differential MITSUBISHI ECLIPSE 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 798 of 1216

21-104MANUAL TRANSAXLE

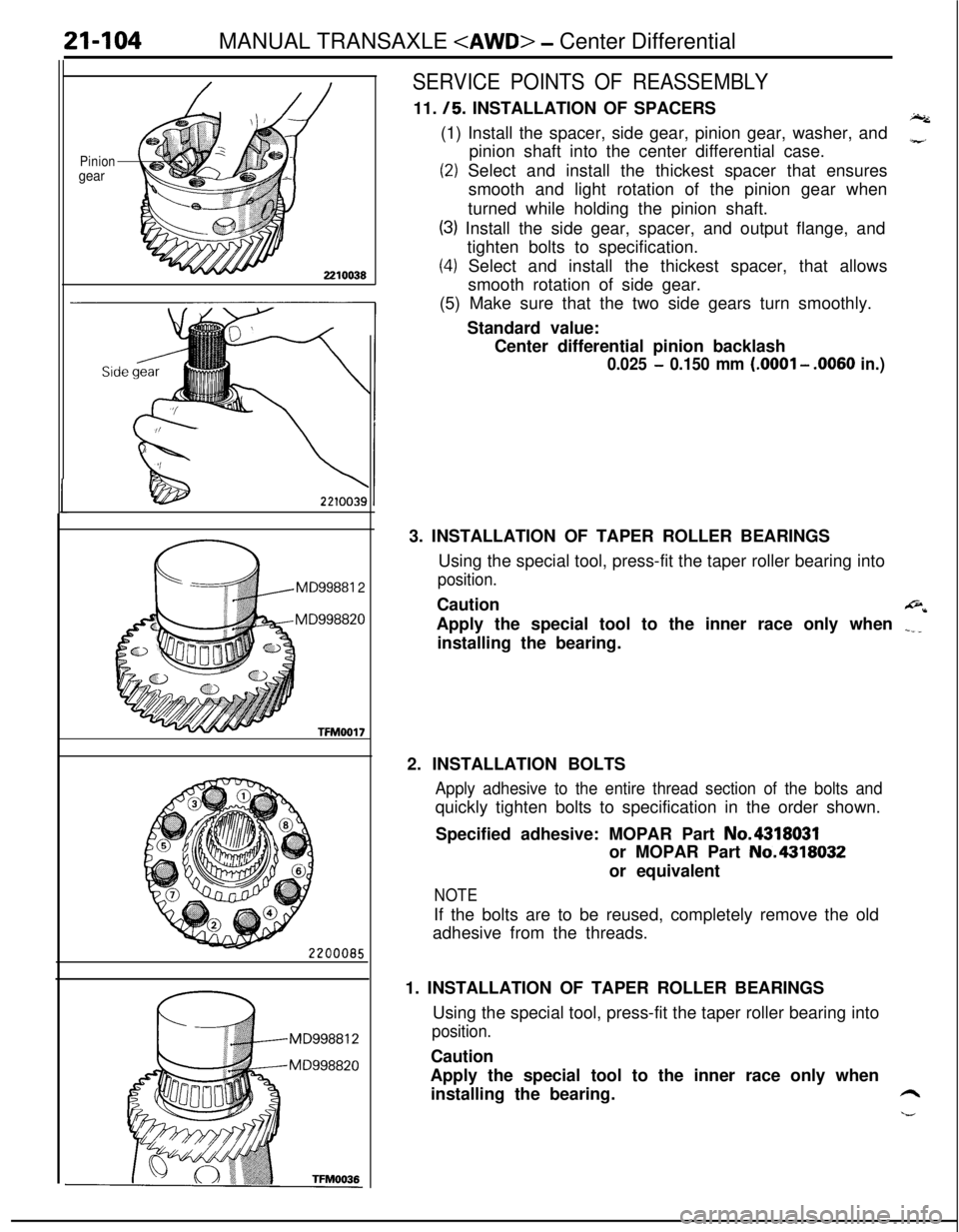

Piniongear

MD99881 2

MD998820

TFM0017

SERVICE POINTS OF REASSEMBLY11.

/5. INSTALLATION OF SPACERSI.(1) Install the spacer, side gear, pinion gear, washer, and

pinion shaft into the center differential case.

z

(2) Select and install the thickest spacer that ensures

smooth and light rotation of the pinion gear when

turned while holding the pinion shaft.

(3) Install the side gear, spacer, and output flange, and

tighten bolts to specification.

(4) Select and install the thickest spacer, that allows

smooth rotation of side gear.

(5) Make sure that the two side gears turn smoothly.

Standard value:

Center differential pinion backlash

0.025 - 0.150 mm (.OOOl - .0060 in.)3. INSTALLATION OF TAPER ROLLER BEARINGS

Using the special tool, press-fit the taper roller bearing into

position.Caution

@*Apply the special tool to the inner race only when

.___installing the bearing.

2. INSTALLATION BOLTS

Apply adhesive to the entire thread section of the bolts andquickly tighten bolts to specification in the order shown.

Specified adhesive: MOPAR Part No.4318031

or MOPAR Part No.4318032

or equivalent

NOTEIf the bolts are to be reused, completely remove the old

adhesive from the threads.

1. INSTALLATION OF TAPER ROLLER BEARINGS

Using the special tool, press-fit the taper roller bearing into

position.Caution

Apply the special tool to the inner race only when

installing the bearing.

