MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: maintenance schedule, manifold, ELECTRICAL DIAGRAM, warning, traction control, trunk, power steering

Page 1341 of 3870

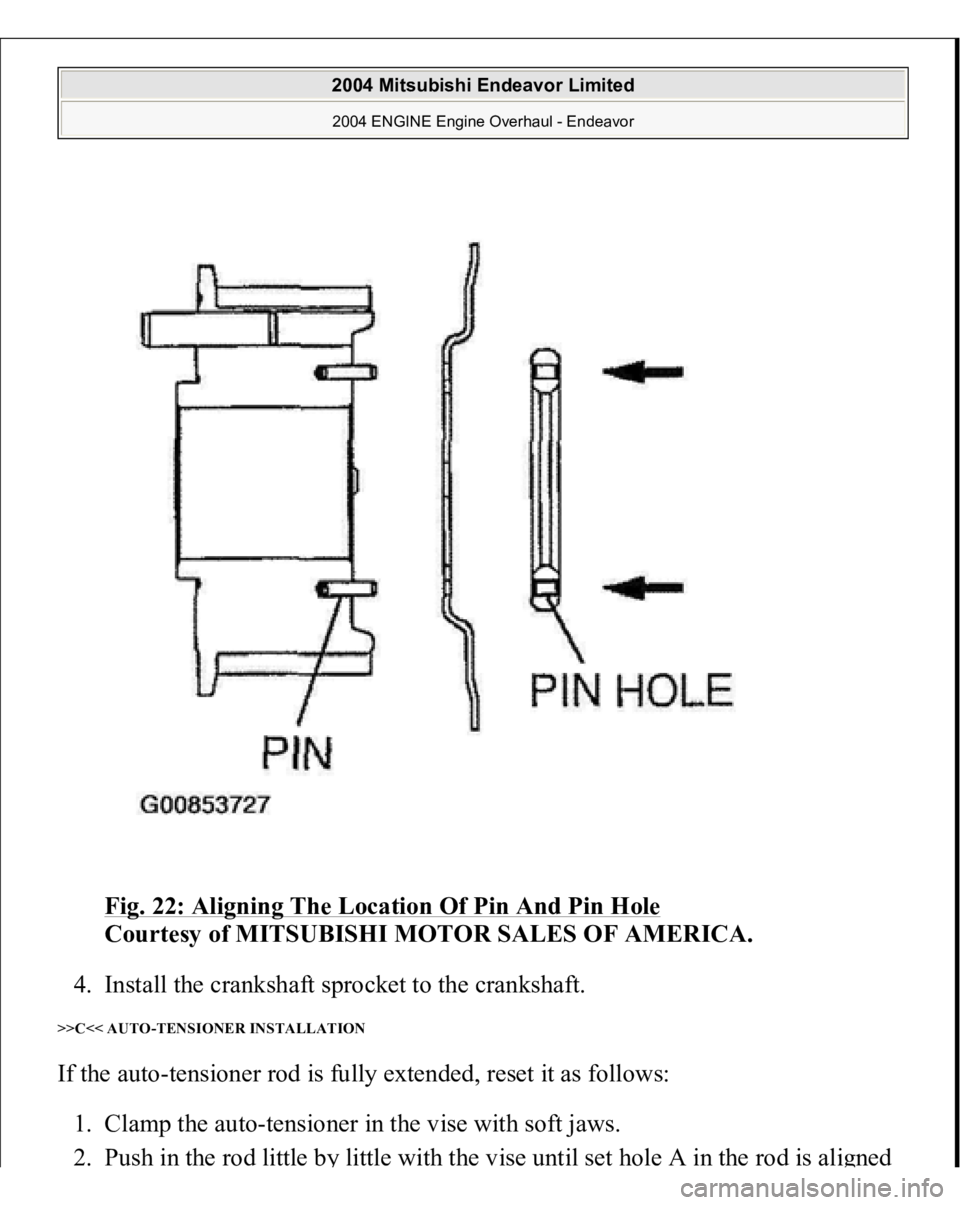

Fig. 22: Aligning The Location Of Pin And Pin Hole

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Install the crankshaft sprocket to the crankshaft.

>>C<< AUTO-TENSIONER INSTALLATION If the auto-tensioner rod is fully extended, reset it as follows:

1. Clamp the auto-tensioner in the vise with soft jaws.

2. Push in the rod little b

y little with the vise until set hole A in the rod is ali

gned

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1342 of 3870

with hole B in the cylinder.

Fig. 23: Installing Auto

-Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Insert a wire [1.4 mm (0.055 inch) in diameter] into the set holes. This auto-

tensioner setting wire will be used during timing belt alignment.

