lock MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 638 of 1216

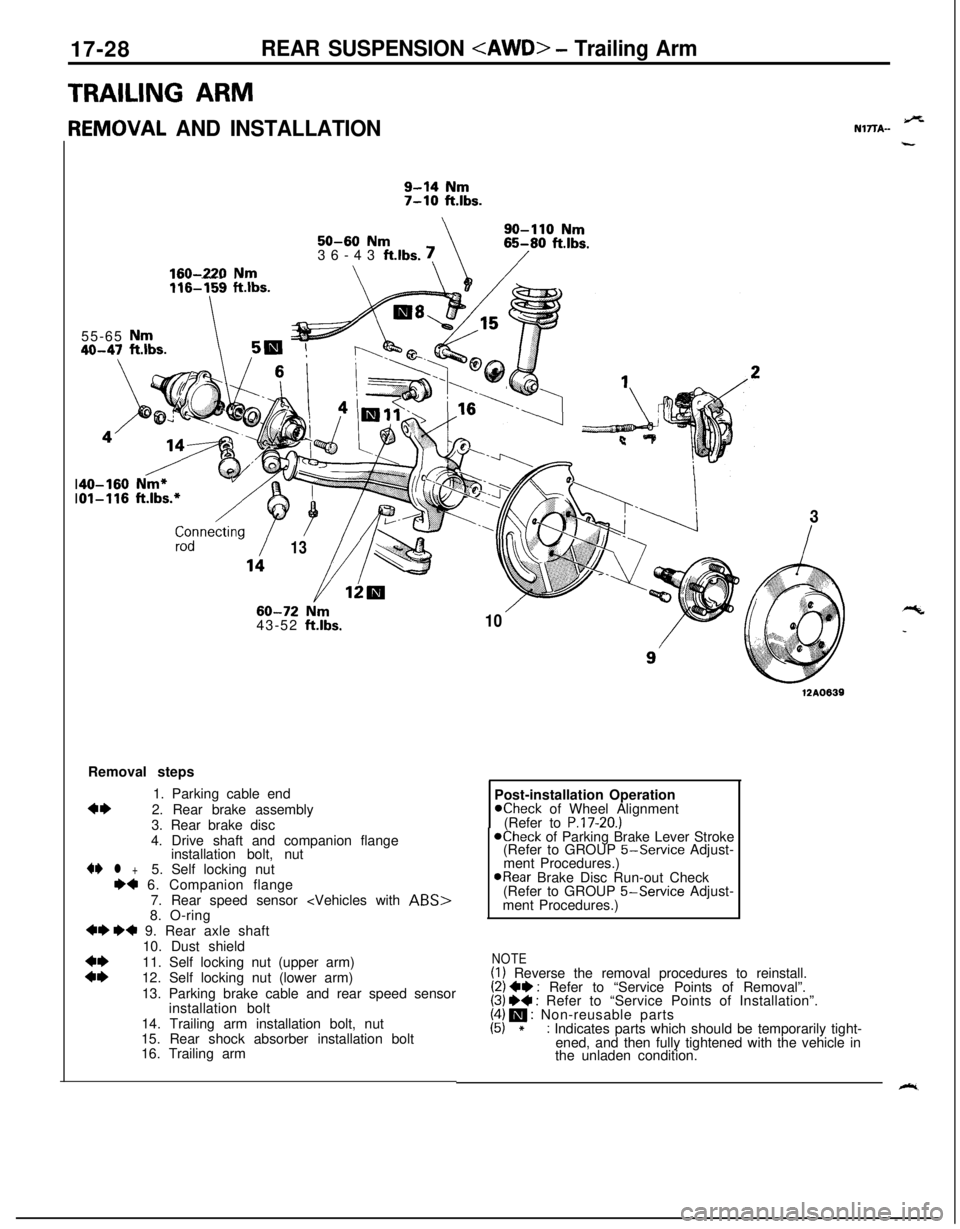

17-28REAR SUSPENSION

TRAILING ARMr

{EMOVAL AND INSTALLATION

9-14 Nm7-10 ft.lbs.

\SO-110

Nm50-60 Nm36-43 ft.lbs. !65-80 ftlbs.

/160-220 Nm\\\ /zdnnecting

/

/

13

_-_ --- .~~~~116-159 ftlbs.55-65

Nm40-47 ft.lbs.5m

60-72 Nrn43-52 ft.lbs.

/-\

103Removal steps

1. Parking cable end

4*2. Rear brake assembly

3. Rear brake disc

4. Drive shaft and companion flange

installation bolt, nut4I)

l +5. Self locking nut++ 6. Companion flange

7. Rear speed sensor

+I) ++ 9. Rear axle shaft

10. Dust shield

::11. Self locking nut (upper arm)

12. Self locking nut (lower arm)

13. Parking brake cable and rear speed sensor

installation bolt

14. Trailing arm installation bolt, nut

15. Rear shock absorber installation bolt

16. Trailing arm

12A0639Post-installation Operation

Kheck of Wheel Alignment

(Refer to P.17-20.)@Check of Parking Brake Lever Stroke

(Refer to GROUP 5-Service Adjust-

ment Procedures.)

@Rear Brake Disc Run-out Check

(Refer to GROUP 5-Service Adjust-

ment Procedures.)

NOTE(I) Reverse the removal procedures to reinstall.(2) ++ : Refer to “Service Points of Removal”.(3) W : Refer to “Service Points of Installation”.(4) m : Non-reusable parts(5) *: Indicates parts which should be temporarily tight-

ened, and then fully tightened with the vehicle in

the unladen condition.

9%NlTTA-

“c

_

k.

