lock MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 541 of 1216

FUEL SYSTEM - Throttle Bodv <1.8L Engine>

Throttle position

sensor connectorINSPECTIONN14SHAC4

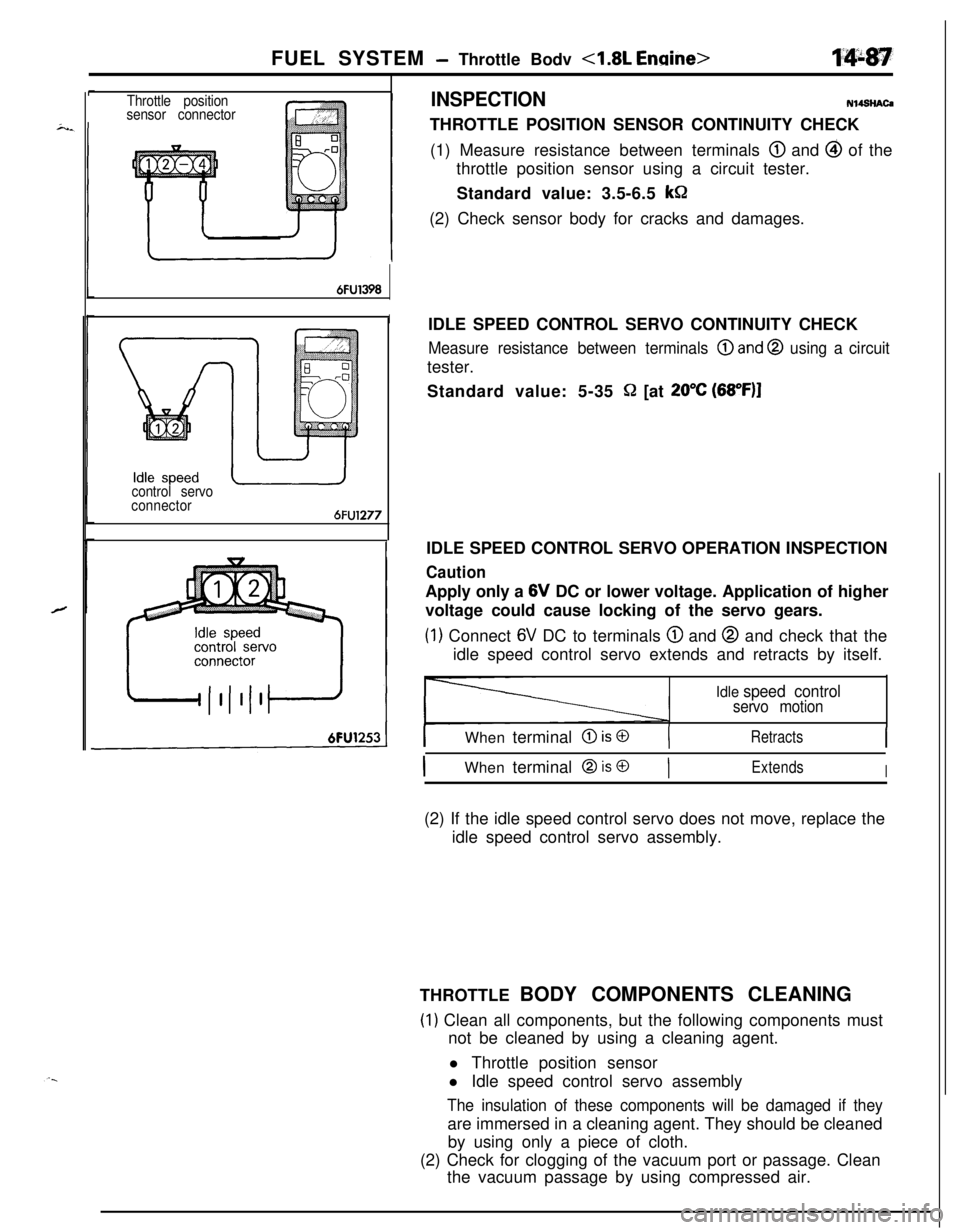

THROTTLE POSITION SENSOR CONTINUITY CHECK

(1) Measure resistance between terminals

@ and @ of the

throttle position sensor using a circuit tester.

Standard value: 3.5-6.5

kSZ(2) Check sensor body for cracks and damages.

6FU1398

I

control servo

connector

6FU1277

IIDLE SPEED CONTROL SERVO OPERATION INSPECTIONIDLE SPEED CONTROL SERVO CONTINUITY CHECK

Measure resistance between terminals @and @ using a circuittester.

Standard value: 5-35

Q [at 20°C (68”F)I

CautionApply only a 6V DC or lower voltage. Application of higher

voltage could cause locking of the servo gears.

(1) Connect 6V DC to terminals @ and @ and check that the

idle speed control servo extends and retracts by itself.

Idle speed controlservo motion

I

IWhen terminal @ is @(RetractsI

IWhen terminal @ is @)ExtendsI(2) If the idle speed control servo does not move, replace the

idle speed control servo assembly.

THROTTLE BODY COMPONENTS CLEANING

(1) Clean all components, but the following components must

not be cleaned by using a cleaning agent.

l Throttle position sensor

l Idle speed control servo assembly

The insulation of these components will be damaged if theyare immersed in a cleaning agent. They should be cleaned

by using only a piece of cloth.

(2) Check for clogging of the vacuum port or passage. Clean

the vacuum passage by using compressed air.

