check engine MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1173 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 35-52SERVICE BRAKES - Anti-lock Braking System Troubleshooting

E-7When diagnostic trouble code “52 MOTOR RLY” is displayedI

[Explanation][Hint]

The ABS ECU outputs this diagnostic trouble code for MITSUBISHI GALANT 1989 Service Repair Manual 35-52SERVICE BRAKES - Anti-lock Braking System Troubleshooting

E-7When diagnostic trouble code “52 MOTOR RLY” is displayedI

[Explanation][Hint]

The ABS ECU outputs this diagnostic trouble code for](/img/19/57312/w960_57312-1172.png)

35-52SERVICE BRAKES - Anti-lock Braking System Troubleshooting

E-7When diagnostic trouble code “52 MOTOR RLY” is displayedI

[Explanation][Hint]

The ABS ECU outputs this diagnostic trouble code forIf there is motor operation noise when wheel speed

the motor relay and motor in the following cases. exceeds Gkm/h

(4mph) when starting up after the

l When the motor relay does not function engine is started, or when there is forced scan tool

l When there is trouble with the motor

itself and itdrive, there is a broken or short circuited motor

does not revolve monitor wire.

l When there is trouble with the motor itself and it

the motor does not revolve

l When the motor continues to revolve Yes

Broken wire or short cir-

-Inoise when wheel

speedcuit in motor monitor line

MAIN FUSIBLE

LINK @&

1 j 2 I3 I4 I5 I6 I 7 18 I9 l10l11112113114115116l17 1819p0~1122~3~24l2S~26I27(2~29130131l32l33l3~~3~

(Remove the motor relay>

r

l

-

\

/4~

Remove the motor relay and -check resistance values.No c Motor relay malfunction

No. 85-No. 86:resistance4

value 30-60

QNo.30-No.87: no continui-

Replace motor relay.

t

y

Battery voltage is applied on

terminals No.86

and

No.85groundedNo.30-No.87: continuity 1Yes

Is pump motor ground con-

No

netted normally?

Connect ground wire.

lYes

<

Install motor relay and

move HU connector.

Does voltage between body

connector terminal 11 and

No ) Broken wire in pum

p

ground indicate battery vol- motor power circuit

tage?

4

Yes Repair the harness.I

tor and

remove theECU

Is resistance between body - No - Malfunction of harness

connector terminal No. 2 andNo No.26

30-60 ohms? between HU and ECUI

4 Yes.

Repair harness.II

ABS ECU malfunction

Replace ABS ECU.I

TSB Revision

Page 1174 of 1273

SERVICE BRAKES - Service Adjustment Procedures35-53

switch

switch

c/ 14F516

Pedal

Idown /

\ \

F14517

TSB Revision

F14518

SERVICE ADJUSTMENT PROCEDURES

BRAKE PEDAL INSPECTION AND ADJUSTMAN-

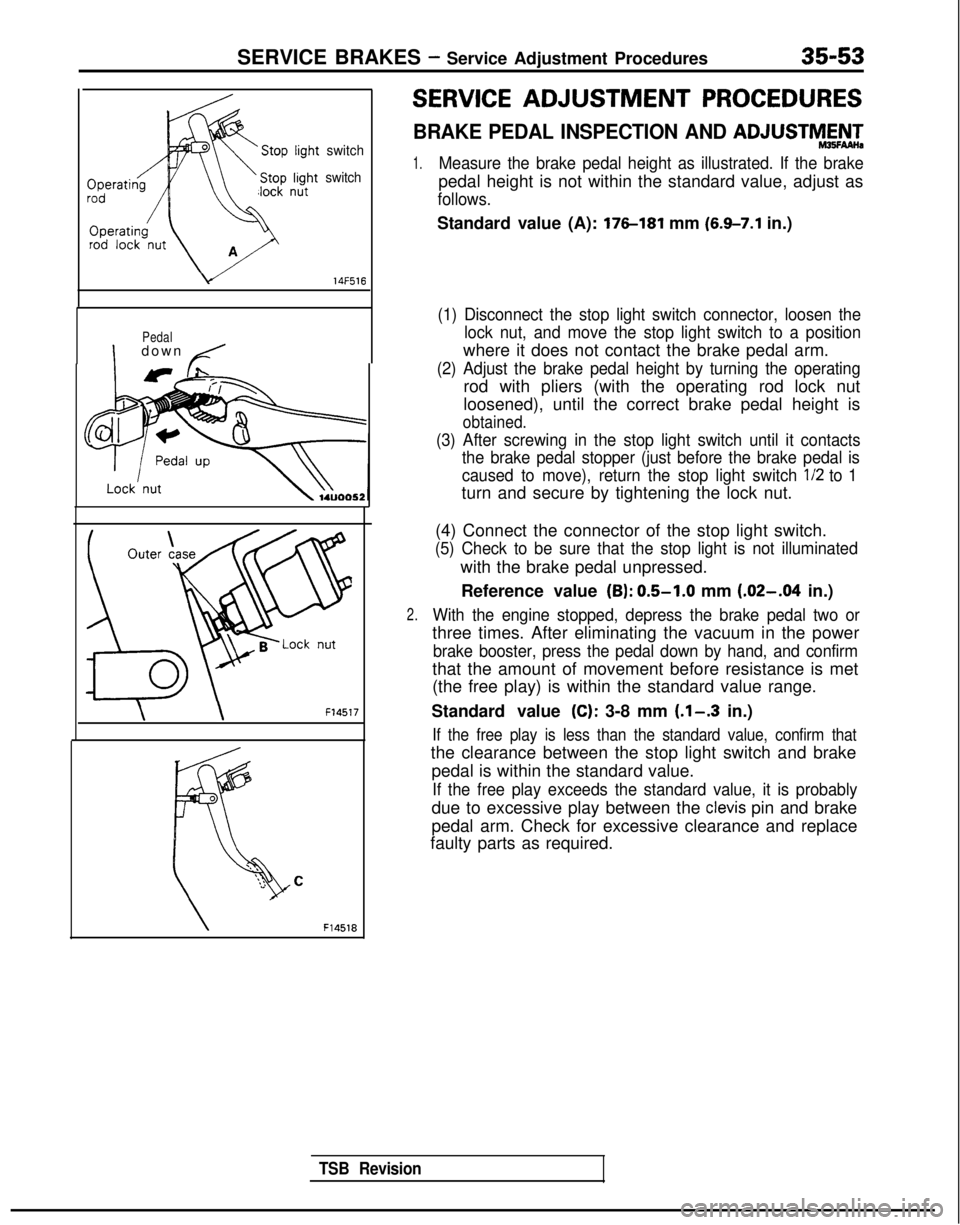

1.Measure the brake pedal height as illustrated. If the brake

pedal height is not within the standard value, adjust as

follows.

