MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: technical data, control module, jump cable, speed sensor, brake, service interval, brake sensor

Page 531 of 3870

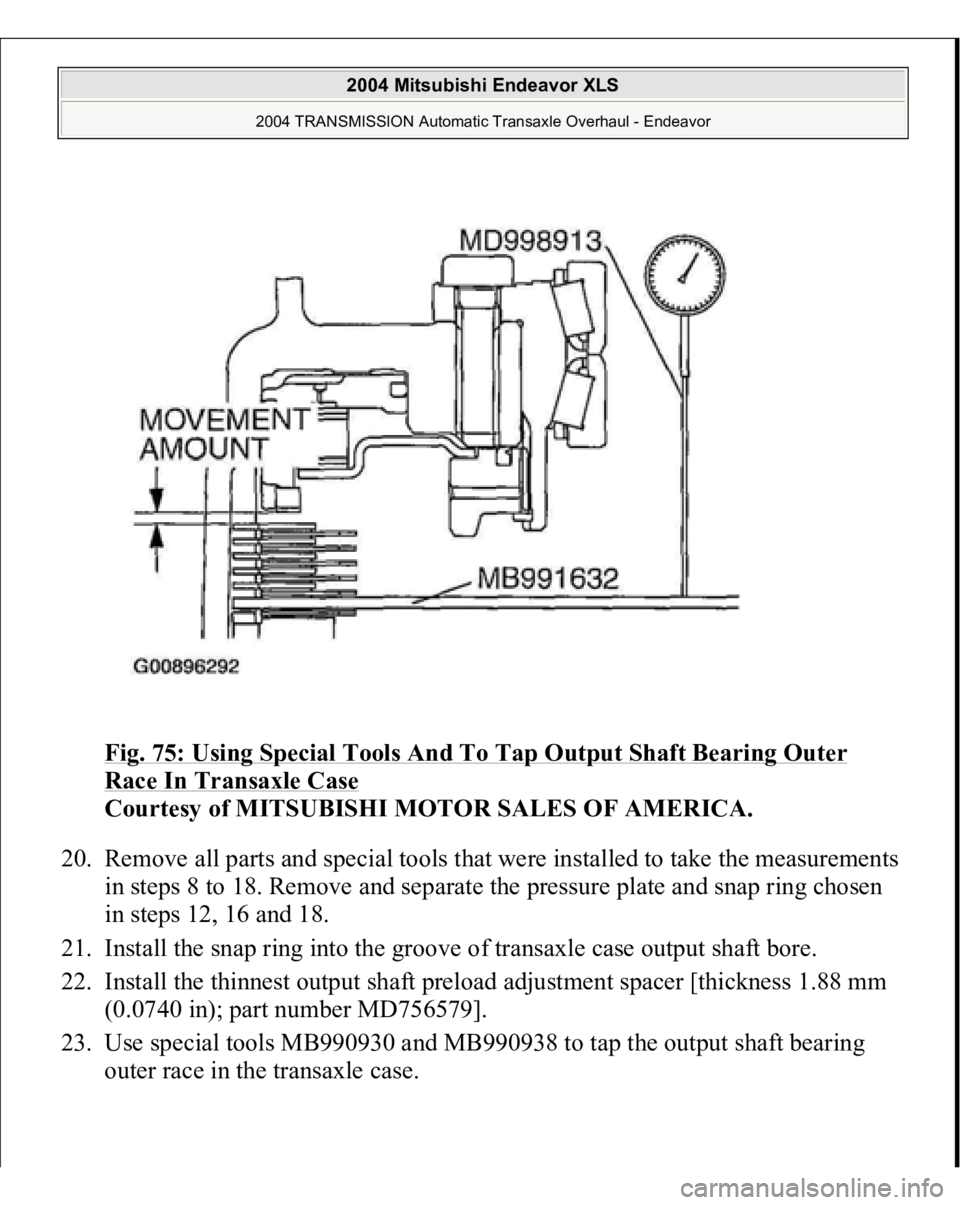

Fig. 75: Using Special Tools And To Tap Output Shaft Bearing Outer Race In Transaxle Case

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

20. Remove all parts and special tools that were installed to take the measurements

in steps 8 to 18. Remove and separate the pressure plate and snap ring chosen

in steps 12, 16 and 18.

21. Install the snap ring into the groove of transaxle case output shaft bore.

22. Install the thinnest output shaft preload adjustment spacer [thickness 1.88 mm

(0.0740 in); part number MD756579].

23. Use special tools MB990930 and MB990938 to tap the output shaft bearing

outer race in the transaxle case.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 532 of 3870

