefer to GROUP

5-Hydraulic Unit.

NO9GEAA

INSPECTIONNOSGCAH4l Check each insulator for cracks or damage.

l Check each bracket for deformation or

dsmage.

Page 363 of 1216

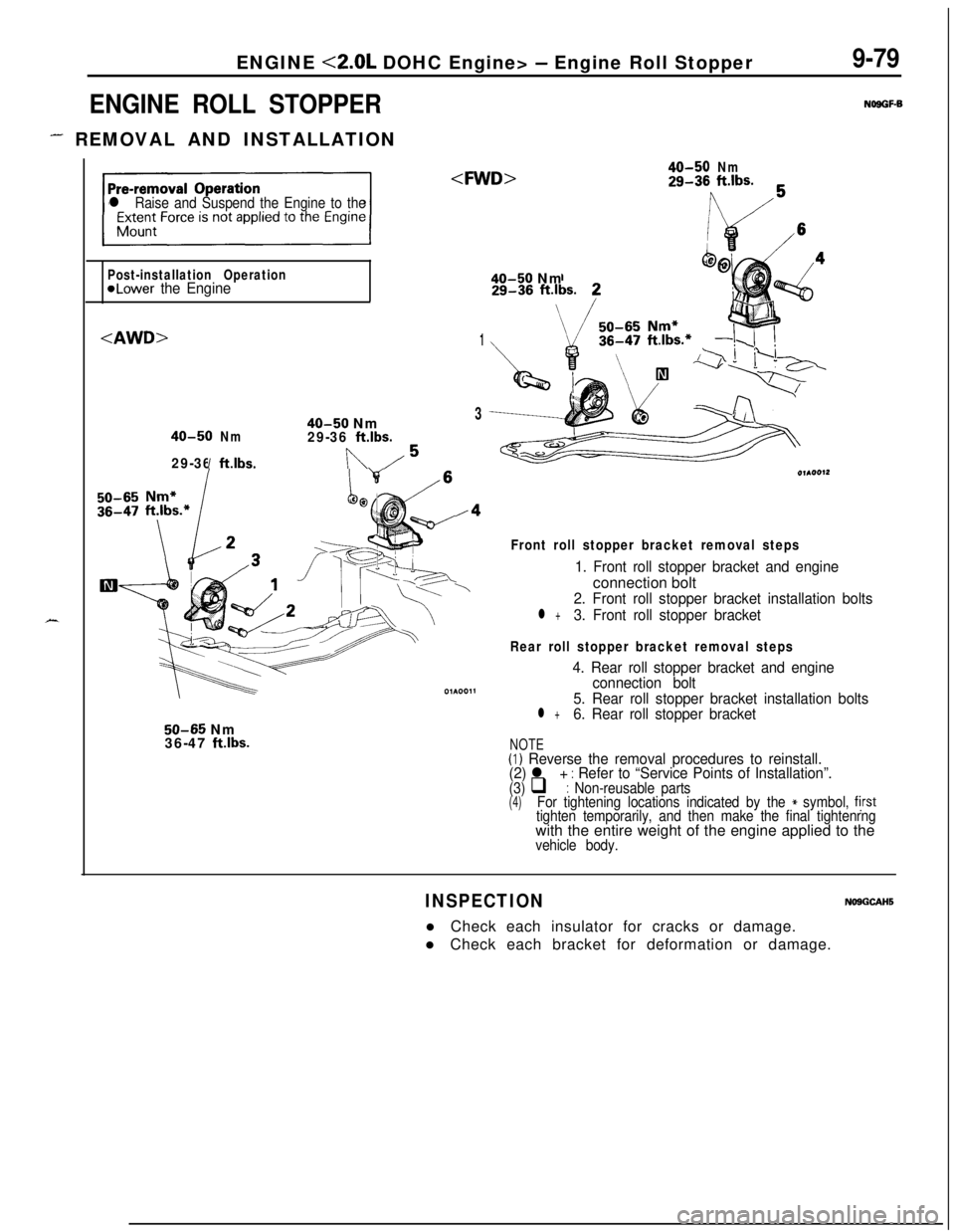

ENGINE <2.0L DOHC Engine> - Engine Roll Stopper

ENGINE ROLL STOPPER

- REMOVAL AND INSTALLATION

9-79

NOSGF-B

X

l Raise and Suspend the Engine to the

40-50Nm29-36ft.lbs.

Post-installation Operation

@Lower the Engine40-50 Nm

1

40-50 Nm3

40-50Nm29-36ft.lbs.