Page 547 of 1216

FUEL SYSTEM - Fuel Tank

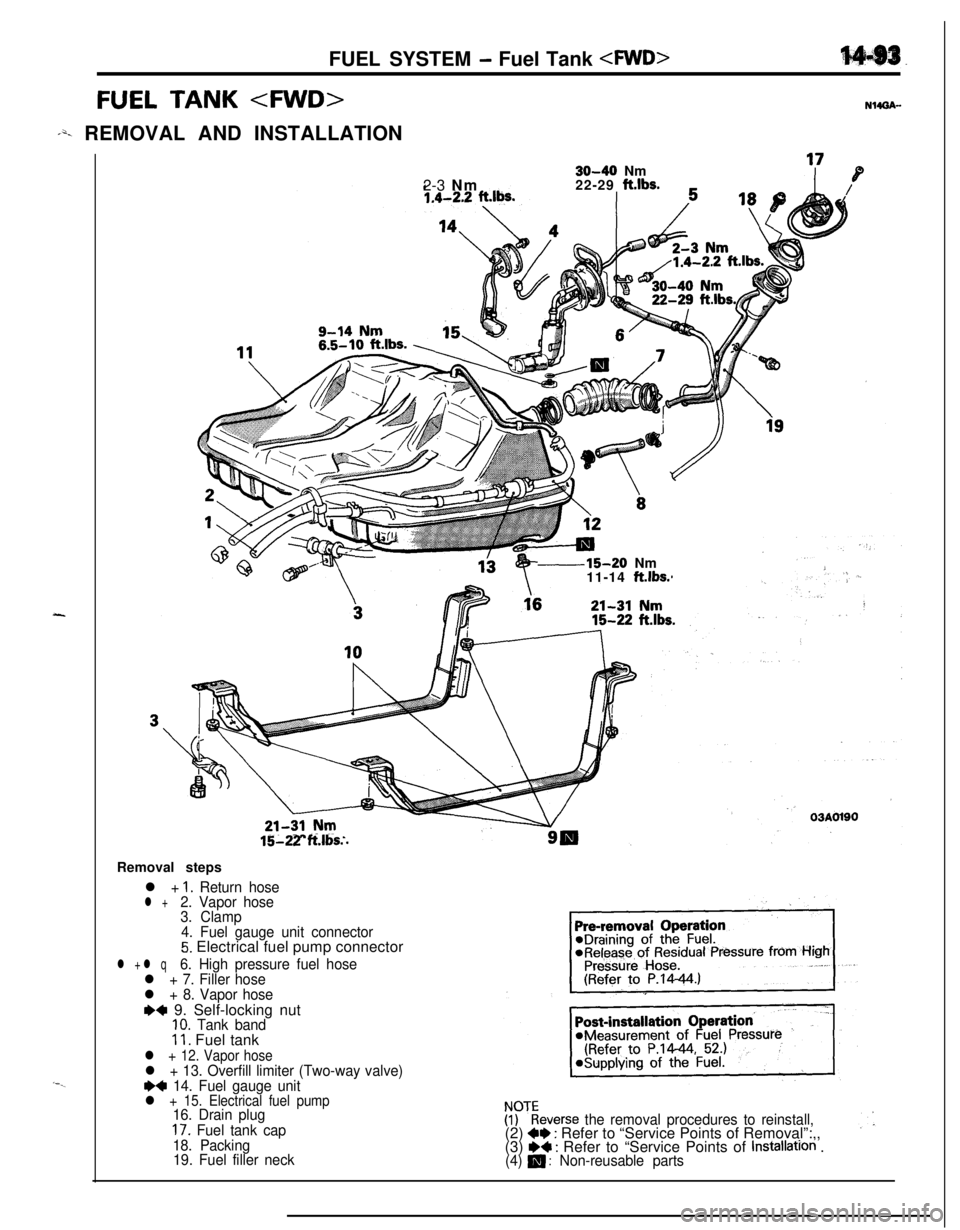

FUEL TANK cFWD>

,*. REMOVAL AND INSTALLATION

q?&g

NlMA-30-40 Nm

2-3 Nm22-29 ft.lbs.

---15-20 Nm

11-14 ft.lbs.

15-22 ft.lbs.Removal steps

l + 1. Return hosel +2. Vapor hose

3. Clamp

4. Fuel gauge unit connector

5. Electrical fuel pump connector

l + l q6. High pressure fuel hose

l + 7. Filler hose

l + 8. Vapor hose

~~ 9. Self-locking nut10. Tank band11. Fuel tank

l + 12. Vapor hosel + 13. Overfill limiter (Two-way valve)I)+ 14. Fuel gauge unitl + 15. Electrical fuel pump16. Drain plug