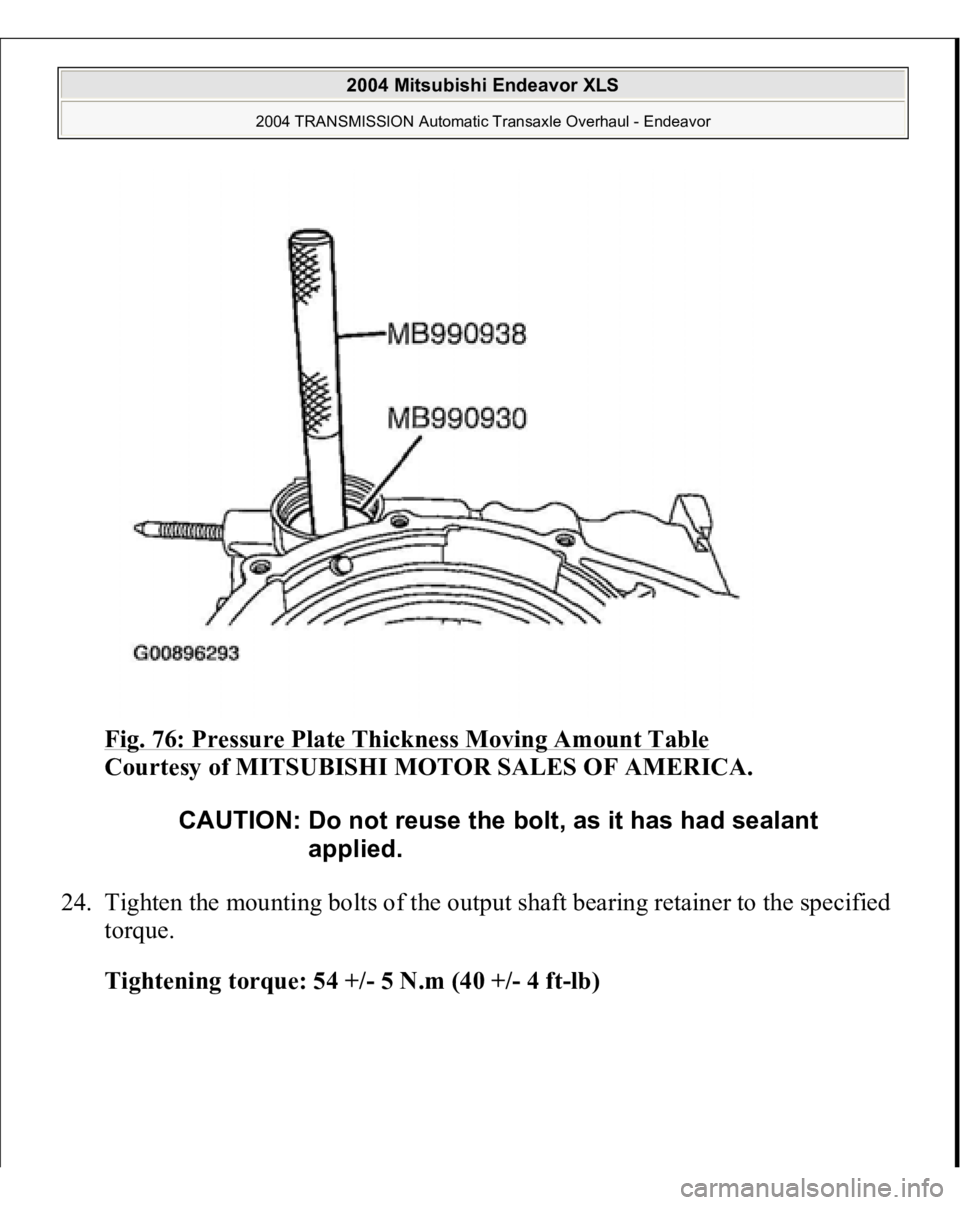

Fig. 76: Pressure Plate Thickness Moving Amount Table

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

24. Tighten the mounting bolts of the output shaft bearing retainer to the specified

torque.

Tightening torque: 54 +/- 5 N.m (40 +/- 4 ft-lb)

