MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: relay, electrical, adding oil, seat memory, mirror, USB port, ESP

Page 2681 of 3870

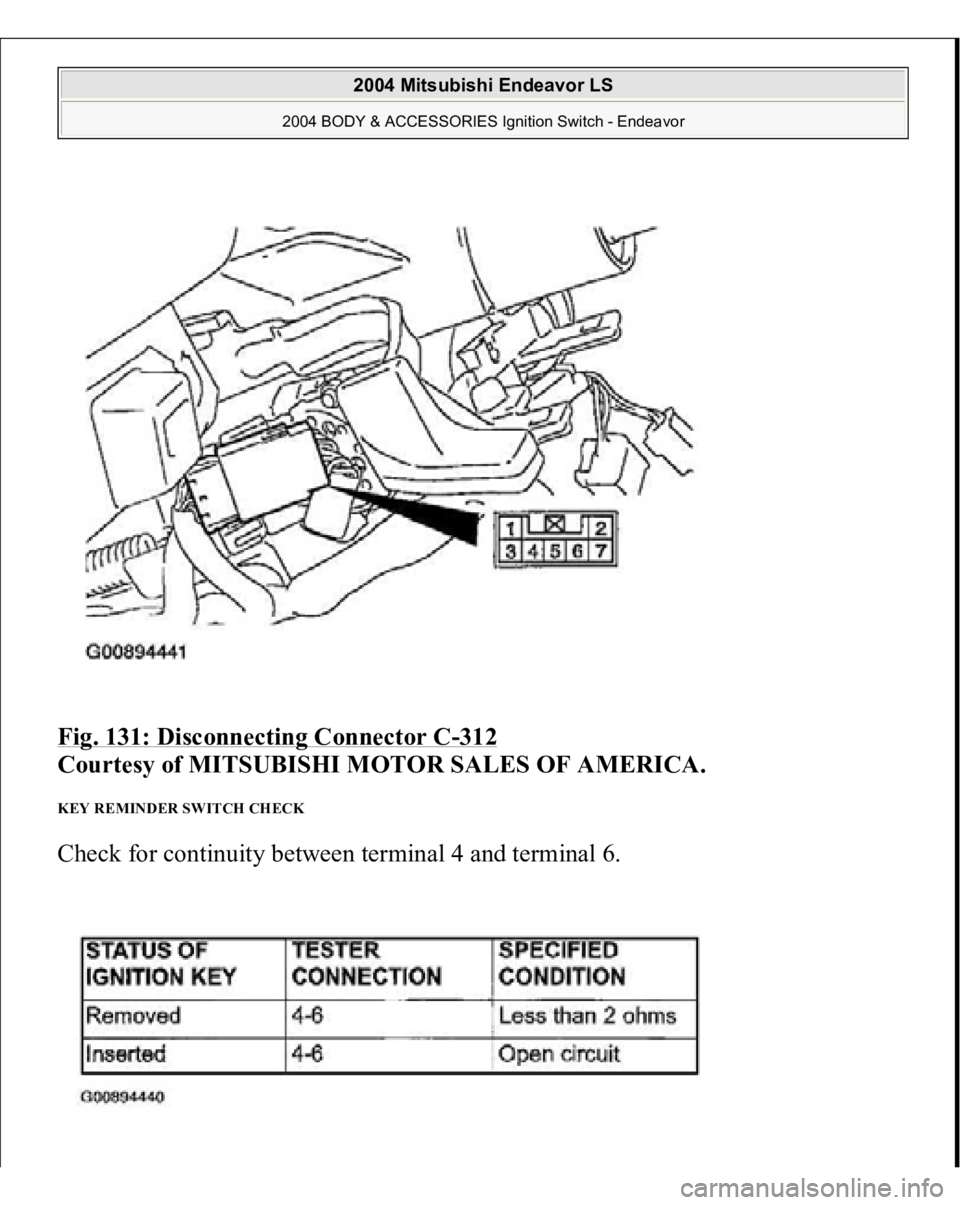

Fig. 131: Disconnecting Connector C

-312

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

KEY REMINDER SWITCH CHECK Check for continuity between terminal 4 and terminal 6.