17. Fuel tank cap

18. Packing

19. Fuel filler neck$TEeverse the removal procedures to reinstall,(2) +e : Refer to “Service Points of Removal”:,,

(3) *+ : Refer to “Service Points of lnstallatlon .(4) m : Non-reusable parts

Page 549 of 1216

FUEL SYSTEM - Fuel Tank

W304I I

I03FDO7 1

Tank band

03AO229

I I\ \\u\ I \I-

03AO189

?4-.03FOO7A

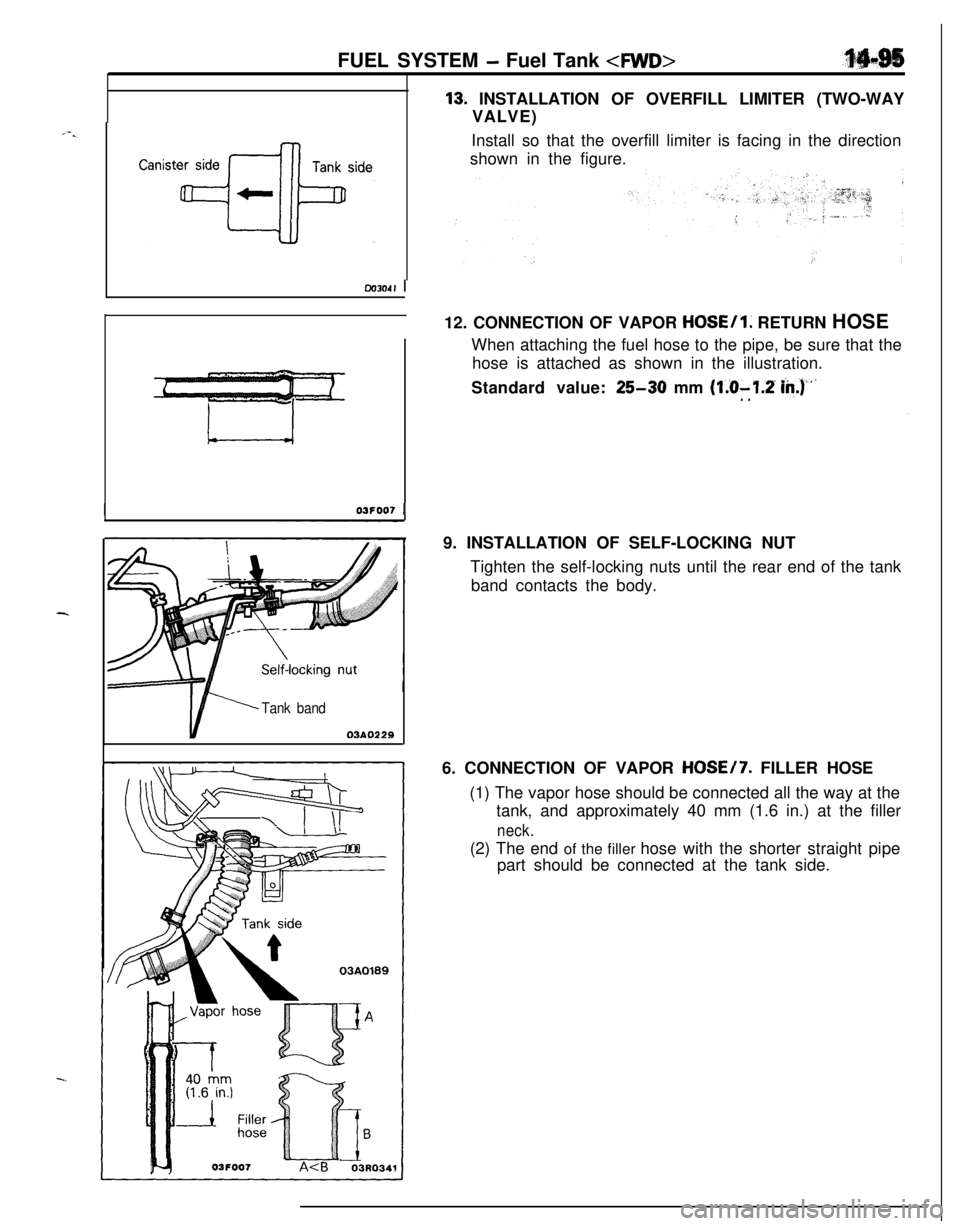

VALVE)

Install so that the overfill limiter is facing in the direction

shown in the figure.

12. CONNECTION OF VAPOR

HOSE/l. RETURN HOSE

When attaching the fuel hose to the pipe, be sure that the

hose is attached as shown in the illustration.

Standard value:

25-30 mm (l&1.2 t@.).”. .9. INSTALLATION OF SELF-LOCKING NUT

Tighten the self-locking nuts until the rear end of the tank

band contacts the body.

6. CONNECTION OF VAPOR

HOSE/7. FILLER HOSE

(1) The vapor hose should be connected all the way at the

tank, and approximately 40 mm (1.6 in.) at the filler

neck.(2) The end of the filler hose with the shorter straight pipe

part should be connected at the tank side.

Page 551 of 1216

FUEL SYSTEM - Fuel Tank

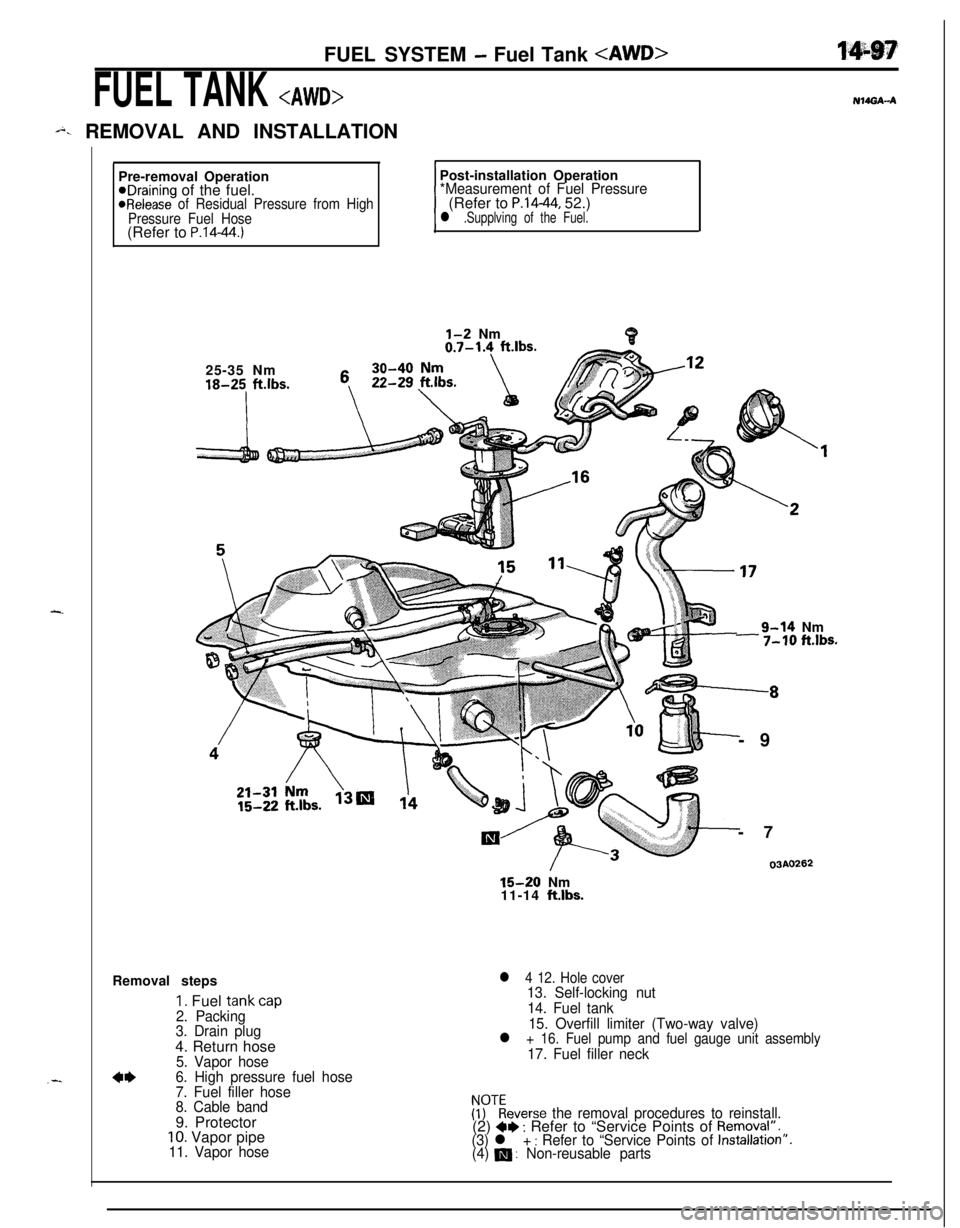

FUEL TANK

i. REMOVAL AND INSTALLATION

N140A-A

_-Pre-removal Operation

eDraining of the fuel.@Release of Residual Pressure from High

Pressure Fuel Hose(Refer to

P.14-44.)Post-installation Operation

*Measurement of Fuel Pressure(Refer to P.14-44, 52.)l .Supplving of the Fuel.

