torque MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1015 of 1216

AUTOMATIC TRANSAXLE - Differential21-321

. MD99881 2

MD998822

TFY0040

I166630

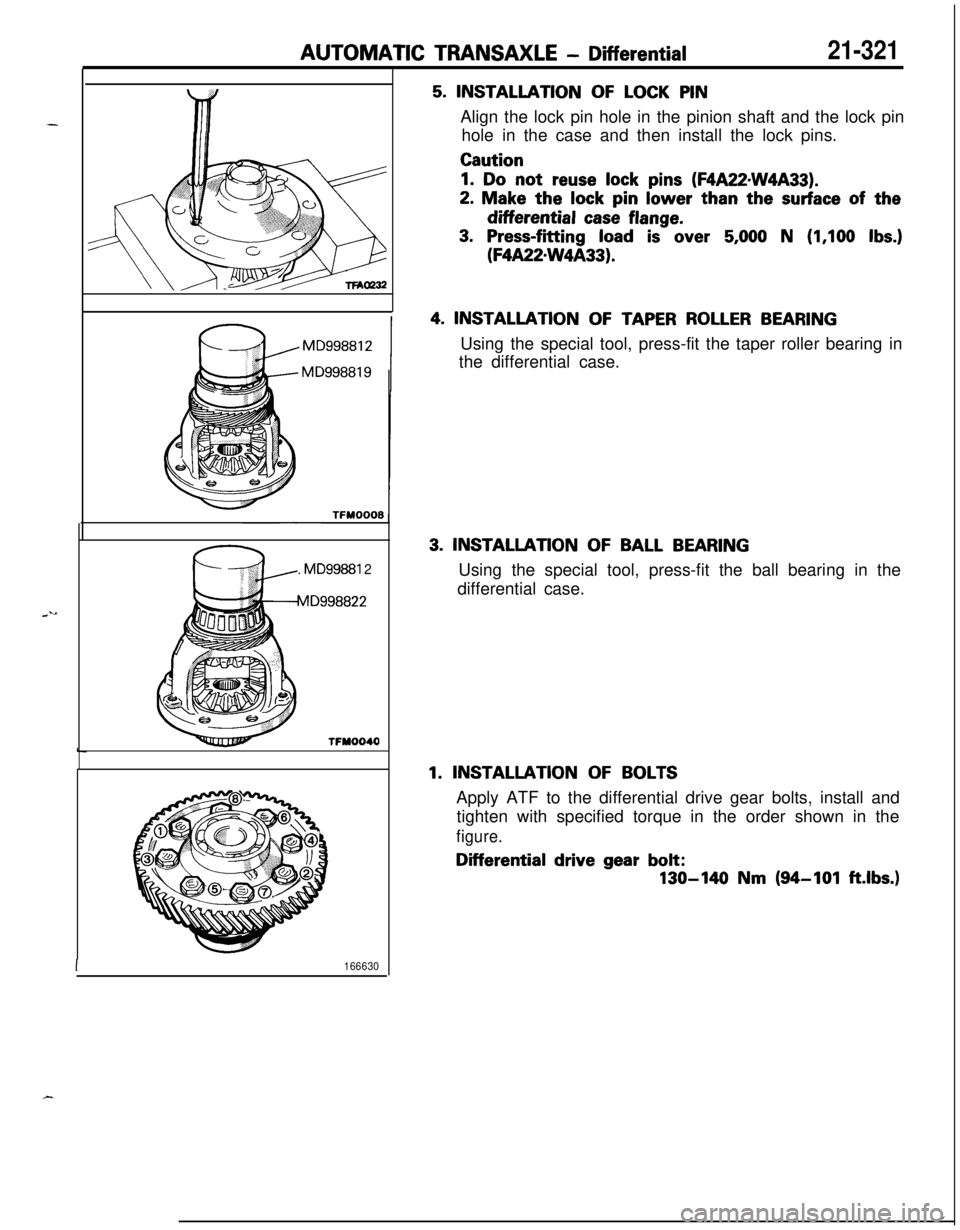

5. INSTALLATION OF LOCK PINAlign the lock pin hole in the pinion shaft and the lock pin

hole in the case and then install the lock pins.Caution

1. Do not reuse lock pins (F4A22wW4A33).

2. Make the lock pin lower than the surface of thedifferential

case flange.

3. Press-fitting load is over 5,000 N (1,100 Ibs.)

(F4A22sW4A33).

4. INSTALLATION OF TAPER ROLLER BEARINGUsing the special tool, press-fit the taper roller bearing in

the differential case.

3. INSTALLATION OF BALL BEARINGUsing the special tool, press-fit the ball bearing in the

differential case.

1. INSTALLATION OF BOLTSApply ATF to the differential drive gear bolts, install and

tighten with specified torque in the order shown in the

figure.Differential drive gear bolt:

130-140 Nm (94-101 ft.lbs.)

