ECU MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 91 of 1216

FRONT SUSPENSION - Stabilizer Bar2-43SERVICE POINTS OF REMOVAL

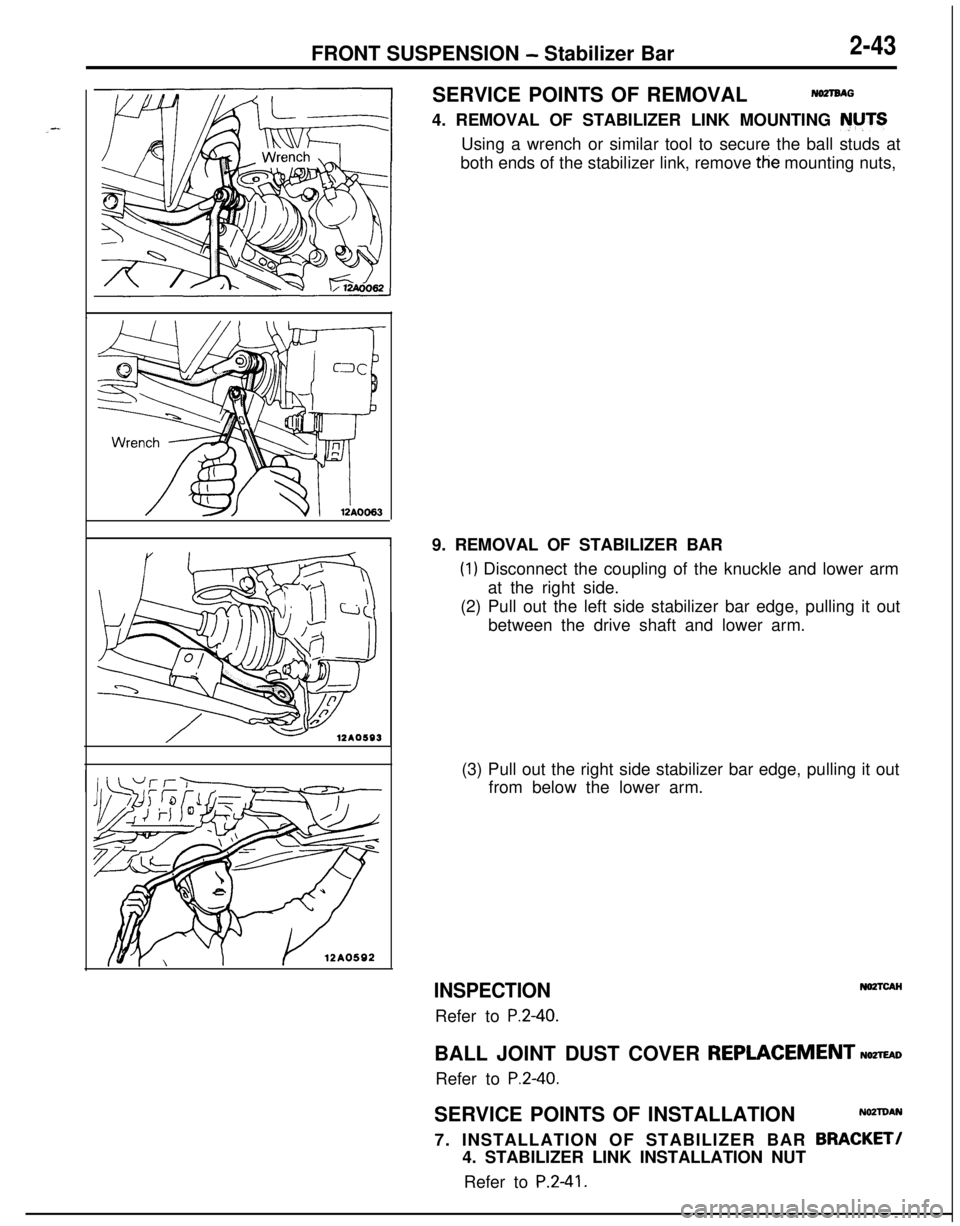

NOZlBAG4. REMOVAL OF STABILIZER LINK MOUNTING NUTS

Using a wrench or similar tool to secure the ball studs at

both ends of the stabilizer link, remove tfie mounting nuts,

19. REMOVAL OF STABILIZER BAR

(1) Disconnect the coupling of the knuckle and lower arm

at the right side.

(2) Pull out the left side stabilizer bar edge, pulling it out

between the drive shaft and lower arm.

(3) Pull out the right side stabilizer bar edge, pulling it out

from below the lower arm.

INSPECTIONRefer to

P.2-40.

NOZTCAHBALL JOINT DUST COVER

REPLACEMENTNomDRefer to

P.2-40.SERVICE POINTS OF INSTALLATION

NOZTDAN7. INSTALLATION OF STABILIZER BAR

BRACKET!4. STABILIZER LINK INSTALLATION NUT

Refer to

P.2-41.

