torque MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 964 of 1216

-m-m AUTOMATIC TRANSAXLE -Transaxle Assembly

DISASSEMBLYN21WMCaution

%T1. Since the automatic transaxle is made of particularly

~_,high precision parts, be very careful when handling

them during disassembly and reassembly so that they

are not scratched.

2. Spread a rubber mat on the workbench and keep it

clean.3. Do not use cotton gloves or cloth rags during dis-

assembly. If they are needed, use nylon cloth or paper

towels.

4. Clean all disassembled parts. Clean metal

parts with

normal cleanser and completely dry with air.

5. Clean the clutch disc, resin thrust plate and rubber

parts with ATF (automatic transmission fluid) and do

not get any dirt on them.

6. If the transaxle itself is damaged, disassemble and

clean the cooler system also.

1. Remove the torque converter.

2. Mount the dial gauge on the transaxle case and measure

the end play of the input shaft.

3. Remove the brackets.

4. Remove the oil level gauge and oil level gauge guide.

1:5. Remove the pulse generator A and B.

6.First remove the manual control lever and then remove theinhibitor switch.

7. Remove the speedometer driven gear assembly.

Page 976 of 1216

21-282 AUTOMATIC TRANSAXLE - Transaxle Assembly

\TFAOi57

AWDTFAOl63

bearing retainerTFA0156

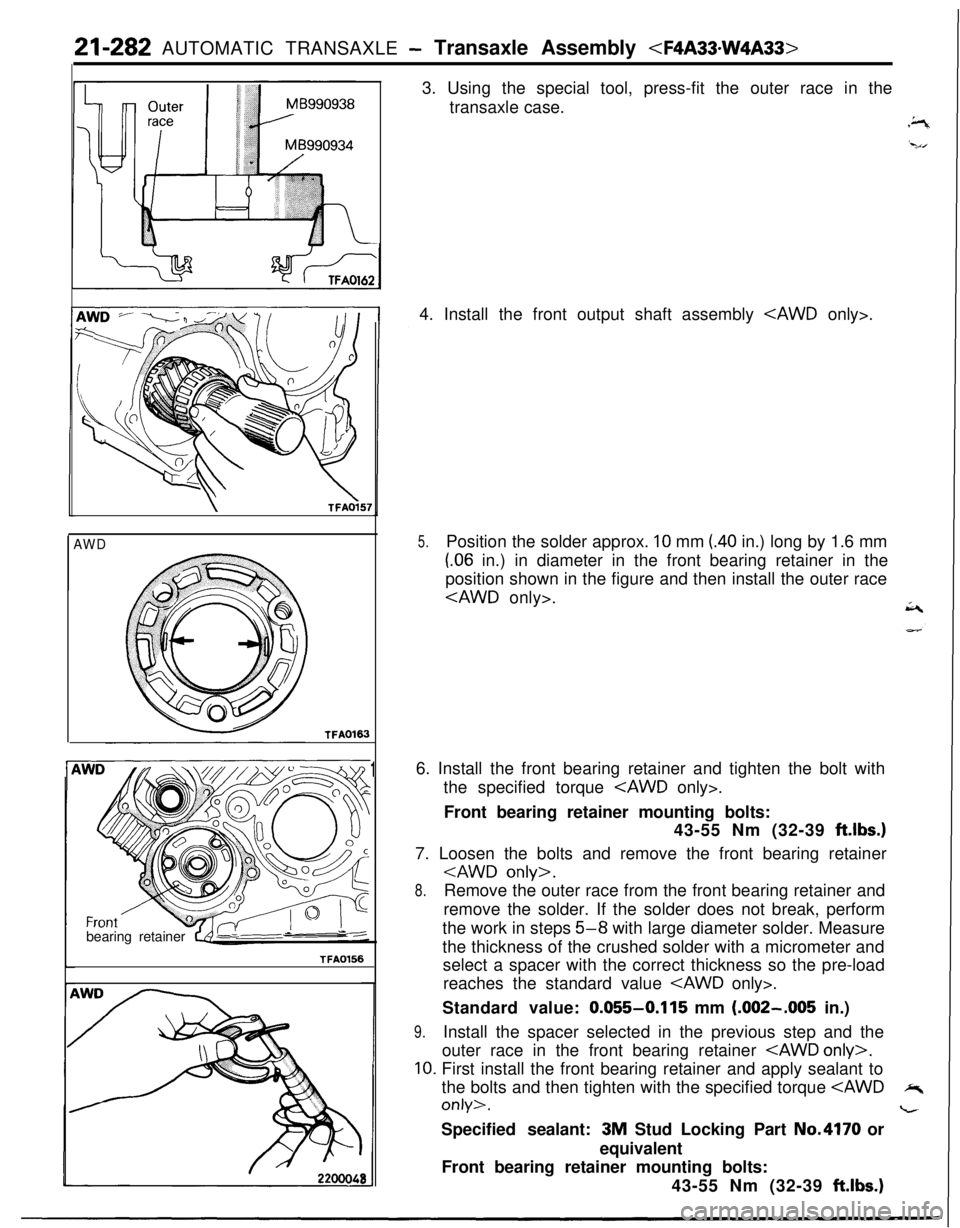

13. Using the special tool, press-fit the outer race in the

transaxle case.