r

Page 1019 of 1216

AUTOMATIC TRANSAXLE - Valve Bodv2646

38

I24

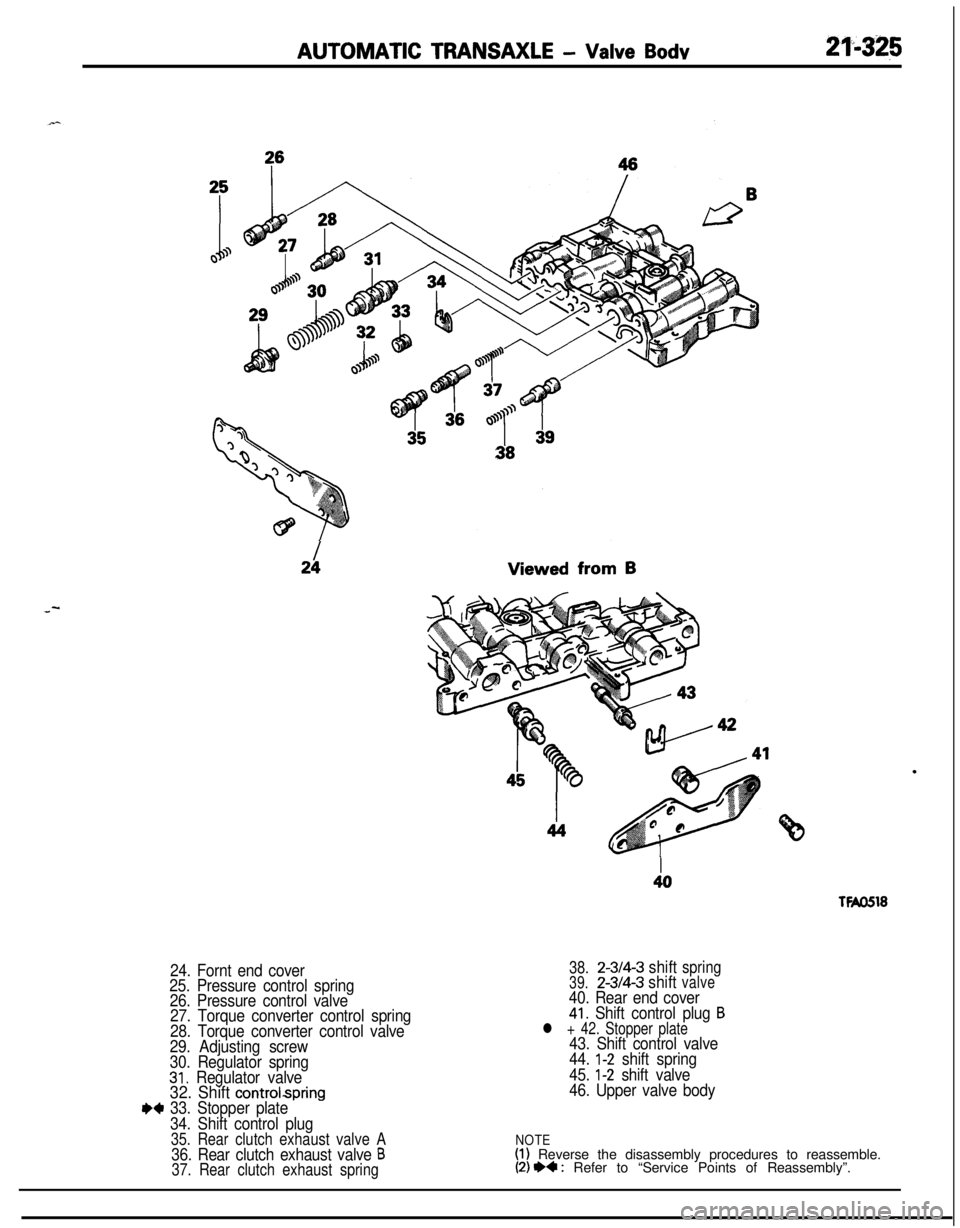

24. Fornt end cover

25. Pressure control spring

26. Pressure control valve

27. Torque converter control spring

28. Torque converter control valve

29. Adjusting screw

30. Regulator spring

31. Regulator valve32. Shift controlspring++ 33. Stopper plate

34. Shift control plug

35. Rear clutch exhaust valve A36. Rear clutch exhaust valve B37. Rear clutch exhaust springViewed from

B

.

I40

TFA0518

38.2-314-3shiftspring39.2-3/4-3shiftvalve40. Rear end cover41. Shift control plug Bl + 42. Stopper plate43. Shift control valve

44. l-2 shift spring

45.

l-2 shift valve

46. Upper valve body

NOTE(1) Reverse the disassembly procedures to reassemble.(2) I)4 : Refer to “Service Points of Reassembly”.