Standard value (A): 176-181 mm (6.9-7.1 in.)

(1) Disconnect the stop light switch connector, loosen the

lock nut, and move the stop light switch to a position

where it does not contact the brake pedal arm.

(2) Adjust the brake pedal height by turning the operating

rod with pliers (with the operating rod lock nut

loosened), until the correct brake pedal height is

obtained.

(3) After screwing in the stop light switch until it contactsthe brake pedal stopper (just before the brake pedal is

caused to move), return the stop light switch l/2

to 1

turn and secure by tightening the lock nut.

2.

(4) Connect the connector of the stop light switch.

(5) Check to be sure that the stop light is not illuminated

with the brake pedal unpressed.

Reference value

(B): 0.5-1.0 mm (.02-.04 in.)

With the engine stopped, depress the brake pedal two or

three times. After eliminating the vacuum in the power

brake booster, press the pedal down by hand, and confirm

that the amount of movement before resistance is met

(the free play) is within the standard value range.

Standard value

(C): 3-8 mm (.l-.3 in.)

If the free play is less than the standard value, confirm that

the clearance between the stop light switch and brake pedal is within the standard value.

If the free play exceeds the standard value, it is probably

due to excessive play between the clevis pin and brake

pedal arm. Check for excessive clearance and replace

faulty parts as required.

Page 1175 of 1273

35-54SERVICE BRAKES - Service Adjustment Procedures

F14519

14UOO61

When engine isstopped

No good

0

w

\/‘14UOO62z;redengine

is

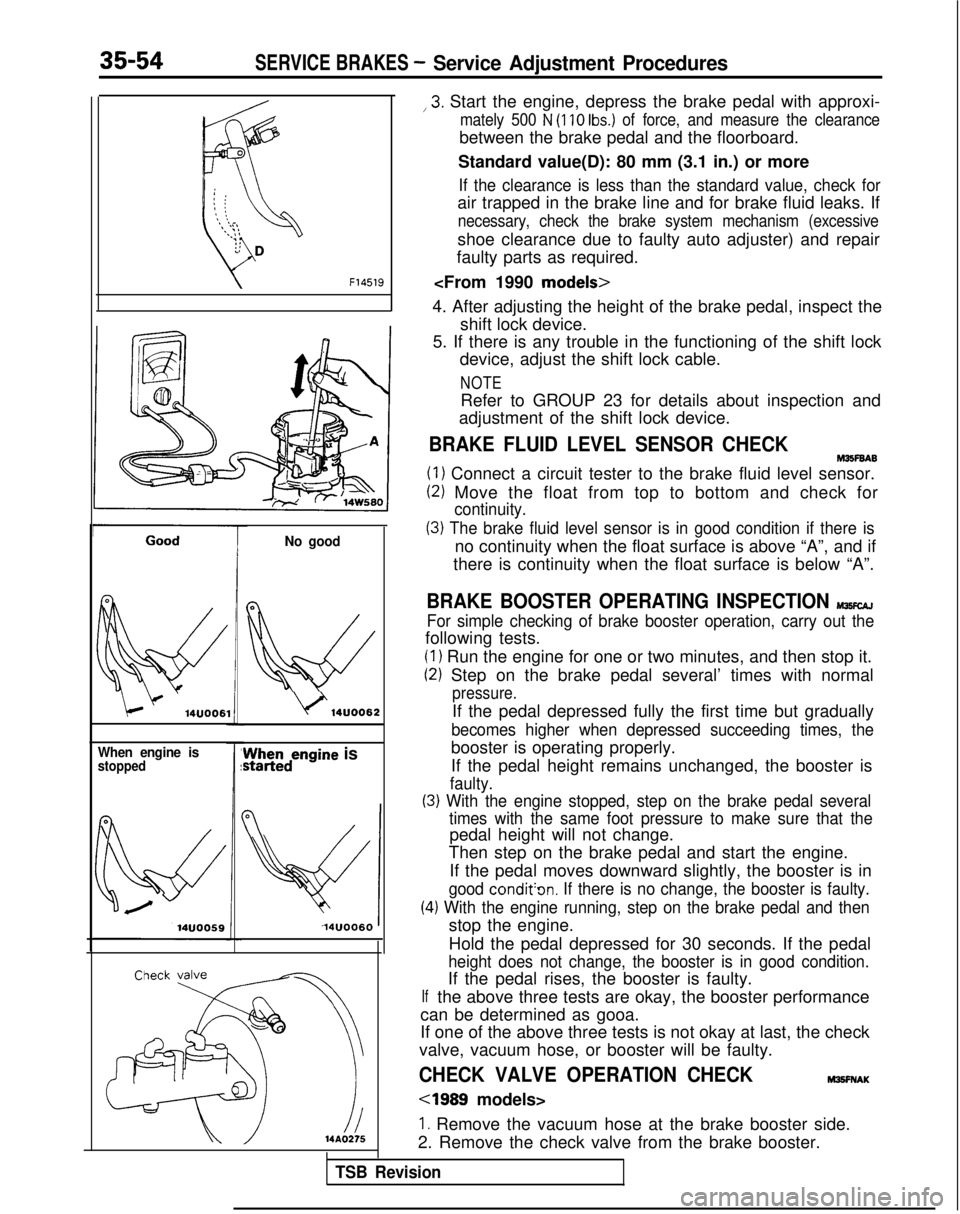

14UOO60 ,3.

Start the engine, depress the brake pedal with approxi-

mately 500 N (110 Ibs.) of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value(D): 80 mm (3.1 in.) or more

If the clearance is less than the standard value, check for

air trapped in the brake line and for brake fluid leaks. If

necessary, check the brake system mechanism (excessive

shoe clearance due to faulty auto adjuster) and repair

faulty parts as required.

4. After adjusting the height of the brake pedal, inspect the shift lock device.

5. If there is any trouble in the functioning of the shift lock device, adjust the shift lock cable.

NOTE

Refer to GROUP 23 for details about inspection and

adjustment of the shift lock device.

BRAKE FLUID LEVEL SENSOR CHECKM35F6A6

(1) Connect a circuit tester to the brake fluid level sensor.

(2) Move the float from top to bottom and check for

continuity.

(3) The brake fluid level sensor is in good condition if there is

no continuity when the float surface is above “A”, and if

there is continuity when the float surface is below “A”.

BRAKE BOOSTER OPERATING INSPECTION MlKcAJ

For simple checking of brake booster operation, carry out the

following tests.

