engine MITSUBISHI ECLIPSE 1991 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 277 of 1216

,-

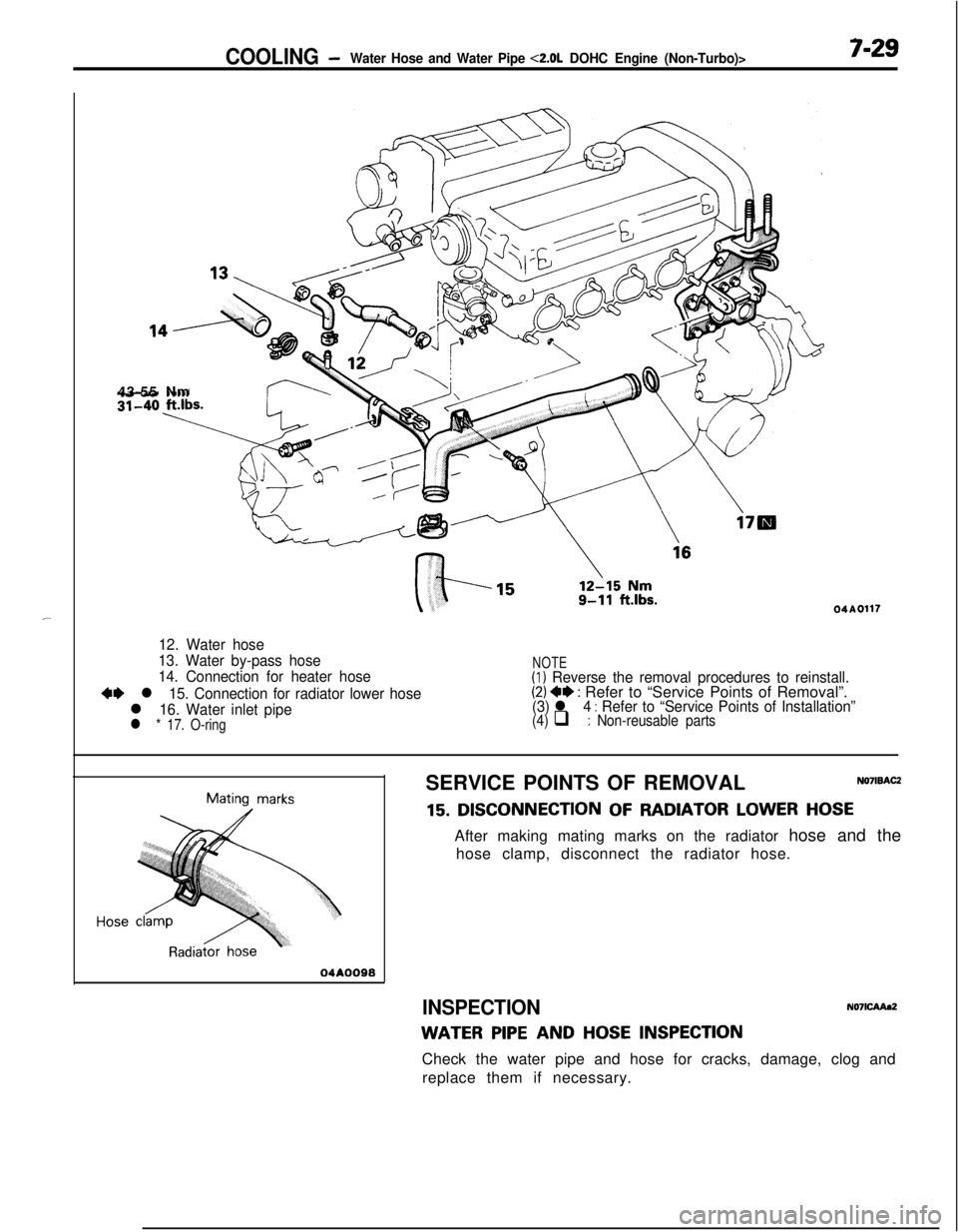

COOLING -Water Hose and Water Pipe <2.0L DOHC Engine (Non-Turbo)>7-2943-55 Nm

04A0117

12. Water hose

13. Water by-pass hose

14. Connection for heater hose

+I) l 15. Connection for radiator lower hose

l 16. Water inlet pipel * 17. O-ring

NOTE(1) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”(4) q : Non-reusable parts

Mating marks

04AOO98SERVICE POINTS OF REMOVAL

NO’IISACZ

15. DISCONNECTION OF RADIATOR LOWER HOSEAfter making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

INSPECTIONN071CAAa2

WATER PIPE AND HOSE INSPECTIONCheck the water pipe and hose for cracks, damage, clog and

replace them if necessary.