4. Unclamp the auto-tensioner from the vise.

>>D<< TIMING BELT INSTALLATION

CAUTION: Do not turn the camshaft when the piston in No. 1

cylinder is at top dead center on the compression

stroke. Doing so can cause the lifted valve to hit

against the piston, damaging parts.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1343 of 3870

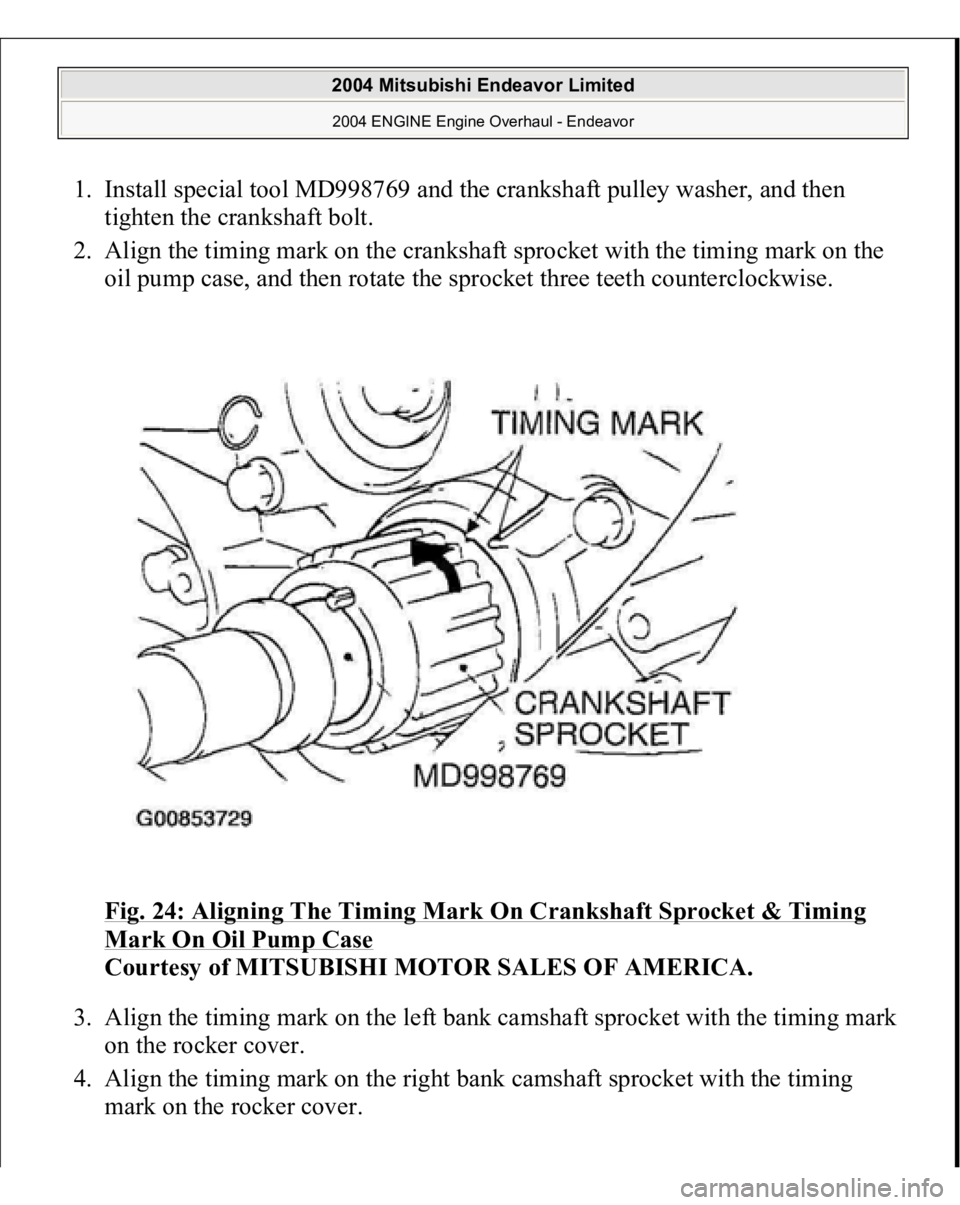

1. Install special tool MD998769 and the crankshaft pulley washer, and then

tighten the crankshaft bolt.

2. Align the timing mark on the crankshaft sprocket with the timing mark on the

oil pump case, and then rotate the sprocket three teeth counterclockwise.

