lock MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1005 of 1216

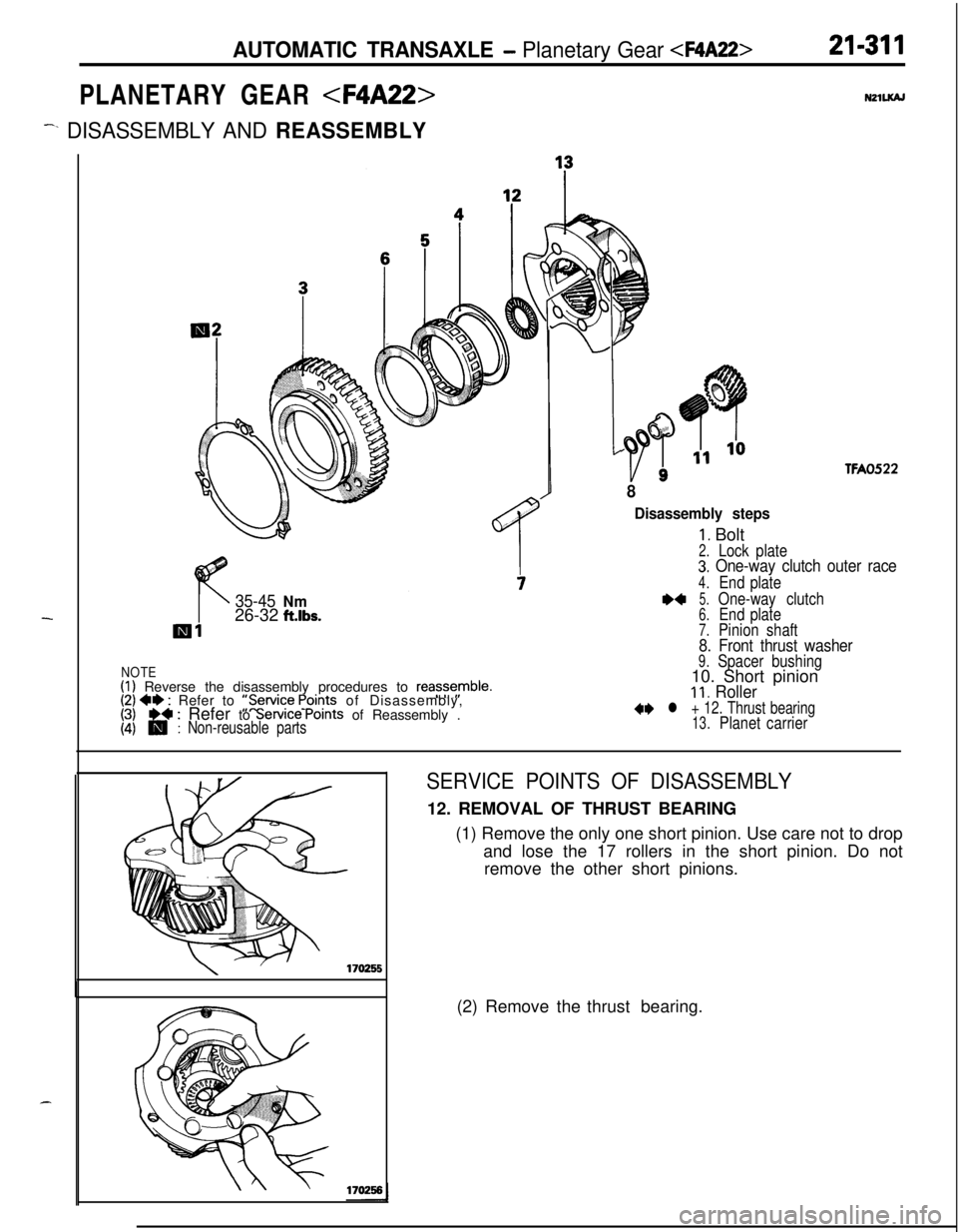

AUTOMATIC TRANSAXLE - Planetary Gear

PLANETARY GEAR

-. DISASSEMBLY AND REASSEMBLY

35-45 Nm26-32 ft.lbs.

NOTE(I) Reverse the disassembly procedures to reass$mble.(2) *I) : Refer to ::Servjce Points of Disassembly,Ii/+ : Refer to Service Points of Reassembly .b: Non-reusable parts

NZlLKAJ

,. /.

ep4”

I9

TFAOS22

8

Disassembly stepsI. Bolt

2.Lock plate3. One-way clutch outer race

4.End plate

1)45.One-way clutch6.End plate7.Pinion shaft8. Front thrust washer9.Spacer bushing10. Short pinion

Il. Roller+e

l + 12. Thrust bearing13.Planet carrier

i

SERVICE POINTS OF DISASSEMBLY12. REMOVAL OF THRUST BEARING

(1) Remove the only one short pinion. Use care not to drop

and lose the 17 rollers in the short pinion. Do not

remove the other short pinions.

(2) Remove the thrust bearing.