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Ignition Switch - Endeavor

Page 2682 of 3870

Fig. 132: Checking Key Reminder Switch Continuit

y

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor LS

2004 BODY & ACCESSORIES Ignition Switch - Endeavor

Page 2683 of 3870

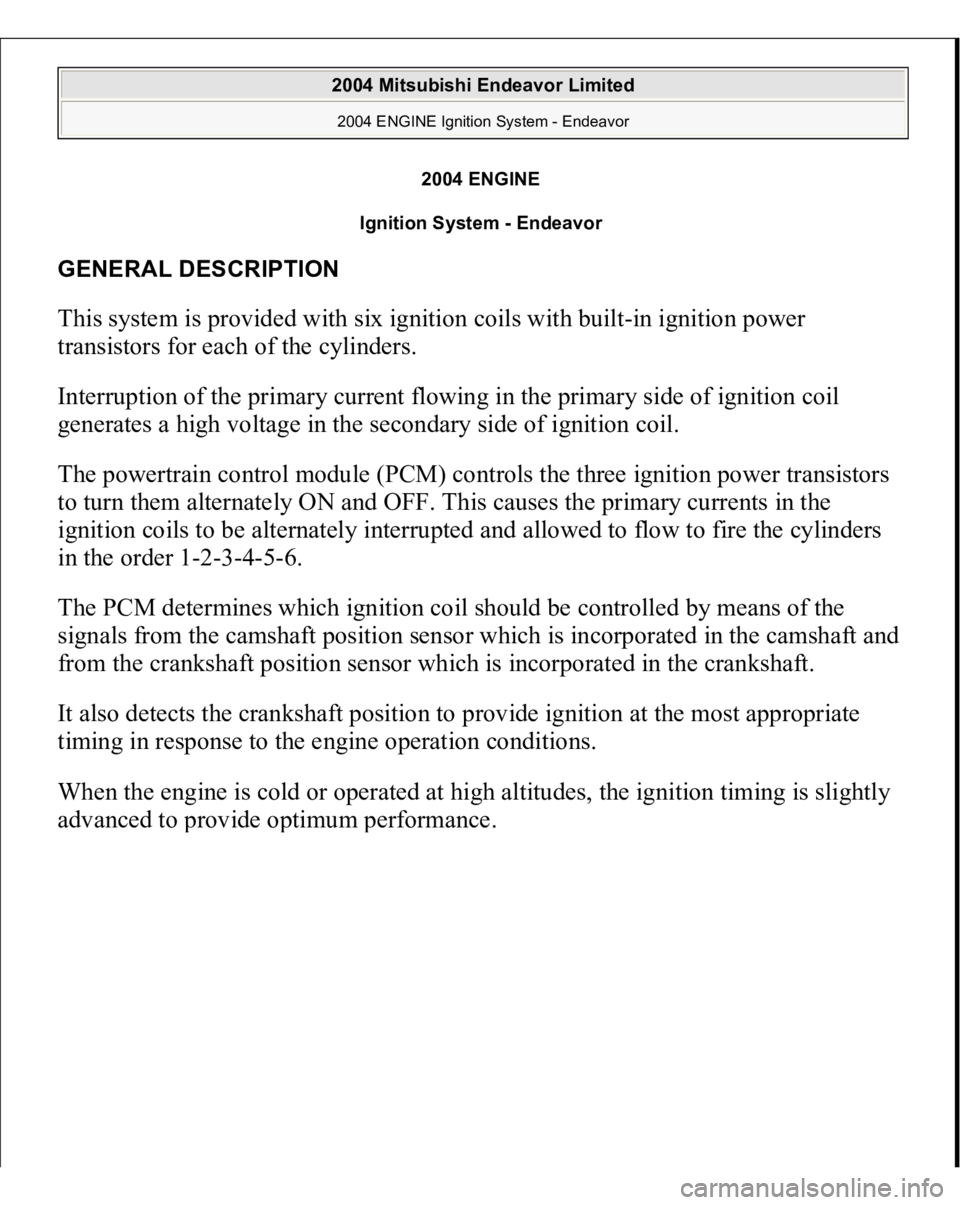

2004 ENGINE

Ignition System - Endeavor

GENERAL DESCRIPTION This system is provided with six ignition coils with built-in ignition power

transistors for each of the cylinders.

Interruption of the primary current flowing in the primary side of ignition coil

generates a high voltage in the secondary side of ignition coil.

The powertrain control module (PCM) controls the three ignition power transistors

to turn them alternately ON and OFF. This causes the primary currents in the

ignition coils to be alternately interrupted and allowed to flow to fire the cylinders

in the order 1-2-3-4-5-6.

The PCM determines which ignition coil should be controlled by means of the

signals from the camshaft position sensor which is incorporated in the camshaft and

from the crankshaft position sensor which is incorporated in the crankshaft.

It also detects the crankshaft position to provide ignition at the most appropriate

timing in response to the engine operation conditions.

When the engine is cold or operated at high altitudes, the ignition timing is slightly