(1) Run the engine for one or two minutes, and then stop it.

(2) Step on the brake pedal several’ times with normal

pressure.

If the pedal depressed fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

(3) With the engine stopped, step on the brake pedal several

(4

If

times with the same foot pressure to make sure that the

pedal height will not change.

Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condit’on. If there is no change, the booster is faulty.

.) With the engine running, step on the brake pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

the above three tests are okay, the booster performance

can be determined as gooa.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

CHECK VALVE OPERATION CHECKM3!3FNAK

cl989 models>

1. Remove the vacuum hose at the brake booster side.

2. Remove the check valve from the brake booster.

TSB Revision

Page 1178 of 1273

SERVICE, BRAKES - Service Adjustment Procedures35-57

4

1

2314AQ456

FWD

Delay valve L

flc ’

-c

i1

L

3

14AO4l

mit

14RD120

AWD

51

6 2414AO4E

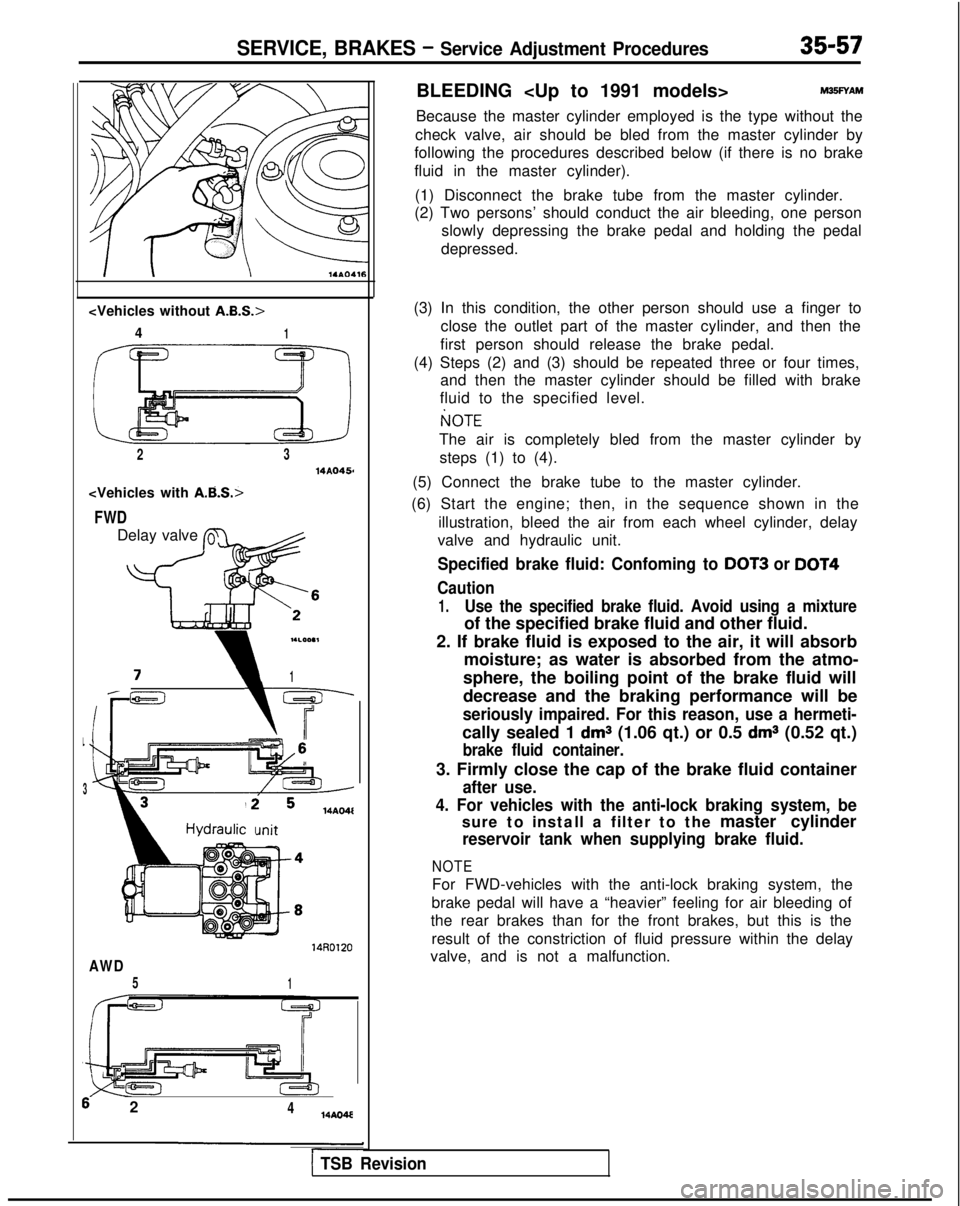

BLEEDING

Because the master cylinder employed is the type without the

check valve, air should be bled from the master cylinder by

following the procedures described below (if there is no brake

fluid in the master cylinder).

(1) Disconnect the brake tube from the master cylinder.

(2) Two persons’ should conduct the air bleeding, one person

slowly depressing the brake pedal and holding the pedal

depressed.

(3) In this condition, the other person should use a finger to close the outlet part of the master cylinder, and then the

first person should release the brake pedal.

(4) Steps (2) and (3) should be repeated three or four times, and then the master cylinder should be filled with brake

fluid to the specified level.

I(]OTE

The air is completely bled from the master cylinder by

steps (1) to (4).

(5) Connect the brake tube to the master cylinder.

(6) Start the engine; then, in the sequence shown in the illustration, bleed the air from each wheel cylinder, delay

valve and hydraulic unit.

Specified brake fluid: Confoming to DOT3 or DOT4

Caution

1.Use the specified brake fluid. Avoid using a mixture

of the specified brake fluid and other fluid.

2. If brake fluid is exposed to the air, it will absorb moisture; as water is absorbed from the atmo-

sphere, the boiling point of the brake fluid will

decrease and the braking performance will be

seriously impaired. For this reason, use a hermeti-

cally sealed 1 dms (1.06 qt.) or 0.5 dms (0.52 qt.)

brake fluid container.

3. Firmly close the cap of the brake fluid container

after use.

4. For vehicles with the anti-lock braking system, be

sure to install a filter to the master cylinder

reservoir tank when supplying brake fluid.

NOTE

For FWD-vehicles with the anti-lock braking system, the

brake pedal will have a “heavier” feeling for air bleeding of

the rear brakes than for the front brakes, but this is the

result of the constriction of fluid pressure within the delay

valve, and is not a malfunction.

