check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1034 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - ;;:i~%:?~~“~

33B-95

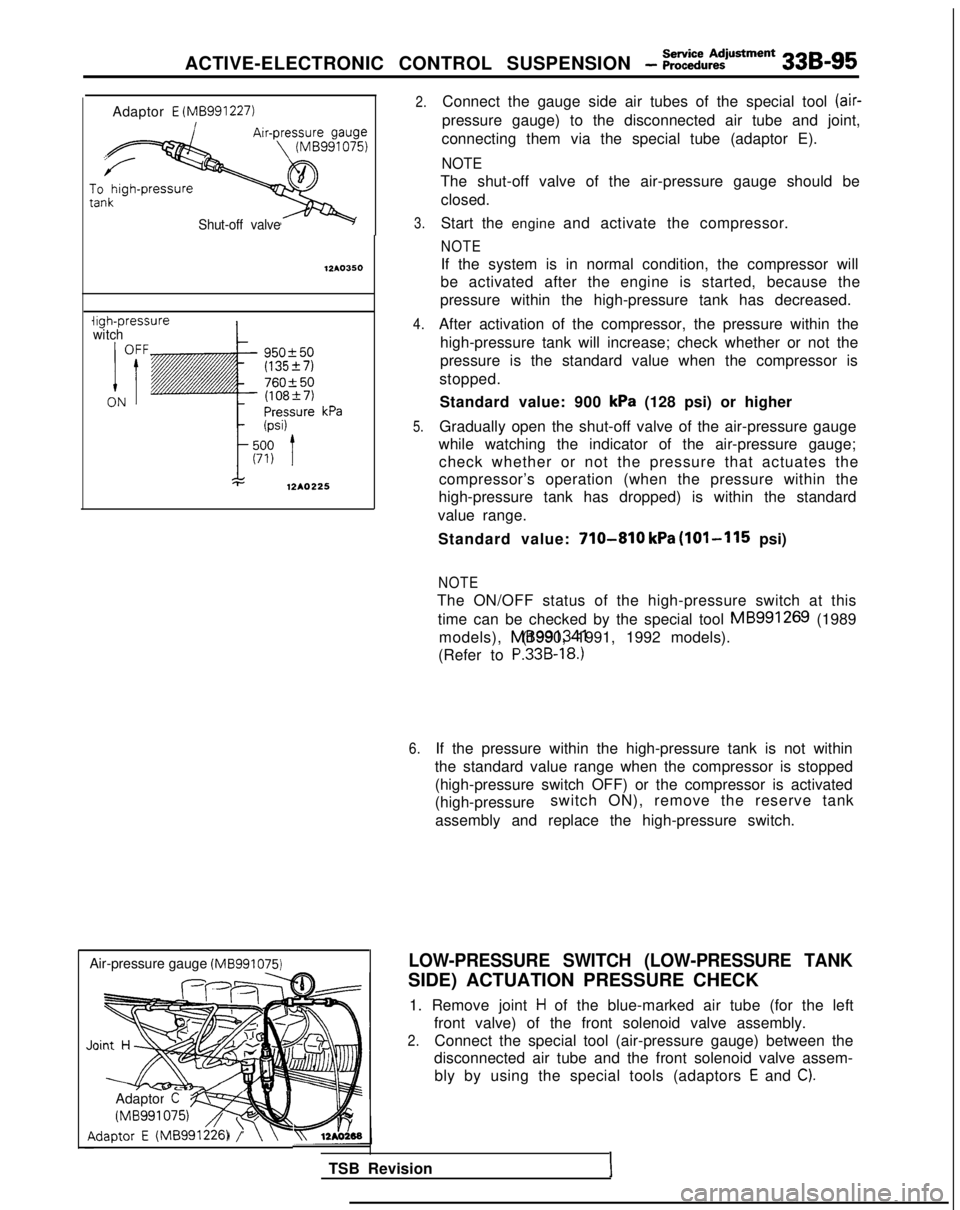

Adaptor E (MB991227)

Shut-off valve 12A.0350

iigh-pressure

witch

Air-pressure gauge (MB991075)

Adaptor C

(MB991 075.q

,daptor E (MB991226) /P-

3intH &‘xb

2.

3.

4.

5.

Connect the gauge side air tubes of the special tool (air-

pressure gauge) to the disconnected air tube and joint,

connecting them via the special tube (adaptor E).

NOTE

The shut-off valve of the air-pressure gauge should be closed.

Start the engine and activate the compressor.

NOTE

If the system is in normal condition, the compressor will

be activated after the engine is started, because the

pressure within the high-pressure tank has decreased.

After activation of the compressor, the pressure within the high-pressure tank will increase; check whether or not the

pressure is the standard value when the compressor is

stopped.

Standard value: 900

kPa (128 psi) or higher

Gradually open the shut-off valve of the air-pressure gauge

while watching the indicator of the air-pressure gauge; check whether or not the pressure that actuates the

compressor’s operation (when the pressure within the

high-pressure tank has dropped) is within the standard

value range.

Standard value:

710-810 kPa (101-115 psi)

NOTE

The ON/OFF status of the high-pressure switch at this time can be checked by the special tool MB991269

(1989

models), MB991341 (1990, 1991, 1992 models).

(Refer to

P.33B-18.)

6.If the pressure within the high-pressure tank is not within

the standard value range when the compressor is stopped

(high-pressure switch OFF) or the compressor is activated

(high-pressure switch ON), remove the reserve tank

assembly and replace the high-pressure switch.

LOW-PRESSURE SWITCH (LOW-PRESSURE TANK

SIDE) ACTUATION PRESSURE CHECK

1. Remove joint

H of the blue-marked air tube (for the left

front valve) of the front solenoid valve assembly.

