lock MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 786 of 1216

MANUAL TRANSAXLE

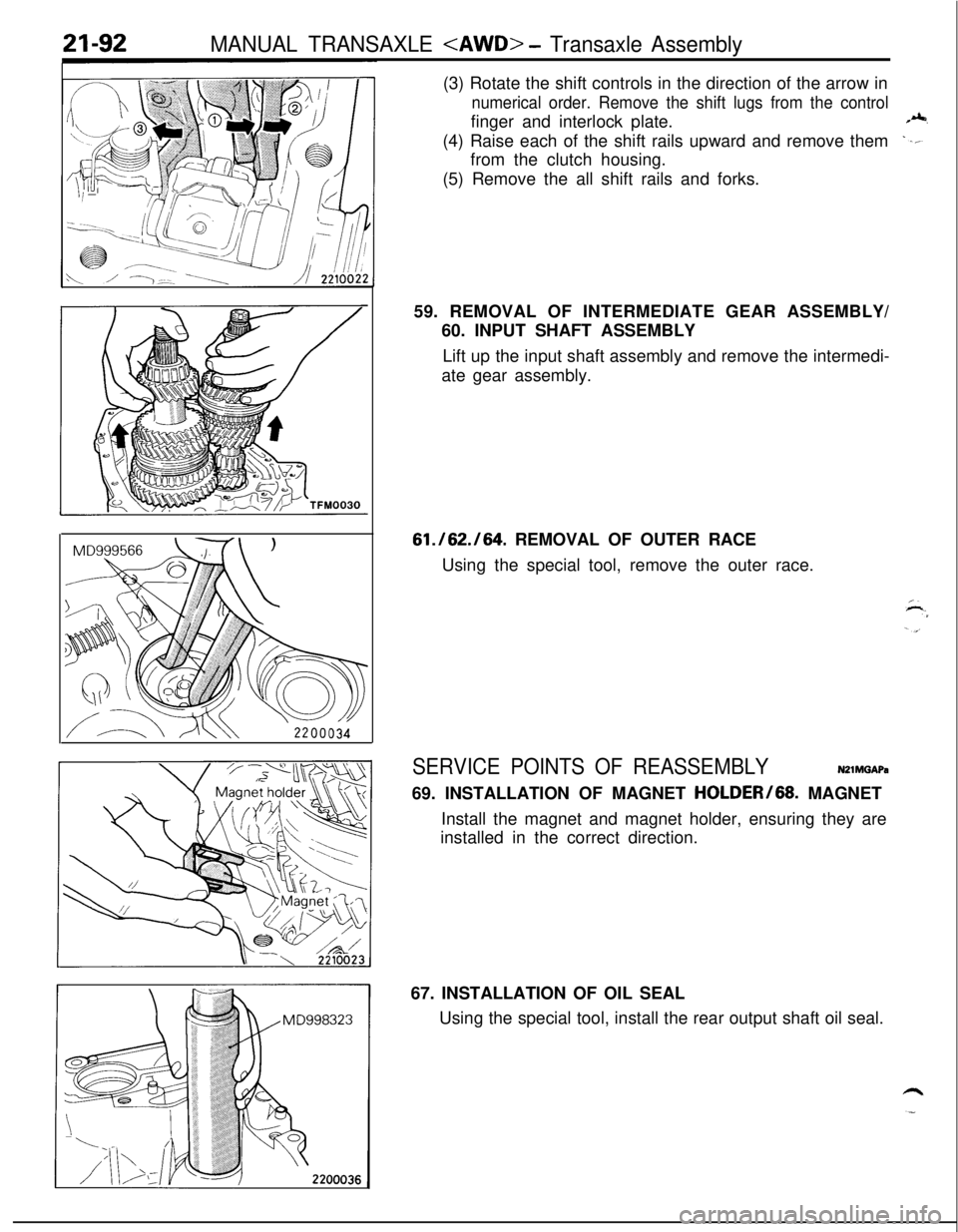

numerical order. Remove the shift lugs from the controlfinger and interlock plate.

(4) Raise each of the shift rails upward and remove them

from the clutch housing.

(5) Remove the all shift rails and forks.

59. REMOVAL OF INTERMEDIATE GEAR ASSEMBLY/

60. INPUT SHAFT ASSEMBLY

Lift up the input shaft assembly and remove the intermedi-

ate gear assembly.

61./62./64. REMOVAL OF OUTER RACE

Using the special tool, remove the outer race.

SERVICE POINTS OF REASSEMBLYN21MGAPa69. INSTALLATION OF MAGNET HOLDER/68. MAGNET

Install the magnet and magnet holder, ensuring they are

installed in the correct direction.

67. INSTALLATION OF OIL SEAL

Using the special tool, install the rear output shaft oil seal.