1 TSB Revision

Page 1181 of 1273

35-60SERVICE BRAKES - Service Adjustment Procedures

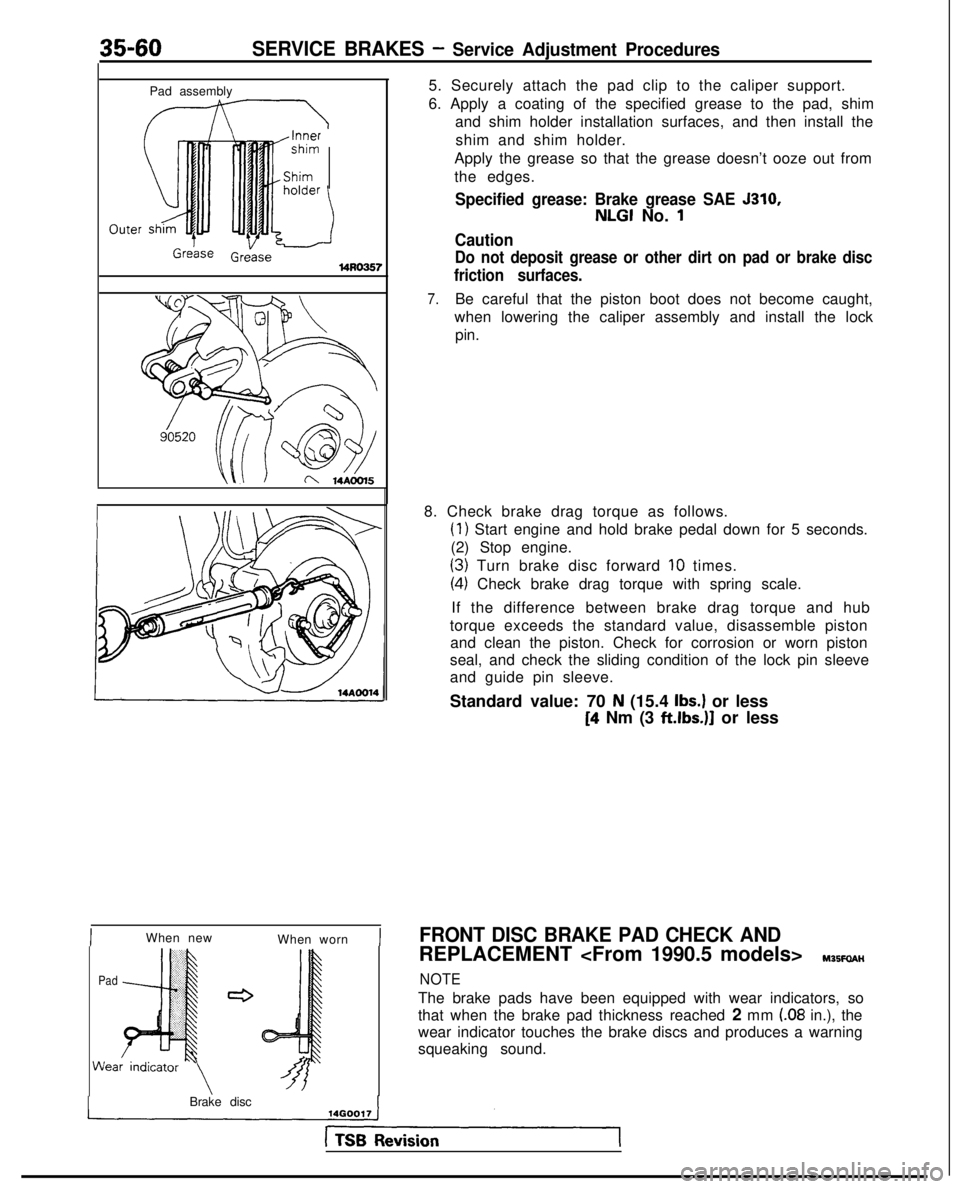

Pad assembly

\

l4RO367

IWhen newWhen wornI

PadWea 5. Securely attach the pad clip to the caliper support.

6. Apply a coating of the specified grease to the pad, shim

and shim holder installation surfaces, and then install the

shim and shim holder.

Apply the grease so that the grease doesn’t ooze out from

the edges.

Specified grease: Brake grease SAE 5310,

NLGI No. 1

Caution

Do not deposit grease or other dirt on pad or brake disc

friction surfaces.

7.Be careful that the piston boot does not become caught,

when lowering the caliper assembly and install the lock pin.

8. Check brake drag torque as follows.

(1) Start engine and hold brake pedal down for 5 seconds.

(2) Stop engine.

(3) Turn brake disc forward IO times.

(4) Check brake drag torque with spring scale.

If the difference between brake drag torque and hub

torque exceeds the standard value, disassemble piston and clean the piston. Check for corrosion or worn piston

seal, and check the sliding condition of the lock pin sleeve

and guide pin sleeve.

Standard value: 70

N (15.4 Ibs.) or less

[4 Nm (3 ftlbs.)]

or less

FRONT DISC BRAKE PAD CHECK AND

REPLACEMENT

NOTE

The brake pads have been equipped with wear indicators, so

that when the brake pad thickness reached 2 mm

(.08 in.), the

wear indicator touches the brake discs and produces a warning

squeaking sound.

Brake disc

Page 1183 of 1273

35-62SERVICE BRAKES - Service Adjustment Procedures

u /@$fi 14A0Ol5CM-R56W>

II

I

Pad

c

4s14FOO97

!m

!