6

h--

Page 800 of 1216

21-106MANUAL TRANSAXLE

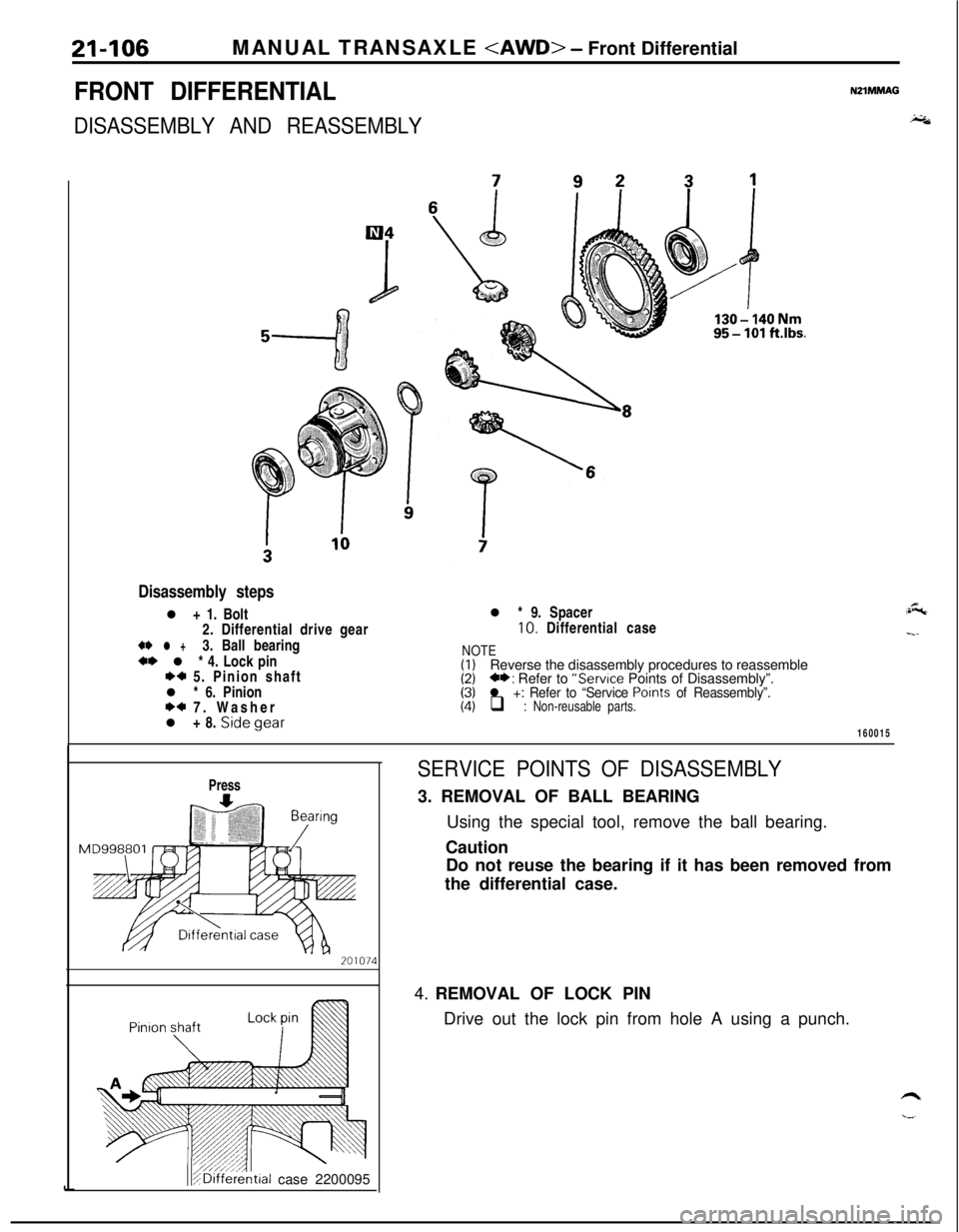

FRONT DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

NZIMMAG

i;&

Disassembly stepsl + 1. Bolt

2. Differential drive gear

** l +3. Ball bearing+* l * 4. Lock pinI)+ 5. Pinion shaft

l * 6. Pinion

I)+ 7. Washer

l + 8. Sidegear

95-lOl ft.lbs.l * 9. Spacer10. Differential case

NOTE(I)Reverse the disassembly procedures to reassemble(2)C*: Refer to “Service Points of Disassembly”.(3)l +: Refer to “Service Points of Reassembly”.(4)q : Non-reusable parts.

:&

-_-

160015

Press

teal case 2200095

SERVICE POINTS OF DISASSEMBLY3. REMOVAL OF BALL BEARING

Using the special tool, remove the ball bearing.

Caution

Do not reuse the bearing if it has been removed from

the differential case.

4. REMOVAL OF LOCK PIN

Drive out the lock pin from hole A using a punch.