Page 788 of 1216

21-94MANUAL TRANSAXLE

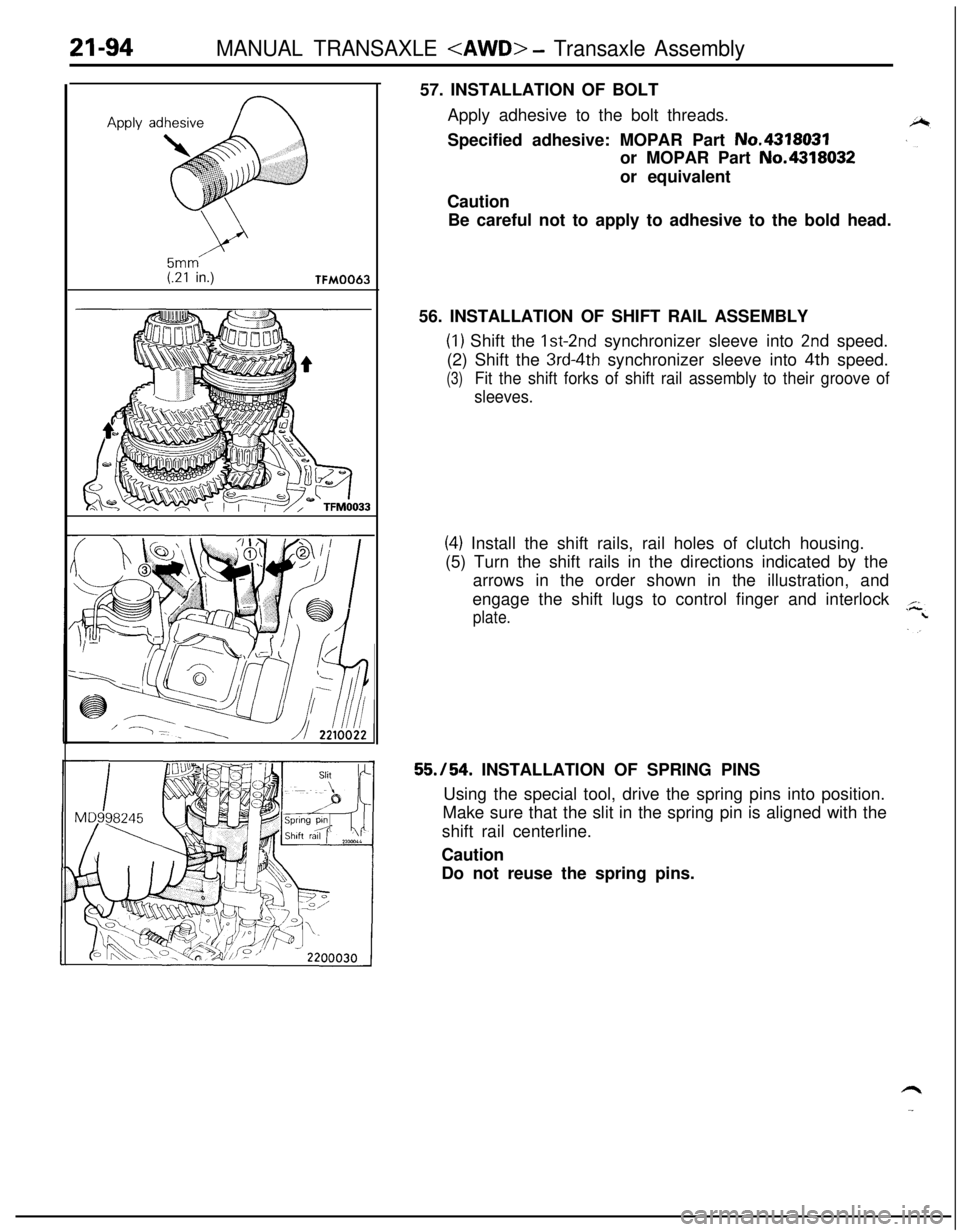

5mm(.21 in.)TFM006357. INSTALLATION OF BOLT

Apply adhesive to the bolt threads.

Specified adhesive: MOPAR Part No.4318031

or MOPAR Part No.4318032

or equivalent

Caution

Be careful not to apply to adhesive to the bold head.

56. INSTALLATION OF SHIFT RAIL ASSEMBLY

(1) Shift the Ist-2nd synchronizer sleeve into 2nd speed.

(2) Shift the

3rd-4th synchronizer sleeve into 4th speed.

(3)Fit the shift forks of shift rail assembly to their groove of

sleeves.

(4) Install the shift rails, rail holes of clutch housing.

(5) Turn the shift rails in the directions indicated by the

arrows in the order shown in the illustration, and

engage the shift lugs to control finger and interlock

plate.

55./54. INSTALLATION OF SPRING PINS

Using the special tool, drive the spring pins into position.

Make sure that the slit in the spring pin is aligned with the

shift rail centerline.

Caution

Do not reuse the spring pins.