29-36ft.lbs.In/5

/4

\

50-65 Nm

36-47 ftlbs.

Front roll stopper bracket removal steps

1. Front roll stopper bracket and engineconnection bolt

2. Front roll stopper bracket installation bolts

l +3. Front roll stopper bracket

Rear roll stopper bracket removal steps

4. Rear roll stopper bracket and engine

connection bolt

5. Rear roll stopper bracket installation bolts

l +6. Rear roll stopper bracket

NOTE(I) Reverse the removal procedures to reinstall.

(2) l + : Refer to “Service Points of Installation”.(3) q : Non-reusable parts(4)For tightening locations indicated by the * symbol, fjrsttighten temporarily, and then make the final tightenrngwith the entire weight of the engine applied to the

vehicle body.

INSPECTIONNOSGCAHSl Check each insulator for cracks or damage.

l Check each bracket for deformation or damage.

Page 364 of 1216

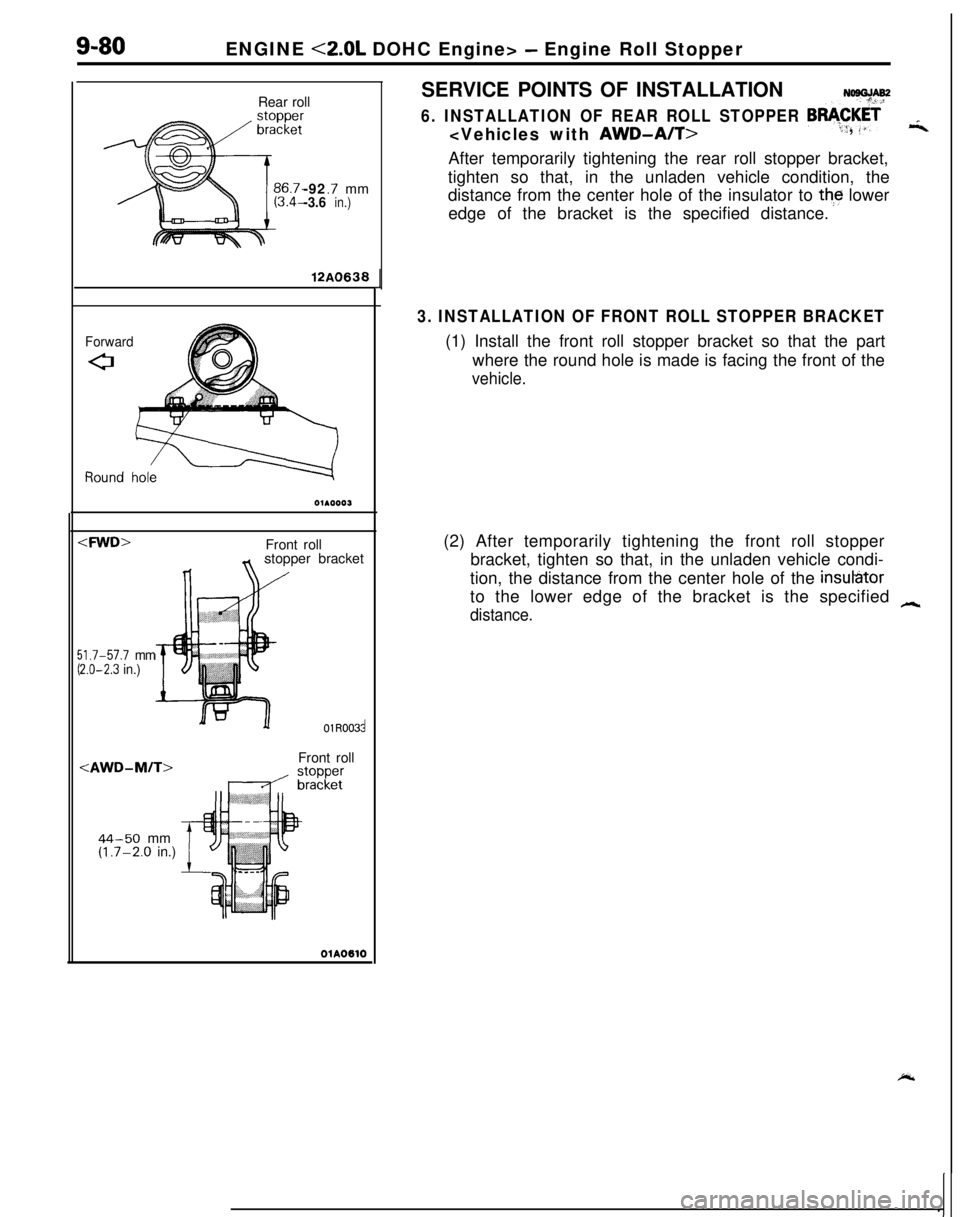

9-80ENGINE <2.0L DOHC Engine> - Engine Roll Stopper

Rear roll

-92

.7 mm-3.6in.)12A0638

Forward

0

:fYVD>Front roll

stopper bracket

/

jl.7-57.7 mm2.0-2.3 in.)olR003t

44-50 mm(1.7-2.0 in.)Front rollOlAO610

J

ISERVICE POINTS OF INSTALLATION

N-$?y

6. INSTALLATION OF REAR ROLL STOPPER BMFKE?

tighten so that, in the unladen vehicle condition, the

distance from the center hole of the insulator to

th:e lower

edge of the bracket is the specified distance.

3. INSTALLATION OF FRONT ROLL STOPPER BRACKET(1) Install the front roll stopper bracket so that the part

where the round hole is made is facing the front of the

vehicle.(2) After temporarily tightening the front roll stopper

bracket, tighten so that, in the unladen vehicle condi-

tion, the distance from the center hole of the

insul&torto the lower edge of the bracket is the specified

-

distance.