2.Connect the special tool (air-pressure gauge) between the

disconnected air tube and the front solenoid valve assem-

bly by using the special tools (adaptors

E and C).

TSB RevisionI

Page 1035 of 1273

338-96

ACTIVE-ELECTRONIC CONTROL SUSPENSION - ;;~:;u~:iusment

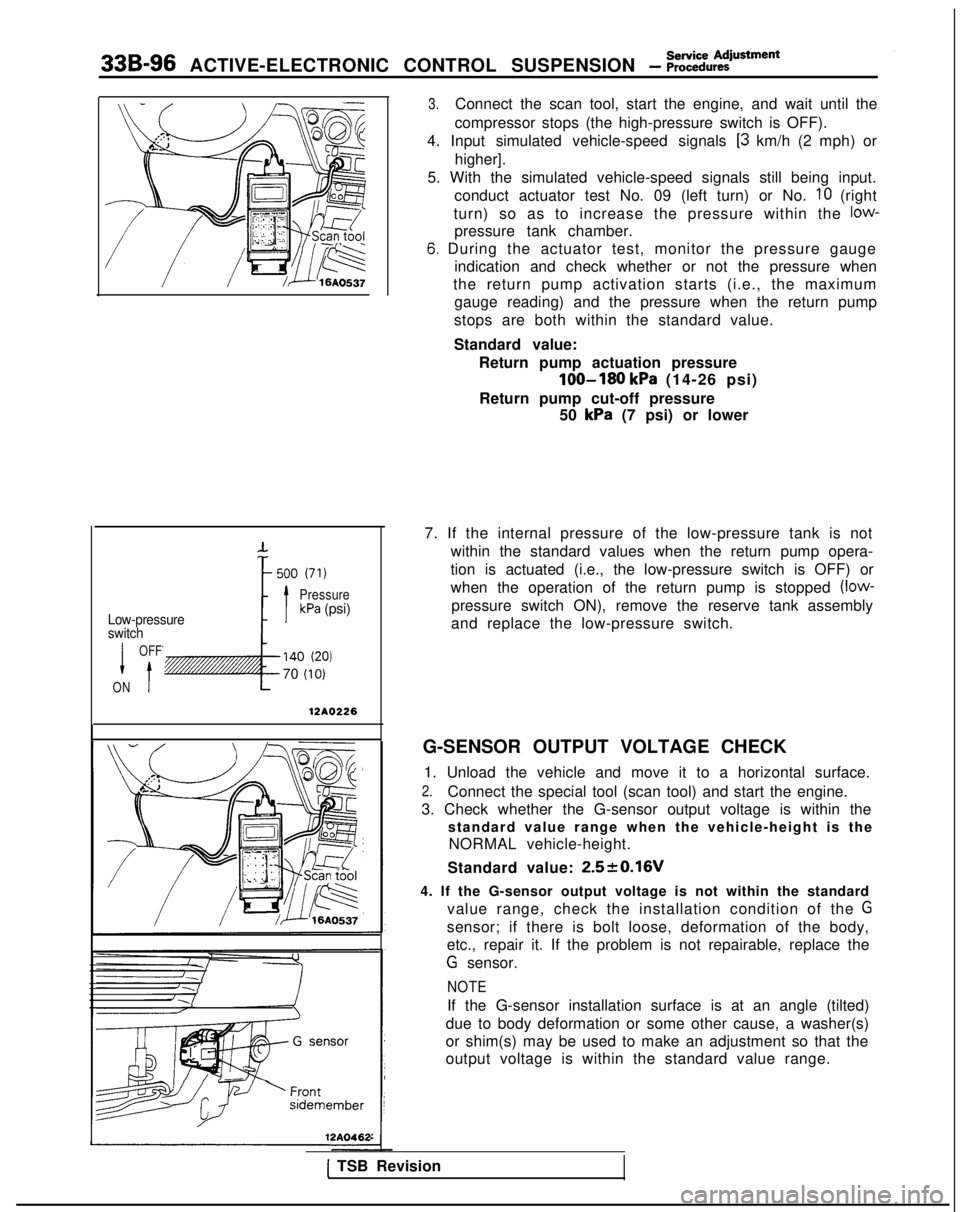

Low-pressure

switch

PressurekPa (psi)

I

OFF

t

140 (20)

70 (10)

ON

12AO226

12A04P

3.Connect the scan tool, start the engine, and wait until the

compressor stops (the high-pressure switch is OFF).

4. Input simulated vehicle-speed signals

[3 km/h (2 mph) or

higher].

5. With the simulated vehicle-speed signals still being input. conduct actuator test No. 09 (left turn) or No.

IO (right

turn) so as to increase the pressure within the

low-

pressure tank chamber.

6. During the actuator test, monitor the pressure gauge indication and check whether or not the pressure when

the return pump activation starts (i.e., the maximum gauge reading) and the pressure when the return pump

stops are both within the standard value.

Standard value: Return pump actuation pressure

loo-180 kPa (14-26 psi)

Return pump cut-off pressure 50

kPa (7 psi) or lower

7. If the internal pressure of the low-pressure tank is not within the standard values when the return pump opera-

tion is actuated (i.e., the low-pressure switch is OFF) or

when the operation of the return pump is stopped

(low-

pressure switch ON), remove the reserve tank assembly

and replace the low-pressure switch.

G-SENSOR OUTPUT VOLTAGE CHECK 1. Unload the vehicle and move it to a horizontal surface.

2.Connect the special tool (scan tool) and start the engine.

3. Check whether the G-sensor output voltage is within the standard value range when the vehicle-height is theNORMAL vehicle-height.