Page 1013 of 1216

AUTOMATIC TRANSAXLE - Differential

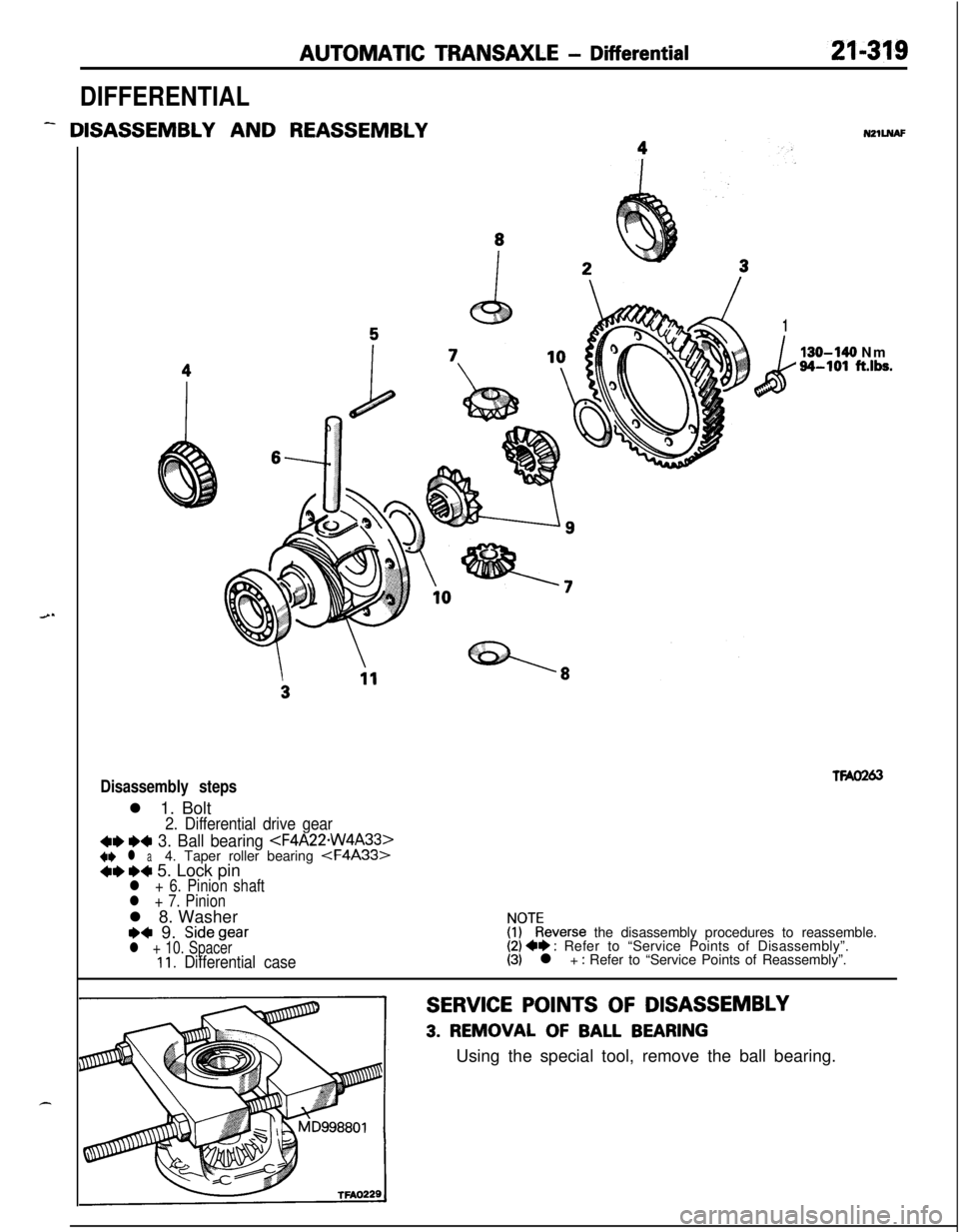

DIFFERENTIAL

- DISASSEMBLY AND REASSEMBLYNZlLNAF

1

k

130-140 Nm34-101 ft.lbs.

TWO263Disassembly stepsl 1. Bolt

2. Differential drive gear

4e e4 3. Ball bearing

l + 7. Pinionl 8. Washer

e+ 9. Sidegearl + 10. SpacerIl. Differential case

$?everse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.