4. Install the front output shaft assembly

5.Position the solder approx. 10 mm (.40 in.) long by 1.6 mm

(.06 in.) in diameter in the front bearing retainer in the

position shown in the figure and then install the outer race

cAWD only>.A6. Install the front bearing retainer and tighten the bolt with

the specified torque

Front bearing retainer mounting bolts:

43-55 Nm (32-39

ft.lbs.)7. Loosen the bolts and remove the front bearing retainer

8.Remove the outer race from the front bearing retainer and

remove the solder. If the solder does not break, perform

the work in steps

5-8 with large diameter solder. Measure

the thickness of the crushed solder with a micrometer and

select a spacer with the correct thickness so the pre-load

reaches the standard value

Standard value:

0.055-0.115 mm (.002-.005 in.)

9.Install the spacer selected in the previous step and the

outer race in the front bearing retainer

10. First install the front bearing retainer and apply sealant to

the bolts and then tighten with the specified torque

equivalent

Front bearing retainer mounting bolts:

43-55 Nm (32-39

ftlbs.)

Page 978 of 1216

21-284 AUTOMATIC TRANSAXLE - Transaxle Assemblv

//TFAOlSO

TFA0167

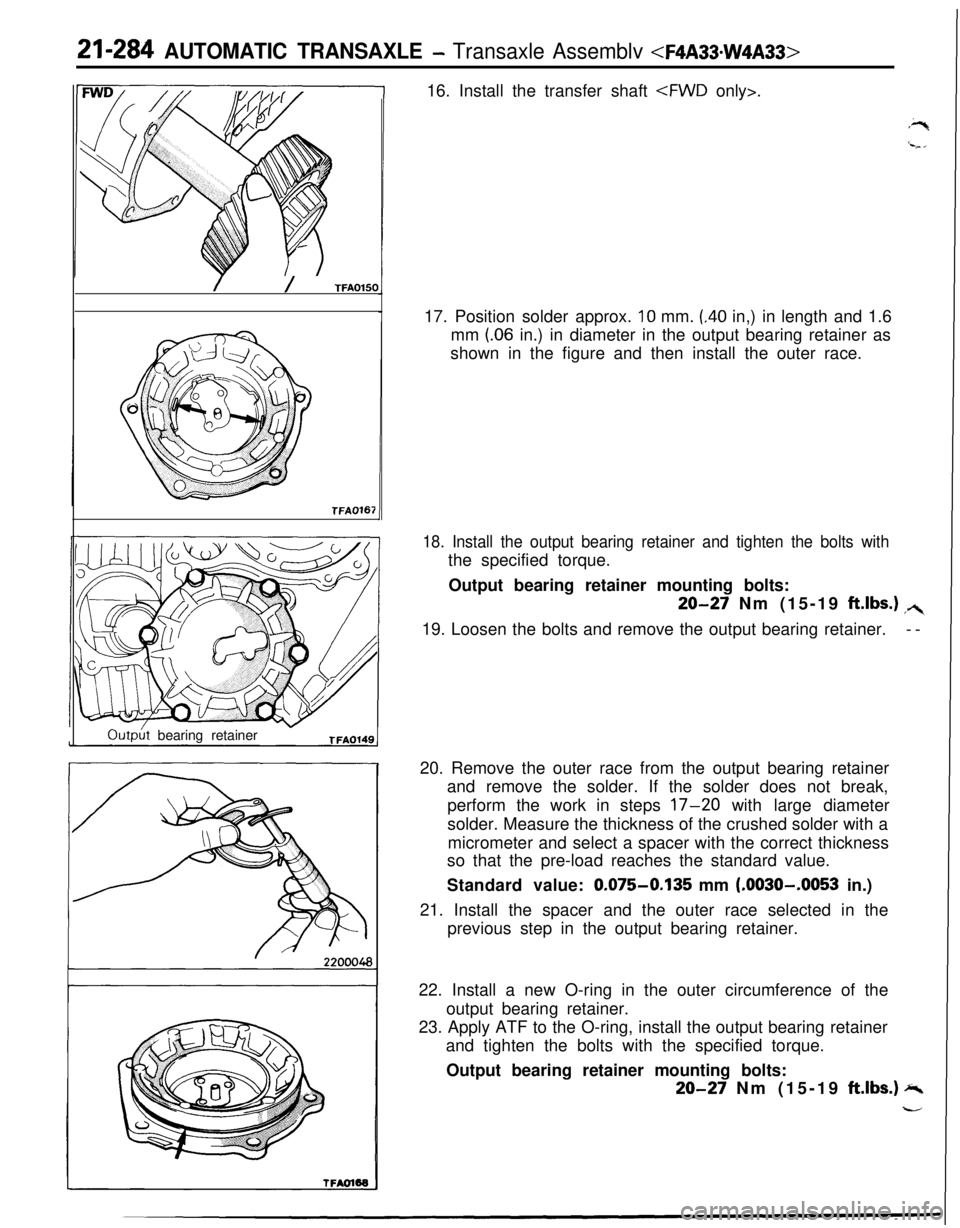

Outph bearing retainerTFAOl4916. Install the transfer shaft

17. Position solder approx.

10 mm. (.40 in,) in length and 1.6

mm

(06 in.) in diameter in the output bearing retainer as

shown in the figure and then install the outer race.

