MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 321 of 1273

On-Vehicle Inspection of MFI

FUEL SYSTEM

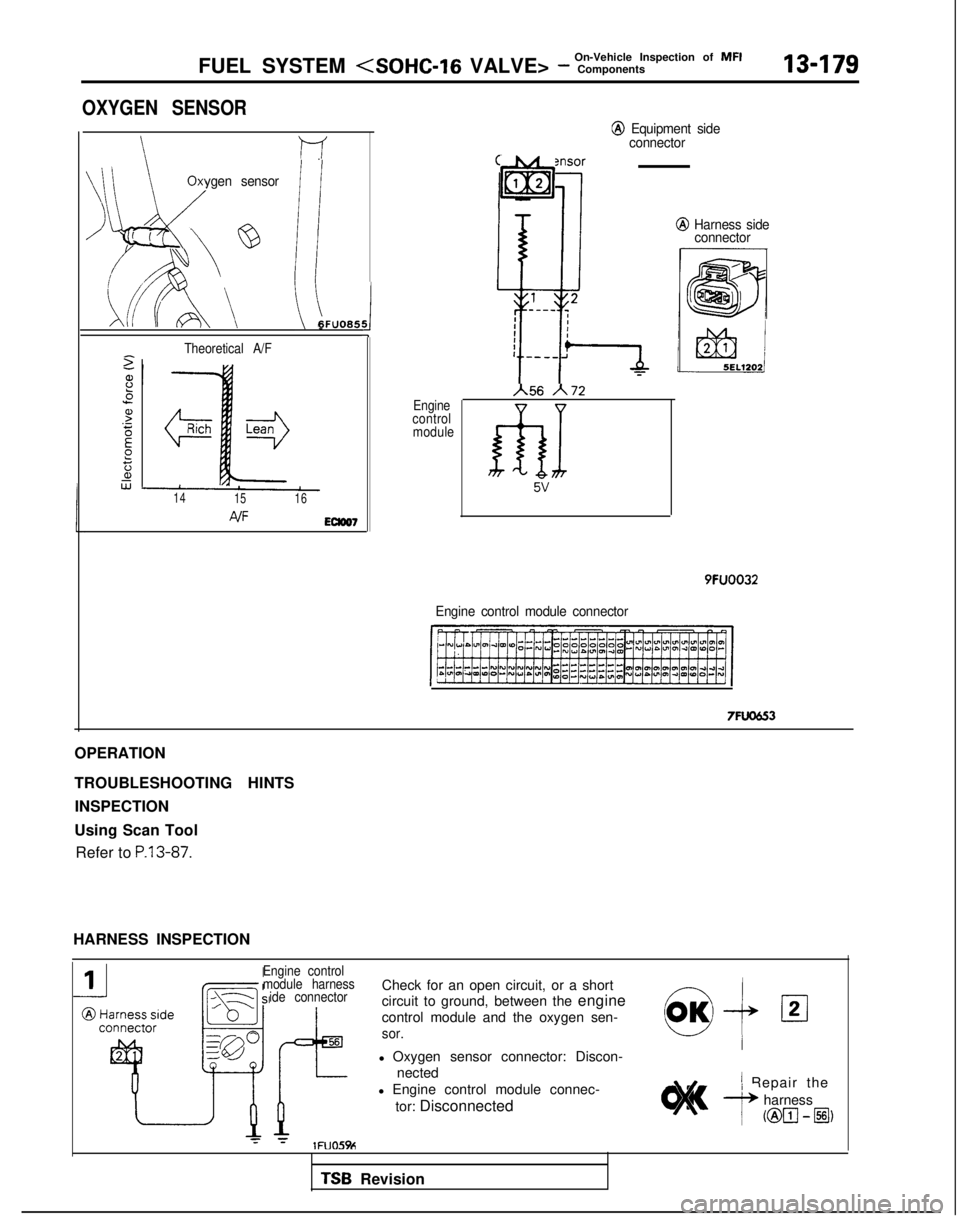

OXYGEN SENSOR

\l-f

\

Oxygen sensor

J

q :

i’ 1%

Lkm uA6FUO6.5

2

8

.5

s.-EE?za,w

Theoretical A/F

14 1516

4/FEClW7

j5

Engine

control module

@ Equipment side

connector

iIxy;n se;‘i,G,

A56 h72

fhx 5v

@ Harness side

connector

9FUOO32

Engine control module connector

7FL0553

OPERATION

TROUBLESHOOTING HINTS

INSPECTION

Using Scan Tool Refer to

P.13-87.

HARNESS INSPECTION

Engine control

module harness ide connector

56

1’r YlFUO5%

Check for an open circuit, or a short

circuit to ground, between the engine

control module and the oxygen sen-

sor.

l Oxygen sensor connector: Discon-

nected

l Engine control module connec-

tor: Disconnected

cl OK+02

’ Repair the

A harness

( @El-@I)