Page 792 of 1216

21-98MANUAL TRANSAXLE

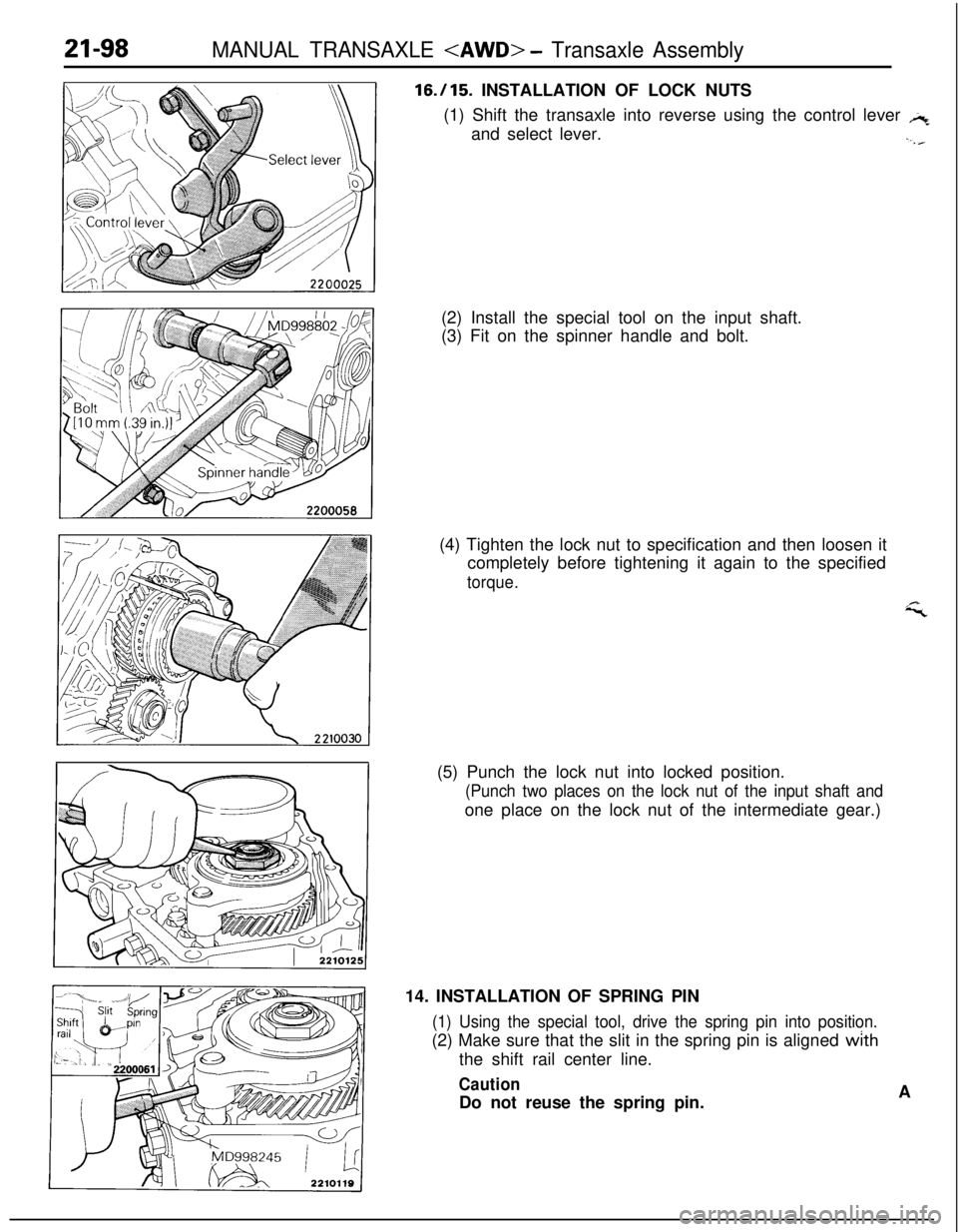

16.115. INSTALLATION OF LOCK NUTS

(1) Shift the transaxle into reverse using the control lever

,+and select lever.

.,./(2) Install the special tool on the input shaft.

(3) Fit on the spinner handle and bolt.

(4) Tighten the lock nut to specification and then loosen it

completely before tightening it again to the specified

torque.

i;(5) Punch the lock nut into locked position.

(Punch two places on the lock nut of the input shaft andone place on the lock nut of the intermediate gear.)

14. INSTALLATION OF SPRING PIN

(1) Using the special tool, drive the spring pin into position.(2) Make sure that the slit in the spring pin is aligned with

the shift rail center line.