Page 278 of 1216

7-30COOLING - waterHose and Water Piue <2.0L DOHC Ermine (Non-Turbo)>

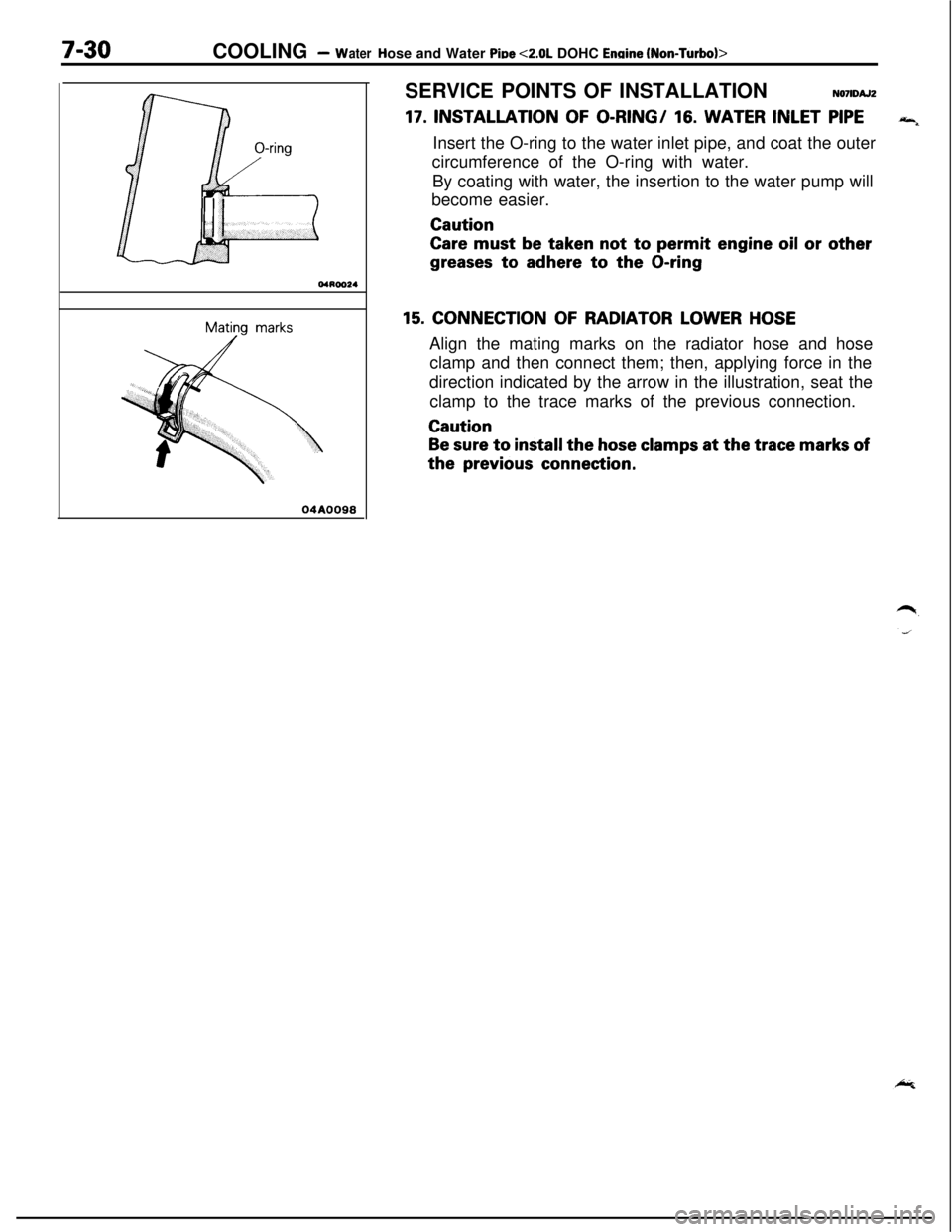

04ROO24

04AOO98SERVICE POINTS OF INSTALLATION

N071DAJZ

17. INSTALLATION OF O-RING/ 16. WATER INLET PIPE“4Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.Caution

Care must be taken not to permit engine oil or other

greases to adhere to the O-ring

15. CONNECTION OF RADIATOR LOWER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

Page 279 of 1216

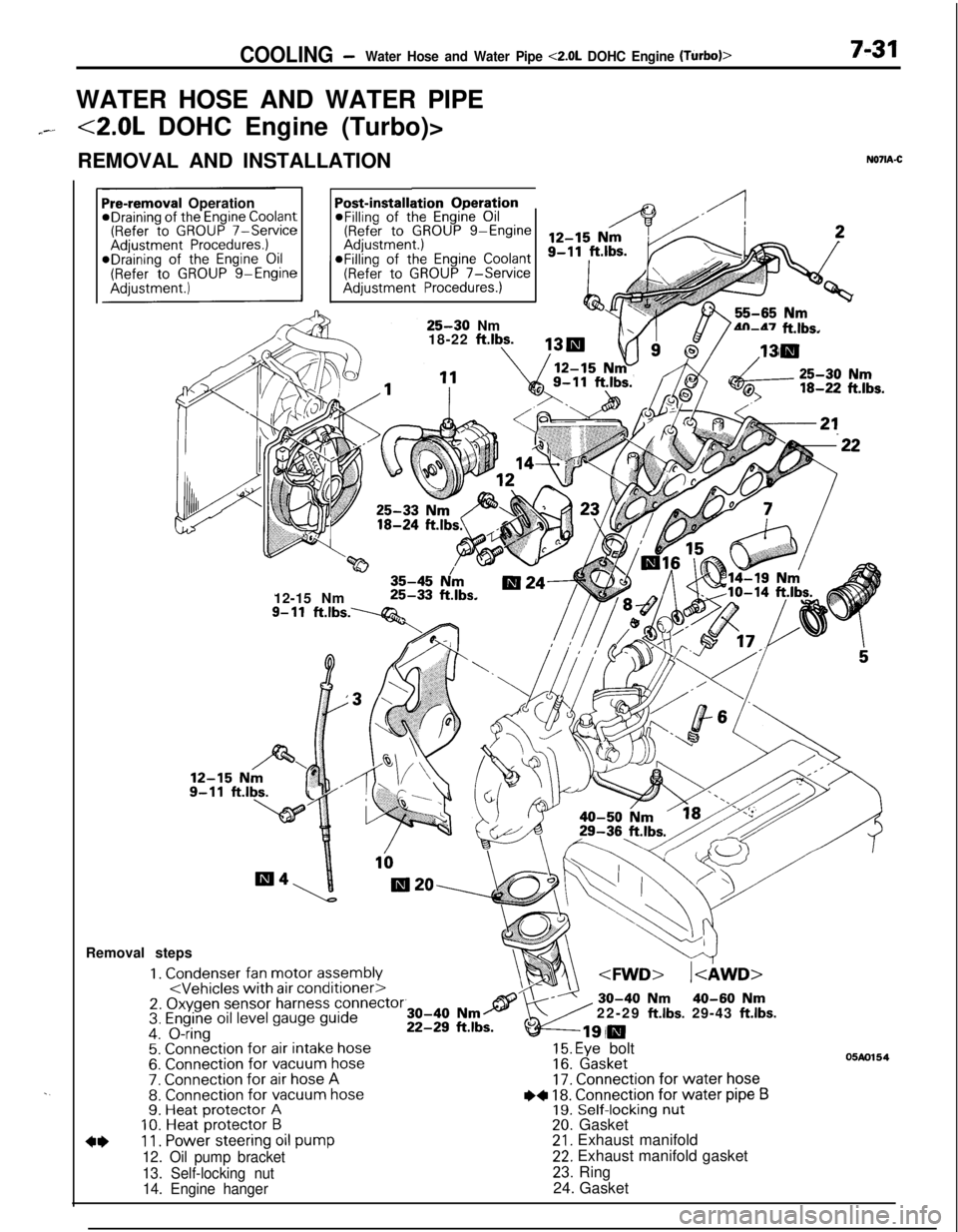

COOLING -Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>7-31WATER HOSE AND WATER PIPE