Page 801 of 1216

MANUAL TRANSAXLE

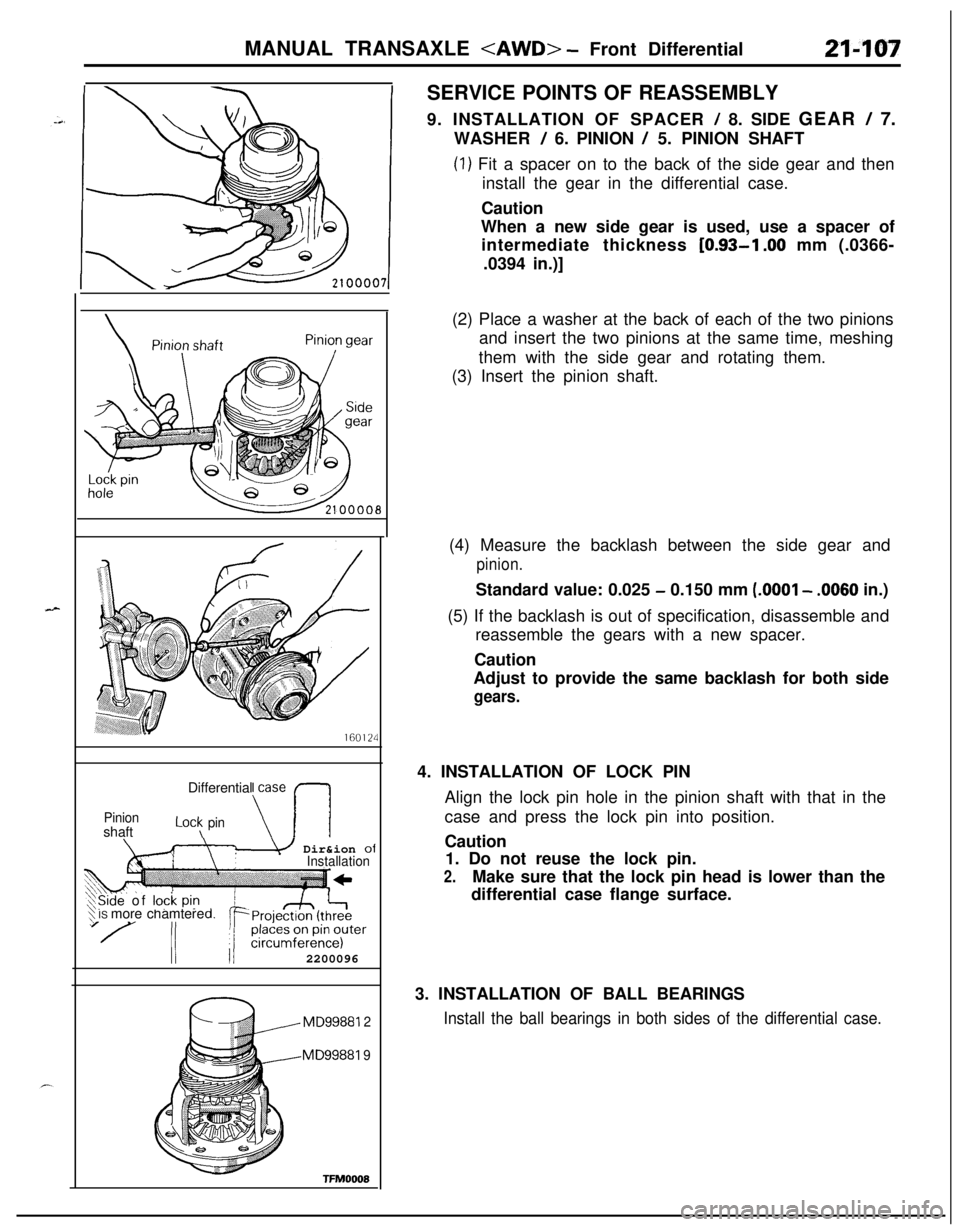

9. INSTALLATION OF SPACER

! 8. SIDE GEAR / 7.

WASHER

/ 6. PINION / 5. PINION SHAFT

(1) Fit a spacer on to the back of the side gear and then

install the gear in the differential case.

Caution

When a new side gear is used, use a spacer of

intermediate thickness

[0.93-l .OO mm (.0366-

.0394 in.)]

160124Differential case

PinionshaftLot\ pin\-I\m Dir&ion ofInstallation

‘$ IS more chamtereXSide of lock pi? d,

II II2200096

MD99881 2

MD99881 9

TFMOOOE(2) Place a washer at the back of each of the two pinions

and insert the two pinions at the same time, meshing

them with the side gear and rotating them.

(3) Insert the pinion shaft.

(4) Measure the backlash between the side gear and

pinion.Standard value: 0.025

- 0.150 mm (.OOOl - .0060 in.)

(5) If the backlash is out of specification, disassemble and

reassemble the gears with a new spacer.

Caution

Adjust to provide the same backlash for both side

gears.4. INSTALLATION OF LOCK PIN

Align the lock pin hole in the pinion shaft with that in the

case and press the lock pin into position.

Caution

1. Do not reuse the lock pin.

2.Make sure that the lock pin head is lower than the

differential case flange surface.

3. INSTALLATION OF BALL BEARINGS

Install the ball bearings in both sides of the differential case.

Page 802 of 1216

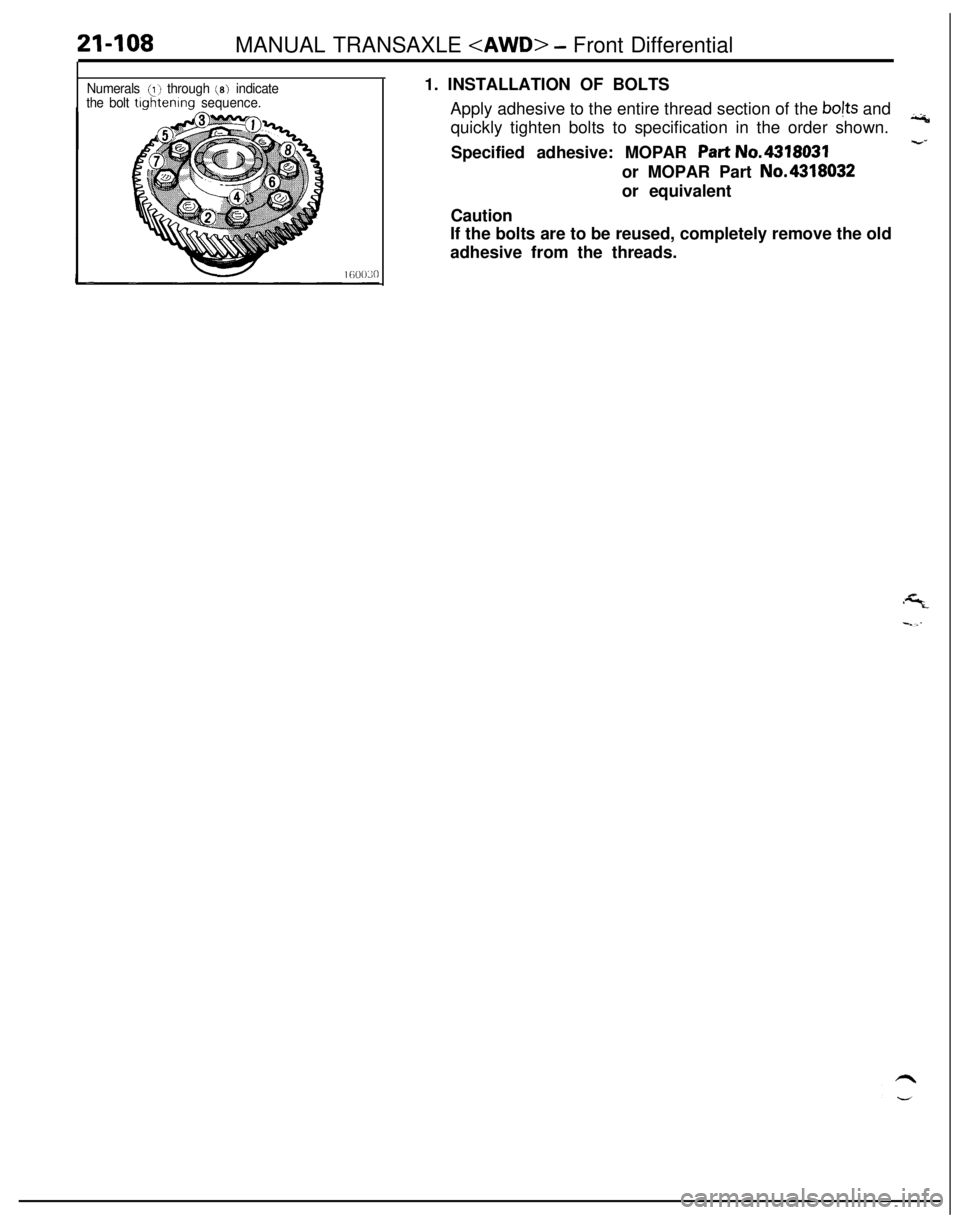

21-108MANUAL TRANSAXLE

Numerals (I) through (8) indicate

the bolt tlghtenlng sequence.1. INSTALLATION OF BOLTS

Apply adhesive to the entire thread section of the bojts and

quickly tighten bolts to specification in the order shown.iii

-2Specified adhesive: MOPAR Part No.4318031

or MOPAR Part No.4318032

or equivalent

Caution

If the bolts are to be reused, completely remove the old

adhesive from the threads.