CAUTION: Do not reuse the bolt, as it has had sealant

applied.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 533 of 3870

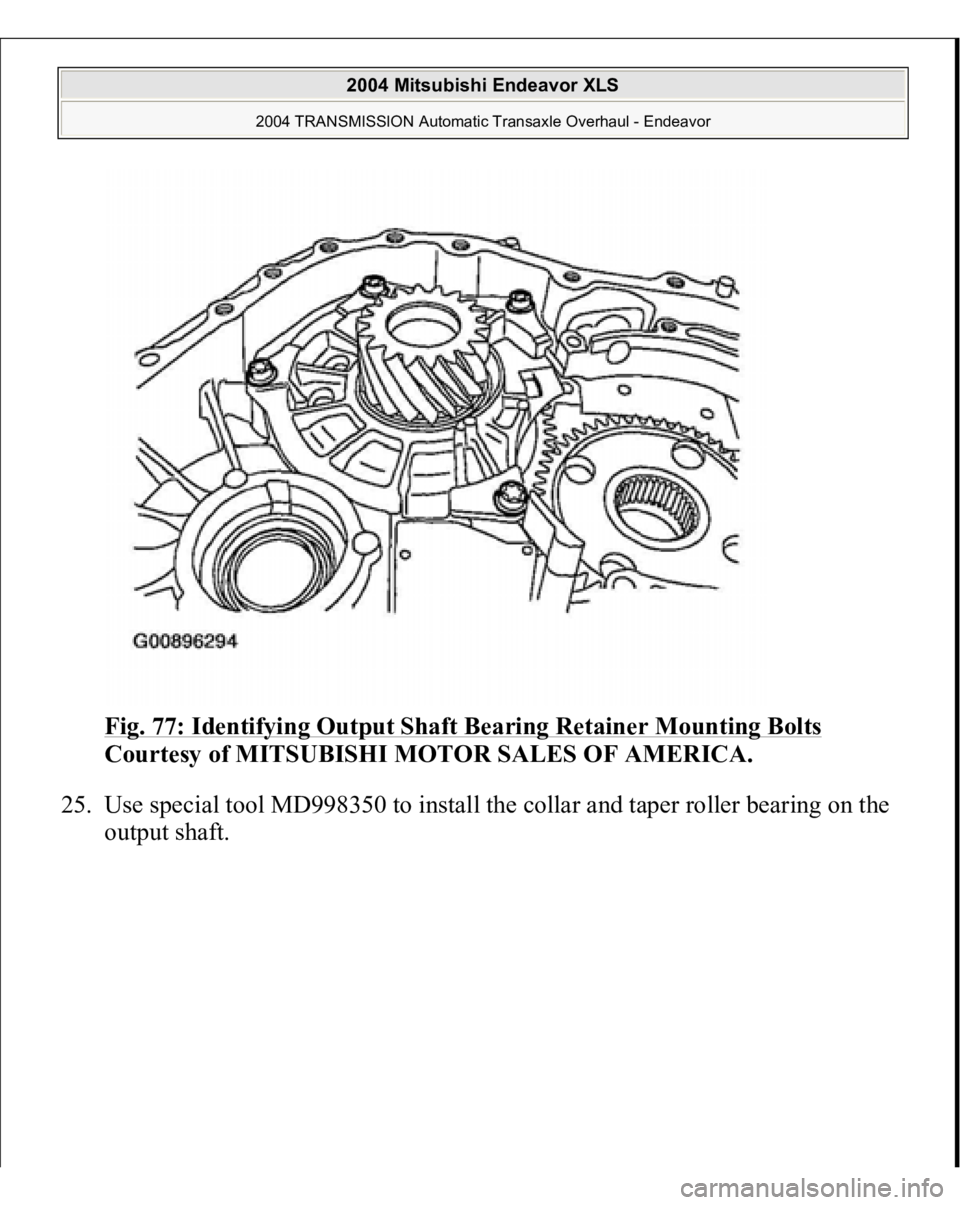

Fig. 77: Identifying Output Shaft Bearing Retainer Mounting Bolts

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

25. Use special tool MD998350 to install the collar and taper roller bearing on the

out

put shaft.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 534 of 3870