bly

c

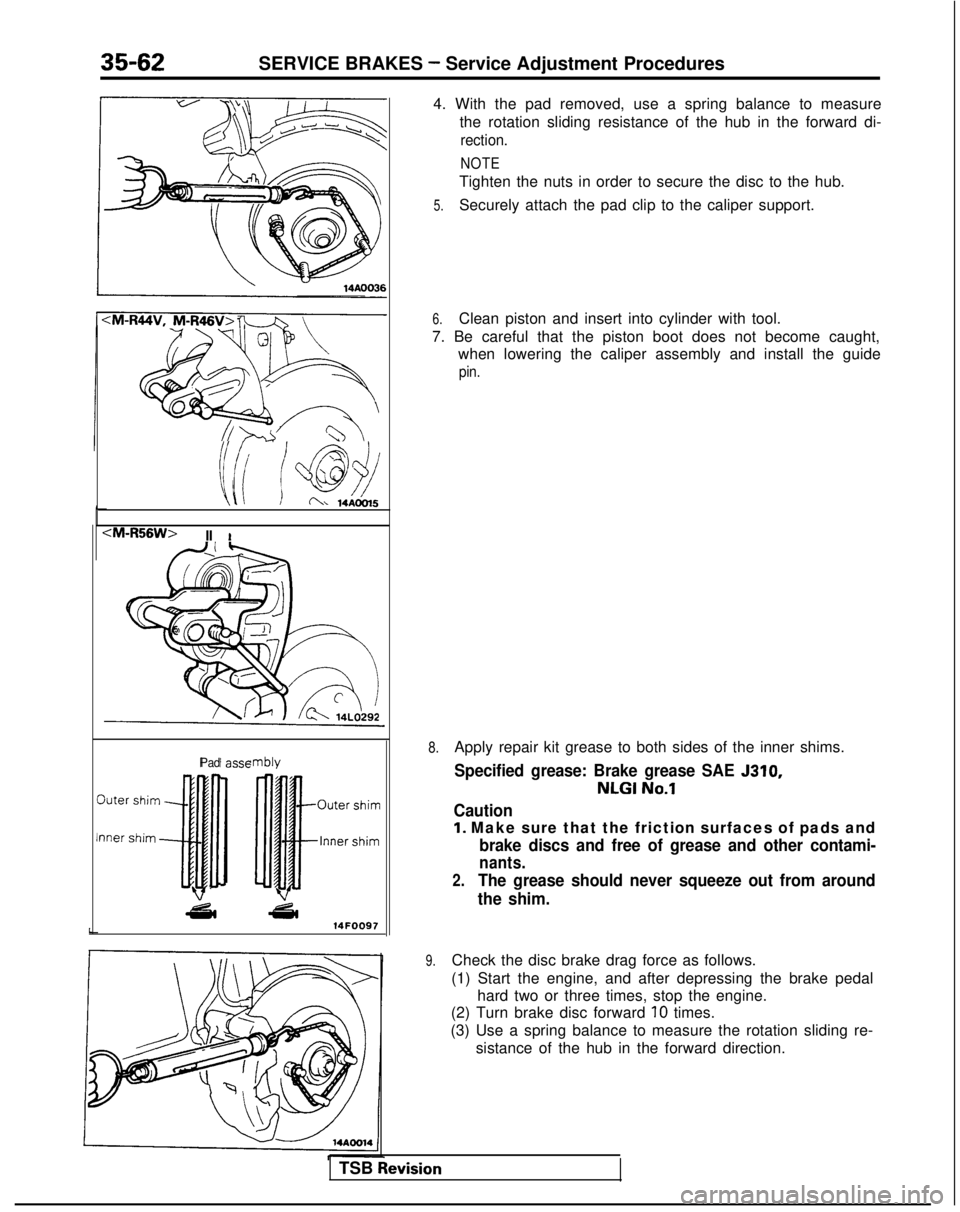

4. With the pad removed, use a spring balance to measure

the rotation sliding resistance of the hub in the forward di-

rection.

NOTE

Tighten the nuts in order to secure the disc to the hub.

5.Securely attach the pad clip to the caliper support.

6.Clean piston and insert into cylinder with tool.

7. Be careful that the piston boot does not become caught, when lowering the caliper assembly and install the guide

pin.

8.Apply repair kit grease to both sides of the inner shims.

Specified grease: Brake grease SAE 5310,

NLGI No.1

Caution

1. Make sure that the friction surfaces of pads and

brake discs and free of grease and other contami-

nants.

2.The grease should never squeeze out from around

the shim.

9.Check the disc brake drag force as follows.

(1) Start the engine, and after depressing the brake pedal hard two or three times, stop the engine.

(2) Turn brake disc forward

10 times.

(3) Use a spring balance to measure the rotation sliding re- sistance of the hub in the forward direction.

TSB

hevision

Page 1186 of 1273

SERVICE BRAKES - Service Adjustment Procedures35-65’