18. Install the output bearing retainer and tighten the bolts withthe specified torque.

Output bearing retainer mounting bolts:

20-27 Nm (15-19 ft.lbs.) ,+19. Loosen the bolts and remove the output bearing retainer.--

20. Remove the outer race from the output bearing retainer

and remove the solder. If the solder does not break,

perform the work in steps

17-20 with large diameter

solder. Measure the thickness of the crushed solder with a

micrometer and select a spacer with the correct thickness

so that the pre-load reaches the standard value.

Standard value:

0.075-0.135 mm (.0030--0053 in.)

21. Install the spacer and the outer race selected in the

previous step in the output bearing retainer.

22. Install a new O-ring in the outer circumference of the

output bearing retainer.

23. Apply ATF to the O-ring, install the output bearing retainer

and tighten the bolts with the specified torque.

Output bearing retainer mounting bolts:

20-27 Nm (15-19 ft.lbs.) -

-

Page 986 of 1216

21-292 AUTOMATIC TRANSAXLE - Transaxle Assembly

cover

I

TFAOl2r

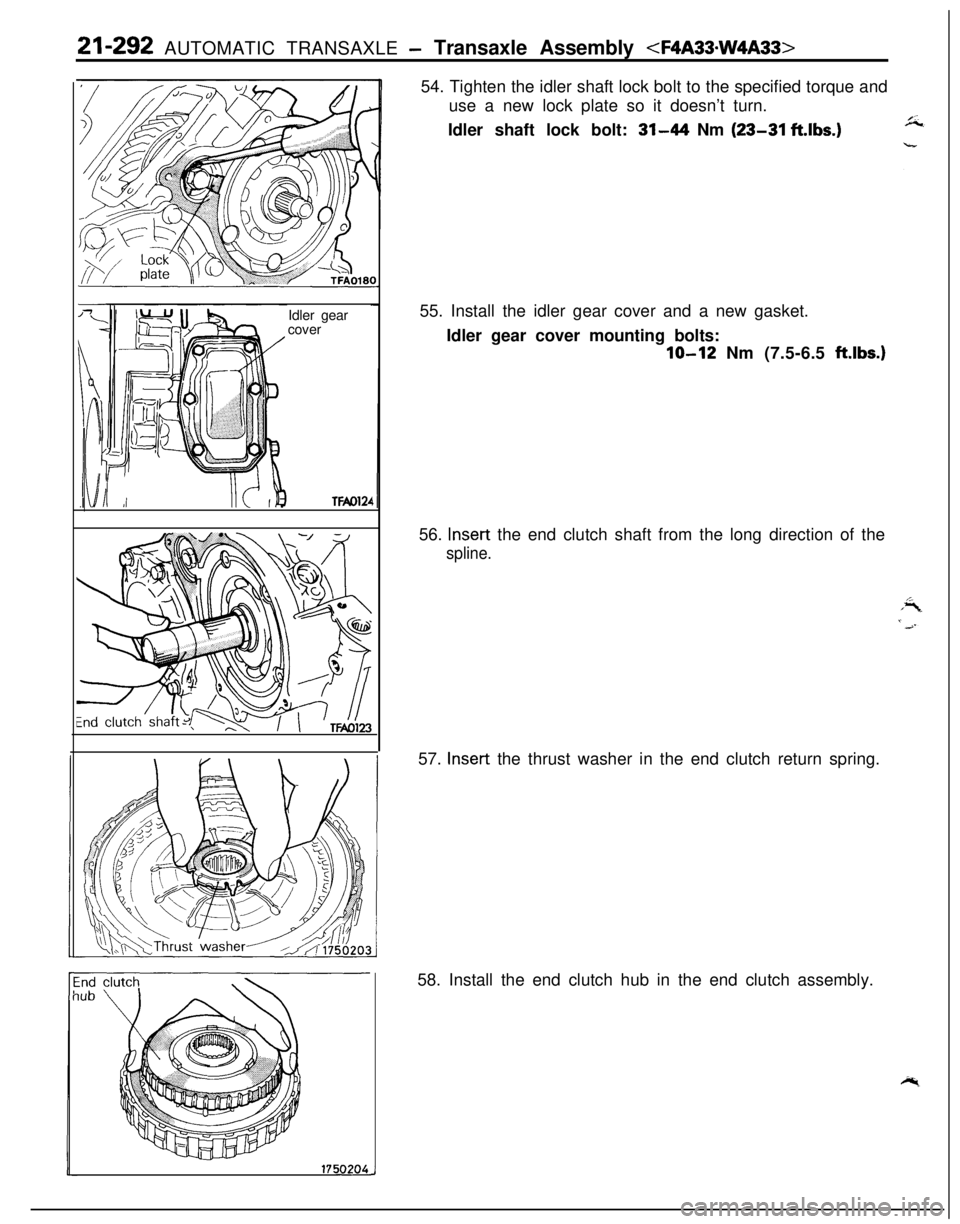

17502XJ54. Tighten the idler shaft lock bolt to the specified torque and

use a new lock plate so it doesn’t turn.