advanced to

provide o

ptimum

performance.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 2684 of 3870

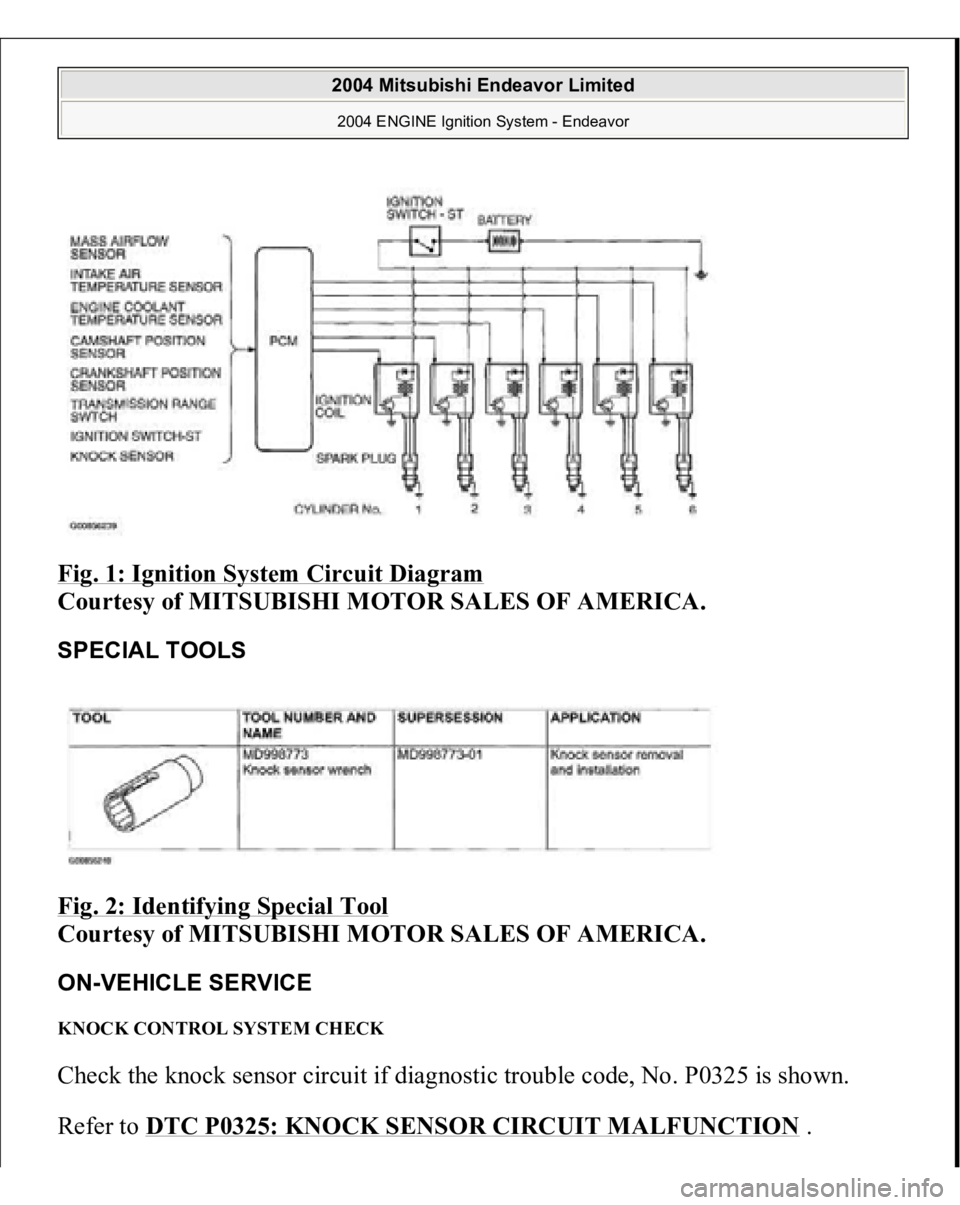

Fig. 1: Ignition System Circuit Diagram

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SPECIAL TOOLS Fig. 2: Identifying Special Tool

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

ON-VEHICLE SERVICE KNOCK CONTROL SYSTEM CHECK Check the knock sensor circuit if diagnostic trouble code, No. P0325 is shown.