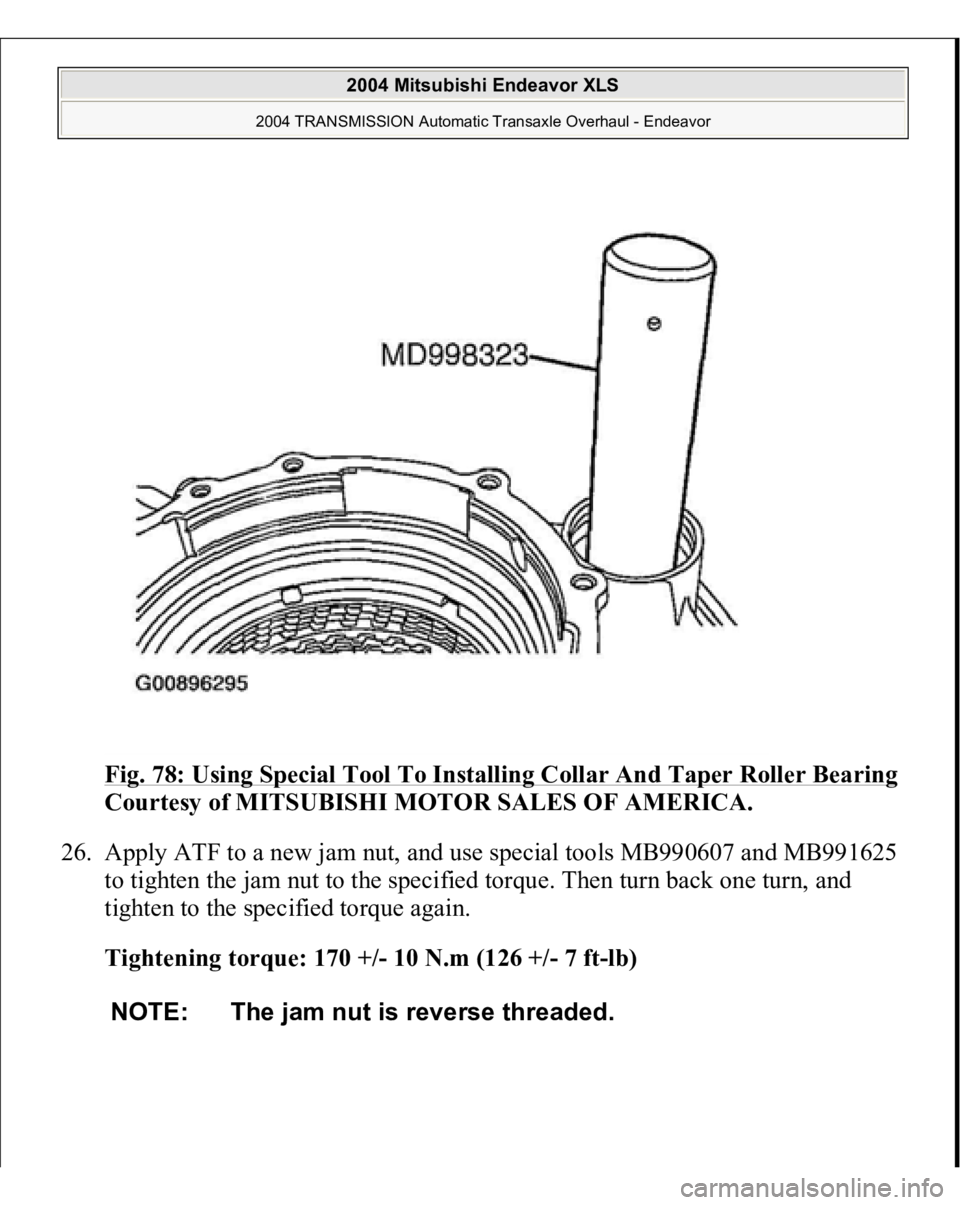

Fig. 78: Using Special Tool To Installing Collar And Taper Roller Bearing

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

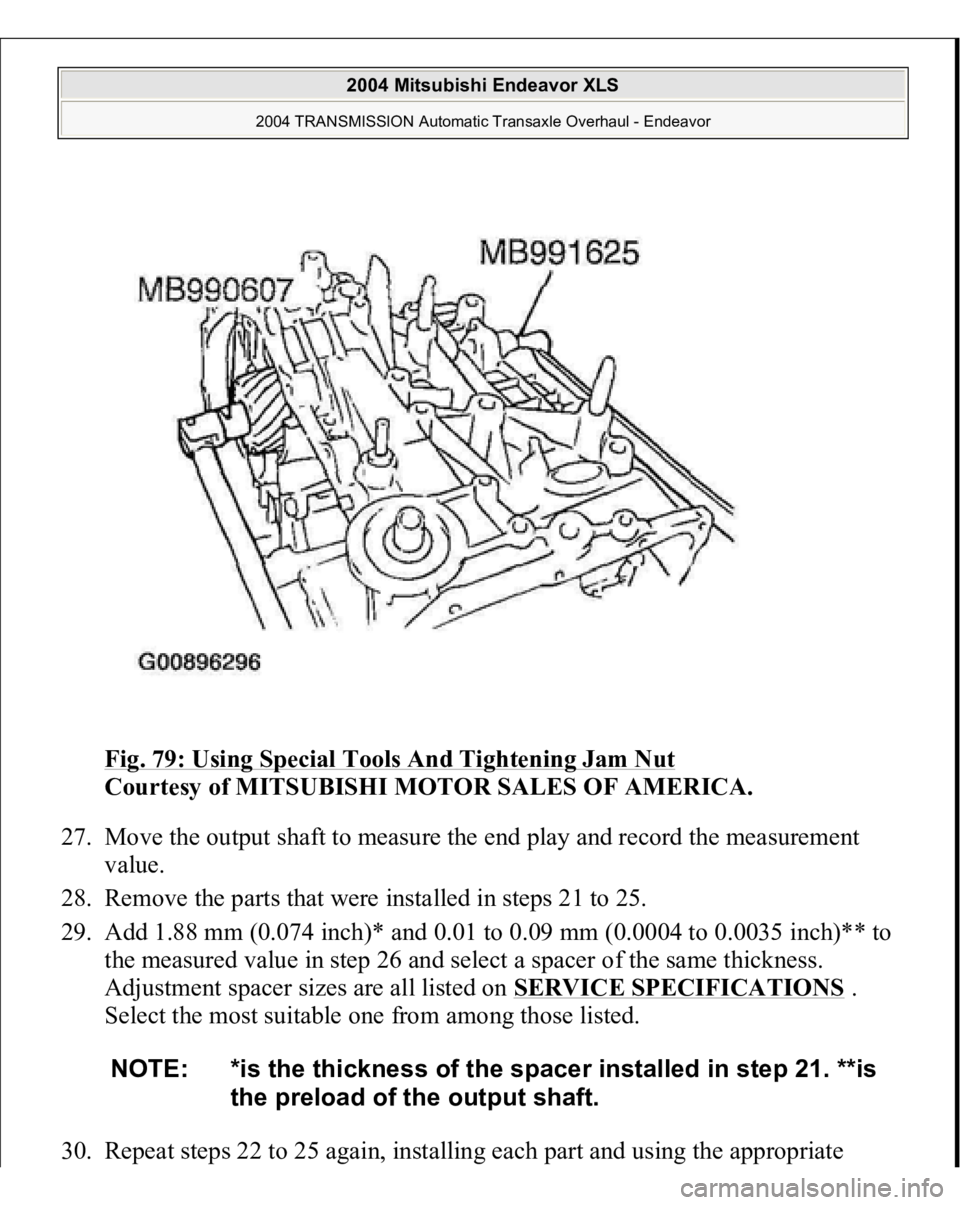

26. Apply ATF to a new jam nut, and use special tools MB990607 and MB991625

to tighten the jam nut to the specified torque. Then turn back one turn, and

tighten to the specified torque again.

