MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 331 of 1273

On-Vehicle Inspection of MFI

FUEL SYSTEM (SOHC-16 VALVE> - Components13-189

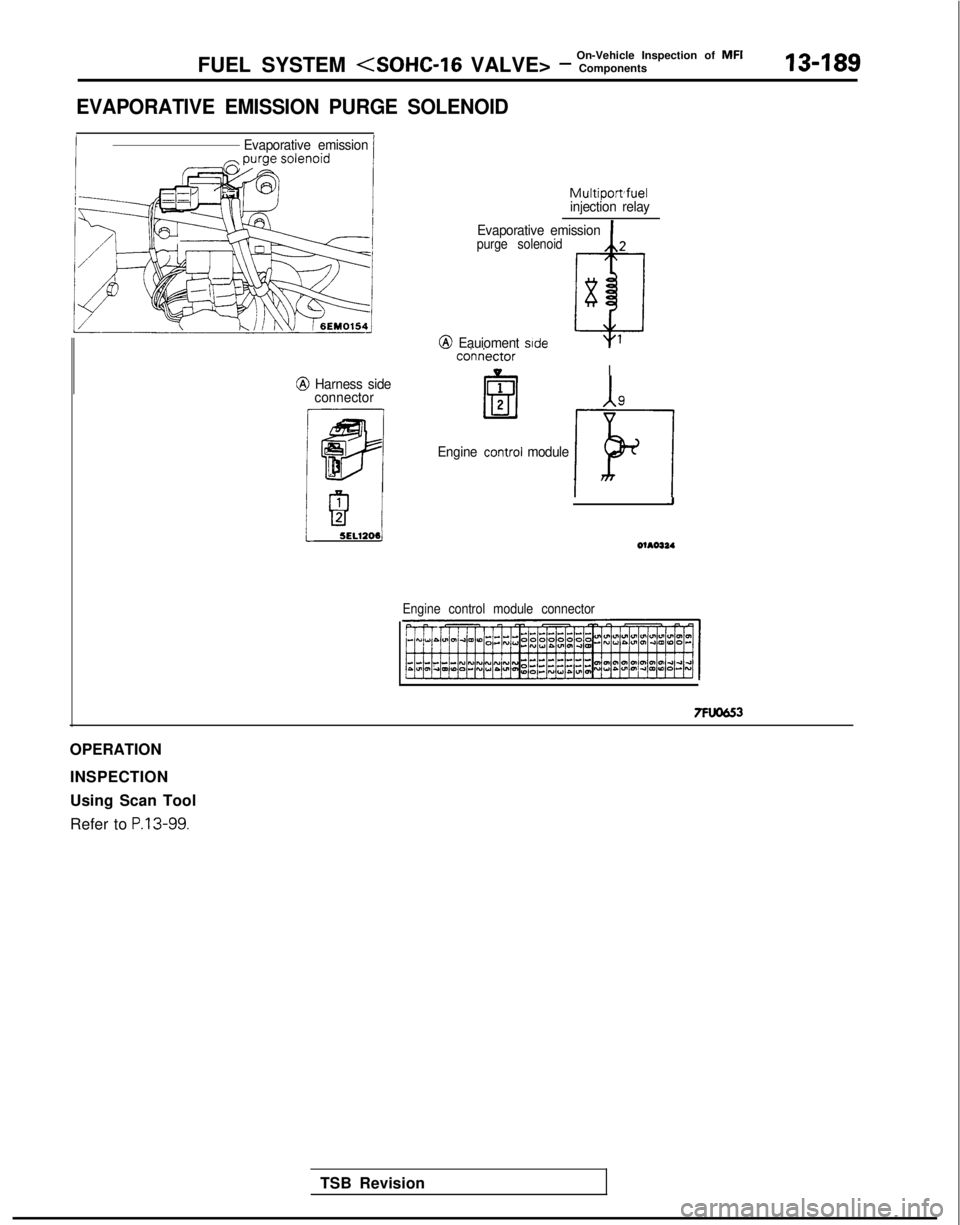

EVAPORATIVE EMISSION PURGE SOLENOID

IEvaporative emission/

Multipomfuel

injection relay

Evaporative emission

purge solenoid

-cofxiectorVI@ Harness side connector

p

Q I:

1

@ Eauioment side

Engine !!!I module ki

J

5ELl205)

TSB Revision

Engine control module connector

OPERATION

INSPECTION

Using Scan Tool

Refer to

P.13-99.