Page 365 of 1216

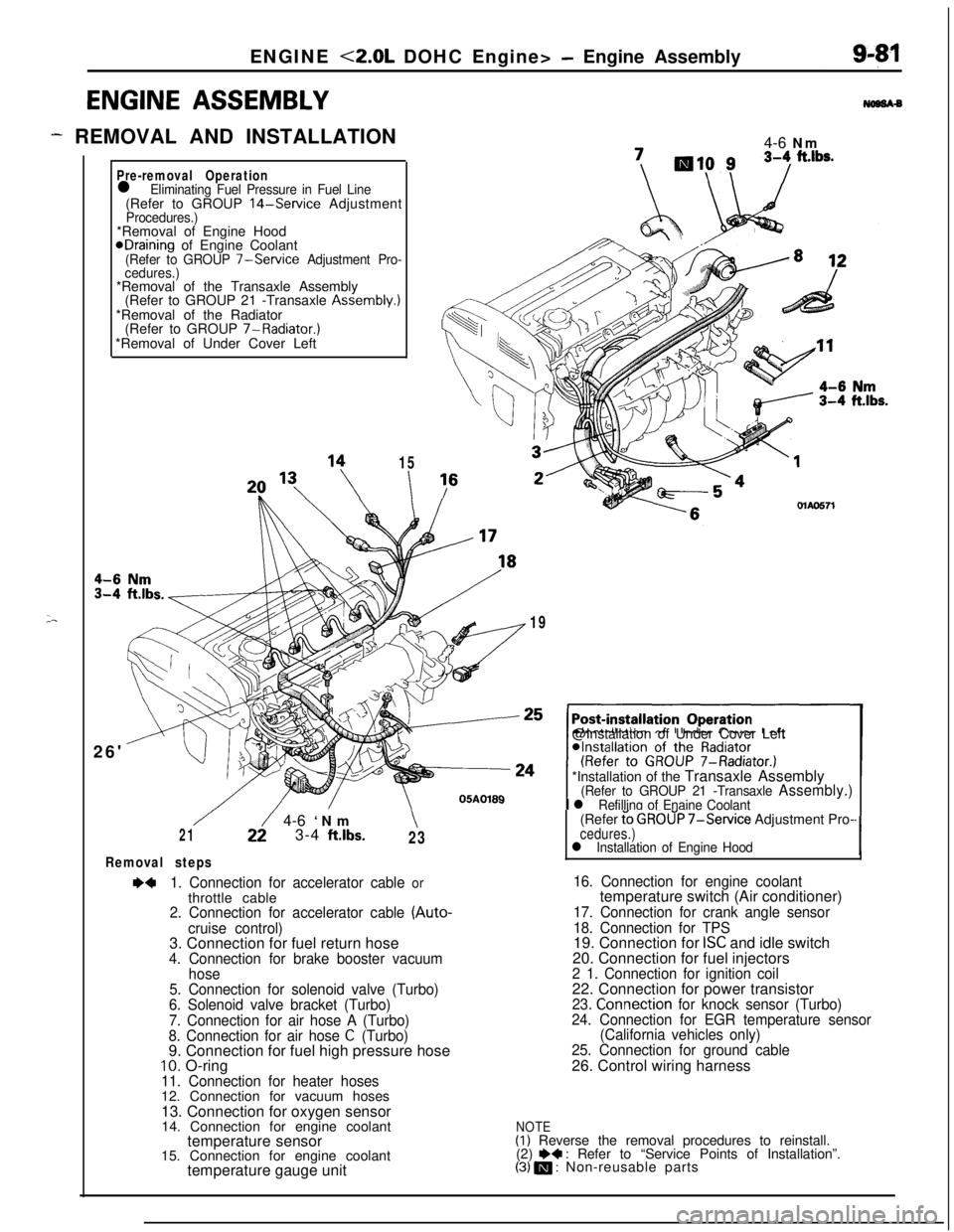

ENGINE <2.0L DOHC Engine> - Engine Assembly

ENGINE ASSEMBLY

- REMOVAL AND INSTALLATION

;-

Pre-removal Operationl Eliminating Fuel Pressure in Fuel Line(Refer to GROUP 14-Service AdjustmentProcedures.)*Removal of Engine Hood

@Draining of Engine Coolant(Refer to GROUP 7-Service Adjustment Pro-

cedures.)*Removal of the Transaxle Assembly

(Refer to GROUP 21 -Transaxle Assembly.)

*Removal of the Radiator

(Refer to GROUP 7-Radiator.)

*Removal of Under Cover Left

26'

15

I4-6 Nm\I /MAO571

19@Installation of Under Cover Left

*Installation of the Transaxle Assembly

(Refer to GROUP 21 -Transaxle Assembly.)

I l Refilling of Enaine Coolant

/22/ 4-6 ‘Nm\213-4 ftlbs.23

Removal steps

~~1. Connection for accelerator cable orthrottle cable

2. Connection for accelerator cable (Auto-

cruise control)3. Connection for fuel return hose

4. Connection for brake booster vacuum

hose

5. Connection for solenoid valve (Turbo)

6. Solenoid valve bracket (Turbo)

7. Connection for air hose A (Turbo)

8. Connection for air hose

C (Turbo)9. Connection for fuel high pressure hose

10. O-ring11. Connection for heater hoses12. Connection for vacuum hoses

13. Connection for oxygen sensor

14. Connection for engine coolant

temperature sensor

15. Connection for engine coolant

temperature gauge unit(Refer

t’o GROUP 7-Service Adjustment Pro-cedures.)l Installation of Engine Hood‘I

16. Connection for engine coolanttemperature switch (Air conditioner)

17. Connection for crank angle sensor

18. Connection for TPS19. Connection for

ISC and idle switch

20. Connection for fuel injectors

2 1. Connection for ignition coil22. Connection for power transistor

23. Connection for knock sensor (Turbo)

24. Connection for EGR temperature sensor

(California vehicles only)

25. Connection for ground cable26. Control wiring harness

NOTE(I) Reverse the removal procedures to reinstall.