7--<2.0L DOHC Engine (Turbo)>

REMOVAL AND INSTALLATION

N071A-C

. .

ation OperationPost-installi@Filling of the Engine Oil(Refer to GROUP g-EngineaFilling of the

Engine Coolant(Refer to GROUP 7-ServiceAdjustment Procedures.)

Pre-removal OperationeDraining of the Engine Coolant(Refer to GROUP 7-ServiceAdjustment Procedures.)*Draining of the Engine Oil(Refer to GROUP g-Engine

25-30 Nm

18-22 ftlbs.4n-47 ft.lbs.

w35-45 N/m12-15 Nm25-33 ft.lbs.

9- 11ft.lbs.----Q&Removal steps

1. Condenser fan motor assembly

4*11. Power steering oil pump

12. Oil pump bracket

13. Self-locking nut

14. Engine hanger22-29

ft.lbs. 29-43 ft.lbs.

15. Eye bolt16. Gasket17. Connection for water hose

I)+ 18. Connection for water pipe B19. Self-locking nut20. Gasket21. Exhaust manifold22. Exhaust manifold gasket

23. Ring

24. Gasket

05m154

Page 280 of 1216

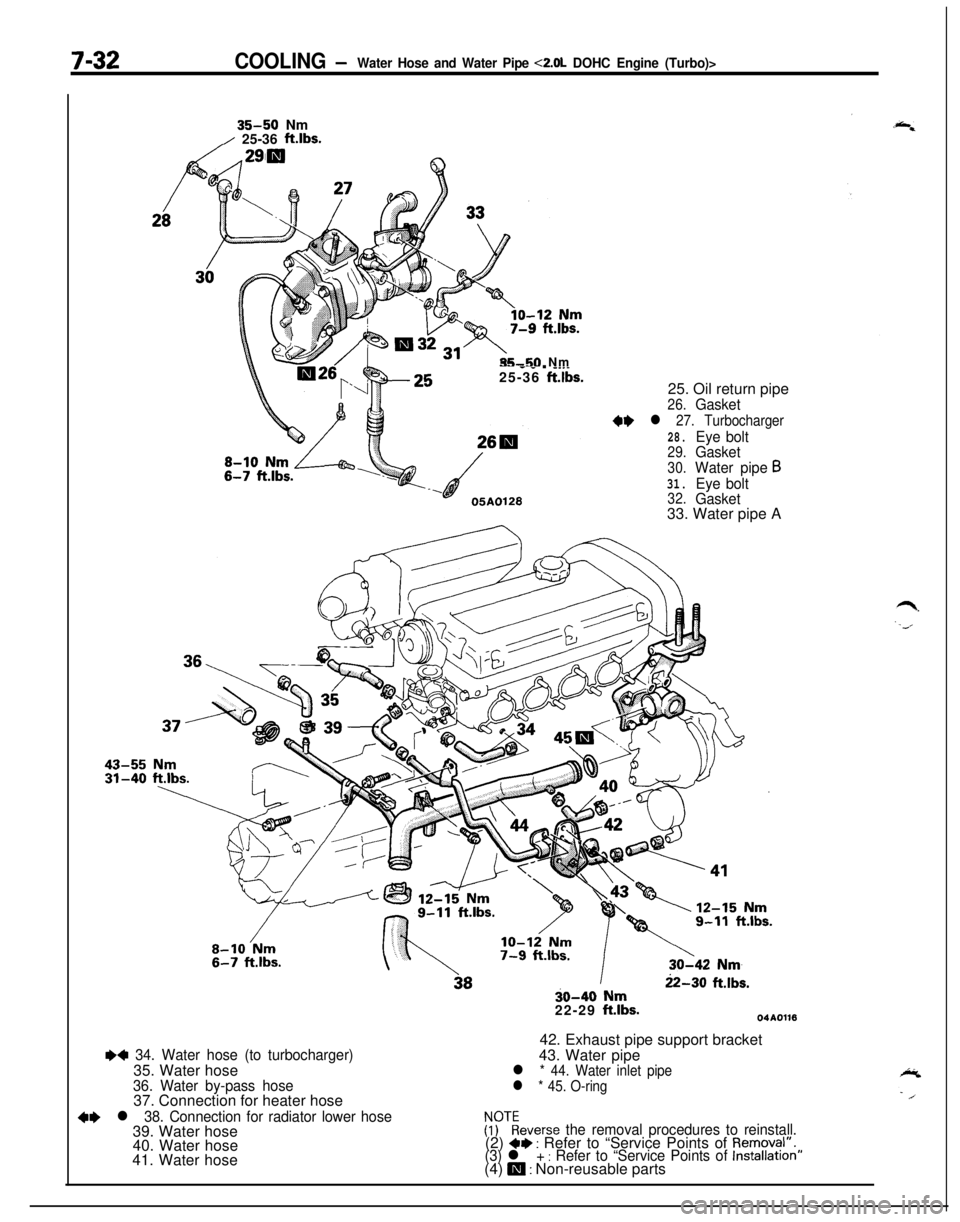

7-32COOLING -Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>

35-50 Nm/ 25-36 ft.lbs.