Tightening torque: 170 +/- 10 N.m (126 +/- 7 ft-lb)

NOTE: The jam nut is reverse threaded.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 535 of 3870

Fig. 79: Using Special Tools And Tightening Jam Nut

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

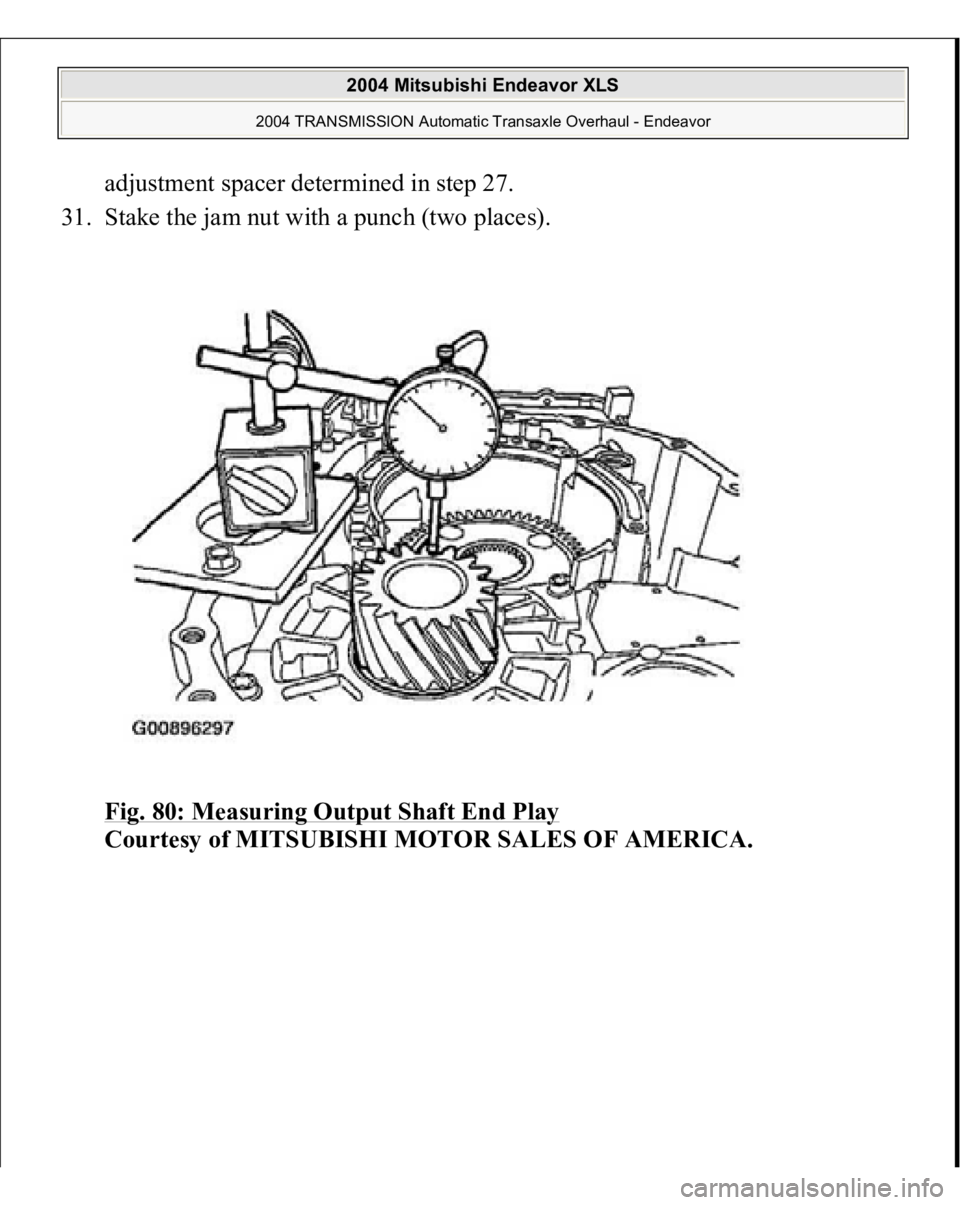

27. Move the output shaft to measure the end play and record the measurement

value.

28. Remove the parts that were installed in steps 21 to 25.

29. Add 1.88 mm (0.074 inch)* and 0.01 to 0.09 mm (0.0004 to 0.0035 inch)** to

the measured value in step 26 and select a spacer of the same thickness.

Adjustment spacer sizes are all listed on SERVICE SPECIFICATIONS

.

Select the most suitable one from among those listed.

30. Repeat steps 22 to 25 again, installing each part and using the appropriate

NOTE: *is the thickness of the spacer installed in step 21. **is

the preload of the output shaft.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 536 of 3870

adjustment spacer determined in step 27.