Idler shaft lock bolt:

31-44 Nm (23-31 ft.lbs.)55. Install the idler gear cover and a new gasket.

Idler gear cover mounting bolts:

lo-12 Nm (7.5-6.5 ftlbs.)56.

Insert the end clutch shaft from the long direction of the

spline.57.

Insert the thrust washer in the end clutch return spring.

58. Install the end clutch hub in the end clutch assembly.

Page 987 of 1216

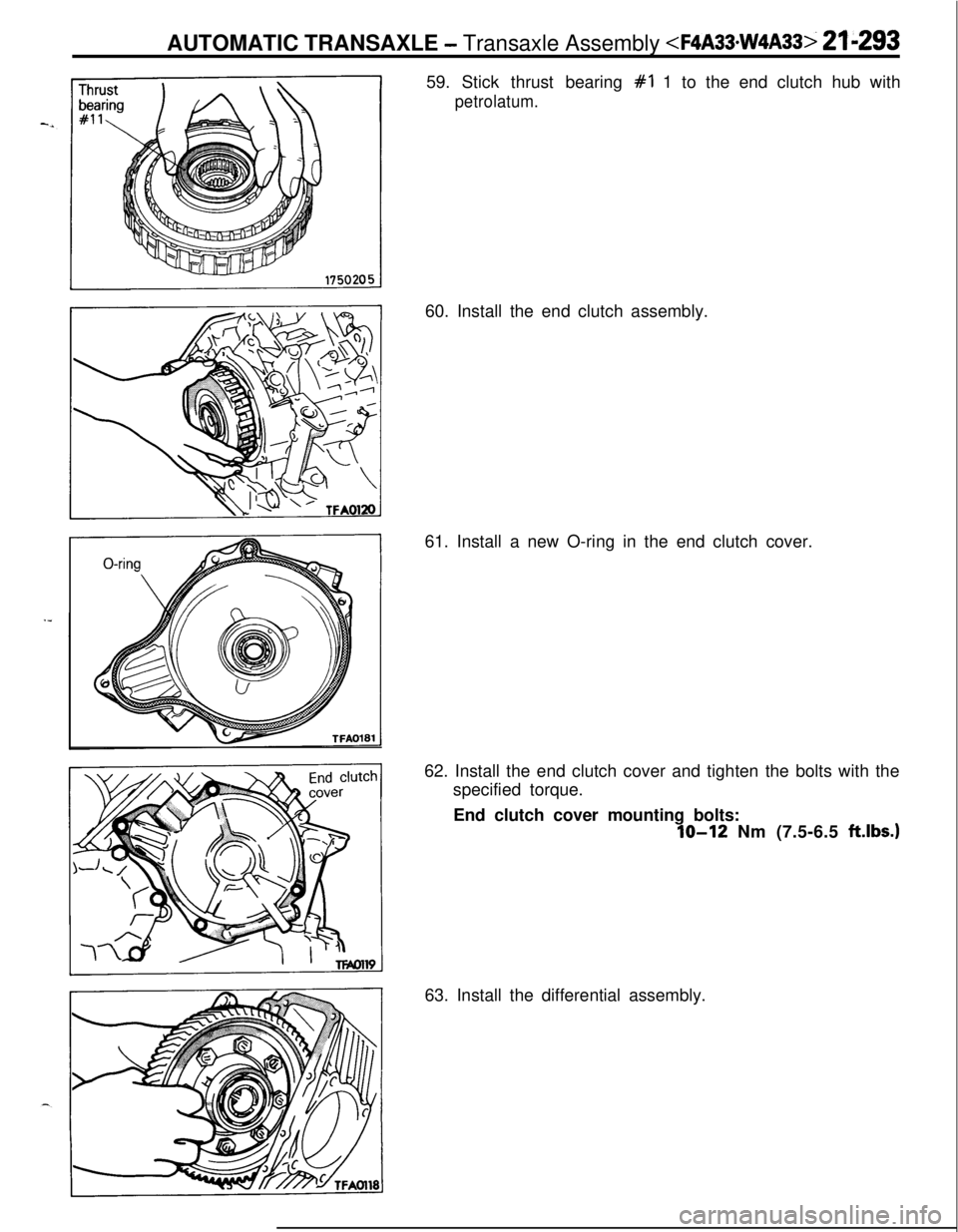

AUTOMATIC TRANSAXLE - Transaxle Assembly

petrolatum.60. Install the end clutch assembly.

61. Install a new O-ring in the end clutch cover.

62. Install the end clutch cover and tighten the bolts with the

specified torque.

End clutch cover mounting bolts:

IO-12 Nm (7.5-6.5 ftlbs.)63. Install the differential assembly.