Page 332 of 1273

13-190

On-Vehicle Inspection of MFI

FUEL SYSTEM

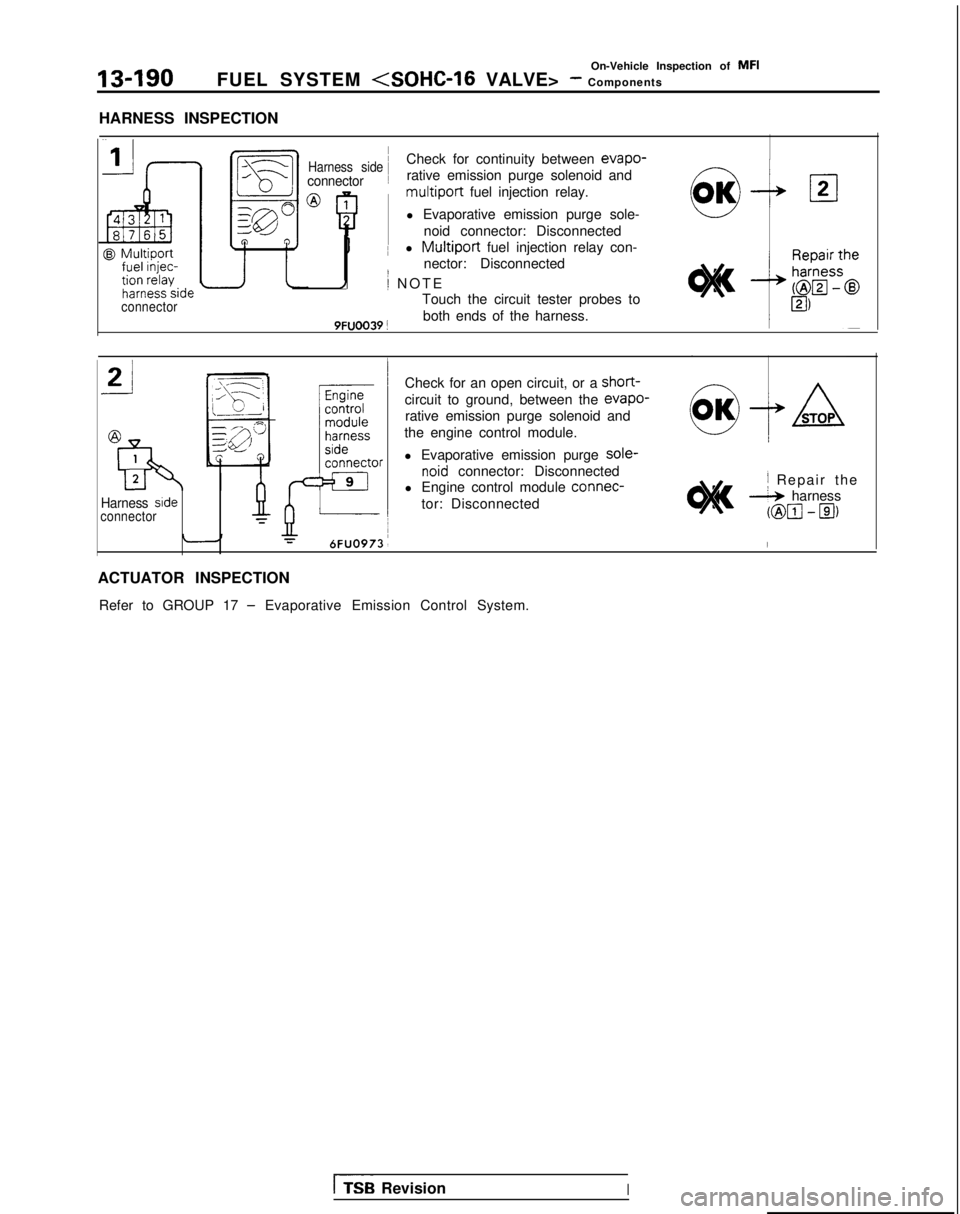

HARNESS INSPECTION

@ Multiport

connector ~

Harness sideCheck for continuity between evapo-

connector

~

rative emission purge solenoid andmultiport fuel injection relay.

l Evaporative emission purge sole- noid connector: Disconnected

I ~

l Multiport fuel injection relay con-

nector: Disconnected

1; NOT

E

Touch the circuit tester probes to

9FUOO39 !both ends of the harness.