Page 113 of 1216

12A0611

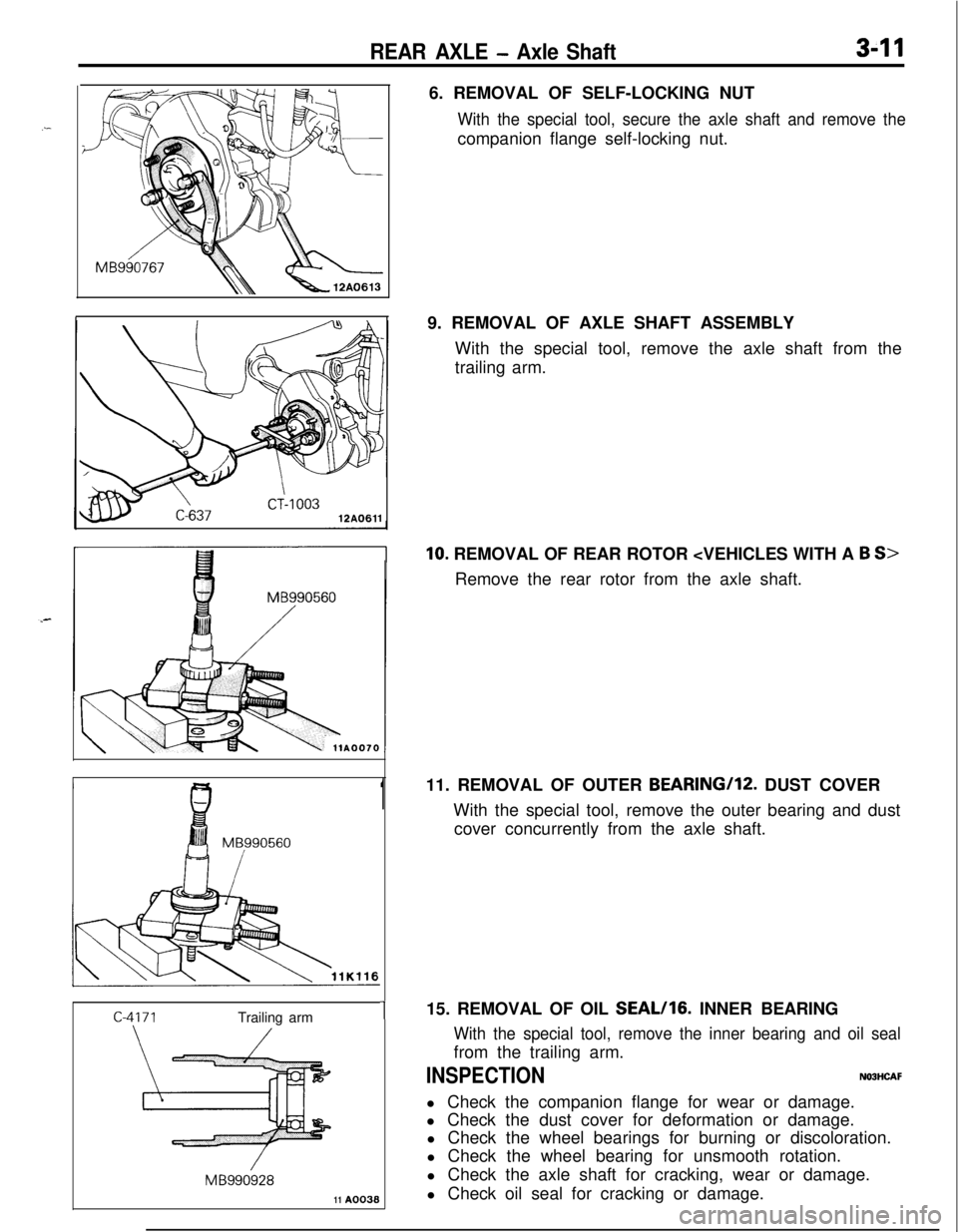

REAR AXLE - Axle Shaft3-116. REMOVAL OF SELF-LOCKING NUT

With the special tool, secure the axle shaft and remove thecompanion flange self-locking nut.

9. REMOVAL OF AXLE SHAFT ASSEMBLY

With the special tool, remove the axle shaft from the

trailing arm.

10. REMOVAL OF REAR ROTOR

111. REMOVAL OF OUTER BEARING/lZ. DUST COVER

With the special tool, remove the outer bearing and dust

cover concurrently from the axle shaft.

115. REMOVAL OF OIL SEAL/lG. INNER BEARING

MB990560

/Trailing arm

/

/MB99092811

A0038

With the special tool, remove the inner bearing and oil sealfrom the trailing arm.

INSPECTIONNOBHCAFl Check the companion flange for wear or damage.

l Check the dust cover for deformation or damage.

l Check the wheel bearings for burning or discoloration.

l Check the wheel bearing for unsmooth rotation.

l Check the axle shaft for cracking, wear or damage.

l Check oil seal for cracking or damage.