Page 639 of 1216

REAR SUSPENSION

12A008’I

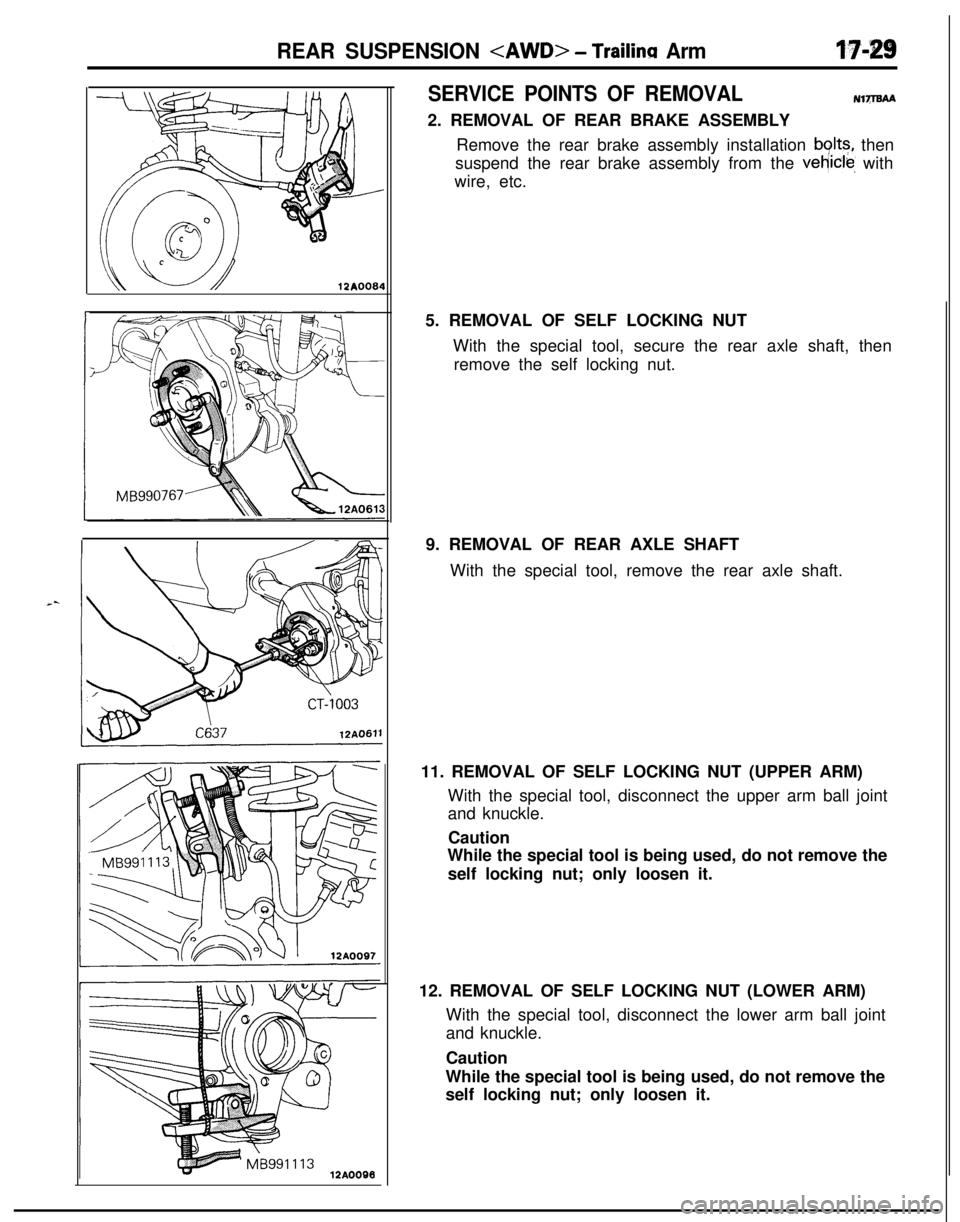

SERVICE POINTS OF REMOVALu17mAA2. REMOVAL OF REAR BRAKE ASSEMBLY

Remove the rear brake assembly installation

bolts, then

suspend the rear brake assembly from the

vehrcle, with

wire, etc.

5. REMOVAL OF SELF LOCKING NUT

With the special tool, secure the rear axle shaft, then

remove the self locking nut.

9. REMOVAL OF REAR AXLE SHAFT

With the special tool, remove the rear axle shaft.

11. REMOVAL OF SELF LOCKING NUT (UPPER ARM)

With the special tool, disconnect the upper arm ball joint

and knuckle.

Caution

While the special tool is being used, do not remove the

self locking nut; only loosen it.

12. REMOVAL OF SELF LOCKING NUT (LOWER ARM)

With the special tool, disconnect the lower arm ball joint

and knuckle.

Caution

While the special tool is being used, do not remove the

self locking nut; only loosen it.