Fig. 24: Aligning The Timing Mark On Crankshaft Sprocket & Timing

Mark On Oil Pump Case

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

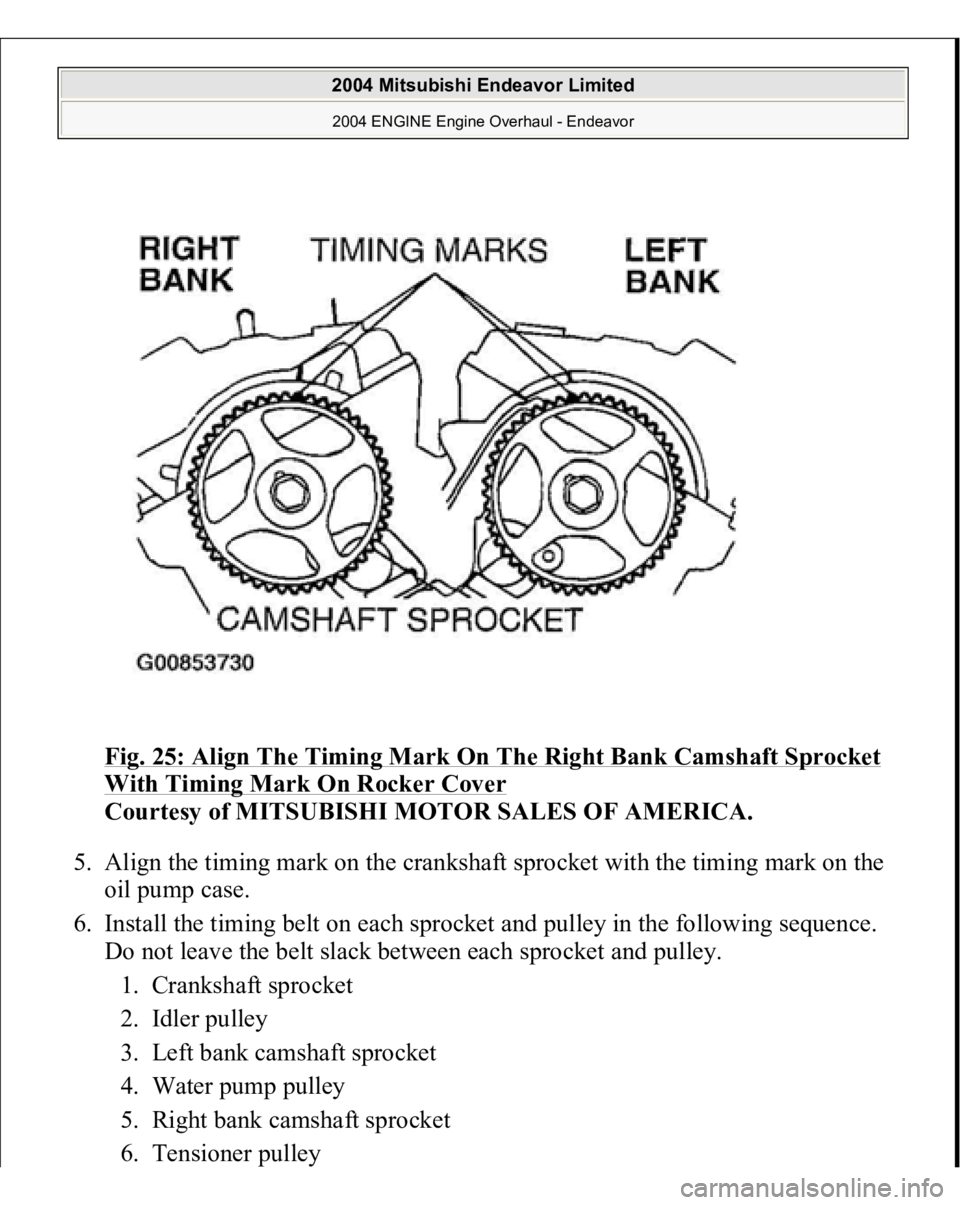

3. Align the timing mark on the left bank camshaft sprocket with the timing mark

on the rocker cover.

4. Align the timing mark on the right bank camshaft sprocket with the timing

mark on the rocker cover.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1344 of 3870

Fig. 25: Align The Timing Mark On The Right Bank Camshaft Sprocket With Timing Mark On Rocker Cover

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

5. Align the timing mark on the crankshaft sprocket with the timing mark on the

oil pump case.

6. Install the timing belt on each sprocket and pulley in the following sequence.

Do not leave the belt slack between each sprocket and pulley.

