MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 221 of 1273

FUEL SYSTEM

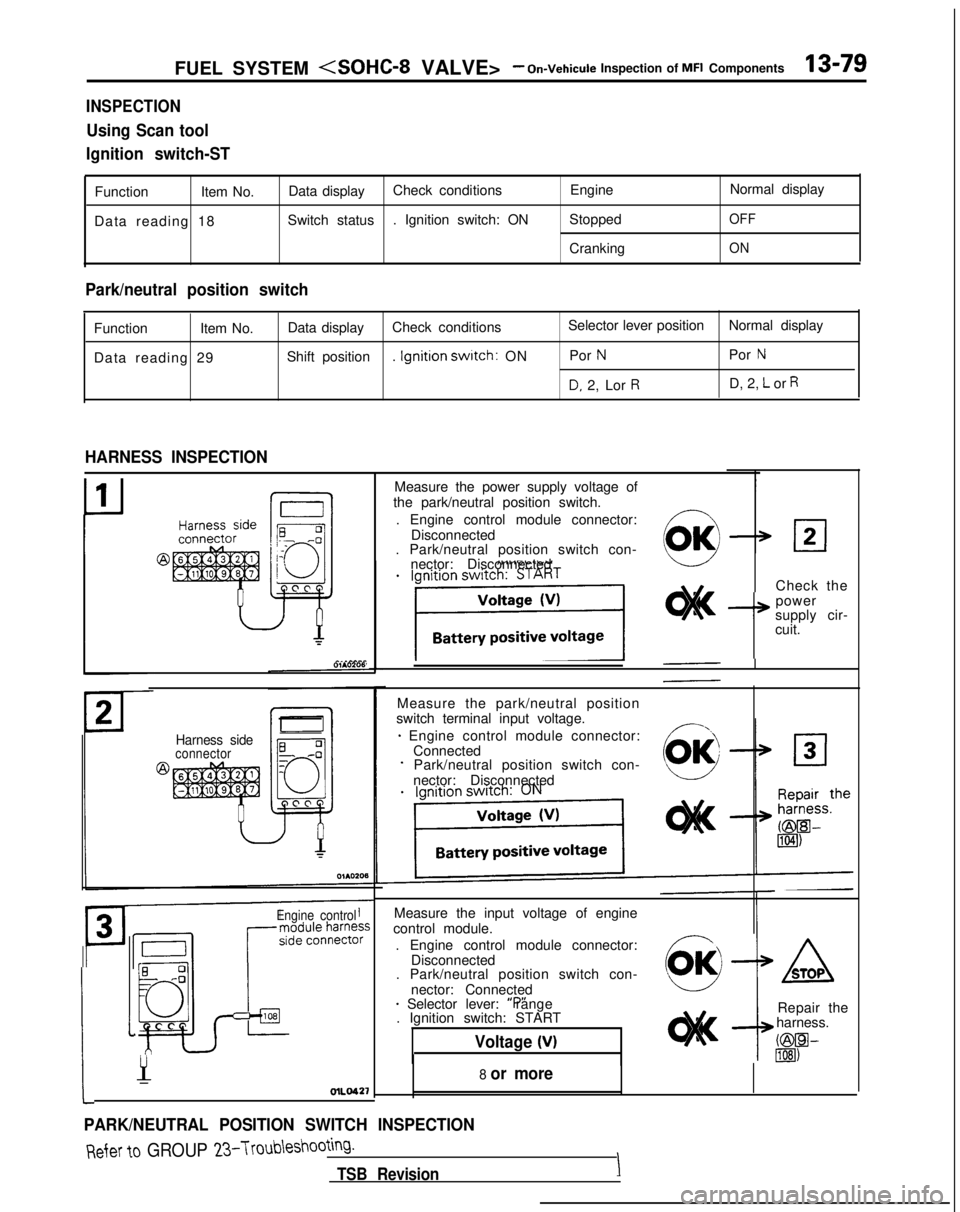

INSPECTION

Using Scan tool

Ignition switch-ST

Function Item No.Data display Check conditions

EngineNormal display

Data reading 18 Switch status

. Ignition switch: ON Stopped

OFF

CrankingON

Park/neutral position switch

Function

Item No.Data display

Check conditions Selector lever position

Normal display

Data reading 29 Shift position

. Ignition

swatch: ON Por NPor N

D, 2, Lor RD, 2, L or R

HARNESS INSPECTION

Harness sideconnector

Engine control

Measure the input voltage of engine

control module.

. Engine control module connector: Disconnected

. Park/neutral position switch con-

nector: Connected

* Selector lever: “P” range

. Ignition switch: START

Voltage (V)

:

1

Y-OlLO42’f

PARK/NEUTRAL POSITION SWITCH INSPECTION

Measure the power supply voltage of

the park/neutral position switch.

. Engine control module connector: Disconnected

. Park/neutral position switch con-

nector: Disconnected

Check the

I+

power

supply cir-

cuit.

Measure the park/neutral position

switch terminal input voltage.

* Engine control module connector: ConnectedPark/neutral position switch con-

nector: Disconnected

8 or more

ASTOP

Repair the

harness.

C@W lIEI)

Refer to GROUP 23-Troubleshooting.