Page 641 of 1216

REAR SUSPENSION

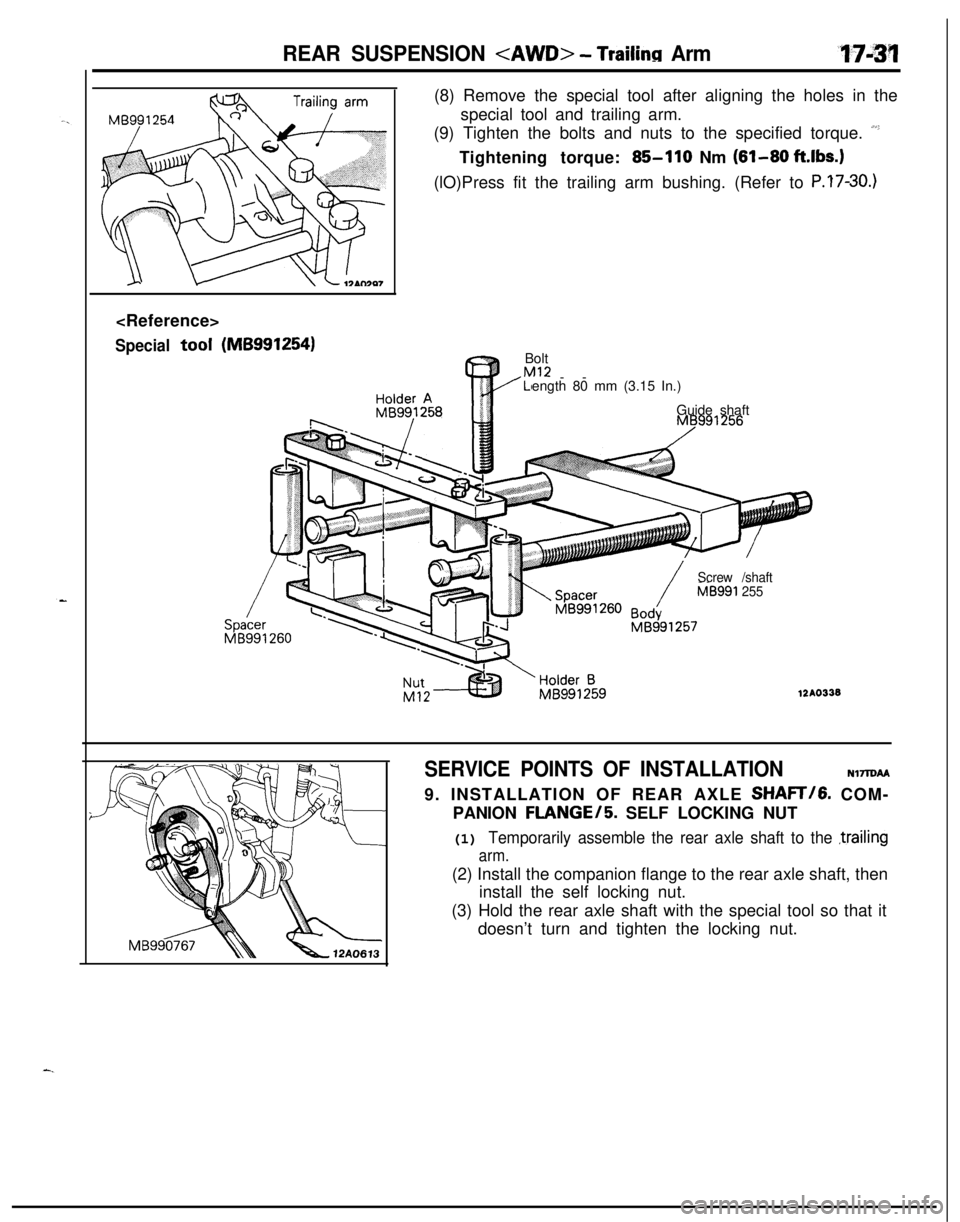

Specialtool(MB9912541(8) Remove the special tool after aligning the holes in the

special tool and trailing arm.

(9) Tighten the bolts and nuts to the specified torque.

“’Tightening torque:

85-110 Nm (81-80 ft.lbs.)(lO)Press fit the trailing arm bushing. (Refer to

P.?7-30.)Bolt

Ml2LI--

ength 80 mm (3.15 In.)

Guide shaft

/Screw /shaft

/MB591 255

12AO338

SERVICE POINTS OF INSTALLATION

NlTlDAA9. INSTALLATION OF REAR AXLE SHAFT/G. COM-

PANION

FLANGE/5. SELF LOCKING NUT

(1) Temporarily assemble the rear axle shaft to the ,trailing

arm.(2) Install the companion flange to the rear axle shaft, then

install the self locking nut.

(3) Hold the rear axle shaft with the special tool so that it

doesn’t turn and tighten the locking nut.

Page 645 of 1216

-.

J-

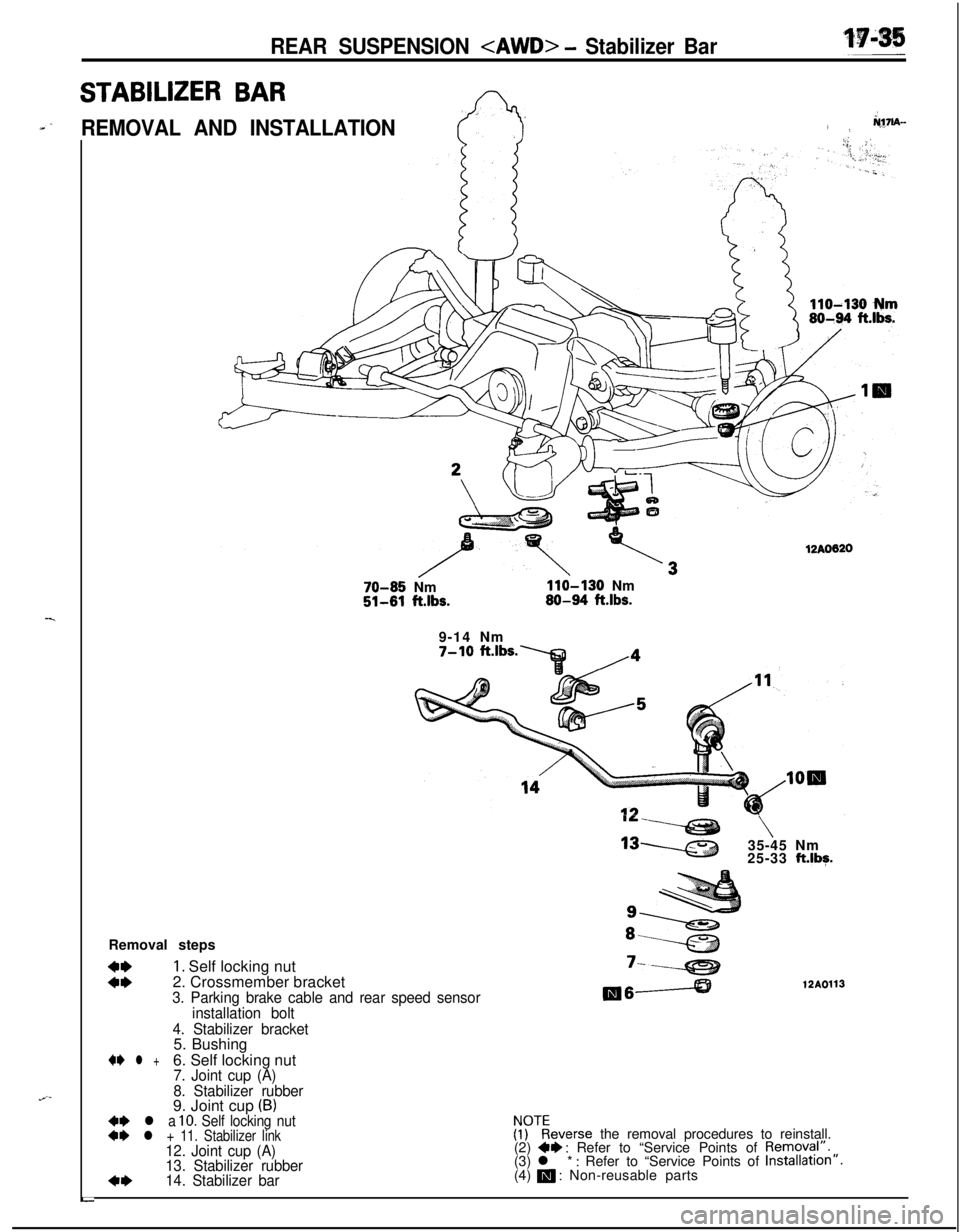

REAR SUSPENSION

STABILIZER BAR:_-REMOVAL AND INSTALLATION/rq7lA-i.i;: 112AO620

70-85 Nm110-130 Nm51-81 ft.lbs.80-94 ftlbs.9-14 Nm

7-10 ft.lbs./4

IL-v \

‘3w35-45 Nm

25-33 ft.lbg.Removal steps

::

1. Self locking nut

2. Crossmember bracket‘----e212A01133. Parking brake cable and rear speed sensormeA

installation bolt

4. Stabilizer bracket5. Bushing

+e l +6. Self locking nut7. Joint cup (A)

8. Stabilizer rubber9. Joint cup

(B)+e l a 10. Self locking nut++ l + 11. Stabilizer link!ykeverse the removal procedures to reinstall.