Page 832 of 1216

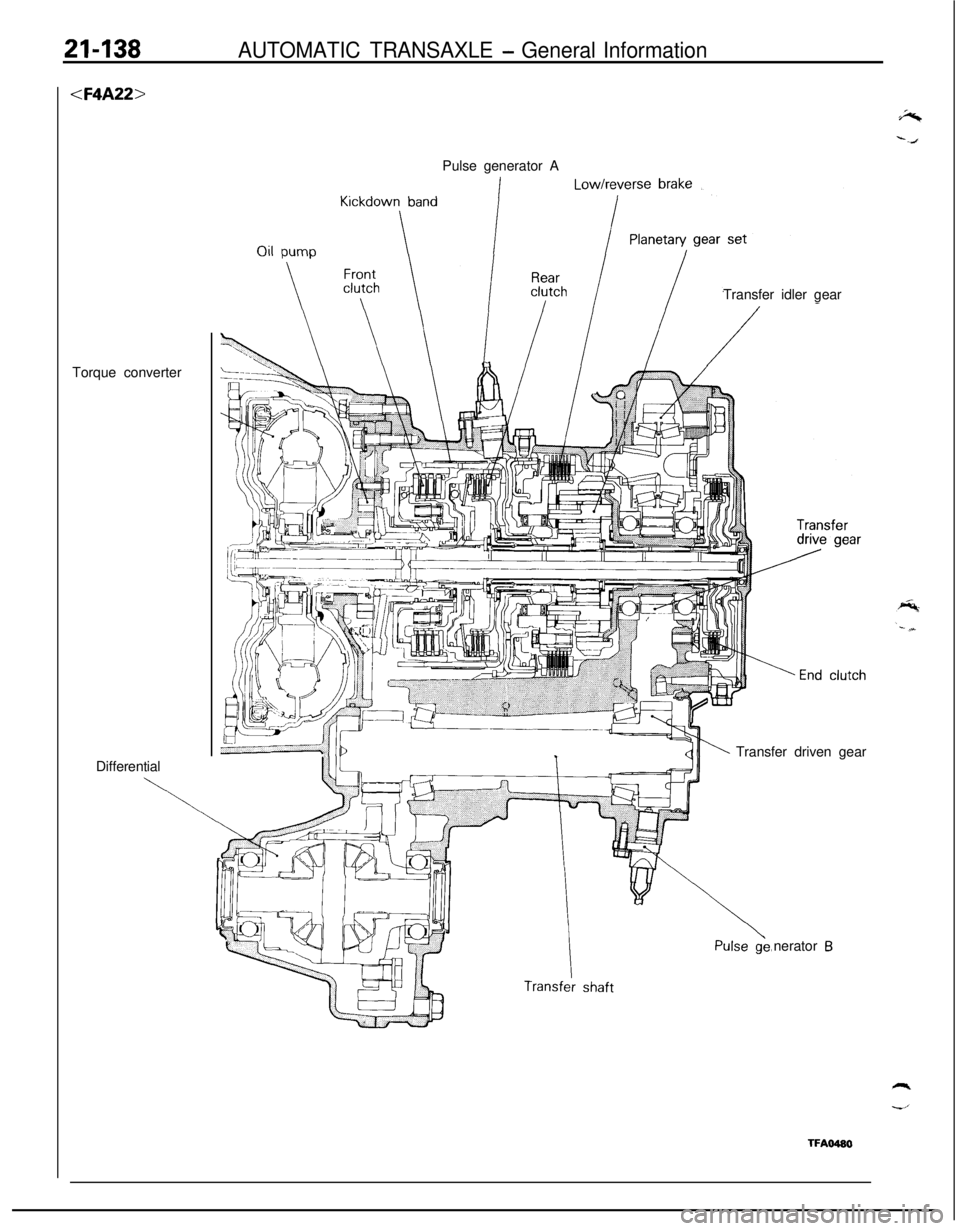

21-138AUTOMATIC TRANSAXLE - General Information

DifferentialPulse generator A

Transfer idler gear

Transfer driven gear

nerator

B

TFAO480

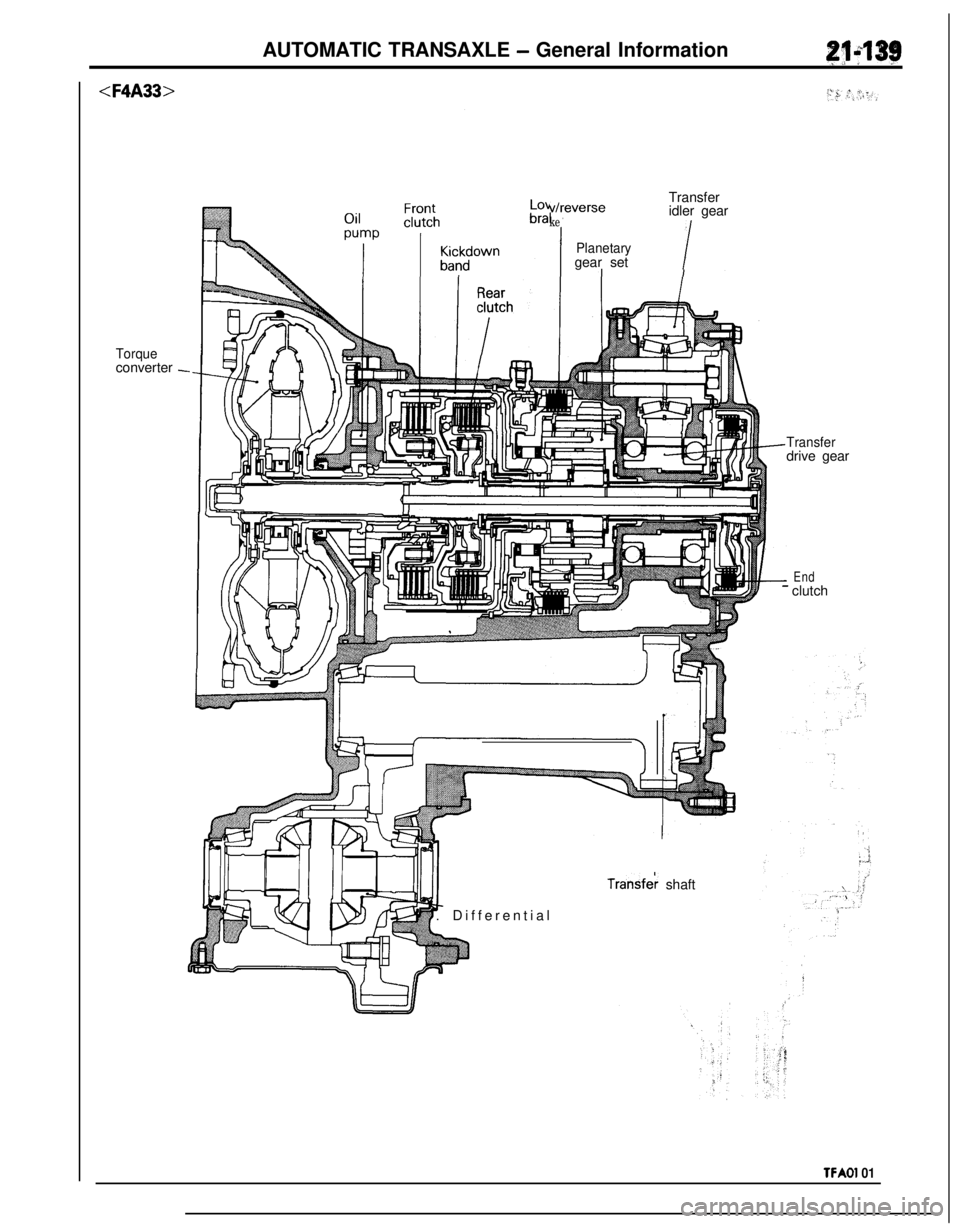

Page 833 of 1216

AUTOMATIC TRANSAXLE - General Information

Torqueconverter -werseTransfer

idler gear

Planetarygear set

