MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 231 of 1273

FUEL SYSTEM

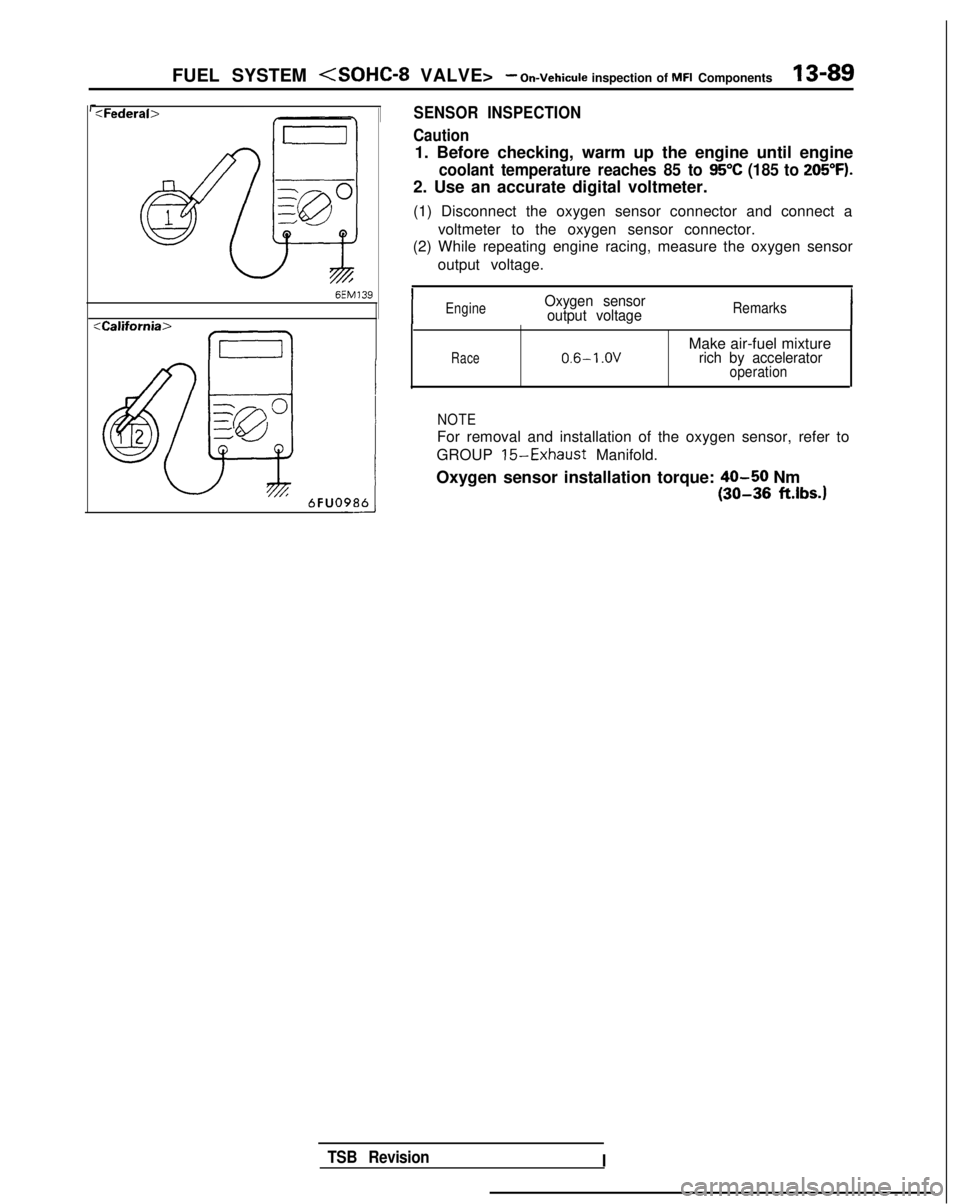

:Federab

:California>

Ea

SENSOR INSPECTION

Caution

1. Before checking, warm up the engine until engine

coolant temperature reaches 85 to 95°C (185 to 205°F).

2. Use an accurate digital voltmeter.

(1) Disconnect the oxygen sensor connector and connect a voltmeter to the oxygen sensor connector.

(2) While repeating engine racing, measure the oxygen sensor

output voltage.

,

IEngineOxygen sensoroutput voltageRemarks

Race0.6-l .OVMake air-fuel mixturerich by acceleratoroperation

NOTE

For removal and installation of the oxygen sensor, refer to

GROUP

15-Exhaust Manifold.

Oxygen sensor installation torque:

40-50 Nm

(30-36 ft.lbs.1

TSB Revision I

Page 232 of 1273

13-90 FUEL SYSTEM

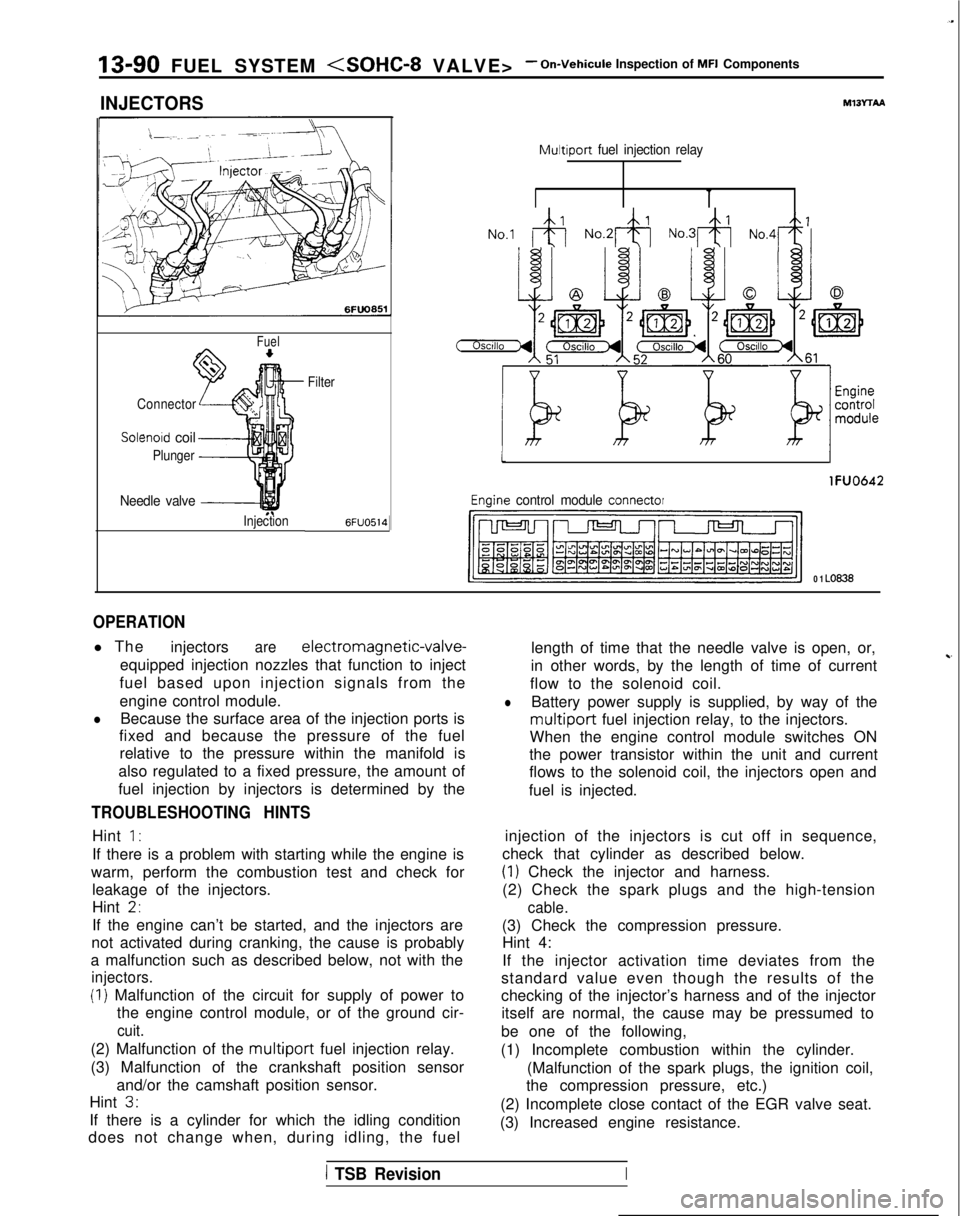

INJECTORS

Fuel

Connector

Solenoid coil

Plunger

Needle valve -----I

InjectionFilter6FUO514

M13rrAA

Multiport

fuel injection relay

No.1 &j No.2& No.3& No,4+

tI

lFUO642

Engine control module connector

CJ=JW=U-I

0 1 LO636

OPERATION

l The

injectorsare electromagnetic-valve-

equipped injection nozzles that function to inject

fuel based upon injection signals from the

engine control module.

lBecause the surface area of the injection ports is

fixed and because the pressure of the fuel

relative to the pressure within the manifold is

also regulated to a fixed pressure, the amount of

fuel injection by injectors is determined by the

TROUBLESHOOTING HINTS

Hint 1:

If there is a problem with starting while the engine is

warm, perform the combustion test and check for leakage of the injectors.

Hint

2,

If the engine can’t be started, and the injectors are

not activated during cranking, the cause is probably

a malfunction such as described below, not with the

injectors.

(I) Malfunction of the circuit for supply of power to the engine control module, or of the ground cir-

cuit.

(2) Malfunction of the multiport fuel injection relay.

(3) Malfunction of the crankshaft position sensor and/or the camshaft position sensor.

Hint

3.

If there is a cylinder for which the idling condition

does not change when, during idling, the fuel length of time that the needle valve is open, or,

in other words, by the length of time of current

~-

flow to the solenoid coil.

lBattery power supply is supplied, by way of the

multiport fuel injection relay, to the injectors.

When the engine control module switches ON

the power transistor within the unit and current

flows to the solenoid coil, the injectors open and

fuel is injected.

injection of the injectors is cut off in sequence,

check that cylinder as described below.

(1) Check the injector and harness.

(2) Check the spark plugs and the high-tension

cable.

(3) Check the compression pressure. Hint 4:

If the injector activation time deviates from the

standard value even though the results of the

checking of the injector’s harness and of the injector itself are normal, the cause may be pressumed to

be one of the following,

(1) Incomplete combustion within the cylinder. (Malfunction of the spark plugs, the ignition coil,

the compression pressure, etc.)

(2) Incomplete close contact of the EGR valve seat.

(3) Increased engine resistance.