Refer to DTC P0325: KNOCK SENSOR CIRCUIT MALFUNCTION

.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 2685 of 3870

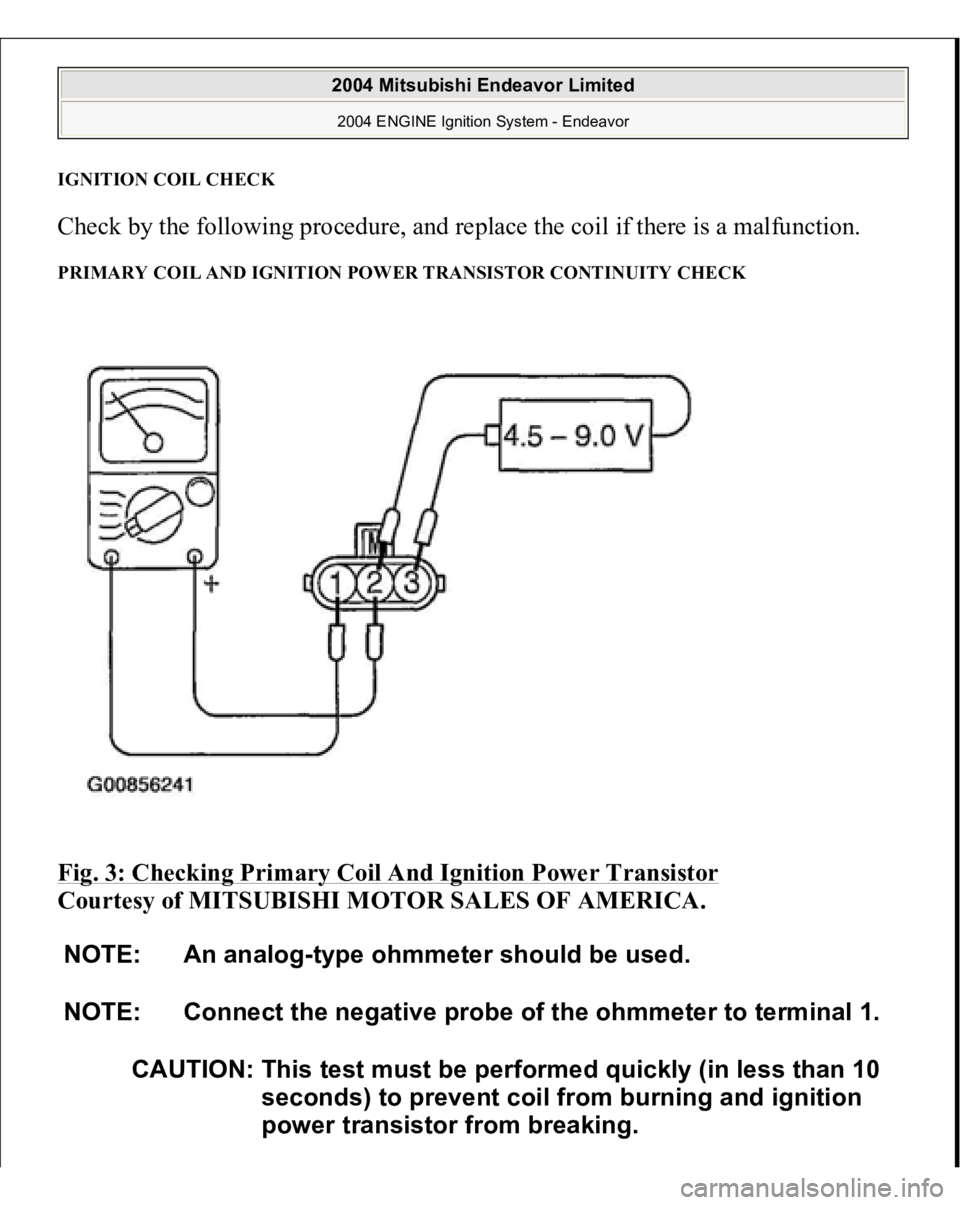

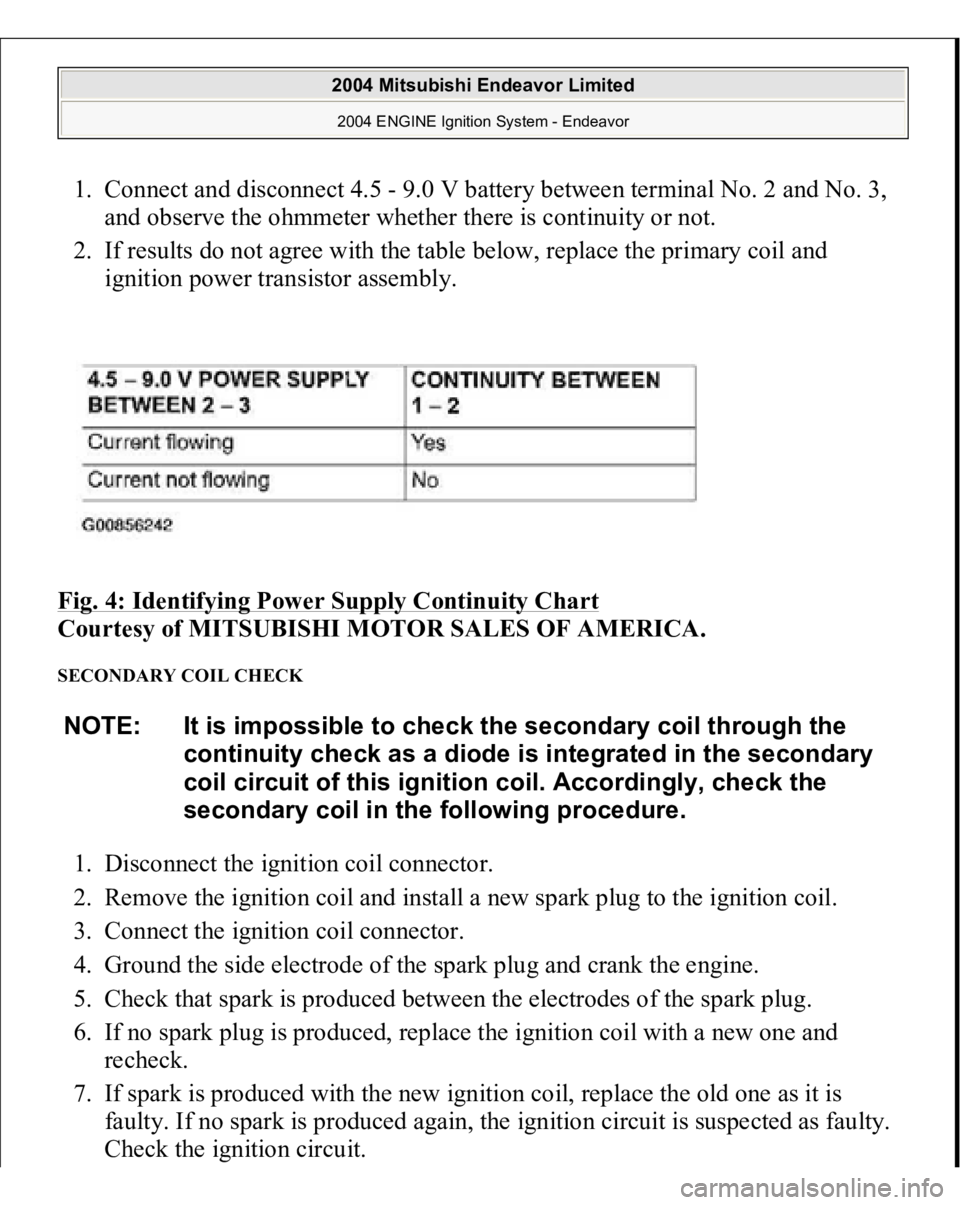

IGNITION COIL CHEC

K

Check by the following procedure, and replace the coil if there is a malfunction. PRIMARY COIL AND IGNITION POWER TRANSISTOR CONTINUITY CHECK Fig. 3: Checking Primary Coil And Ignition Power Transistor

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

NOTE: An analog-type ohmmeter should be used.

NOTE: Connect the negative probe of the ohmmeter to terminal 1.