!v/n

ke

Transferdrive gear

Transfek shaft

. Differential

End- clutch

TFAOl 01

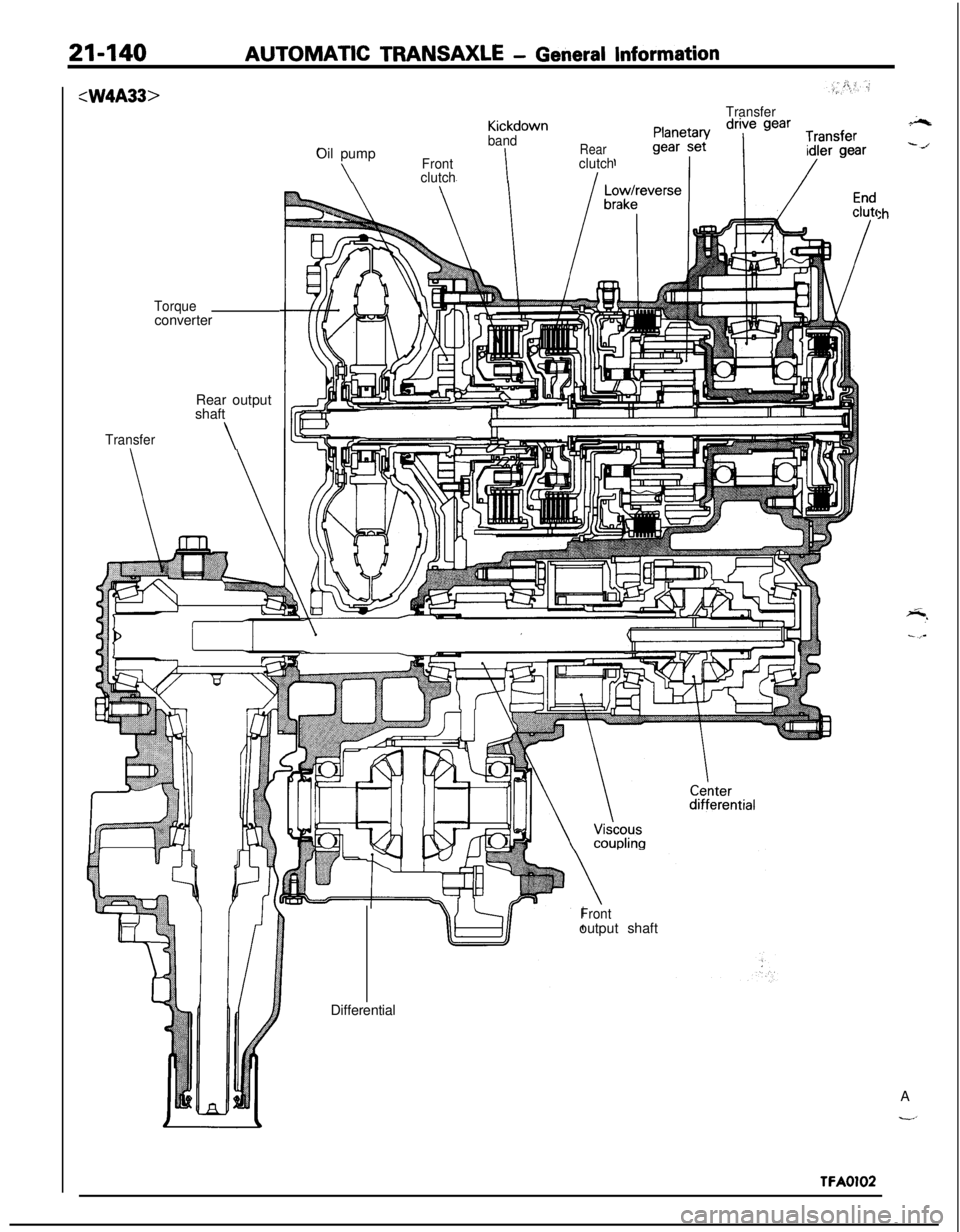

Page 834 of 1216

21-140AUTOMATIC TRANSAXLE - General Information:W4A33>

Torqueconverter

Rear output

shaft

Transfer\

TransferKickdown

bandOil pump

Rear

\FrontIclutch

clutchI

:h

Frontoutput shaft

2%

--/Differential

A

-’