Standard value:

2.520.16V

4. If the G-sensor output voltage is not within the standard value range, check the installation condition of the

G

sensor; if there is bolt loose, deformation of the body,

etc., repair it. If the problem is not repairable, replace the

G sensor.

NOTE

If the G-sensor installation surface is at an angle (tilted)

due to body deformation or some other cause, a washer(s)

or shim(s) may be used to make an adjustment so that the

output voltage is within the standard value range.

1 TSB Revision

Page 1136 of 1273

SERVICE BRAKES - Anti-lock Braking System Troubleshooting35-15

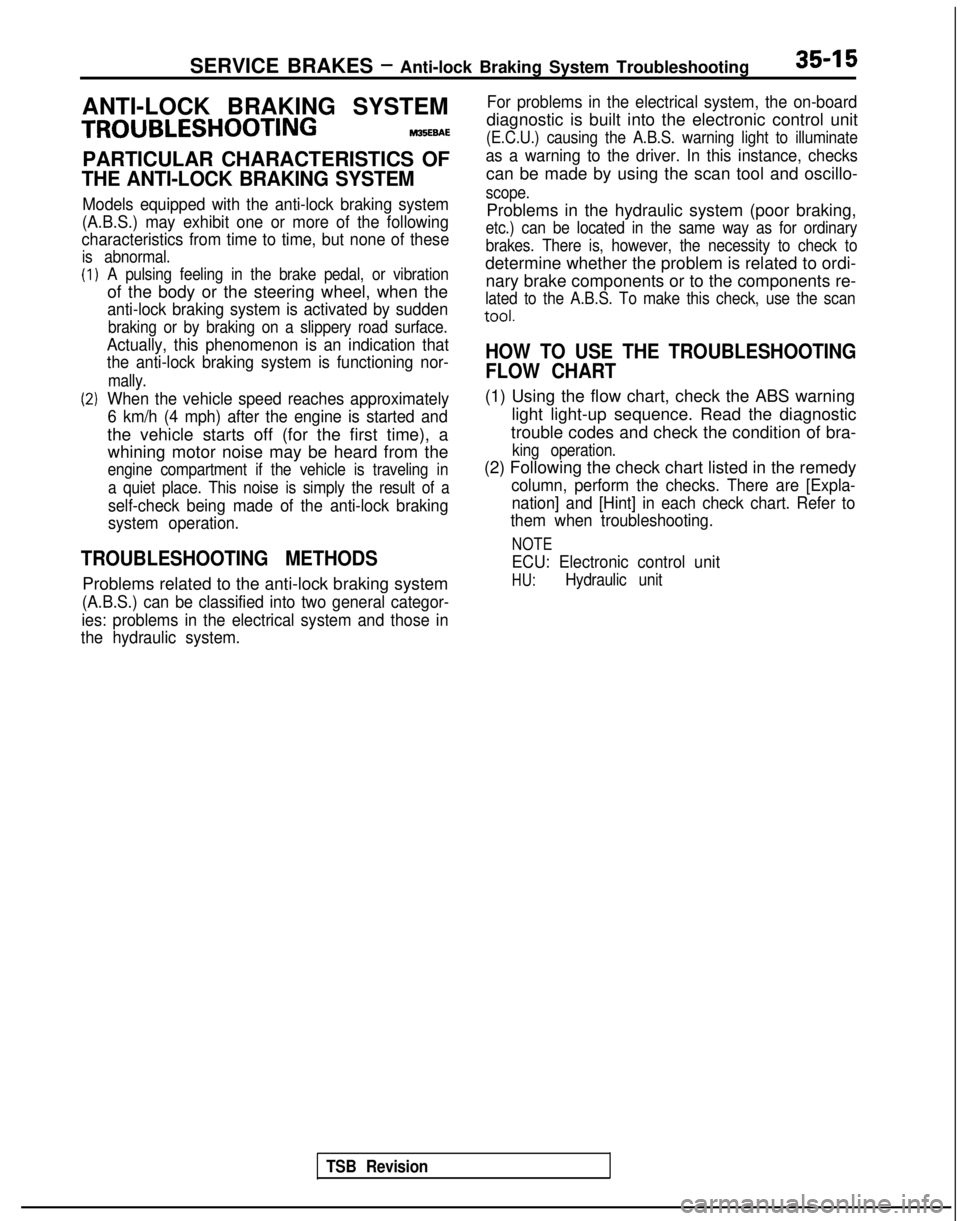

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTINGM35EElAE

PARTICULAR CHARACTERISTICS OF

THE ANTI-LOCK BRAKING SYSTEM

Models equipped with the anti-lock braking system

(A.B.S.) may exhibit one or more of the following

characteristics from time to time, but none of these

is abnormal.

(1)

(2)

A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.

Actually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.

When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), awhining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place. This noise is simply the result of a

self-check being made of the anti-lock braking

system operation.

TROUBLESHOOTING METHODS

Problems related to the anti-lock braking system

(A.B.S.) can be classified into two general categor-

ies: problems in the electrical system and those in

the hydraulic system. For problems in the electrical system, the on-board

diagnostic is built into the electronic control unit

(E.C.U.) causing the A.B.S. warning light to illuminate

as a warning to the driver. In this instance, checks

can be made by using the scan tool and oscillo-

scope.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check to

determine whether the problem is related to ordi-

nary brake components or to the components re-

lated to the A.B.S. To make this check, use the scan

tool.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART

(1) Using the flow chart, check the ABS warning

light light-up sequence. Read the diagnostic

trouble codes and check the condition of bra-

king operation.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Expla- nation] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTE

ECU: Electronic control unit

HU:Hydraulic unit

TSB Revision

Page 1137 of 1273

35-16SERVICE BRAKES - Anti-lock Braking System Troubleshooting

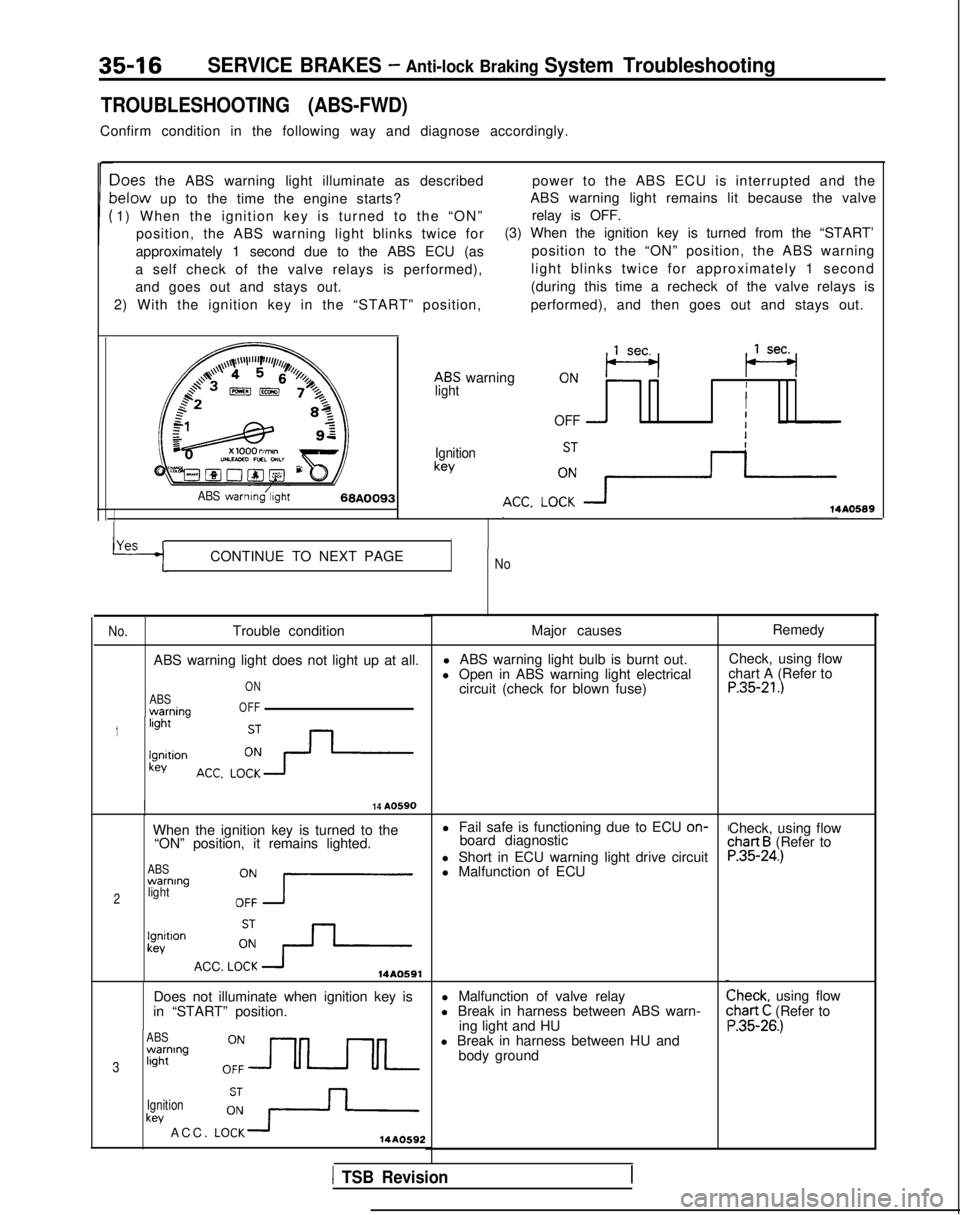

TROUBLESHOOTING (ABS-FWD)

Confirm condition in the following way and diagnose accordingly.

Ioes the ABS warning light illuminate as describedpower to the ABS ECU is interrupted and the

lelow up to the time the engine starts?ABS warning light remains lit because the valve

1) When the ignition key is turned to the “ON” relay is OFF.

position, the ABS warning light blinks twice for (3) When the ignition key is turned from the “START’

approximately 1 second due to the ABS ECU (as position to the “ON” position, the ABS warning

a self check of the valve relays is performed), light blinks twice for approximately 1 second

and goes out and stays out. (during this time a recheck of the valve relays is

2) With the ignition key in the “START” position, performed), and then goes out and stays out.

ABS warning

,,lseq (se+

lightII

OFF -I

Ignitionkey

ABS warnmg/;,ght68A009314A0589

YAS rICONTINUE TO NEXT PAGENo

No.

Trouble condition

ABS warning light does not light up at all.

ABSwarnina

ON

OFF

1light -

lgnltionkey

I14 A0590

When the ignition key is turned to the l Fail safe is functioning due to ECU on-

“ON” position, it remains lighted. board diagnostic

ABSwarning

2lightOZ7

l Short in ECU warning light drive circuit

l Malfunction of ECU

lgnitlonkev

ACC. LOi+14A0591

Does not illuminate when ignition key is

in “START” position.

ABSwarning

3light

Ignition

key ACC. LO:+14AO592

Major causes

l ABS warning light bulb is burnt out.

l Open in ABS warning light electrical circuit (check for blown fuse)

l Malfunction of valve relay

l Break in harness between ABS warn- ing light and HU

l Break in harness between HU and body ground Remedy

Check, using flow

chart A (Refer to

P.35-21.)

Check, using flowchart B (Refer toP.35-24.)