1-2 Nm825-35 Nm

‘*-*: ft-‘bs*

9-14 Nm- 7-10 ft.lbs.-9

-7

03AO262

15-20 Nm

11-14 ftlbs.Removal steps

1. Fuel tankcap2. Packing

3. Drain plug4. Return hose

5. Vapor hose

4*6. High pressure fuel hose

7. Fuel filler hose

8. Cable band9. Protector

10. Vapor pipe11. Vapor hose

l 4 12. Hole cover13. Self-locking nut

14. Fuel tank

15. Overfill limiter (Two-way valve)

l + 16. Fuel pump and fuel gauge unit assembly

17. Fuel filler neck

FyTEeverse the removal procedures to reinstall.(2) ~~ : Refer to “Service Points of RemoveI”.(3) l + : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 553 of 1216

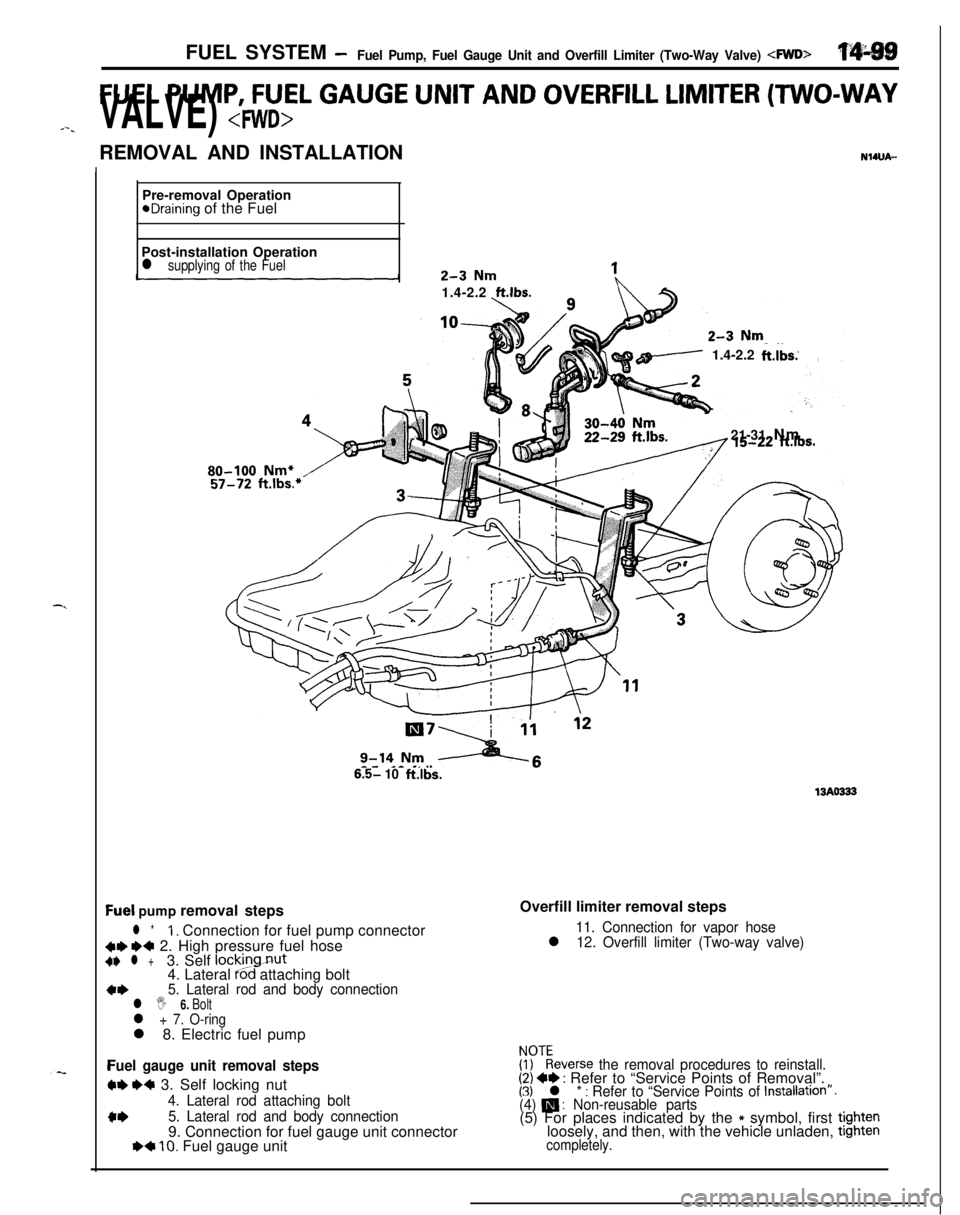

FUEL SYSTEM -Fuel Pump, Fuel Gauge Unit and Overfill Limiter (Two-Way Valve)

FUEL PUMP, FUEL GAUGE UNIT AND OVERFILL LIMITER (TWO-WAY

J-.VALVE)

NWJA-Pre-removal Operation

eDraining of the Fuel

Post-installation Operation

l supplying of the Fuel1.4-2.2

ft.lbs.

/ 1.4-2.2ft.lbs.

21-31 Nm

80-100 Nm+

6.5- 10ftlbs.

13AO333

Qel pump removal steps

l *1. Connection for fuel pump connector

C+ ~~ 2. High pressure fuel hoseC+ l +3. Self lockingnut

4. Lateral Pod attaching bolt

a*5. Lateral rod and body connectionl I 6. Boltl + 7. O-ringl 8. Electric fuel pump

Fuel gauge unit removal steps

W e+ 3. Self locking nut

4. Lateral rod attaching bolt

c*5. Lateral rod and body connection9. Connection for fuel gauge unit connector

I)+ 10. Fuel gauge unitOverfill limiter removal steps

11. Connection for vapor hosel 12. Overfill limiter (Two-way valve)

FF:everse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.(4) m : Non-reusable parts(5) For places indicated by the * symbol, first tightenloosely, and then, with the vehicle unladen, tighten

completely.