TSB RevisionI

Page 222 of 1273

13-80 FUEL SYSTEM

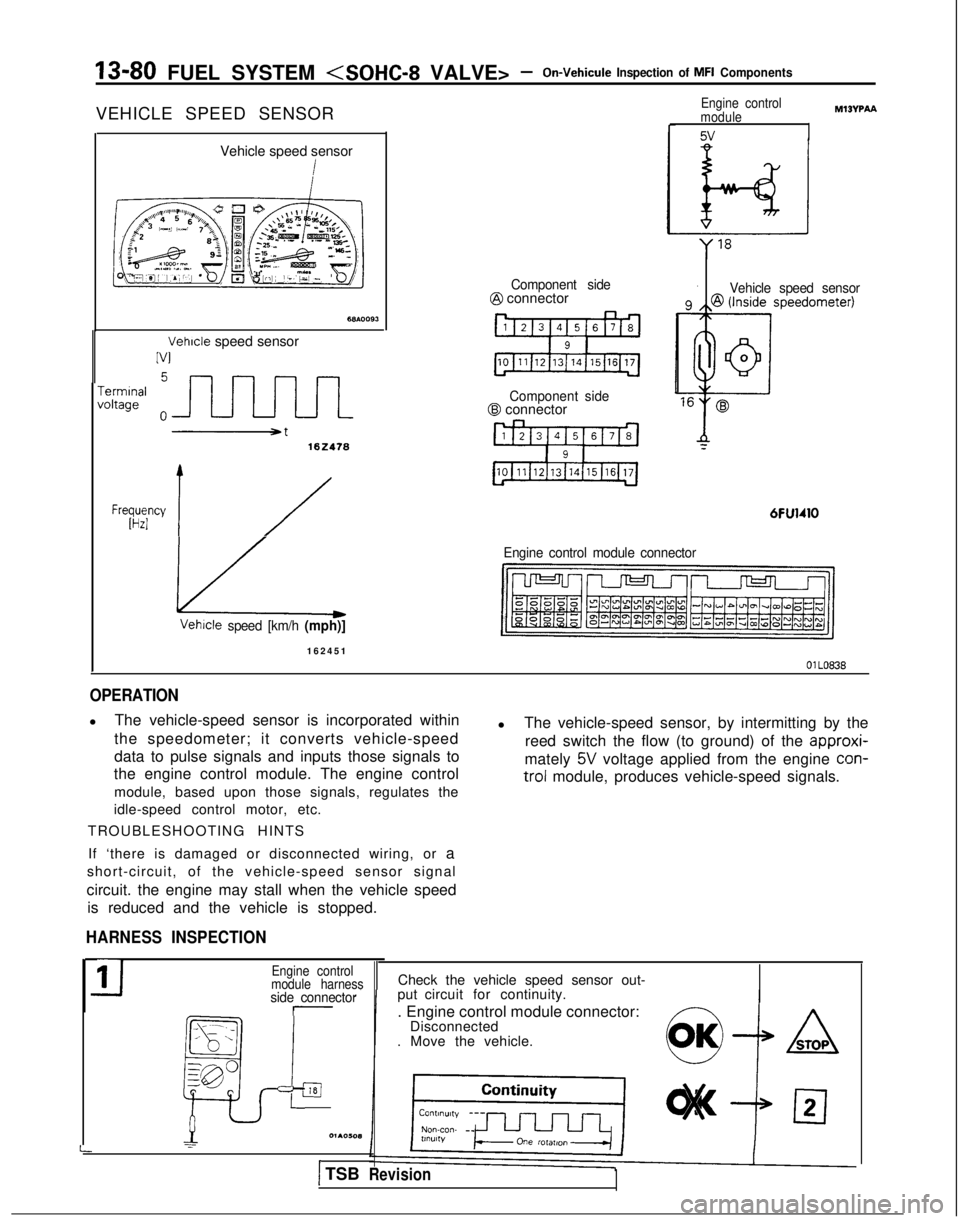

VEHICLE SPEED SENSOR

Vehicle speed sensor

Vehicle speed sensor

IV1

-errnInafoltage

102418

Frwyy 1/

Component side@ connector

Component side@ connector

6FU1410

Engine control

module

5v

MIBVPAA

Vehicle speed sensor

Engine control module connector Vetwle

speed [km/h (mph)]

16245

1

OlLO838

OPERATION

l

The vehicle-speed sensor is incorporated within

the speedometer; it converts vehicle-speed

data to pulse signals and inputs those signals to

the engine control module. The engine control

module, based upon those signals, regulates the

idle-speed control motor, etc.

TROUBLESHOOTING HINTS l

The vehicle-speed sensor, by intermitting by the

reed switch the flow (to ground) of the approxi-

mately

5V voltage applied from the engine con-

trol

module, produces vehicle-speed signals.

If ‘there is damaged or disconnected wiring, or a

short-circuit, of the vehicle-speed sensor signal

circuit. the engine may stall when the vehicle speed is reduced and the vehicle is stopped.

HARNESS INSPECTION

-side connector

_--- _

ia

_, - .,

:_--

gp

p

L

11Engine control

module harness

=l01AOW(1

I

Check the vehicle speed sensor out-

put circuit for continuity.

. Engine control module connector: Disconnected

. Move the vehicle.