Page 115 of 1216

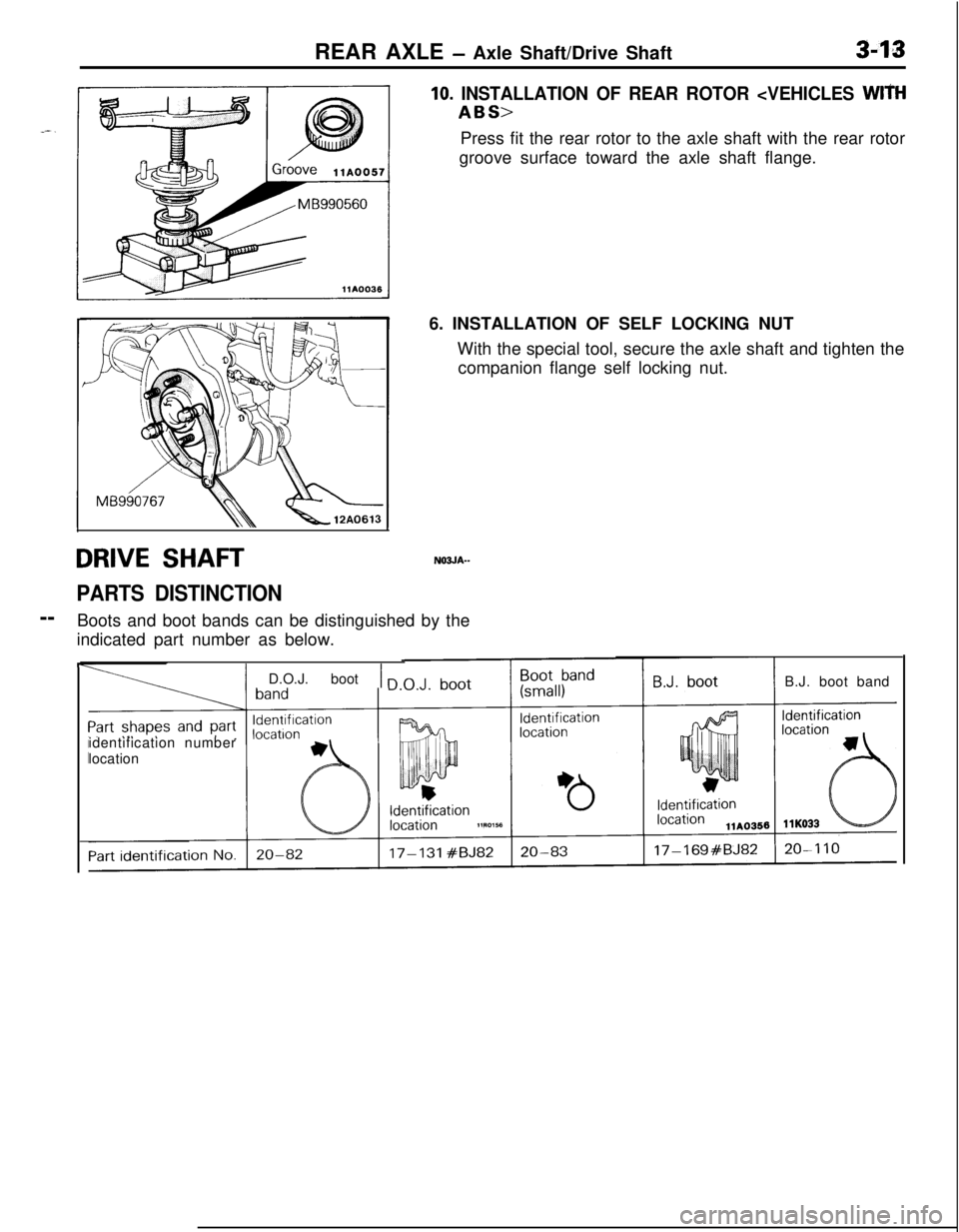

REAR AXLE - Axle Shaft/Drive Shaft3-13

DRIVE SHAFTN03JA--

PARTS DISTINCTION--

Boots and boot bands can be distinguished by the

indicated part number as below.

10. INSTALLATION OF REAR ROTOR

groove surface toward the axle shaft flange.

6. INSTALLATION OF SELF LOCKING NUT

With the special tool, secure the axle shaft and tighten the

companion flange self locking nut.

F

I

IIidentification number

location

1 D.O.J. boot 1 nB.J. boot band

Page 120 of 1216

3-18REAR AXLE - Drive Shaft

ring

\

Inner race

1180116

llE507

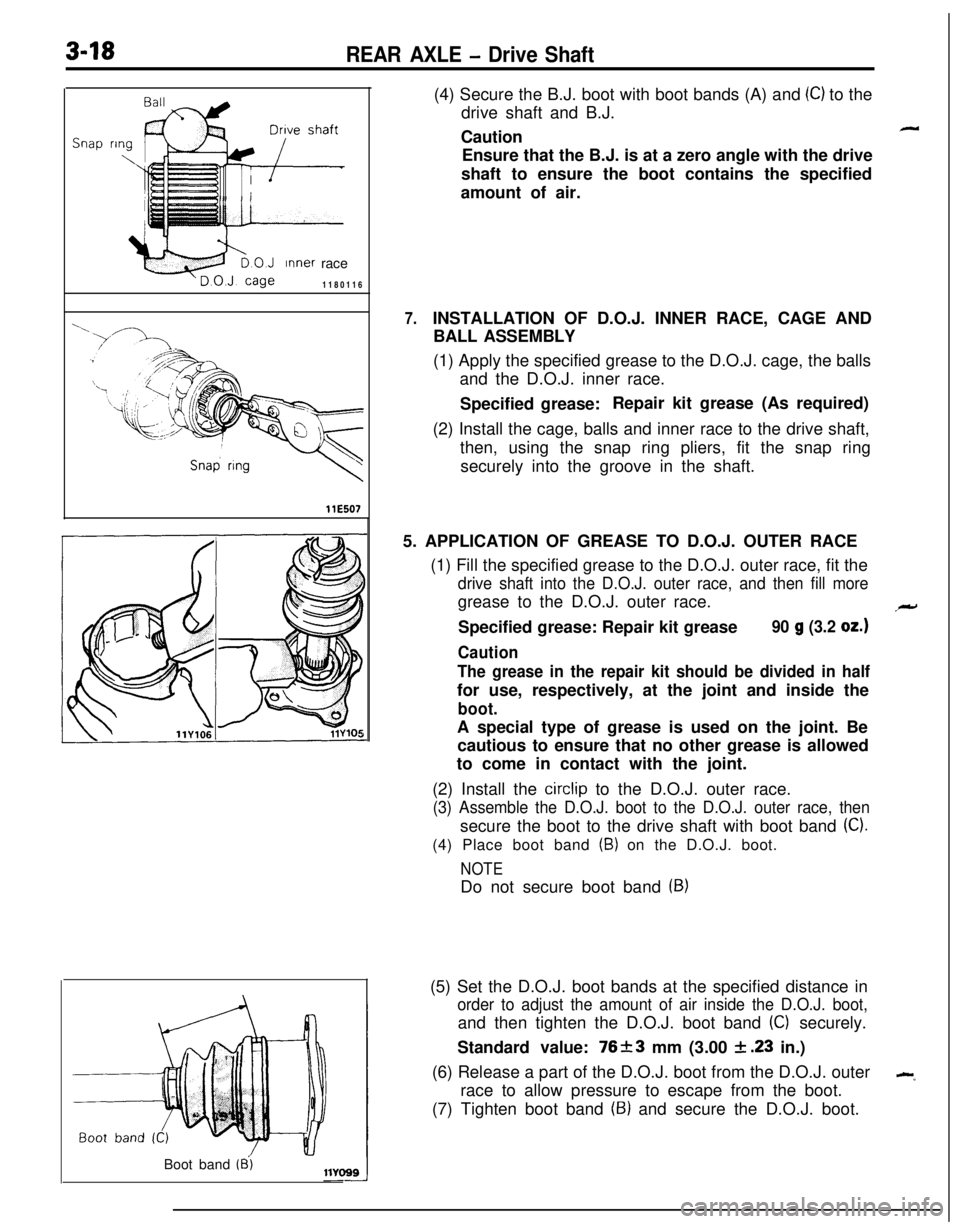

7.(4) Secure the B.J. boot with boot bands (A) and

(C) to the

drive shaft and B.J.