12. Joint cup (A)(2) +I) : Refer to “Service Points of Removyl”.

13. Stabilizer rubber(3) l * : Refer to “Service Points of Installation”.

4*14. Stabilizer bar(4) m : Non-reusable parts

L

Page 646 of 1216

17-36REAR SUSPENSION

/12AOllO

\.1210111

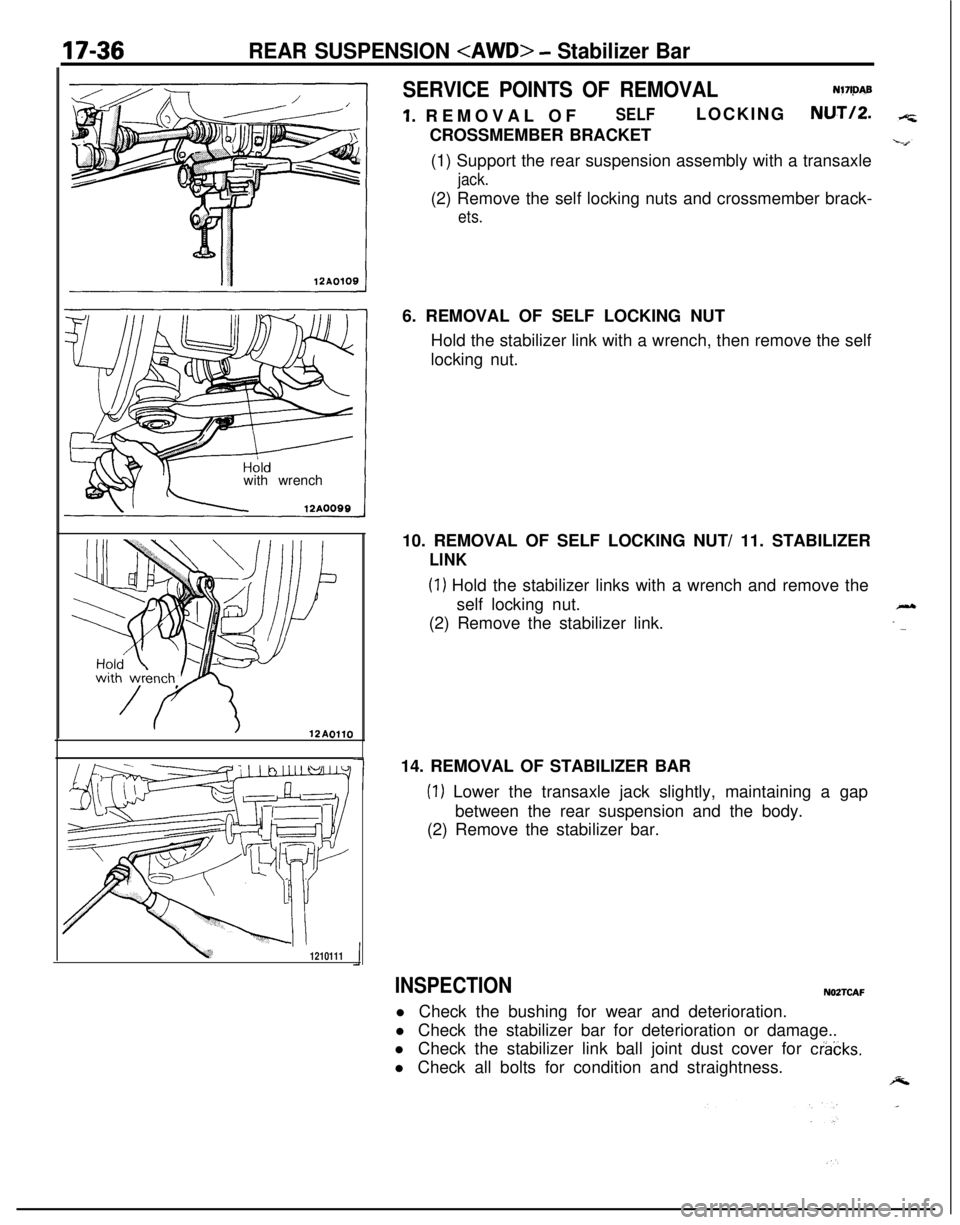

SERVICE POINTS OF REMOVALNl7ljMB

1. REMOVAL OFSELFLOCKINGNUT/P.CROSSMEMBER BRACKET

(1) Support the rear suspension assembly with a transaxle

jack.(2) Remove the self locking nuts and crossmember brack-

ets.6. REMOVAL OF SELF LOCKING NUT

Hold the stabilizer link with a wrench, then remove the self

locking nut.

10. REMOVAL OF SELF LOCKING NUT/ 11. STABILIZER

LINK

(1) Hold the stabilizer links with a wrench and remove the

self locking nut.

(2) Remove the stabilizer link.

14. REMOVAL OF STABILIZER BAR

(1) Lower the transaxle jack slightly, maintaining a gap

between the rear suspension and the body.

(2) Remove the stabilizer bar.7

INSPECTIONNOZTCAFl Check the bushing for wear and deterioration.

l Check the stabilizer bar for deterioration or damage..

l Check the stabilizer link ball joint dust cover for

cracks.l Check all bolts for condition and straightness.