1 TSB RevisionI

Page 233 of 1273

FUEL SYSTEM

Inspection of MFI Components13-91

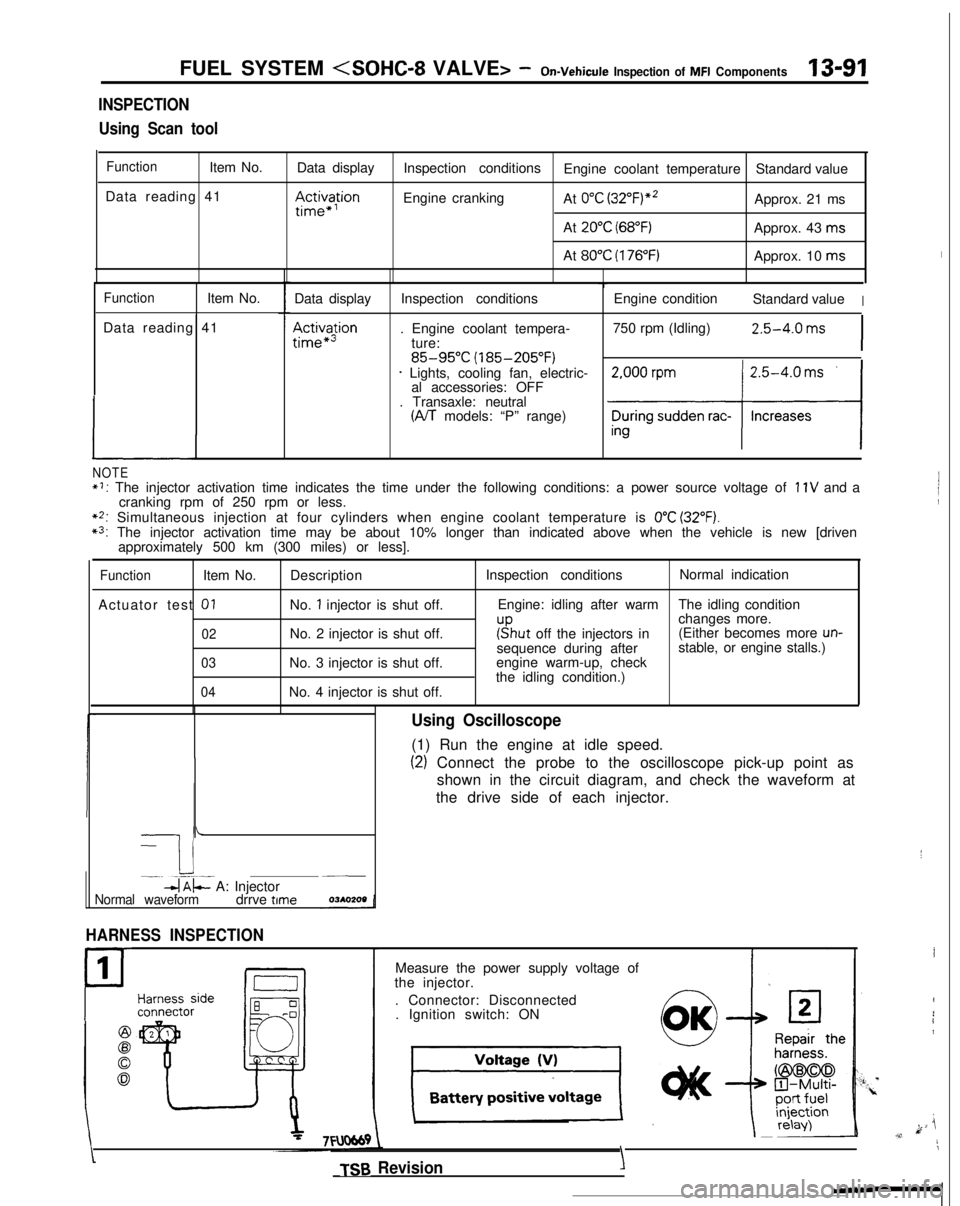

INSPECTION

Using Scan tool

FunctionItem No. Data display

Data reading 41

III~~~ion

Inspection conditions Engine coolant temperature Standard value

Engine cranking At

0°C (3~2°F)“~Approx. 21 ms

At

20°C (68°F)Approx. 43 ms

At

80°C (176°F)Approx. 10 ms

FunctionItem No.

Data reading 41

L

Data display

Ac&a$ion

Inspection conditions

. Engine coolant tempera- ture:

85-95°C (185-205°F)* Lights, cooling fan, electric-al accessories: OFF

. Transaxle: neutral

(A/T models: “P” range) Engine condition

Standard value

I

750 rpm (Idling)2.5-4.0 ms

I

NOTE*I: The injector activation time indicates the time under the following con\

ditions: a power source voltage of 11V and a

cranking rpm of 250 rpm or less.

**: Simultaneous injection at four cylinders when engine coolant temperatur\

e is 0°C (32°F).*3: The injector activation time may be about 10% longer than indicated abo\

ve when the vehicle is new [driven approximately 500 km (300 miles) or less].

FunctionItem No.

Actuator test

01

02

03

04

Description

No.

1 injector is shut off.

No. 2 injector is shut off.

No. 3 injector is shut off.

No. 4 injector is shut off. Inspection conditions

Normal indication

Engine: idling after warm The idling condition

changes more.

r”sput off the injectors in(Either becomes more un-sequence during after stable, or engine stalls.)

engine warm-up, check

the idling condition.)

-

I i-. --.-~-db$- A: Injector~__

Normal waveformdrrve time

HARNESS INSPECTION

1

P

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

Measure the power supply voltage of

the injector.

. Connector: Disconnected. Ignition switch: ON

TSB Revision

I

I

4

i1

k ji,v,11

\

YIY’.