Page 1024 of 1216

21-330AUTOMATIC TRANSAXLE - Center Differential

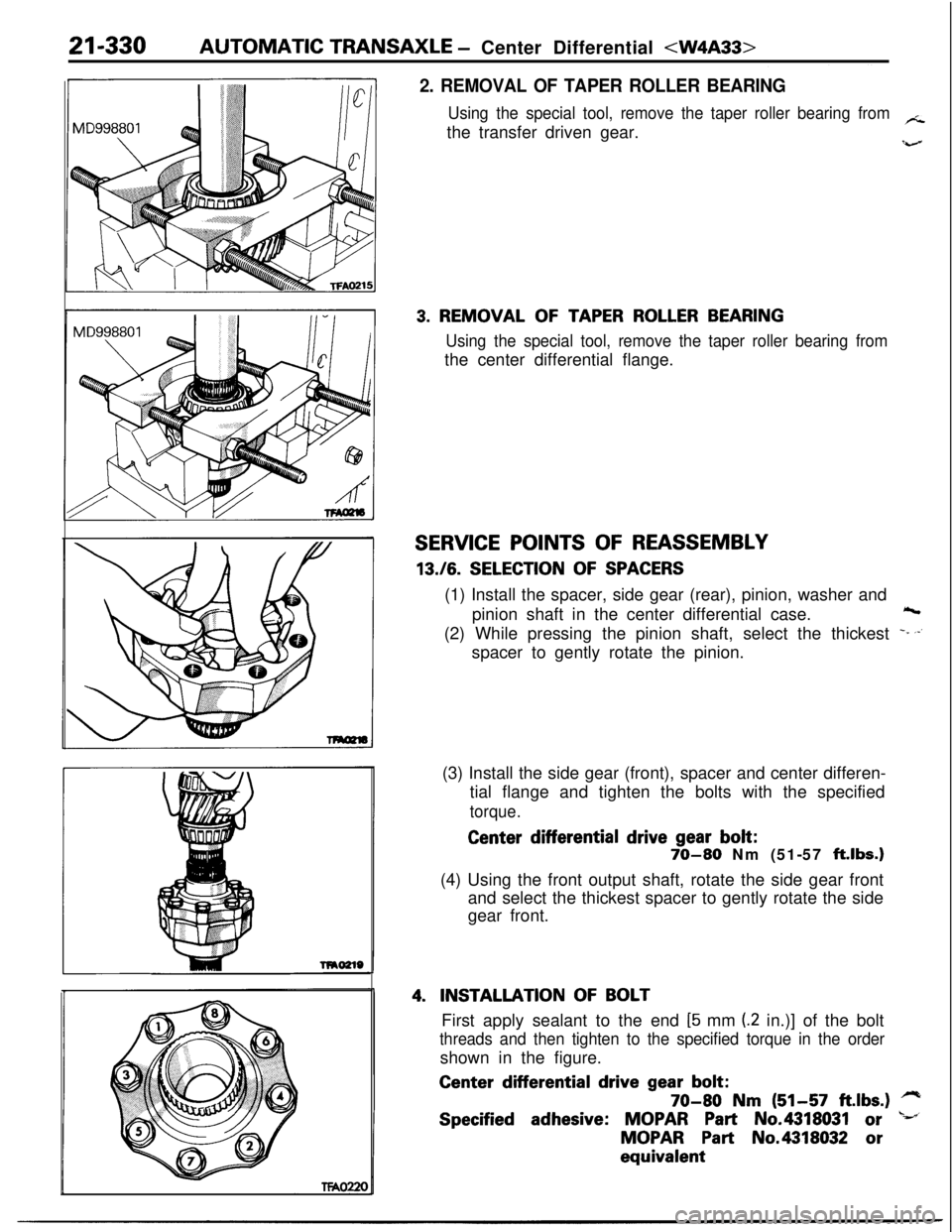

2. REMOVAL OF TAPER ROLLER BEARING

Using the special tool, remove the taper roller bearing from/icthe transfer driven gear.

‘;-

3. REMOVAL OF TAPER ROLLER BEARING

Using the special tool, remove the taper roller bearing fromthe center differential flange.

SERVICE POINTS OF REASSEMBLY

13.16. SELECTION OF SPACERS(1) Install the spacer, side gear (rear), pinion, washer and

pinion shaft in the center differential case.

rs,(2) While pressing the pinion shaft, select the thickest

-m ,-’spacer to gently rotate the pinion.

(3) Install the side gear (front), spacer and center differen-

tial flange and tighten the bolts with the specified

torque.Center differential

drive gear bolt:

70-80 Nm (51-57 ft.lbs.)(4) Using the front output shaft, rotate the side gear front

and select the thickest spacer to gently rotate the side

gear front.

4.INSTALLATION OF BOLTFirst apply sealant to the end

[5 mm (2 in.)] of the bolt

threads and then tighten to the specified torque in the ordershown in the figure.Center differential

drive gear bolt:

70-80 Nm (51-57 ft.lbs.) *

Specified adhesive: MOPAR Part No.4318031 or +’MOPAR

Part No.4318032 orequivalent

Page 1028 of 1216

21-334AUTOMATIC TRANSAXLE - Transfer Assemblv

2210050

-TifAO315

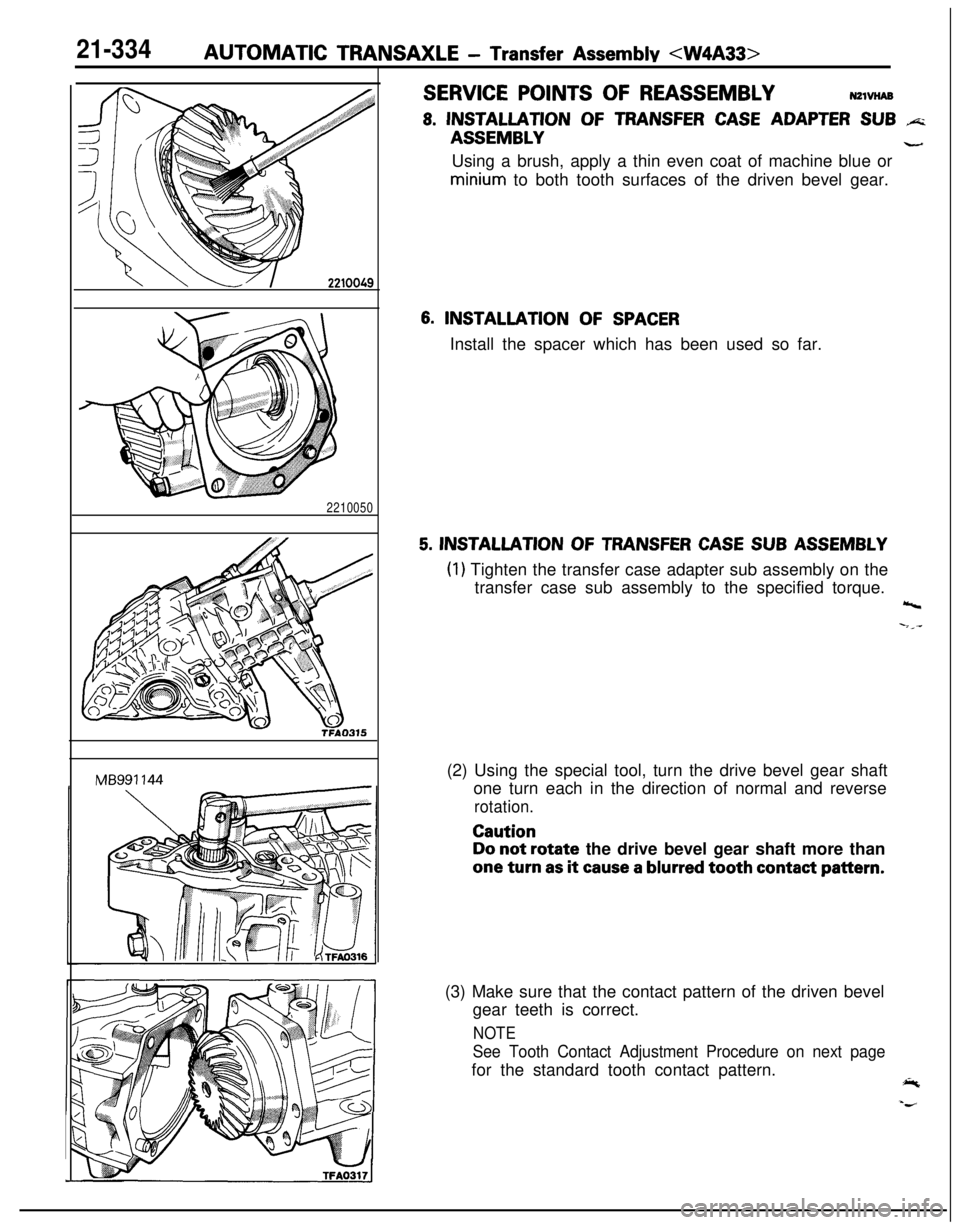

SERVICE POINTS OF REASSEMBLYWmnAE

8. INSTALLATION OF TRANSFER CASE ADAPTER SUB +=GASSEMBLY

-Using a brush, apply a thin even coat of machine blue orminium to both tooth surfaces of the driven bevel gear.

6. INSTALLATION OF SPACERInstall the spacer which has been used so far.

5. INSTALLATION OF TRANSFER CASE SUB ASSEMBLY

(1) Tighten the transfer case adapter sub assembly on the

transfer case sub assembly to the specified torque.

\

-;--.(2) Using the special tool, turn the drive bevel gear shaft

one turn each in the direction of normal and reverse

rotation.Caution

Do not rotate the drive bevel gear shaft more thanone turn

as it cause a blurred tooth contact pattern.

MB991144(3) Make sure that the contact pattern of the driven bevel

gear teeth is correct.

NOTE

See Tooth Contact Adjustment Procedure on next pagefor the standard tooth contact pattern.