SERVICE POINTS OF DISASSEMBLY

3. REMOVAL OF BALL BEARINGUsing the special tool, remove the ball bearing.

Page 1014 of 1216

21-320AUTOMATIC TRANSAXLE - Differential

TFA0231

Pinion, shaftPinion gear/

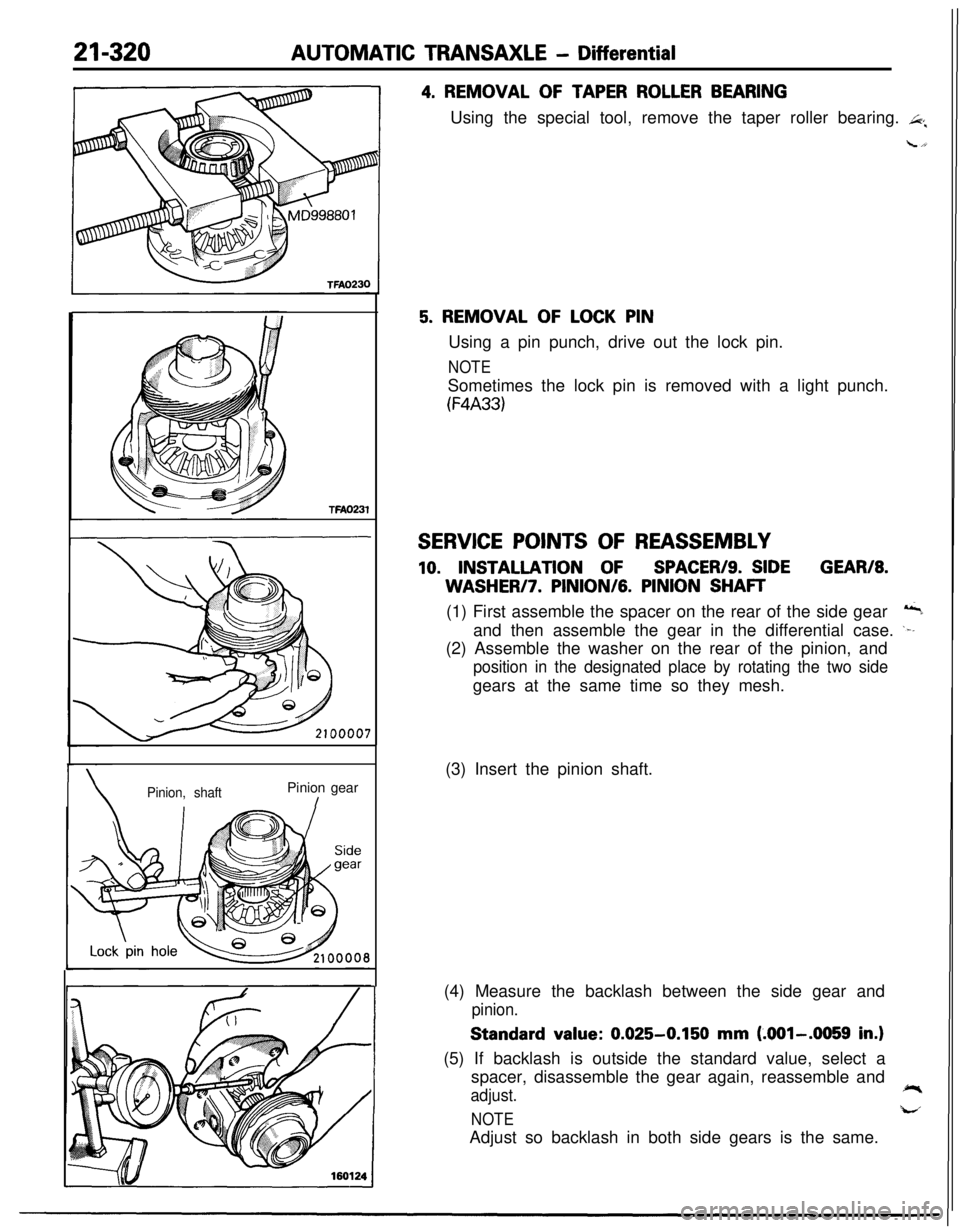

4. REMOVAL OF TAPER ROLLER BEARINGUsing the special tool, remove the taper roller bearing.

L+

5. REMOVAL OF LOCK PINUsing a pin punch, drive out the lock pin.

NOTESometimes the lock pin is removed with a light punch.

(F4A33)

SERVICE POINTS OF REASSEMBLY

10. INSTALLATION OFSPACER/S. SIDEGEAR/8.WASHERI7.

PINION/G. PINION SHAFT(1) First assemble the spacer on the rear of the side gear

&aand then assemble the gear in the differential case.

.--(2) Assemble the washer on the rear of the pinion, and

position in the designated place by rotating the two sidegears at the same time so they mesh.

(3) Insert the pinion shaft.

(4) Measure the backlash between the side gear and

pinion.Standard value:

0.025-0.150 mm (.OOl-.0059 in.)(5) If backlash is outside the standard value, select a

spacer, disassemble the gear again, reassemble and

adjust.

NOTELd

Adjust so backlash in both side gears is the same.