Page 234 of 1273

13-92 FUEL SYSTEM

- On-Vehicule Inspection of MFI Components

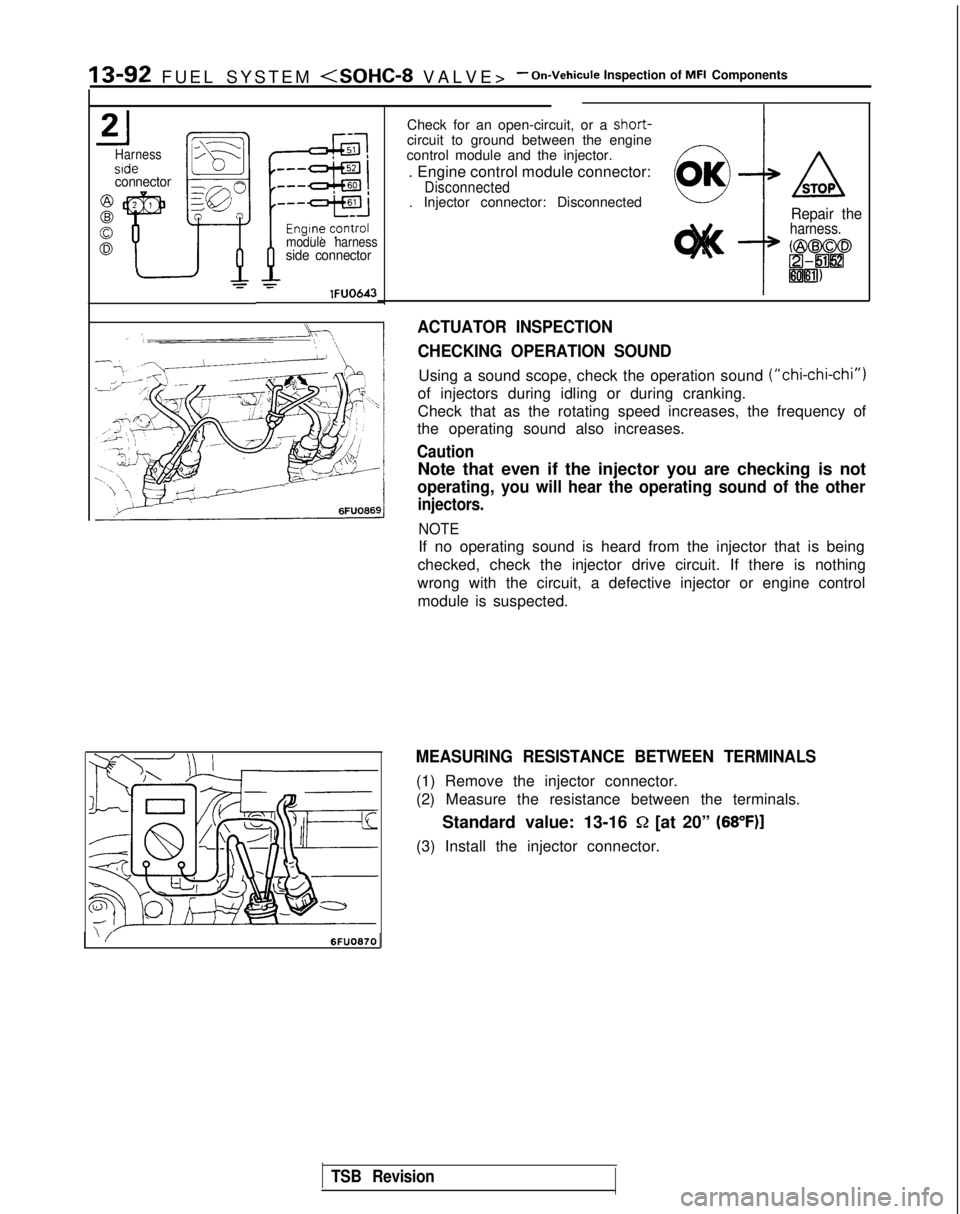

21Harnesssideconnector

g *’

gr

module harnessside connector

-rlFUO643

‘/6FUO870

Check for an open-circuit, or a short-circuit to ground between the engine

control module and the injector.

. Engine control module connector:

Disconnected. Injector connector: Disconnected

:

ASTOP

Repair theharness.

ACTUATOR INSPECTION

CHECKING OPERATION SOUND

Using a sound scope, check the operation sound (“chi-chi-chi”)

of injectors during idling or during cranking.

Check that as the rotating speed increases, the frequency of

the operating sound also increases.

Caution

Note that even if the injector you are checking is not

operating, you will hear the operating sound of the other

injectors.

NOTE

If no operating sound is heard from the injector that is being

checked, check the injector drive circuit. If there is nothing

wrong with the circuit, a defective injector or engine control module is suspected.

MEASURING RESISTANCE BETWEEN TERMINALS

(1) Remove the injector connector.

(2) Measure the resistance between the terminals.

Standard value: 13-16

Q [at 20” (68”F)]

(3) Install the injector connector.

TSB Revision

Page 235 of 1273

FUEL SYSTEM

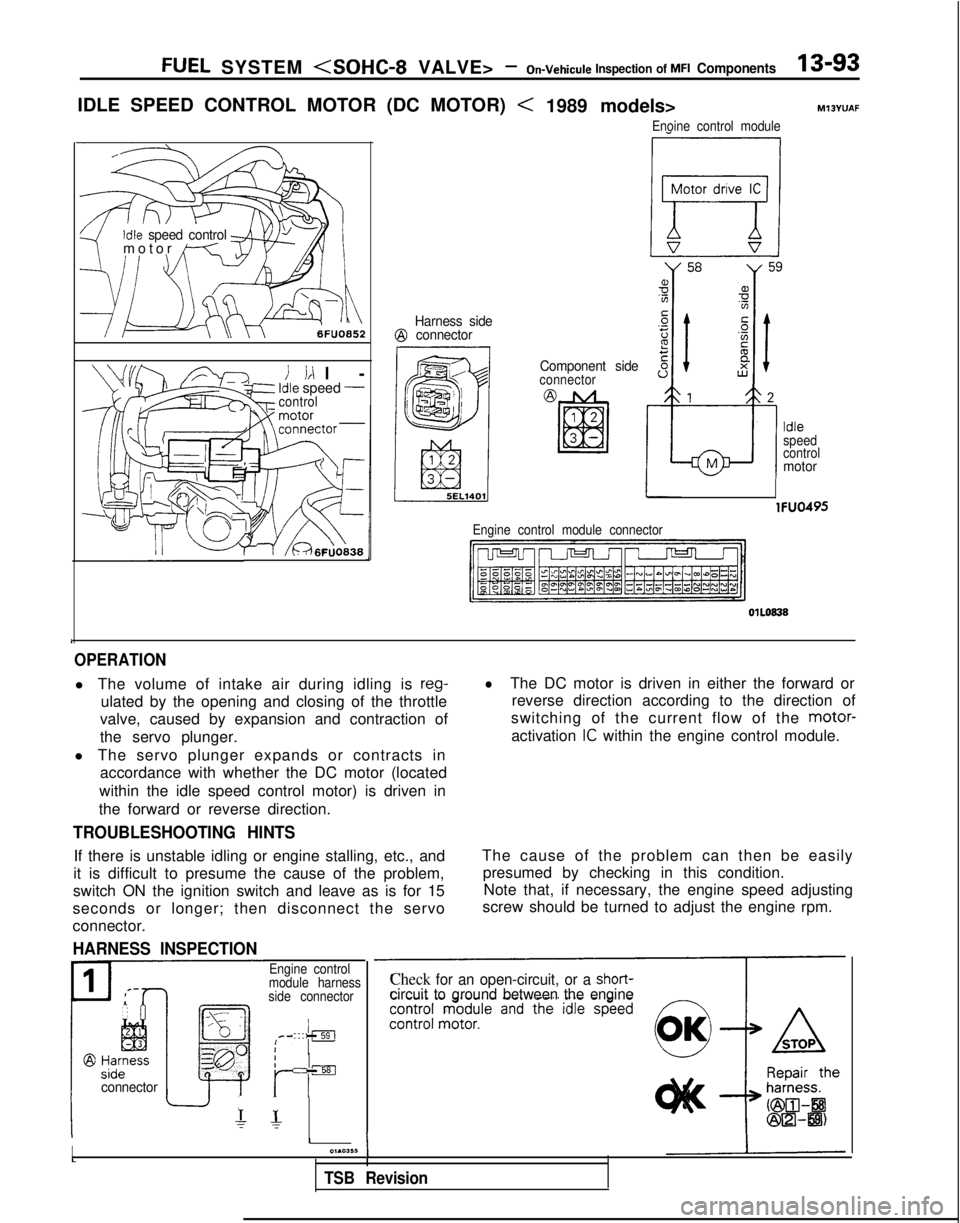

IDLE SPEED CONTROL MOTOR (DC MOTOR)

Idle speed control9-/

motor

/---T-,I \

6FUO852

i id l

-

Idle speed -control

r1 /&46~U0838

Harness side@ connector

< 1989 models>

Enoine control module

M13YUAF

Component sideconnector

!

a,Yg

z.-t;Fs 8

B

12

d

Idle

speed

control

Mmotor

lFUO495

Engine control module connector

1

OPERATION

l The volume of intake air during idling is reg-

ulated by the opening and closing of the throttle

valve, caused by expansion and contraction of

the servo plunger.

l The servo plunger expands or contracts in accordance with whether the DC motor (located

within the idle speed control motor) is driven in

the forward or reverse direction.

lThe DC motor is driven in either the forward or reverse direction according to the direction of

switching of the current flow of the motor-

activation

IC within the engine control module.

