engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 328 of 1216

9-44ENGINE <1.8L Engine> - Timing Belt

Rubber

exposedTooth missing and

1 EN0002

Crankshaftsprocket “6

Crankshaft 6EN304

Spacer

Chamfered

6EN009

J

TiGGrnmarkCrankshaft

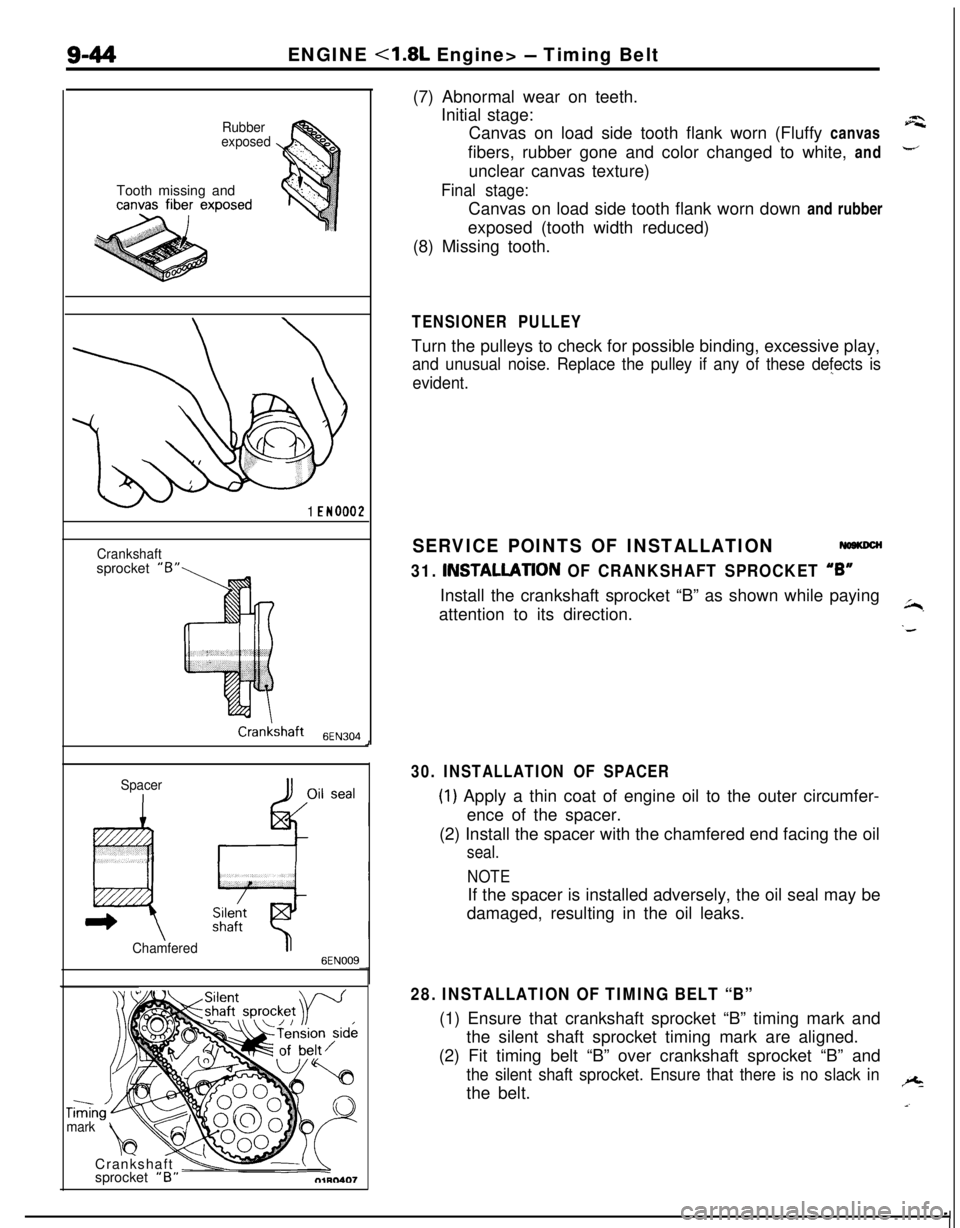

\vsprocket “B”(7) Abnormal wear on teeth.

Initial stage:

Canvas on load side tooth flank worn (Fluffy canvas

afibers, rubber gone and color changed to white, and

-unclear canvas texture)

Final stage:Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth.

TENSIONER PULLEYTurn the pulleys to check for possible binding, excessive play,

and unusual noise. Replace the pulley if any of these defects is

evident.”

SERVICE POINTS OF INSTALLATION

31. INSTALLATlON OF CRANKSHAFT SPROCKET “6”Install the crankshaft sprocket “B” as shown while paying

attention to its direction.

~,

‘d

30. INSTALLATION OF SPACER

(1) Apply a thin coat of engine oil to the outer circumfer-

ence of the spacer.

(2) Install the spacer with the chamfered end facing the oil

seal.

NOTEIf the spacer is installed adversely, the oil seal may be

damaged, resulting in the oil leaks.

28. INSTALLATION OF TIMING BELT “B”(1) Ensure that crankshaft sprocket “B” timing mark and

the silent shaft sprocket timing mark are aligned.

(2) Fit timing belt “B” over crankshaft sprocket “B” and

the silent shaft sprocket. Ensure that there is no slack inthe belt.+

a.

Page 329 of 1216

ENGINE <1.8L Engine> - Timing Belt9-45

J

I01R0409

Crankshaftsprocket )IB”