Page 1015 of 1216

AUTOMATIC TRANSAXLE - Differential21-321

. MD99881 2

MD998822

TFY0040

I166630

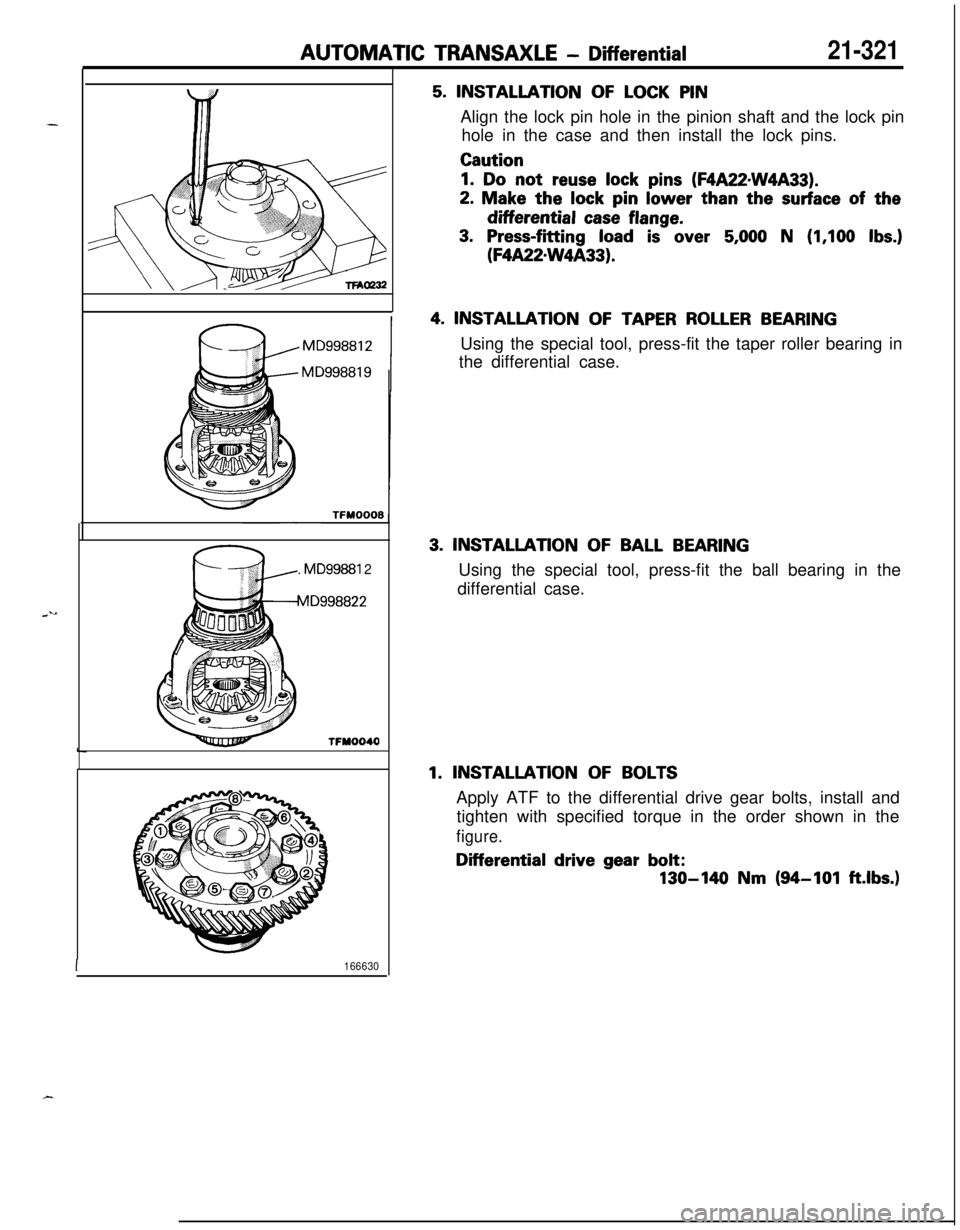

5. INSTALLATION OF LOCK PINAlign the lock pin hole in the pinion shaft and the lock pin

hole in the case and then install the lock pins.Caution

1. Do not reuse lock pins (F4A22wW4A33).

2. Make the lock pin lower than the surface of thedifferential

case flange.

3. Press-fitting load is over 5,000 N (1,100 Ibs.)

(F4A22sW4A33).

4. INSTALLATION OF TAPER ROLLER BEARINGUsing the special tool, press-fit the taper roller bearing in

the differential case.

3. INSTALLATION OF BALL BEARINGUsing the special tool, press-fit the ball bearing in the

differential case.

1. INSTALLATION OF BOLTSApply ATF to the differential drive gear bolts, install and

tighten with specified torque in the order shown in the

figure.Differential drive gear bolt:

130-140 Nm (94-101 ft.lbs.)

r

Page 1016 of 1216

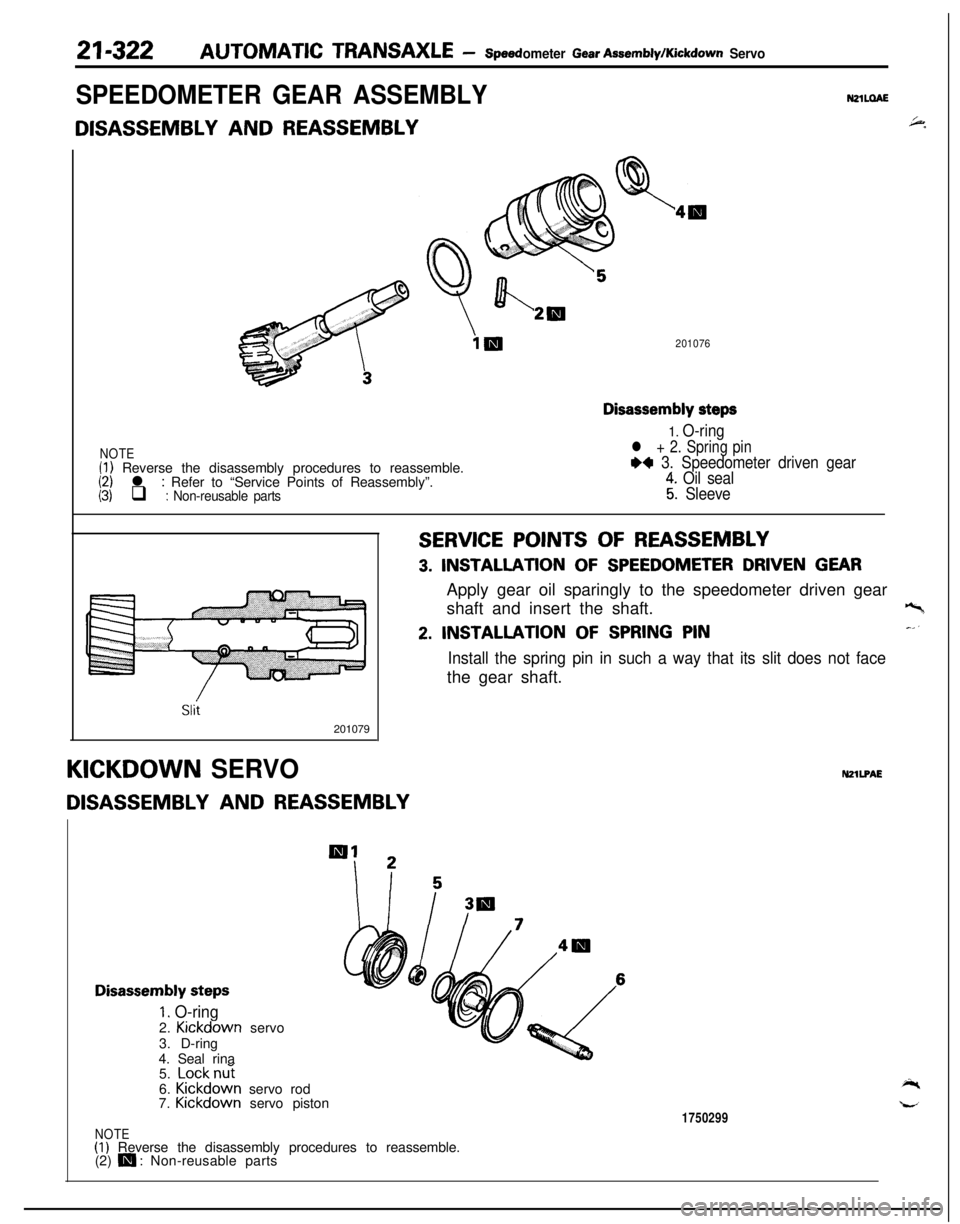

21-322AUTOMATIC TRANSAXLE - speedometer Gear AssemMylKickdown Servo

SPEEDOMETER GEAR ASSEMBLY

DISASSEMBLY AND REASSEMBLYNzlLaA6+.