Page 647 of 1216

-.REAR SUSPENSION

- Stabilizer Bar17-37Clip

ring

12LO217

Jrpose

\12LQ243

Hold with

wrench

12AOlOO

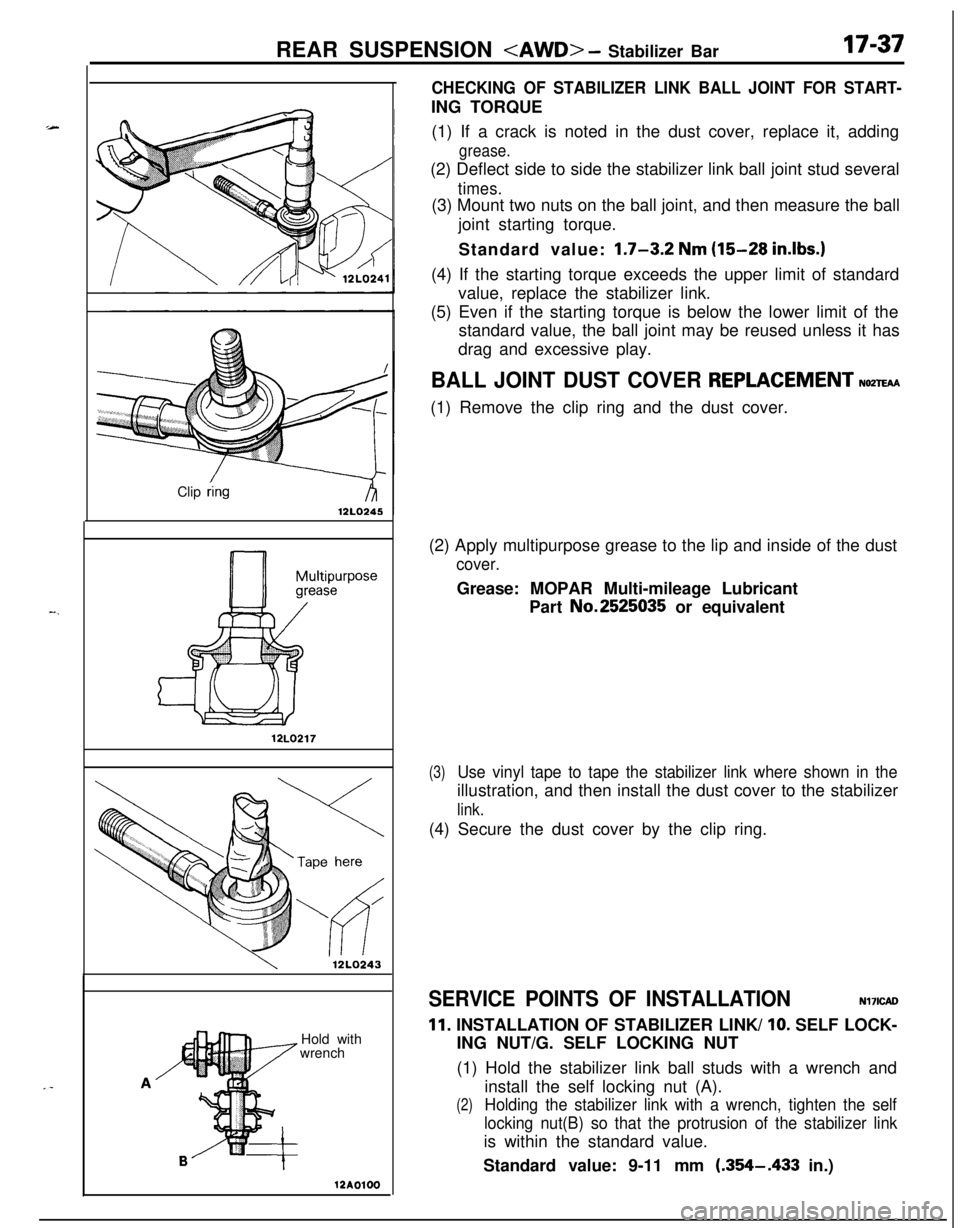

CHECKING OF STABILIZER LINK BALL JOINT FOR START-ING TORQUE

(1) If a crack is noted in the dust cover, replace it, adding

grease.(2) Deflect side to side the stabilizer link ball joint stud several

times.(3) Mount two nuts on the ball joint, and then measure the ball

joint starting torque.

Standard value:

1.7-3.2 Nm (15-28 in.lbs.)(4) If the starting torque exceeds the upper limit of standard

value, replace the stabilizer link.

(5) Even if the starting torque is below the lower limit of the

standard value, the ball joint may be reused unless it has

drag and excessive play.

BALL JOINT DUST COVER REPLACEMENTNozm(1) Remove the clip ring and the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust

cover.Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(3)Use vinyl tape to tape the stabilizer link where shown in theillustration, and then install the dust cover to the stabilizer

link.(4) Secure the dust cover by the clip ring.

SERVICE POINTS OF INSTALLATIONNl7ICAO

11. INSTALLATION OF STABILIZER LINK/ 10. SELF LOCK-

ING NUT/G. SELF LOCKING NUT

(1) Hold the stabilizer link ball studs with a wrench and

install the self locking nut (A).

(2)Holding the stabilizer link with a wrench, tighten the self

locking nut(B) so that the protrusion of the stabilizer linkis within the standard value.

Standard value: 9-11 mm

(.354-.433 in.)

Page 651 of 1216

-

STEERING - Specificdions

i’.g=s

“,.

itemsSpecifications

Oil pump pressure

MPa (psi.)

Pressure gauge valve closed7.5-8.2 (1,067-1,166)

Pressure gauge valve opened0.8-I .O (114-142)

Oil pressure switch operating pressure

MPa (psi1Oil pressure switch contacts closed (continuity)

1.5-2.0 (213-284)Oil pressure switch contacts opened (no continuity)

0.7-1.2 (100-171)Total pinion torque

Nm

(in.lbs.)0.6-I .3 (5-l 1)Tie-rod joint swing resistance

N (Ibs.18-20 (1.9-4.6)Tie-rod joint swing torque

Nm

(in.lbs. 12-5 (17-43)

LimitSteering wheel free play (when hydraulic operation)

30

(1.2)mm (in.)Variation of tie rod end ball joint shaft direction

mm

(in.) 1.5 (.059)

Oil pump pressure

Pressure gauge valve openedMPa (psi)1.5 (213)Space between vane and rotor

mm

(in.)0.06 i.0024)Shaft backlash of pump body bushing and pulley assembly

0.1

i.004)mm (in.)