Check, using flow:hart C (Refer to ‘.35-26.)

1 TSB Revision

Page 1143 of 1273

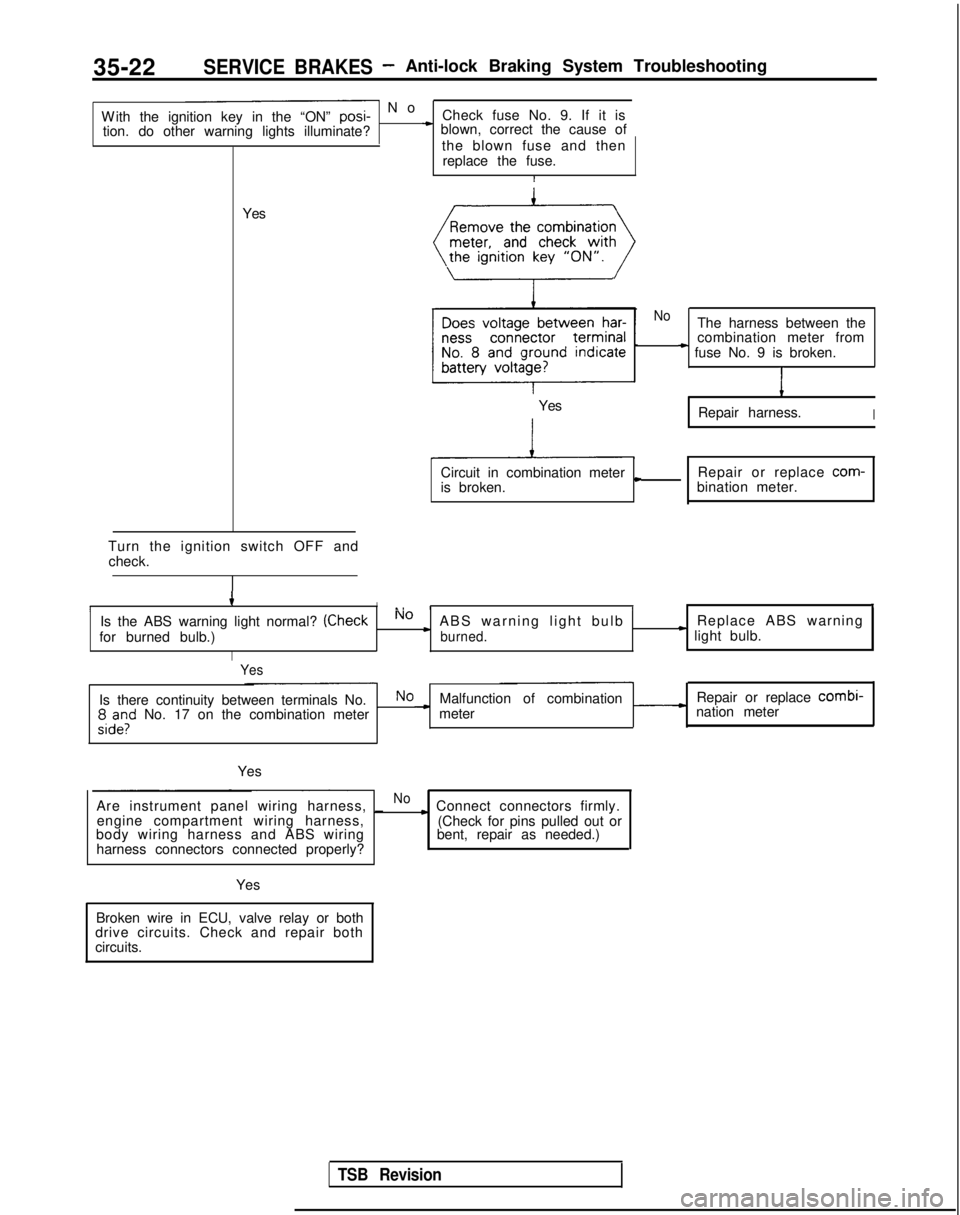

35-22SERVICE BRAKES- Anti-lock Braking System Troubleshooting

- N

o

With the ignition key in the “ON” posi-

Check fuse No. 9. If it is

tion. do other warning lights illuminate?

* blown, correct the cause of

the blown fuse and thenreplace the fuse.

I

Yes

Turn the ignition switch OFF and check.

4II., III,

Is the ABS warning light normal? (CheckNo cABS warning light bulb Replace ABS warning

for burned bulb.)burned.* light bulb.

I

Yes

NoThe harness between the

combination meter from

* fuse No. 9 is broken.

1

Repair harness.I

Circuit in combination metercRepair or replace com-

is broken. bination meter.

Yes

Is there continuity between terminals No.NoMalfunction of combination Repair or replace combi-

;,d”,l” No. 17 on the combination meter -meter

nation meter

Yes

Are instrument panel wiring harness, _

Noc Connect connectors firmly.

engine compartment wiring harness,

body wiring harness and ABS wiring

harness connectors connected properly? (Check for pins pulled out or

bent, repair as needed.)

Yes

Broken wire in ECU, valve relay or both

drive circuits. Check and repair both

circuits.

TSB Revision

Page 1145 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 35-24

SERVICE BRAKES - Anti-lock Braking System Troubleshooting

B ABS warning light illuminated after the engine is started and remains o\

n.

[Explanation]

This is the symptom when the ABS ECU does no MITSUBISHI GALANT 1989 Service Repair Manual 35-24

SERVICE BRAKES - Anti-lock Braking System Troubleshooting

B ABS warning light illuminated after the engine is started and remains o\

n.