Check for an open circuit, or a

short-

circuit to ground, between the evapo-

rative emission purge solenoid and

the engine control module.

Harness srdeconnector

l Evaporative emission purge sole-

noid connector: Disconnected

l Engine control module connec-

tor: Disconnected,I Repair th

e

* harness

@m-El)

I

ACTUATOR INSPECTION

Refer to GROUP 17

- Evaporative Emission Control System.

I%% RevisionI

Page 333 of 1273

FUEL SYSTEM

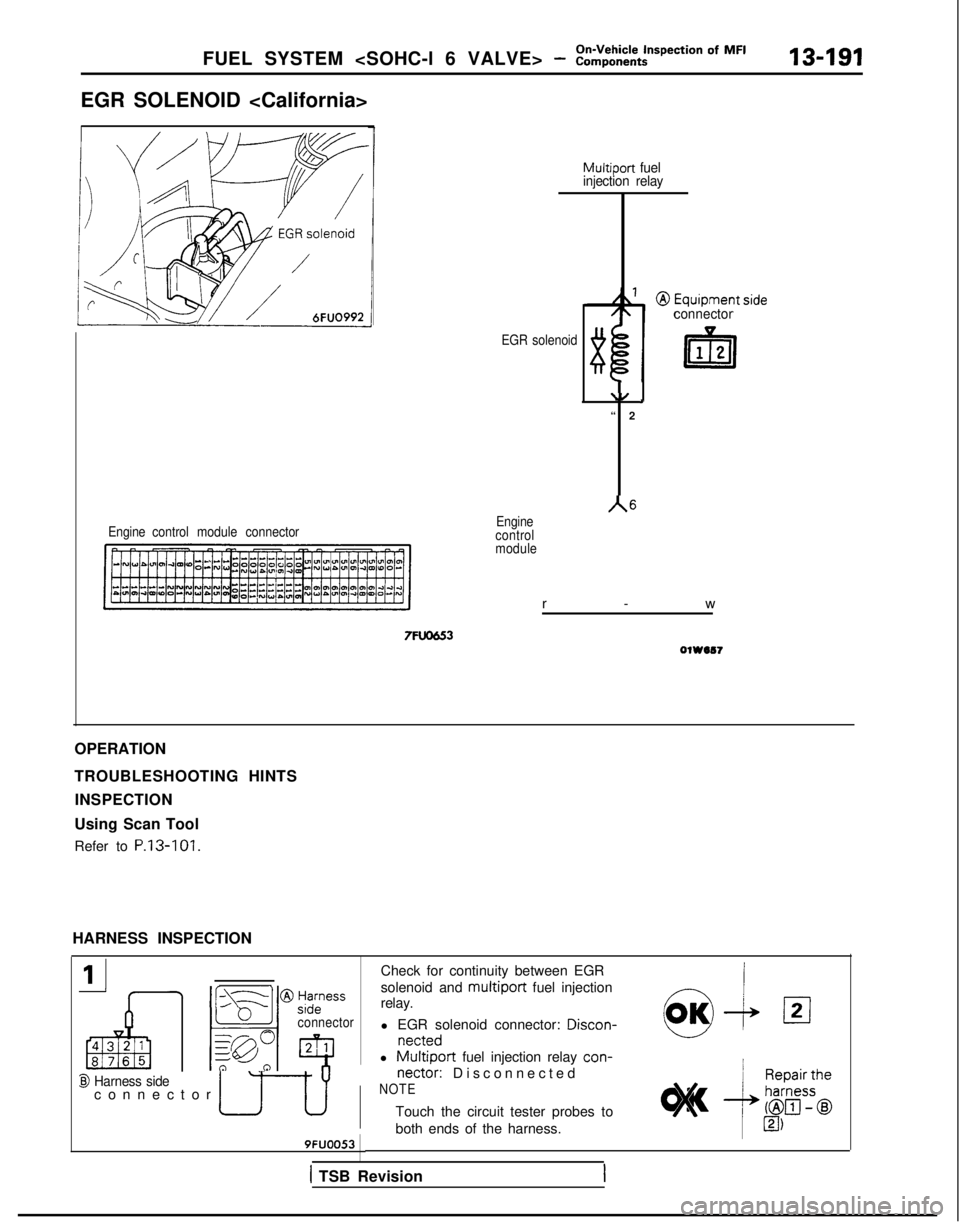

EGR SOLENOID

I

Engine

control module connector

Multiport fuel

injection relay

EGR solenoid

connector

\/ ‘

“

2

A6Engine

control

module

r-

w

7FlJOU3OlWIS7

OPERATION

TROUBLESHOOTING HINTS

INSPECTION

Using Scan Tool

Refer to P.13-101.