) TSBRevision

Page 223 of 1273

FUEL SYSTEM

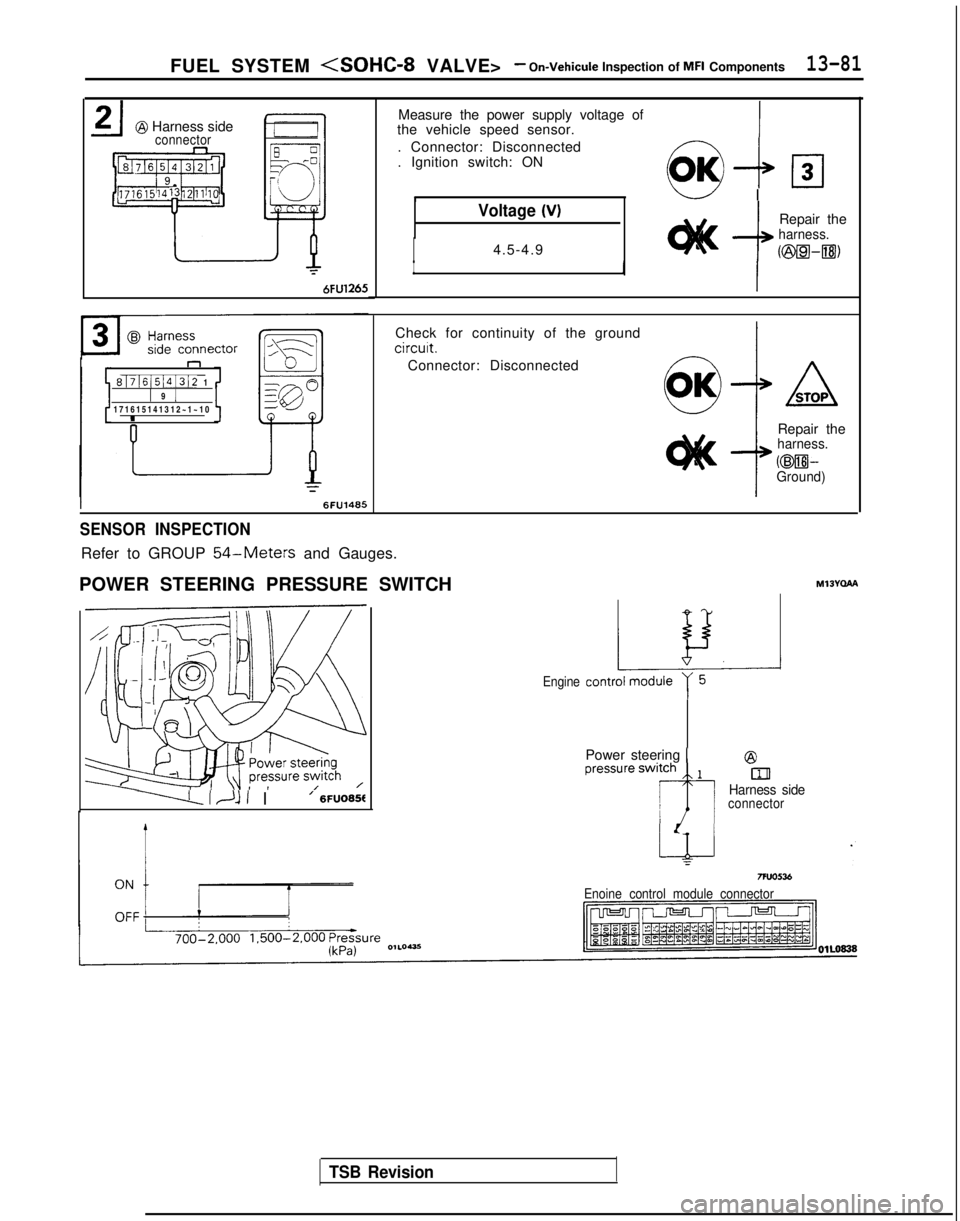

@ Harness sideconnector

6FU1265

n

8171615141312 11 9 1171615141312~1~1

0

I

Measure the power supply voltage of

the vehicle speed sensor.

. Connector: Disconnected

. Ignition switch: ON

6&loIw I

Voltage (V)

I4.5-4.9--I

Repair theharness.

II

I

Check for continuity of the ground

circuit.

Connector: Disconnected

Repair the

harness.

@WGround)

SENSOR INSPECTION

Refer to GROUP 54-Meters and Gauges.

POWER STEERING PRESSURE SWITCH MI3Yclha

------LI~lI I’ 6FUO65f

TSB Revision

Engine

Power steering 1@

blHarness sideconnector

Enoine control module connector

Page 224 of 1273

13-82 FUEL SYSTEM

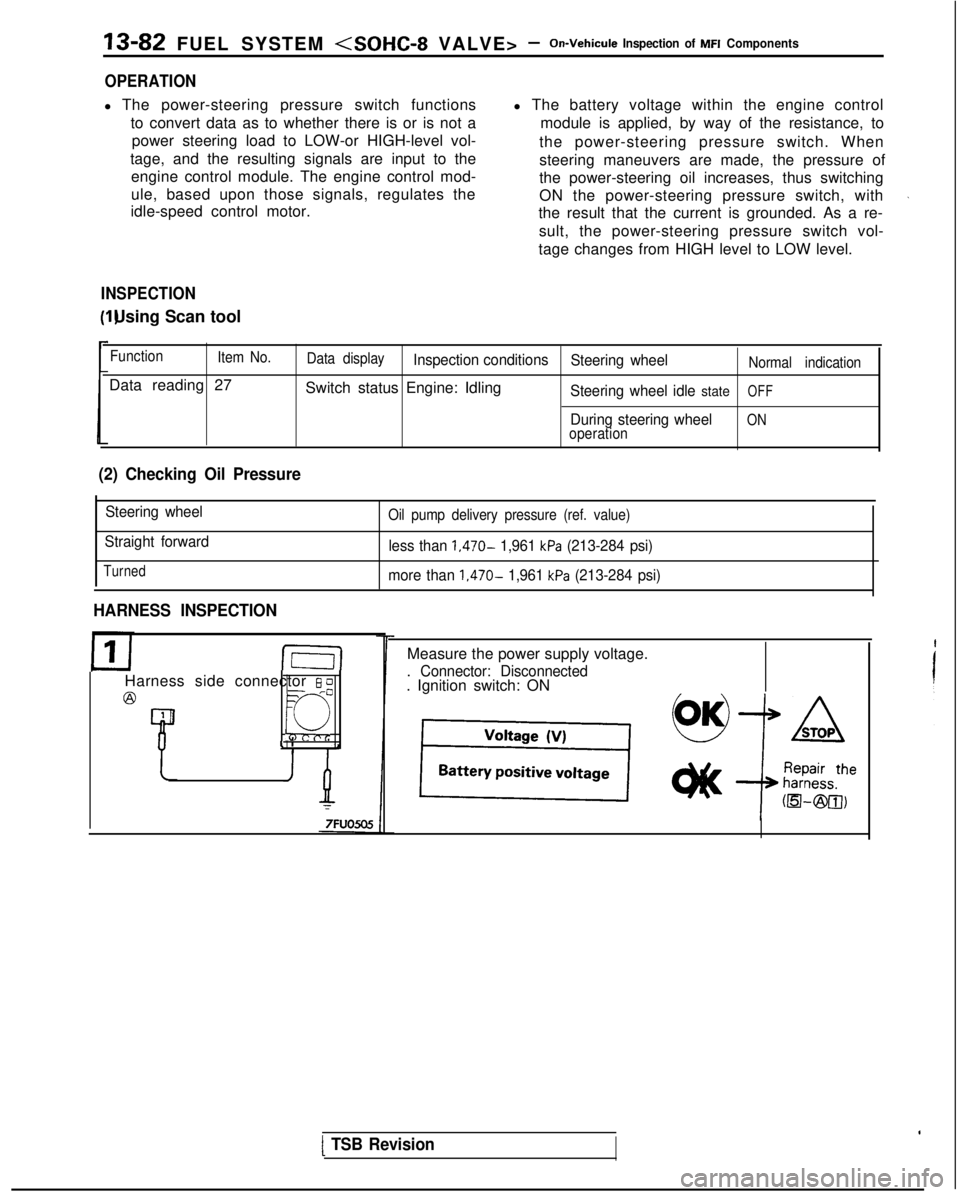

OPERATION

l The power-steering pressure switch functions

to convert data as to whether there is or is not apower steering load to LOW-or HIGH-level vol-

tage, and the resulting signals are input to the engine control module. The engine control mod-

ule, based upon those signals, regulates the

idle-speed control motor. l The battery voltage within the engine control

module is applied, by way of the resistance, to

the power-steering pressure switch. When

steering maneuvers are made, the pressure of

the power-steering oil increases, thus switching

ON the power-steering pressure switch, with

the result that the current is grounded. As a re-

sult, the power-steering pressure switch vol-

tage changes from HIGH level to LOW level.