201076

NOTE(1) Reverse the disassembly procedures to reassemble.(2) l : Refer to “Service Points of Reassembly”.(3) q : Non-reusable parts

Disassembly steps

1. O-ring

l + 2. Spring pin

H 3. Speedometer driven gear

4. Oil seal

5. Sleeve

SERVICE POINTS OF REASSEMBLY

3. INSTALLATION OF SPEEDOMETER DRIVEN GEARApply gear oil sparingly to the speedometer driven gear

shaft and insert the shaft.“c,

2. INSTALLATION OF SPRING PINL_,

Install the spring pin in such a way that its slit does not facethe gear shaft.

Slit201079

KICKDOWN SERVONZlLPAE

DISASSEMBLY AND REASSEMBLY

Disassembly steps

I. O-ring2. Kickdown servo

3. D-ring

4. Seal rina

65.

Locknuj6. Kickdown servo rod

7. Kickdown servo piston1750299

NOTE(1) Reverse the disassembly procedures to reassemble.

(2) m : Non-reusable parts

Page 1018 of 1216

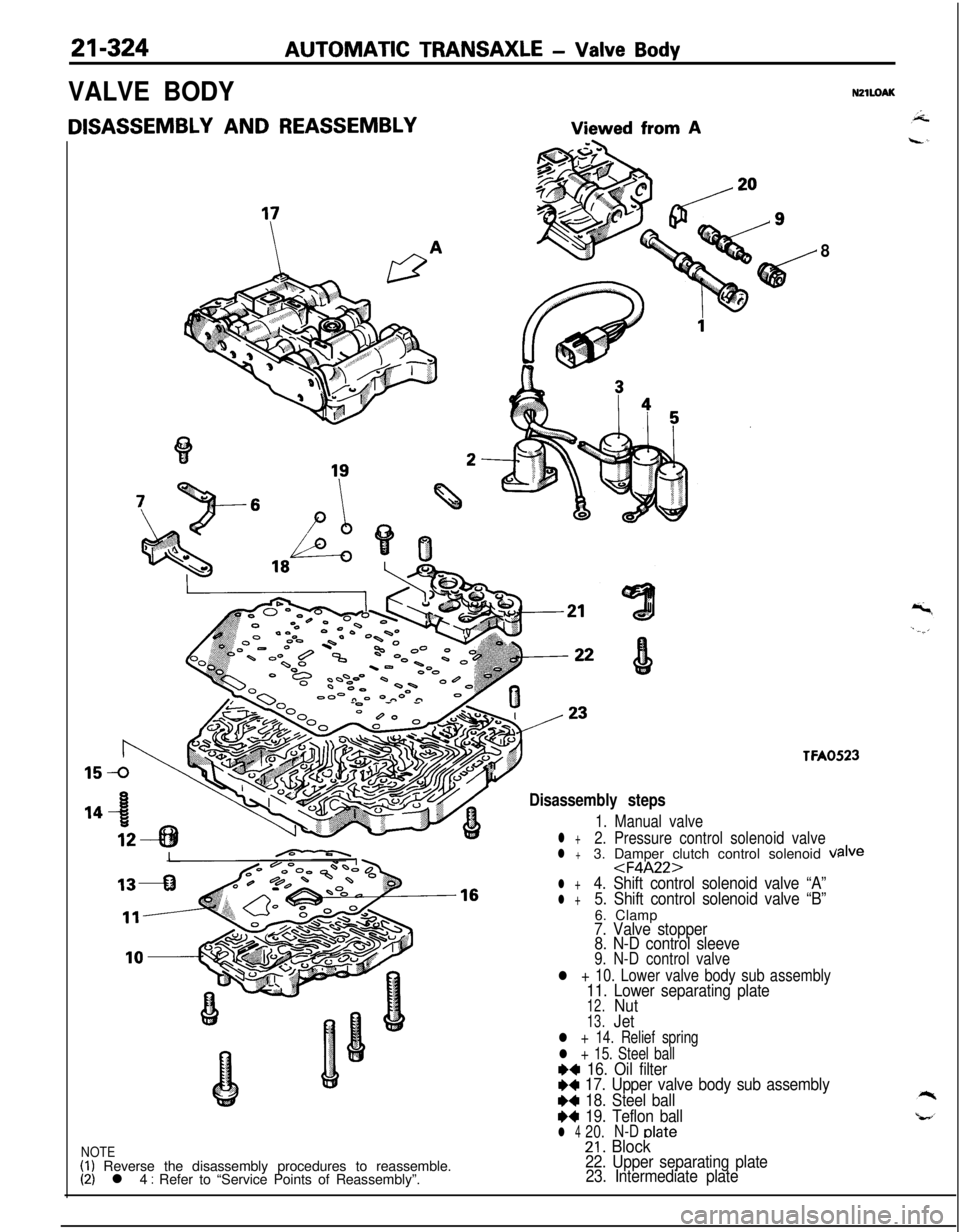

21-324AUTOMATIC TRANSAXLE - Valve Body

VALVE BODY

DISASSEMBLY AND REASSEMBLYViewed from A

NZlLOAK

-0 - -

8

TFA0523

Disassembly steps

1. Manual valve

l +2. Pressure control solenoid valvel +3. Damper clutch control solenoid v

l +5. Shift control solenoid valve “B”6. Clamp

7. Valve stopper

8. N-D control sleeve

9. N-D control valve

l + 10. Lower valve body sub assembly11. Lower separating plate12.Nut13.Jet

l + 14. Relief spring

l + 15. Steel ballH 16. Oil filterW 17. Upper valve body sub assemblyWI

18. Steel ball

H 19. Teflon balll 420.N-Delate

NOTE(1) Reverse the disassembly procedures to reassemble.(2) l 4 : Refer to “Service Points of Reassembly”.