I

CrankshafisprocketCrankshaft

6EN2721

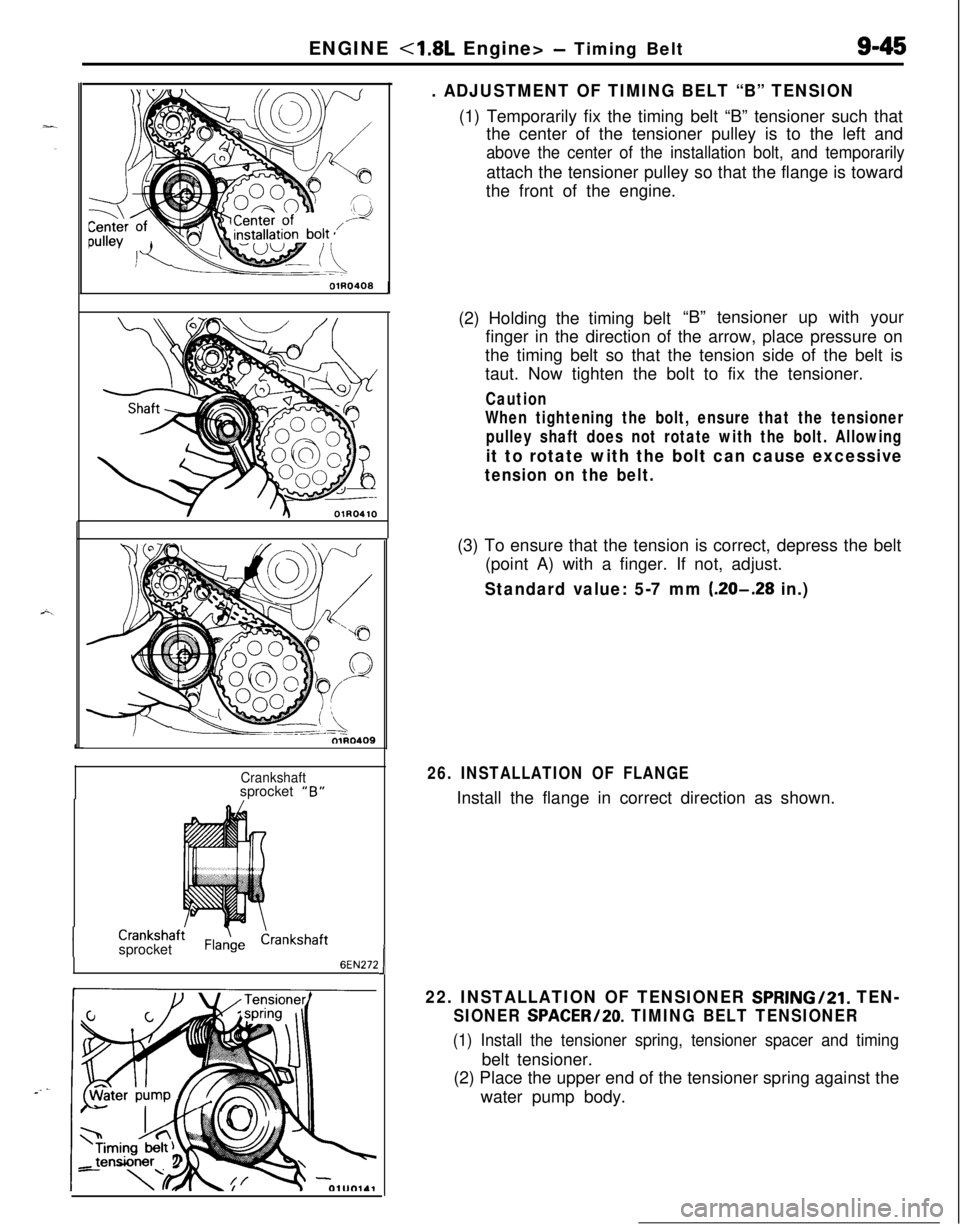

. ADJUSTMENT OF TIMING BELT “B” TENSION(1) Temporarily fix the timing belt “B” tensioner such that

the center of the tensioner pulley is to the left and

above the center of the installation bolt, and temporarilyattach the tensioner pulley so that the flange is toward

the front of the engine.

(2) Holding the timing belt“B” tensioner up with your

finger in the direction of the arrow, place pressure on

the timing belt so that the tension side of the belt is

taut. Now tighten the bolt to fix the tensioner.

Caution

When tightening the bolt, ensure that the tensioner

pulley shaft does not rotate with the bolt. Allowing

it to rotate with the bolt can cause excessive

tension on the belt.(3) To ensure that the tension is correct, depress the belt

(point A) with a finger. If not, adjust.

Standard value: 5-7 mm (.20-.28 in.)

26. INSTALLATION OF FLANGEInstall the flange in correct direction as shown.

22. INSTALLATION OF TENSIONER SPRING/21. TEN-

SIONER SPACERI20. TIMING BELT TENSIONER

(1) Install the tensioner spring, tensioner spacer and timingbelt tensioner.

(2) Place the upper end of the tensioner spring against the

water pump body.

Page 330 of 1216

9-46ENGINE <1.8L Engine> - Timing Belt

Timing mark

Q1hQS4.9

3EN005

OlA0549

c

::