INSPECTION I) Using Scan tool

Function

Item No.

Data reading 27

Data displayInspection conditions Steering wheelNormal indication

Switch status Engine: IdlingSteering wheel idle stateOFF

During steering wheelONoperation

(2) Checking Oil Pressure

Steering wheel

Straight forward

Turned

Oil pump delivery pressure (ref. value)

less than 1,470- 1,961 kPa (213-284 psi)

more than

1,470- 1,961 kPa (213-284 psi)

HARNESS INSPECTION

I-E-I

Harness side connector 6 0

@=- -0

Q

4 1

Measure the power supply voltage.

. Connector: Disconnected. Ignition switch: ON

[ TSB Revision

Page 225 of 1273

FUEL SYSTEM

inspection of MFI Components13-83

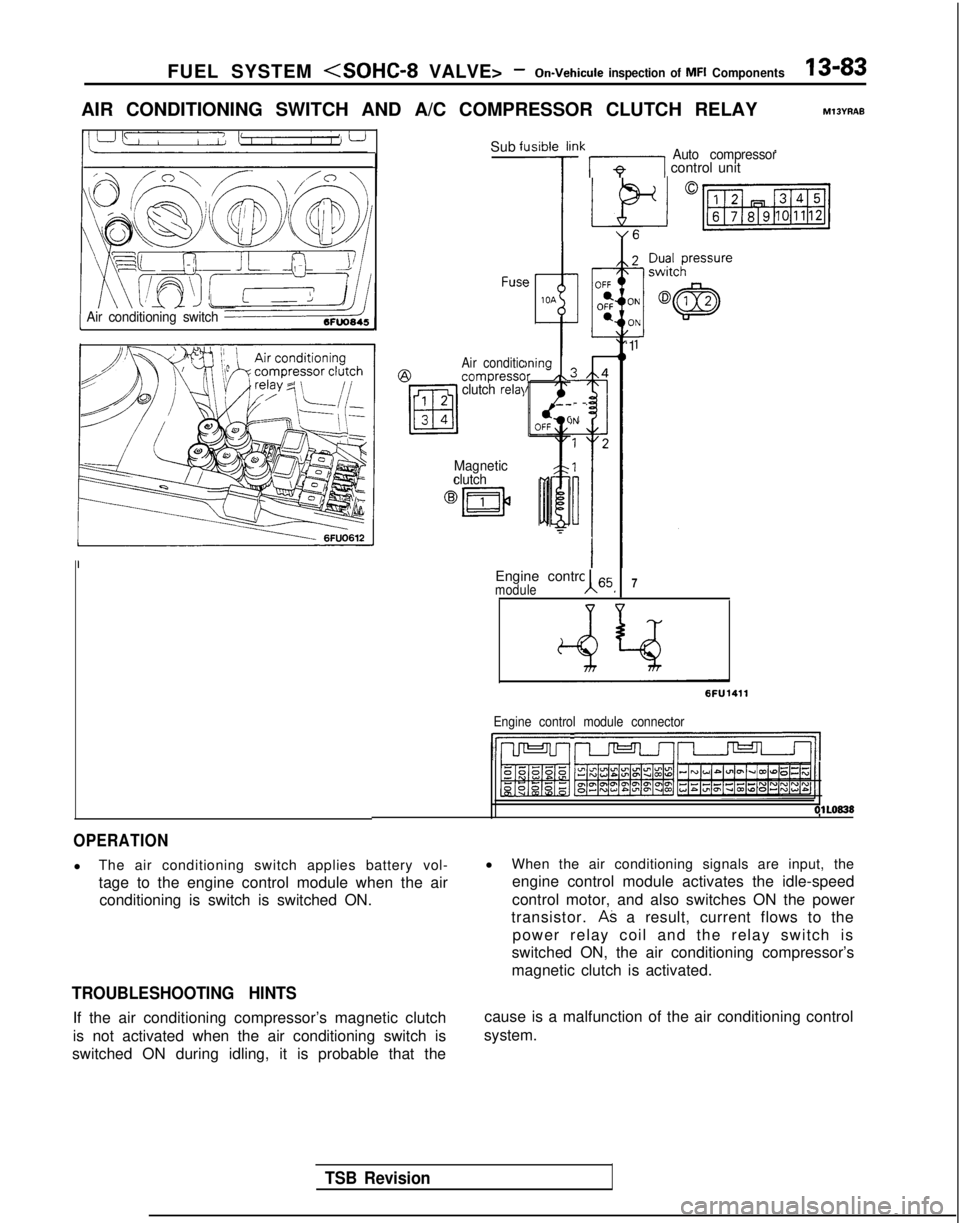

AIR CONDITIONING SWITCH AND A/C COMPRESSOR CLUTCH RELAYM13YRAE

Air conditioning switch

Sub fl

FUSC?

Air conditic@compresscclutch relal

Magnetic

clutch

Jsibie li

7

)ningIr /k

!Ik 171 control unitAuto compressor

-

-

)N

Engine control 65moduleA I7

‘1

6FU1411

Engine control module connector

IhJ-Jl r--vrJ=-Jl/l

OlLO838

OPERATION

l

The air conditioning switch applies battery vol-

tage to the engine control module when the air

conditioning is switch is switched ON.

TROUBLESHOOTING HINTS

If the air conditioning compressor’s magnetic clutch

is not activated when the air conditioning switch is

switched ON during idling, it is probable that the l

When the air conditioning signals are input, the

engine control module activates the idle-speed

control motor, and also switches ON the power

transistor.

AS a result, current flows to the

power relay coil and the relay switch is

switched ON, the air conditioning compressor’s

magnetic clutch is activated.

cause is a malfunction of the air conditioning control

system.