CautionDo not reuse the spring pin.A

Page 800 of 1216

21-106MANUAL TRANSAXLE

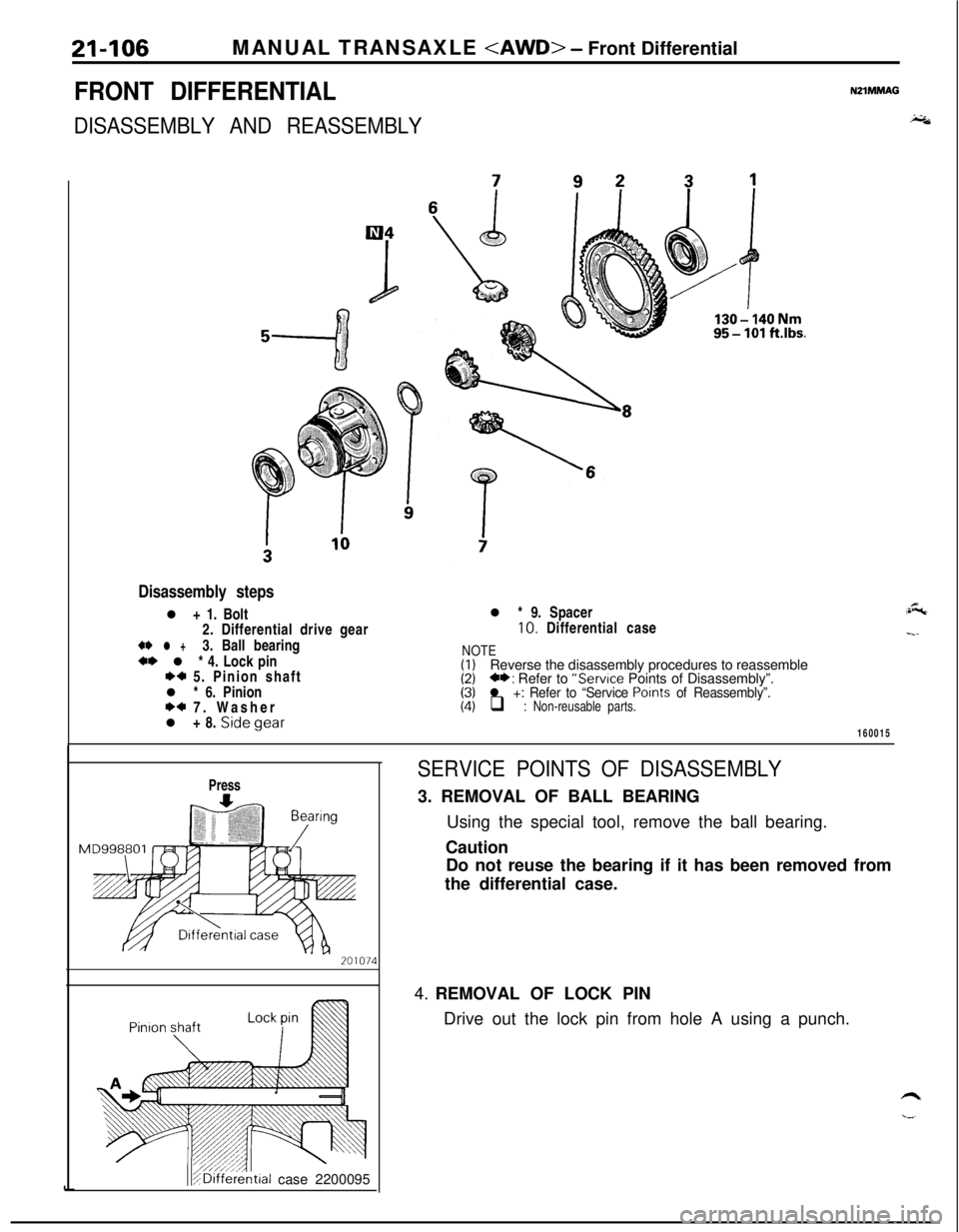

FRONT DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

NZIMMAG

i;&

Disassembly stepsl + 1. Bolt

2. Differential drive gear

** l +3. Ball bearing+* l * 4. Lock pinI)+ 5. Pinion shaft

l * 6. Pinion

I)+ 7. Washer

l + 8. Sidegear

95-lOl ft.lbs.l * 9. Spacer10. Differential case

NOTE(I)Reverse the disassembly procedures to reassemble(2)C*: Refer to “Service Points of Disassembly”.(3)l +: Refer to “Service Points of Reassembly”.(4)q : Non-reusable parts.

:&

-_-

160015

Press

teal case 2200095

SERVICE POINTS OF DISASSEMBLY3. REMOVAL OF BALL BEARING

Using the special tool, remove the ball bearing.

Caution

Do not reuse the bearing if it has been removed from

the differential case.

4. REMOVAL OF LOCK PIN

Drive out the lock pin from hole A using a punch.

Page 801 of 1216

MANUAL TRANSAXLE

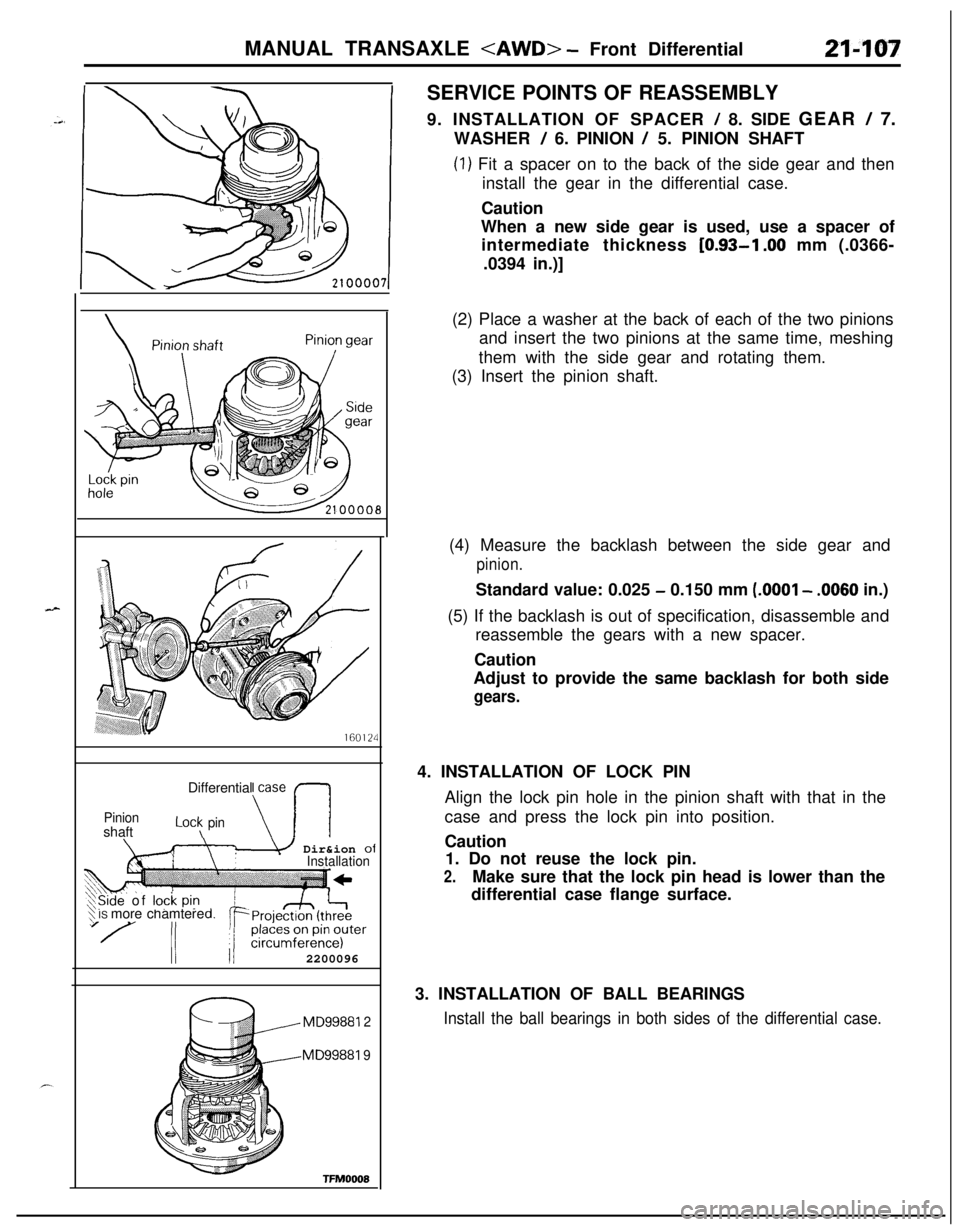

9. INSTALLATION OF SPACER

! 8. SIDE GEAR / 7.

WASHER

/ 6. PINION / 5. PINION SHAFT

(1) Fit a spacer on to the back of the side gear and then

install the gear in the differential case.

Caution

When a new side gear is used, use a spacer of

intermediate thickness

[0.93-l .OO mm (.0366-

.0394 in.)]

160124Differential case

PinionshaftLot\ pin\-I\m Dir&ion ofInstallation

‘$ IS more chamtereXSide of lock pi? d,

II II2200096

MD99881 2

MD99881 9

TFMOOOE(2) Place a washer at the back of each of the two pinions

and insert the two pinions at the same time, meshing

them with the side gear and rotating them.

(3) Insert the pinion shaft.