CAUTION: This test must be performed quickly (in less than 10

seconds) to prevent coil from burning and ignition

power transistor from breaking.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 2686 of 3870

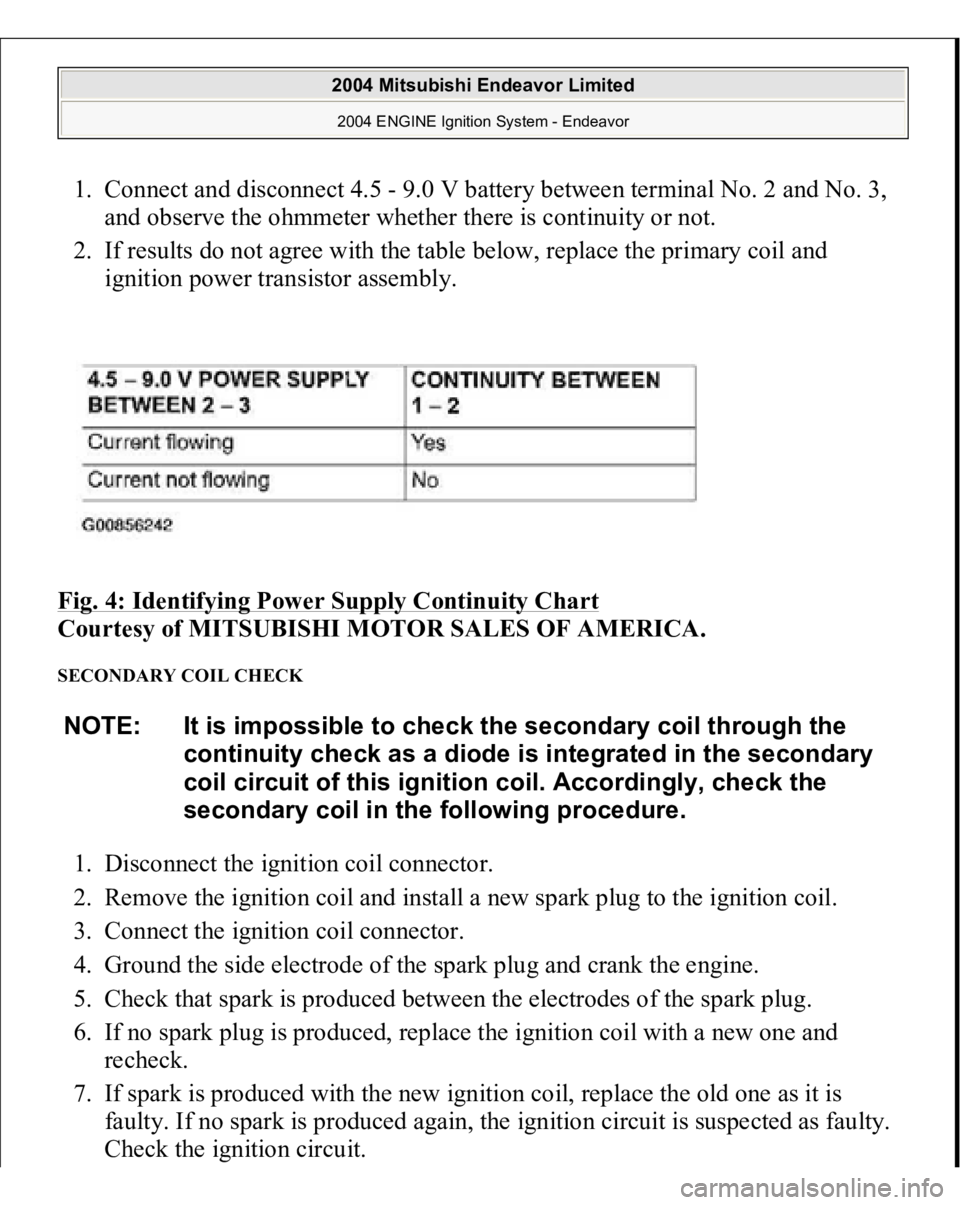

1. Connect and disconnect 4.5 - 9.0 V battery between terminal No. 2 and No. 3,

and observe the ohmmeter whether there is continuity or not.

2. If results do not agree with the table below, replace the primary coil and

ignition power transistor assembly.

Fig. 4: Identifying Power Supply Continuity Chart

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SECONDARY COIL CHECK 1. Disconnect the ignition coil connector.

2. Remove the ignition coil and install a new spark plug to the ignition coil.

3. Connect the ignition coil connector.

4. Ground the side electrode of the spark plug and crank the engine.

5. Check that spark is produced between the electrodes of the spark plug.

6. If no spark plug is produced, replace the ignition coil with a new one and

recheck.

7. If spark is produced with the new ignition coil, replace the old one as it is

faulty. If no spark is produced again, the ignition circuit is suspected as faulty.

Check the ignition circuit. NOTE: It is impossible to check the secondary coil through the

continuity check as a diode is integrated in the secondary

coil circuit of this ignition coil. Accordingly, check the

secondary coil in the following procedure.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 2687 of 3870