1. Crankshaft sprocket

2. Idler pulley

3. Left bank camshaft sprocket

4. Water pump pulley

5. Right bank camshaft sprocket

6. Tensioner

pulle

y

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1345 of 3870

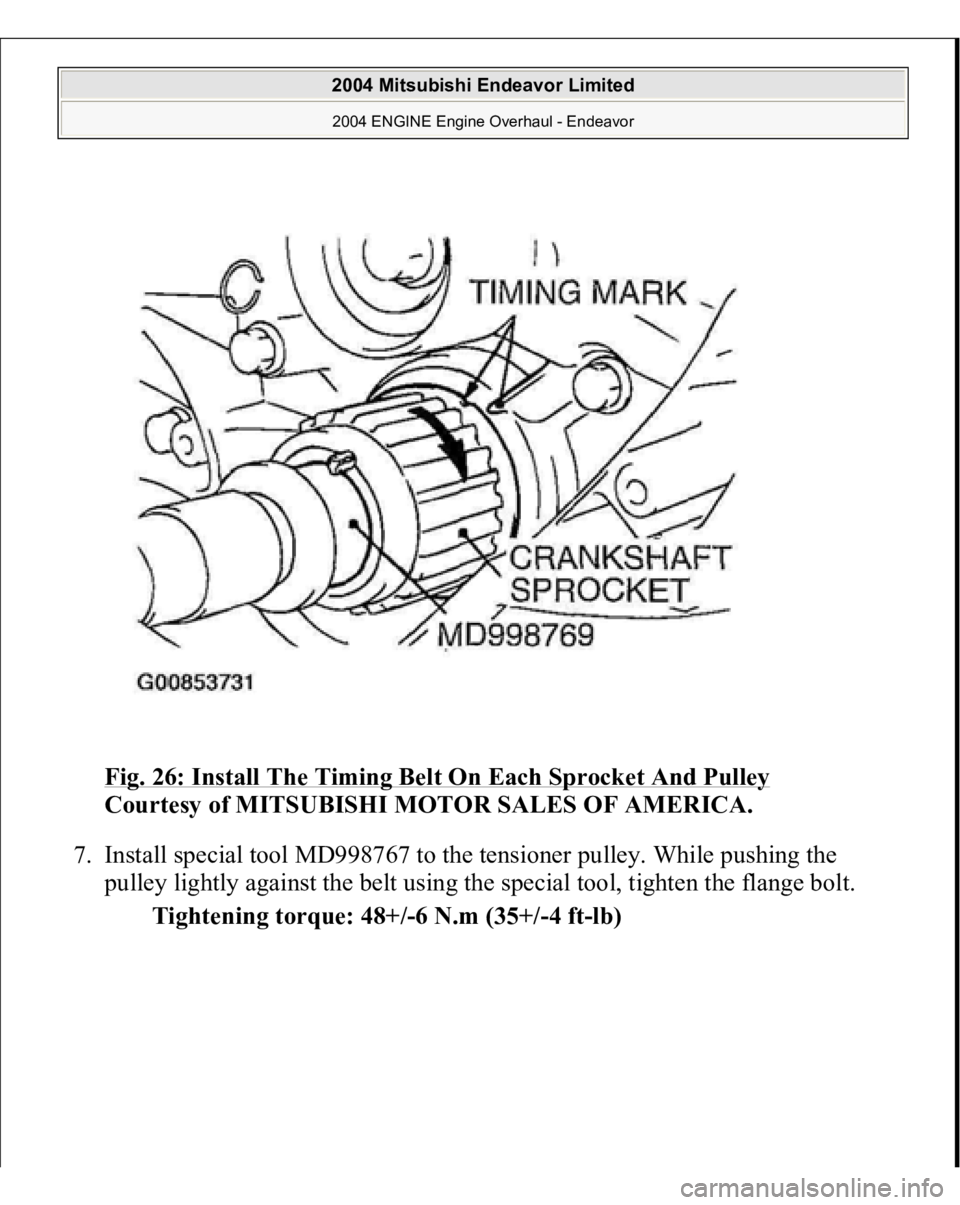

Fig. 26: Install The Timing Belt On Each Sprocket And Pulley