(4) Measure the backlash between the side gear and

pinion.Standard value: 0.025

- 0.150 mm (.OOOl - .0060 in.)

(5) If the backlash is out of specification, disassemble and

reassemble the gears with a new spacer.

Caution

Adjust to provide the same backlash for both side

gears.4. INSTALLATION OF LOCK PIN

Align the lock pin hole in the pinion shaft with that in the

case and press the lock pin into position.

Caution

1. Do not reuse the lock pin.

2.Make sure that the lock pin head is lower than the

differential case flange surface.

3. INSTALLATION OF BALL BEARINGS

Install the ball bearings in both sides of the differential case.

Page 803 of 1216

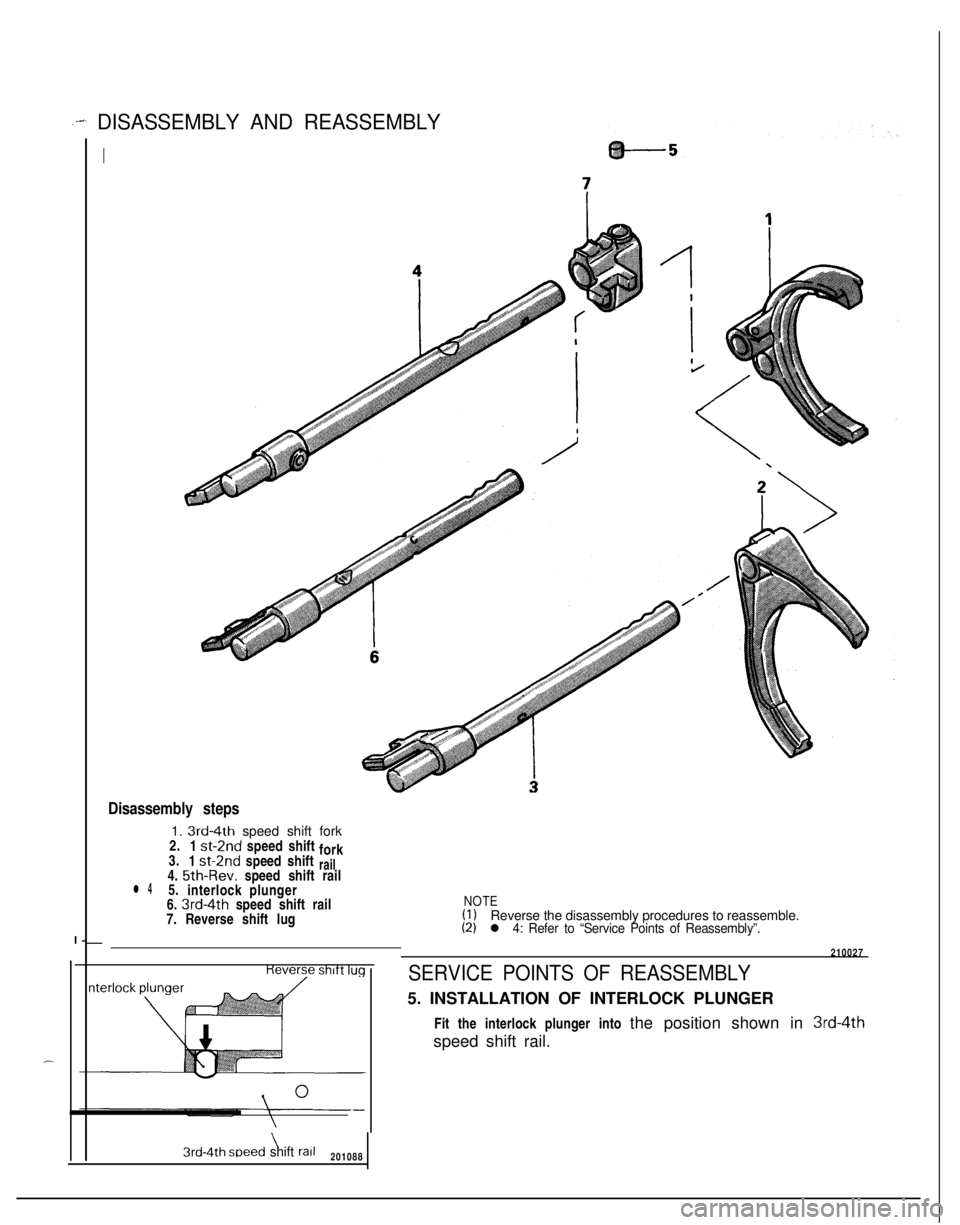

,-’ DISASSEMBLY AND REASSEMBLY

II-

Disassembly steps1.

3rd-4th speed shift fork

2.

1

st-2nd speed shift

fork

3.

1 st-2nd speed shiftrail4. 5th-Rev. speed shift raill 45.

interlock plunger

6.

3rd-4th speed shift railNOTE7. Reverse shift lug(1)Reverse the disassembly procedures to reassemble.(2)l 4: Refer to “Service Points of Reassembly”.-

\3rd-4th speed shift rail201088210027

SERVICE POINTS OF REASSEMBLY5. INSTALLATION OF INTERLOCK PLUNGER

Fit the interlock plunger into the position shown in

3rd-4thspeed shift rail.