TSB Revision

Page 322 of 1273

13-180FUEL SYSTEM

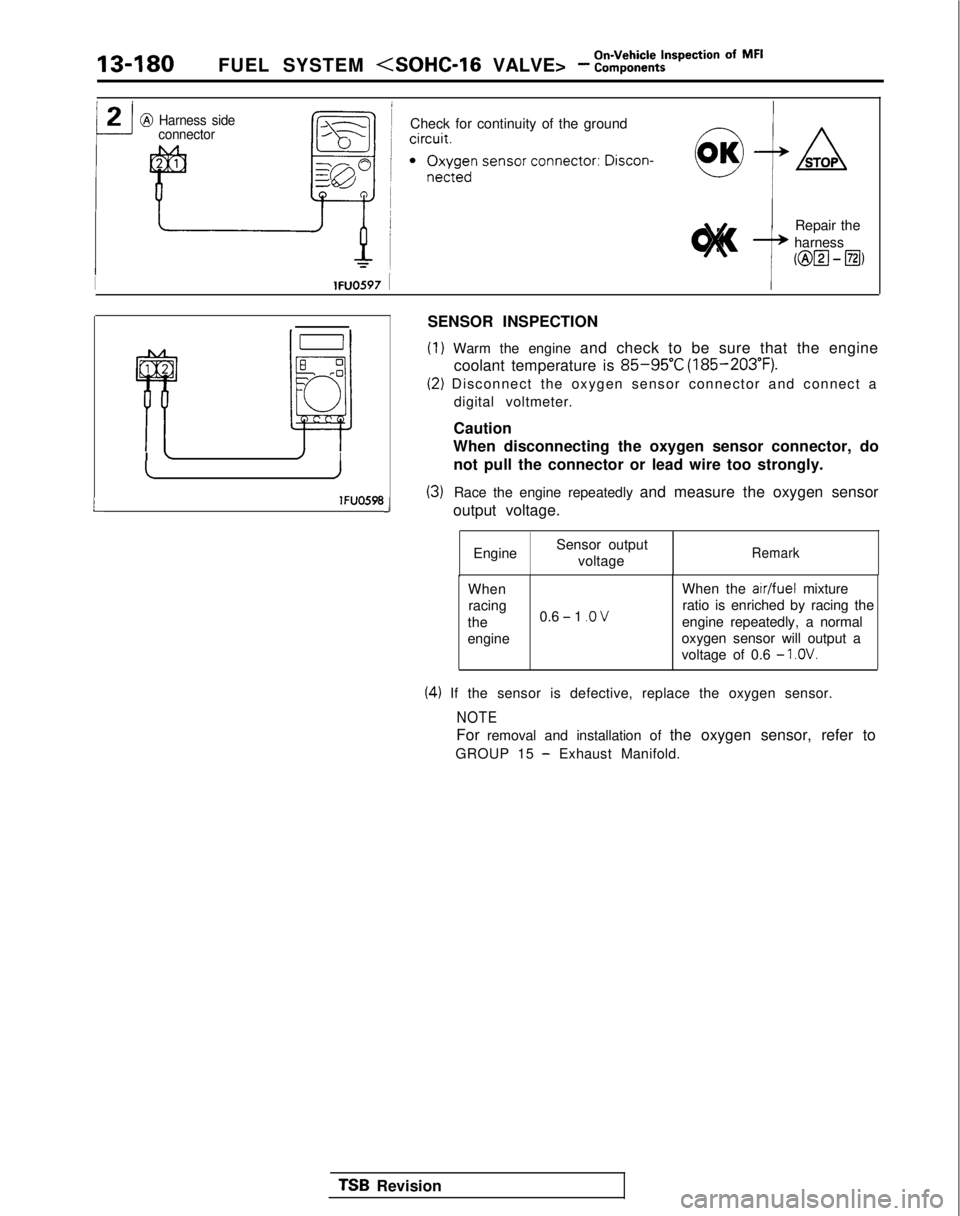

@ Harness sideconnectorCheck for continuity of the ground

Repair the

harness

(@lzl - El)

IlFUOS97 1I

L

G-lI’ ‘Ila

r rI L/I

IJ

lFUO598J

SENSOR INSPECTION

(I) Warm the engine and check to be sure that the engine

coolant temperature is

85-95°C (185-203°F).

(2) Disconnect the oxygen sensor connector and connect a

digital voltmeter.

Caution

When disconnecting the oxygen sensor connector, do

not pull the connector or lead wire too strongly.

(3)Race the engine repeatedly and measure the oxygen sensor

output voltage.

Engine Sensor output

voltage

Remark

When When the a/r/fuel

mixture

racing

the 0.6

- 1 .O Vratio is enriched by racing the

engine repeatedly, a normal

engine oxygen sensor will output a

voltage of 0.6

- 1 .OV.

(4) If the sensor is defective, replace the oxygen sensor.

NOTE

For removal and installation of the oxygen sensor, refer to

GROUP 15

- Exhaust Manifold.