Caution

-Ensure that the B.J. is at a zero angle with the drive

shaft to ensure the boot contains the specified

amount of air.

INSTALLATION OF D.O.J. INNER RACE, CAGE AND

BALL ASSEMBLY

(1) Apply the specified grease to the D.O.J. cage, the balls

and the D.O.J. inner race.

Specified grease:Repair kit grease (As required)

(2) Install the cage, balls and inner race to the drive shaft,

then, using the snap ring pliers, fit the snap ring

securely into the groove in the shaft.

5. APPLICATION OF GREASE TO D.O.J. OUTER RACE

(1) Fill the specified grease to the D.O.J. outer race, fit the

drive shaft into the D.O.J. outer race, and then fill moregrease to the D.O.J. outer race.

Specified grease: Repair kit grease

90 g (3.2 oz.)

Caution

The grease in the repair kit should be divided in halffor use, respectively, at the joint and inside the

boot.A special type of grease is used on the joint. Be

cautious to ensure that no other grease is allowed

to come in contact with the joint.

(2) Install the

circlip to the D.O.J. outer race.

(3) Assemble the D.O.J. boot to the D.O.J. outer race, thensecure the boot to the drive shaft with boot band

(C).(4) Place boot band

(B) on the D.O.J. boot.

NOTEDo not secure boot band

(9)(5) Set the D.O.J. boot bands at the specified distance in

order to adjust the amount of air inside the D.O.J. boot,and then tighten the D.O.J. boot band

(C) securely.

Standard value: 76+-3 mm (3.00

& .23 in.)

(6) Release a part of the D.O.J. boot from the D.O.J. outer

--race to allow pressure to escape from the boot.

(7) Tighten boot band

(9) and secure the D.O.J. boot.

Boot band

(8’)

Page 136 of 1216

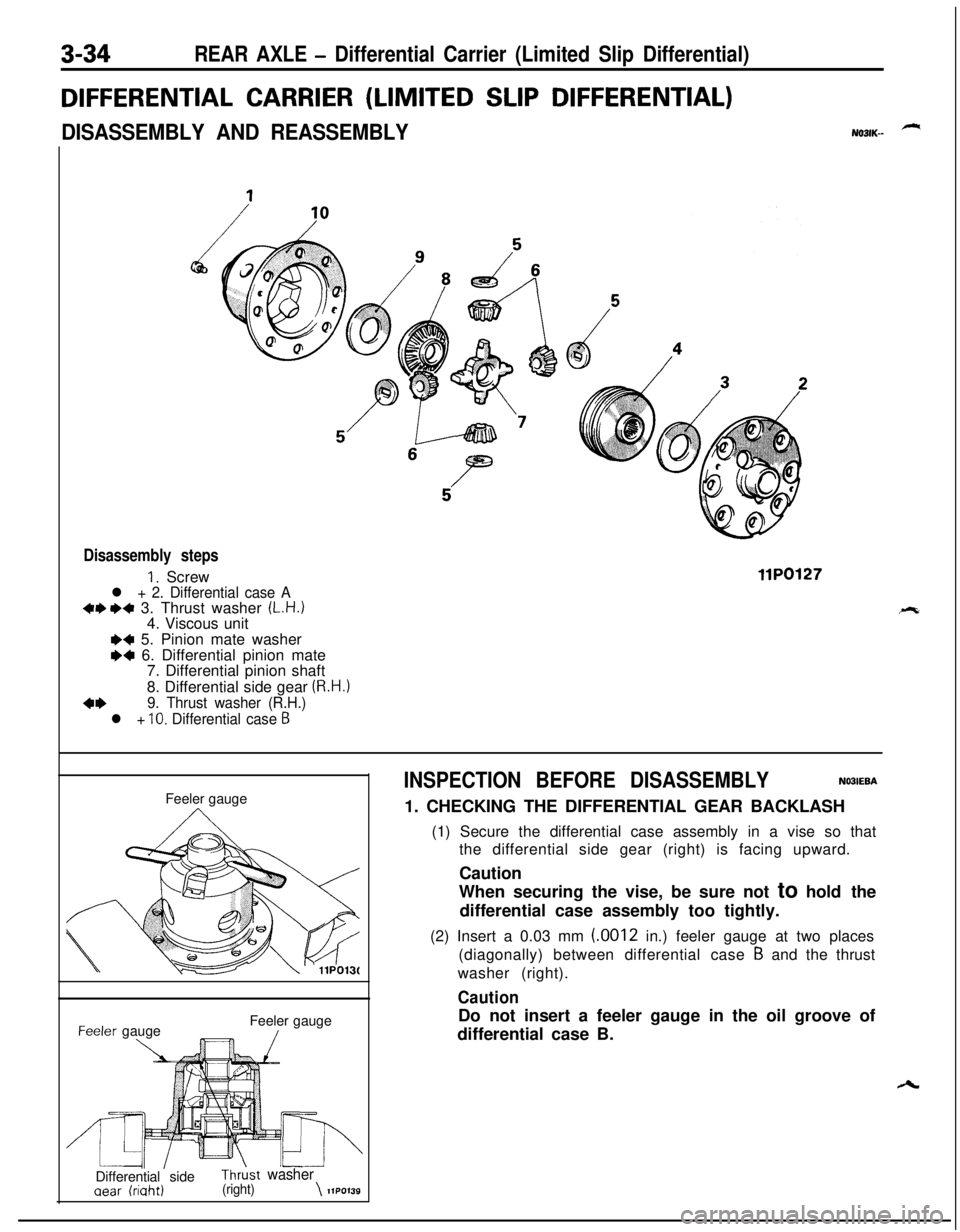

3-34REAR AXLE - Differential Carrier (Limited Slip Differential)

DIFFERENTIAL CARRIER (LIMITED SLIP DIFFERENTIAL)

DISASSEMBLY AND REASSEMBLYNO31K--

Disassembly steps

1. Screwl + 2. Differential case A+e I)+ 3. Thrust washer (L.H.)4. Viscous unit

llP0127

I)+ 5. Pinion mate washer

M 6. Differential pinion mate

7. Differential pinion shaft

8. Differential side gear

(R.H.)