(2) e+ : Refer to “Service Points of Installation”.(3) m : Non-reusable parts

Page 366 of 1216

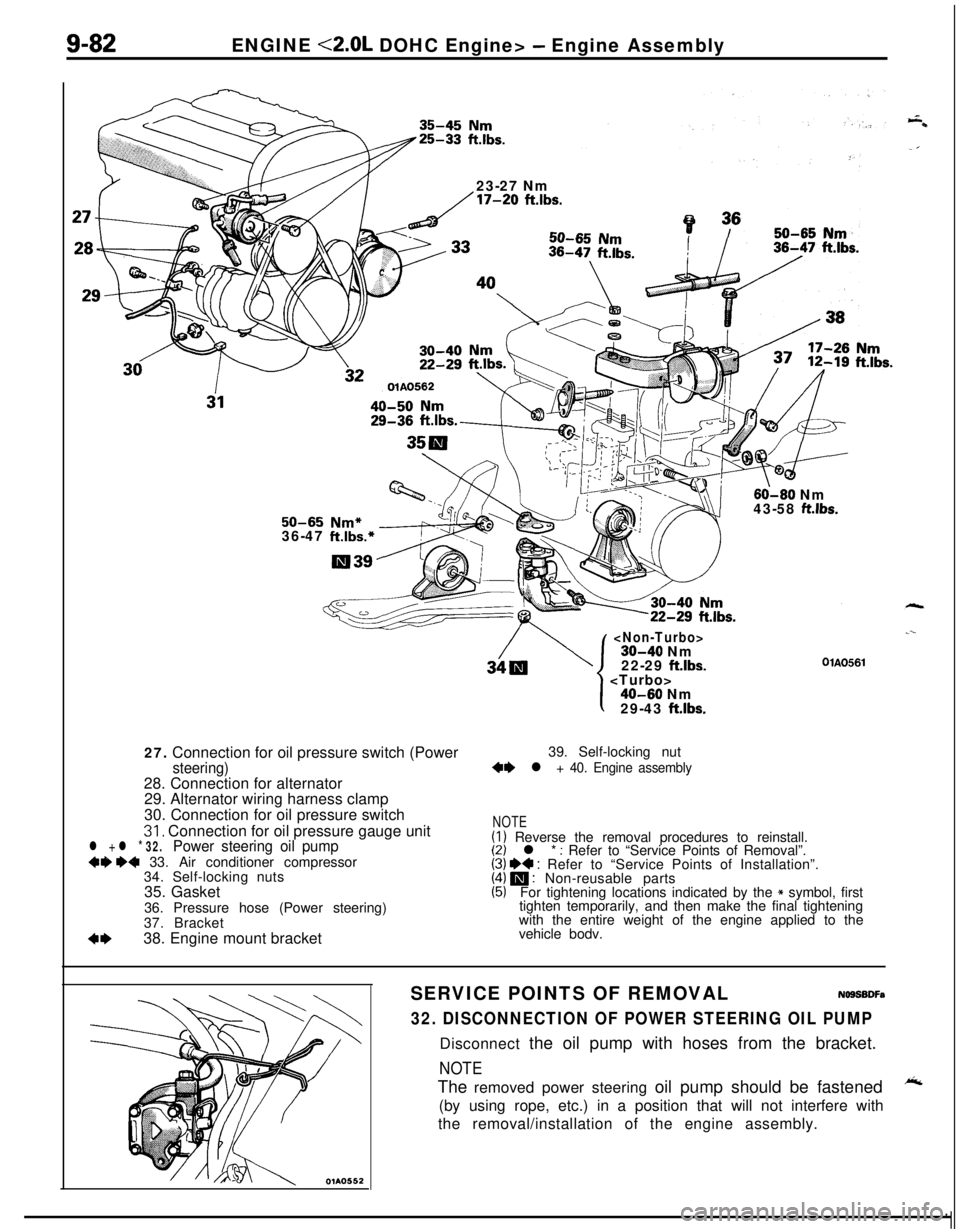

9-82ENGINE <2.0L DOHC Engine> - Engine Assembly

23-27 Nm

/17-20 ftlbs.

60-60 Nm

43-58 ft.lbs.50-65 Nm*36-47 ft.lbs.*27. Connection for oil pressure switch (Power

steering)28. Connection for alternator

29. Alternator wiring harness clamp

30. Connection for oil pressure switch

31, Connection for oil pressure gauge unitl + l * 32.Power steering oil pump+9 ~~ 33. Air conditioner compressor

34. Self-locking nuts

35. Gasket

36. Pressure hose (Power steering)

37. Bracket

4*38. Engine mount bracket

22-29 ftlbs.

.--

OlAO561

1

I40-60 Nm

29-43 ft.lbs.39. Self-locking nut

+e l + 40. Engine assembly

NOTE(I) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.(3) I)+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts(5)For tightening locations indicated by the * symbol, first

tighten temporarily, and then make the final tightening

with the entire weight of the engine applied to the

vehicle bodv.

SERVICE POINTS OF REMOVALNOSSBDFa

32. DISCONNECTION OF POWER STEERING OIL PUMPDisconnect the oil pump with hoses from the bracket.

NOTEThe removed power steering oil pump should be fastened

A(by using rope, etc.) in a position that will not interfere with

the removal/installation of the engine assembly.