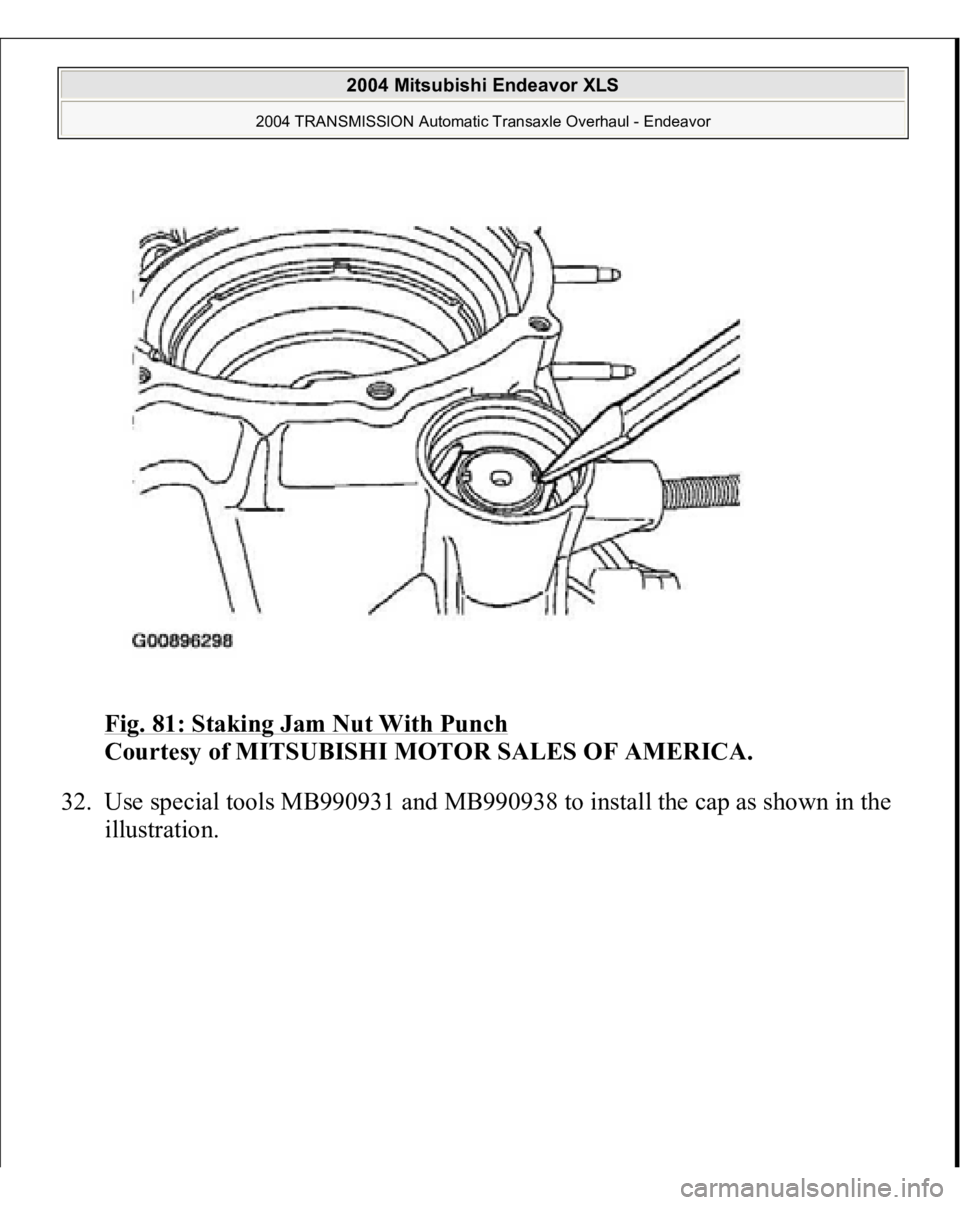

31. Stake the jam nut with a punch (two places).

Fig. 80: Measuring Output Shaft End Play

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 537 of 3870

Fig. 81: Staking Jam Nut With Punch

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

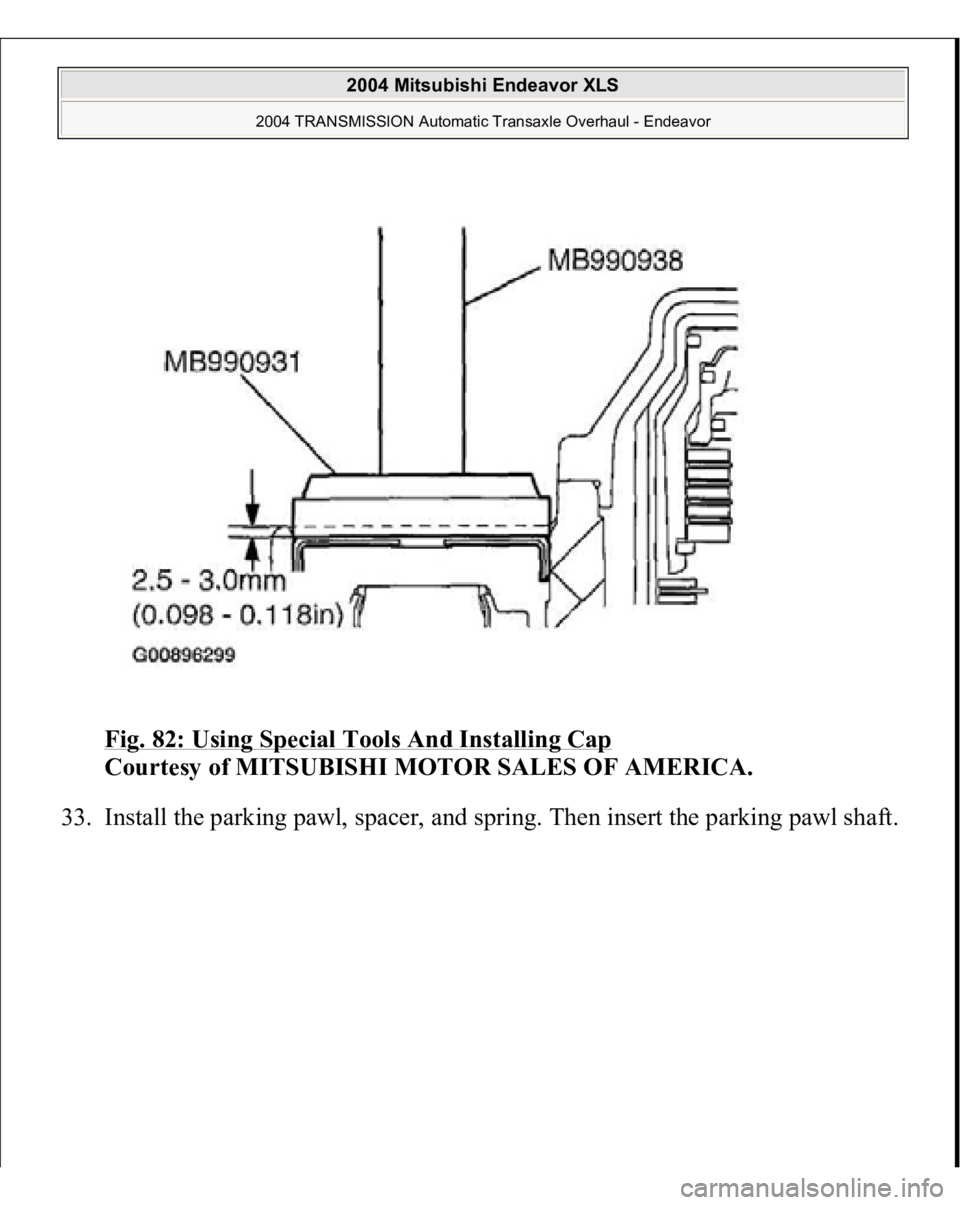

32. Use special tools MB990931 and MB990938 to install the cap as shown in the

illustration.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 538 of 3870