35-50 Nm-- - _ . __._25-36 ft.lbs.25. Oil return pipe

26.Gasket

++ l 27. Turbocharger

28.Eye bolt29.Gasket

30.Water pipe631.Eye bolt32.Gasket33. Water pipe A

++ 34. Water hose (to turbocharger)35. Water hose

36. Water by-pass hose37. Connection for heater hose

+e l 38. Connection for radiator lower hose39. Water hose

40. Water hose

41. Water hose

22-30 ft.lbs.30-40 Nm

22-29 ft.lbs.04A011642. Exhaust pipe support bracket

43. Water pipe

l * 44. Water inlet pipe

l * 45. O-ring

FFTkeverse the removal procedures to reinstall.(2) a+ : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”(4) m : Non-reusable parts

Page 281 of 1216

COOLING- Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>7-330140552

Mating marks

04A0090

rMating marks

04A0090

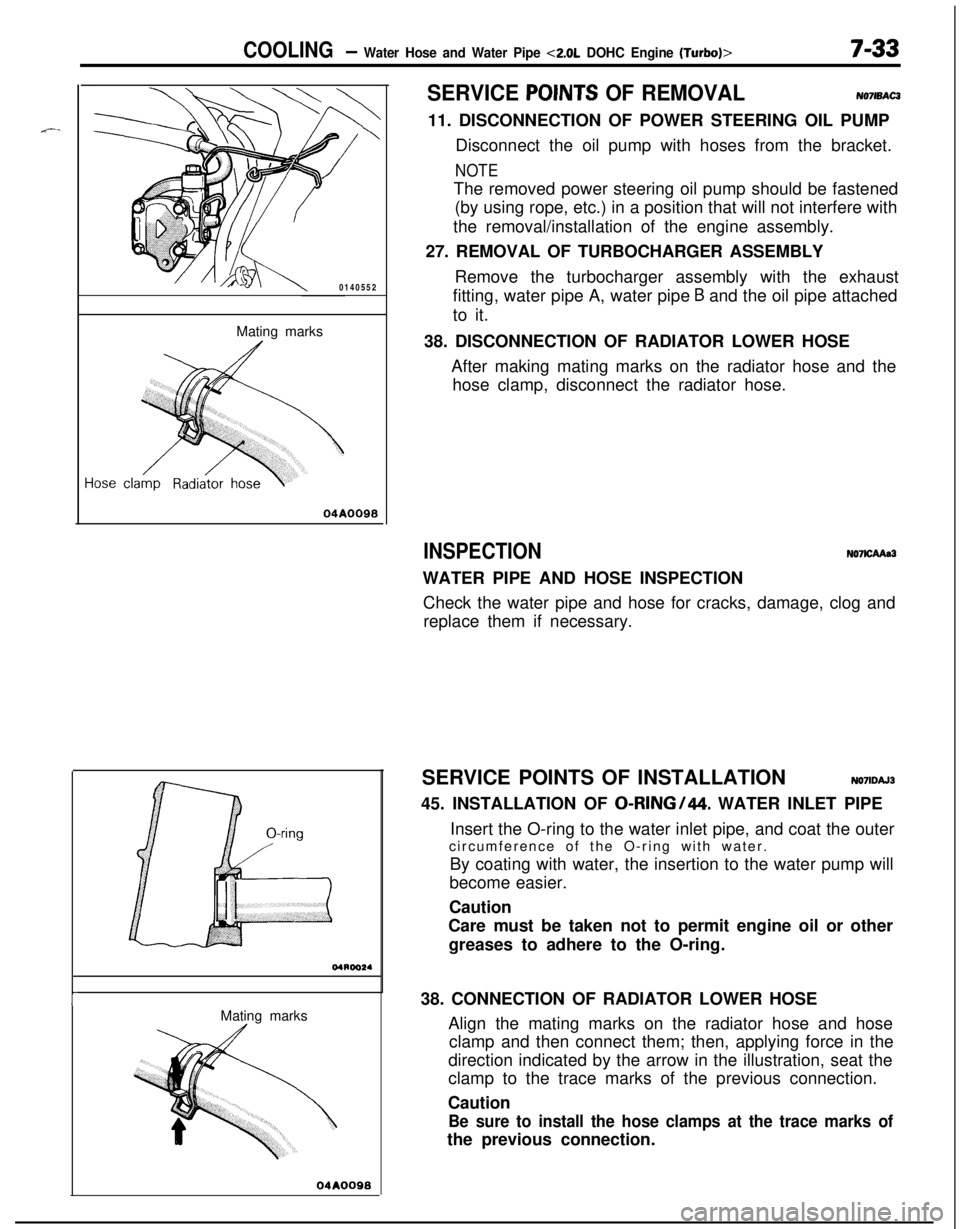

SERVICE POINTS OF REMOVALNO7lBAC311. DISCONNECTION OF POWER STEERING OIL PUMP

Disconnect the oil pump with hoses from the bracket.

NOTEThe removed power steering oil pump should be fastened

(by using rope, etc.) in a position that will not interfere with

the removal/installation of the engine assembly.

27. REMOVAL OF TURBOCHARGER ASSEMBLY

Remove the turbocharger assembly with the exhaust

fitting, water pipe A, water pipe

B and the oil pipe attached

to it.

38. DISCONNECTION OF RADIATOR LOWER HOSE

After making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

INSPECTIONN07lCAAa3WATER PIPE AND HOSE INSPECTION

Check the water pipe and hose for cracks, damage, clog and

replace them if necessary.