TSB Revision

Page 323 of 1273

FUEL SYSTEM

Of MF’13-181

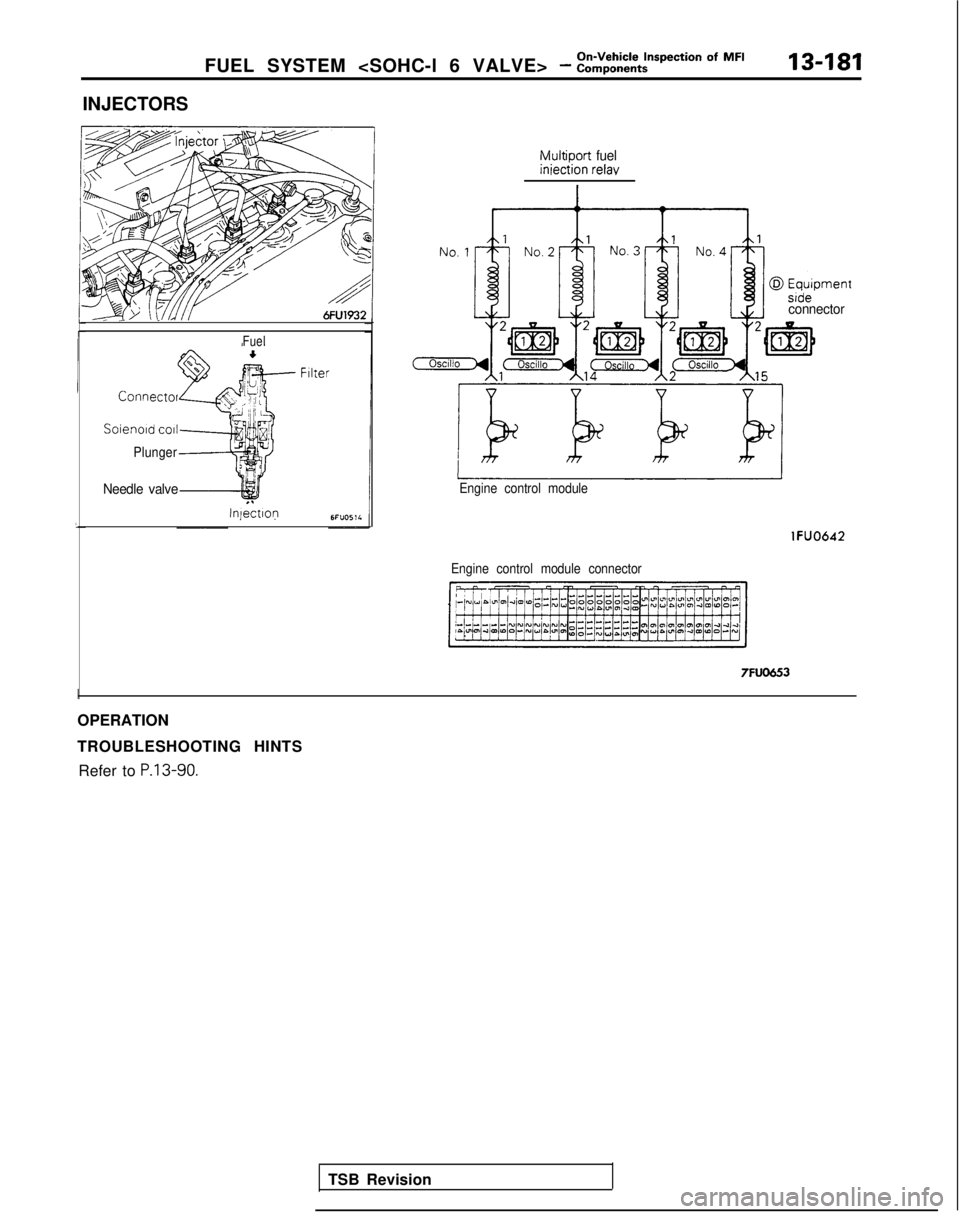

INJECTORS

Fuel

Connect01

Soienold co11

Plunger

Needle valve

Injectlop

Multiport fueliniection relay

TSB Revision

connector

Engine control module

Engine control module connector

lFUO642 7FUO653

I

OPERATION

TROUBLESHOOTING HINTS

Refer to

P.13-90.

Page 324 of 1273

13-182FUEL SYSTEM

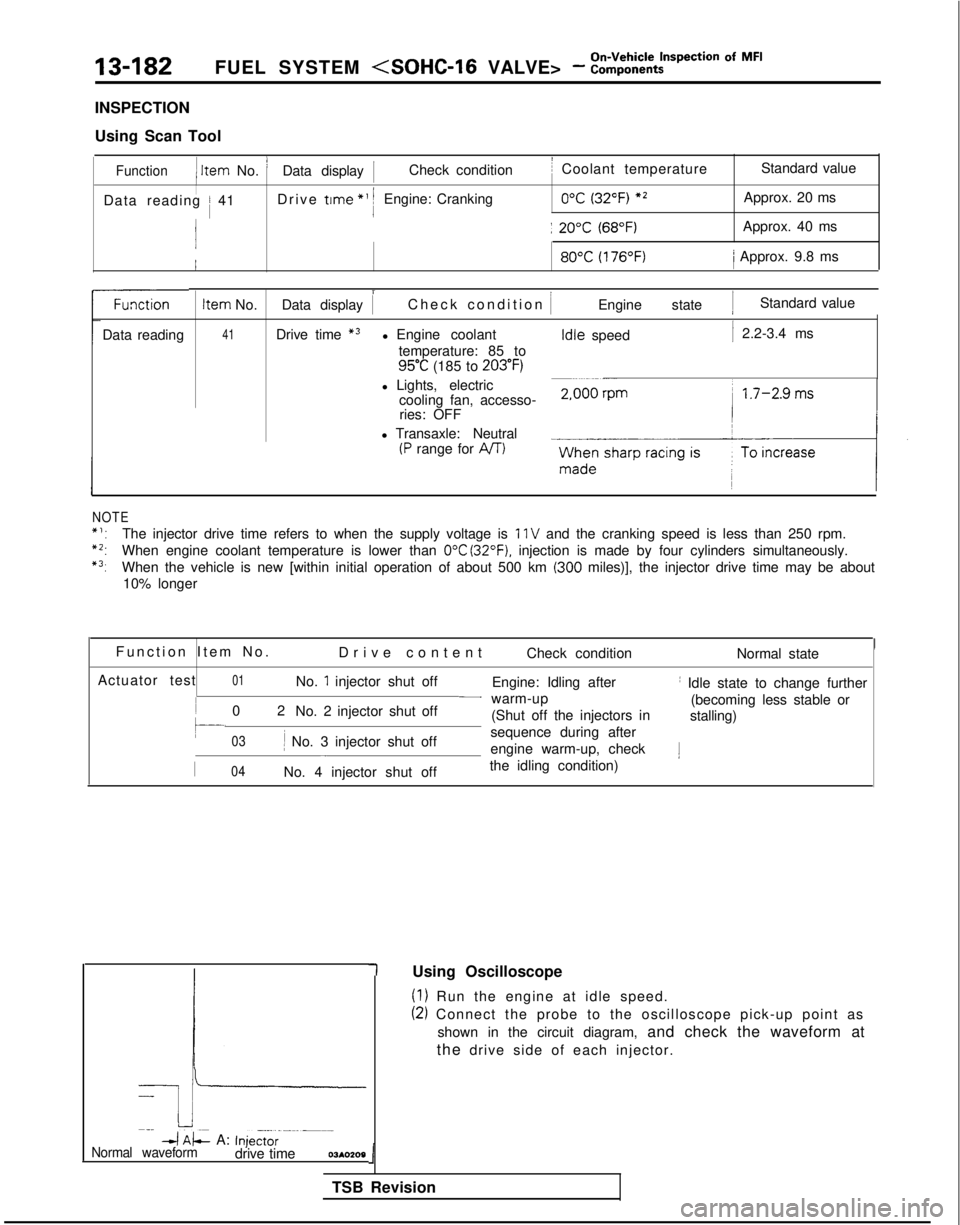

INSPECTION

Using Scan Tool

Function1 Item

No. ’Data display 1Check conditionI Coolant temperature Standard value

IData reading / 41Drive trme

*’ 1Engine: Cranking0°C (32°F) *2Approx. 20 ms

j: 20°C (68°F)Approx. 40 ms 80°C

(176°F)/ Approx. 9.8 ms

Data reading

NOTE Item

No.