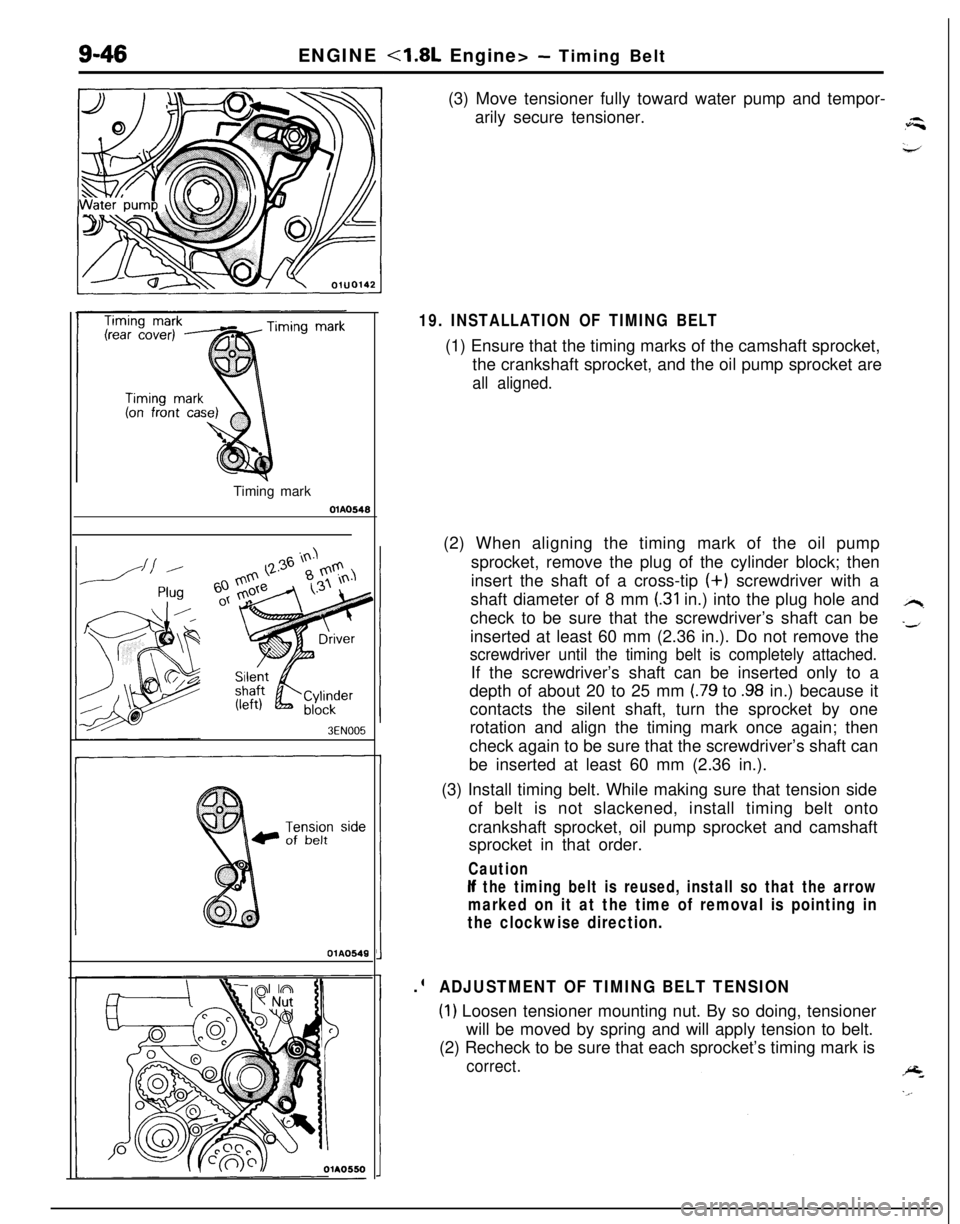

OlAO550-(3) Move tensioner fully toward water pump and tempor-

arily secure tensioner.

19. INSTALLATION OF TIMING BELT(1) Ensure that the timing marks of the camshaft sprocket,

the crankshaft sprocket, and the oil pump sprocket are

all aligned.(2) When aligning the timing mark of the oil pump

sprocket, remove the plug of the cylinder block; then

insert the shaft of a cross-tip (+) screwdriver with a

shaft diameter of 8 mm

(.31 in.) into the plug hole and

check to be sure that the screwdriver’s shaft can be

inserted at least 60 mm (2.36 in.). Do not remove the

screwdriver until the timing belt is completely attached.If the screwdriver’s shaft can be inserted only to a

depth of about 20 to 25 mm

(.79 to .98 in.) because it

contacts the silent shaft, turn the sprocket by one

rotation and align the timing mark once again; then

check again to be sure that the screwdriver’s shaft can

be inserted at least 60 mm (2.36 in.).

(3) Install timing belt. While making sure that tension side

of belt is not slackened, install timing belt onto

crankshaft sprocket, oil pump sprocket and camshaft

sprocket in that order.

Caution

If the timing belt is reused, install so that the arrow

marked on it at the time of removal is pointing in

the clockwise direction..

ADJUSTMENT OF TIMING BELT TENSION

(1) Loosen tensioner mounting nut. By so doing, tensioner

will be moved by spring and will apply tension to belt.

(2) Recheck to be sure that each sprocket’s timing mark is

correct.

Page 331 of 1216

ENGINE <1.8L Engine> - Timing Belt9-47

Timing mark

Nut

;olt diameter x lengthim (in.)

6x50(.23 x 1.97)