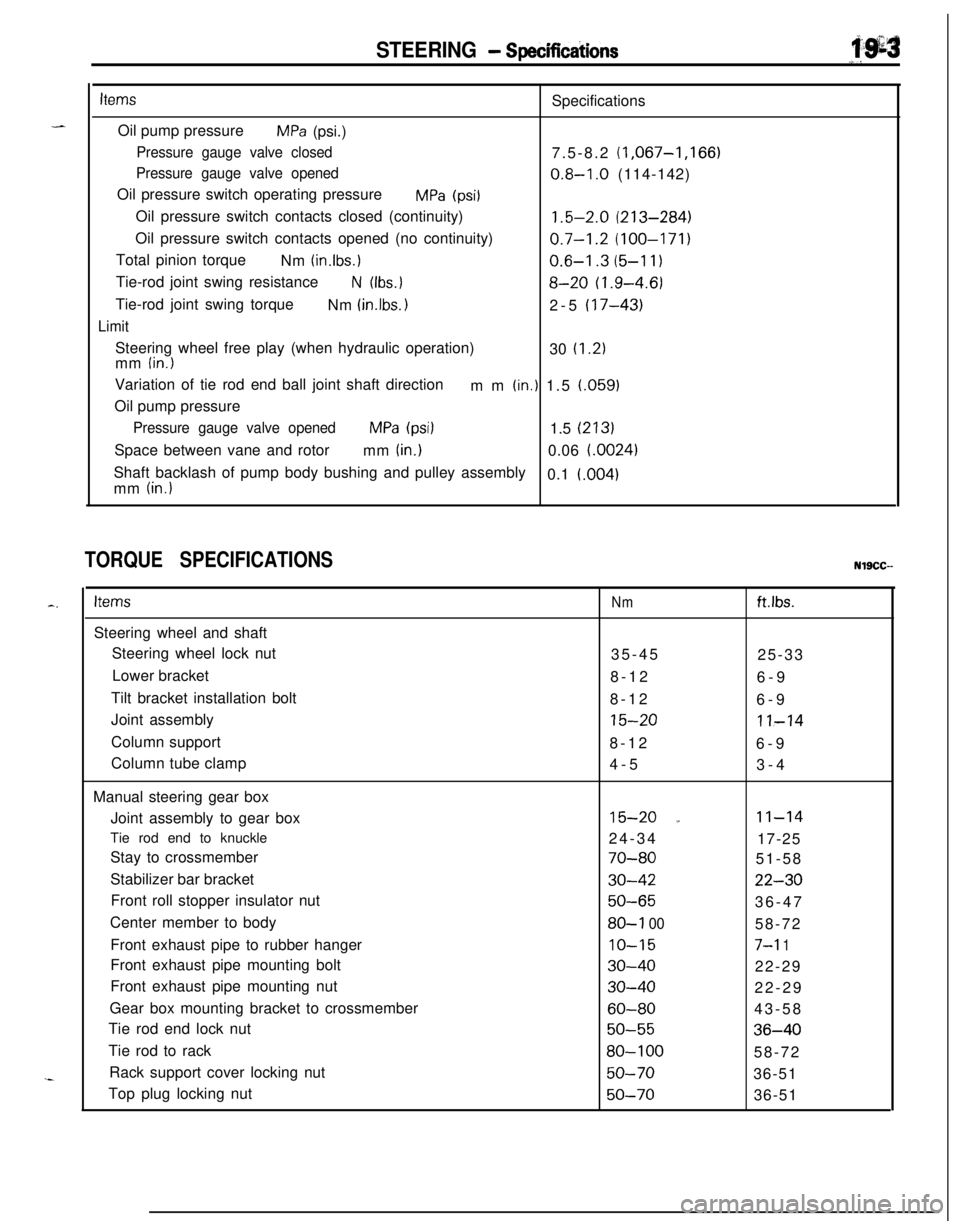

TORQUE SPECIFICATIONSNlSCC--

c.ItemsSteering wheel and shaft

Steering wheel lock nut

Lower bracket

Tilt bracket installation bolt

Joint assembly

Column support

Column tube clamp

Manual steering gear box

Joint assembly to gear box

Tie rod end to knuckle

Stay to crossmember

Stabilizer bar bracket

Front roll stopper insulator nut

Center member to body

Front exhaust pipe to rubber hanger

Front exhaust pipe mounting bolt

Front exhaust pipe mounting nut

Gear box mounting bracket to crossmember

Tie rod end lock nut

Tie rod to rack

Rack support cover locking nut

Top plug locking nutNmftlbs.35-45

25-33

8-12

6-9

8-12

6-9

15-2011-148-12

6-9

4-5

3-4

15-20 a11-1424-34

17-25

70-8051-58

30-4222-30

50-6536-47

80-l 0058-72

IO-157-l 1

30-4022-29

30-4022-29

60-8043-58

50-5536-40

80-10058-72

50-7036-51

50-7036-51

Page 652 of 1216

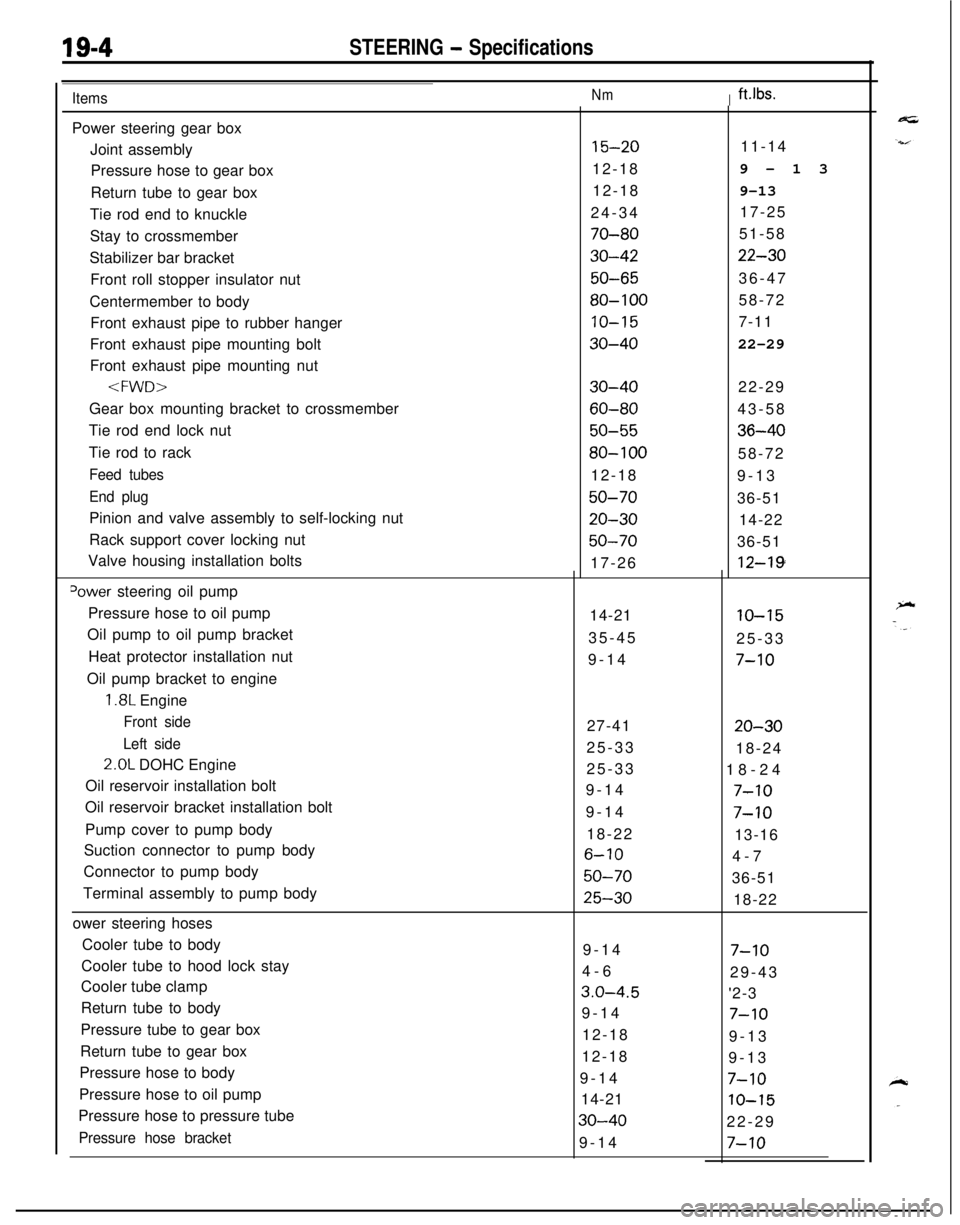

19-4STEERING - Specifications

ItemsNmIft.lbs.Power steering gear box

Joint assembly

Pressure hose to gear box

Return tube to gear box

Tie rod end to knuckle

Stay to crossmember

Stabilizer bar bracket

Front roll stopper insulator nut

Centermember to body

Front exhaust pipe to rubber hanger

Front exhaust pipe mounting bolt

Front exhaust pipe mounting nut

Tie rod end lock nut

Tie rod to rack

Feed tubes

End plugPinion and valve assembly to self-locking nut

Rack support cover locking nut

Valve housing installation bolts