41 i

Data display 1

Check condition

IEngine state 1Standard value

Drive time

*3l Engine coolant temperature: 85 to

95°C (185 to 203°F)

l Lights, electric cooling fan, accesso-ries: OFF

l Transaxle: Neutral

(P range for AIT) Idle

speed

1 2.2-3.4 ms

*‘:The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

*2:When engine coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

*3:When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer

Function Item No

.

Drive content Check condition Normal state

Actuator test

01No. 1 injector shut off Engine: Idling afterI Idle state to change further

0

2

No. 2 injector shut off

- warm-up

(becoming less stable or

(Shut off the injectors in stalling)

03li No. 3 injector shut off sequence during after-engine warm-up, check1

I04No. 4 injector shut off

the idling condition)

-k

Imp

4 AL A: Inje,t,r--m--m-Normal waveformdrive time03*0209

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

1

TSB Revision 1

Using Oscilloscope

Page 325 of 1273

FUEL SYSTEM

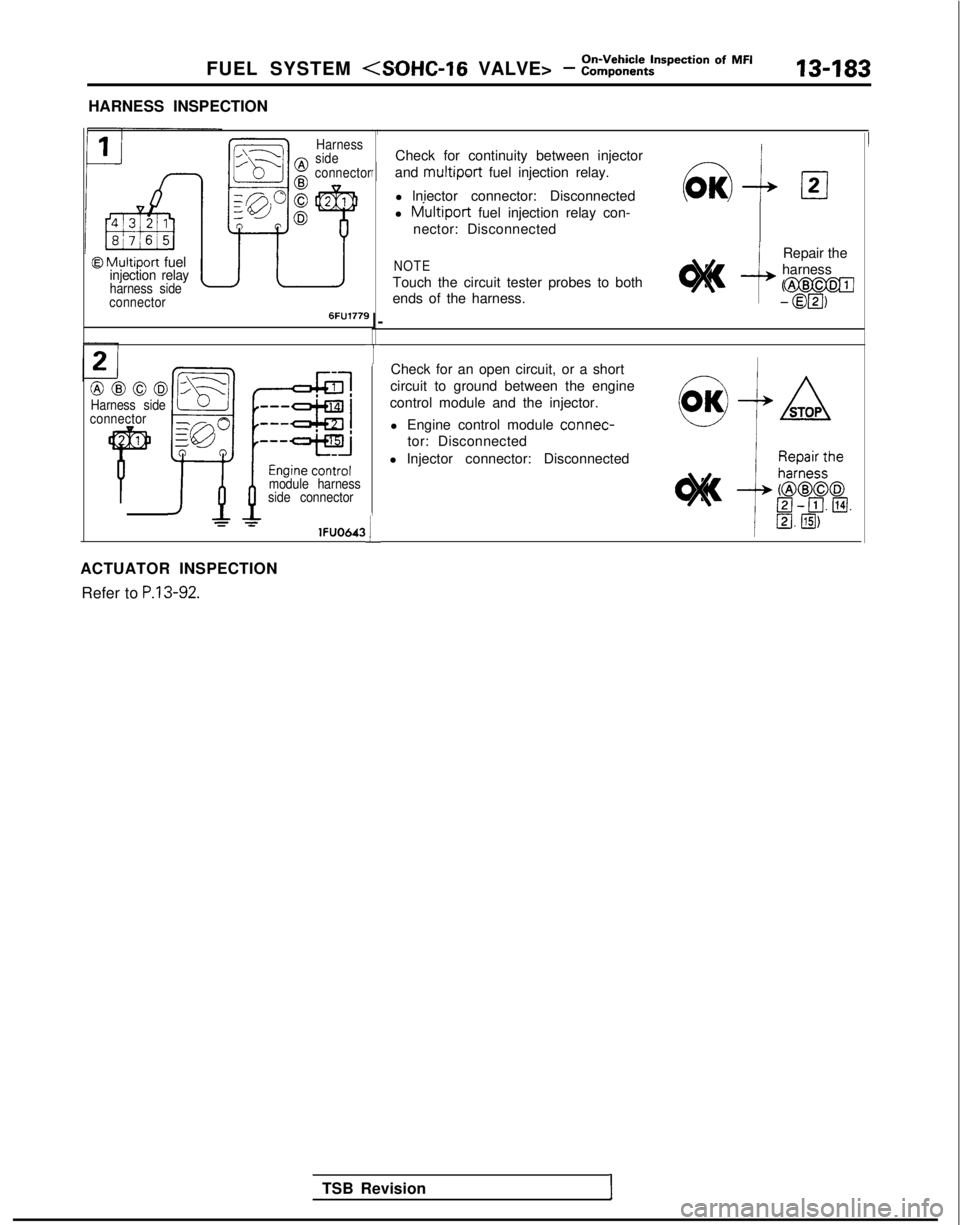

HARNESS INSPECTION

@ Multiport fuelinjection relayharness side

connector

,\---L

Ell---l0

!I?

pJ”

D

Harness

side

connector

6FU1779

@@@03Harness side

connector

1

Pmodule harness

side connector

=lFUO643

ACTUATOR INSPECTION

Refer to

P.13-92.

r I

I-

T

L

Check for continuity between injector

and

multiport fuel injection relay.

l lniector connector: Disconnected

l

tviultiport fuel injection relay con-

nector: Disconnected

NOTE

Touch the circuit tester probes to both

ends of the harness. Repair the

harnessCm

- 0@3,

Check for an open circuit, or a short

circuit to ground between the engine

control module and the injector.