Page 554 of 1216

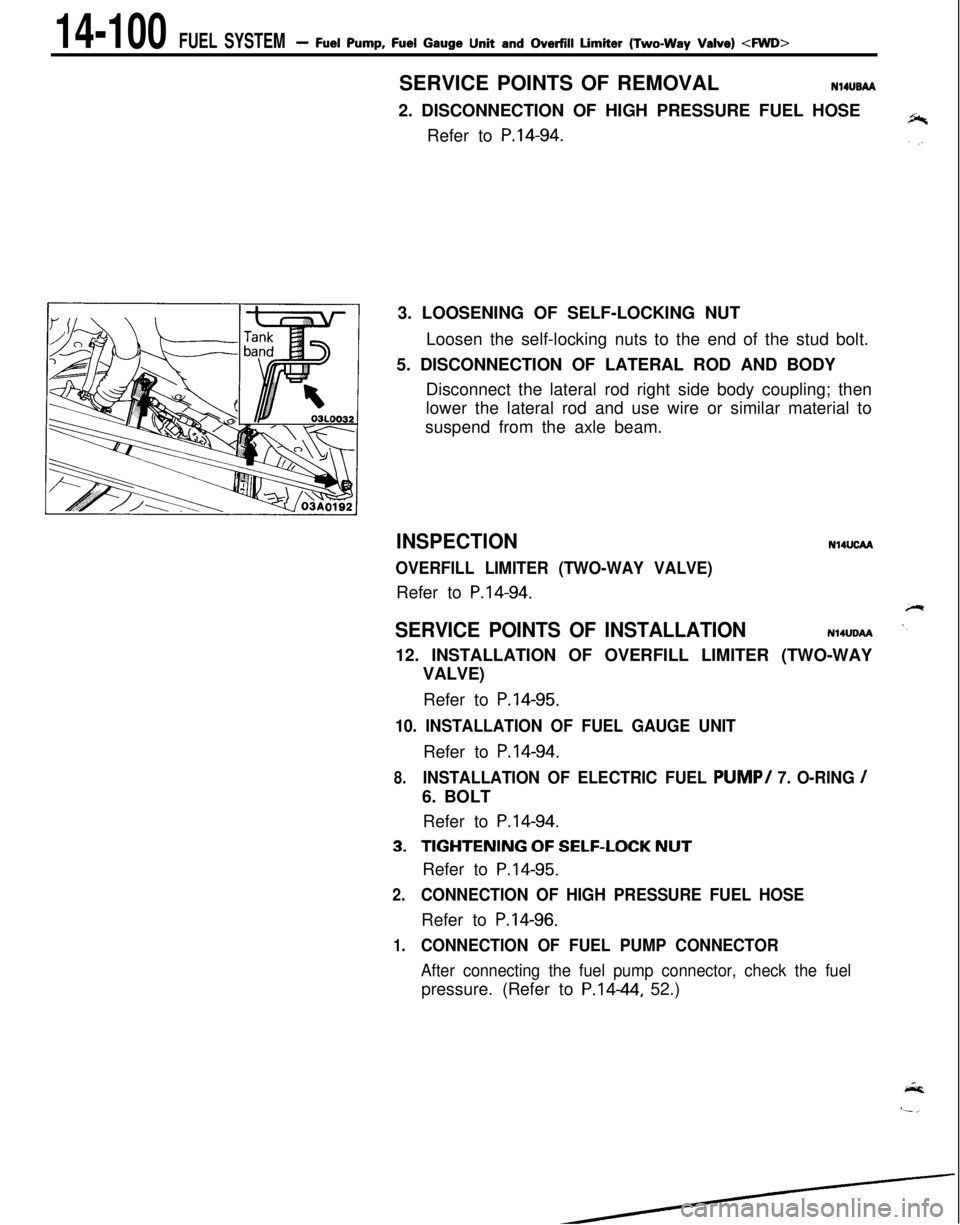

14-100 FUEL SYSTEM- Fuel Pump, Fuel Gauge Unit and Overfill Limiter (Two-Way Valve) 4WD>SERVICE POINTS OF REMOVAL

NI4tmM2. DISCONNECTION OF HIGH PRESSURE FUEL HOSE

Refer to

P.14-94.3. LOOSENING OF SELF-LOCKING NUT

Loosen the self-locking nuts to the end of the stud bolt.

5. DISCONNECTION OF LATERAL ROD AND BODY

Disconnect the lateral rod right side body coupling; then

lower the lateral rod and use wire or similar material to

suspend from the axle beam.

INSPECTION

OVERFILL LIMITER (TWO-WAY VALVE)Refer to

P.14-94.

N14UcM

SERVICE POINTS OF INSTALLATIONN14UDAA12. INSTALLATION OF OVERFILL LIMITER (TWO-WAY

VALVE)

Refer to

P.14-95.

10. INSTALLATION OF FUEL GAUGE UNITRefer to

P.14-94.

8.INSTALLATION OF ELECTRIC FUEL PUMP/ 7. O-RING /6. BOLT

Refer to

P.14-94.

3.TIGHTENING OF SELF-LOCK NUTRefer to

P.14-95.

2.CONNECTION OF HIGH PRESSURE FUEL HOSERefer to

P.14-96.

1.CONNECTION OF FUEL PUMP CONNECTOR

After connecting the fuel pump connector, check the fuelpressure. (Refer to P.1444, 52.)