TSB Revision

Page 226 of 1273

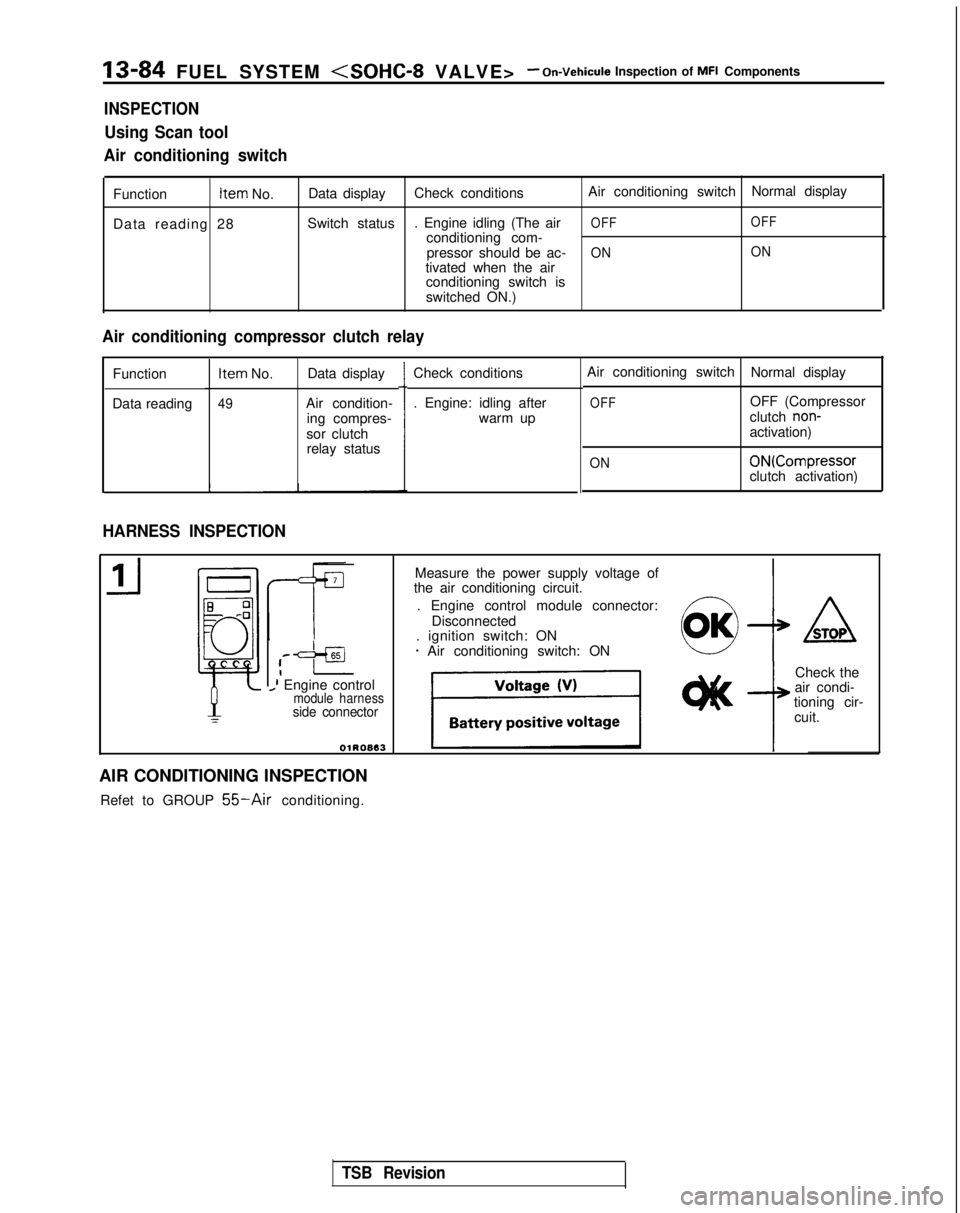

13-84 FUEL SYSTEM

INSPECTION

Using Scan tool

Air conditioning switch

Function Item

No.

Data reading 28 Data display

Check conditions Air conditioning switch

Normal display

Switch status . Engine idling (The air

OFF OFFconditioning com-

pressor should be ac-ON ONtivated when the air

conditioning switch is

switched ON.)

Air conditioning compressor clutch relay

Function

Data reading Item

No. Data display

49Air condition-

ing compres-

sor clutch relay status Check conditions

. Engine: idling after

warm up

HARNESS INSPECTION

Air conditioning switch Normal display

OFFOFF (Compressor

clutch non-activation)

ON ON(Compressor

clutch activation)

,--=+aI_I Engine controlmodule harnessside connector

OlROB13

Measure the power supply voltage of

the air conditioning circuit.

. Engine control module connector: Disconnected

. ignition switch: ON

* Air conditioning switch: ON4

ASTOP

Check the

air condi-

tioning cir-

cuit.

AIR CONDITIONING INSPECTION Refet to GROUP

55-Air conditioning.