TROUBLESHOOTING HINTS

If there is unstable idling or engine stalling, etc., and

it is difficult to presume the cause of the problem,

switch ON the ignition switch and leave as is for 15

seconds or longer; then disconnect the servo

connector.

HARNESS INSPECTION

The cause of the problem can then be easily presumed by checking in this condition.Note that, if necessary, the engine speed adjusting

screw should be turned to adjust the engine rpm.

Iconnector

Engine control

module harness

side connector

IIrIsEI

r- r-

II01.03,~I

TSB Revision

Check for an open-circuit, or a short-circuit to ground between the engine

Page 236 of 1273

13-94 FUEL SYSTEM

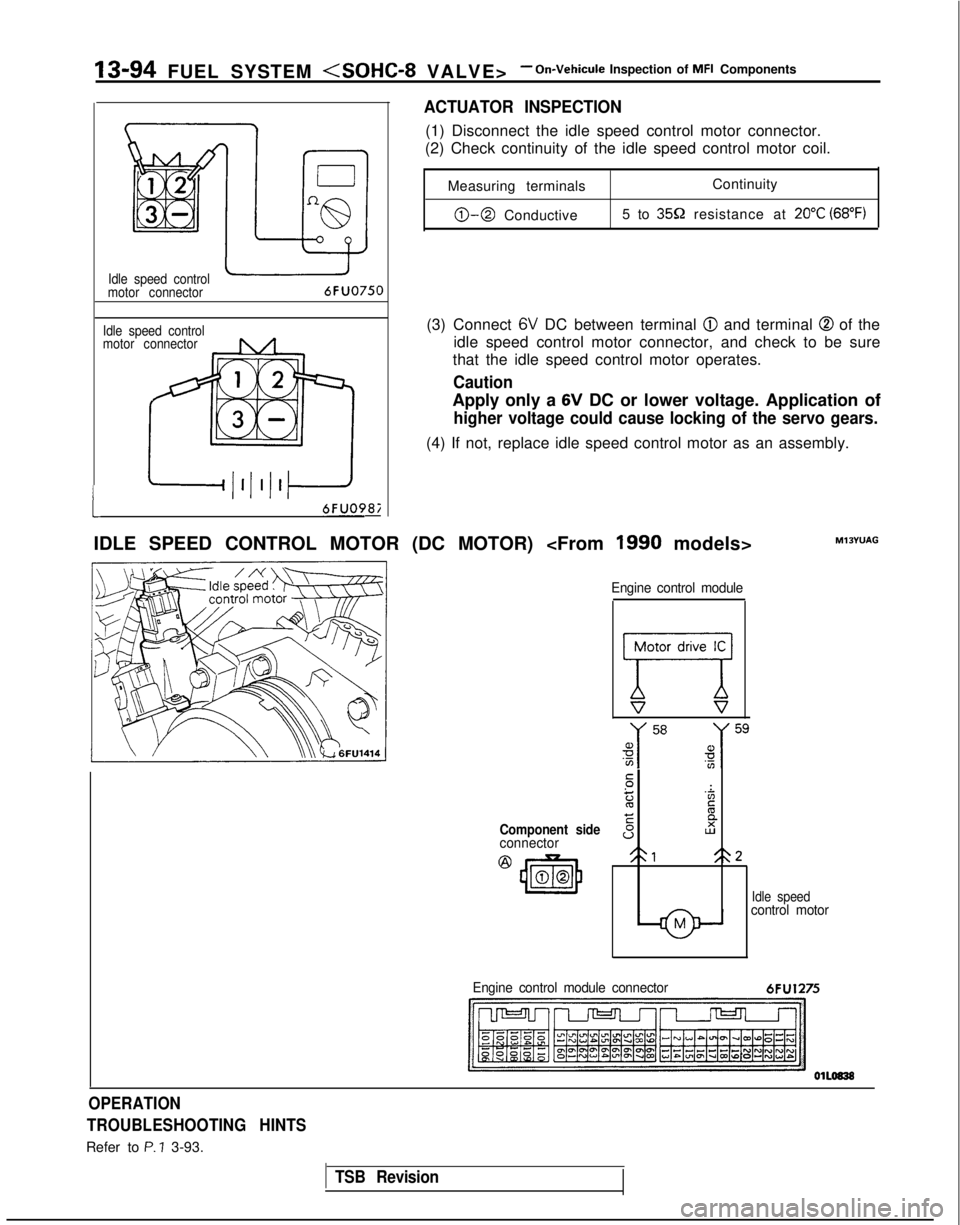

1

Idle speed control

motor connector

Idle speed control

motor connector6FUO750

6FUO9&

ACTUATOR INSPECTION

(1) Disconnect the idle speed control motor connector.

(2) Check continuity of the idle speed control motor coil.

Measuring terminals Continuity

0-0 Conductive

5 to 359 resistance at 20°C (68°F)

(3) Connect 6V DC between terminal @I and terminal @ of the

idle speed control motor connector, and check to be sure

that the idle speed control motor operates.

Caution

Apply only a 6V DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(4) If not, replace idle speed control motor as an assembly.

IDLE SPEED CONTROL MOTOR (DC MOTOR)

Component sideconnector

@

43m00

Engine control module

77V s

.-:

z'Zc

EE

sI2

21<\2

Idle speedcontrol motor

MlOYUAG

Engine control module connector

6FU1275

OPERATION

TROUBLESHOOTING HINTS

Refer to P. ? 3-93.