4+9. Thrust washer (R.H.)

l +

10. Differential case 6Feeler gauge-eeler gauge

\Feeler gauge/

’ IL4l\’IIDifferential sideThrkt washer

aear (riaht)(right)\llPO139

INSPECTION BEFORE DISASSEMBLYNO3IEBA1. CHECKING THE DIFFERENTIAL GEAR BACKLASH

(1) Secure the differential case assembly in a vise so that

the differential side gear (right) is facing upward.

Caution

When securing the vise, be sure not to hold the

differential case assembly too tightly.

(2) Insert a 0.03 mm (.0012 in.) feeler gauge at two places

(diagonally) between differential case

B and the thrust

washer (right).

CautionDo not insert a feeler gauge in the oil groove of

differential case B.

Page 138 of 1216

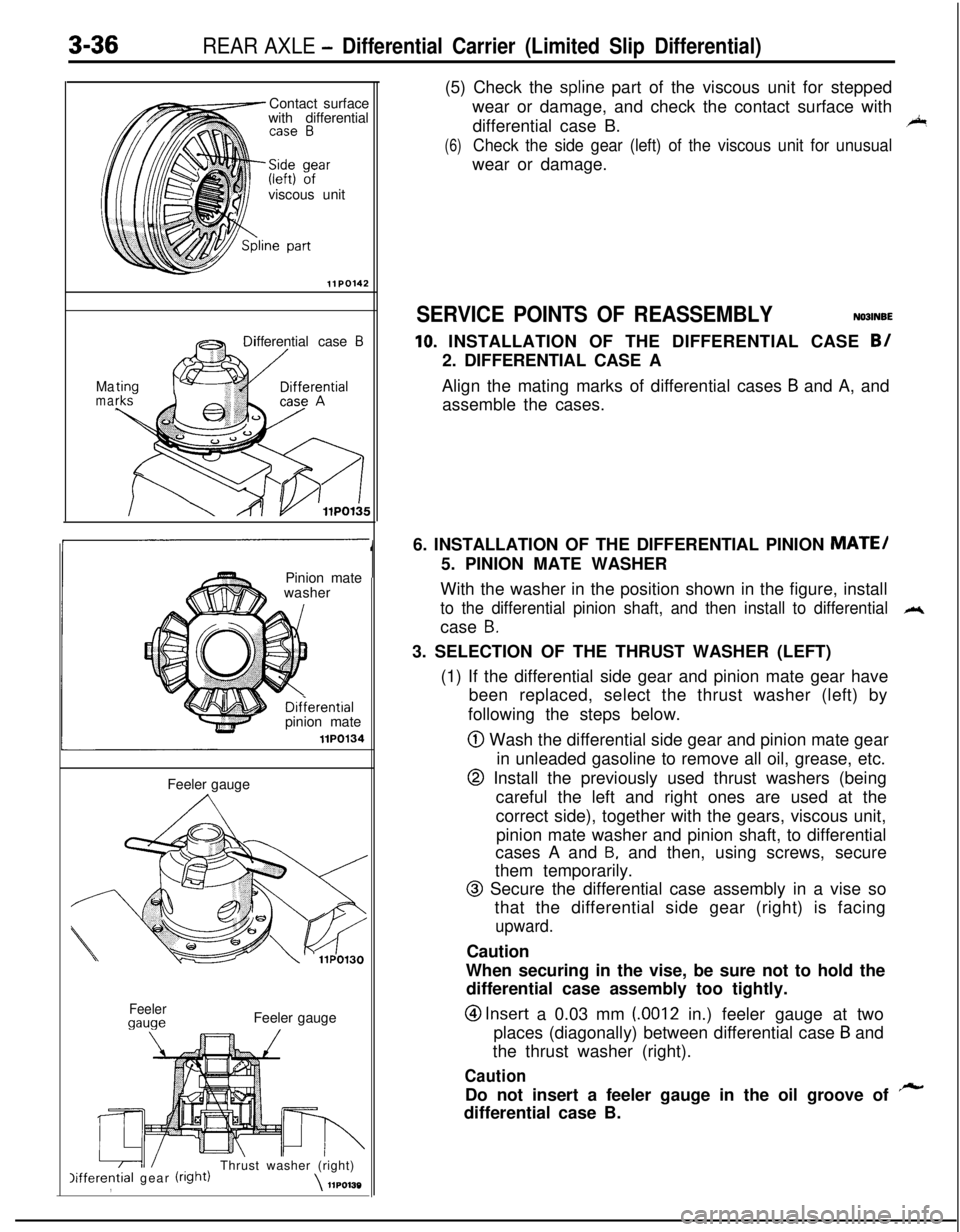

3-36REAR AXLE - Differential Carrier (Limited Slip Differential)Contact surface

with differential

viscous unit

llPO142

Mamaifferential case

BPinion mate

washer

bDifierential7-pinion matellPO134Feeler gauge

Feeler

gaugeFeeler gauge

lifferential gear (right)Thrust washer (right),\llPO130

1(5) Check the

spline part of the viscous unit for stepped

wear or damage, and check the contact surface with

differential case B.

45

(6)Check the side gear (left) of the viscous unit for unusualwear or damage.

SERVICE POINTS OF REASSEMBLYNOOINBE

10. INSTALLATION OF THE DIFFERENTIAL CASE B/2. DIFFERENTIAL CASE A

Align the mating marks of differential cases

B and A, and

assemble the cases.

6. INSTALLATION OF THE DIFFERENTIAL PINION

MATE/5. PINION MATE WASHER

With the washer in the position shown in the figure, install

to the differential pinion shaft, and then install to differentialM.case

B.3. SELECTION OF THE THRUST WASHER (LEFT)

(1) If the differential side gear and pinion mate gear have

been replaced, select the thrust washer (left) by

following the steps below.

@ Wash the differential side gear and pinion mate gear

in unleaded gasoline to remove all oil, grease, etc.