6

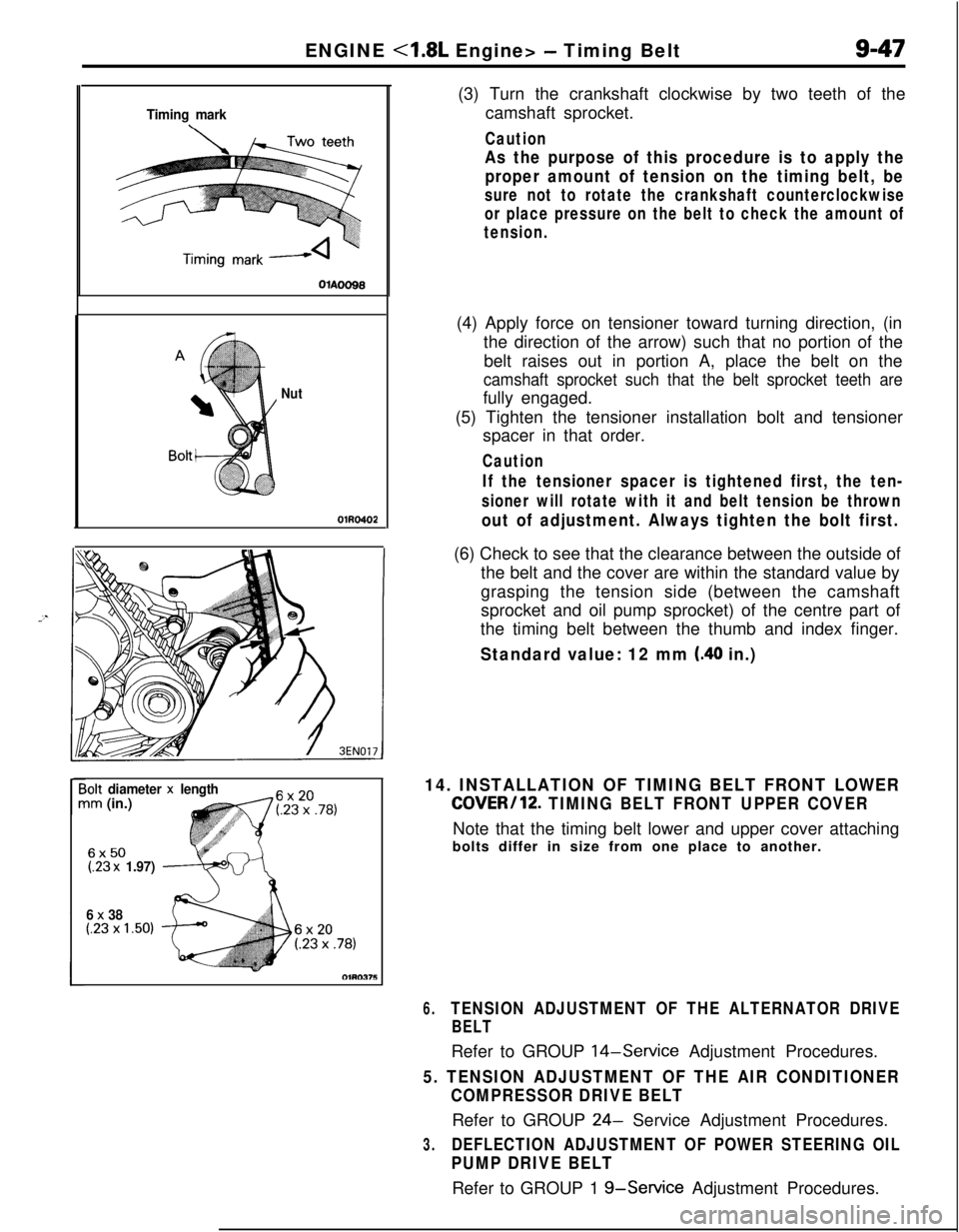

x 38(.23 x 1.50)(3) Turn the crankshaft clockwise by two teeth of the

camshaft sprocket.

Caution

As the purpose of this procedure is to apply the

proper amount of tension on the timing belt, be

sure not to rotate the crankshaft counterclockwise

or place pressure on the belt to check the amount of

tension.(4) Apply force on tensioner toward turning direction, (in

the direction of the arrow) such that no portion of the

belt raises out in portion A, place the belt on the

camshaft sprocket such that the belt sprocket teeth arefully engaged.

(5) Tighten the tensioner installation bolt and tensioner

spacer in that order.

Caution

If the tensioner spacer is tightened first, the ten-

sioner will rotate with it and belt tension be thrown

out of adjustment. Always tighten the bolt first.(6) Check to see that the clearance between the outside of

the belt and the cover are within the standard value by

grasping the tension side (between the camshaft

sprocket and oil pump sprocket) of the centre part of

the timing belt between the thumb and index finger.

Standard value: 12 mm (.40 in.)

14. INSTALLATION OF TIMING BELT FRONT LOWER

COVER/12. TIMING BELT FRONT UPPER COVERNote that the timing belt lower and upper cover attaching

bolts differ in size from one place to another.

6.TENSION ADJUSTMENT OF THE ALTERNATOR DRIVE

BELTRefer to GROUP

14-Service Adjustment Procedures.

5. TENSION ADJUSTMENT OF THE AIR CONDITIONER

COMPRESSOR DRIVE BELTRefer to GROUP

24- Service Adjustment Procedures.

3.DEFLECTION ADJUSTMENT OF POWER STEERING OIL

PUMP DRIVE BELTRefer to GROUP 1

g-Service Adjustment Procedures.

Page 332 of 1216

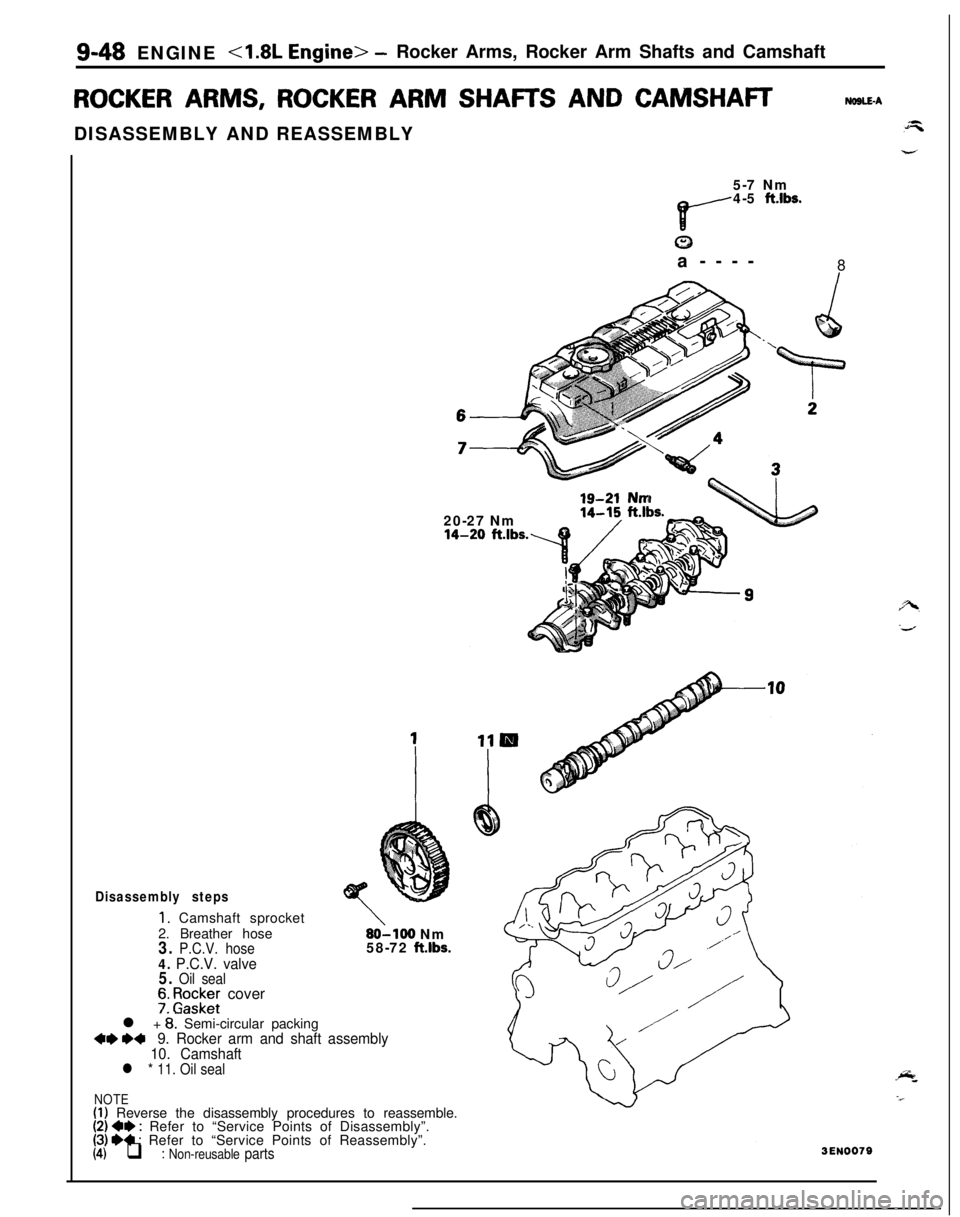

9-48 ENGINE <1.8L Engine> -Rocker Arms, Rocker Arm Shafts and Camshaft

ROCKER ARMS, ROCKER ARM SHAFTS AND CAMSHAFTUOSLE-ADISASSEMBLY AND REASSEMBLY

5-7 Nm

4-5 ft.lbr

8a----

20-27 Nm

19-21 Nm8

Disassembly steps

1. Camshaft sprocket

2. Breather hose

3. P.C.V. hose4. P.C.V. valve5. Oil seal;. Fbz;~; cover

SO-100 Nm

58-72 ft.lbs.l +

8: Semi-circular packing+e I)+9. Rocker arm and shaft assembly

10. Camshaft

l * 11. Oil seal

NOTE(1) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) W : Refer to “Service Points of Reassembly”.(4) q : Non-reusable parts