Page 815 of 1216

MANUAL TRANSAXLE

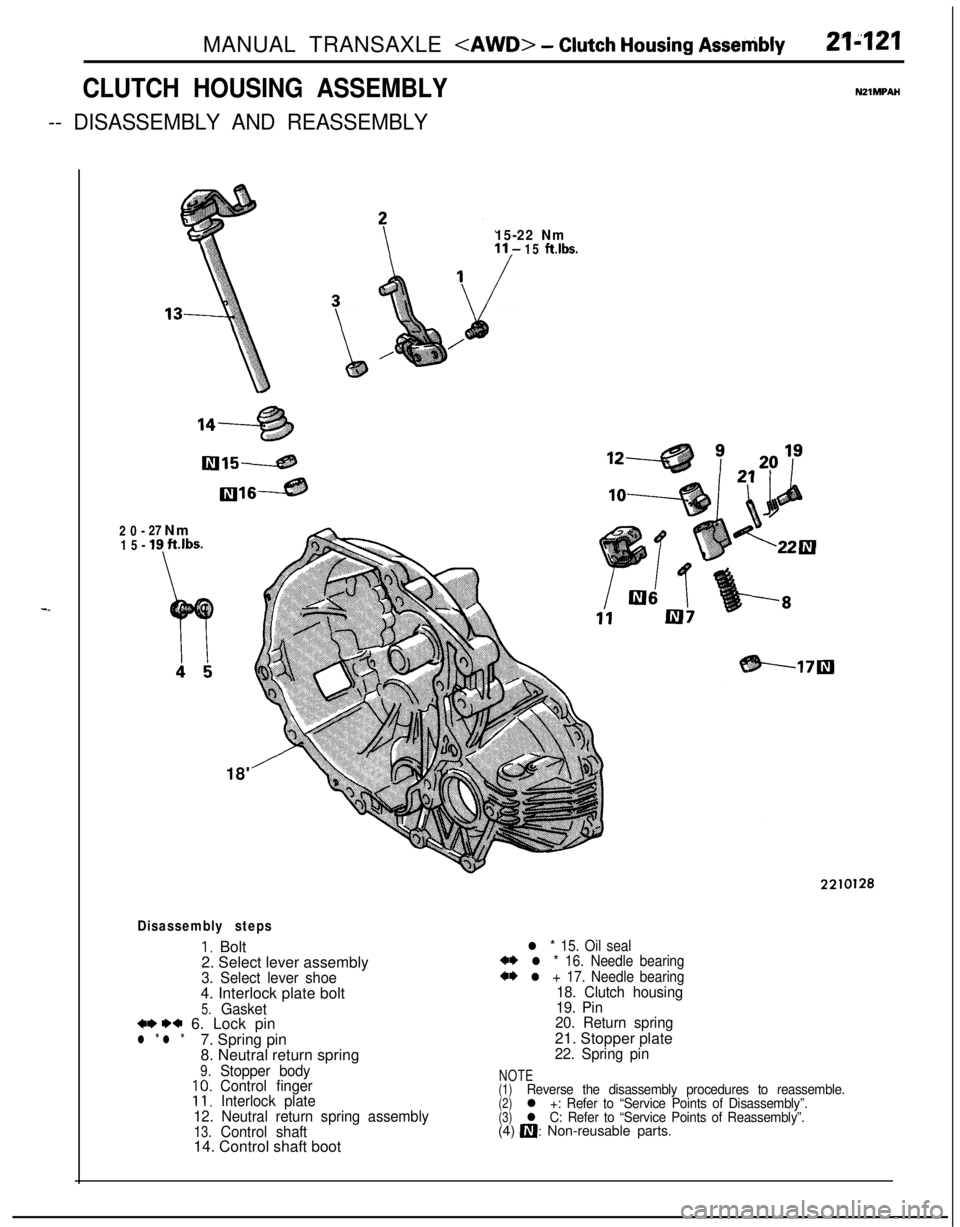

CLUTCH HOUSING ASSEMBLY

-- DISASSEMBLY AND REASSEMBLY

NZlMPAH

-20-27 Nm

15-

19 ft.lbs.

15-22 Nm15 ft.lbs.18'

Disassembly steps

I, Bolt

2. Select lever assembly

3. Select lever shoe4. Interlock plate bolt

5.Gasket+* WC 6. Lock pinl * l *7. Spring pin

8. Neutral return spring

9.Stopper body10.Control finger11,Interlock plate

12. Neutral return spring assembly

13.Control shaft14. Control shaft boot

2210128

l * 15. Oil seal*I) l * 16. Needle bearing

a* l + 17. Needle bearing18. Clutch housing

19. Pin

20. Return spring21. Stopper plate

22. Spring pin

NOTE(1)Reverse the disassembly procedures to reassemble.(2)l +: Refer to “Service Points of Disassembly”.(3)l C: Refer to “Service Points of Reassembly”.(4) a: Non-reusable parts.