[Explanation]

This is the symptom when the ABS ECU does no](/img/19/57312/w960_57312-1144.png)

35-24

SERVICE BRAKES - Anti-lock Braking System Troubleshooting

B ABS warning light illuminated after the engine is started and remains o\

n.

[Explanation]

This is the symptom when the ABS ECU does not

power up due to broken ECU power circuit, etc.,

when the fail safe function operates and isolates the

system or when the warning light drive circuit is

short circuited.

[Hint]

Check the on-board diagnostic output and if there is

no output voltage or if the scan tool and ABS ECU

cannot communicate, there is a good possibilit

y

that power is not flowing to the ECU.

Caution

l If there is no output of diagnostic trouble

codes, there is a good possibility that the

fail safe is functioning.

J/B

IGNITION

%FH

z

&7

i

CD10A

728

Is there on-board diagnostic No )output? (Is there communi-cation with scan tool?) CONTINUE TONEXT PAGE

Yes

TSB Revision

Does the ABS warning light

remain illuminated

even

with the ECU connector dis-

connected?

YesNoShort in ECU transistor

1 Replace ECU.I

Page 1154 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual MAIN FUSIBLE

LINK @

SERVICE BRAKES - Anti-lock Braking System Troubleshooting35-33

E-6When diagnostic trouble code “52 MOTOR RLY” is displayed

[Explanation][Hint]

The ABS ECU outputs this diagnost MITSUBISHI GALANT 1989 Service Repair Manual MAIN FUSIBLE

LINK @

SERVICE BRAKES - Anti-lock Braking System Troubleshooting35-33

E-6When diagnostic trouble code “52 MOTOR RLY” is displayed

[Explanation][Hint]

The ABS ECU outputs this diagnost](/img/19/57312/w960_57312-1153.png)

MAIN FUSIBLE

LINK @

SERVICE BRAKES - Anti-lock Braking System Troubleshooting35-33

E-6When diagnostic trouble code “52 MOTOR RLY” is displayed

[Explanation][Hint]

The ABS ECU outputs this diagnostic trouble code forIf there is motor operation noise when wheel speed

the motor relay and motor in the following cases.

exceeds Gkm/h (4mph) when starting up after the

l When the motor relay does not function

engine is started, or when there is forced scan tool

lWhen there is trouble with the motor itself and itdrive, there is a broken or short circuited motor

does not revolve

monitor wire.

lWhen the motor ground line is disconnected and

the motor does not revolve

l When the motor continues to revolve Does the motor make a

YesBroken wire or short cir-noise when wheel speed)

1

cuit in motor monitor line

exceeds 6 km/h (4 mph) or1

[ 1 ,2

/ 3 14 15 I6 1 I 18 I9l10l11112113114115116117l1sJ~l9~0~1~2tz3l2~~25t6~27~2~29~~~31~32b3134135/

14A0684

L

Remove the motor relay andcheck resistance values.No. 85-No. 86:resistancevalue 30-60 9No. 30-No. 87: no continui-

Motor relay malfunction

4

Replace motor relay.I

tYBattery voltage is applied onterminals No.85 and No.86grounded.No. 30-No. 87: continuity

Yes

Is pump motor ground con-netted normally? Connect ground wire.

\/i

Does voltage between bodyBroken wire in pump

connector terminal 11 andNo *motor power circuit

ground indicate battery vol-

tage?

1

Repair the harness.

Yes

Connect the HU

tonnetor and remove theECUconnector.

I

Is resistance between bodyNo - Malfunction of harness

connector terminal No. 2 and- between HU and ECU No.26 30-60 ohms?

1 Yes

Is resistance between ECUharness side connector ter- NO

minal No. 5 and ground 0.1 -0.3 ohm?

Yes

ABS ECU malfunction

1 TSB Revision

Replace ABS ECU.