Page 988 of 1216

21-294 AUTOMATIC TRANSAXLE - Transaxle Assemblv

‘/TFAOl16

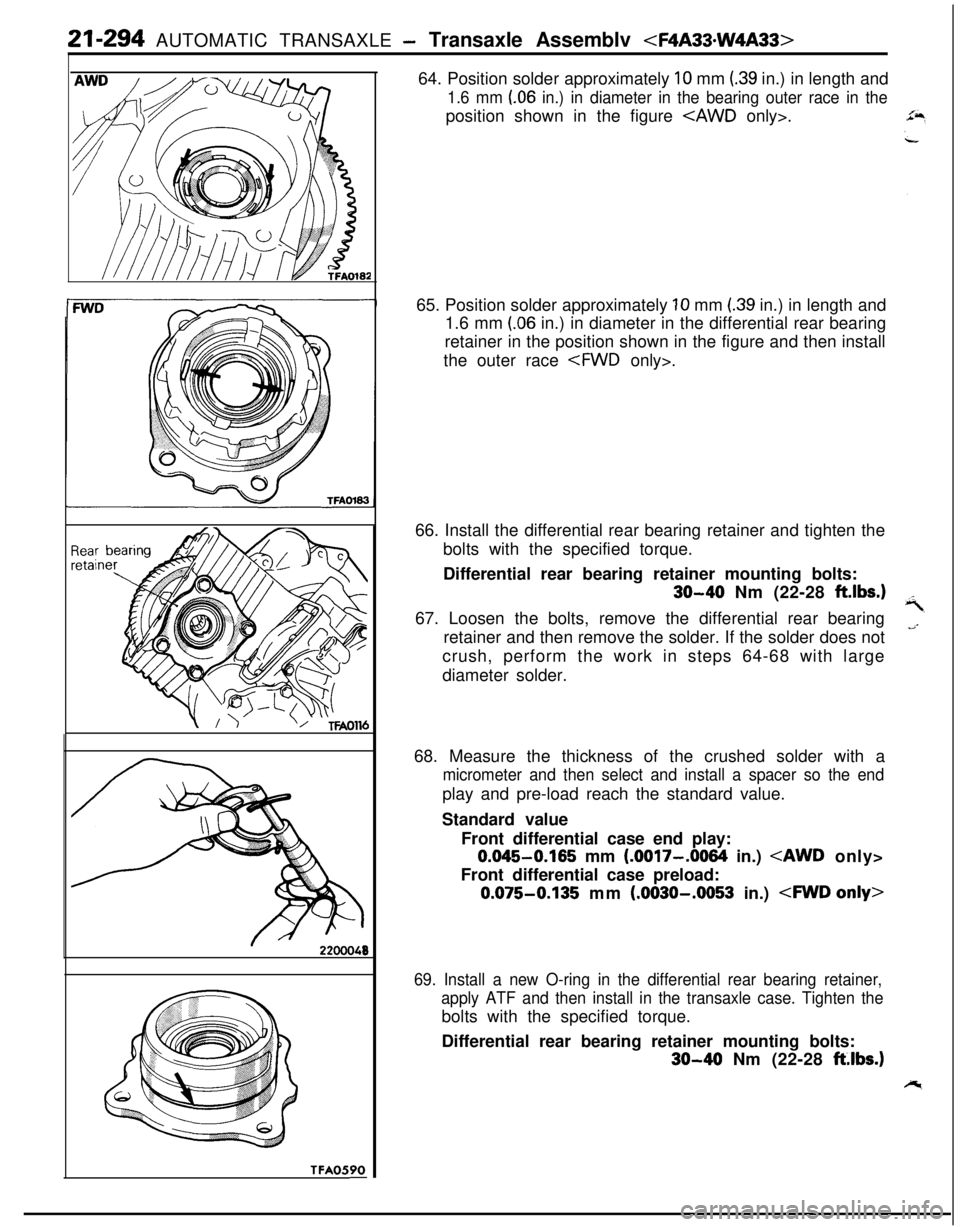

TFA0590-64. Position solder approximately

10 mm (39 in.) in length and

1.6 mm (06 in.) in diameter in the bearing outer race in theposition shown in the figure

65. Position solder approximately

10 mm (39 in.) in length and

1.6 mm

(.06 in.) in diameter in the differential rear bearing

retainer in the position shown in the figure and then install

the outer race

66. Install the differential rear bearing retainer and tighten the

bolts with the specified torque.

Differential rear bearing retainer mounting bolts:

30-40 Nm (22-28 ft.lbs.167. Loosen the bolts, remove the differential rear bearing

retainer and then remove the solder. If the solder does not

crush, perform the work in steps 64-68 with large

diameter solder.

68. Measure the thickness of the crushed solder with a

micrometer and then select and install a spacer so the endplay and pre-load reach the standard value.

Standard value

Front differential case end play:

0.045-0.165 mm (.0017-.0064 in.)

Front differential case preload:

0.075-0.135 mm (.0030-.0053 in.)

69. Install a new O-ring in the differential rear bearing retainer,

apply ATF and then install in the transaxle case. Tighten thebolts with the specified torque.

Differential rear bearing retainer mounting bolts:

30-40 Nm (22-28 ft.lbs.)