Page 568 of 1216

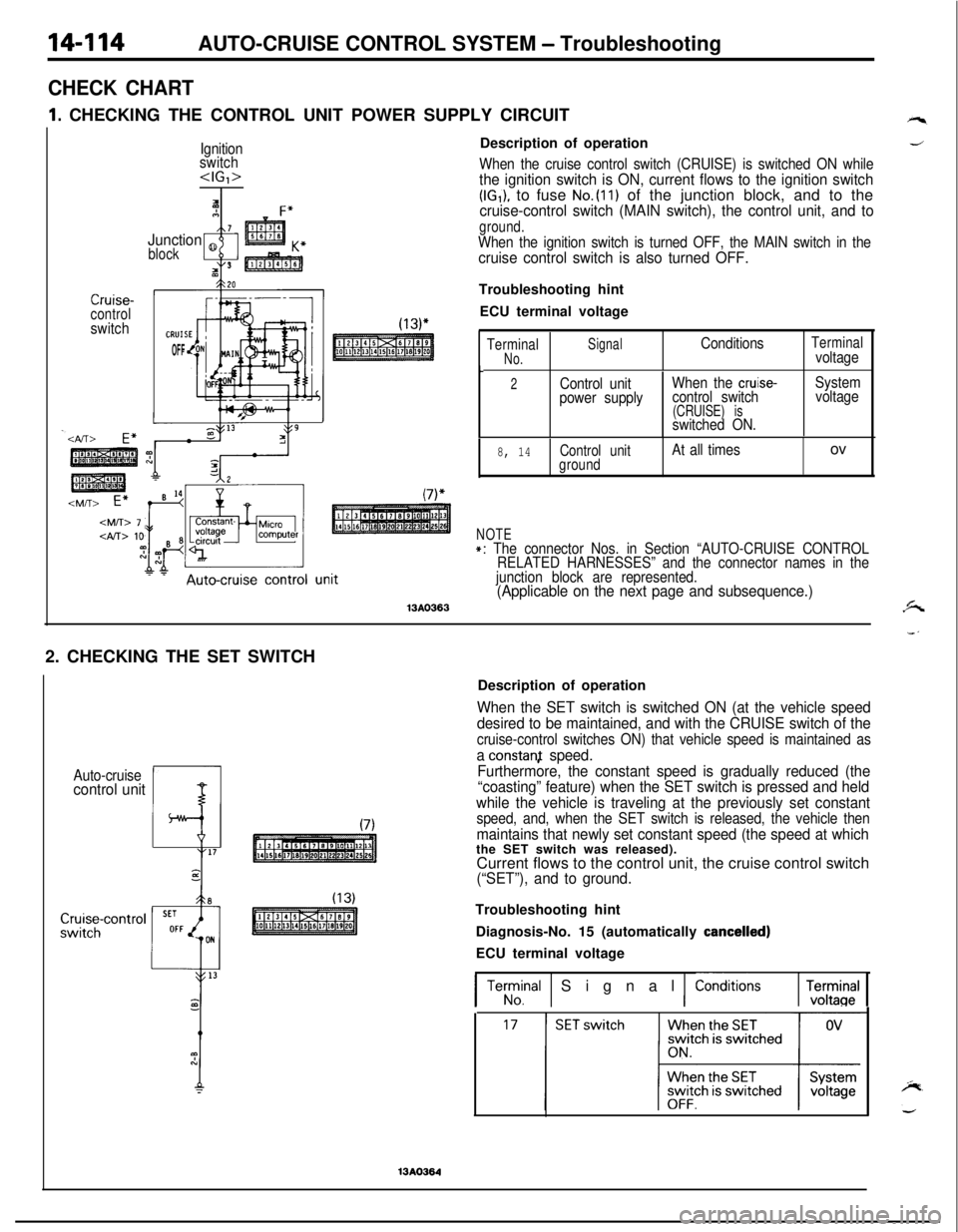

14-114AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

CHECK CHART

1I. CHECKING THE CONTROL UNIT POWER SUPPLY CIRCUIT

Ignition

switch

IAF”7Junction 8

block

tI3

Crurse-controlswitch

OFFDescription of operation

When the cruise control switch (CRUISE) is switched ON whilethe ignition switch is ON, current flows to the ignition switch(IG,), to fuse No.(ll) of the junction block, and to thecruise-control switch (MAIN switch), the control unit, and to

ground.When the ignition switch is turned OFF, the MAIN switch in thecruise control switch is also turned OFF.Troubleshooting hint

ECU terminal voltage

TerminalSignal

No.ConditionsTerminalvoltage

t2Control unitWhen the cruise-System

power supplycontrol switchvoltage

(CRUISE) isswitched ON.

8, 14Control unitAt all timesovground

NOTE+: The connector Nos. in Section “AUTO-CRUISE CONTROL

RELATED HARNESSES” and the connector names in the

junction block are represented.

(Applicable on the next page and subsequence.)13AO3632. CHECKING THE SET SWITCH

Auto-cruisecontrol unitDescription of operation

When the SET switch is switched ON (at the vehicle speed

desired to be maintained, and with the CRUISE switch of the

cruise-control switches ON) that vehicle speed is maintained as

a constanf speed.

Furthermore, the constant speed is gradually reduced (the

“coasting” feature) when the SET switch is pressed and held

while the vehicle is traveling at the previously set constant

speed, and, when the SET switch is released, the vehicle then

maintains that newly set constant speed (the speed at whichthe SET switch was released).

Current flows to the control unit, the cruise control switch

(“SET”), and to ground.Troubleshooting hint

Diagnosis-No. 15 (automatically

cancelled)ECU terminal voltage

1 Terrrnal 1 Signal 1 ConditionsrEl

13AO364

Page 569 of 1216

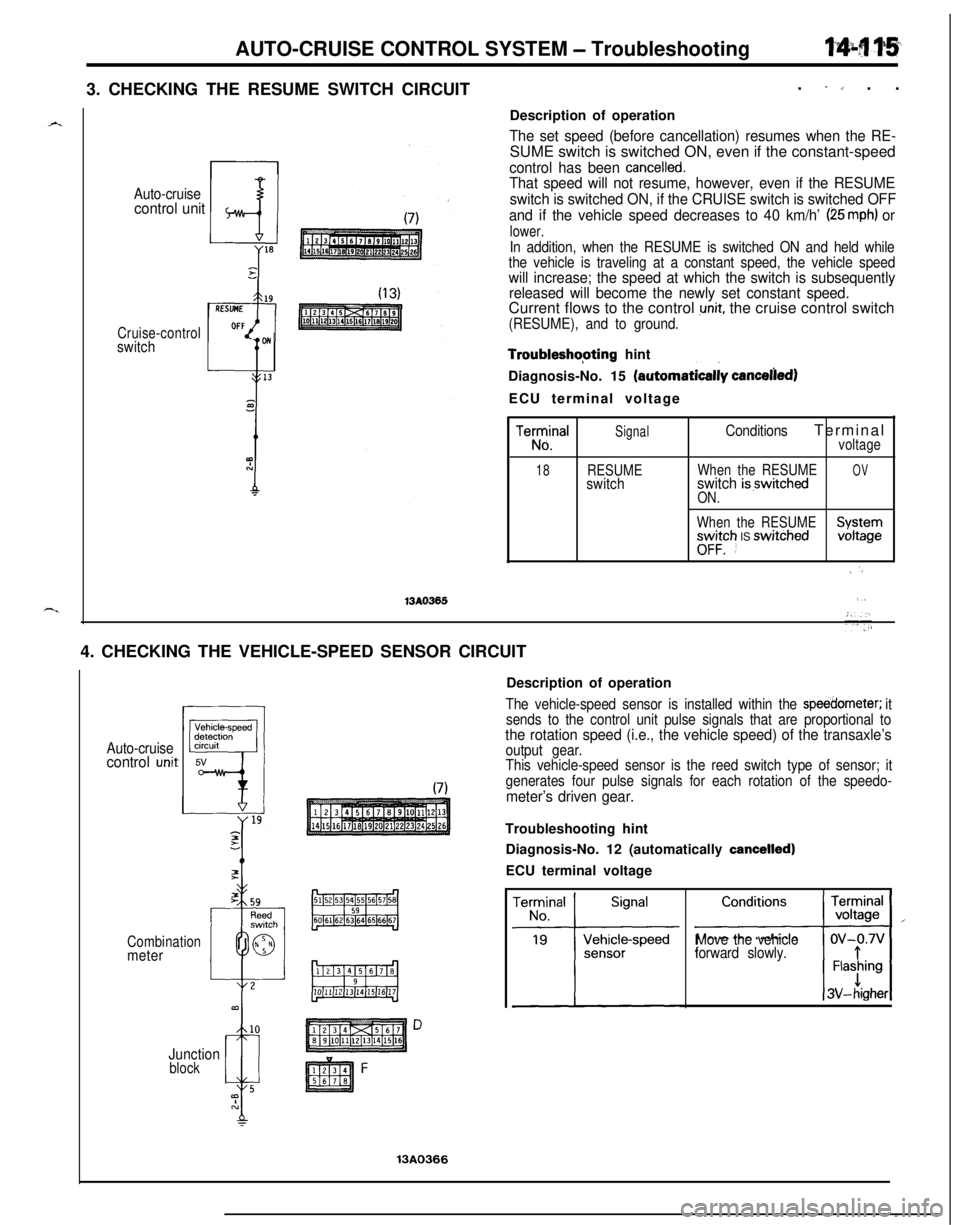

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

3. CHECKING THE RESUME SWITCH CIRCUIT.

” ,, . .