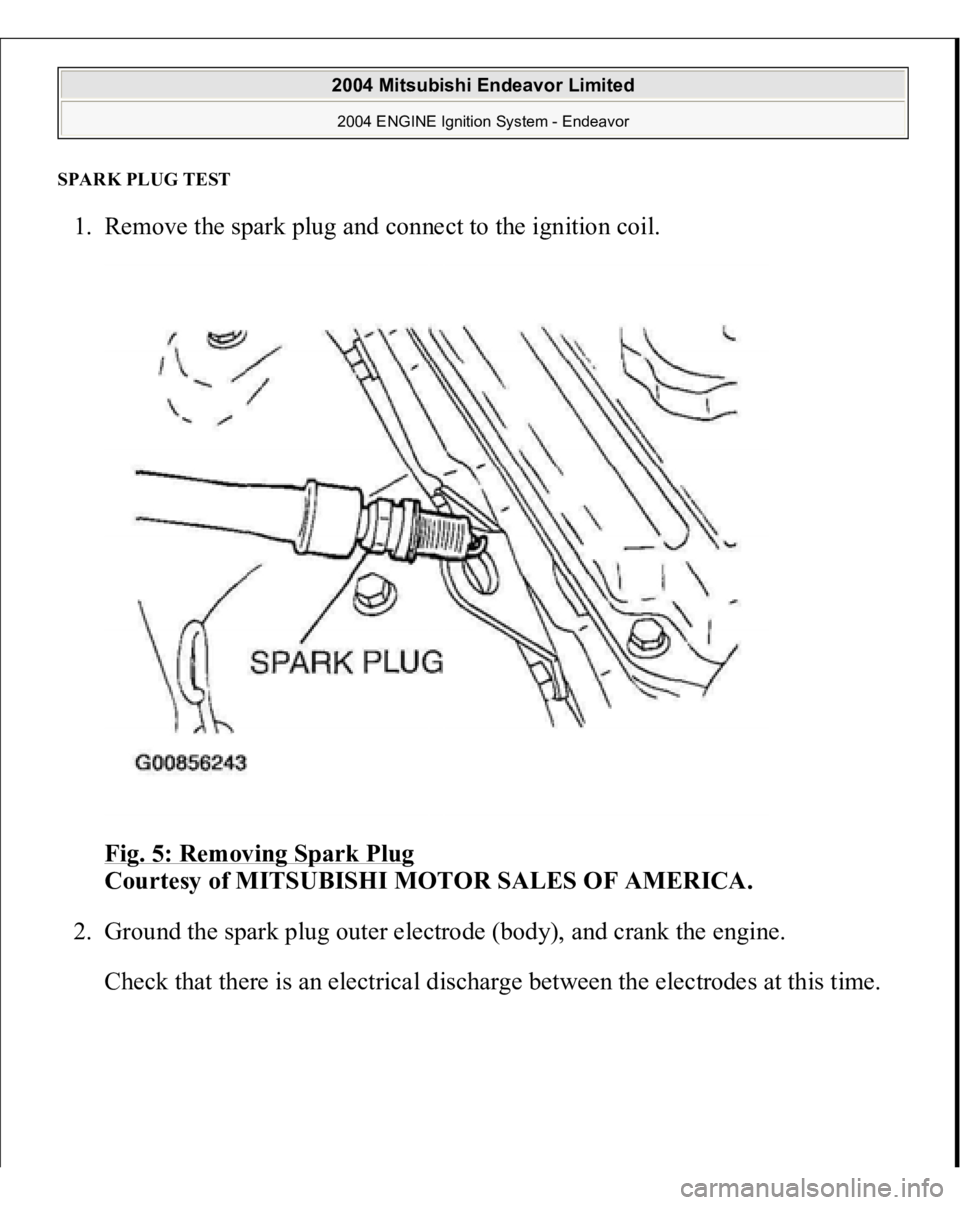

SPARK PLUG TEST 1. Remove the spark plug and connect to the ignition coil.

Fig. 5: Removing Spark Plug

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Ground the spark plug outer electrode (body), and crank the engine.

Check that there is an electrical dischar

ge between the electrodes at this time.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 2688 of 3870