SERVICE POINTS OF INSTALLATION

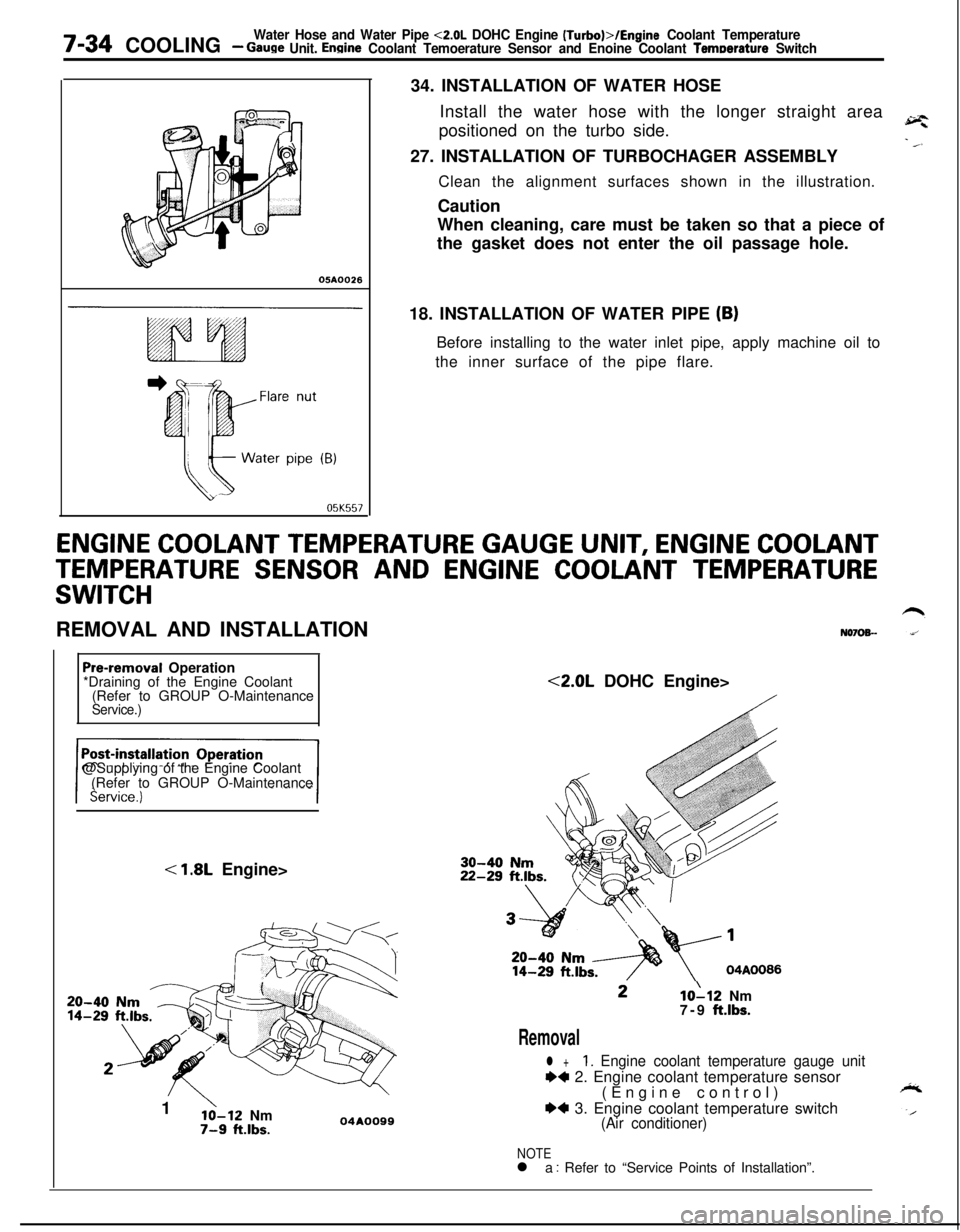

N071DAJ345. INSTALLATION OF

0-RING/44. WATER INLET PIPE

Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.

Caution

Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

38. CONNECTION OF RADIATOR LOWER HOSE

Align the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks ofthe previous connection.

Page 282 of 1216

7-34 COOLINGWater Hose and Water Pipe <2.0L DOHC Engine (Turbo)>/Engine Coolant Temperature- Gauge Unit. Engine Coolant Temoerature Sensor and Enoine Coolant Temoerature Switch

05A0026

05K55734. INSTALLATION OF WATER HOSE

Install the water hose with the longer straight area

positioned on the turbo side.

27. INSTALLATION OF TURBOCHAGER ASSEMBLY

Clean the alignment surfaces shown in the illustration.

Caution

When cleaning, care must be taken so that a piece of

the gasket does not enter the oil passage hole.

18. INSTALLATION OF WATER PIPE

(B)Before installing to the water inlet pipe, apply machine oil to

the inner surface of the pipe flare.

ENGINE COOLANT TEMPERATURE GAUGE UNIT, ENGINE COOLANT

TEMPERATURE SENSOR AND ENGINE COOLANT TEMPERATURE

SWITCHREMOVAL AND INSTALLATION

N070%-

Pre-removal Operation

*Draining of the Engine Coolant

(Refer to GROUP O-Maintenance

Service.)@Supplying of the Engine Coolant

(Refer to GROUP O-Maintenance

< 1.8L Engine>

20-4014-291

’lo-12 Nm7-9 ft.lbs.04AOO99<2.0L DOHC Engine>10112 Nm

7-9 ft.lbs.

Removal

l +1. Engine coolant temperature gauge unit

++ 2. Engine coolant temperature sensor

(Engine control)

*4 3. Engine coolant temperature switch(Air conditioner)

NOTEl a : Refer to “Service Points of Installation”.

Page 283 of 1216

COOLINGEngine Coolant Temperature Gauge Unit, Engine Coolant- TemDerature Sensor and Enaine Coolant Temperature Switch7-35