TSB Revision

Page 227 of 1273

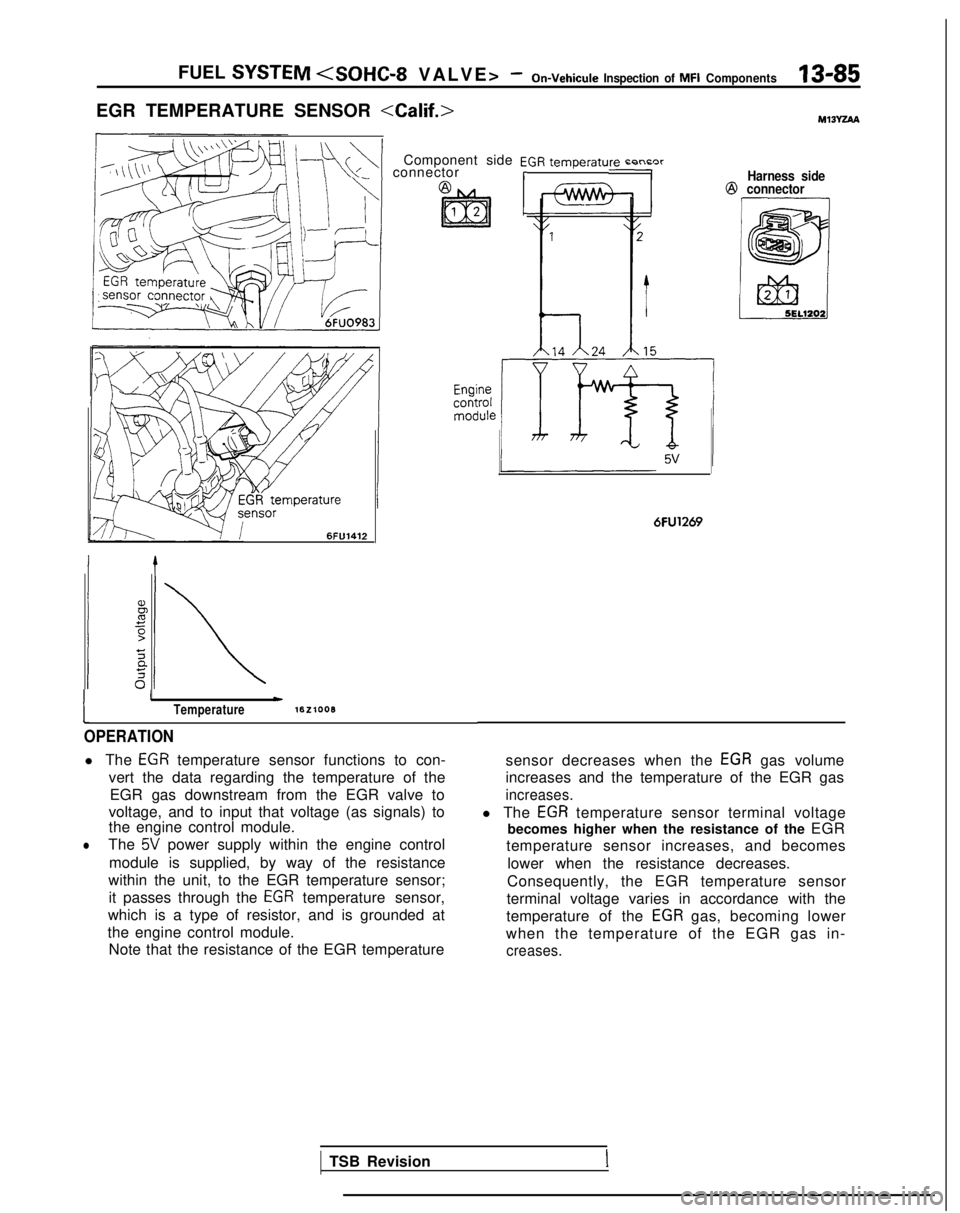

FUEL SYSTEnrll (SOHC-8 VALVE> -On-Vehicule

Inspection of MFI Components13-85

EGR TEMPERATURE SENSOR

\+\+I connectorComponent side EGR temperaturn r-n~nrrHarness side@

connector 6FlJ1412

1

IwTemperaturelEzlooB

OPERATION

l The EGR temperature sensor functions to con-

vert the data regarding the temperature of the EGR gas downstream from the EGR valve to

voltage, and to input that voltage (as signals) to

the engine control module.

lThe 5V power supply within the engine control

module is supplied, by way of the resistance

within the unit, to the EGR temperature sensor; it passes through the

EGR temperature sensor,

which is a type of resistor, and is grounded at

the engine control module. Note that the resistance of the EGR temperature

6FU1269

sensor decreases when the EGR gas volume

increases and the temperature of the EGR gas

increases.

l The EGR temperature sensor terminal voltage

becomes higher when the resistance of the EGR

temperature sensor increases, and becomes

lower when the resistance decreases.

Consequently, the EGR temperature sensor

terminal voltage varies in accordance with the

temperature of the

EGR gas, becoming lower

when the temperature of the EGR gas in-

creases.