l Engine control module connec-

tor: Disconnected

l Injector connector: Disconnected

TSB Revision

I

Page 326 of 1273

13-184

On-Vehicle Inspection of MFI

FUEL SYSTEM (SOHC-16 VALVE> - Components

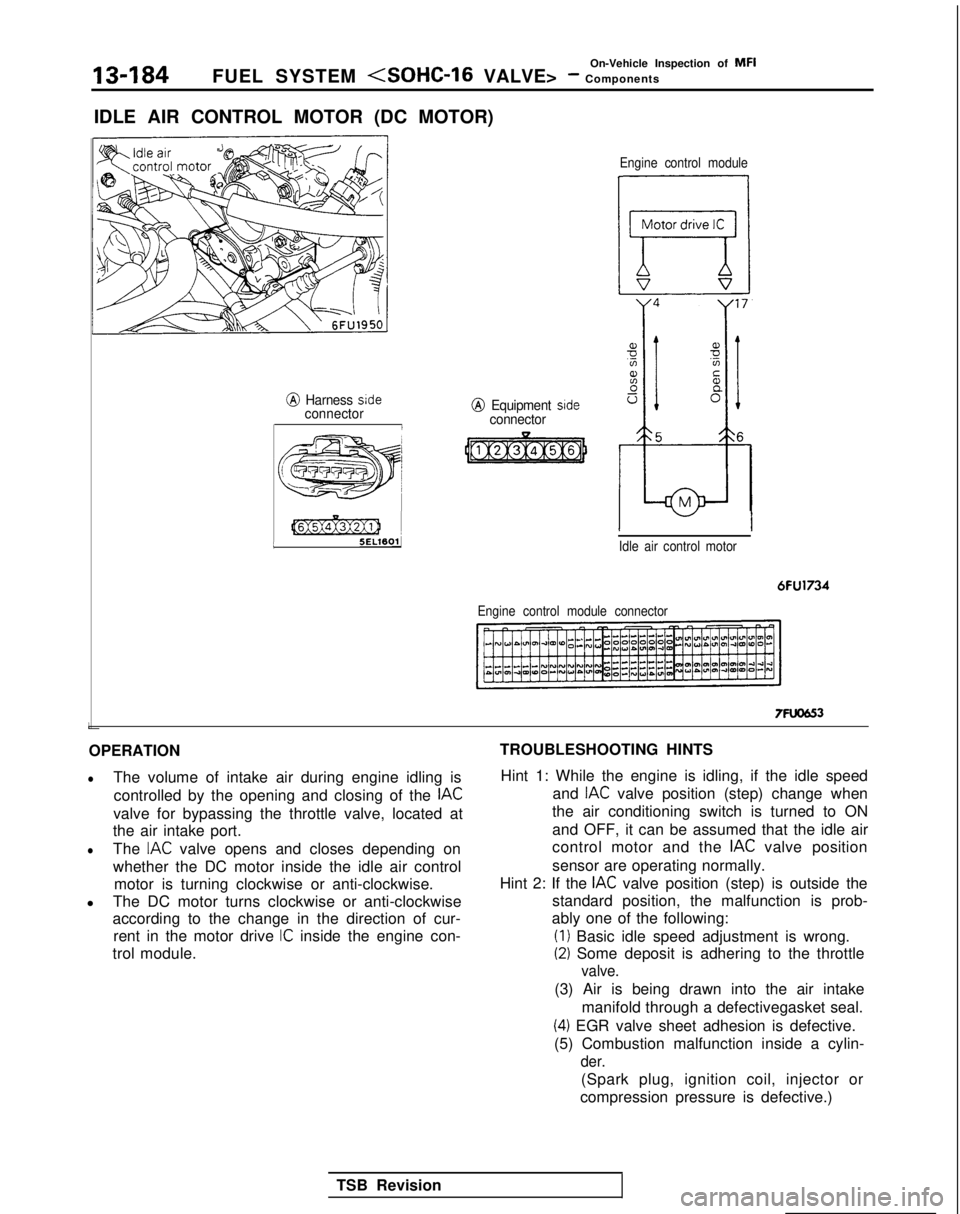

IDLE AIR CONTROL MOTOR (DC MOTOR)

@ Harness sideconnectorI L

[@Ex@ziJ 1

5ELWOlJ

j

e;

j 55ww3 )A’,’/

@ Equipment sideconnector

Engine control module

Idle air control motor

6FU1734

Engine control module connector

7FUCJG3

OPERATION

lThe volume of intake air during engine idling is controlled by the opening and closing of the

IAC

valve for bypassing the throttle valve, located at

the air intake port.

lThe IAC valve opens and closes depending on

whether the DC motor inside the idle air control motor is turning clockwise or anti-clockwise.

l The DC motor turns clockwise or anti-clockwise

according to the change in the direction of cur-

rent in the motor drive

IC inside the engine con-

trol module. TROUBLESHOOTING HINTS

Hint 1: While the engine is idling, if the idle speed and

IAC valve position (step) change when

the air conditioning switch is turned to ON

and OFF, it can be assumed that the idle air

control motor and the

IAC valve position

sensor are operating normally.

Hint 2: If the

IAC valve position (step) is outside the

standard position, the malfunction is prob-

ably one of the following: (I)

Basic idle speed adjustment is wrong.

(2) Some deposit is adhering to the throttle

valve.

(3) Air is being drawn into the air intake

manifold through a defectivegasket seal.

(4) EGR valve sheet adhesion is defective.

(5) Combustion malfunction inside a cylin-

der.

(Spark plug, ignition coil, injector or

compression pressure is defective.)