TSB Revision

Page 237 of 1273

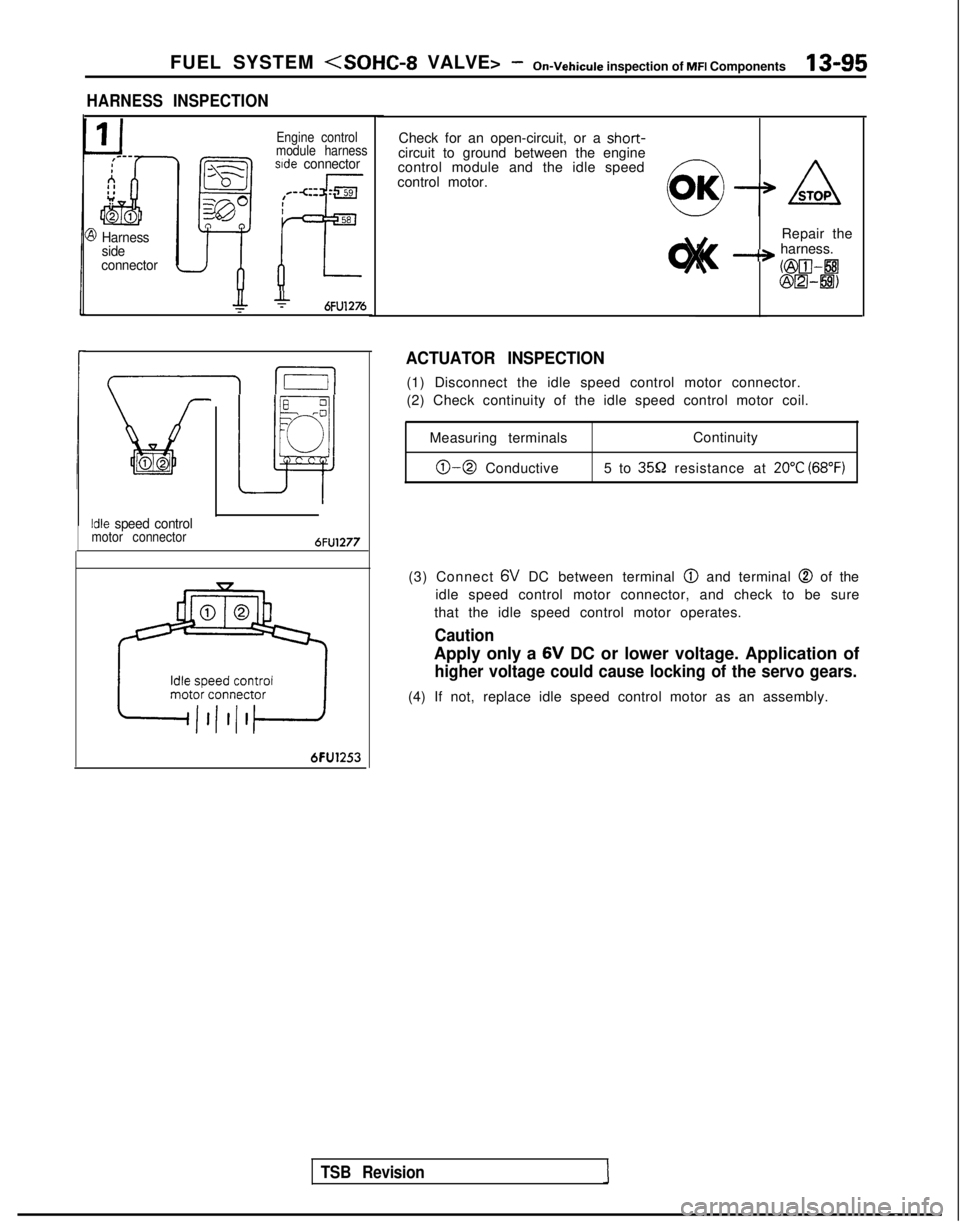

FUEL SYSTEM

HARNESS INSPECTION

3 Harness

side

connector

Engine control

module harness

sde connector

+6FU1276

I I

Lit02

Idle speed controlmotor connector6FU1277

6FU1253

Check for an open-circuit, or a short-circuit to ground between the engine

control module and the idle speed

control motor.

Repair the

-+ harness.

OZGII-8@m-8)

TSB Revision

ACTUATOR INSPECTION

(1) Disconnect the idle speed control motor connector.

(2) Check continuity of the idle speed control motor coil.Measuring terminals Continuity

0-0 Conductive

5 to 3552 resistance at 20°C (68°F)

(3) Connect 6V

DC between terminal @

and terminal @ of the

idle speed control motor connector, and check to be sure

that the idle speed control motor operates.

Caution

Apply only a 6V

DC or lower voltage. Application of

higher voltage could cause locking of the servo gears.

(4) If not, replace idle speed control motor as an assembly.