Auto-cruisecontrol unit

Cruise-controlswitchDescription of operation

The set speed (before cancellation) resumes when the RE-SUME switch is switched ON, even if the constant-speed

control has been cancelled.That speed will not resume, however, even if the RESUME

switch is switched ON, if the CRUISE switch is switched OFF

and if the vehicle speed decreases to 40 km/h’

(25 mph) or

lower.

In addition, when the RESUME is switched ON and held while

the vehicle is traveling at a constant speed, the vehicle speed

will increase; the speed at which the switch is subsequently

released will become the newly set constant speed.Current flows to the control

unit, the cruise control switch

(RESUME), and to ground.

Troubleshopting hint

Diagnosis-No. 15

(automatica& canceelied)ECU terminal voltage

Tez3!alSignalConditionsTerminalvoltage

18RESUMEWhen the RESUMEOVswitchswitch is,switchedON.

When the RESUME

“o”;:“h IS swrtched;;;;g;

\ ‘)

13AO365,,4. CHECKING THE VEHICLE-SPEED SENSOR CIRCUIT

Auto-cruisecontrol unit

Combination

meter

Junction

block

13A0366Description of operation

The vehicle-speed sensor is installed within the sljeedometer; it

sends to the control unit pulse signals that are proportional to

the rotation speed (i.e., the vehicle speed) of the transaxle’soutput gear.

This vehicle-speed sensor is the reed switch type of sensor; it

generates four pulse signals for each rotation of the speedo-

meter’s driven gear.Troubleshooting hint

Diagnosis-No. 12 (automatically

cancelled)ECU terminal voltage

Move the vehicle

forward slowly.

Page 571 of 1216

i-._AUTO-CRUISE CONTROL SYSTEM

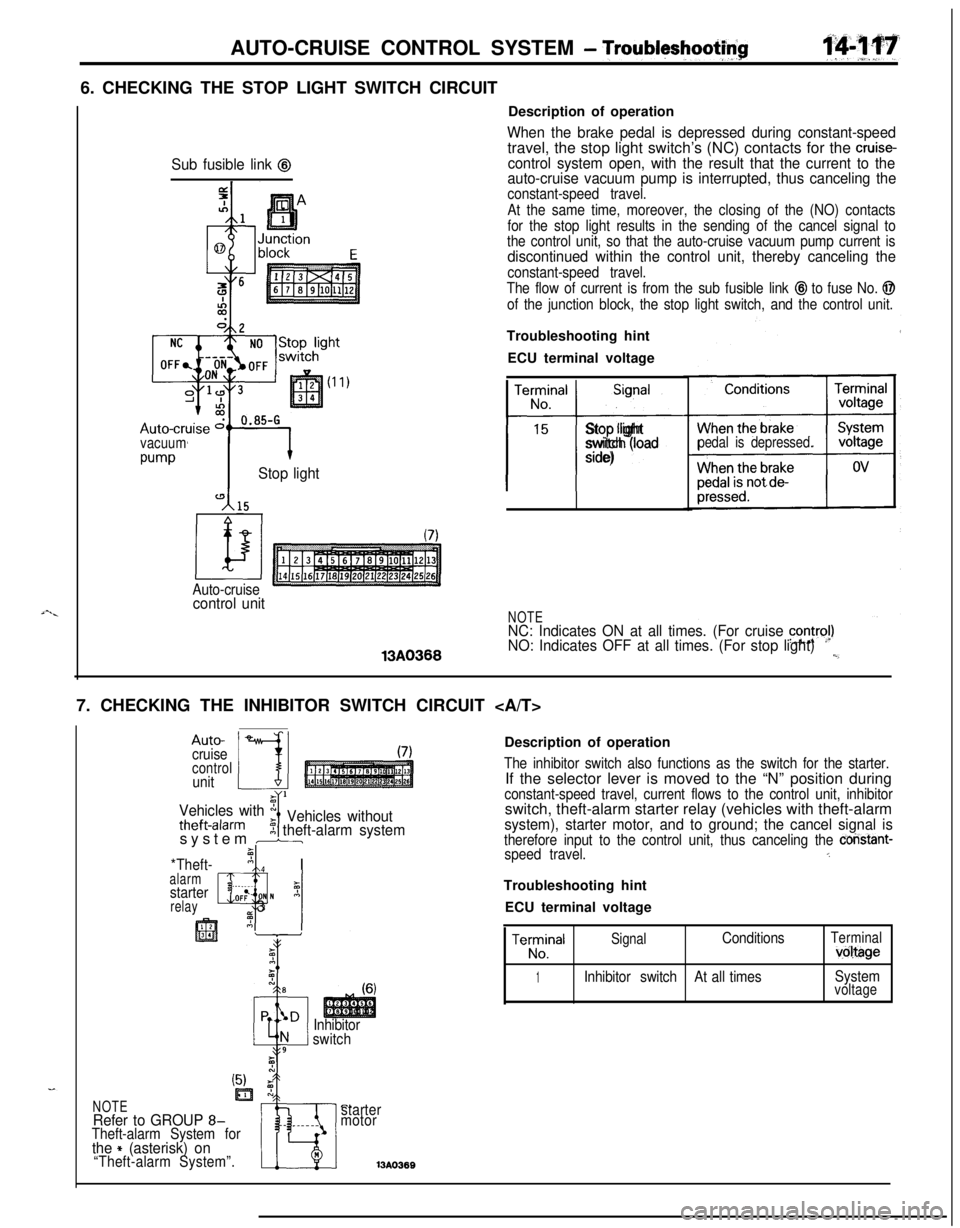

- Troubltyshootf$6. CHECKING THE STOP LIGHT SWITCH CIRCUIT

Sub fusible link @

vacuum

w-vStop light

Auto-cruisecontrol unit13A0366Description of operation

When the brake pedal is depressed during constant-speedtravel, the stop light switch’s (NC) contacts for the cruise-control system open, with the result that the current to the

auto-cruise vacuum pump is interrupted, thus canceling the

constant-speed travel.

At the same time, moreover, the closing of the (NO) contacts

for the stop light results in the sending of the cancel signal to

the control unit, so that the auto-cruise vacuum pump current is

discontinued within the control unit, thereby canceling the

constant-speed travel.