Page 367 of 1216

r-.ENGINE <2.0L DOHC Engine>

- Engine AssemblyS-83

OlA0177

-mpp.-/- --OlA0553

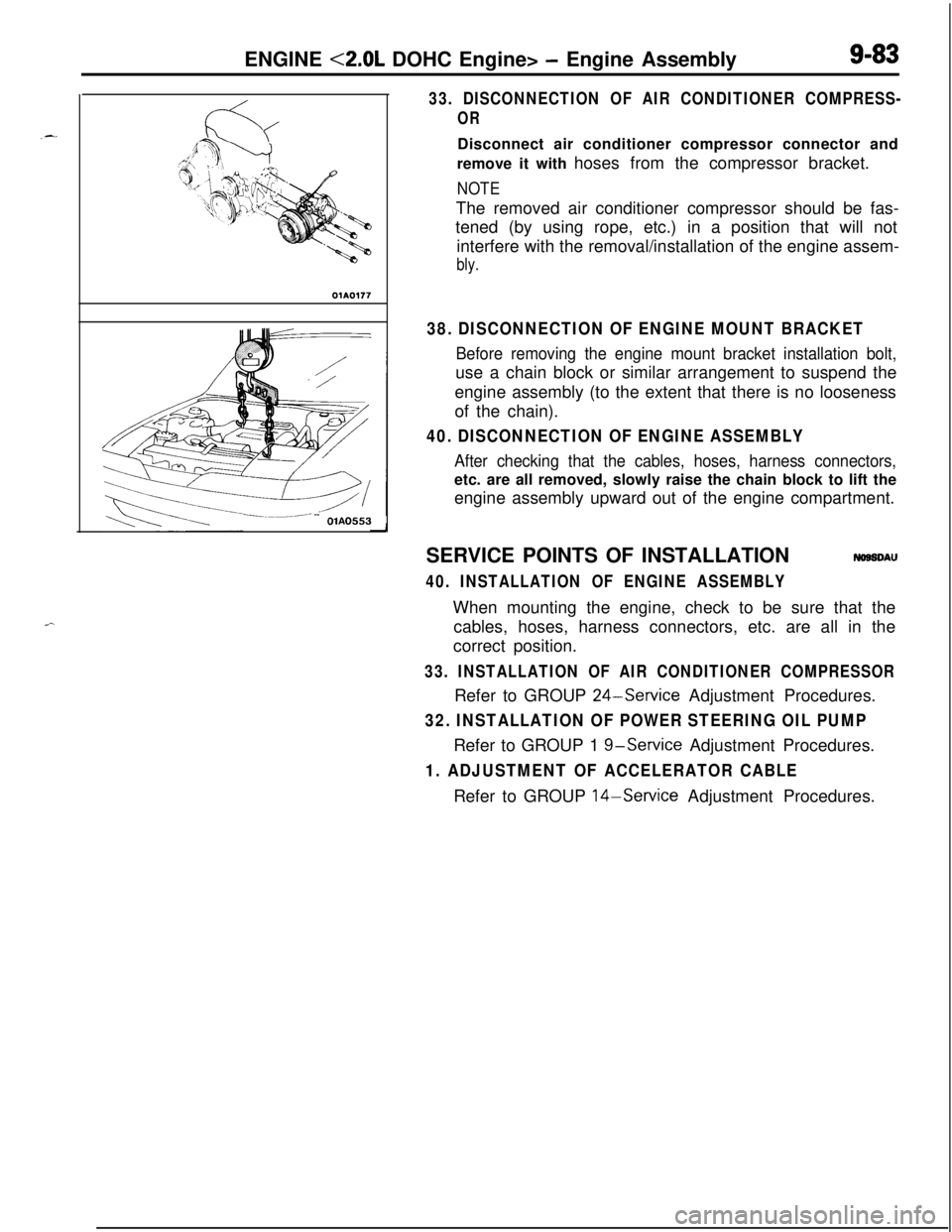

33. DISCONNECTION OF AIR CONDITIONER COMPRESS-

ORDisconnect air conditioner compressor connector and

remove it with hoses from the compressor bracket.

NOTEThe removed air conditioner compressor should be fas-

tened (by using rope, etc.) in a position that will not

interfere with the removal/installation of the engine assem-

bly.

38. DISCONNECTION OF ENGINE MOUNT BRACKET

Before removing the engine mount bracket installation bolt,use a chain block or similar arrangement to suspend the

engine assembly (to the extent that there is no looseness

of the chain).

40. DISCONNECTION OF ENGINE ASSEMBLY

After checking that the cables, hoses, harness connectors,etc. are all removed, slowly raise the chain block to lift the

engine assembly upward out of the engine compartment.

SERVICE POINTS OF INSTALLATION

NOSSDAU

40. INSTALLATION OF ENGINE ASSEMBLYWhen mounting the engine, check to be sure that the

cables, hoses, harness connectors, etc. are all in the

correct position.

33. INSTALLATION OF AIR CONDITIONER COMPRESSORRefer to GROUP

24-Service Adjustment Procedures.

32. INSTALLATION OF POWER STEERING OIL PUMPRefer to GROUP 1

g-service Adjustment Procedures.

1. ADJUSTMENT OF ACCELERATOR CABLERefer to GROUP 14-Service Adjustment Procedures.