HARNESS INSPECTION

_11

I IIF5

connector

@I Harness sideconnector ul[ J

9FUOO53

Check for continuity between EGR

solenoid and

multiport fuel injection-!relay.

l EGR solenoid connector: Discon-

nettedw

l Multiport fuel injection relay

con-I

nectar:

Disconnected

NOTE

Touch the circuit tester probes to

both ends of the harness. 1

MI,

1 TSB Revision

Page 334 of 1273

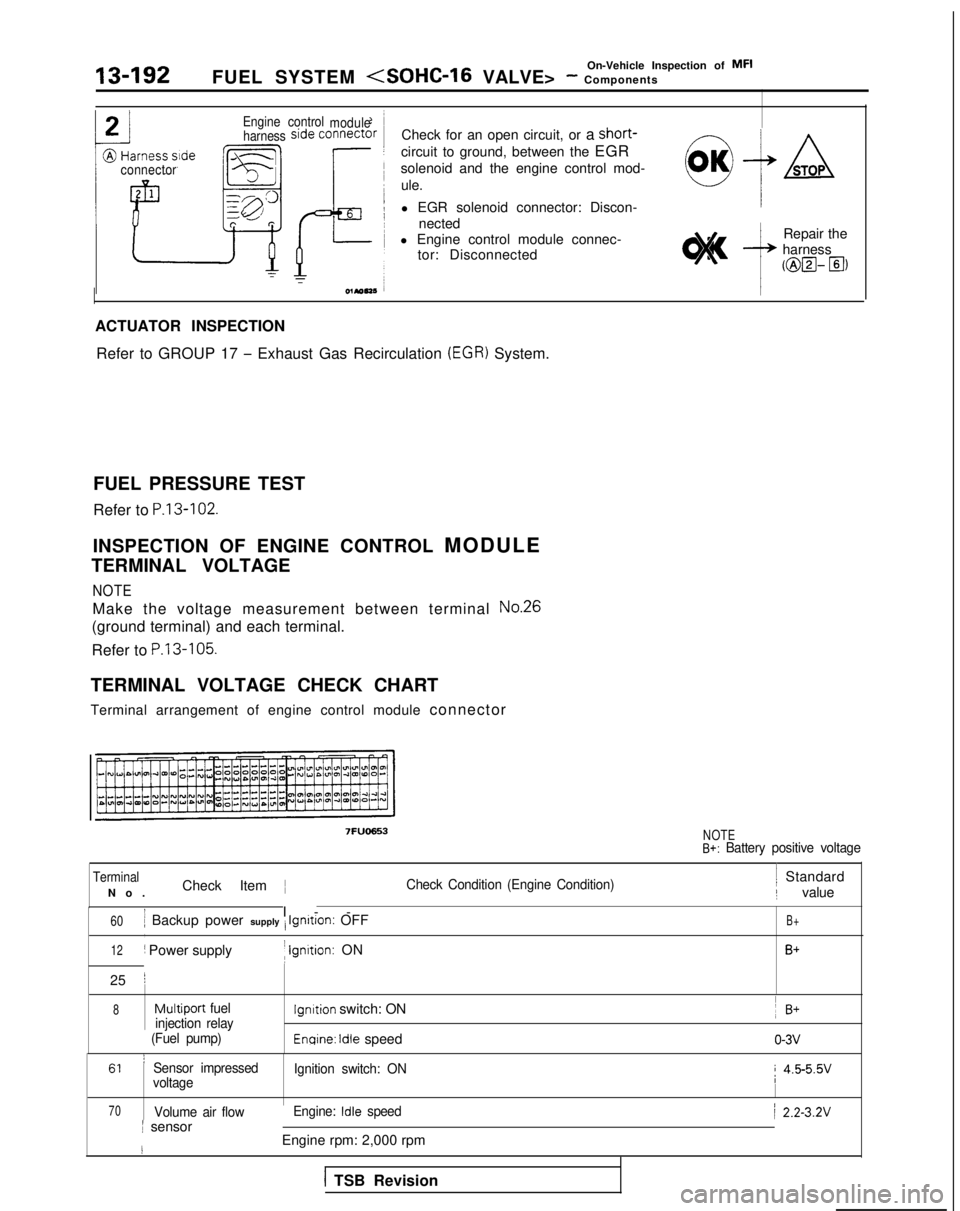

On-Vehicle Inspection of MFI13-192FUEL SYSTEM (SOHC-16 VALVE> - Components

connector

Engine control

module

harness

Check for an open circuit, or a short-

circuit to ground, between the EGR

solenoid and the engine control mod-

ule.