4

-am--

Page 1033 of 1216

AUTOMATIC TRANSAXLE - Transfer Case Adapter Sub Assembly

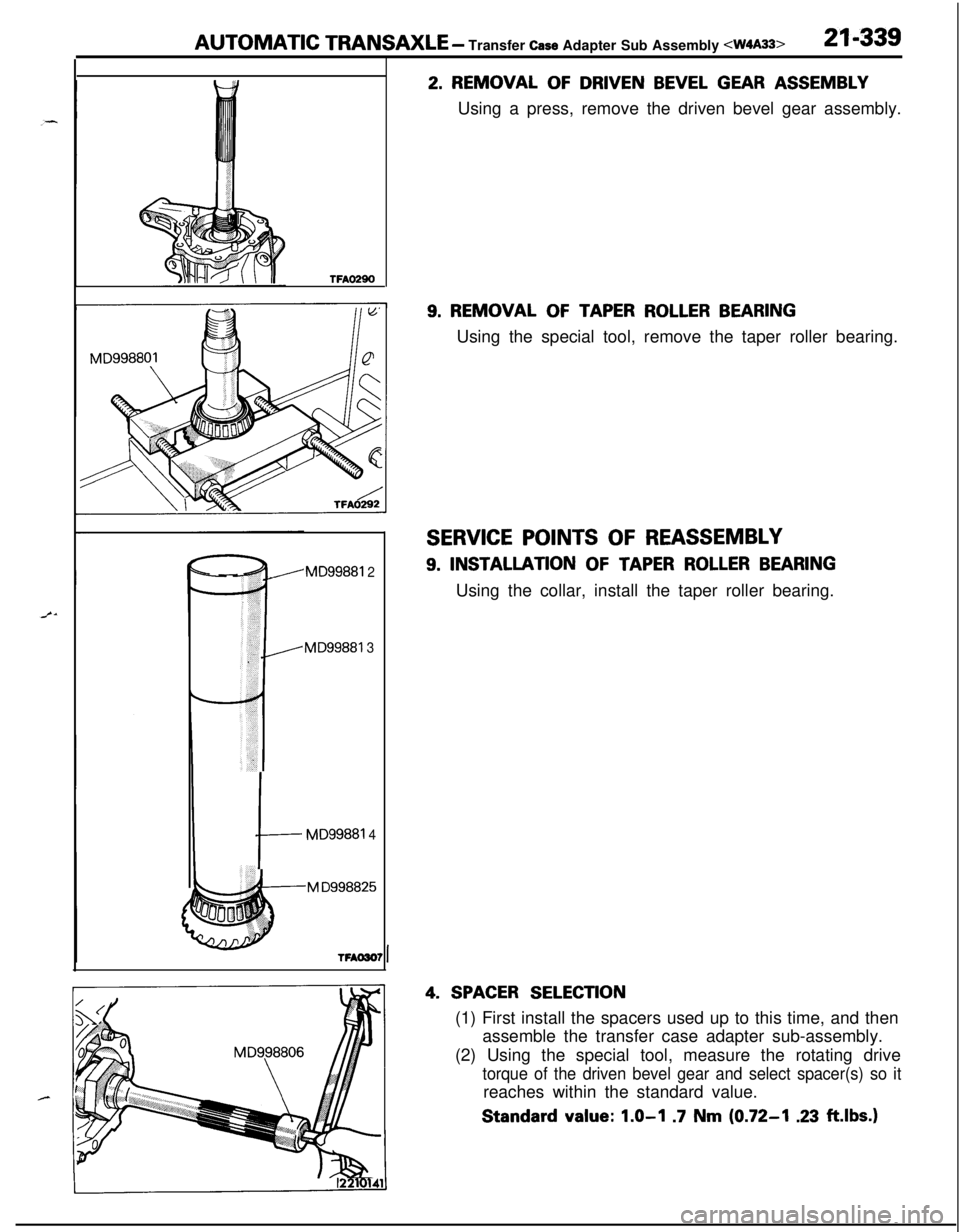

TFAO290

MD99881 2

MD99881 3

M D998825

I

MD99881 4

2. REMOVAL OF DRIVEN BEVEL GEAR ASSEMBLY

Using a press, remove the driven bevel gear assembly.

9. REMOVAL OF TAPER ROLLER BEARINGUsing the special tool, remove the taper roller bearing.

SERVICE POINTS OF REASSEMBLY

9. INSTALLATION OF TAPER ROLLER BEARINGUsing the collar, install the taper roller bearing.

4. SPACER SELECTION(1) First install the spacers used up to this time, and then

assemble the transfer case adapter sub-assembly.

(2) Using the special tool, measure the rotating drive

torque of the driven bevel gear and select spacer(s) so itreaches within the standard value.Standard

value: 1.0-l .7 Nm (0.72-I .23 ft.lbs.)

Page 1034 of 1216

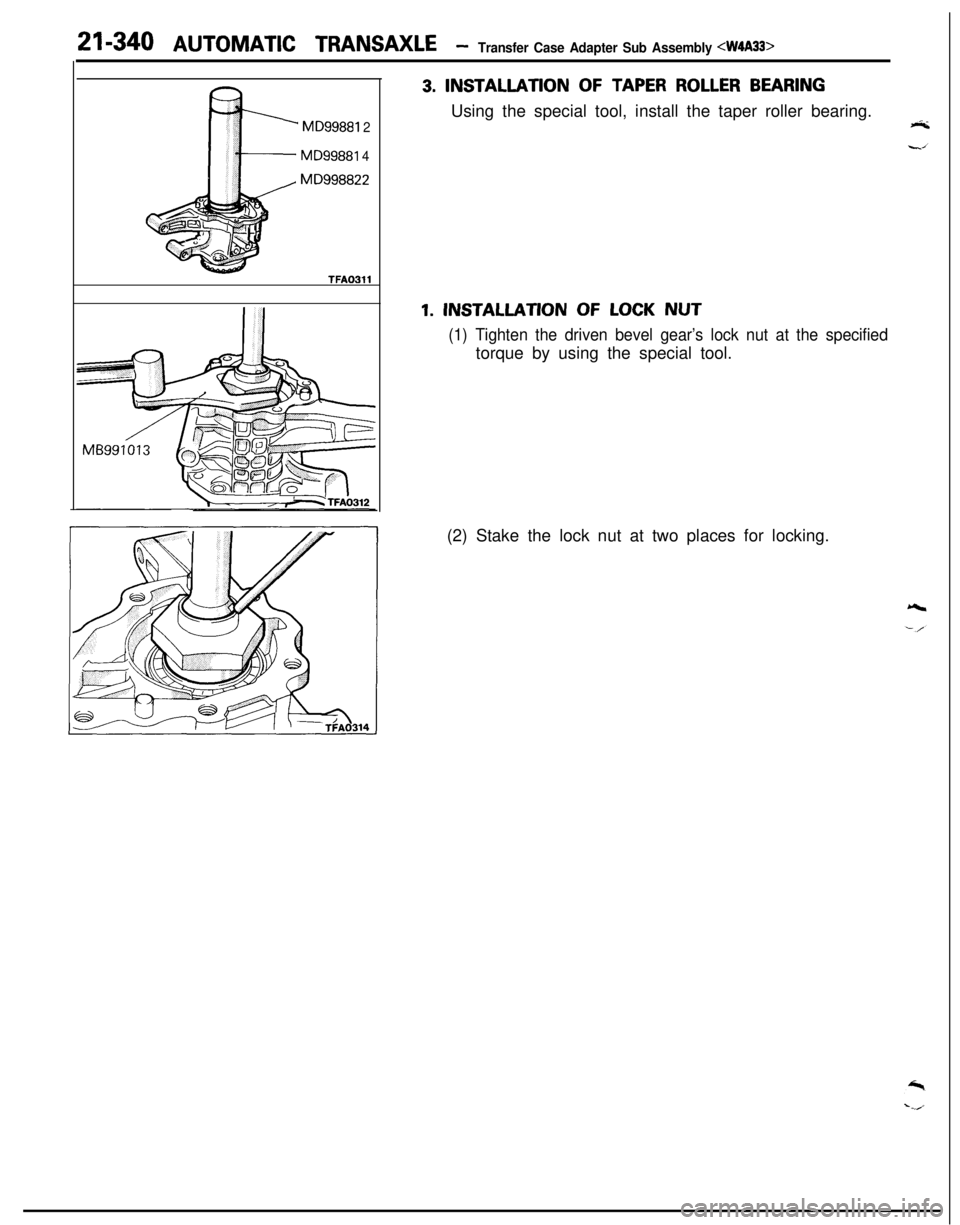

21-340 AUTOMATIC TRANSAXLE -Transfer Case Adapter Sub Assembly

MD99881 2

MD99881 4

MD998822

TFAO311

3. INSTALLATION OF TAPER ROLLER BEARINGUsing the special tool, install the taper roller bearing.

1. INSTALLATION OF LOCK NUT

(1) Tighten the driven bevel gear’s lock nut at the specifiedtorque by using the special tool.