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

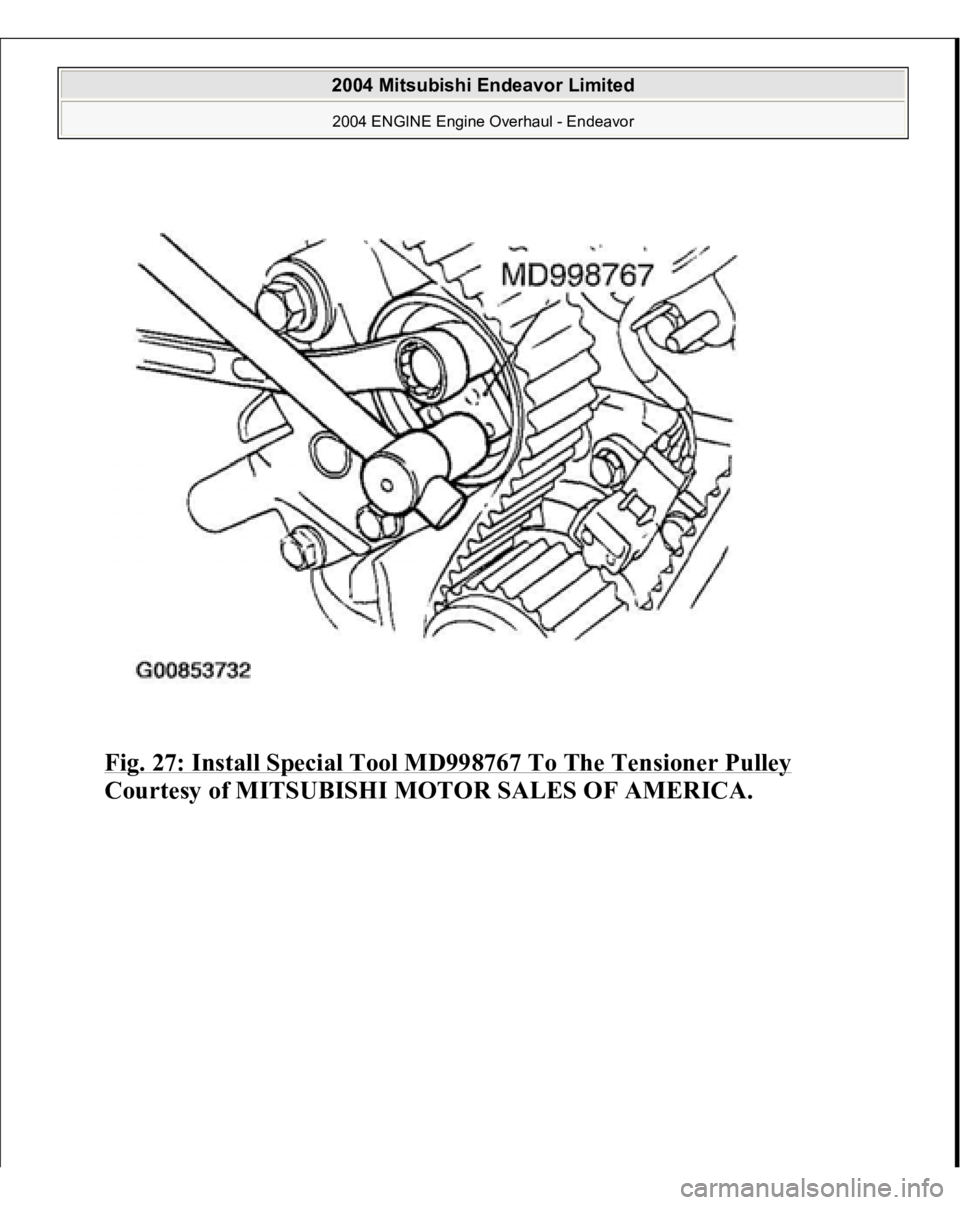

7. Install special tool MD998767 to the tensioner pulley. While pushing the

pulley lightly against the belt using the special tool, tighten the flange bolt.

Tightening torque: 48+/-6 N.m (35+/-4 ft-lb)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1346 of 3870