Page 989 of 1216

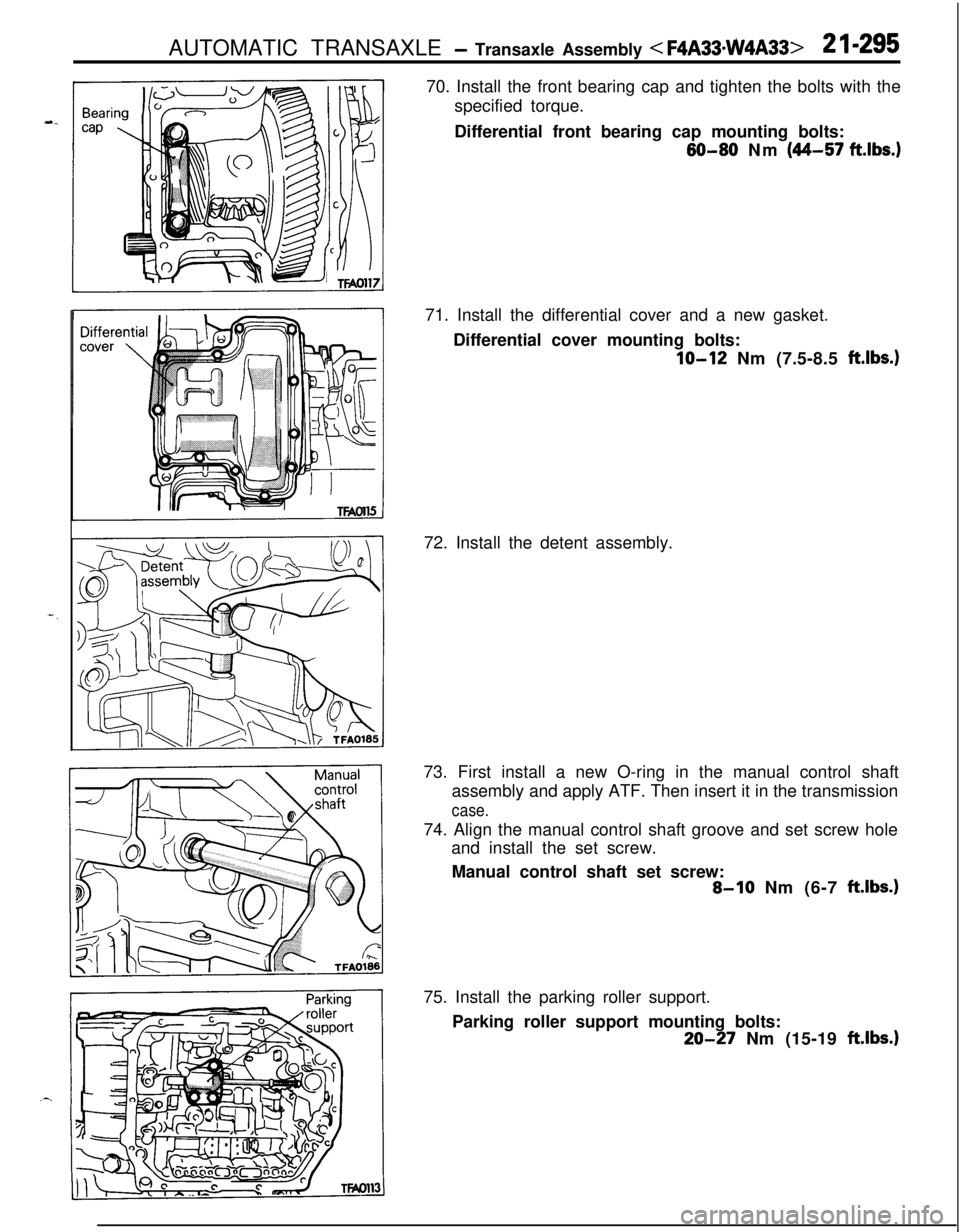

AUTOMATIC TRANSAXLE - Transaxle Assembly < F4A33*w4A33>2 I-29570. Install the front bearing cap and tighten the bolts with the

specified torque.

Differential front bearing cap mounting bolts:

60-80 Nm (44-57 ft.lbs.)71. Install the differential cover and a new gasket.

Differential cover mounting bolts:

IO-12 Nm (7.5-8.5 ft.lbs.)72. Install the detent assembly.

73. First install a new O-ring in the manual control shaft

assembly and apply ATF. Then insert it in the transmission

case.74. Align the manual control shaft groove and set screw hole

and install the set screw.

Manual control shaft set screw:

8-10 Nm (6-7 ft.lbs.)75. Install the parking roller support.

Parking roller support mounting bolts:

20-27 Nm (15-19 ft.lbs.1

Page 990 of 1216

21-296 AUTOMATIC TRANSAXLE - Transaxle Assembly

77. Install an O-ring in the O-ring groove on top of the valve

body assembly.

78. Replace the solenoid valve harness grommet O-ring with anew O-ring.

79. Pass the solenoid valve connector through from the inside

of the transaxle case hole.

80. Insert the solenoid valve harness grommet in the case hole.,**%4

81. Temporarily install the valve body while inserting the detentplate pin in the manual valve groove. Then install the oil

temperature sensor and holder and tighten the bolts with

the specified torque.

A bolt

= 18 mm (.71 in.)

B bolt = 25 mm (.98 in.)

C bolt = 40 mm (1.57 in.)

Valve body assembly mounting bolts:

lo-12 Nm (7.5-8.5 fklbs.)