TFA0102

Page 853 of 1216

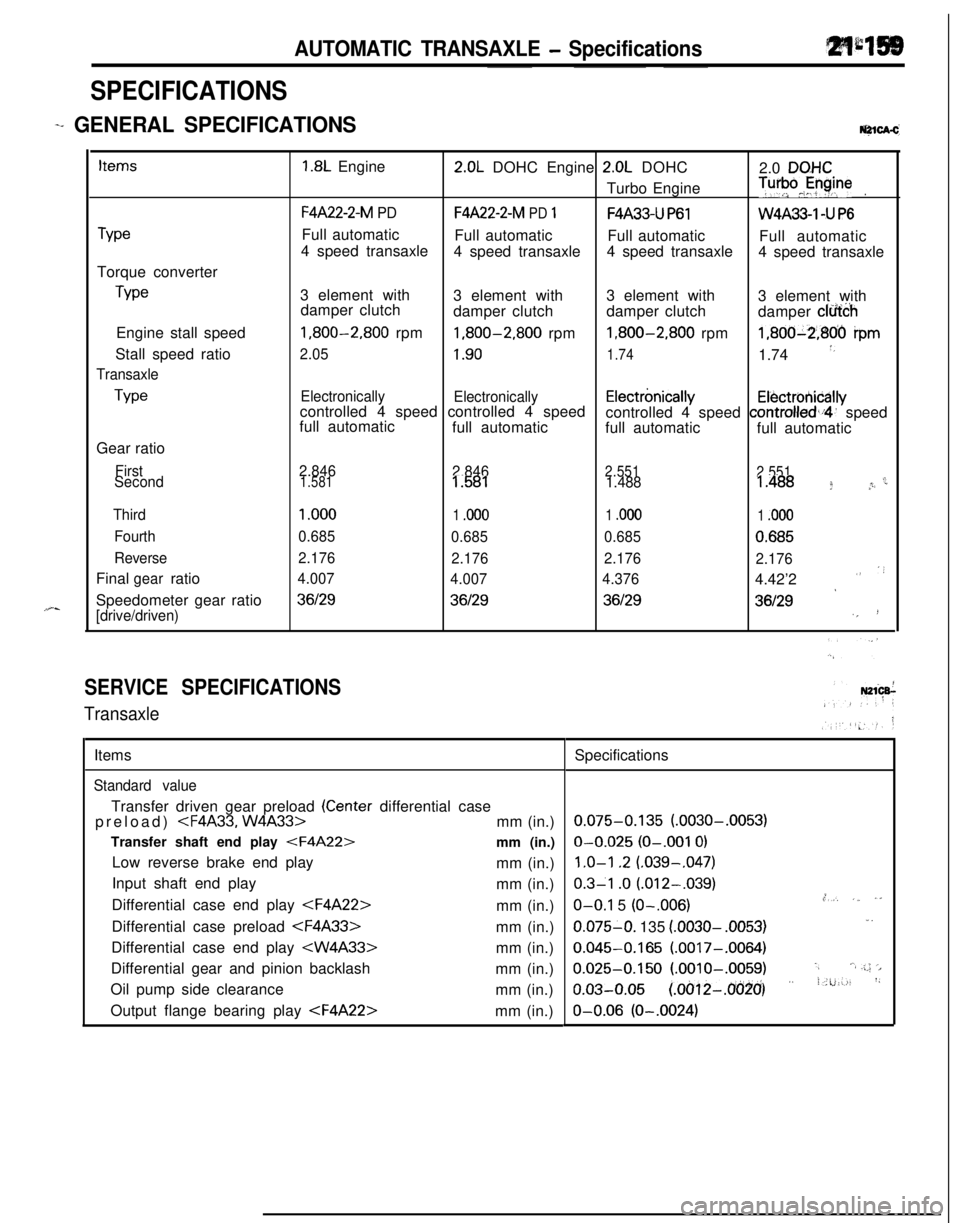

AUTOMATIC TRANSAXLE - Specifications

SPECIFICATIONS

-+ GENERAL [email protected]

TypeTorque converter

TypeEngine stall speed

Stall speed ratio

Transaxle

TypeGear ratio

First

Second

Third

Fourth

ReverseFinal ratio

gearSpeedometer gear ratio

[drive/driven)

1.8L Engine2.0L DOHC Engine 2.0L DOHC

2.0 DQHCTurbo Engine

T”‘pJyine.

F4A22-2-M PDF4A22-2-M PD 1F4A33-U P61W4A33-1 -U P6Full automatic

Full automatic

Full automatic

Full automatic

4 speed transaxle

4 speed transaxle4 speed transaxle

4 speed transaxle

3 element with

3 element with3 element with

3 element with

damper clutch

damper clutchdamper clutch

damper clfi&h

1,800-2,800 rpm1,800-2,800 rpm1,800-2,800 rpm1,800-2,806 ipm

2.051.901.741.74 *,

Electronically

Electronicallycontrolled 4 speed controlled 4 speedElectrbnicallyElectrotiicallyfull automaticcontrolled 4 speed controlled,i4’ speed

full automatic

full automatic

full automatic

2.846

2.8462.551

2.551c1.5811.5811.4881.488 f *r

1 .ooo

1 .ooo1 .ooo1 .ooo

0.685

0.6850.6850.685

2.176

2.1762.176

2.176

4.007

4.0074.3764.42’2

””

*36129361293612936129‘,!

SERVICE SPECIFICATIONS

TransaxleItems

Standard valueTransfer driven gear preload

(Center differential case

preload)

Transfer shaft end play

Low reverse brake end play

mm (in.)

Input shaft end play

mm (in.)

Differential case end play

Differential case preload

Differential case end play

Differential gear and pinion backlash

mm (in.)

Oil pump side clearance

mm (in.)

Output flange bearing play

0.075-0.135 (.0030-.0053)O-0.025

(O-.001 0)

1.0-l .2 (.039-,047)

0.3-l .o (.012-.039).,O-O.1 5 (O-.006),*, ,_ ,”0.075-O. 135

(.0030- .0053)1.