TSB RevisionI

Page 228 of 1273

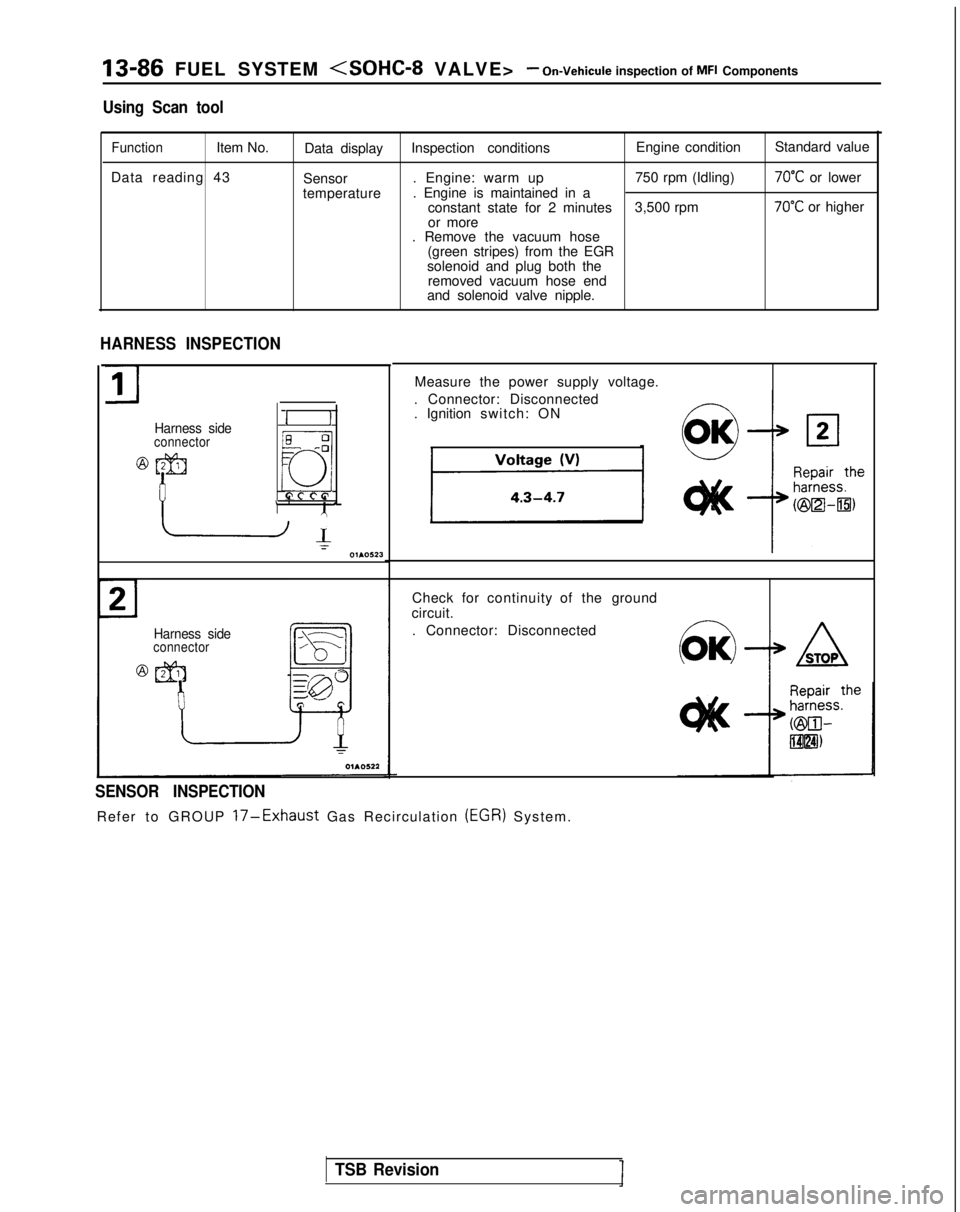

13-86 FUEL SYSTEM

Using Scan tool

FunctionItem No.Data display Inspection conditions Engine condition

Standard value

Data reading 43 Sensor. Engine: warm up

750 rpm (Idling)

70°C or lower

temperature . Engine is maintained in a

constant state for 2 minutes 3,500 rpm

70°C or higher

or more

. Remove the vacuum hose

(green stripes) from the EGR

solenoid and plug both the removed vacuum hose end

and solenoid valve nipple.

HARNESS INSPECTION

Harness sideconnector

@qqJ

I

II

EL -:

f7

Q,

L *A’

-1I01.0523

Measure the power supply voltage.

. Connector: Disconnected

. Ignition switch: ON

Harness sideconnector

Check for continuity of the ground

circuit.

. Connector: Disconnected

SENSOR INSPECTION

Refer to GROUP 17-Exhaust Gas Recirculation (EGR)

System.

-w

STOP

TSB Revision

Page 229 of 1273

FUEL SYSTEM

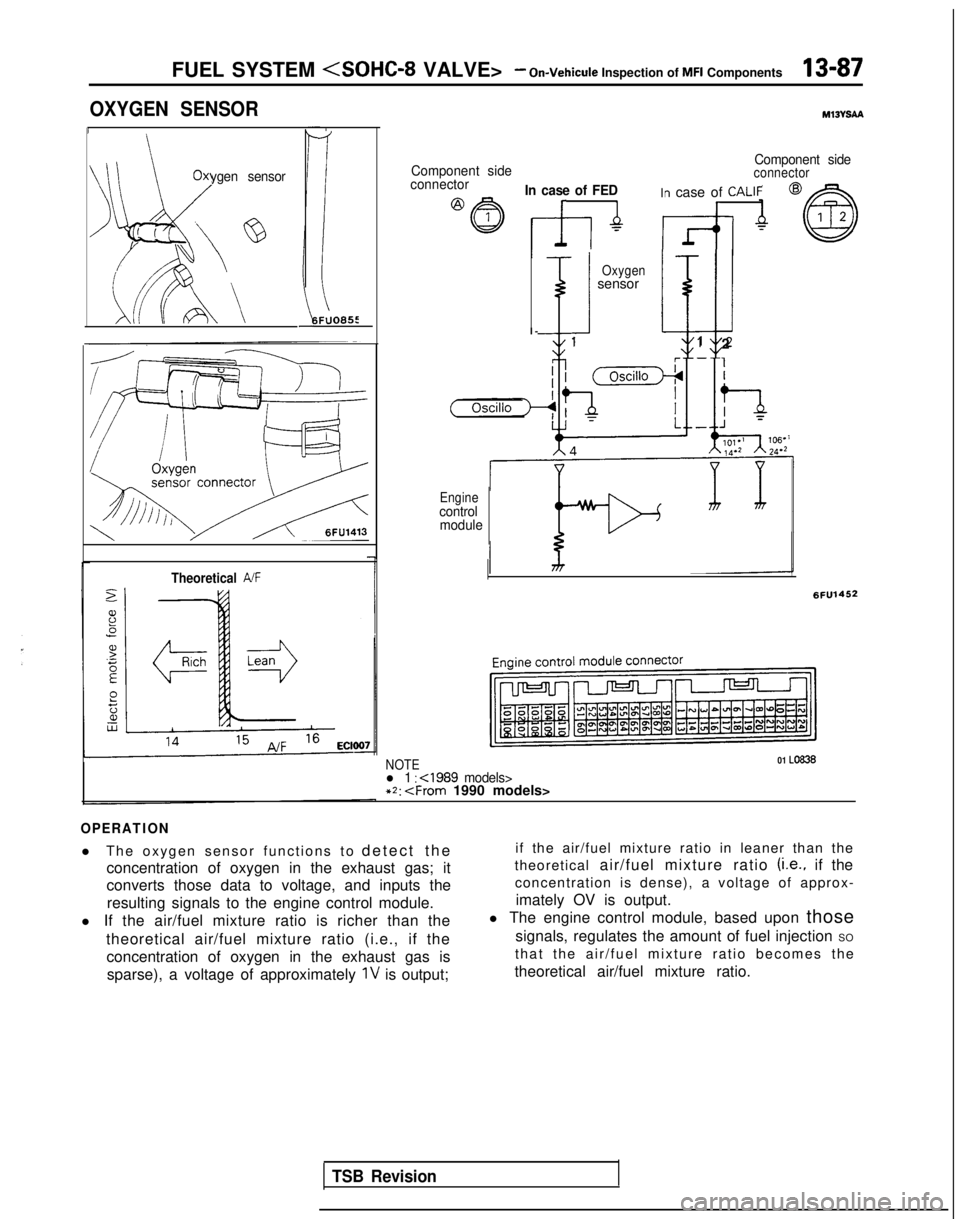

OXYGEN SENSORM13VSAa

/

Oxygen sensor

)G/’ ‘;‘@

i b\A

-

I6FUO659

Theoretical A/F

Component side

Component sideconnectorconnectorIn case of FEDIn case of CALIFI r

Oxygensensor

i klJ

I

-

11 2

Enginecontrol

module

6FU1452

NOTE01 Lo836

l 1 :

OPERATION

l The oxygen sensor functions to

detect th

e

concentration of oxygen in the exhaust gas; it

converts those data to voltage, and inputs the

resulting signals to the engine control module.

l If the air/fuel mixture ratio is richer than the

theoretical air/fuel mixture ratio (i.e., if theconcentration of oxygen in the exhaust gas issparse), a voltage of approximately

1V is output; if the air/fuel mixture ratio in leaner than the

theoretical air/fuel mixture ratio

(Le., if the

concentration is dense), a voltage of approx-

imately OV is output.

l The engine control module, based upon those

signals, regulates the amount of fuel injection SO

that the air/fuel mixture ratio becomes th

e

theoretical air/fuel mixture ratio.