21. Block22. Upper separating plate

23. Intermediate plate

Page 1032 of 1216

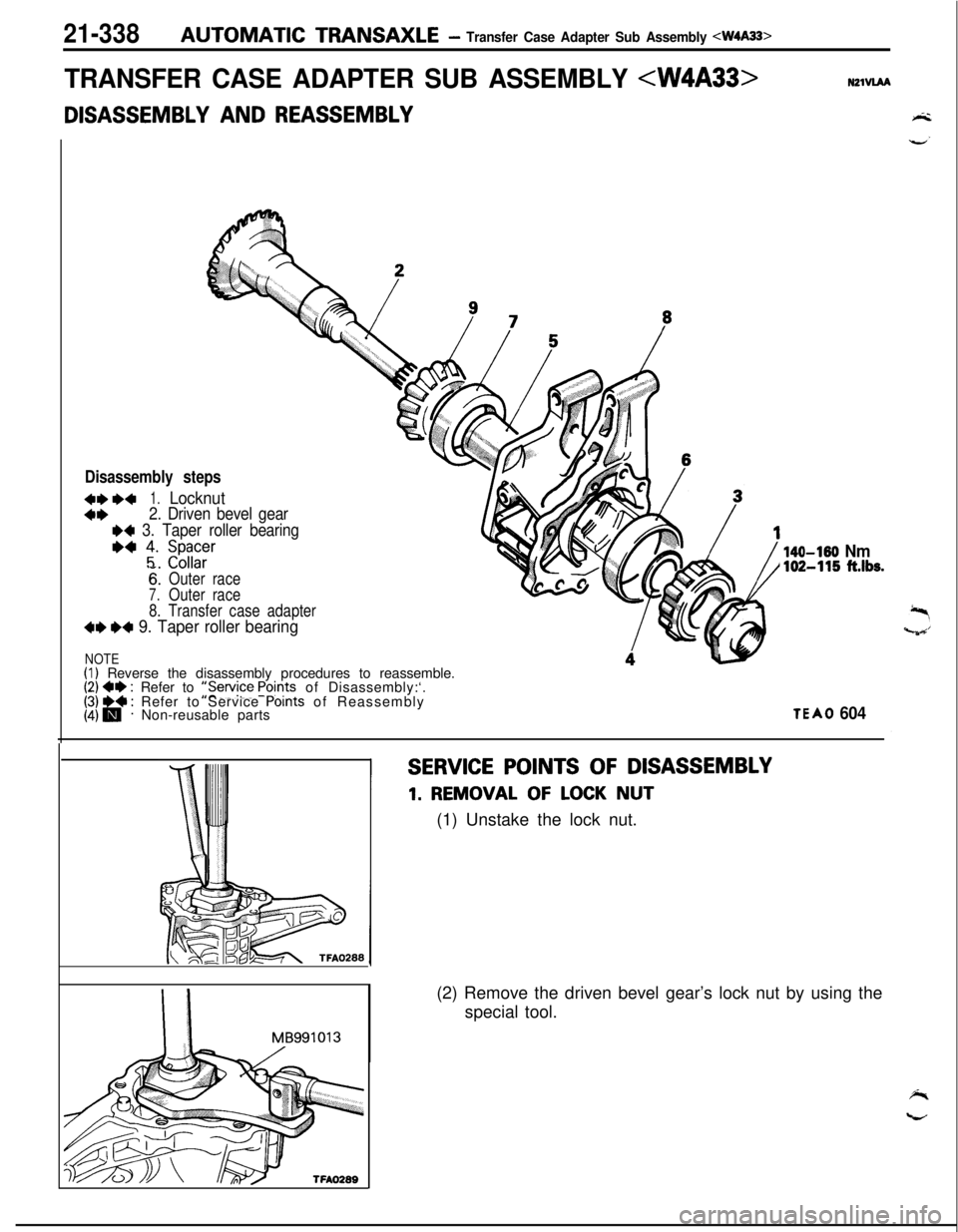

21-338AUTOMATIC TRANSAXLE- Transfer Case Adapter Sub Assembly 4W4A33>

TRANSFER CASE ADAPTER SUB ASSEMBLY

AND REASSEMBLY

Disassembly steps

4**+1.Locknut

4*2. Driven bevel gear

I)4 3. Taper roller bearing

*4 ;. ;z;;r

6:Outer race

7.Outer race

8. Transfer case adapter

4e W 9. Taper roller bearing

NOTE(I) Reverse the disassembly procedures to reassemble.(2) 4e : Refer to ::Service Points of Disassembly:‘.[j &@ j Refer to Service Points of Reassembly

Non-reusable parts

140-150 Nm102-115 ft.lbs.

TEA0 604

SERVICE POINTS OF DISASSEMBLY

1. REMOVAL OF LOCK NUT

(1) Unstake the lock nut.

I IMB991013

TFAO289(2) Remove the driven bevel gear’s lock nut by using the

special tool.