.---

Sensor04GO033

0400032

1c0010

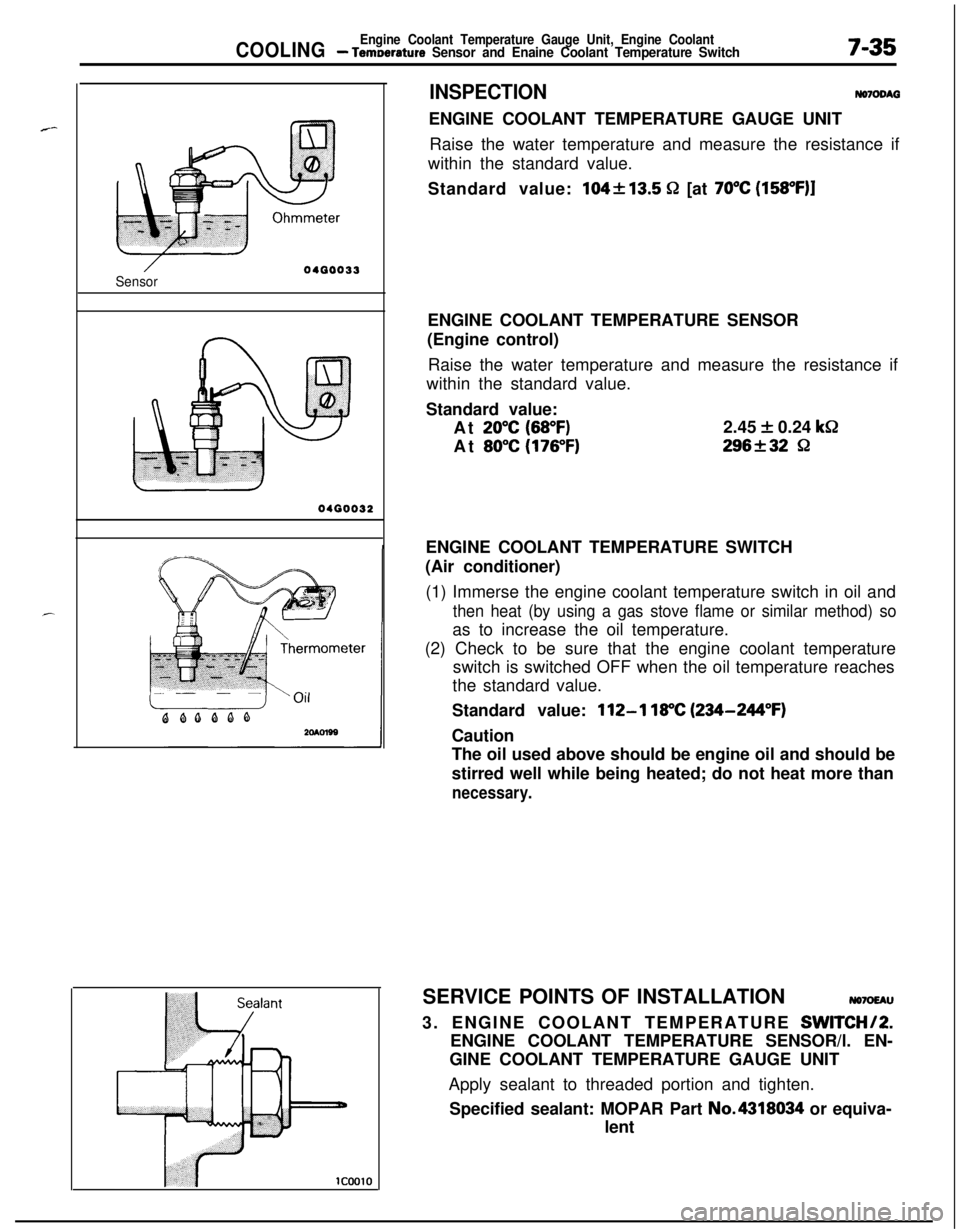

INSPECTIONNomDM3ENGINE COOLANT TEMPERATURE GAUGE UNIT

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

104213.5 52 [at 70°C (158OF)lENGINE COOLANT TEMPERATURE SENSOR

(Engine control)

Raise the water temperature and measure the resistance if

within the standard value.

Standard value:

At

20°C (68°F)2.45 + 0.24 k&

At

80°C (176°F)296f32 8ENGINE COOLANT TEMPERATURE SWITCH

(Air conditioner)

(1) Immerse the engine coolant temperature switch in oil and

then heat (by using a gas stove flame or similar method) soas to increase the oil temperature.

(2) Check to be sure that the engine coolant temperature

switch is switched OFF when the oil temperature reaches

the standard value.

Standard value:

112-l 18°C (234-244°F)Caution

The oil used above should be engine oil and should be

stirred well while being heated; do not heat more than

necessary.SERVICE POINTS OF INSTALLATION

NO7OEAU3. ENGINE COOLANT TEMPERATURE

SWITCHI2.ENGINE COOLANT TEMPERATURE SENSOR/l. EN-

GINE COOLANT TEMPERATURE GAUGE UNIT

Apply sealant to threaded portion and tighten.