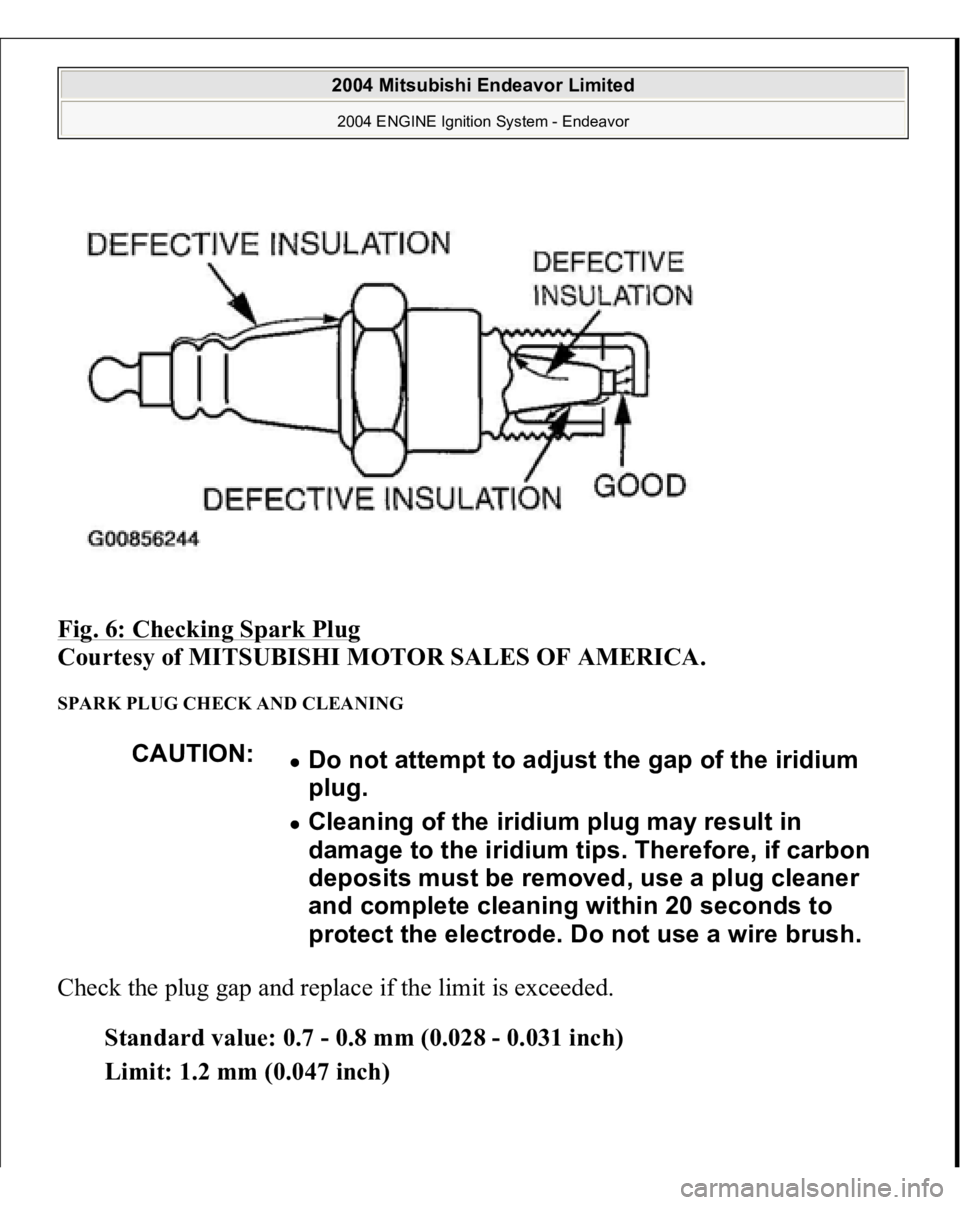

Fig. 6: Checking Spark Plug

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

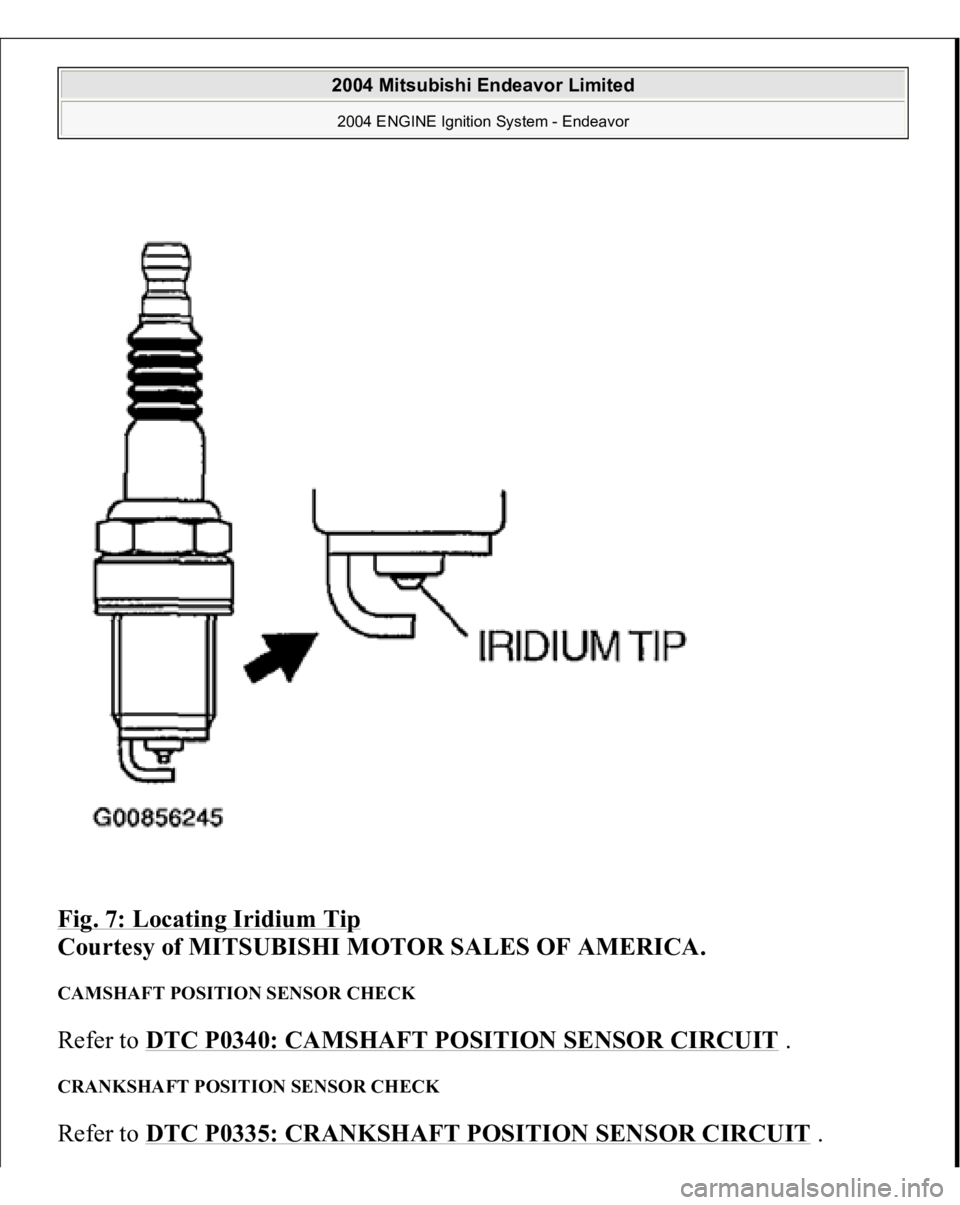

SPARK PLUG CHECK AND CLEANING Check the plug gap and replace if the limit is exceeded.