14AO281

WA0204

grooves

Q

0 0

Projection

1410037I-

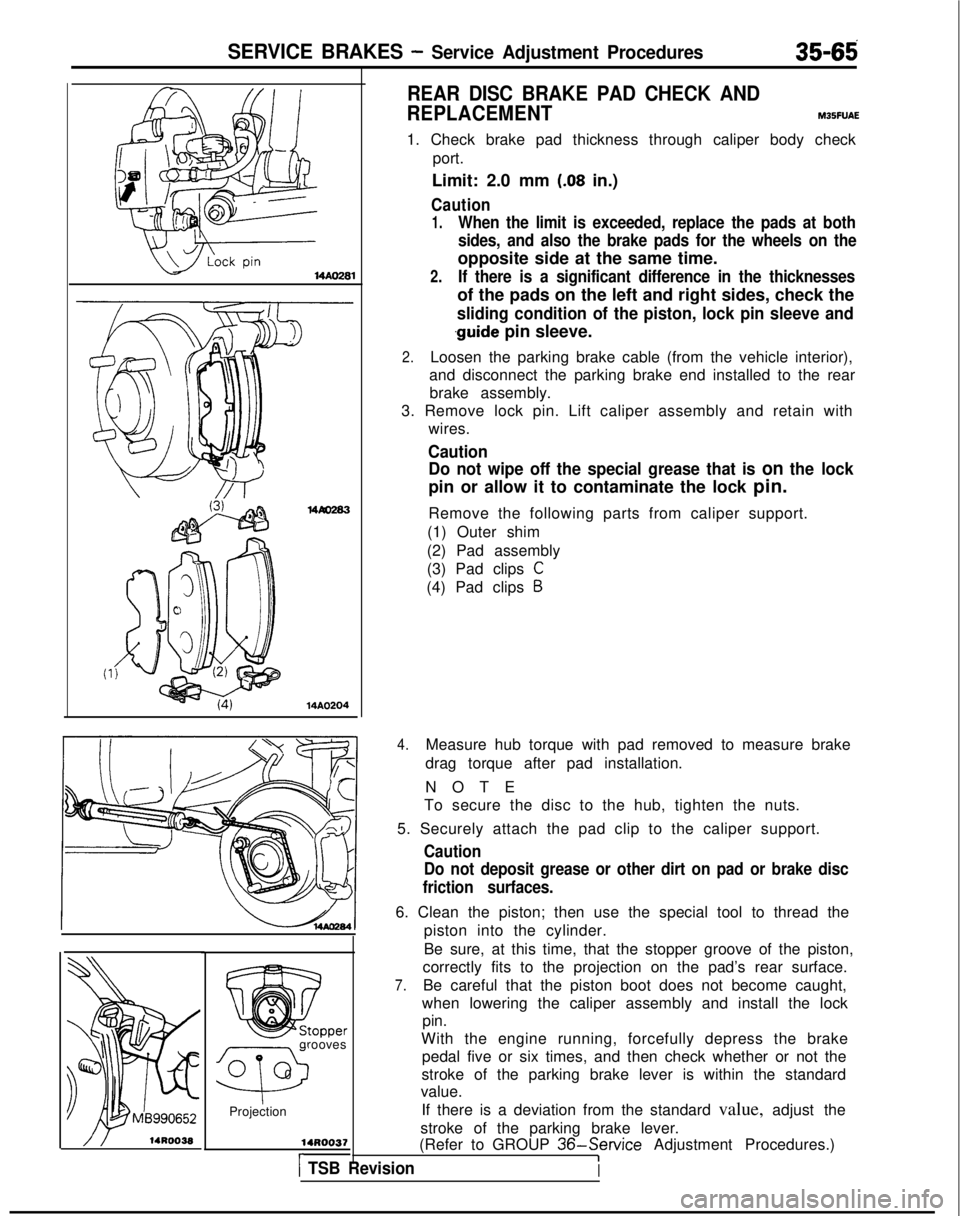

REAR DISC BRAKE PAD CHECK AND

REPLACEMENT

MBBFUAE

1. Check brake pad thickness through caliper body check port.

Limit: 2.0 mm

(.08 in.)

Caution

1.When the limit is exceeded, replace the pads at both

sides, and also the brake pads for the wheels on the

opposite side at the same time.

2.If there is a significant difference in the thicknesses

of the pads on the left and right sides, check the

sliding condition of the piston, lock pin sleeve and

.guide pin sleeve.

2.Loosen the parking brake cable (from the vehicle interior),

and disconnect the parking brake end installed to the rear brake assembly.

3. Remove lock pin. Lift caliper assembly and retain with wires.

CautionDo not wipe off the special grease that is

on the lock

pin or allow it to contaminate the lock pin.

Remove the following parts from caliper support.

(1) Outer shim

(2) Pad assembly

(3) Pad clips

C

(4) Pad clips B

4.Measure hub torque with pad removed to measure brake

drag torque after pad installation.

NOT

E

To secure the disc to the hub, tighten the nuts.

5. Securely attach the pad clip to the caliper support.

Caution

Do not deposit grease or other dirt on pad or brake disc

friction surfaces.

6. Clean the piston; then use the special tool to thread the piston into the cylinder.

Be sure, at this time, that the stopper groove of the piston,

correctly fits to the projection on the pad’s rear surface.

7.Be careful that the piston boot does not become caught,

when lowering the caliper assembly and install the lock pin.

With the engine running, forcefully depress the brake pedal five or six times, and then check whether or not the

stroke of the parking brake lever is within the standard

value.

If there is a deviation from the standard value, adjust the

stroke of the parking brake lever.

(Refer to GROUP

36-Service Adjustment Procedures.)I) TSB RevisionI

Page 1187 of 1273

35-66SERVICE BRAKES - Service

Adjustment Procedures

14AOO67

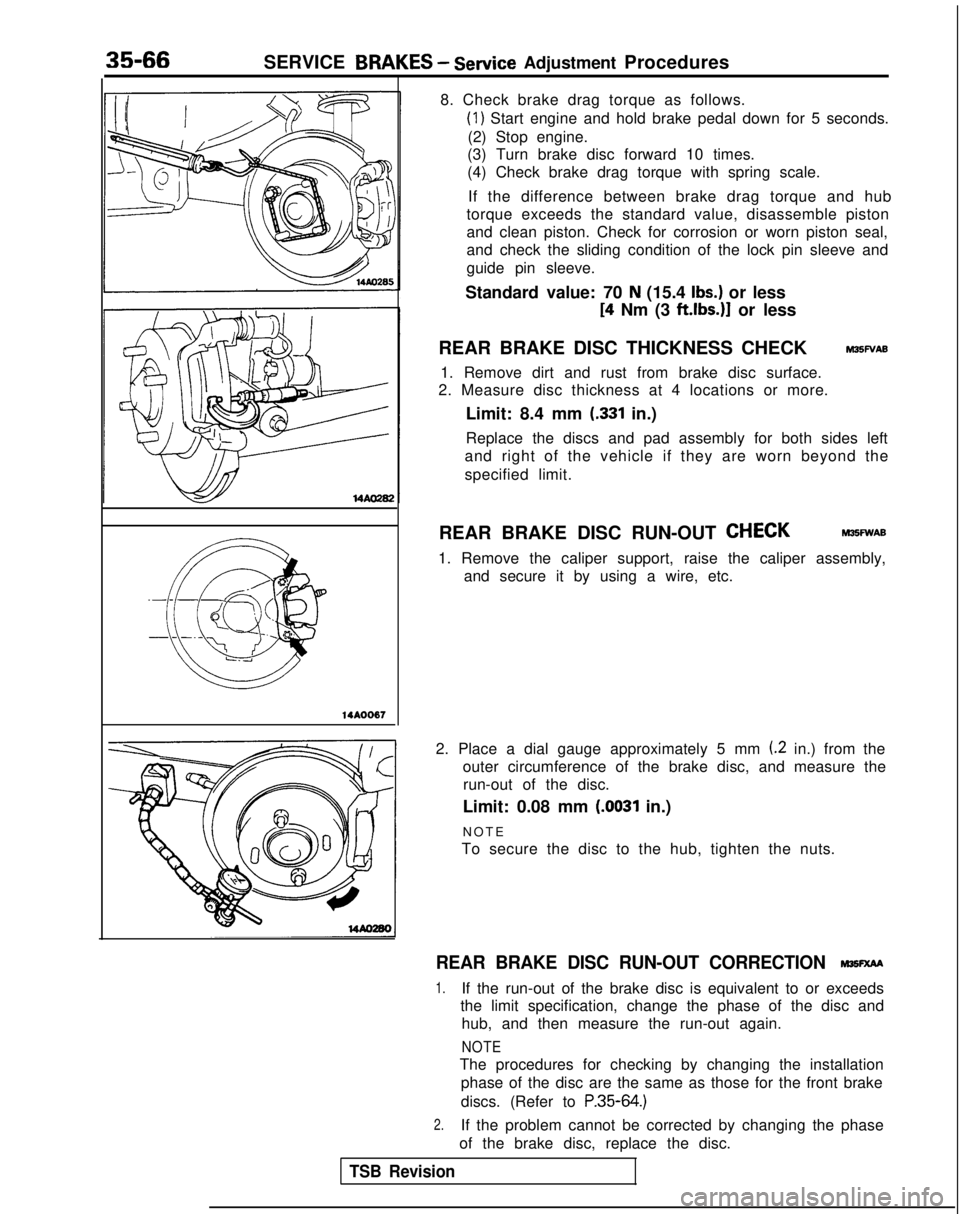

8. Check brake drag torque as follows.

(1) Start engine and hold brake pedal down for 5 seconds.