Specified sealant: MOPAR Part No.4318034 or equiva-

lent

Page 285 of 1216

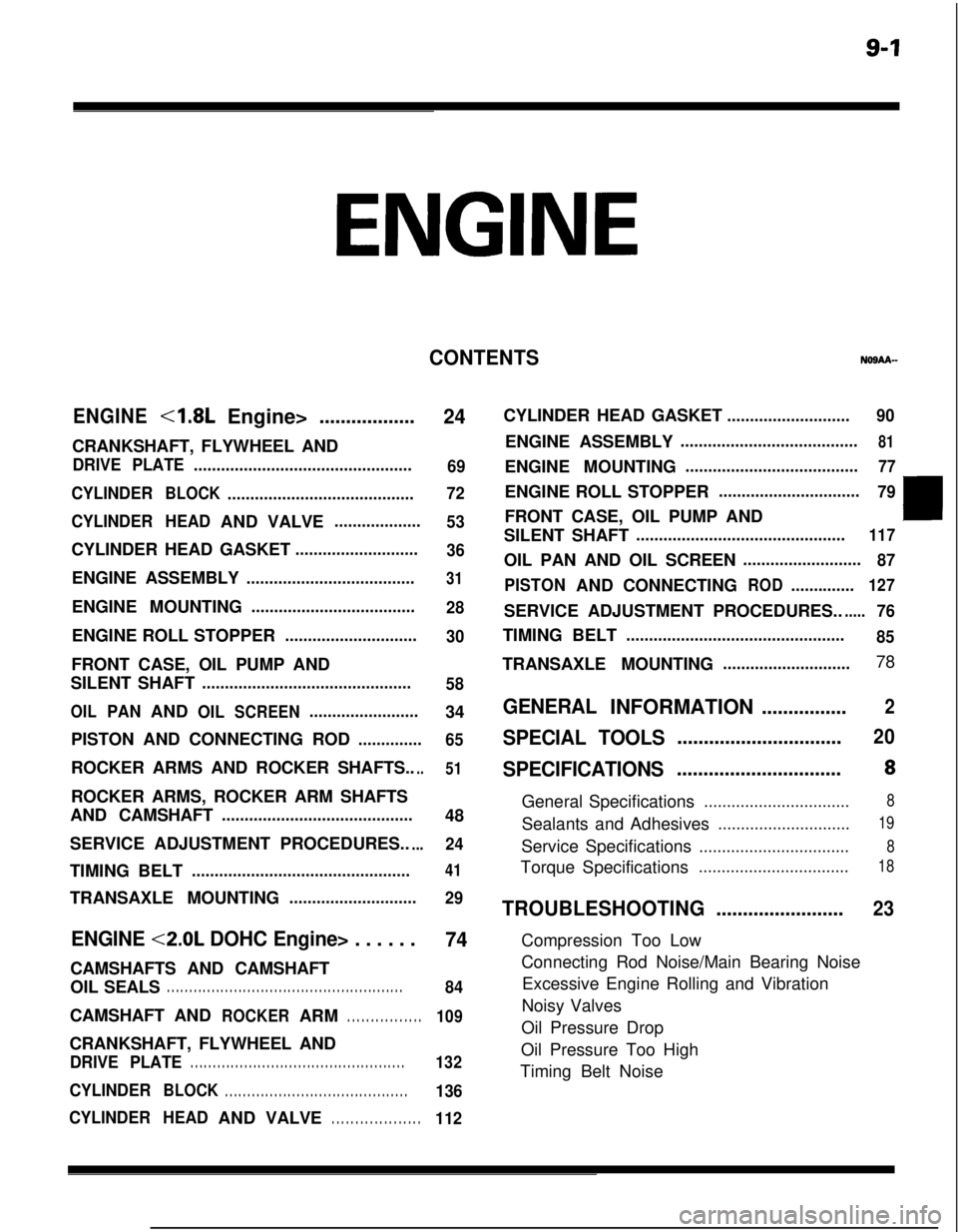

9-1

ENGINE

CONTENTSNOSAA-

ENGINE<1.8L

Engine>..................

24CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE................................................

69

CYLINDER

BLOCK.........................................72

CYLINDERHEADANDVALVE

...................

53CYLINDER HEAD GASKET

...........................

36ENGINE ASSEMBLY

.....................................31ENGINE MOUNTING

....................................

28ENGINE ROLL STOPPER

.............................

30FRONT CASE, OIL PUMP AND

SILENT SHAFT

..............................................

58

OILPANANDOILSCREEN........................34

PISTON AND CONNECTING ROD

..............

65ROCKER ARMS AND ROCKER SHAFTS..

..51ROCKER ARMS, ROCKER ARM SHAFTS

AND CAMSHAFT

..........................................48

SERVICE ADJUSTMENT PROCEDURES..

...24TIMING BELT

................................................41TRANSAXLE MOUNTING

............................

29

ENGINE <2.0L DOHC Engine> . . . . . .

74CAMSHAFTS AND CAMSHAFT

OIL SEALS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84CAMSHAFTAND

ROCKERARM. . . . . . . . . . . . . . . .109CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

CYLINDERBLOCK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

CYLINDERHEADANDVALVE

. . . . . . . . . . . . . . . . . . .112CYLINDER HEAD GASKET

...........................90ENGINE ASSEMBLY

.......................................81ENGINE MOUNTING

......................................77ENGINE ROLL STOPPER

...............................

79FRONT CASE, OIL PUMP AND

SILENT SHAFT

..............................................117OIL PAN AND OIL SCREEN

..........................

87

PISTONANDCONNECTING

ROD..............127SERVICE ADJUSTMENT PROCEDURES..

.....76TIMING BELT

................................................