Fig. 82: Using Special Tools And Installing Cap

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

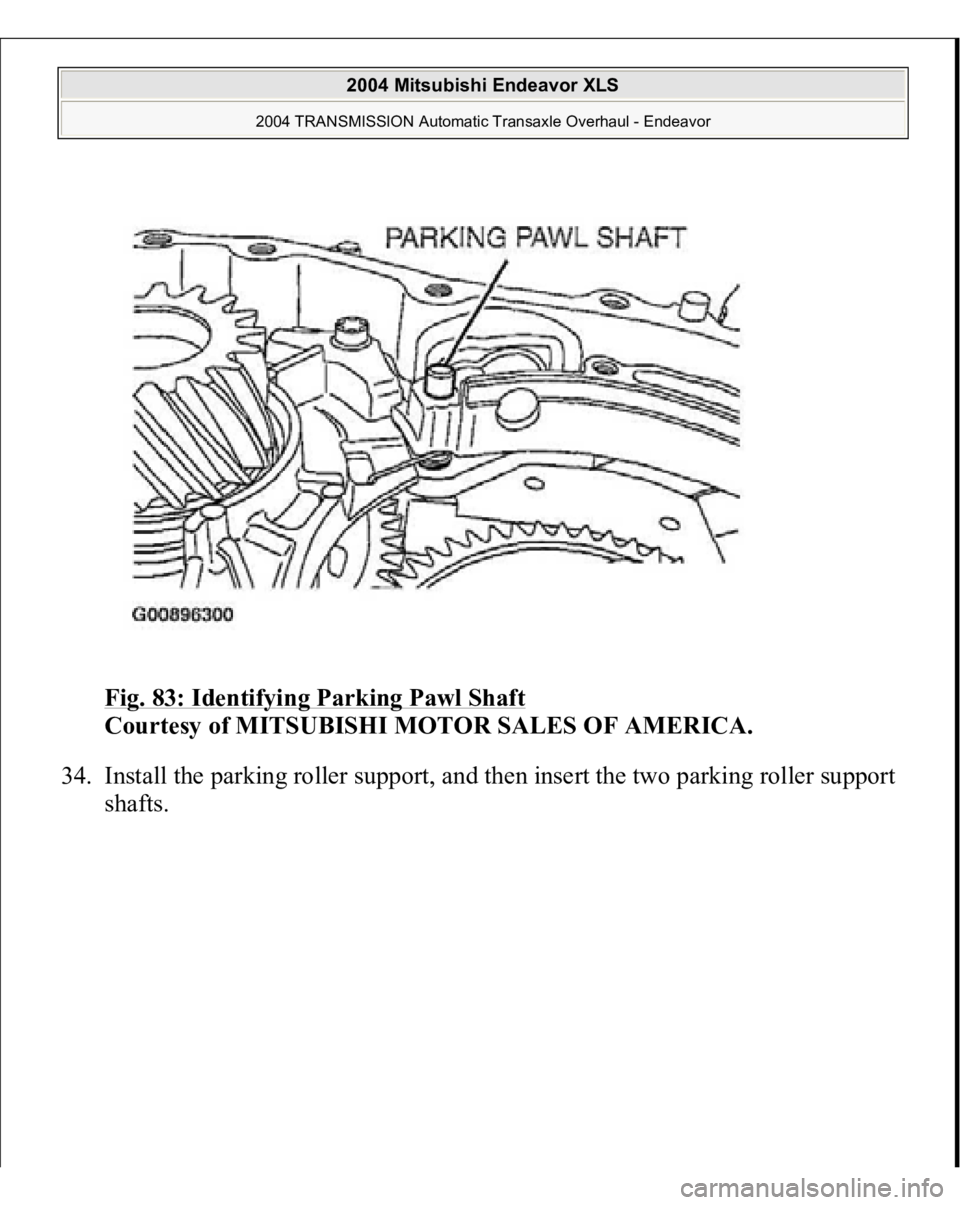

33. Install the

parkin

g pawl, s

pacer, and s

prin

g. Then insert the

parkin

g pawl shaft.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 539 of 3870

Fig. 83: Identifying Parking Pawl Shaft

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

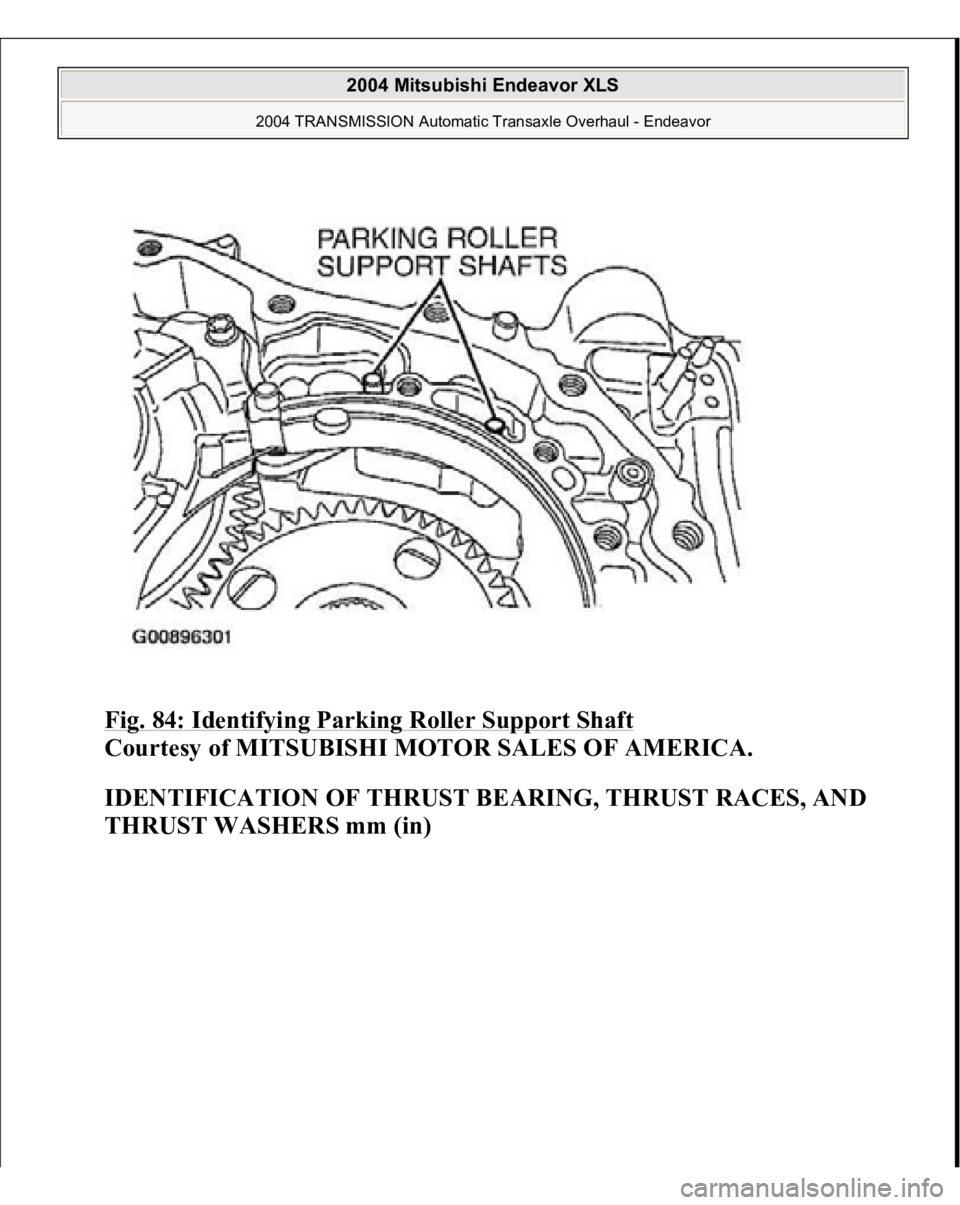

34. Install the parking roller support, and then insert the two parking roller support

shafts.

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Page 540 of 3870

Fig. 84: Identifying Parking Roller Support Shaft

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

IDENTIFICATION OF THRUST BEARING, THRUST RACES, AND

THRUST WASHERS mm (in)

2004 Mitsubishi Endeavor XLS

2004 TRANSMISSION Automatic Transaxle Overhaul - Endeavor

Trending: clock setting, weight, wheel, Lift, CD changer, coolant temperature, Intake