l EGR solenoid connector: Discon- nected

l Engine control module connec- tor: Disconnected

0OK+ASTOP

,

wsL

Repair the

harness

mzl- El)

ACTUATOR INSPECTION

Refer to GROUP 17

- Exhaust Gas Recirculation (EGR) System.

FUEL PRESSURE TEST

Refer to

P.13-102.

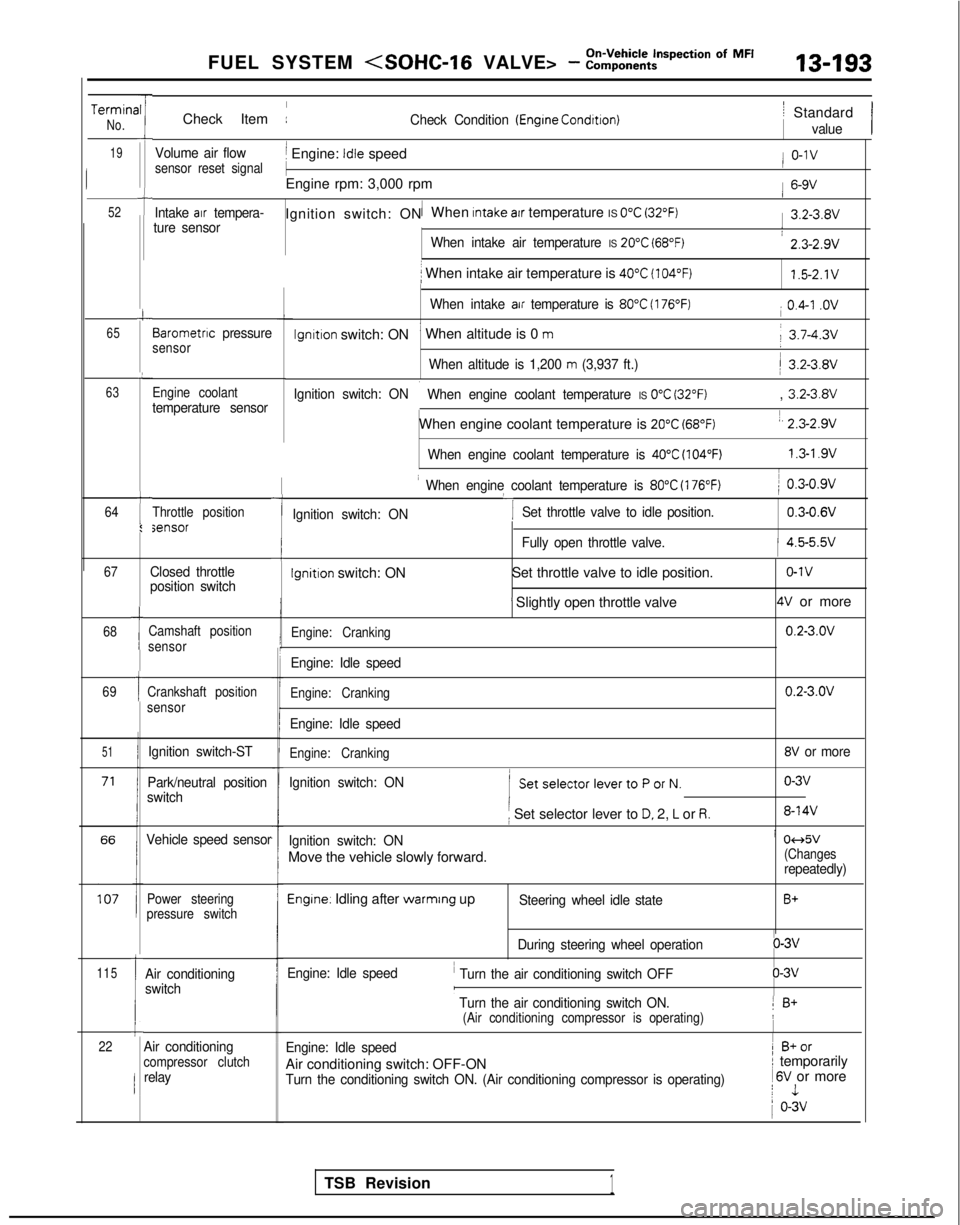

INSPECTION OF ENGINE CONTROL MODUL

E

TERMINAL VOLTAGE

NOTE

Make the voltage measurement between terminal No.26

(ground terminal) and each terminal.

Refer to

P.13-105.

TERMINAL VOLTAGE CHECK CHART

Terminal arrangement of engine control module connector

7FUQ653NOTEB+: Battery positive voltage

Terminal ~

No

.

Check Item ~

Check Condition (Engine Condition)/ Standard

/ value

60j Backup power supply i Ignrtron: OFF

I-

-

,

12/ Power supplyI Ignrtion: ON

25

j

B+

B+

8

Multiport fuellgnrtion switch: ON ~

B+injection relay~ (Fuel pump)Enqine: Idle speedo-3v

61 ’Sensor impressed

Ignition switch: ONi 4.5-5.5v

voltage

70Volume air flow Engine: Idle speed/ 2.2-3.2Vj sensor

IEngine rpm: 2,000 rpm

1 TSB Revision

Page 335 of 1273

FUEL SYSTEM

TerminaNo.

19

52

-rII

i

t

c

65

L

63

64t

I:

I

Check Item :Check Condition (Engrne Condrtron)

Volume air flowj Engine: Idle speedsensor reset signal

1

Engine rpm: 3,000 rpm

Intake air tempera-1Ignition switch: ON When Intake atr temperature IS 0°C (32°F)ture sensor

When intake air temperature IS 20°C (68°F)

i When intake air temperature is 40°C (104°F)

When intake air temperature is 80°C (176°F)

lgnltlon switch: ON’ When altitude is 0 m

When altitude is 1,200 m (3,937 ft.)

Ignition switch: ON

i When engine coolant temperature IS 0°C (32°F)