Page 333 of 1216

ENGINE <1.8L Ennine> -Rocker Arms, Rocker Arm Shafts and Camshaft&49

MD9984431

6EN245

IFuel pump

3EN287

r

0

Camheight6EN0184

hl,

3EN153, Oil seal

MD998364

DEN632

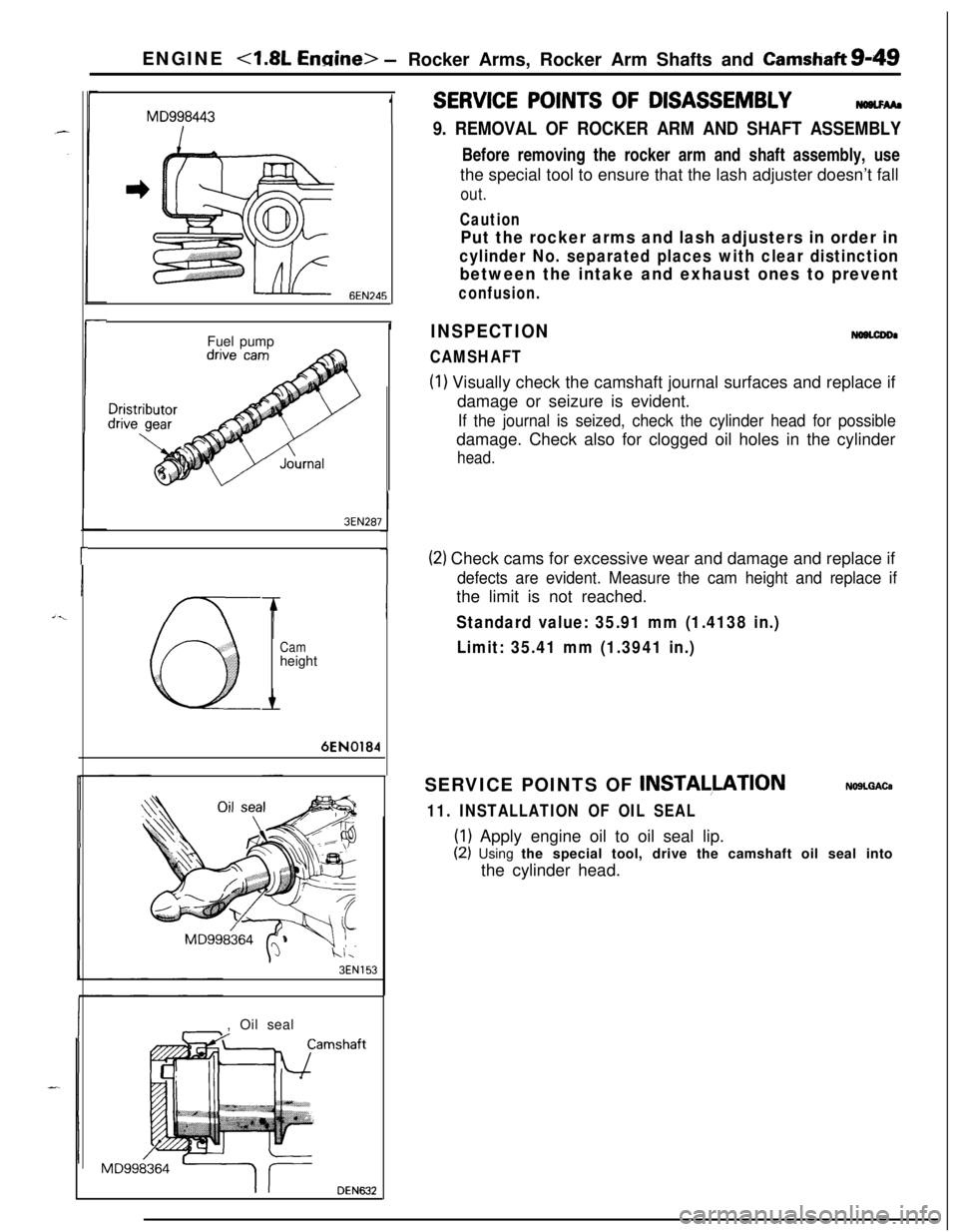

SERVICE POINTS OF DISASSEMBLYNWLFM.

9. REMOVAL OF ROCKER ARM AND SHAFT ASSEMBLYBefore removing the rocker arm and shaft assembly, use

the special tool to ensure that the lash adjuster doesn’t fall

out.

Caution

Put the rocker arms and lash adjusters in order in

cylinder No. separated places with clear distinction

between the intake and exhaust ones to prevent

confusion.

INSPECTION

CAMSHAFT

NOBLCDDI

(1) Visually check the camshaft journal surfaces and replace if

damage or seizure is evident.

If the journal is seized, check the cylinder head for possibledamage. Check also for clogged oil holes in the cylinder

head.

(2) Check cams for excessive wear and damage and replace if

defects are evident. Measure the cam height and replace ifthe limit is not reached.

Standard value: 35.91 mm (1.4138 in.)

Limit: 35.41 mm (1.3941 in.)SERVICE POINTS OF

INSTALLATIONNOSLQACa

11. INSTALLATION OF OIL SEAL

(1) Apply engine oil to oil seal lip.

(2) Using the special tool, drive the camshaft oil seal into

the cylinder head.