(2) Stake the lock nut at two places for locking.

Page 1037 of 1216

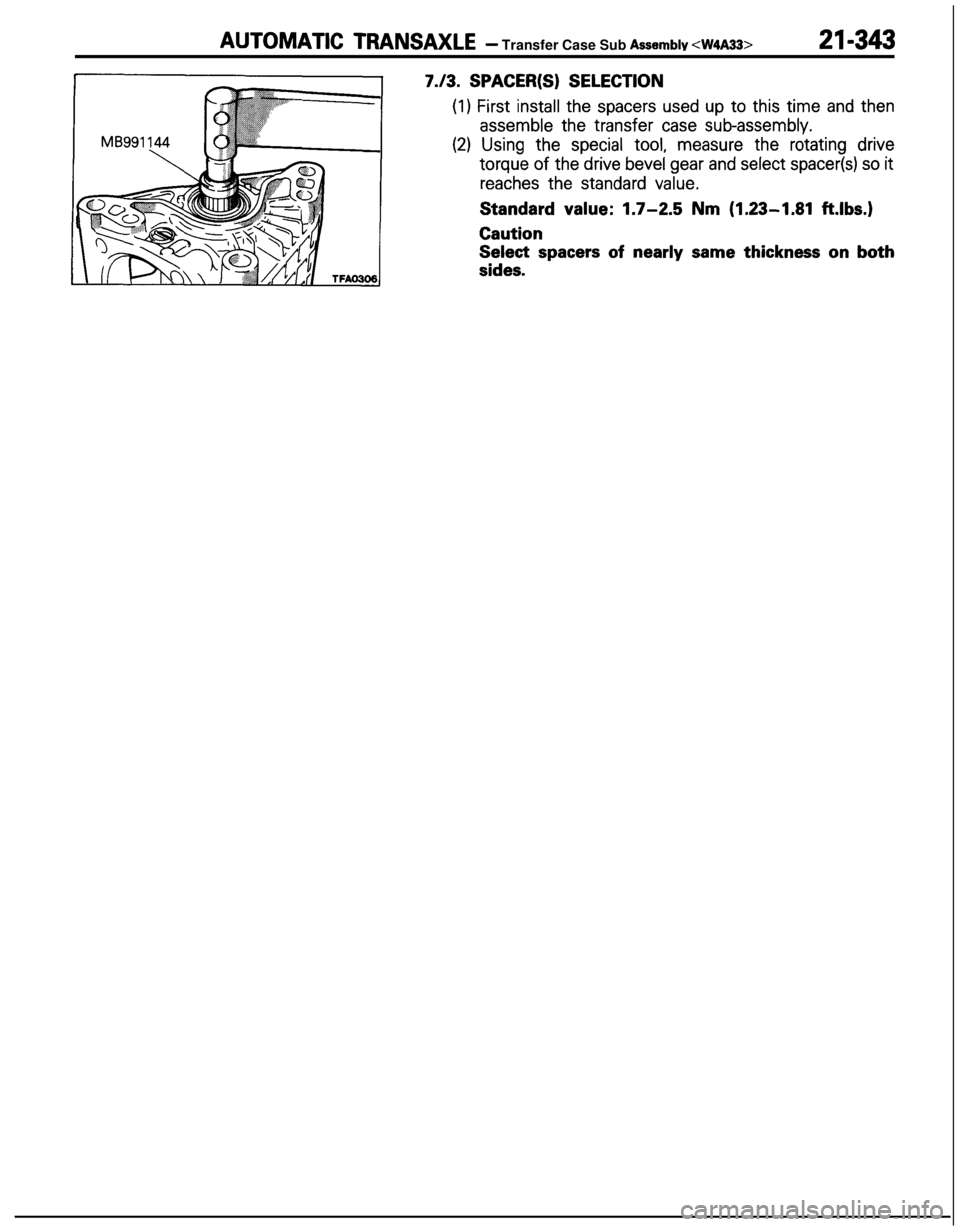

AUTOMATIC TRANSAXLE- Transfer Case Sub Assembly

7.13. SPACER(S) SELECTION

(1) First install the spacers used up to this time and then

assemble the transfer case subassembly.

(2) Using the special tool, measure the rotating drive

torque of the drive bevel gear and select spacer(s) so it

reaches the standard value.Standard value:

1.7-2.5 Nm (1.23-1.81 ft.lbs.)CautionSelect

spacers of nearly same thickness on both

sides.

Page 1039 of 1216

22-l-.