Fig. 27: Install Special Tool MD998767 To The Tensioner Pulley

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1347 of 3870

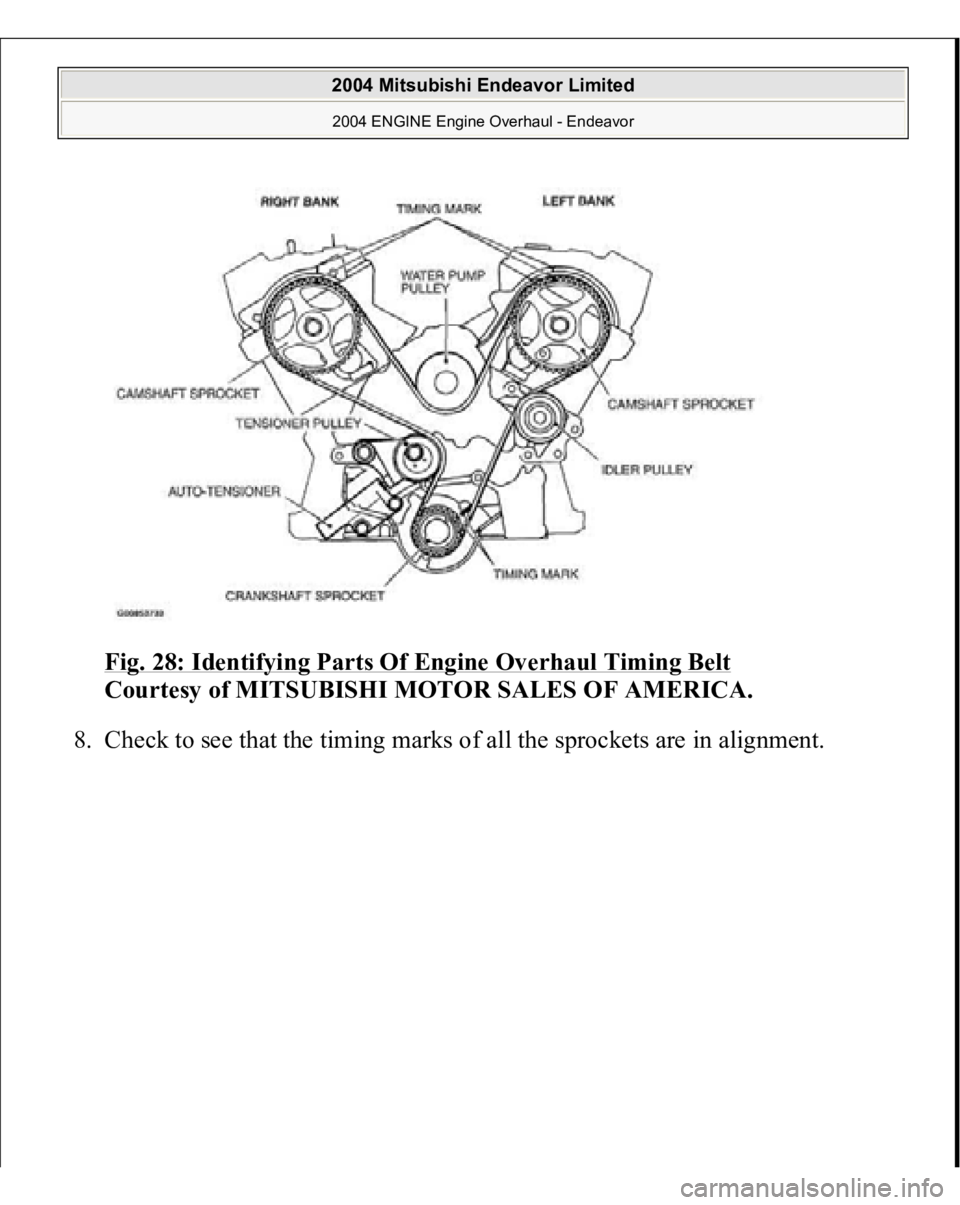

Fig. 28: Identifying Parts Of Engine Overhaul Timing Belt

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

8. Check to see that the timin

g marks of all the s

prockets are in ali

gnment.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1348 of 3870

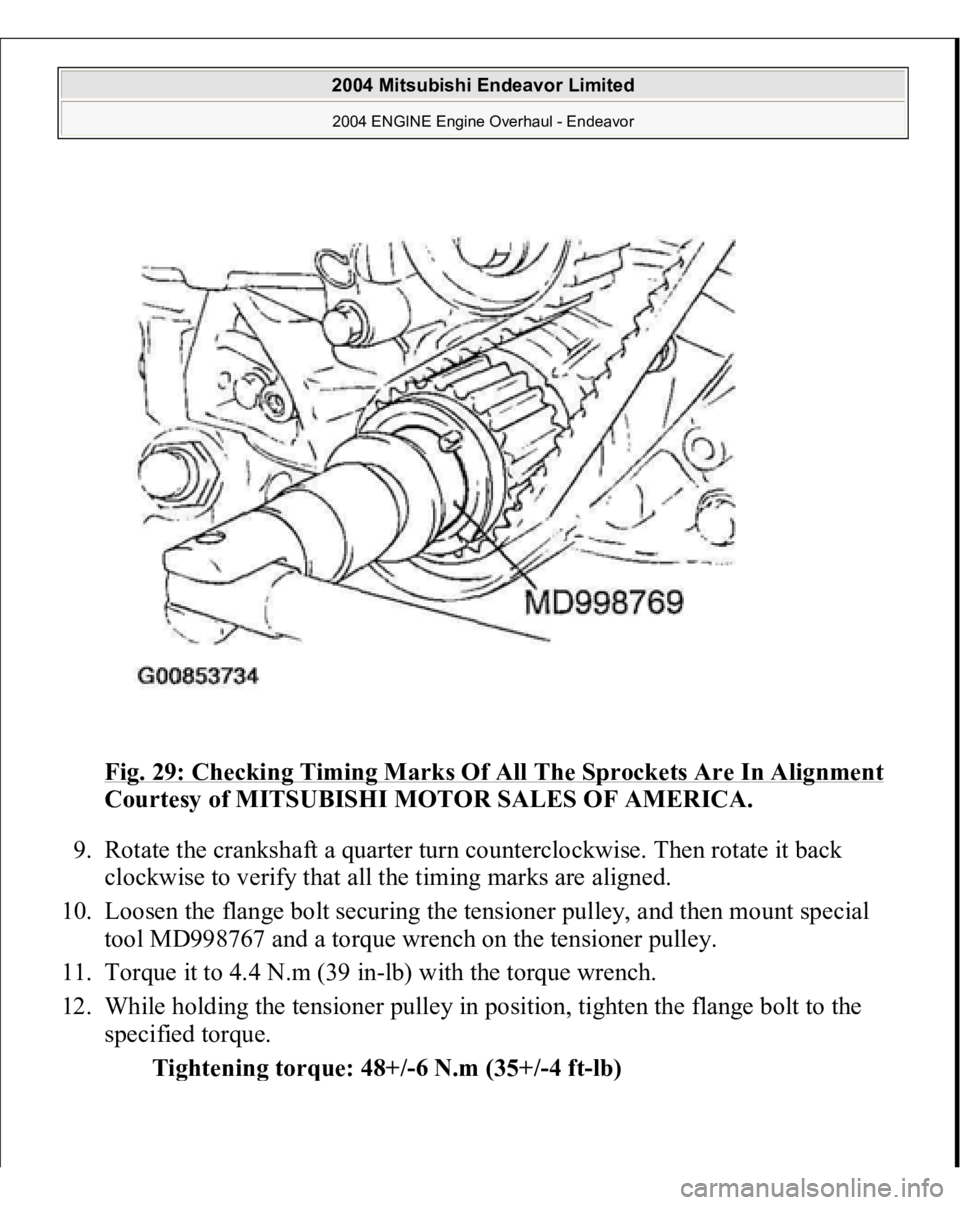

Fig. 29: Checking Timing Marks Of All The Sprockets Are In Alignment

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

9. Rotate the crankshaft a quarter turn counterclockwise. Then rotate it back

clockwise to verify that all the timing marks are aligned.