Page 334 of 1216

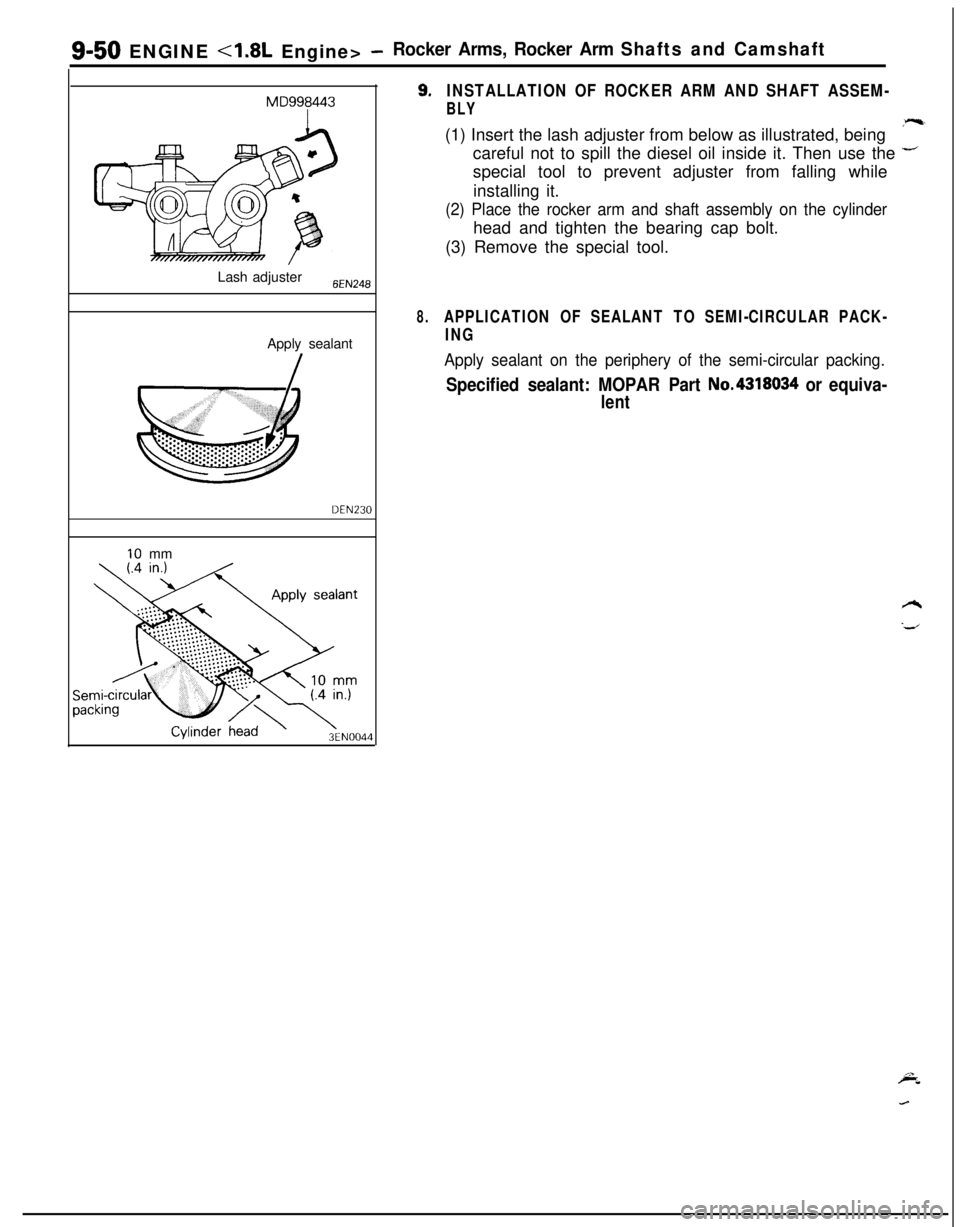

S-50 ENGINE 4.8L Engine> -Rocker Arms, Rocker Arm Shafts and Camshaft

MD998443Lash adjuster

6EN248Apply sealant

DEN230

10 mm

3EN0044

9.INSTALLATION OF ROCKER ARM AND SHAFT ASSEM-

BLY(1) Insert the lash adjuster from below as illustrated, being

*-careful not to spill the diesel oil inside it. Then use the

+special tool to prevent adjuster from falling while

installing it.

(2) Place the rocker arm and shaft assembly on the cylinderhead and tighten the bearing cap bolt.

(3) Remove the special tool.

8.APPLICATION OF SEALANT TO SEMI-CIRCULAR PACK-

ING

Apply sealant on the periphery of the semi-circular packing.