Page 816 of 1216

21-122MANUAL TRANSAXLE

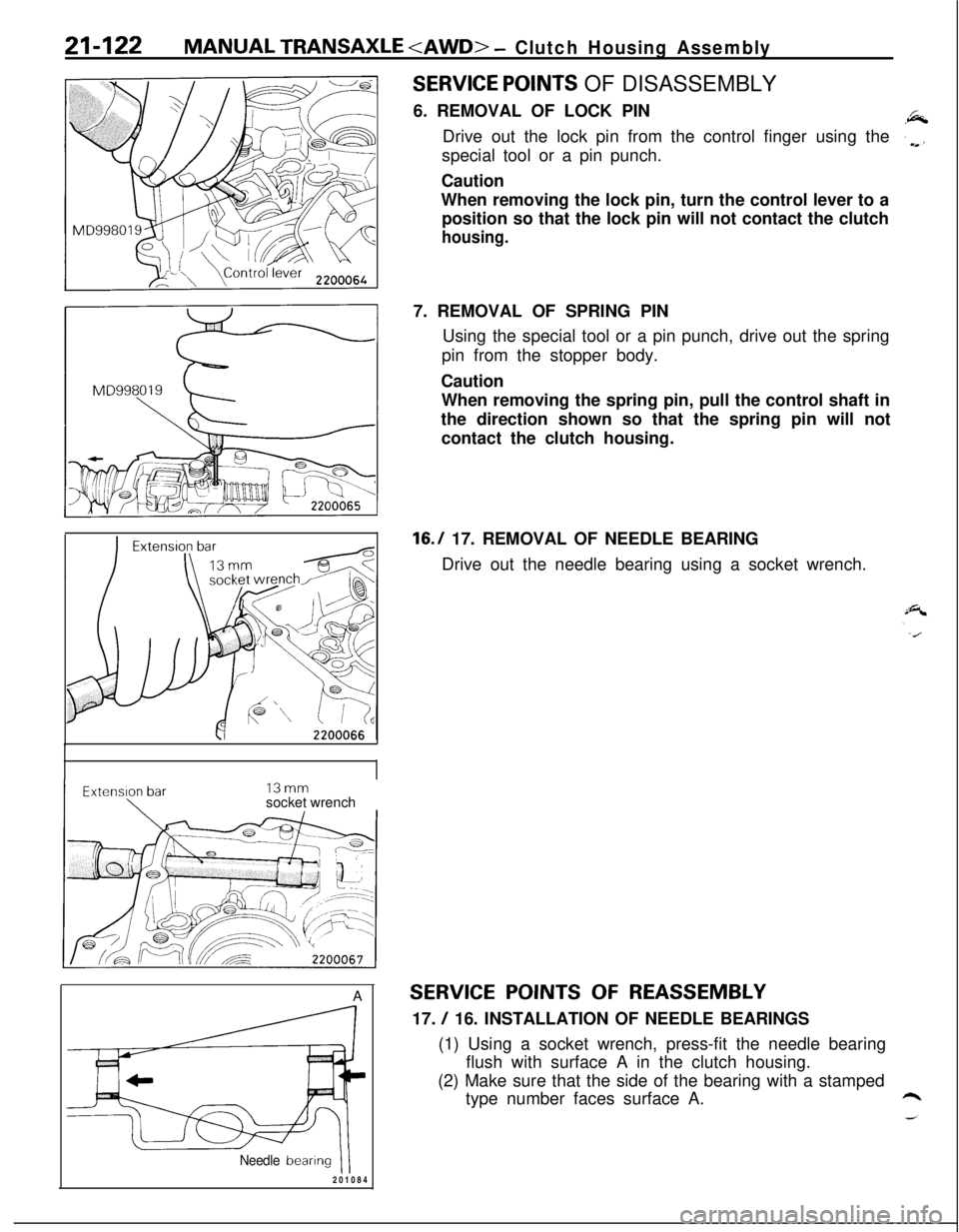

SERVICE POINTS OF DISASSEMBLY

6. REMOVAL OF LOCK PIN

Drive out the lock pin from the control finger using the

special tool or a pin punch.

Caution

When removing the lock pin, turn the control lever to a

position so that the lock pin will not contact the clutch

housing.13mm

socket wrench

A

Needle bearingII2010847. REMOVAL OF SPRING PIN

Using the special tool or a pin punch, drive out the spring

pin from the stopper body.

Caution

When removing the spring pin, pull the control shaft in

the direction shown so that the spring pin will not

contact the clutch housing.

16.7 17. REMOVAL OF NEEDLE BEARING

Drive out the needle bearing using a socket wrench.

SERVICE POINTS OF REASSEMBLY17.

/ 16. INSTALLATION OF NEEDLE BEARINGS

(1) Using a socket wrench, press-fit the needle bearing

flush with surface A in the clutch housing.

(2) Make sure that the side of the bearing with a stamped

type number faces surface A.