Page 238 of 1273

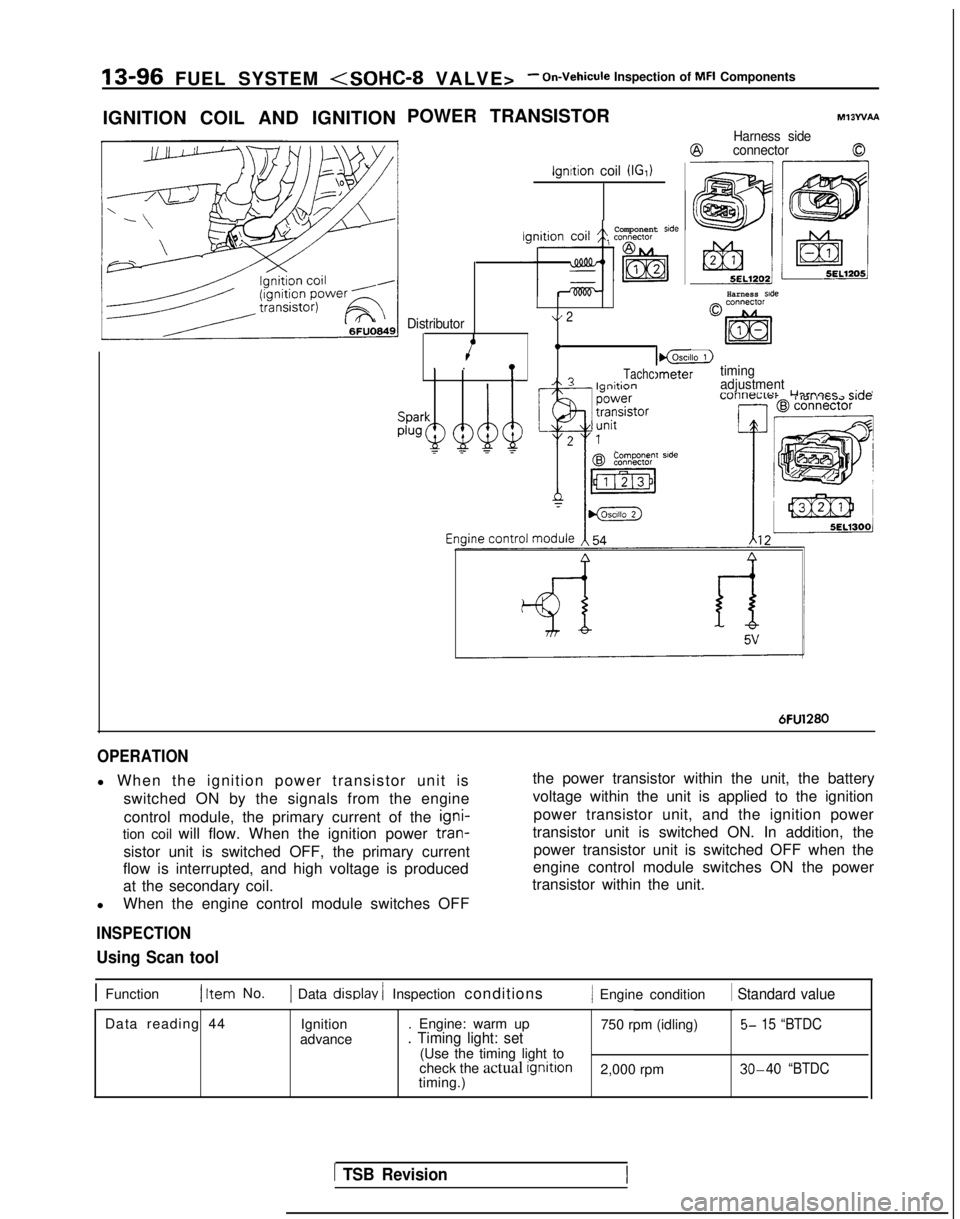

13-96 FUEL SYSTEM

IGNITION COIL AND IGNITION POWER TRANSISTOR

ignition coil (IGI)

Ml3WAA

Harness side

@connector0

Harness side

Component side

Distributor\/ 2

4.I_lgnltion. .!

I@LZ)

TachcImetertimingA? I--:*:^^adjustment-_

Lllrnacr

r;rlnI 101 i IG.72 Jl”F

Componenr side

6FU1280

OPERATION

l When the ignition power transistor unit is

switched ON by the signals from the engine

control module, the primary current of the igni-

tion coil will flow. When the ignition power tran-

sistor unit is switched OFF, the primary current

flow is interrupted, and high voltage is produced

at the secondary coil.

l When the engine control module switches OFF

INSPECTION

the power transistor within the unit, the battery

voltage within the unit is applied to the ignition

power transistor unit, and the ignition power

transistor unit is switched ON. In addition, the power transistor unit is switched OFF when the

engine control module switches ON the power

transistor within the unit.

Using Scan tool

1 Function1 Item No.1 Data display / Inspection conditions/ Engine condition 1 Standard value

Data reading 44

Ignition

advance . Engine: warm up

750 rpm (idling)5- 15 “BTDC. Timing light: set(Use the timing light to

check the actual ignition

2,000 rpm 30-40 “BTDCtiming.)