10. Loosen the flange bolt securing the tensioner pulley, and then mount special

tool MD998767 and a torque wrench on the tensioner pulley.

11. Torque it to 4.4 N.m (39 in-lb) with the torque wrench.

12. While holding the tensioner pulley in position, tighten the flange bolt to the

specified torque.

Ti

ghtenin

g tor

que: 48+

/-6 N.m (35+

/-4 f

t-lb)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1349 of 3870

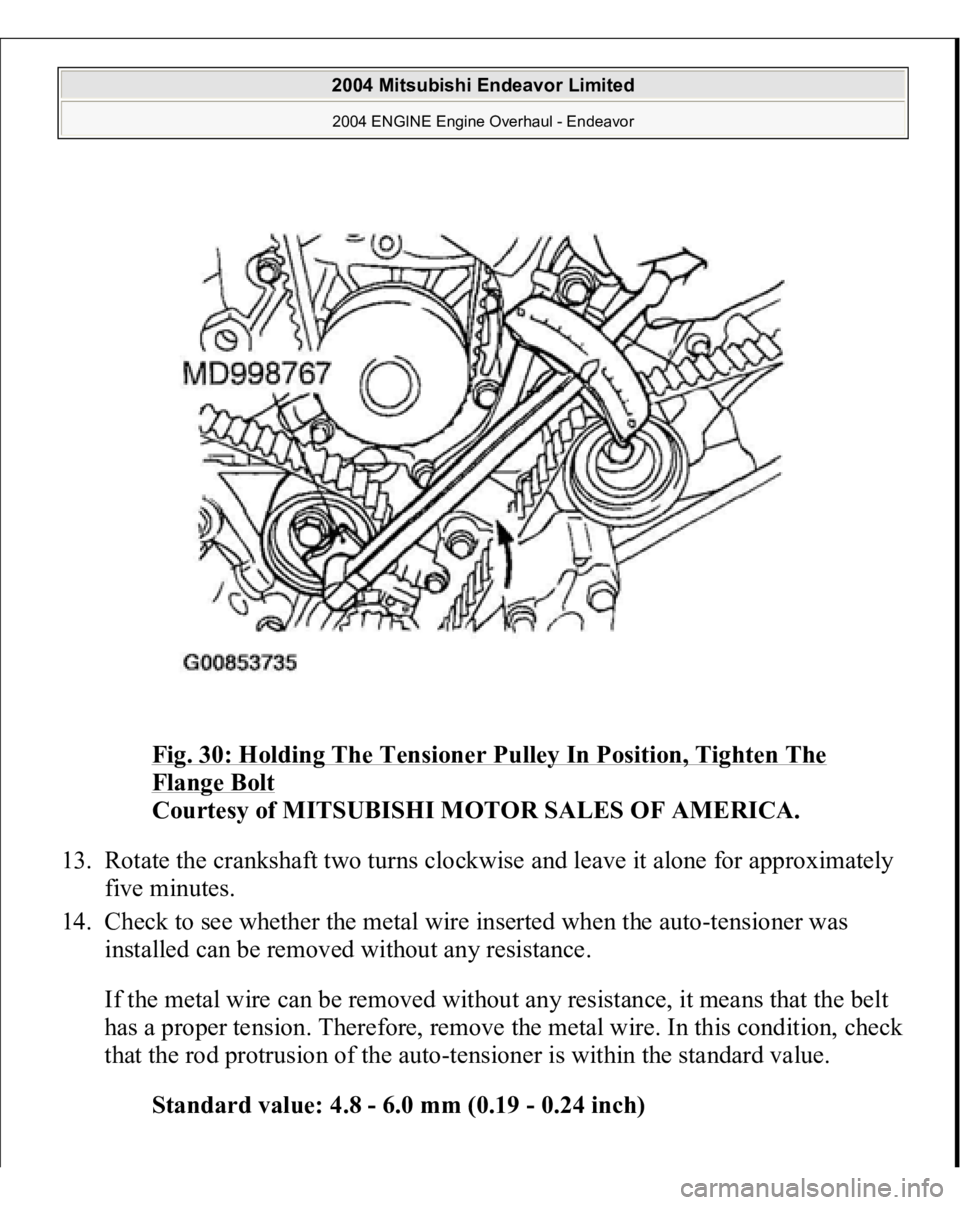

Fig. 30: Holding The Tensioner Pulley In Position, Tighten The Flange Bolt

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

13. Rotate the crankshaft two turns clockwise and leave it alone for approximately

five minutes.

14. Check to see whether the metal wire inserted when the auto-tensioner was

installed can be removed without any resistance.

If the metal wire can be removed without any resistance, it means that the belt

has a proper tension. Therefore, remove the metal wire. In this condition, check

that the rod protrusion of the auto-tensioner is within the standard value.