(2) Stop engine.

(3) Turn brake disc forward 10 times.

(4) Check brake drag torque with spring scale.

If the difference between brake drag torque and hub

torque exceeds the standard value, disassemble piston

and clean piston. Check for corrosion or worn piston seal,

and check the sliding condition of the lock pin sleeve and

guide pin sleeve.

Standard value: 70

N (15.4 Ibs.) or less

14 Nm (3 ft.lbs.)J or less

REAR BRAKE DISC THICKNESS CHECK

M35FVAB

1. Remove dirt and rust from brake disc surface.

2. Measure disc thickness at 4 locations or more.

Limit: 8.4 mm

(.331 in.)

Replace the discs and pad assembly for both sides left

and right of the vehicle if they are worn beyond the

specified limit.

REAR BRAKE DISC RUN-OUT

CHECKM35FWAB

1. Remove the caliper support, raise the caliper assembly, and secure it by using a wire, etc.

2. Place a dial gauge approximately 5 mm

(.2 in.) from the

outer circumference of the brake disc, and measure the run-out of the disc.

Limit: 0.08 mm

(.0031 in.)

NOT

E

To secure the disc to the hub, tighten the nuts.

REAR BRAKE DISC RUN-OUT CORRECTIONMFXAA

1.If the run-out of the brake disc is equivalent to or exceeds

the limit specification, change the phase of the disc and

hub, and then measure the run-out again.

NOTE

The procedures for checking by changing the installation

phase of the disc are the same as those for the front brake

discs. (Refer to

P.35-64.)

2.If the problem cannot be corrected by changing the phase

of the brake disc, replace the disc.

TSB Revision

Page 1189 of 1273

35-68SERVICE BRAKES - Service Adjustment Procedures

A.B.S. warning light

Ignition switch

sT;!i;%

lARD175

Filter4

kR

14A0171

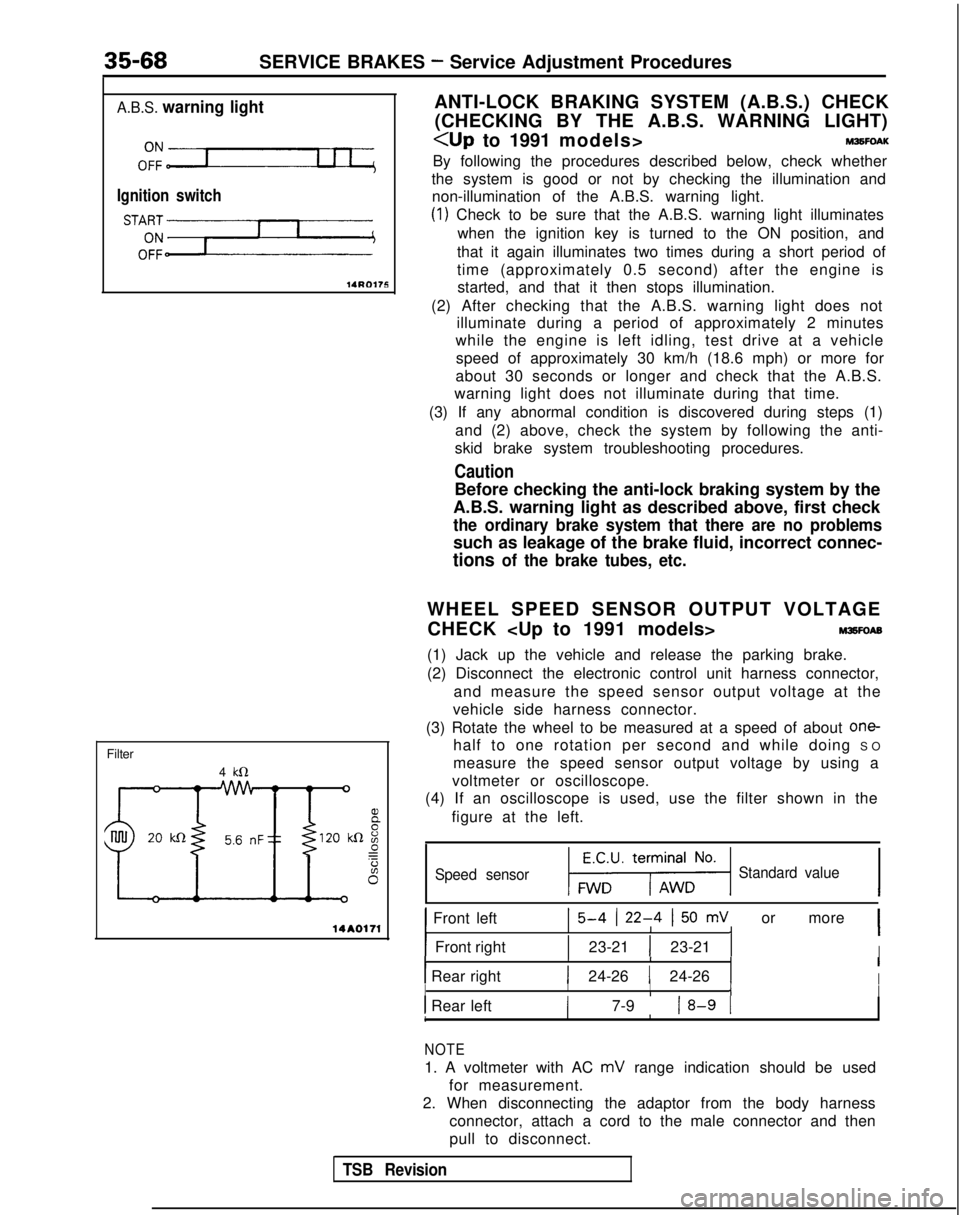

ANTI-LOCK BRAKING SYSTEM (A.B.S.) CHECK

(CHECKING BY THE A.B.S. WARNING LIGHT)

By following the procedures described below, check whether

the system is good or not by checking the illumination and non-illumination of the A.B.S. warning light.

(1) Check to be sure that the A.B.S. warning light illuminates

when the ignition key is turned to the ON position, and

that it again illuminates two times during a short period of

time (approximately 0.5 second) after the engine is started, and that it then stops illumination.