@ Install the previously used thrust washers (being

careful the left and right ones are used at the

correct side), together with the gears, viscous unit,

pinion mate washer and pinion shaft, to differential

cases A and

B, and then, using screws, secure

them temporarily.

@ Secure the differential case assembly in a vise so

that the differential side gear (right) is facing

upward.Caution

When securing in the vise, be sure not to hold the

differential case assembly too tightly.

@I Insert a 0.03 mm LOO12 in.) feeler gauge at two

places (diagonally) between differential case

B and

the thrust washer (right).

CautionDo not insert a feeler gauge in the oil groove of

rsrdifferential case B.

Page 149 of 1216

BRAKES - Anti-lock Braking System Troubleshooting5-9

ANTI-LOCK BRAKING SYSTEM

-- TROUBLESHOOTINGNO!JEBAE

PARTICULAR CHARACTERISTICS OF

THE ANTI-LOCK BRAKING SYSTEMModels equipped with the anti-lock braking system

(A.B.S.) may exhibit one or more of the following

characteristics from time to time, but none of these

is abnormal.

(1) A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.Actually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.(2) When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), a

whining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place, but this noise is simply the result

of a self-check being made of the anti-lock

braking system operation.

TROUBLESHOOTING METHODSProblems related to the anti-lock braking system

(A.B.S.) can be classified into two general categor-

ies: problems in the electrical system and those in

the hydraulic system.For problems in the electrical system, the

self-diagnosis function is built into the electronic control

unit (E.C.U.) causing the A.B.S. warning light to

illuminate as a warning to the driver.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check todetermine whether the problem is related to ordin-

ary brake components or to the components relatedto the A.B.S.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART(1) Using the flow chart, check the ABS warning

light light-up sequence and check the condition

of braking operation.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Explana-tion] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTEECU: Electronic control unit

HU: Hydraulic unit

MUT: Multi-use tester

Page 150 of 1216

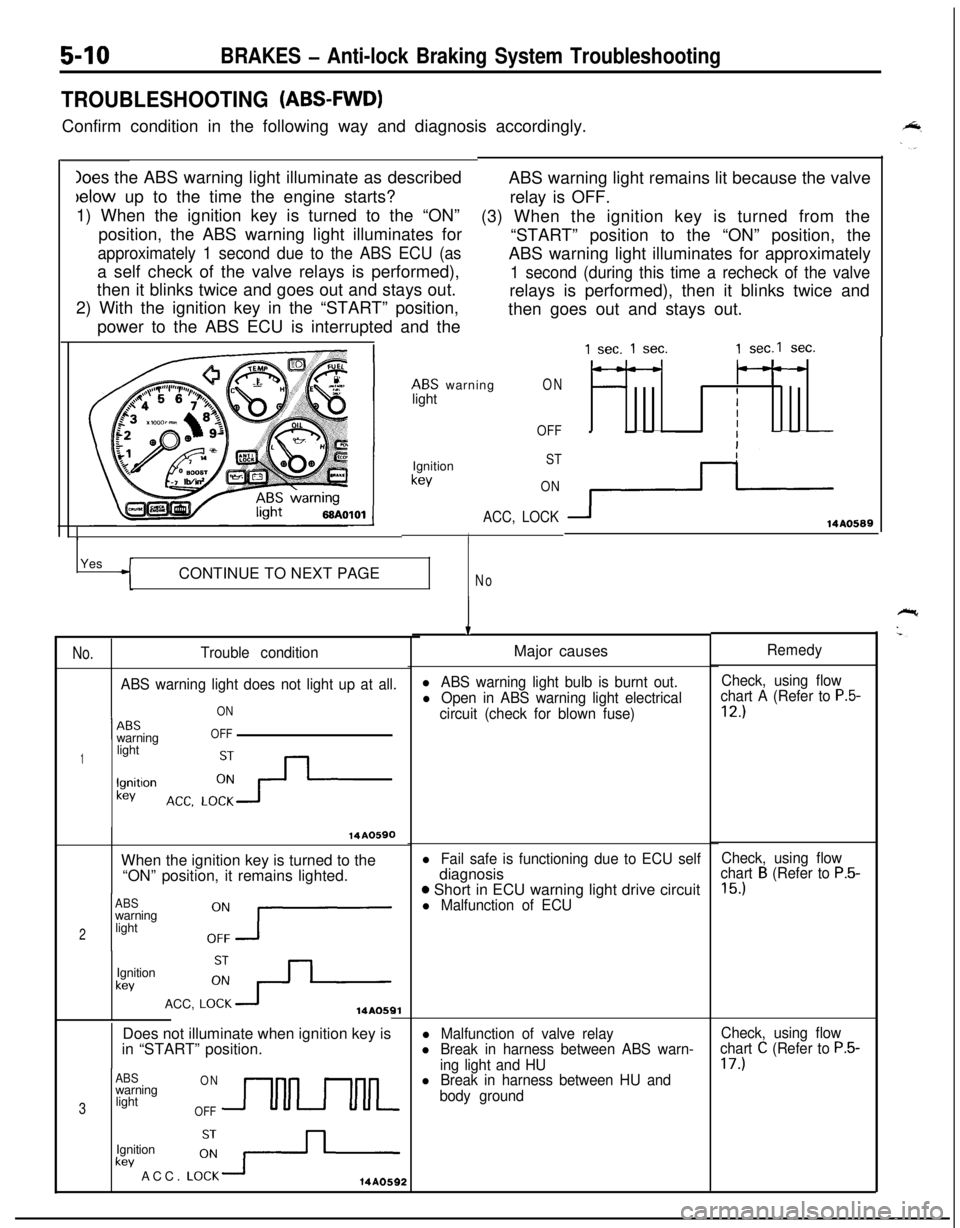

Ioes the ABS warning light illuminate as describedbelow up to the time the engine starts?

1) When the ignition key is turned to the “ON”

position, the ABS warning light illuminates for

approximately 1 second due to the ABS ECU (asa self check of the valve relays is performed),

then it blinks twice and goes out and stays out.