0.045-0.165 (.0017-.0064)

0.025-0.150 (.OOlO-.0059).,‘.a .;.; ‘>

o.03-o.05 (~oo12-~o(j~o’) ” i.u:-., ‘~O-0.06

(O-.0024)

Page 854 of 1216

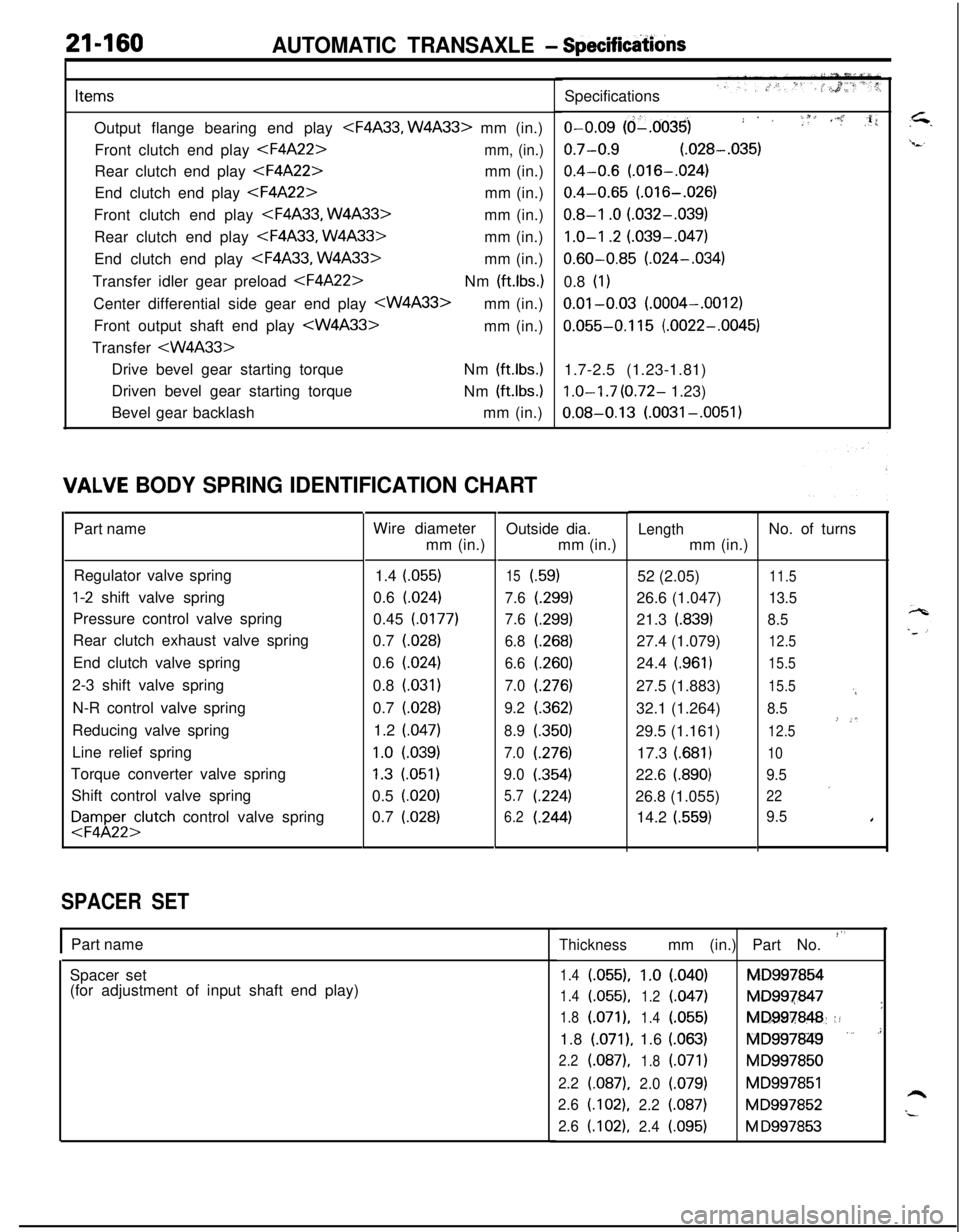

21-160AUTOMATIC TRANSAXLE - Specifidons

ItemsOutput flange bearing end play

Front clutch end play

End clutch end play

Front clutch end play

Rear clutch end play

End clutch end play

Transfer idler gear preload

Front output shaft end play

Transfer

Driven bevel gear starting torque

Bevel gear backlashNm

(ft.lbs.)Nm

(ft.lbs.)mm (in.)

IALVE BODY SPRING IDENTIFICATION CHARTPart name

Regulator valve spring

l-2 shift valve spring

Pressure control valve spring

Rear clutch exhaust valve spring

End clutch valve spring

2-3 shift valve spring

N-R control valve spring

Reducing valve spring

Line relief spring

Torque converter valve spring

Shift control valve spring

FFyl;;;lutch control valve spring

SPACER SETWire diameter

mm (in.)

1.4 (055)

0.6 (024)

0.45 (0177)

0.7 (028)

0.6

(.024)0.8

(.031)0.7 (028)

1.2 (047)

1.0 l.039)

1.3 (051)

0.5 (020)

0.7

(.028)Outside dia.

mm (in.)

15i.59)

7.6

t.299)

7.6(.299)

6.8(.268)

6.6(260)

7.0(276)

9.2(.362)

8.9(350)

7.0(276)

9.0(.354)

5.7(224)

6.2(.244)

IPart name

Spacer set

(for adjustment of input shaft end play)Specifications

o-0.09 (d-.0035); . ,i f 1, ,i’.” :,li

0.7-0.9 (.028-.035)

0.4-0.6 (.016-.024)

0.4-0.65 (.016-.026)

0.8-I .O (.032-.039)

1.0-I .2 (.039-.047)

0.60-0.85 (.024-.034)

0.8

(1)

0.01-0.03 (.0004-.0012)

0.055-0.115 (.0022-.0045)

1.7-2.5 (1.23-1.81)

1.0-I .7 (0.72- 1.23)

0.08-0.13 (.0031-.0051)

Lengthmm (in.)

52 (2.05)

26.6 (1.047)

21.3

(.839)27.4 (1.079)

24.4

(.961)27.5 (1.883)

32.1 (1.264)

29.5 (1.161)

17.3

(.681)22.6

i.890)26.8 (1.055)

14.2

(.559)No. of turns

11.5

13.5

8.5

12.5

15.5

15.5

‘4

8.5

’-*12.5

10

9.5

’22

9.5I

Thicknessmm (in.) Part No. “’

1.4(055).1.0l.040)MD997854

1.4(.055),

1.2(047)MD997847

’1.8(.071),

1.4l.055)MD997848::!1.8

(.071), 1.6 (.063)fQlD997849 ” .’