Caution

Fix the solenoid valve and oil temperature sensor

harness securely in the position shown.

82. Install the oil filter.

Oil filter mounting bolts: 5-7 Nm (4-5

ft.lbs.1

Page 992 of 1216

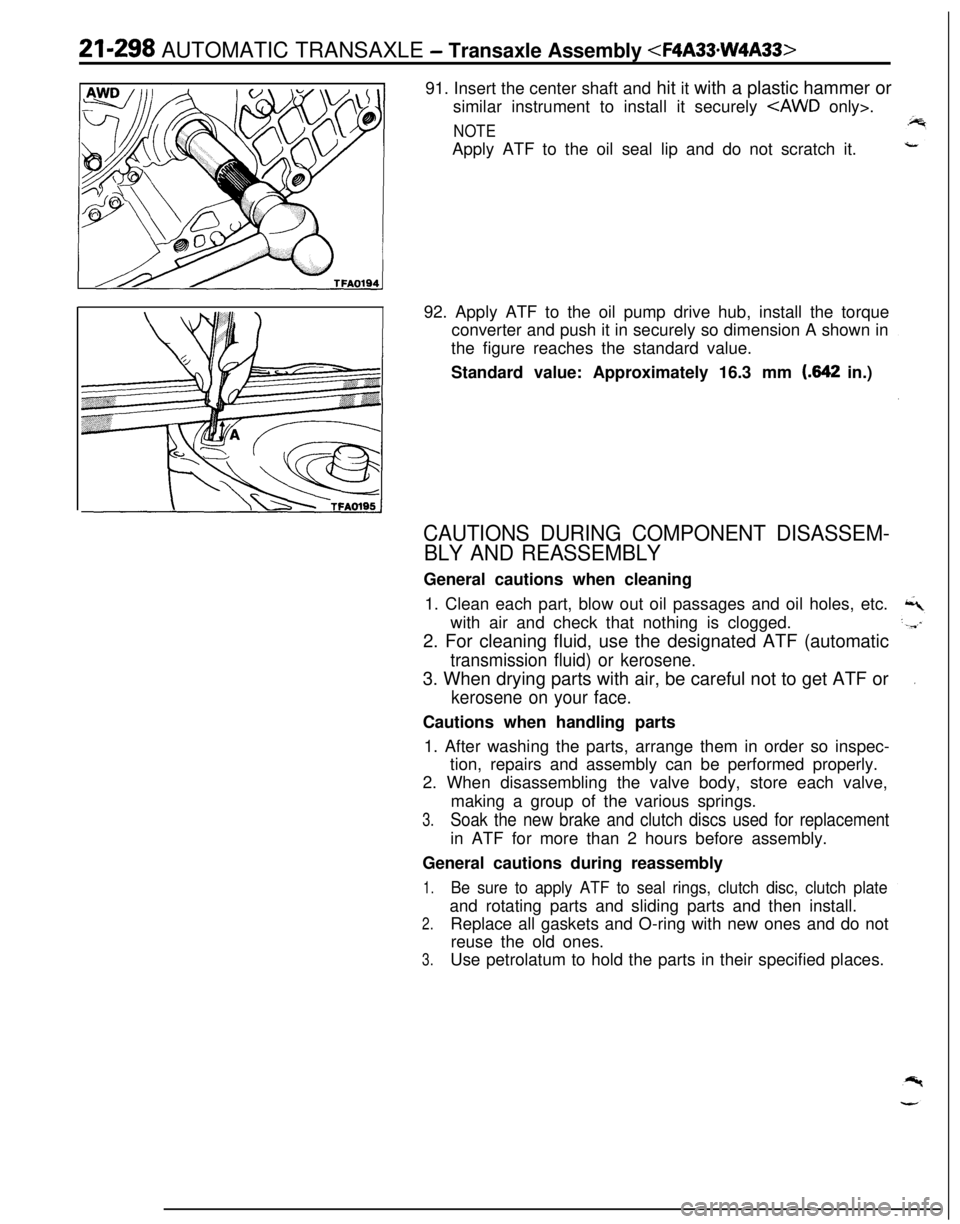

21-298 AUTOMATIC TRANSAXLE - Transaxle Assembly

similar instrument to install it securely

NOTEApply ATF to the oil seal lip and do not scratch it.

92. Apply ATF to the oil pump drive hub, install the torque

converter and push it in securely so dimension A shown in

the figure reaches the standard value.

Standard value: Approximately 16.3 mm

(.642 in.)

CAUTIONS DURING COMPONENT DISASSEM-

BLY AND REASSEMBLYGeneral cautions when cleaning

1. Clean each part, blow out oil passages and oil holes, etc.

with air and check that nothing is clogged.

2. For cleaning fluid, use the designated ATF (automatic

transmission fluid) or kerosene.3. When drying parts with air, be careful not to get ATF or

kerosene on your face.Cautions when handling parts

1. After washing the parts, arrange them in order so inspec-

tion, repairs and assembly can be performed properly.

2. When disassembling the valve body, store each valve,

making a group of the various springs.

3.Soak the new brake and clutch discs used for replacementin ATF for more than 2 hours before assembly.