2) With the ignition key in the “START” position,

power to the ABS ECU is interrupted and the

5-10BRAKES - Anti-lock Braking System Troubleshooting

TROUBLESHOOTING (ABS-FWD)Confirm condition in the following way and diagnosis accordingly.

ABS warning light remains lit because the valve

relay is OFF.

(3) When the ignition key is turned from the

“START” position to the “ON” position, the

ABS warning light illuminates for approximately

1 second (during this time a recheck of the valverelays is performed), then it blinks twice and

then goes out and stays out.

ABS warning

lightON

OFF

1Ignition

kev

ST

ON

ACC, LOCK

IYes

CONTINUE TO NEXT PAGE

No

No.Trouble condition

ABS warning light does not light up at all.

ON

1 --ABSwarningOFF

1lightlgnitlon

kev

14A0590When the ignition key is turned to the

“ON” position, it remains lighted.

ABSwarning

2light

Ignition

kevACC,

LO:+14AOSQlDoes not illuminate when ignition key is

in “START” position.

ABSONwarning

3lightOFFUULkev ACC.

LO:-+-Ignition14A0592

1 sec. 1 sec.1 sec.1 sec.

---

IIII

3114AO589

IMajor causes

l ABS warning light bulb is burnt out.Check, using flow

l Open in ABS warning light electricalchart A (Refer to P.5-

circuit (check for blown fuse)12.)

l Fail safe is functioning due to ECU selfdiagnosis

o Short in ECU warning light drive circuitl Malfunction of ECU

l Malfunction of valve relayl Break in harness between ABS warn-

ing light and HU

l Break in harness between HU and

body groundRemedy

Check, using flow

chart

B (Refer to P.5-

15.)

Check, using flow

chart C (Refer to P.5-17.)

Page 151 of 1216

BRAKES - Anti-lock Braking System Troubleshooting5-14

./

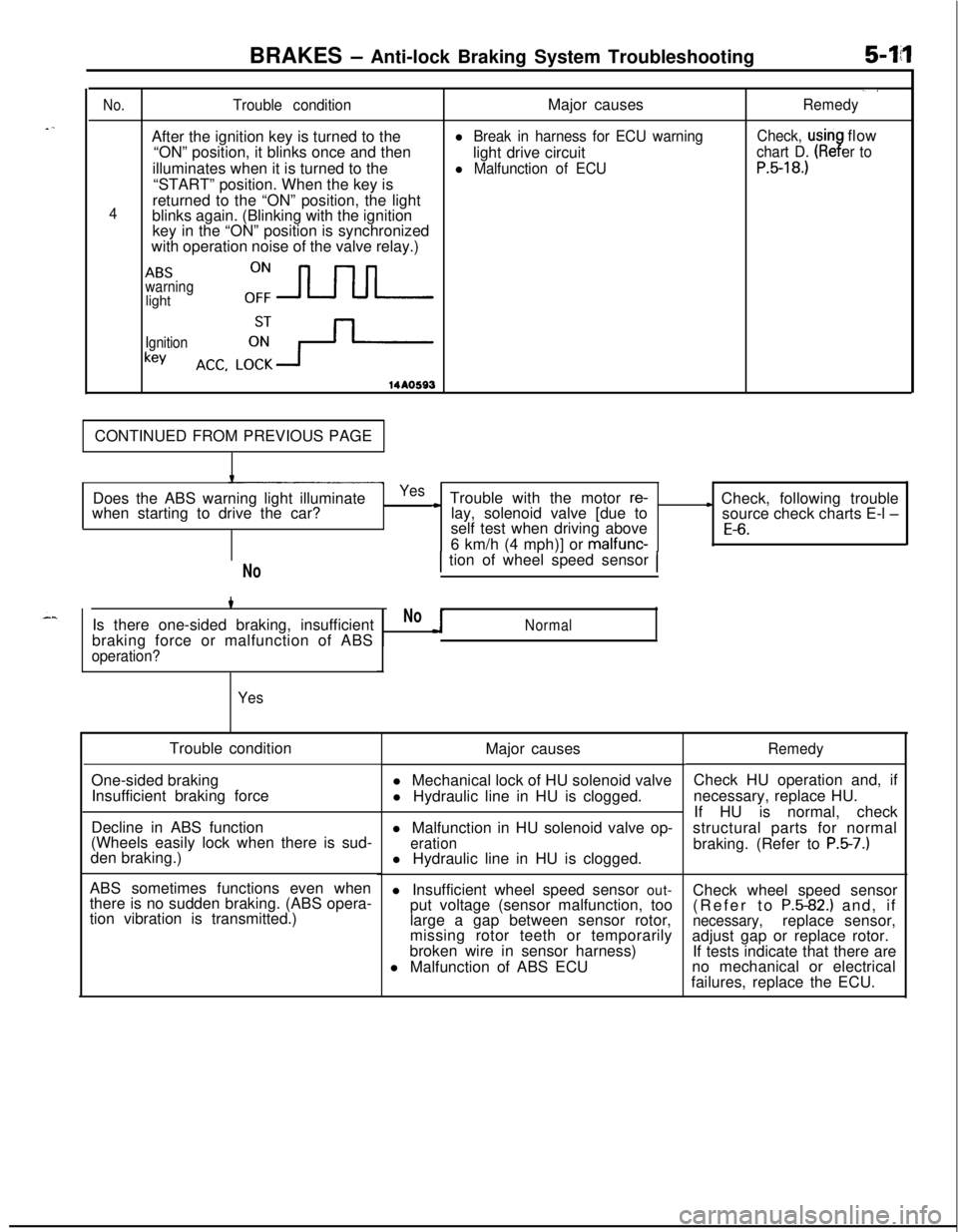

No.Trouble conditionMajor causesRemedyAfter the ignition key is turned to the

l Break in harness for ECU warningCheck, usinflow

“ON” position, it blinks once and then

light drive circuit

chart D. (Re er to9illuminates when it is turned to the

l Malfunction of ECUP.5-18.)“START” position. When the key is

4returned to the “ON” position, the light

blinks again. (Blinking with the ignition

key in the “ON” position is synchronized

with operation noise of the valve relay.)