1 TSB Revision

Page 239 of 1273

FUEL SYSTEM (SOHC-8 VALVE> -On-Vehicule Inspection of MFI Components13-97

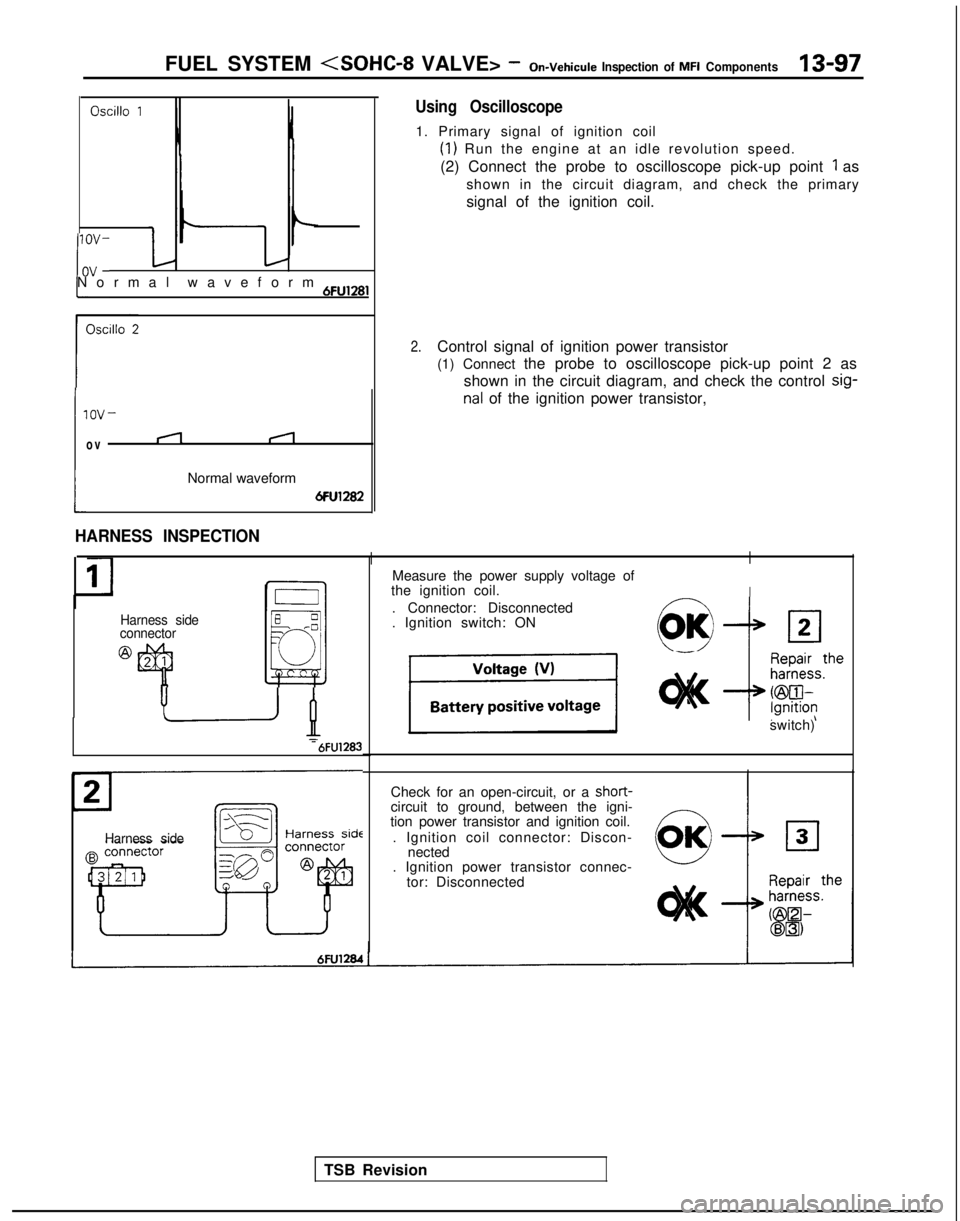

Oscillo 1

If-Normal waveform 6Fu,28,

lOV-

ov

i

nal of the ignition power transistor,

(1

Normal waveform

6Fu1282

Using Oscilloscope

1. Primary signal of ignition coil

(1) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point

1 as

shown in the circuit diagram, and check the primary

signal of the ignition coil.

2.Control signal of ignition power transistor

(1) Connect the probe to oscilloscope pick-up point 2 as shown in the circuit diagram, and check the control sig-

Harness side

connector

@

HARNESS INSPECTION

II

I I

I

Measure the power supply voltage of

the ignition coil.

. Connector: Disconnected

. Ignition switch: ON

c--vOK/III2

-‘B-6FU1283

TSB Revision

Harness side

switch)

Check for an open-circuit, or a short-

circuit to ground, between the igni-

tion power transistor and ignition coil.

. Ignition coil connector: Discon- nected

. Ignition power transistor connec-

tor: Disconnected

Page 240 of 1273

IS-98 FUEL SYSTEM

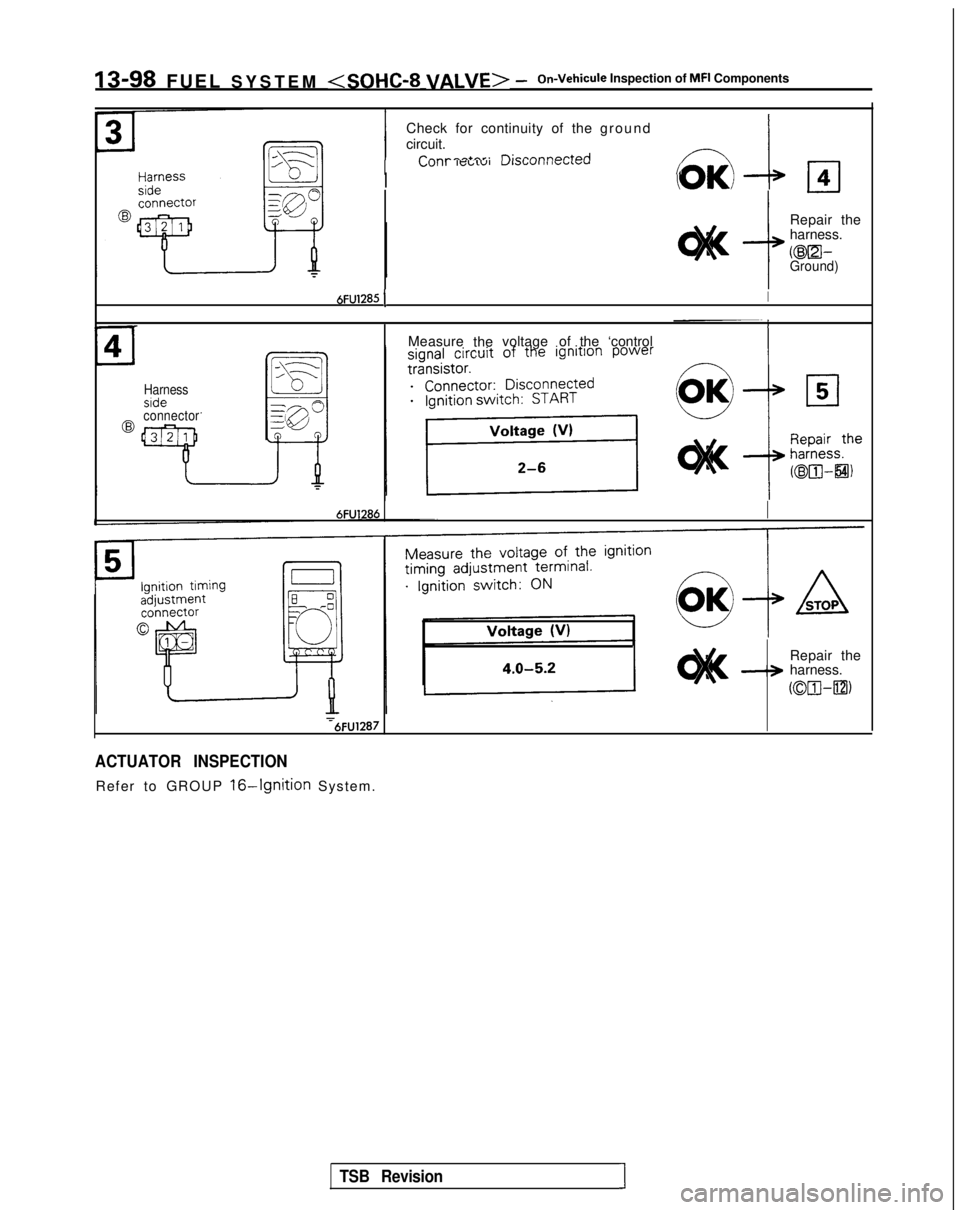

Check for continuity of the ground

circuit.

IP--^^^+rrr. n;ronnnnr+prjL”,,, ,wdL”IVlJlr”l I4 IbUI””

I

r-l4

I -@Repair the

harness.

@El-Ground)

Harness

6FU1285 1I

Measure

thevoltage

of the ‘control

@connector

6FU1286

Repair the-+ harness.

CtxHm

:6FU1287

ACTUATOR INSPECTION

Refer to GROUP 16-Ignition System.

TSB RevisionI