TSB Revision

Page 230 of 1273

13-88 FUEL SYSTEM

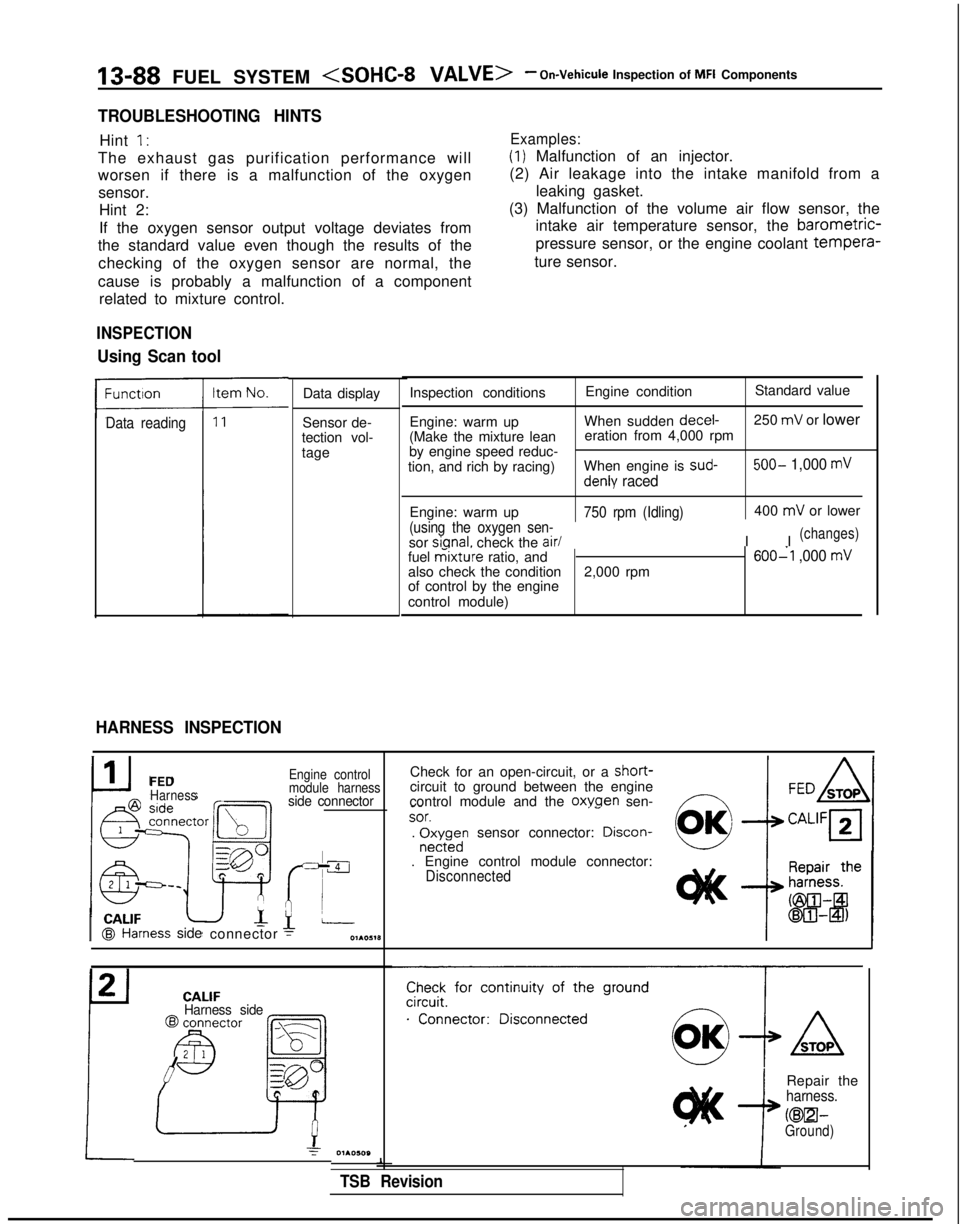

TROUBLESHOOTING HINTS

Hint I’

The exhaust gas purification performance will

Examples:

(1) Malfunction of an injector.

worsen if there is a malfunction of the oxygen sensor. Hint 2:

If the oxygen sensor output voltage deviates from

the standard value even though the results of the

checking of the oxygen sensor are normal, the

cause is probably a malfunction of a component related to mixture control. (2) Air leakage into the intake manifold from a

leaking gasket.

(3) Malfunction of the volume air flow sensor, the intake air temperature sensor, the barometric-

pressure sensor, or the engine coolant tempera-

ture sensor.

Data reading

INSPECTION

Using Scan tool

HARNESS INSPECTION

Data display

Sensor de-

tection vol-

tage Inspection conditions

Engine conditionStandard value

Engine: warm up When sudden decel-

250

mV or lower

(Make the mixture lean eration from 4,000 rpm

by engine speed reduc-

tion, and rich by racing) When engine is sud-

500- 1,000 mV

denly raced

Engine: warm up750 rpm (Idling)

(using the oxygen sen-

sor sianal.

check the air/

400

mV or lower

I I

(changes)

fuel mixture ratio, and600-l ,000 mValso check the condition 2,000 rpm

of control by the engine

control module)

I CALIF@I Hal

FEDHarness

ness

side

connector

Engine control

module harness

side connector

Check for an open-circuit, or a short-circuit to ground between the engine

control module and the oxwen sen-f7 _-

~~SOT.‘-. r$;rdn sensor connector: Drscon-

. Engine control module connector:Disconnected CALIF

Harness side

Check for continuity of the ground

.“‘..“...;;”

Repair theharness.

KEEI-Ground)

1

TSB Revision