Standard value: 0.7 - 0.8 mm (0.028 - 0.031 inch)

Limit: 1.2 mm (0.047 inch)

CAUTION:

Do not attempt to adjust the gap of the iridium

plug. Cleaning of the iridium plug may result in

damage to the iridium tips. Therefore, if carbon

deposits must be removed, use a plug cleaner

and complete cleaning within 20 seconds to

protect the electrode. Do not use a wire brush.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 2689 of 3870

Fig. 7: Locating Iridium Tip

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

CAMSHAFT POSITION SENSOR CHECK Refer to DTC P0340: CAMSHAFT POSITION SENSOR CIRCUIT

.

CRANKSHAFT POSITION SENSOR CHECK Refer to DTC P0335: CRANKSHAFT POSITION SENSOR CIRCUIT

.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 2690 of 3870

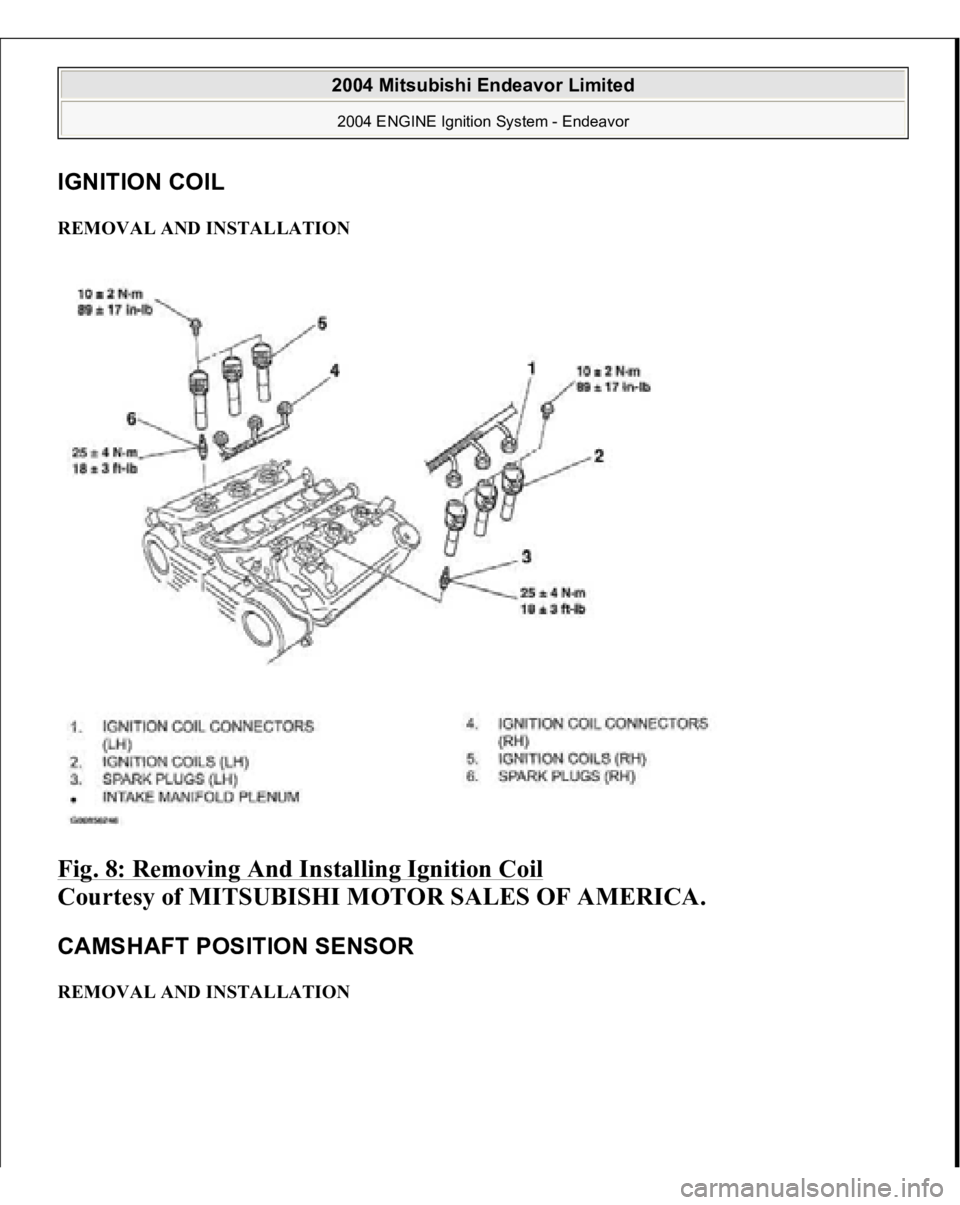

IGNITION COI

L

REMOVAL AND INSTALLATION Fig. 8: Removing And Installing Ignition Coil

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

CAMSHAFT POSITION SENSOR REMOVAL AND INSTALLATION

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Trending: brake pads, turn off alarm, COMMUNICATION ERROR, air bleeding, Speakers, crankshaft position sensor, Compressor