Page 1155 of 1273

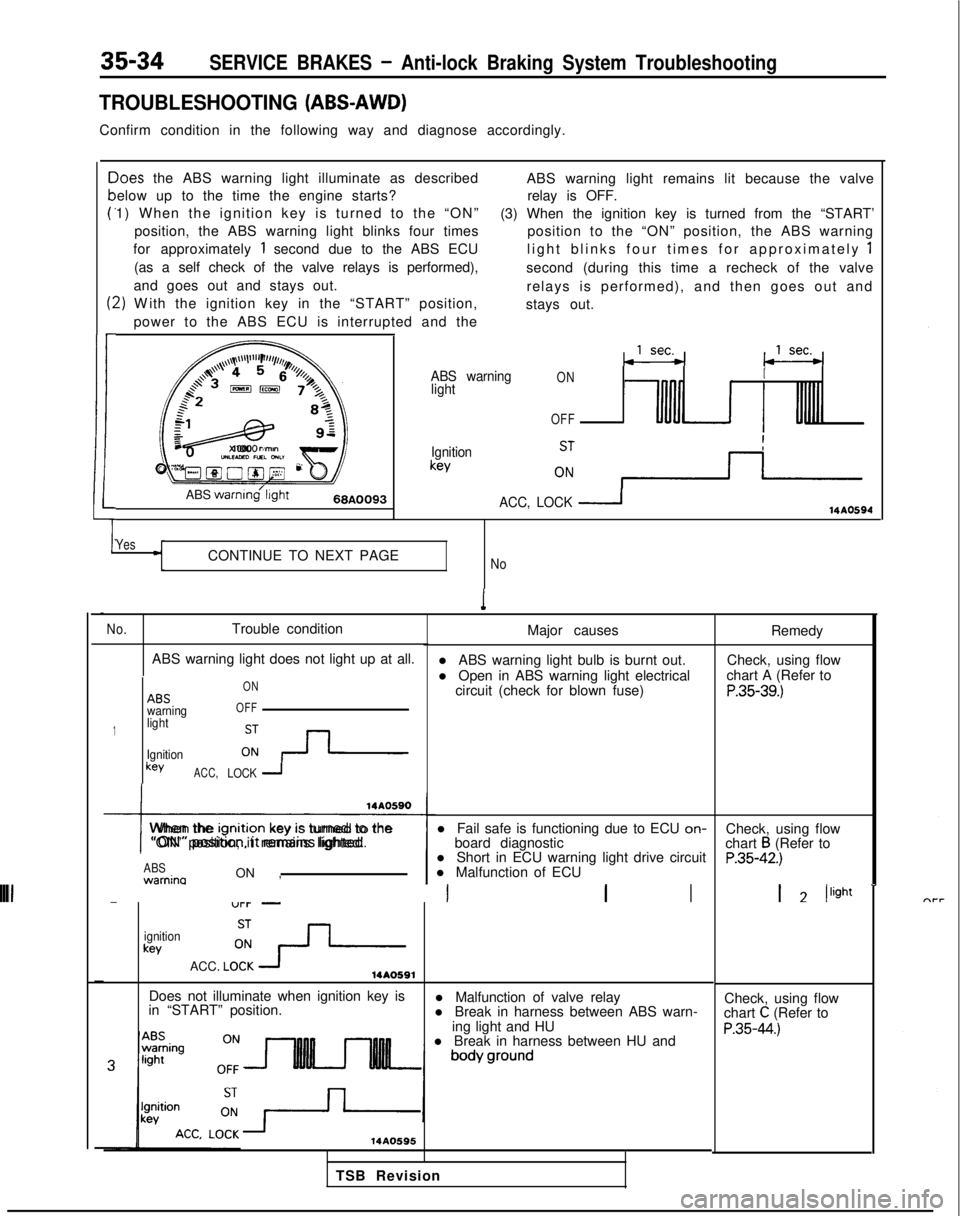

35-34SERVICE BRAKES - Anti-lock Braking System Troubleshooting

TROUBLESHOOTING (ABS-AWD)

Confirm condition in the following way and diagnose accordingly.

c

P

t:

1

-)oes

the ABS warning light illuminate as described

elow up to the time the engine starts?

1) When the ignition key is turned to the “ON”

position, the ABS warning light blinks four times

for approximately

1 second due to the ABS ECU

(as a self check of the valve relays is performed),

and goes out and stays out.

2) W

ith the ignition key in the “START” position,

power to the ABS ECU is interrupted and the ABS warning light remains lit because the valve

relay is OFF.

(3) When the ignition key is turned from the “START’ position to the “ON” position, the ABS warning

light blinks four times for approximately

1

second (during this time a recheck of the valve

relays is performed), and then goes out and

stays out.

,,,\~~\l’l”“F’,r//,,,l/,,

a+’4 4 5r’o, (j /z$$+3,,,,%&73,

:

f=&L-gy

82

1cJz

x 1000

rimonUILEAED nxL GNL”Oyg@O@~ 2F

ABS

warnmg’l~ght66A0093

ABS warning

lightONI

OFF

Ignitionkey

ACC, LOCK

114AO594

YesCONTINUE TO NEXT PAGENo

1

No.Trouble condition

ABS warning light does not light up at all.

1

ABSwarning

light

Ignition

keyACC, ON

OFFLOCK 1

I

When the lgnltlon

key IS turned to the

“ON” position, it remains lighted.

ABS warnina

ON , l Short in ECU warning light drive circuit

l Malfunction of ECU

-“l-l- -III

ignitionkey

ACC. LO!?-14AO591

Major causes

l ABS warning light bulb is burnt out.

l Open in ABS warning light electrical circuit (check for blown fuse)

l Fail safe is functioning due to ECU on-

board diagnostic

Does not illuminate when ignition key is

in “START” position. l Malfunction of valve relay

l Break in harness between ABS warn-

ing light and HU

l Break in harness between HU and

14AO595

Remedy

Check, using flow

chart A (Refer to

P.35-39.)

Check, using flow

chart B (Refer toP.35-42.)

1 2 /light

-

Check, using flow

chart C (Refer to

P.35-44.)