Page 1034 of 1216

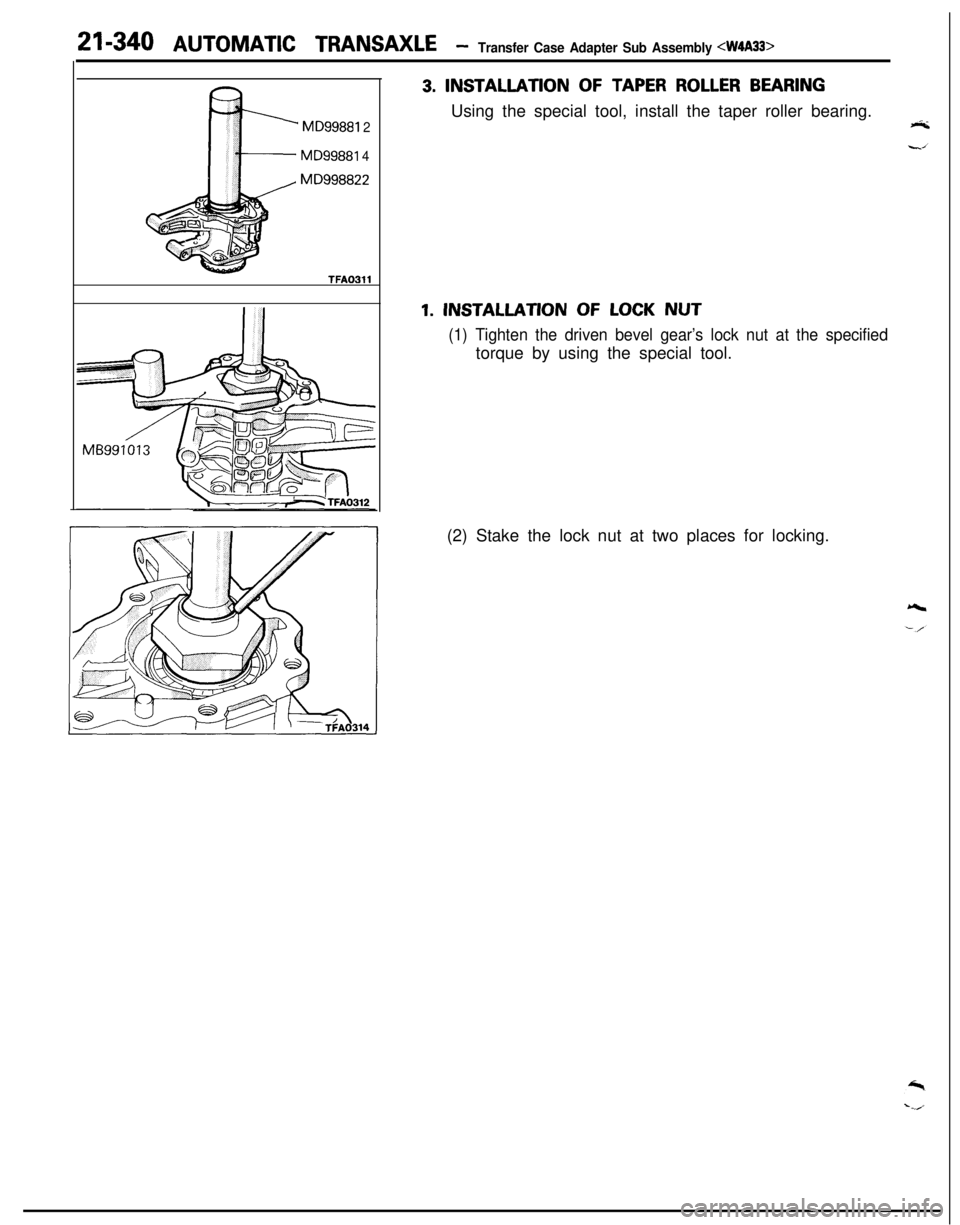

21-340 AUTOMATIC TRANSAXLE -Transfer Case Adapter Sub Assembly

MD99881 2

MD99881 4

MD998822

TFAO311

3. INSTALLATION OF TAPER ROLLER BEARINGUsing the special tool, install the taper roller bearing.

1. INSTALLATION OF LOCK NUT

(1) Tighten the driven bevel gear’s lock nut at the specifiedtorque by using the special tool.

(2) Stake the lock nut at two places for locking.

Page 1045 of 1216

23-lBODY

CONTENTSN23Ak-

AERO PARTS..........................................74

CENTRAL DOOR LOCKING SYSTEM...........70

DOOR ASSEMBLY....................................63

DOOR GLASS AND REGULATOR................66

DOORHANDLEANDLATCH.....................69

DOOR MIRROR........................................72

DOOR MOULDING AND

DRIP LINE WEATHERSTRIP........................72

....DOOR RUNCHANNEL...............................71

DOOR TRIM AND WATERPROOF FILM........65

ELECTRIC REMOTE CONTROLLED

MIRROR SWITCH.....................................73

FENDER..................................................51

FLOOR CONSOLE....................................84

FRONT BUMPER......................................39

FRONT SEAT..........................................90

FUEL TANKFILLERDOOR.........................38

GARNISHES............................................47

HEADLINING...........................................89

HOOD....................................................34

INSTRUMENT PANEL................................79

LIFTGATE...............................................36

LIFTGATE WINDOWGLASS......................62

LOOSE PANEL.........................................53

MOULDING.............................................48

POWER WINDOW....................................67

QUARTERWINDOWGLASS......................61

REAR BUMPER........................................43

REAR SEAT............................................93

SEAT BELT.............................................94

SERVICE ADJUSTMENT PROCEDURES........31

Door Adjustment....................................32

Door Glass Adjustment............................32Door Inside Handle Play Check..................

32

Door Outside Handle Play Check................32

Floor PanInspection...............................

33Fuel Filler Door Adjustment.......................