TSB Revision

Page 327 of 1273

FUEL SYSTEM

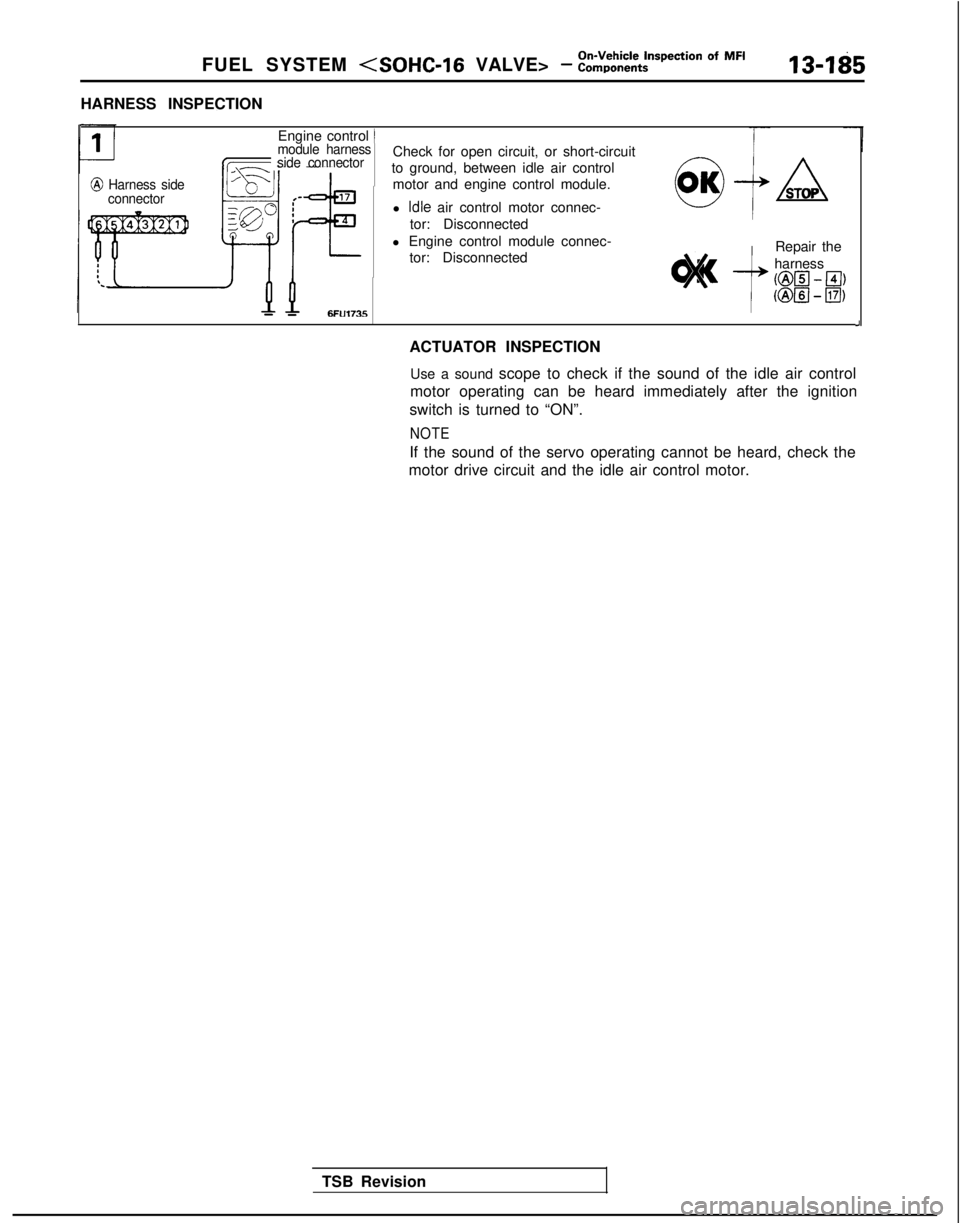

HARNESS INSPECTION

@ Harness side

connector

Engine control )module harness

side connector

- -6FU1735

Check for open circuit, or short-circuit

to ground, between idle air control motor and engine control module.

l

Idle air control motor connec-

tor: Disconnected

l Engine control module connec- tor: Disconnected0 OKSA

STOP

Repair the

harness

ml - El)

Km - El)

J

ACTUATOR INSPECTION

Use a sound scope to check if the sound of the idle air control

motor operating can be heard immediately after the ignition

switch is turned to “ON”.

NOTE

If the sound of the servo operating cannot be heard, check the

motor drive circuit and the idle air control motor.