Page 817 of 1216

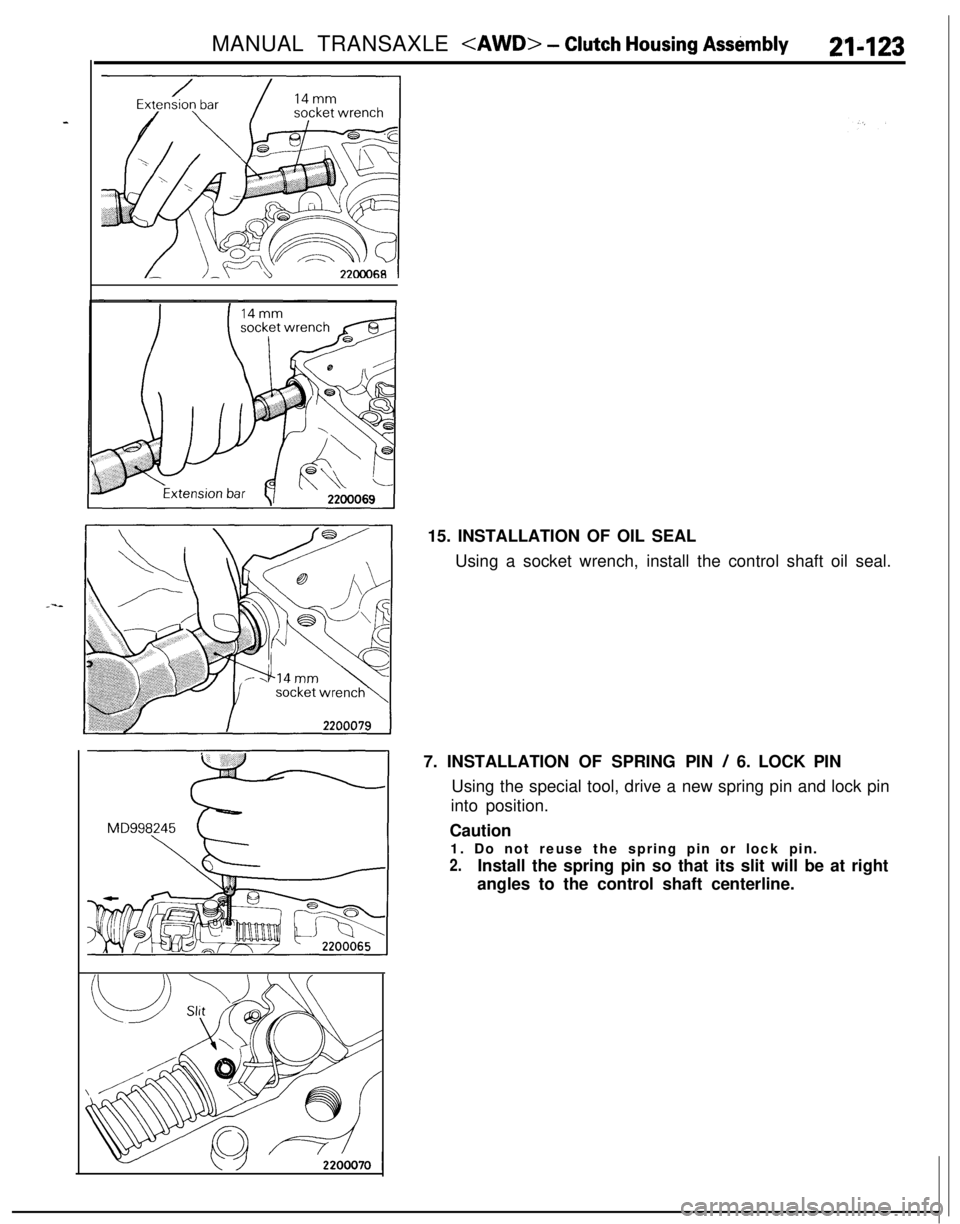

MANUAL TRANSAXLE

Using a socket wrench, install the control shaft oil seal.

7. INSTALLATION OF SPRING PIN

/ 6. LOCK PIN

Using the special tool, drive a new spring pin and lock pin

into position.

Caution

1. Do not reuse the spring pin or lock pin.

2.Install the spring pin so that its slit will be at right

angles to the control shaft centerline.

Page 825 of 1216

MANUAL TRANSAXLE

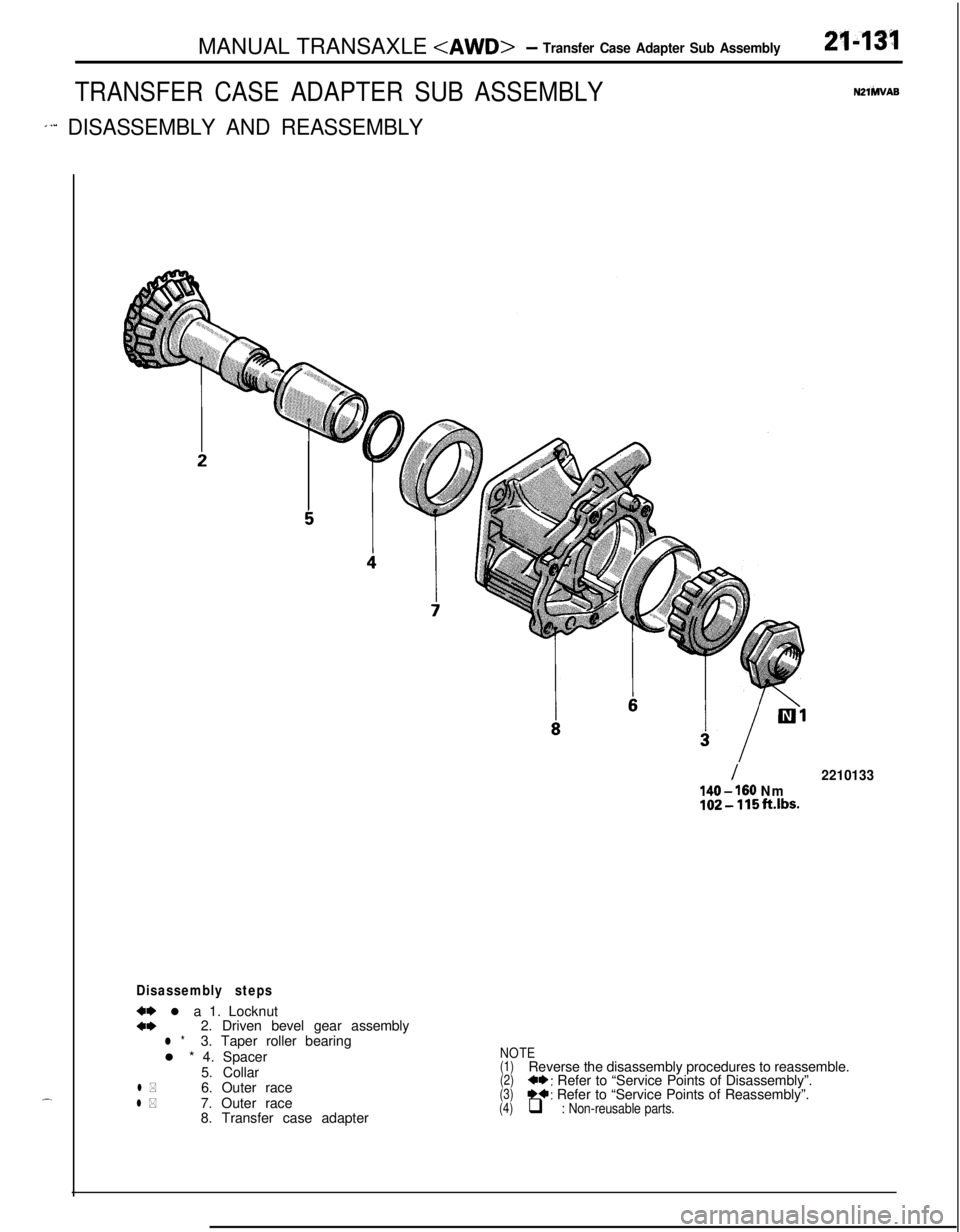

TRANSFER CASE ADAPTER SUB ASSEMBLY

1’” DISASSEMBLY AND REASSEMBLY

2143’1

N2lhlVAS.-

Disassembly steps

w l a 1. Locknuta*2. Driven bevel gear assemblyl *3. Taper roller bearing

l * 4. Spacer

5. Collar

l *6. Outer racel *7. Outer race

8. Transfer case adapter

I2210133

140 - 160 Nm102-115ft.lbs.

NOTE(1)Reverse the disassembly procedures to reassemble.(2)+*: Refer to “Service Points of Disassembly”.(3)*+: Refer to “Service Points of Reassembly”.(4)q : Non-reusable parts.