Specified sealant: MOPAR Part No.4318034 or equiva-

lent

Page 335 of 1216

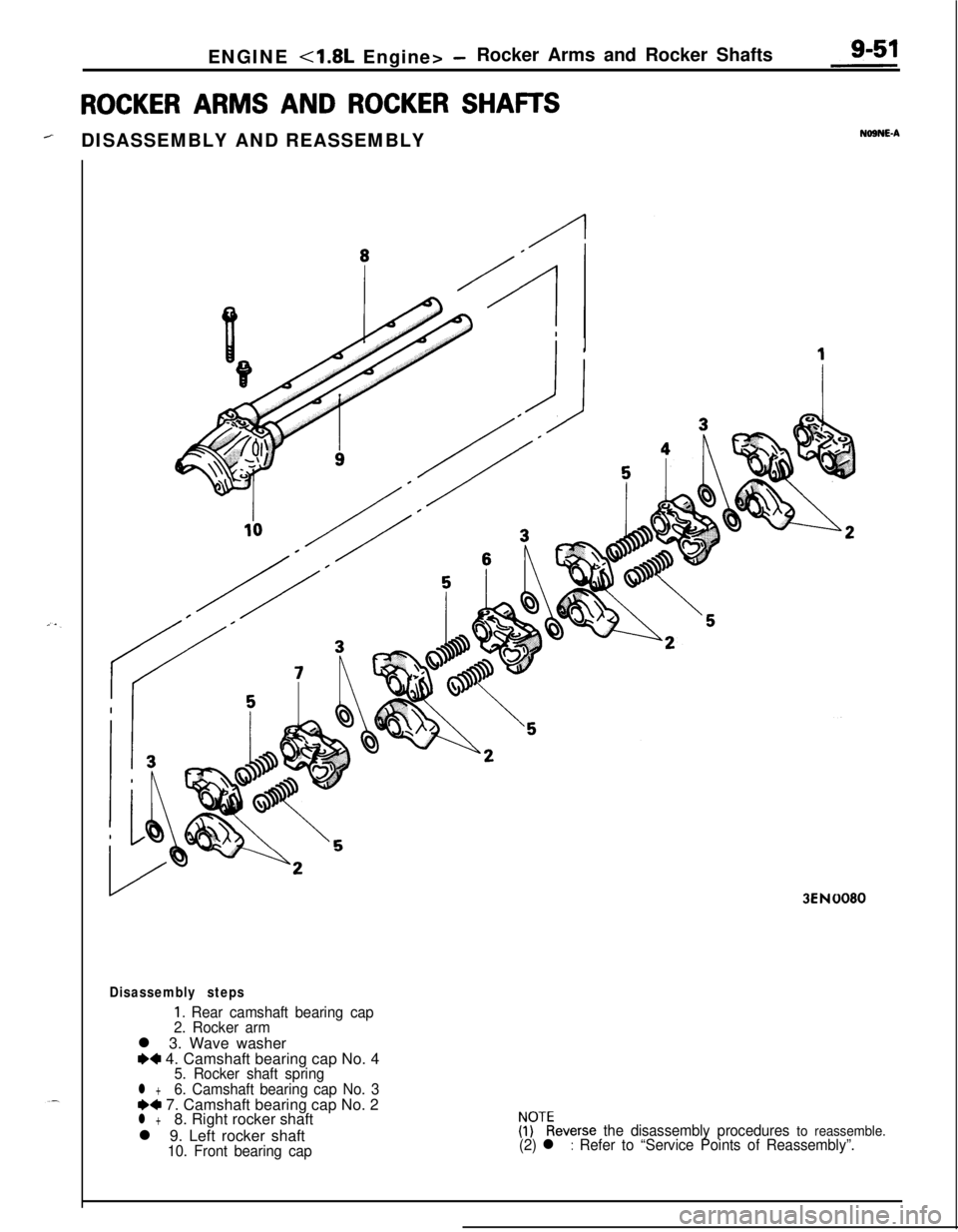

ENGINE <1.8L Engine> -Rocker Arms and Rocker Shafts

ROCKER ARMS AND ROCKER SHAFTS

RDISASSEMBLY AND REASSEMBLYNOSNE-A3EN0080

Disassembly steps

1. Rear camshaft bearing cap

2. Rocker arml 3. Wave washer

~~ 4. Camshaft bearing cap No. 45. Rocker shaft spring

l +6. Camshaft bearing cap No. 3~~ 7. Camshaft bearing cap No. 2l +8. Right rocker shaft

l 9. Left rocker shaft

10. Front bearing cap

lybeverse the disassembly procedures to reassemble.(2) l : Refer to “Service Points of Reassembly”.

Page 336 of 1216

7EN0064

IIENGINE

<1.8L Engine> -Rocker Arms and Rocker Shafts

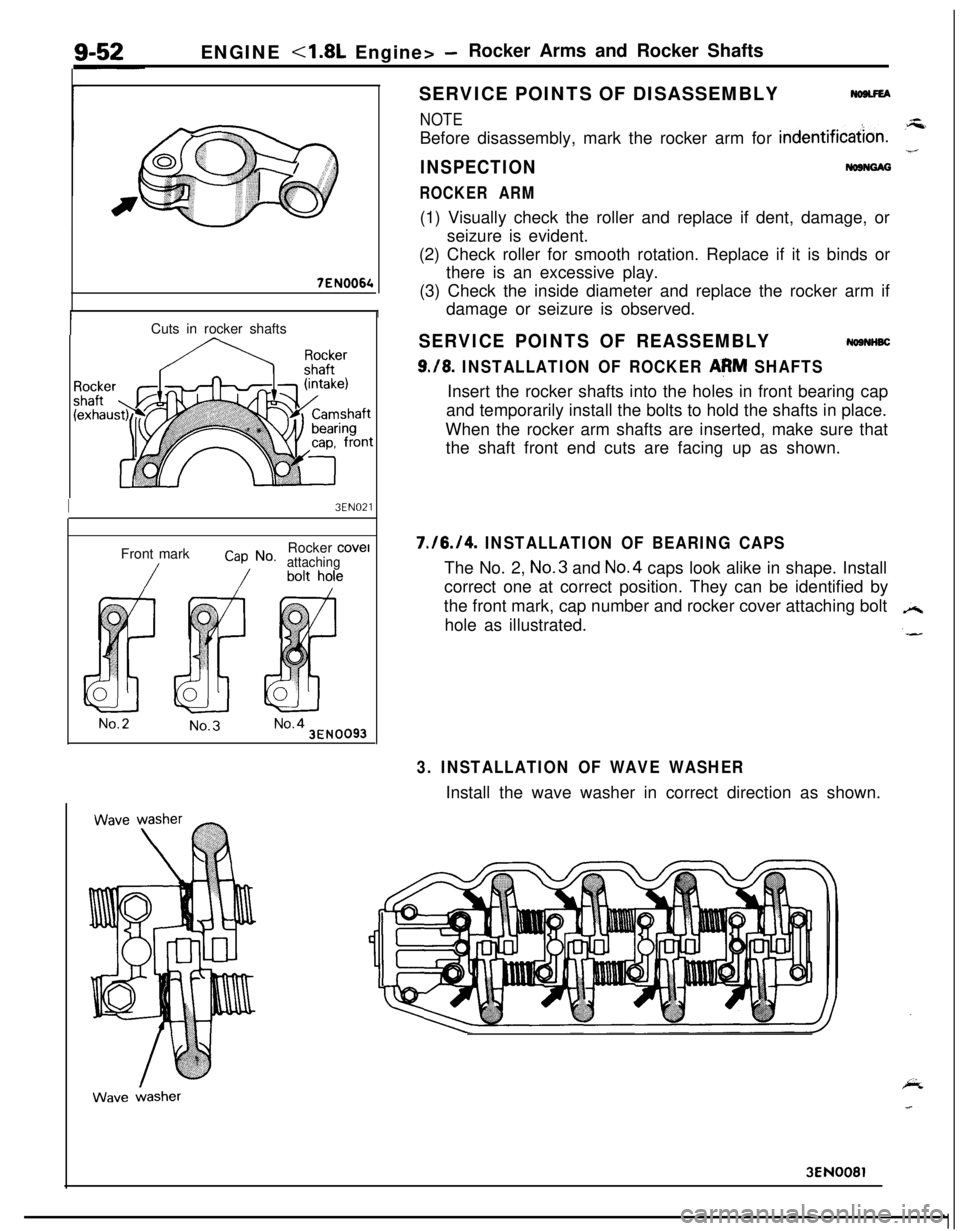

SERVICE POINTS OF DISASSEMBLY

NOTEBefore disassembly, mark the rocker arm for

indentificahon.