TSB Revision

Page 1161 of 1273

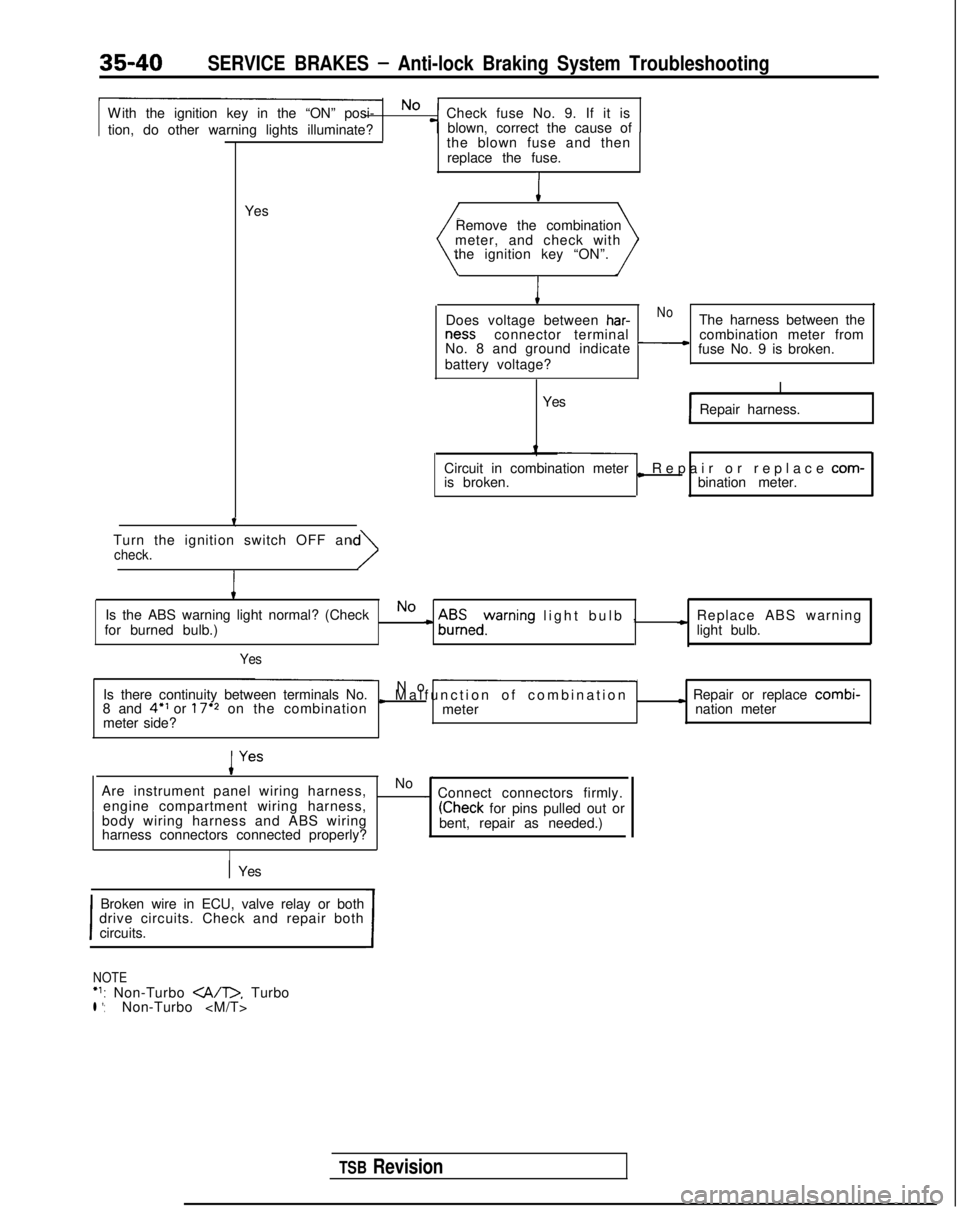

SERVICE BRAKES - Anti-lock Braking System Troubleshooting

W

ith the ignition key in the “ON” posi- No

Check fuse No. 9. If it is

tion, do other warning lights illuminate? blown, correct the cause of

-T-

Yesthe blown fuse and then

replace the fuse.I

Remove the combination

meter, and check with

the ignition key “ON”.

I

Does voltage between har-NoThe harness between the ness

connector terminal

No. 8 and ground indicate

-combination meter from

fuse No. 9 is broken.

battery voltage?

I

Yes Repair harness.

Circuit in combination meter

is broken.

L Repair or replace com-

bination meter.

Turn the ignition switch OFF an

check.

I

Is the ABS warning light normal? (CheckNo

for burned bulb.)c A$Eedyrning light bulb

,

c Replace ABS warning

light bulb.

Yes

Is there continuity between terminals No. No -

8 and 4” or 17’2 on the combinationI Malfunction of combinatio

n

meter

I Repair or replace combi-

meter side? nation meter

Are instrument panel wiring harness, No

-~

engine compartment wiring harness, . Connect connectors firmly.

body wiring harness and ABS wiring

(Check for pins pulled out or

harness connectors connected properly? bent, repair as needed.)

I

1 Yes

I

Broken wire in ECU, valve relay or both

drive circuits. Check and repair both

circuits.

I

NOTE‘1: Non-Turbo . Turbol *:Non-Turbo

TSB Revision

Page 1162 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 35-42

SERVICE BRAKES - Anti-lock Braking System Troubleshooting

BABS warning light illuminated after the engine is started and remains on\

.

[Explanation]

This is the symptom when the ABS ECU does not MITSUBISHI GALANT 1989 Service Repair Manual 35-42

SERVICE BRAKES - Anti-lock Braking System Troubleshooting

BABS warning light illuminated after the engine is started and remains on\

.

[Explanation]

This is the symptom when the ABS ECU does not](/img/19/57312/w960_57312-1161.png)

35-42

SERVICE BRAKES - Anti-lock Braking System Troubleshooting

BABS warning light illuminated after the engine is started and remains on\

.

[Explanation]

This is the symptom when the ABS ECU does not

power up due to broken ECU power circuit, etc.,

when the fail safe function operates and isolates the

system or when the warning light drive circuit is

short circuited.

[Hint]

Check the on-board diagnostic output and if there is

no output voltage or if the scan tool and ABS ECU

cannot communicate, there is a good possibility

that power is not flowing to the ECU.

Caution

l

If there is no output of diagnostic trouble

codes, there is a good possibility that the

fail safe is functioning.

MAINFUSIBLELINK @

IGNITION

SWITCH

(IG1)

ILOIE;NATION

+10

3

@izJ”,HUZ8 p:r12 /e-,

xx

I

I

I*I

; 16 4=

9

II

d

+qfimamq!2 a

I -LQ-7 ABS ECUm1

: Non-Turbo . Turbo: Non-Turbo

output? (Is there communi- NEXT PAGE

cation with scan tool?)

I

Yes

Does diagnostic troublecode output display normalcodes?

No . Check, using the diagnos-tic trouble code checkchart. (Refer to P.35-38.)IIILI

Short in harness betweenrgl;r ECU and ABS warning) Repair harness or replacecombination meter.

II

TSB Revision