WHEELS

AND TIRES

CONTENTSNZZAA-

SERVICE ADJUSTMENT PROCEDURES.......4TROUBLESHOOTING......................................3

Tire

InflationPressureCheck......................4Bald Spots

TireWearCheck..........................................4Cracked Treads

Wheel

RunoutCheck...................................4Feathered Edge

SPECIFICATIONSRapid Wear at Center.............................................2

General

Specifications..................................2Rapid Wear at Shoulders

ServiceSpecificationsScalloped Wear...................................2Wear on One Side

7TorqueSpecifications...................................2

WHEEL AND TIRE..........................................5

Page 1040 of 1216

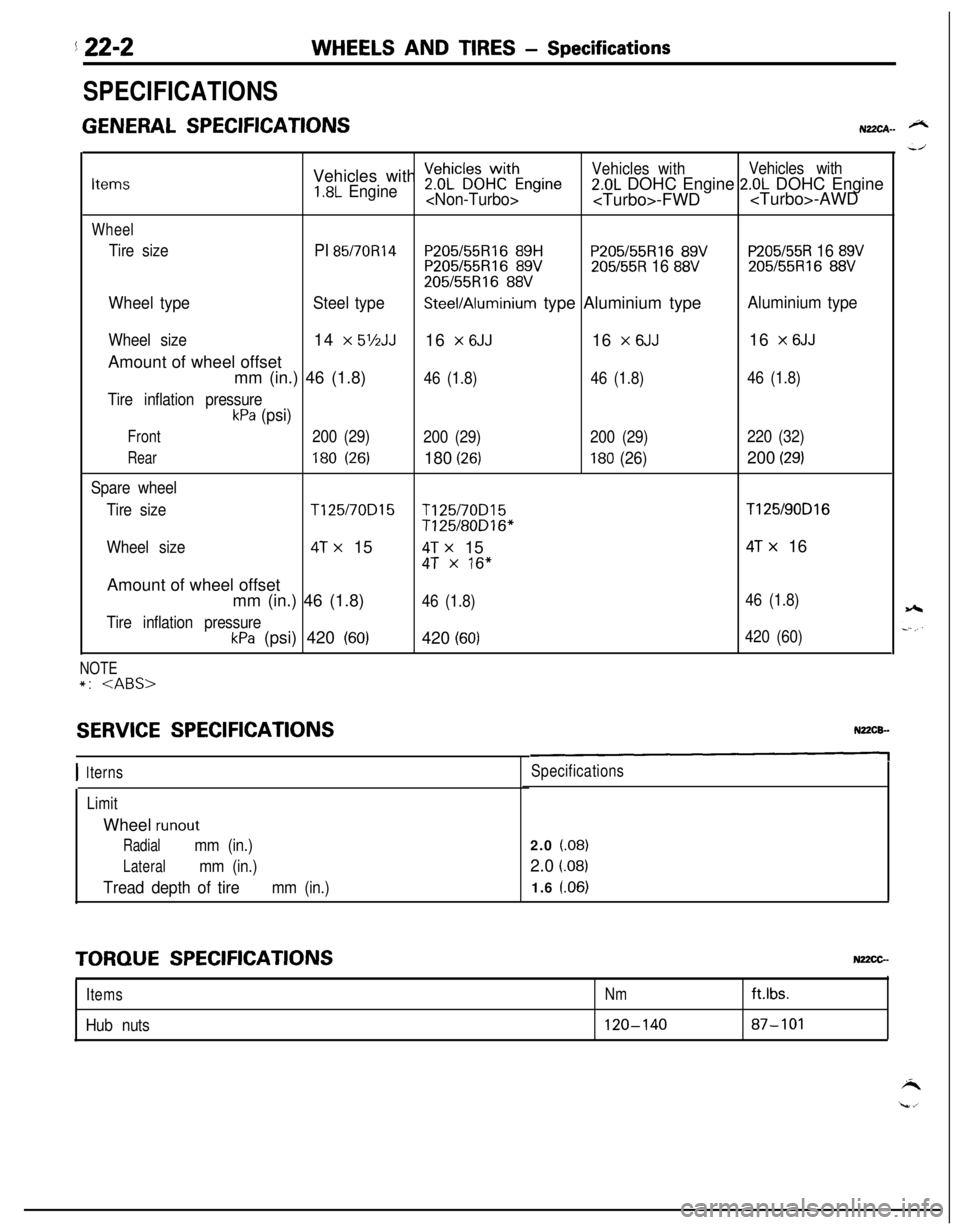

5 22-2WHEELS AND TIRES - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSN22CA- @NVehicles with

~eDhL”~~HWCthEngineVehicles withVehicles withItems1.8L Engine2.0L DOHC Engine 2.0L DOHC Engine

Wheel

Tire sizePI 85/70R14P205155Rl6 89HP205/55R16 89VP205/55R 16 89VP205155R16 89V205/55R 16 88V205/55R16 88V

205/55R16 88V

Wheel typeSteel typeSteel/Aluminium type Aluminium typeAluminium type

Wheel size14 x 5’/2JJ16 x 6JJ16 x 6JJ16 x 6JJAmount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi)

Front200 (29)

200 (29)200 (29)220 (32)

Rear180 (26)180 (26)180 (26)200 (29)

Spare wheel

Tire size

T125/70D15T125/70D15T125/90D16

T125/80D16*

Wheel size

4T x 154T x 154T x 16

4T x 16”Amount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi) 420 (60)420 (60)420 (60)

NOTE*:

SERVICE SPECIFICATIONS

I 1terns

LimitWheel

runout

Radialmm (in.)

Lateralmm (in.)

Tread depth of tiremm (in.)