ABSwarninglighto:-

Ignition

keyACC. LCi+-

14*0593CONTINUED FROM PREVIOUS PAGE

Does the ABS warning light illuminate

when starting to drive the car?

Yes~ Trouble with the motor re-lay, solenoid valve [due toL Check, following trouble

source check charts E-l -self test when driving above

E-6.6 km/h (4 mph)] or malfunc-

NoIs there one-sided braking, insufficient

braking force or malfunction of ABS

operation?

YesTrouble condition

Major causes

One-sided braking

Insufficient braking forcel Mechanical lock of HU solenoid valve

l Hydraulic line in HU is clogged.

Decline in ABS function

(Wheels easily lock when there is sud-

den braking.)

ABS sometimes functions even when

there is no sudden braking. (ABS opera-

tion vibration is transmitted.)

1 tion of wheel speed sensor 1

NoNormall Malfunction in HU solenoid valve op-

erationl Hydraulic line in HU is clogged.

l Insufficient wheel speed sensor out-

put voltage (sensor malfunction, too

large a gap between sensor rotor,

missing rotor teeth or temporarily

broken wire in sensor harness)

l Malfunction of ABS ECU

RemedyCheck HU operation and, if

necessary, replace HU.

If HU is normal, check

structural parts for normal

braking. (Refer to

P.5-7.)Check wheel speed sensor

(Refer to

P.5-82.) and, ifnecessary,replace sensor,

adjust gap or replace rotor.

If tests indicate that there are

no mechanical or electrical

failures, replace the ECU.

Page 152 of 1216

possibility that there is trouble with ABS warning

light or with power to the light.probably blown.

MAIN FUSIBLE

LINK @

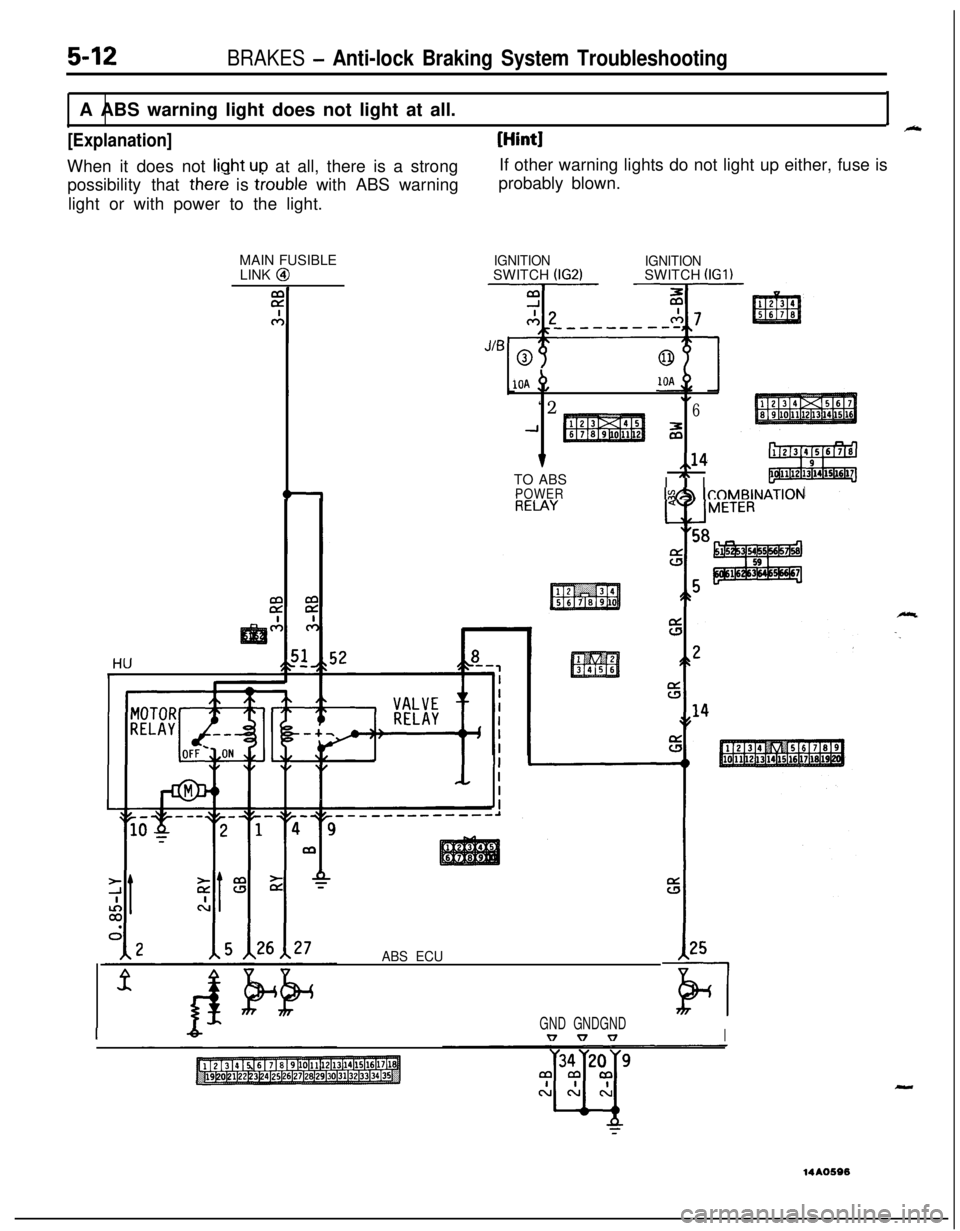

5-12BRAKES - Anti-lock Braking System TroubleshootingA ABS warning light does not light at all.

I_

[Explanation][Hint]When it does not

liuht ULI at all, there is a strongIf other warning lights do not light up either, fuse is

IGNITIONSWITCH (IG2)IGNITIONSWITCH (IGl)

10A +,

“2.I6

-1z

v,,14TO ABS

I

” IPOWERIs&h ICOMBINAT~~N

ABS ECU

IGND GNDGNDv v vI

-14AO596