TSB Revision

Page 328 of 1273

13-186On-Vehicle Inspection of MFI

FUEL SYSTEM

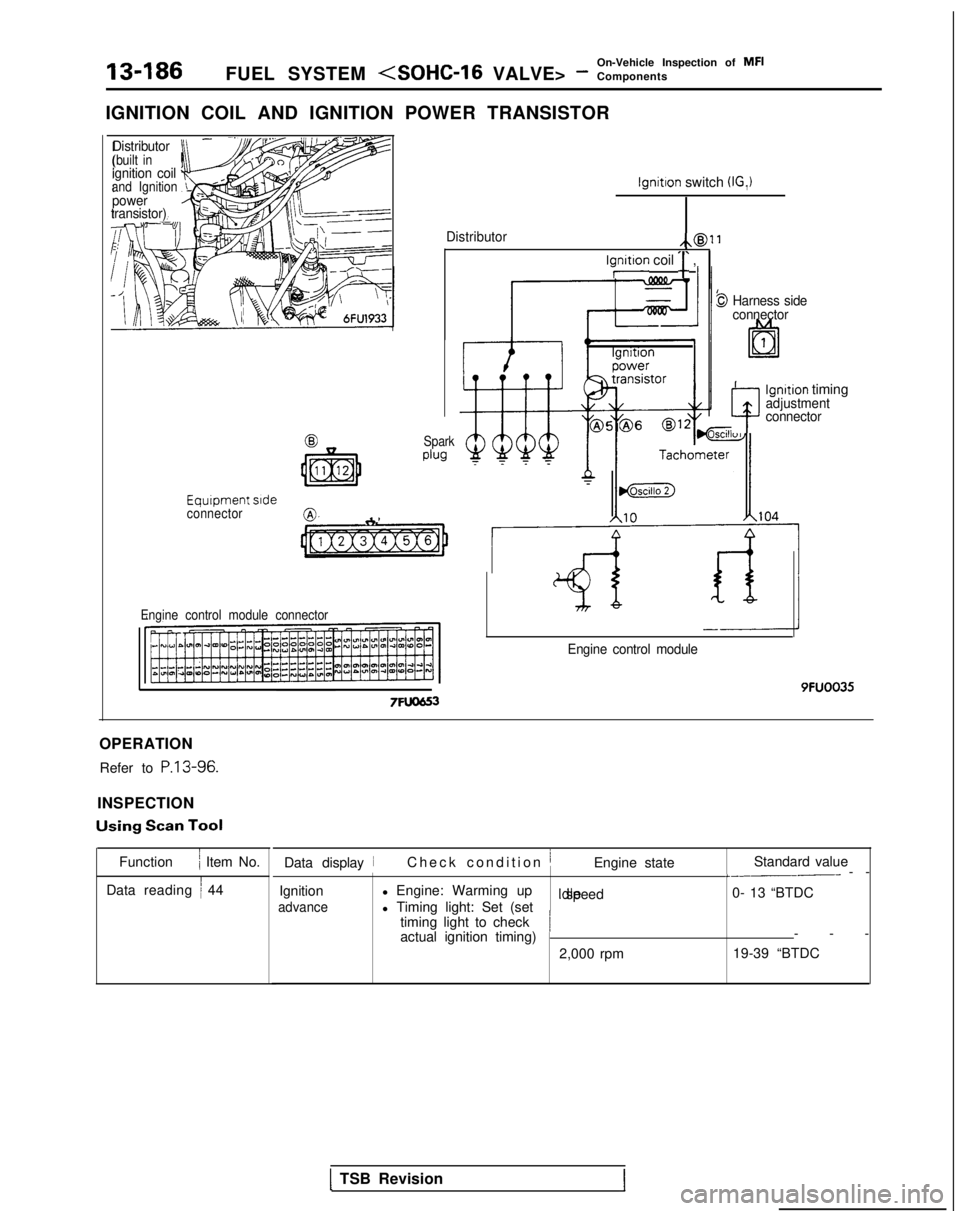

IGNITION COIL AND IGNITION POWER TRANSISTOR

-Distributor(built inignition coiland Ignitionpower

transistor)

Equrpment srdeconnector8”

Engine control module connector Spark

plug

Iynitron coil ‘r ,

lgnitron switch (IG,)

Distributor/,@)f1

9 Harness side

connector

4

lgnrtion timingadjustment

connector

7FU0653

Engine control module 9FUOO35

OPERATION Refer to

P.13-96.

INSPECTION Using

Scan Tool

Function

/ Item No.

Data reading

i 44 Data display

iCheck condition jEngine state

Standard value_.-___-- -

-

Ignition

advance

l Engine: Warming up Idle speed

0- 13 “BTDC

l Timing light: Set (set

timing light to check

actual ignition timing)

/--

-

2,000 rpm 19-39 “BTDC

1 TSB Revision1

Page 329 of 1273

FUEL SYSTEM

\

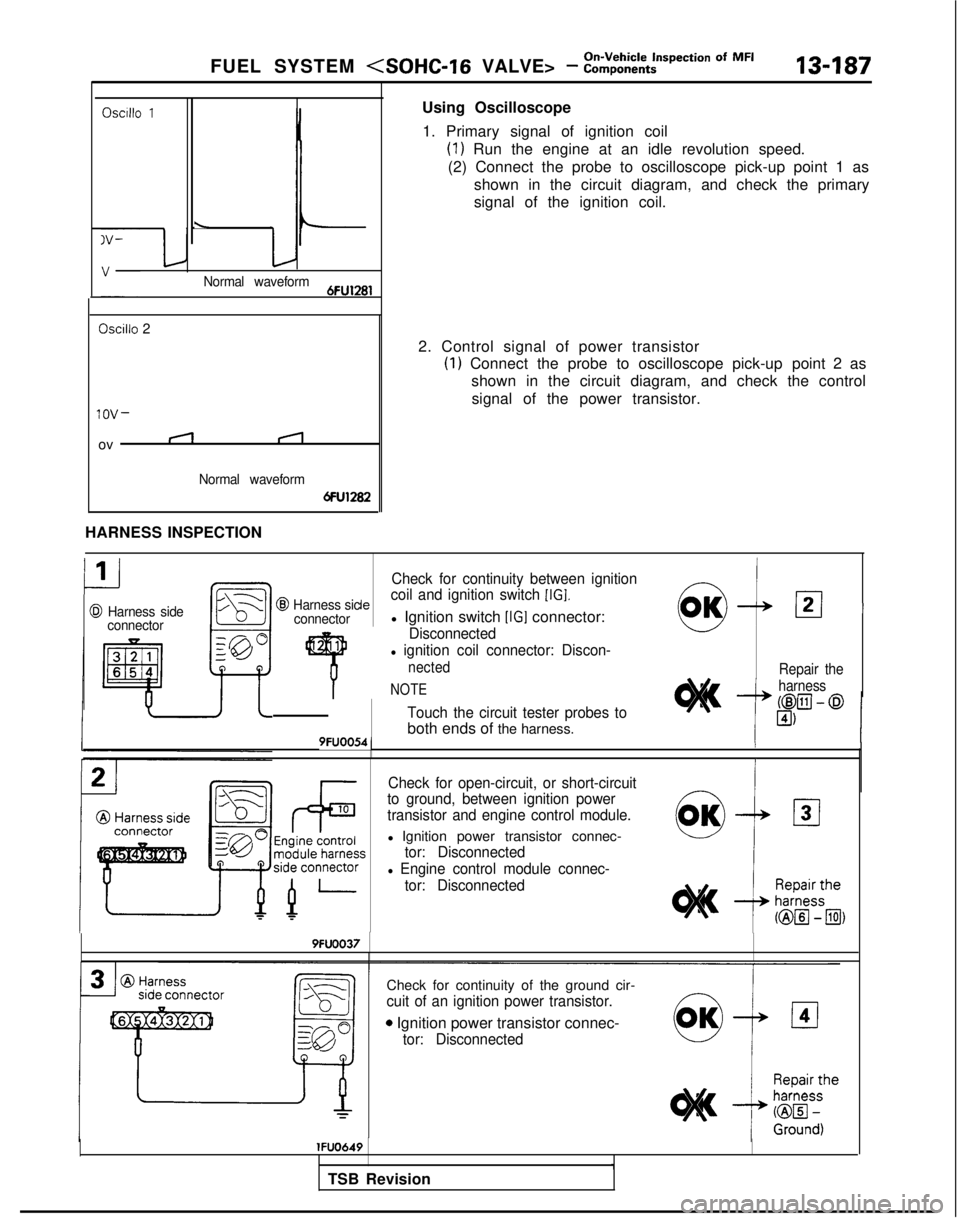

Normal waveform6FU1281

Oscillo 2

lOV-

ovII

Normal waveform

6FU1282

HARNESS

INSPECTION Using Oscilloscope

1. Primary signal of ignition coil

(1) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point 1 as shown in the circuit diagram, and check the primary

signal of the ignition coil.