INSPECTIONNoaNGAG

ROCKER ARM(1) Visually check the roller and replace if dent, damage, or

seizure is evident.

(2) Check roller for smooth rotation. Replace if it is binds or

there is an excessive play.

ICuts in rocker shafts(3) Check the inside diameter and replace the rocker arm if

damage or seizure is observed.SERVICE POINTS OF REASSEMBLYNOBNHBC

9./8. INSTALLATION OF ROCKER AeM SHAFTSInsert the rocker shafts into the holes in front bearing cap

and temporarily install the bolts to hold the shafts in place.

When the rocker arm shafts are inserted, make sure that

the shaft front end cuts are facing up as shown.

I3EN021Front mark

Cap No.Rocker cove1attaching

No.2No.3No.43EN0093

7./6./4. INSTALLATION OF BEARING CAPSThe No. 2, No.3 and No.4 caps look alike in shape. Install

correct one at correct position. They can be identified by

the front mark, cap number and rocker cover attaching bolt

hole as illustrated.

3. INSTALLATION OF WAVE WASHERInstall the wave washer in correct direction as shown.

3EN0081

Page 337 of 1216

ENGINE <1.8L Engine>- Cylinder Head and Valve9-53

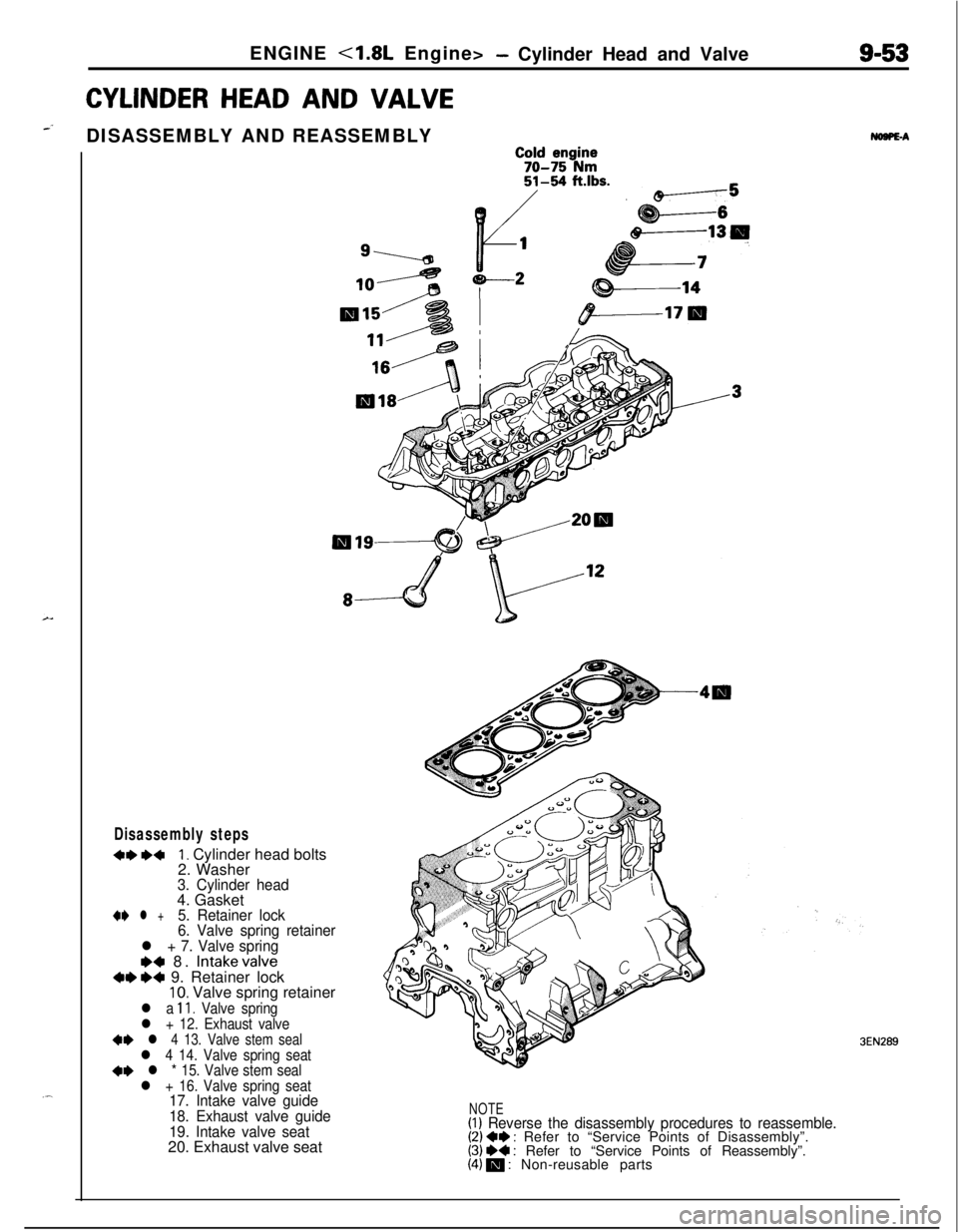

CYLINDERHEADAND VALVE

-’DISASSEMBLY AND REASSEMBLYNDSPE-A

C;;d ;;g$;

51154 ftlbs.

&

, tP-----5

1g-.-a

105 y----2g&---l4

Disassembly steps

+e ~~I. Cylinder head bolts

2. Washer

3. Cylinder head4. Gasket

+e l +5. Retainer lock

6. Valve spring retainer

l + 7. Valve spring

~~ 8. Intakevalve+e e+ 9. Retainer lock10. Valve spring retainer

l a 11. Valve springl + 12. Exhaust valve+* l 4 13. Valve stem seall 4 14. Valve spring seat4I) l * 15. Valve stem seall + 16. Valve spring seat17. Intake valve guide

18. Exhaust valve guide

19. Intake valve seat20. Exhaust valve seatNOTE(I) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) ~~ : Refer to “Service Points of Reassembly”.(4) m : Non-reusable parts

3EN289