Specifications2.0

(.08)2.0

i.08)1.6 l.06)

TORQUE SPECIFICATIONSNz2cG-

ItemsNm

Hub nuts120-140ftlbs.87-101

Page 1045 of 1216

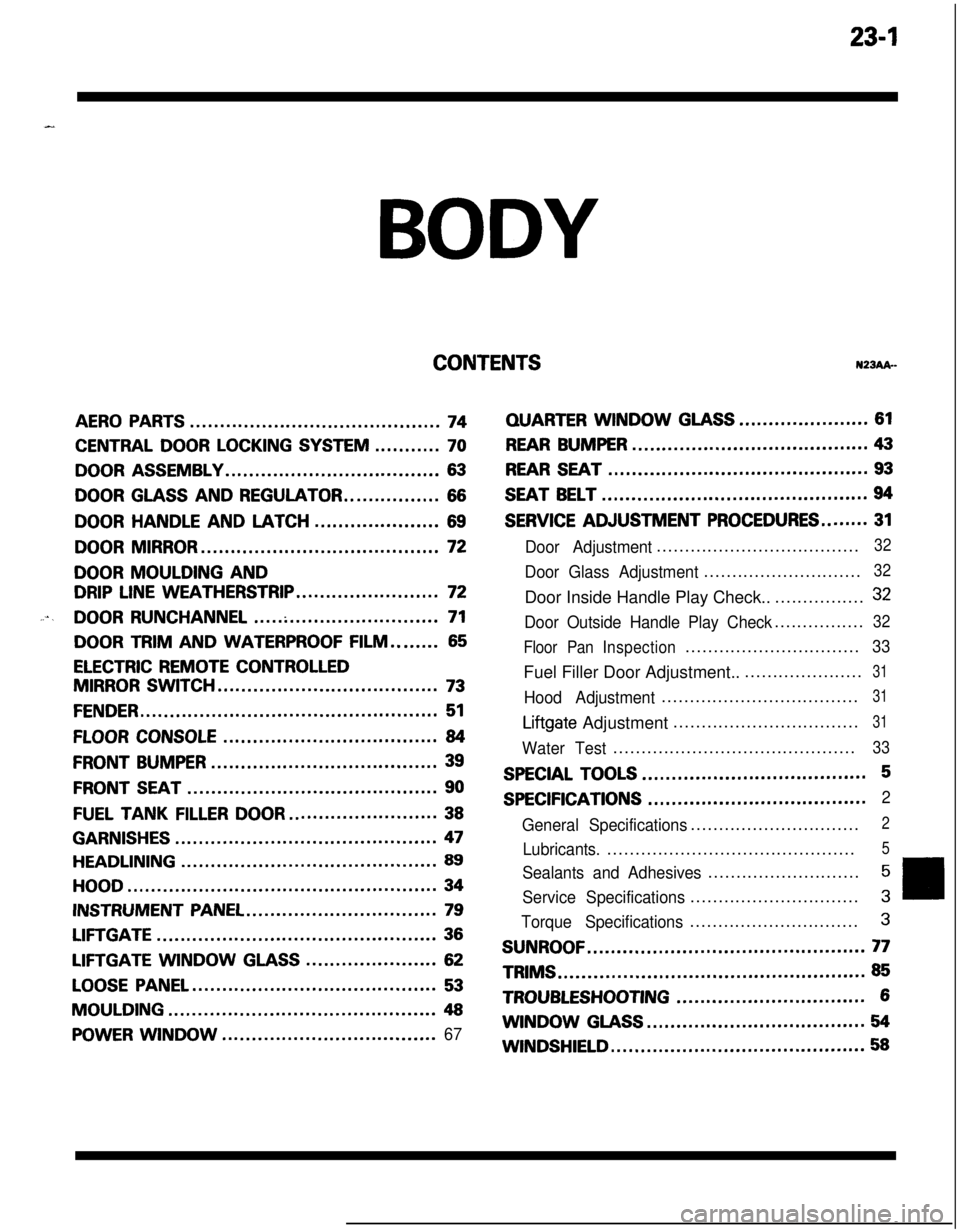

23-lBODY

CONTENTSN23Ak-

AERO PARTS..........................................74

CENTRAL DOOR LOCKING SYSTEM...........70

DOOR ASSEMBLY....................................63

DOOR GLASS AND REGULATOR................66

DOORHANDLEANDLATCH.....................69

DOOR MIRROR........................................72

DOOR MOULDING AND

DRIP LINE WEATHERSTRIP........................72

....DOOR RUNCHANNEL...............................71

DOOR TRIM AND WATERPROOF FILM........65

ELECTRIC REMOTE CONTROLLED

MIRROR SWITCH.....................................73

FENDER..................................................51

FLOOR CONSOLE....................................84

FRONT BUMPER......................................39

FRONT SEAT..........................................90

FUEL TANKFILLERDOOR.........................38

GARNISHES............................................47

HEADLINING...........................................89

HOOD....................................................34

INSTRUMENT PANEL................................79

LIFTGATE...............................................36

LIFTGATE WINDOWGLASS......................62

LOOSE PANEL.........................................53

MOULDING.............................................48

POWER WINDOW....................................67

QUARTERWINDOWGLASS......................61

REAR BUMPER........................................43

REAR SEAT............................................93

SEAT BELT.............................................94

SERVICE ADJUSTMENT PROCEDURES........31

Door Adjustment....................................32

Door Glass Adjustment............................32Door Inside Handle Play Check..................

32

Door Outside Handle Play Check................32

Floor PanInspection...............................

33Fuel Filler Door Adjustment.......................

31

Hood Adjustment...................................31

Liftgate Adjustment.................................31

Water Test...........................................33

SPECIAL TOOLS......................................5

SPECIFICATIONS.....................................2

General Specifications..............................

2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................77TRIMS

....................................................85

TROUBLESHOOTING................................6WINDOW

GLASS.....................................54

WINDSHIELD...........................................58