(2) After checking that the A.B.S. warning light does not illuminate during a period of approximately 2 minutes

while the engine is left idling, test drive at a vehicle

speed of approximately 30 km/h (18.6 mph) or more for

about 30 seconds or longer and check that the A.B.S.

warning light does not illuminate during that time.

(3) If any abnormal condition is discovered during steps (1) and (2) above, check the system by following the anti-

skid brake system troubleshooting procedures.

Caution

Before checking the anti-lock braking system by the

A.B.S. warning light as described above, first check

the ordinary brake system that there are no problems

such as leakage of the brake fluid, incorrect connec-

tions of the brake tubes, etc.

WHEEL SPEED SENSOR OUTPUT VOLTAGE

CHECK

M3sFoAE

(1) Jack up the vehicle and release the parking brake.

(2) Disconnect the electronic control unit harness connector,

and measure the speed sensor output voltage at the

vehicle side harness connector.

(3) Rotate the wheel to be measured at a speed of about

one-

half to one rotation per second and while doing S

O

measure the speed sensor output voltage by using a

voltmeter or oscilloscope.

(4) If an oscilloscope is used, use the filter shown in the

figure at the left.

Speed sensor1-1 Standard value

1 Front left15-4 (22-4 I50 mV or more 1IIIII

IFront rightI1 23-21 1 23-21 1IIIII1 Rear right1 24-26 1 24-26 1II IIIIII Rear left( 7-9 18-9 1IIII1

NOTE

1. A voltmeter with AC mV range indication should be used

for measurement.

2. When disconnecting the adaptor from the body harness connector, attach a cord to the male connector and then

pull to disconnect.

TSB Revision

Page 1196 of 1273

SERVICE BRAKES -Service Adjustment Procedures35-75

14AO197

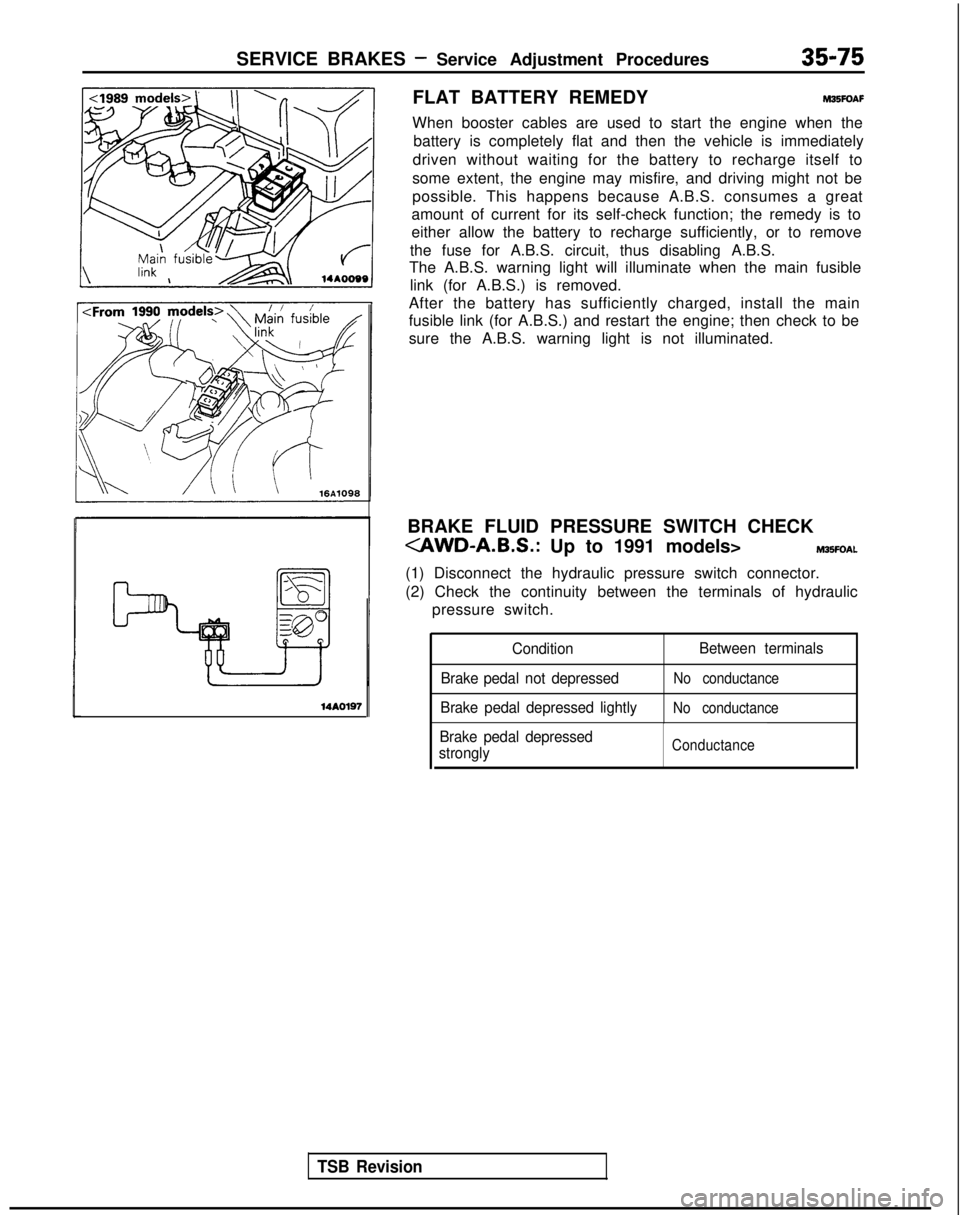

FLAT BATTERY REMEDYM35FOAF

When booster cables are used to start the engine when the

battery is completely flat and then the vehicle is immediately

driven without waiting for the battery to recharge itself to

some extent, the engine may misfire, and driving might not be

possible. This happens because A.B.S. consumes a great

amount of current for its self-check function; the remedy is to

either allow the battery to recharge sufficiently, or to remove

the fuse for A.B.S. circuit, thus disabling A.B.S.

The A.B.S. warning light will illuminate when the main fusible

link (for A.B.S.) is removed.

After the battery has sufficiently charged, install the main

fusible link (for A.B.S.) and restart the engine; then check to be

sure the A.B.S. warning light is not illuminated.

TSB Revision

BRAKE FLUID PRESSURE SWITCH CHECK

(1) Disconnect the hydraulic pressure switch connector.

(2) Check the continuity between the terminals of hydraulic pressure switch.

Condition Between terminals

Brake pedal not depressed

No conductance

Brake pedal depressed lightlyNo conductance

Brake pedal depressed

stronglyConductance