Power steering oil pump

Pressure hose to oil pump

Oil pump to oil pump bracket

Heat protector installation nut

Oil pump bracket to engine

1.8L Engine

Front side

Left side2.0L DOHC Engine

Oil reservoir installation bolt

Oil reservoir bracket installation bolt

Pump cover to pump body

Suction connector to pump body

Connector to pump body

Terminal assembly to pump body

ower steering hoses

Cooler tube to body

Cooler tube to hood lock stay

Cooler tube clamp

Return tube to body

Pressure tube to gear box

Return tube to gear box

Pressure hose to body

Pressure hose to oil pump

Pressure hose to pressure tube

Pressure hose bracket11-14

9-13

9-13

17-25

51-58

22-3036-47

58-72

7-11

22-29

22-29

43-58

36-4058-72

9-13

36-51

14-22

36-51

12-19

15-2012-18

12-18

24-34

70-80

30-42

50-65

80-100

10-15

30-40

30-40

60-80

50-55

80-10012-18

50-70

20-30

50-7017-26

14-21

10-1535-45

25-33

9-14

7-1027-41

20-3025-33

18-24

25-33

18-24

9-14

7-109-14

7-1018-22

13-16

6-104-7

50-7036-51

25-3018-22

9-14

7-104-6

29-43

3.0-4.5'2-3

9-14

7-1012-18

9-13

12-18

9-13

9-14

7-1014-21

IO-15

30-4022-29

9-14

7-10

Page 657 of 1216

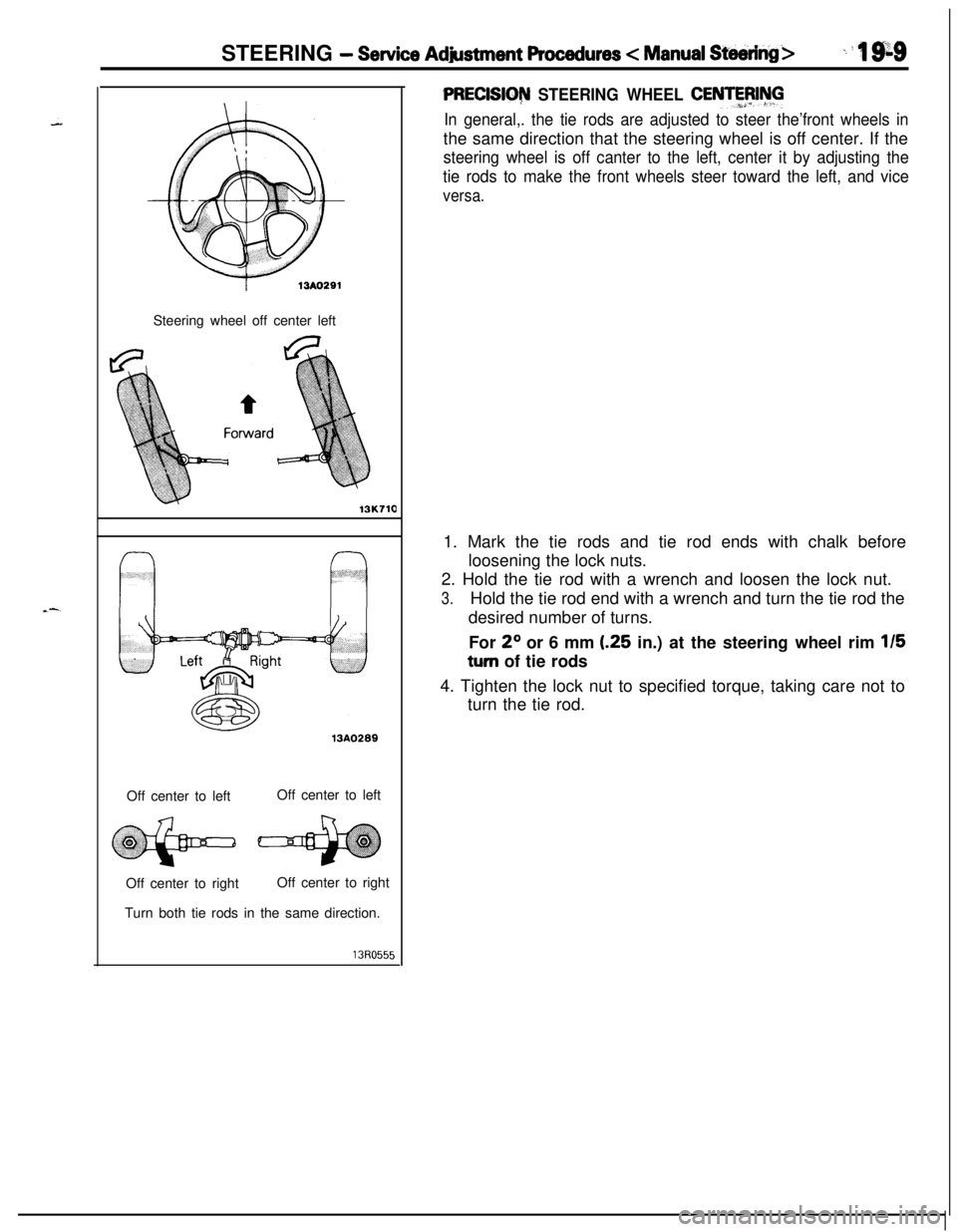

STEERING - Service Adjustment Procedures < Manual Steering>_ i ‘I 9;sSteering wheel off center left

13K71013A0289

Off center to leftOff center to left

Off center to rightOff center to right

Turn both tie rods in the same direction.