The flow of current is from the sub fusible link

@I to fuse No. @

of the junction block, the stop light switch, and the control unit.Troubleshooting hint

ECU terminal voltage

TerminalSignal

No.

15

t-i-

Stop light

switch (load

side)pedal is depressed.

NOTENC: Indicates ON at all times. (For cruise contra!)NO: Indicates OFF at all times. (For stop light)l,_7. CHECKING THE INHIBITOR SWITCH CIRCUIT

Auto-

cruise

controlunit

Vehicles with x

theft-alarmIVehicles without5 theft-alarm systemsystem br

*Theft-’ nI Ialarm, ._I

starterz

relayQlOF: N A_ 3

Inhibitor

switchDescription of operation

The inhibitor switch also functions as the switch for the starter.If the selector lever is moved to the “N” position during

constant-speed travel, current flows to the control unit, inhibitorswitch, theft-alarm starter relay (vehicles with theft-alarm

system), starter motor, and to ground; the cancel signal istherefore input to the control unit, thus canceling the constant-speed travel.5Troubleshooting hint

ECU terminal voltage

TeE!alSignalConditionsTerminalvoltage

1Inhibitor switchAt all timesSystemvoltage

C.starter

motor13A036BNOTERefer to GROUP 8-Theft-alarm System forthe + (asterisk) on“Theft-alarm System”.

Page 572 of 1216

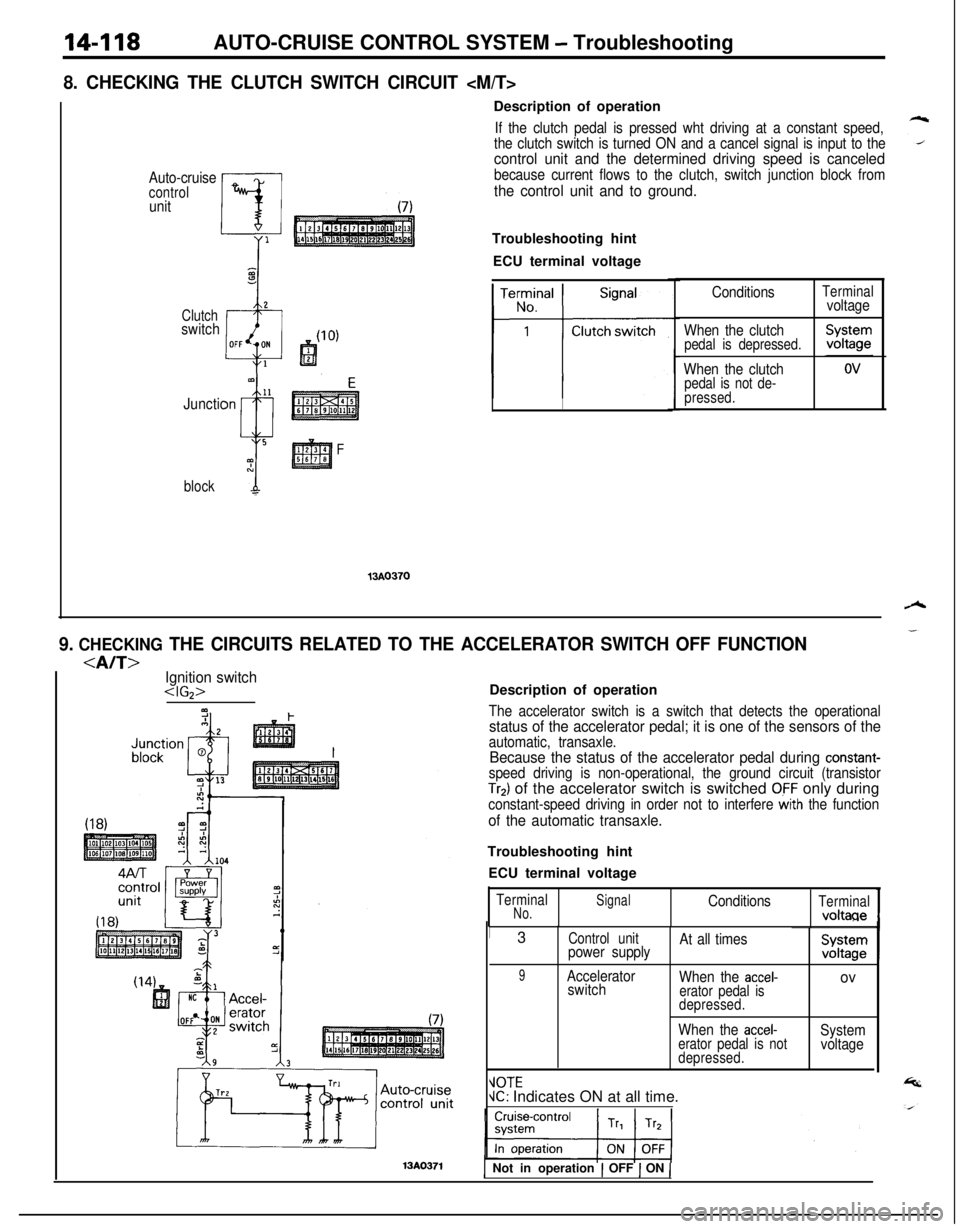

14-118AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

8. CHECKING THE CLUTCH SWITCH CIRCUIT

Auto-cruisecontrolunit9

2ClutchswitchOFF ON

1m11Junction

blockI

13AO370Description of operation

If the clutch pedal is pressed wht driving at a constant speed,

the clutch switch is turned ON and a cancel signal is input to the

control unit and the determined driving speed is canceled

because current flows to the clutch, switch junction block from

the control unit and to ground.Troubleshooting hint

ECU terminal voltage

TerminalSignal

No.

1Clutch switch

t--l--II

ConditionsTerminalvoltage

When the clutch

pedal is depressed.

When the clutchpedal is not de-

pressed.

9. CHECKING THE CIRCUITS RELATED TO THE ACCELERATOR SWITCH OFF FUNCTION

Ignition switch

& Accel-/Description of operation

The accelerator switch is a switch that detects the operationalstatus of the accelerator pedal; it is one of the sensors of theautomatic, transaxle.Because the status of the accelerator pedal during constant-speed driving is non-operational, the ground circuit (transistorTr2) of the accelerator switch is switched OFF only during

constant-speed driving in order not to interfere wtth the function

of the automatic transaxle.Troubleshooting hint

ECU terminal voltage

TerminalNo.SignalConditionsTerminalvoltaoe

’ 3Control unitAt all times

power supply

9Accelerator

When the accel-ovswitcherator pedal is

depressed.

When the accel-Systemerator pedal is not

depressed.voltage

\lOTEJC: Indicates ON at all time.

13AO3711 Not in operation ) OFF 1 ON (