Standard value: 4.8 - 6.0 mm (0.19 - 0.24 inch)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1350 of 3870

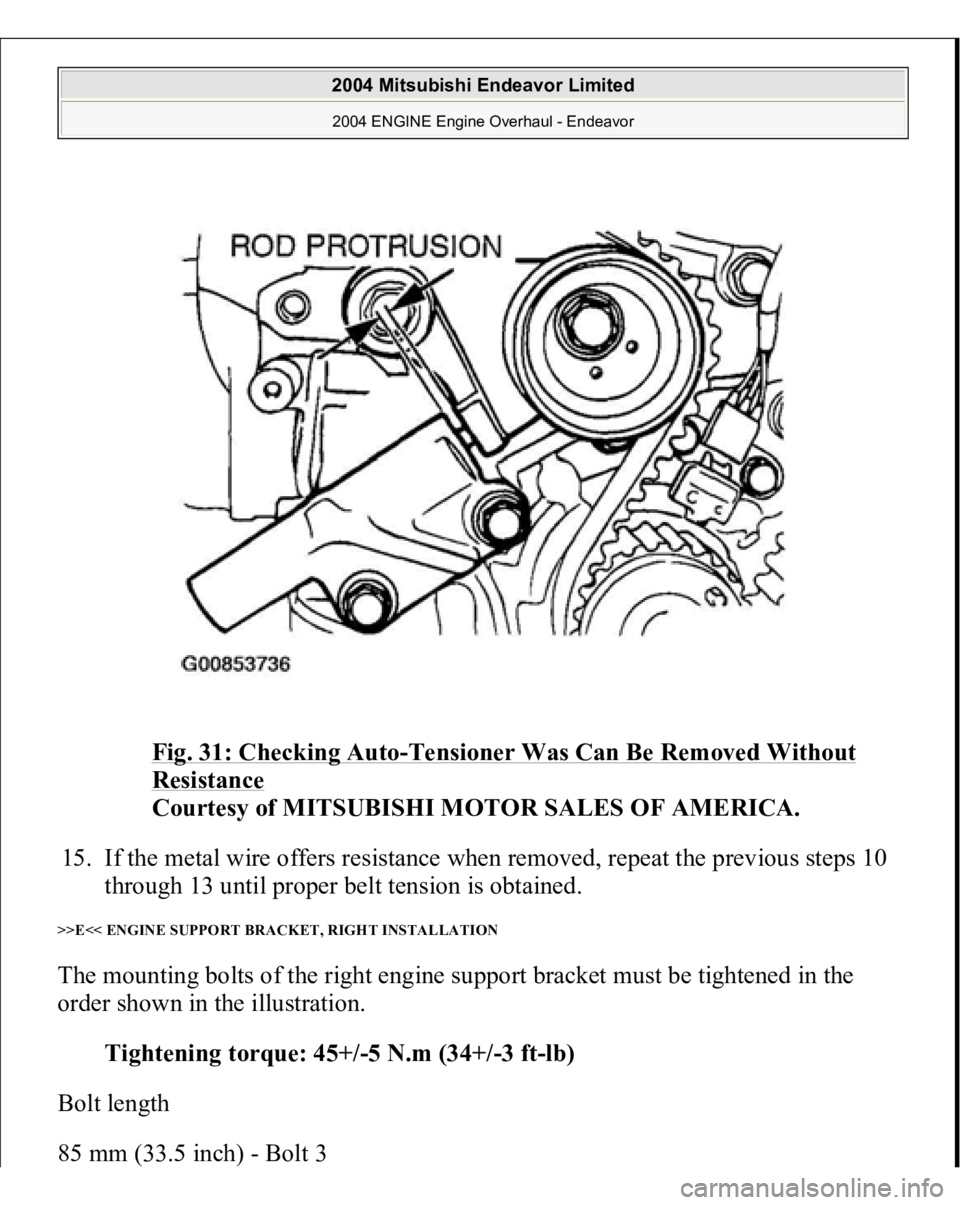

Fig. 31: Checking Auto

-Tensioner Was Can Be Removed Without

Resistance

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

15. If the metal wire offers resistance when removed, repeat the previous steps 10

through 13 until proper belt tension is obtained.

>>E<< ENGINE SUPPORT BRACKET, RIGHT INSTALLATION The mounting bolts of the right engine support bracket must be tightened in the

order shown in the illustration.

Tightening torque: 45+/-5 N.m (34+/-3 ft-lb)

Bolt length

85 mm

(33.5 inch

) - Bolt

3

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Trending: remote control, brake pads replacement, coolant temperature, headlight assembly, hood open, towing, weight

![MITSUBISHI ENDEAVOR 2004 Service Repair Manual with hole B in the cylinder.

Fig. 23: Installing Auto

-Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Insert a wire [1.4 mm (0.055 inch) in diameter] into the set holes. This auto-

t MITSUBISHI ENDEAVOR 2004 Service Repair Manual with hole B in the cylinder.

Fig. 23: Installing Auto

-Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Insert a wire [1.4 mm (0.055 inch) in diameter] into the set holes. This auto-

t](/img/19/57105/w960_57105-1341.png)