PRECISIG~ STEERING WHEEL CENTFFJIhll

In general,. the tie rods are adjusted to steer the’front wheels inthe same direction that the steering wheel is off center. If the

steering wheel is off canter to the left, center it by adjusting the

tie rods to make the front wheels steer toward the left, and vice

versa.1. Mark the tie rods and tie rod ends with chalk before

loosening the lock nuts.

2. Hold the tie rod with a wrench and loosen the lock nut.

3.Hold the tie rod end with a wrench and turn the tie rod the

desired number of turns.

For

2O or 6 mm (.25 in.) at the steering wheel rim 115

turn of tie rods

4. Tighten the lock nut to specified torque, taking care not to

turn the tie rod.

Page 664 of 1216

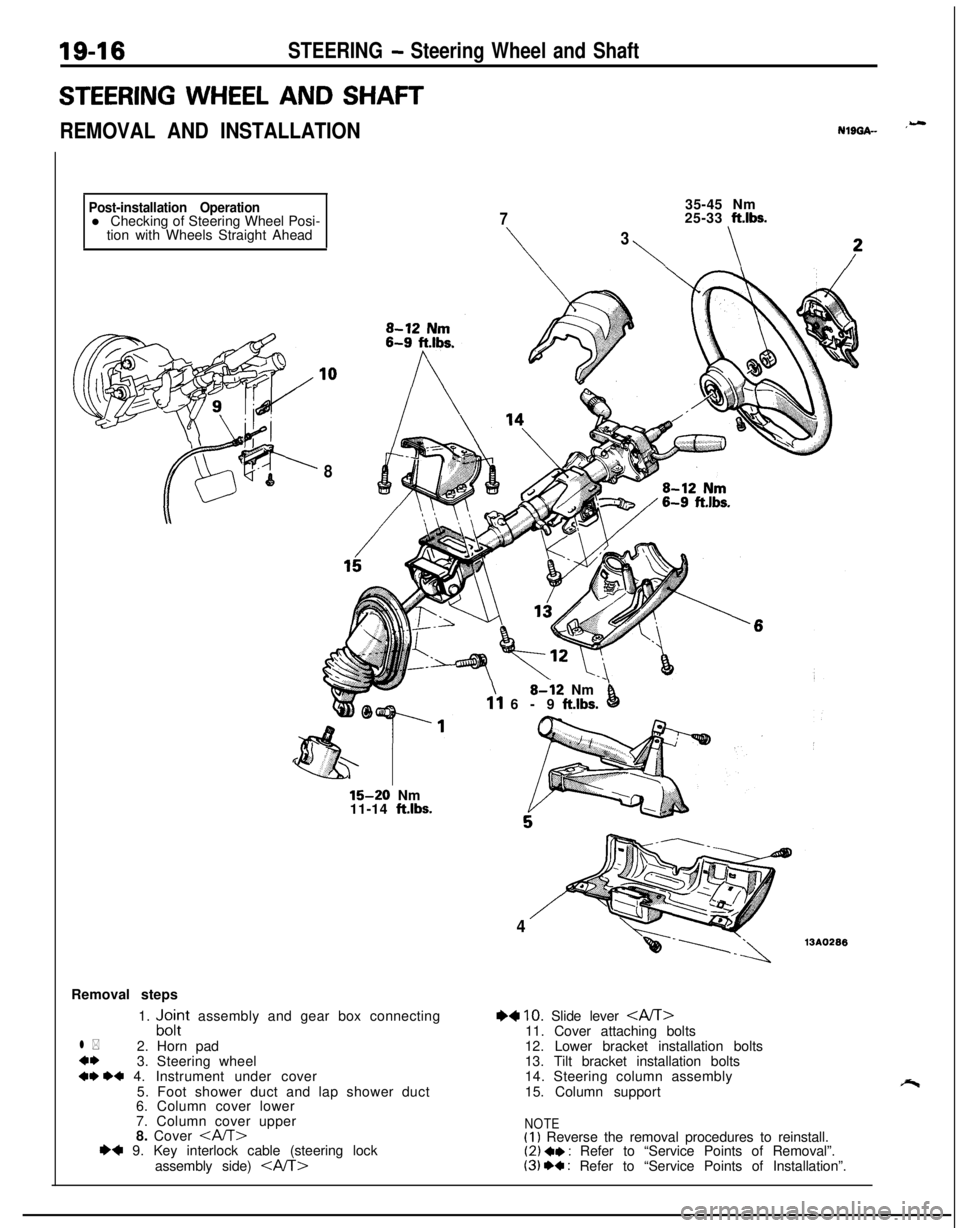

19-16STEERING - Steering Wheel and Shaft

STEERING WHEEL AND SHAFT

REMOVAL AND INSTALLATIONNlL)GA- ‘-

Post-installation Operationl Checking of Steering Wheel Posi-

tion with Wheels Straight Ahead

835-45 Nm

725-33 ft.lbs.

\

3

\\

15-20 Nm

11-14 ft.lbs.Removal steps

1.

“,c$t assembly and gear box connecting

l *2. Horn pad

4*3. Steering wheel

+* ++ 4. Instrument under cover

5. Foot shower duct and lap shower duct

6. Column cover lower

7. Column cover upper

8. Cover

assembly side)

\8-i2 Nm’11 6-9 ft.lbs.0

413AO296

+4 10. Slide lever 11. Cover attaching bolts

12. Lower bracket installation bolts

13. Tilt bracket installation bolts

14. Steering column assembly

15. Column support

NOTE(I) Reverse the removal procedures to reinstall.(2) a* : Refer to “Service Points of Removal”.(3) +a : Refer to “Service Points of Installation”.