General cautions during reassembly

1.Be sure to apply ATF to seal rings, clutch disc, clutch plateand rotating parts and sliding parts and then install.

2.Replace all gaskets and O-ring with new ones and do not

reuse the old ones.

3.Use petrolatum to hold the parts in their specified places.

Page 994 of 1216

21-300AUTOMATIC TRANSAXLE - Oil Pump

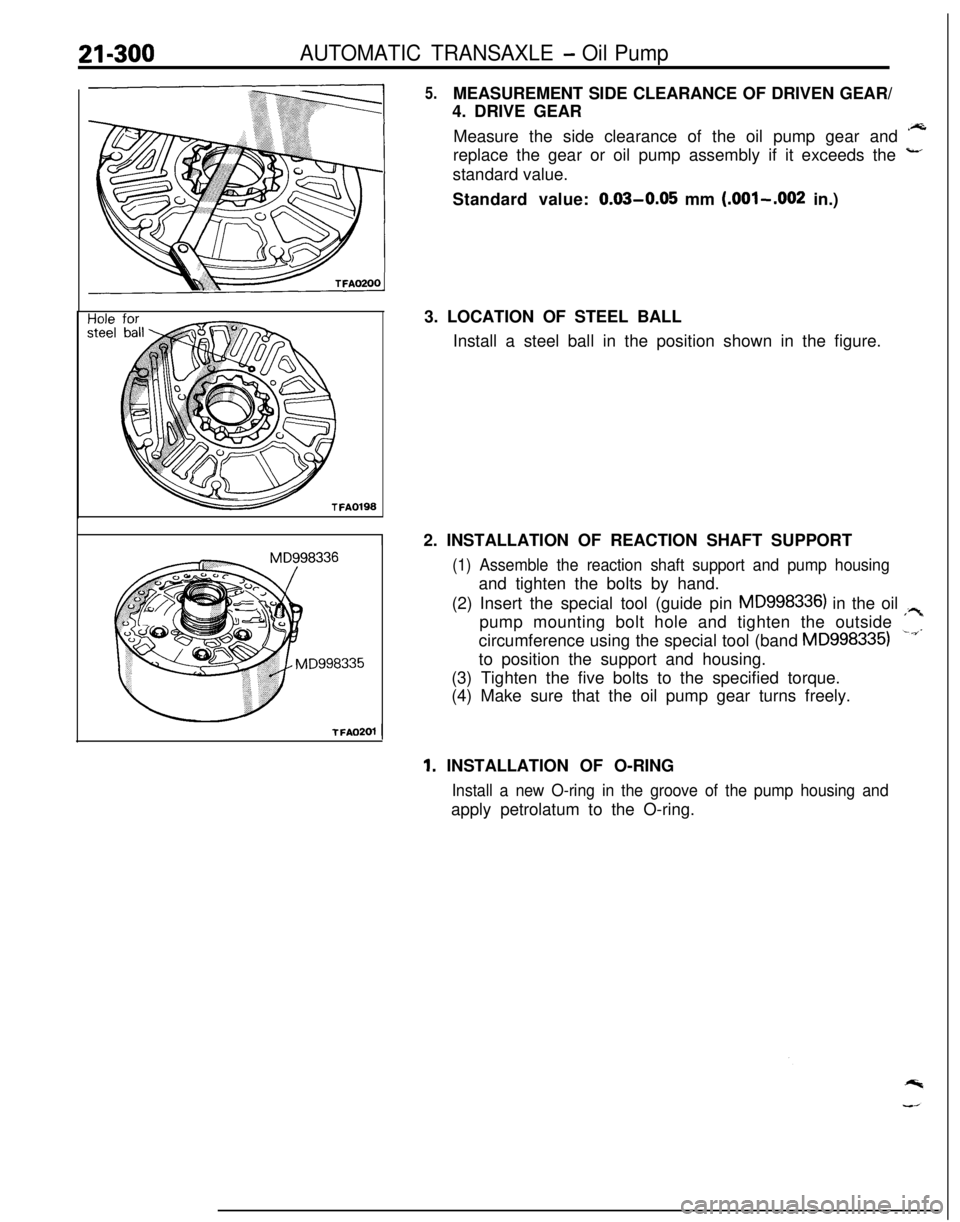

5.MEASUREMENT SIDE CLEARANCE OF DRIVEN GEAR/

4. DRIVE GEAR

Measure the side clearance of the oil pump gear and *A

replace the gear or oil pump assembly if it exceeds the

-’standard value.

Standard value:

0.03-0.05 mm (.OOl-.002 in.)

3. LOCATION OF STEEL BALL

Install a steel ball in the position shown in the figure.

2. INSTALLATION OF REACTION SHAFT SUPPORT

(1) Assemble the reaction shaft support and pump housingand tighten the bolts by hand.

(2) Insert the special tool (guide pin

MD998336) in the oil ;?pump mounting bolt hole and tighten the outside

‘II.circumference using the special tool (band

MD9983351to position the support and housing.

(3) Tighten the five bolts to the specified torque.

(4) Make sure that the oil pump gear turns freely.

ITFA0201

1

1. INSTALLATION OF O-RING

Install a new O-ring in the groove of the pump housing andapply petrolatum to the O-ring.