2.2(.087),

1.8(.071)MD997850

2.2(.087),2.0(.079)MD997851h2.6(.102),2.2(.087)MD997852“-2.6(.102),2.4i.095)M D997853

Page 855 of 1216

AUTOMATIC TRANSAXLE - SDecifications

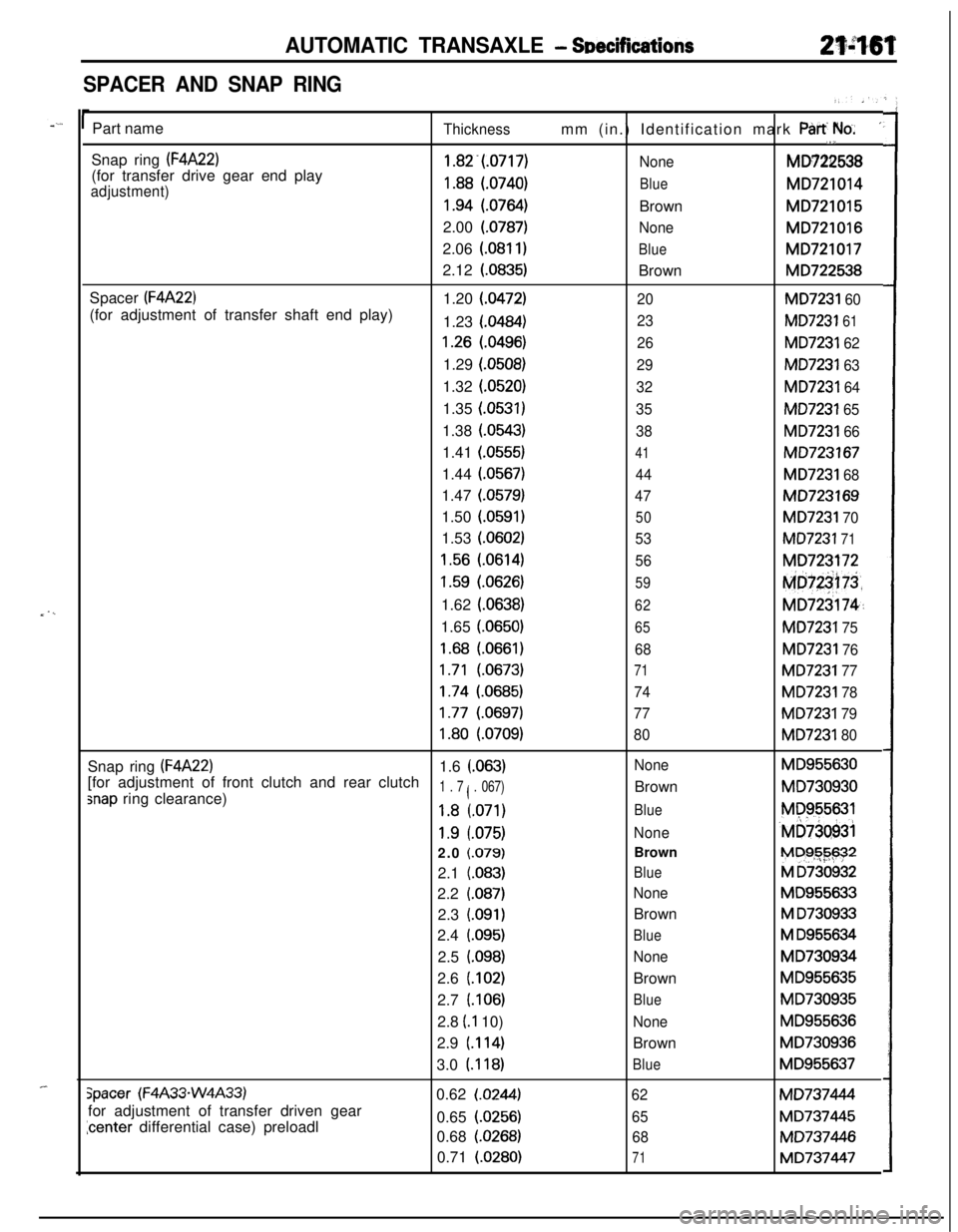

SPACER AND SNAP RING

_ . ,_

_-Part name

Thicknessmm (in.) Identification mark Part We.’,1,Snap ring

(F4A22)1.82.(.0717)

NoneMD722538

(for transfer drive gear end play

adjustment)1.88 (.0740)BlueMD721014

1.94 (.0764)BrownMD721015

2.00 (0787)

NoneMD721016

2.06

(.081 I)BlueMD7210172.12

(.0835)BrownMD722538

Spacer

(F4A22)1.20 (0472)20MD7231 60(for adjustment of transfer shaft end play)

1.23 (0484)

23MD7231 61

1.26 (.0496)26MD7231 621.29 (0508)

29MD7231 631.32 (0520)

32MD7231 641.35 (0531)

35MD7231 651.38 (0543)

38MD7231 661.41 (0555)

41MD7231671.44

(.0567)44MD7231 681.47

(.0579)47MD723169

1.50

(.0591)

50MD7231 701.53 (0602)

53MD7231 71

1.56 (.0614)56MD723172

1.59 (0626)59Md@75,1.62

(.0638)

62MD723174~:1.65 (0650)

65MD7231 75

1.68 (.0661)68MD7231 76

1.71 (.0673)71MD7231 77

1.74 (.0685)74MD7231 78

1.77 (.0697)77MD7231 79

1.80 (.0709)80MD7231 80Snap ring

(F4A22)1.6 (.063)NoneMD955630[for adjustment of front clutch and rear clutch

snap ring clearance)1 . 7 ( . 067)BrownMD730930

1.8 (.071)BlueMP955631

1.9 l.075)None‘MD73Q93i2.0 f.079)BrownM~$G-$$?*

2.1

(.083)BlueM D7309322.2

(.087)NoneMD955633

2.3

(.091)BrownM D7309332.4

(.095)BlueM D9556342.5

i.098)NoneMD730934

2.6

(.102)BrownMD955635

2.7 (106)

BlueMD730935

2.8 (.I 10)

NoneMD9556362.9

(.114)BrownMD730936

3.0 (118)

BlueMD955637

Spacer (F4A33-W4A33)0.62 (.0244)62MD737444

for adjustment of transfer driven gear

icenter differential case) preloadl0.65 (0256)65MD7374450.68

(.0268)68MD737446

0.71 (0280)

71MD737447