2. Control signal of power transistor

(I) Connect the probe to oscilloscope pick-up point 2 as

shown in the circuit diagram, and check the control

signal of the power transistor.

CI1

@ Harness side connector

Check for continuity between ignition

‘R/4(21 I@I Harness siclecoil and ignition switch [IGI.

connectorl Ignition switch [IGI connector:/,‘\0”

Disconnected1

4

l ignition coil connector: Discon-

nected

NOTE

Touch the circuit tester probes to

both ends of the harness.19FUOO54,/I

Repair the

harness

_A- h

Check for open-circuit, or short-circuit

to ground, between ignition power

transistor and engine control module.

l Ignition power transistor connec-

tor: Disconnected

l Engine control module connec-

tor: Disconnected

9FUOO37

Check for continuity of the ground cir-

cuit of an ignition power transistor.

0 Ignition power transistor connec-

tor: Disconnected lFUO649

TSB Revision

Page 330 of 1273

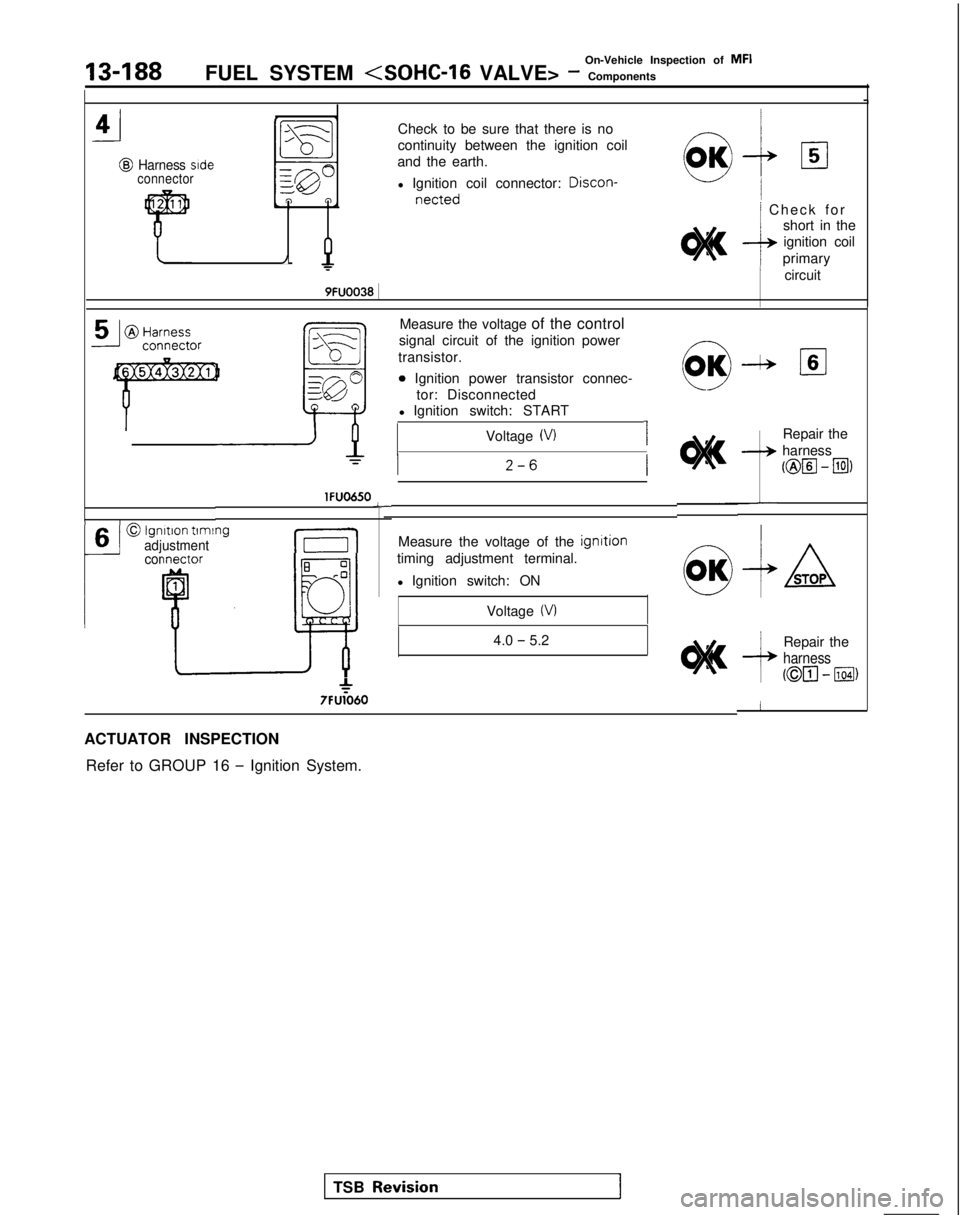

-i4

@Harness side

connector

/

Check to be sure that there is no

continuity between the ignition coil

and the earth.

l Ignition coil connector: Discon-

netted/ Check fo

r

short in the

ignition coil

primary

/ circuit

9FUOO38 1

13-188

On-Vehicle Inspection of MFI

FUEL SYSTEM

6

I

--

ml---X

A!

g@

0

T lFUO650

lgnltion

tlmlngadjustment

connector

E-:1

ll!?!

* 7FU1060

L

Measure the voltage of the control

signal circuit of the ignition power

transistor.

0 Ignition power transistor connec- tor: Disconnected

l Ignition switch: START

Voltage

(VI I

Measure the voltage of the ignrtion

timing adjustment terminal.

l Ignition switch: ON

Voltage

(VI

0 OKlIzI6

Repair the

harness

(@El - Ial

4.0 - 5.2

ACTUATOR INSPECTION Refer to GROUP 16

- Ignition System. Repair the

harness

(@El - 11041)

TSB RevisionI