85TRANSAXLE MOUNTING

............................78

GENERALINFORMATION................2

SPECIAL TOOLS...............................20

SPECIFICATIONS...............................8General Specifications

................................8Sealants and Adhesives

.............................19Service Specifications

.................................8Torque Specifications

.................................18

TROUBLESHOOTING........................23Compression Too Low

Connecting Rod Noise/Main Bearing Noise

Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 286 of 1216

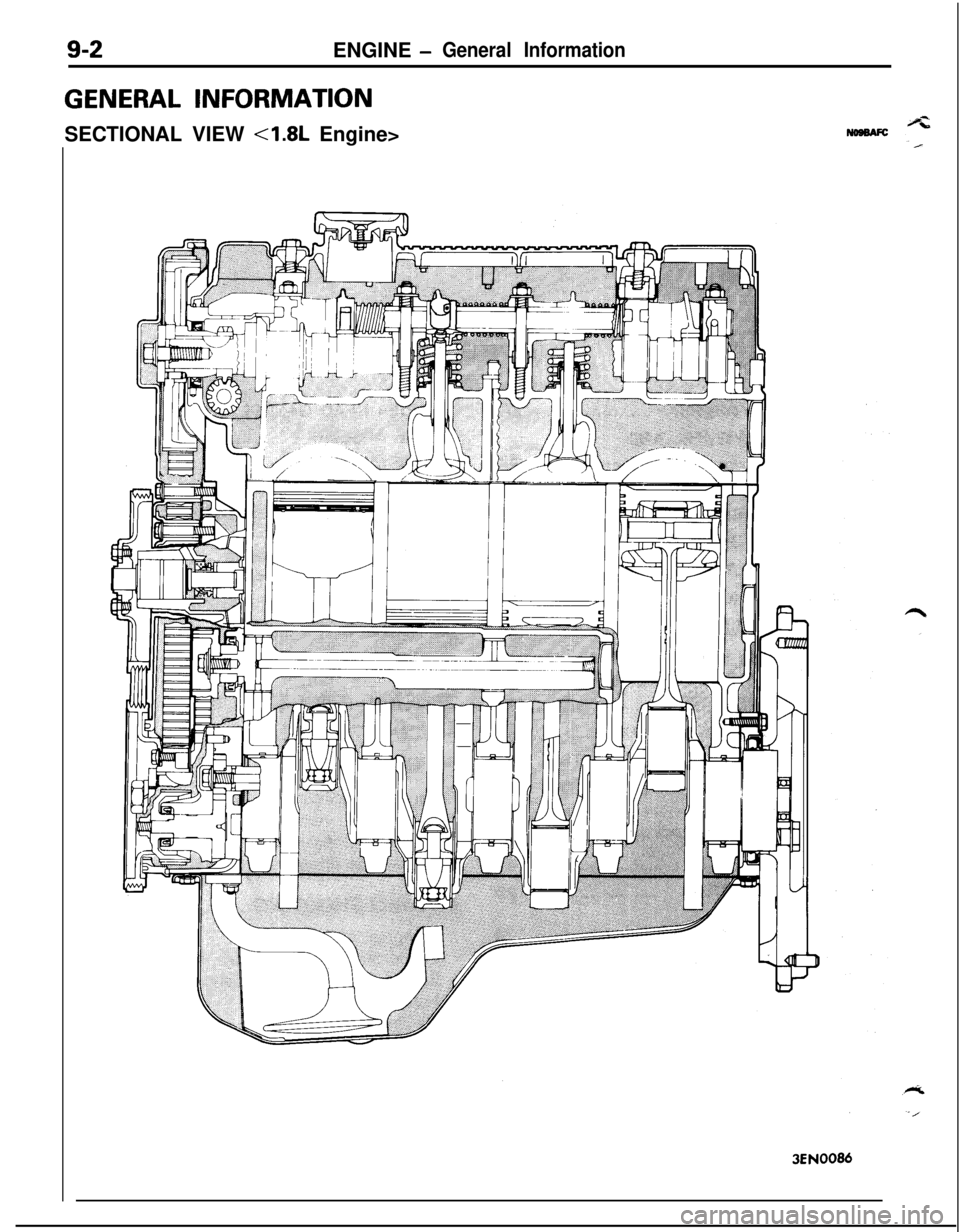

ENGINE -General Information

GENERAL INFORMATIONSECTIONAL VIEW <1.8L Engine>3EN0086

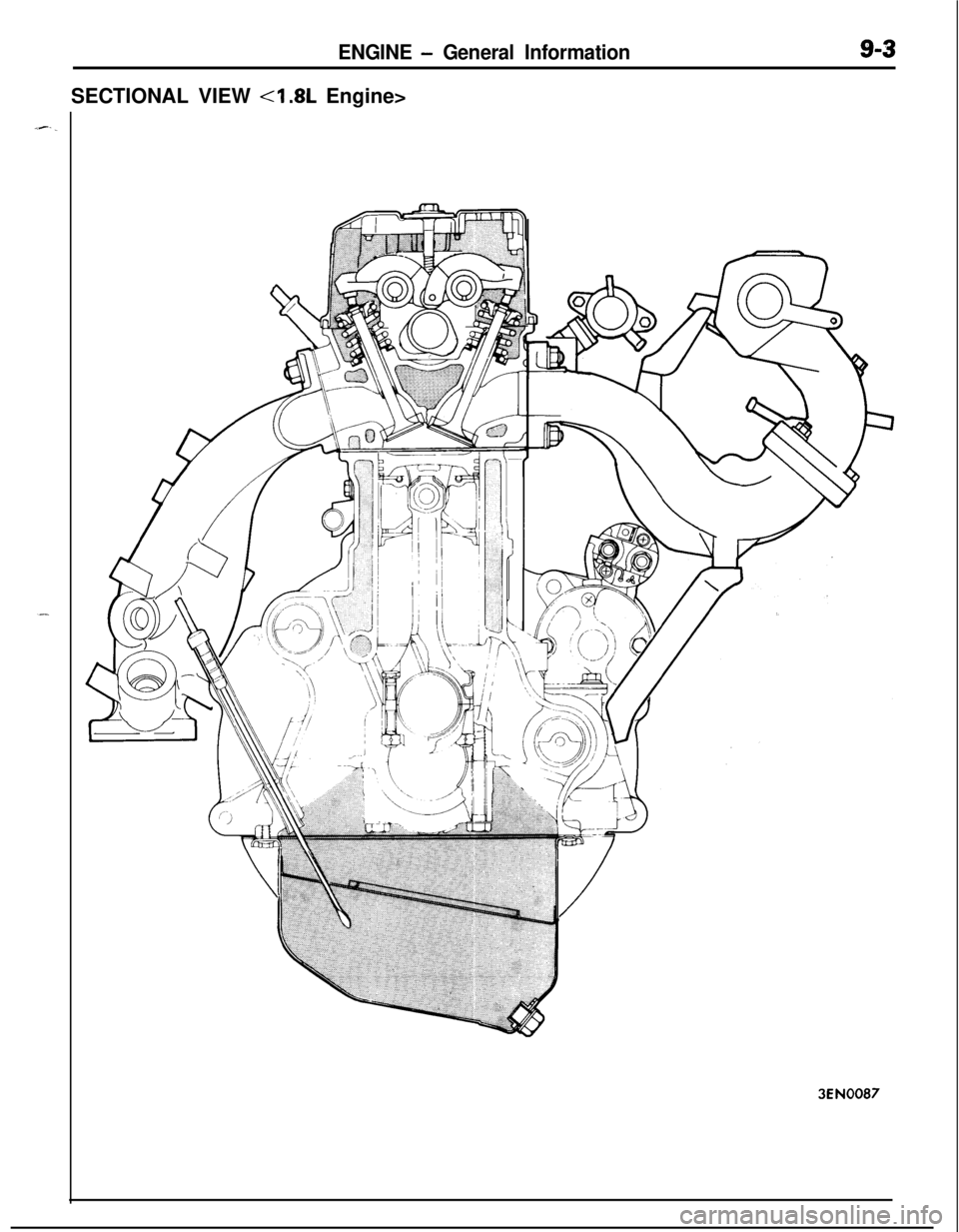

Page 287 of 1216

ENGINE - General InformationSECTIONAL VIEW

3EN0087