31

Hood Adjustment...................................31

Liftgate Adjustment.................................31

Water Test...........................................33

SPECIAL TOOLS......................................5

SPECIFICATIONS.....................................2

General Specifications..............................

2

Lubricants.............................................5

Sealants and Adhesives...........................5

Service Specifications..............................3

Torque Specifications..............................3

SUNROOF...............................................77TRIMS

....................................................85

TROUBLESHOOTING................................6WINDOW

GLASS.....................................54

WINDSHIELD...........................................58

Page 1046 of 1216

23-2

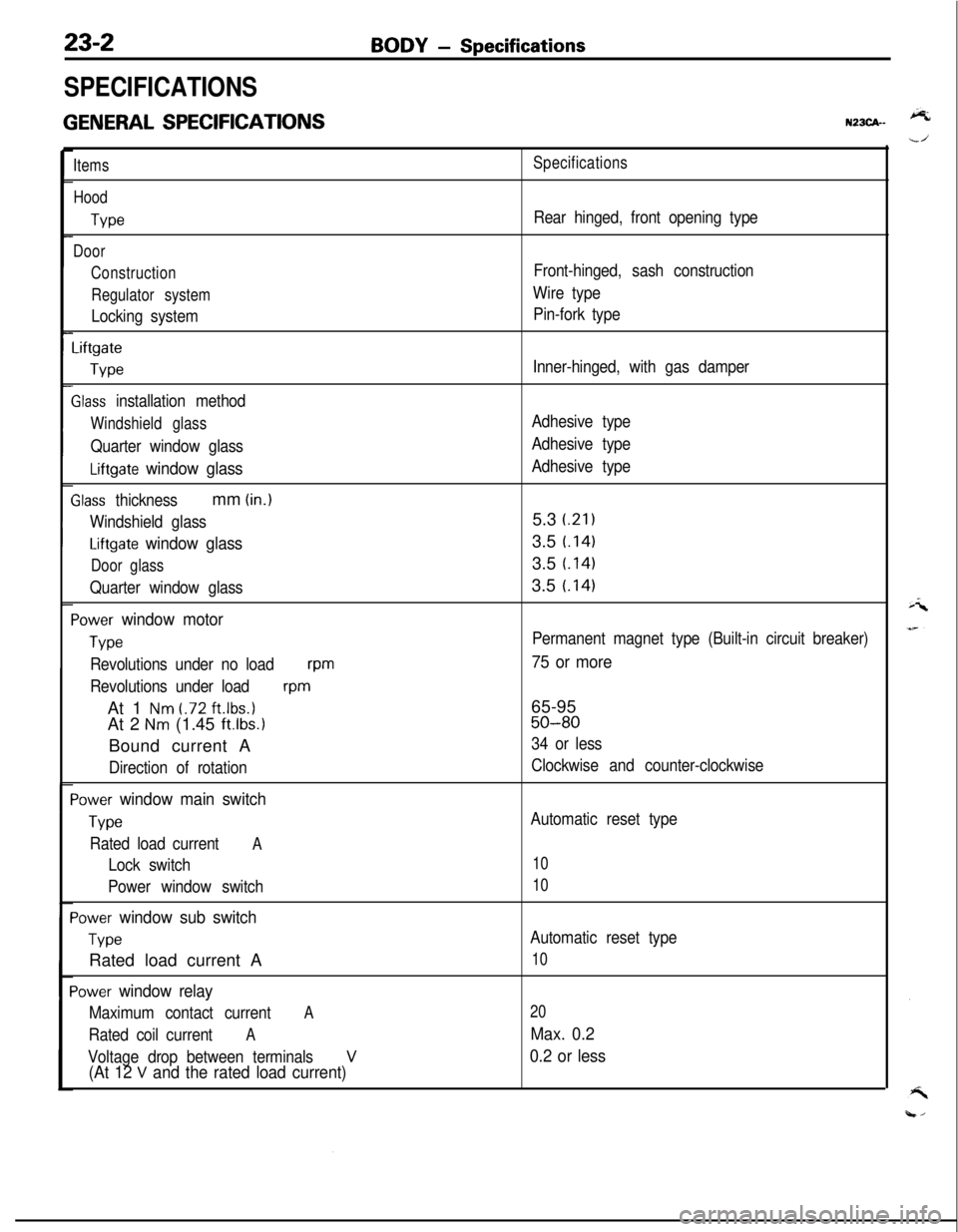

SPECIFICATIONS

GENERAL SPECIFICATIONS

BODY - Specifications

N23CA--

Items

Hood

We

Door

Construction

Regulator system

Locking system

Liftgate

We

Slass installation method

Windshield glass

Quarter window glass

Liftgate window glass

Zlass thicknessmm (in.)

Windshield glass

Liftgate window glass

Door glass

Quarter window glass

‘ower window motor

Type

Revolutions under no loadwm

Revolutions under load

wmAt 1

Nm t.72 ft.lbs.1At 2

Nm (1.45 ft.lbs.1Bound current A

Direction of rotation

‘ower window main switch

Type

Rated load currentA

Lock switch

Power window switch

‘ower window sub switch

TvwRated load current A

‘ower window relay

Maximum contact currentA

Rated coil currentA

Voltage drop between terminalsV(At 12 V and the rated load current)

Specifications

Rear hinged, front opening type

Front-hinged, sash construction

Wire type

Pin-fork type

Inner-hinged, with gas damper

Adhesive type

Adhesive type

Adhesive type5.3

i.21)3.5

t.1413.5

t.1413.5

t.141

Permanent magnet type (Built-in circuit breaker)

75 or more65-95

50-80

34 or less

Clockwise and counter-clockwise

Automatic reset type

10

10

Automatic reset type

10

20

Max. 0.2

0.2 or less