When engine coolant temperature is 20°C (68°F)

When engine coolant temperature is 40°C (104°F)

Barometnc pressuresensor

Engine coolant

temperature sensor

Throttle positionsensor

67

68

69

51

115

1

1

Ic22

Closed throttle

position switch

Camshaft position

sensor

Crankshaft position

sensor

Ignition switch-ST

Park/neutral position

switch

Vehicle speed sensor

Power steering

pressure switch

Air conditioning

switch

-I

I When engine coolant temperature is 80°C (176°F)

‘I

) 0.3-0.9v

Ignition switch: ON Set throttle valve to idle position.

0.3-0.6V

iFully open throttle valve.1 4.5-5.5v

Ignition switch: ON

Set throttle valve to idle position.o-1v

’ Slightly open throttle valve4V or more

Engine: Cranking0.2-3.OV

Engine: Idle speed

Engine: Cranking0.2-3.OV

Engine: Idle speed

Engine: Cranking8V or more

Ignition switch: ON

( SetselectorlevertoPorN.o-3v

i Set selector lever to D. 2, L or R.8-14V

Ignition switch: ONi 04d5v

Move the vehicle slowly forward.(Changesrepeatedly)

Engine. Idling after warmrng upSteering wheel idle stateB+

During steering wheel operationo-3v

Engine: Idle speed

’ Turn the air conditioning switch OFFo-3vI

’ Turn the air conditioning switch ON.1 B+(Air conditioning compressor is operating)!

Engine: Idle speed1 B+or

Air conditioning switch: OFF-ONI temporarily

Turn the conditioning switch ON. (Air conditioning compressor is operat\

ing) 1

6V or morej 1

1 o-3v

/ Standard

value

/ o-1v

1 6-9V

1 3.2-3.8V

: 2.3-2.9v

1.5-2.1V

i 0.4-I .ov

j 3.7-4.3v

/ 3.2-3.8V

, 3.2-3.8V

1, 2.3-2.9v

1.3-l .9vI

Air conditioningcompressor clutchrelay

TSB Revision1

Page 336 of 1273

13-194FUEL SYSTEM

7-

i

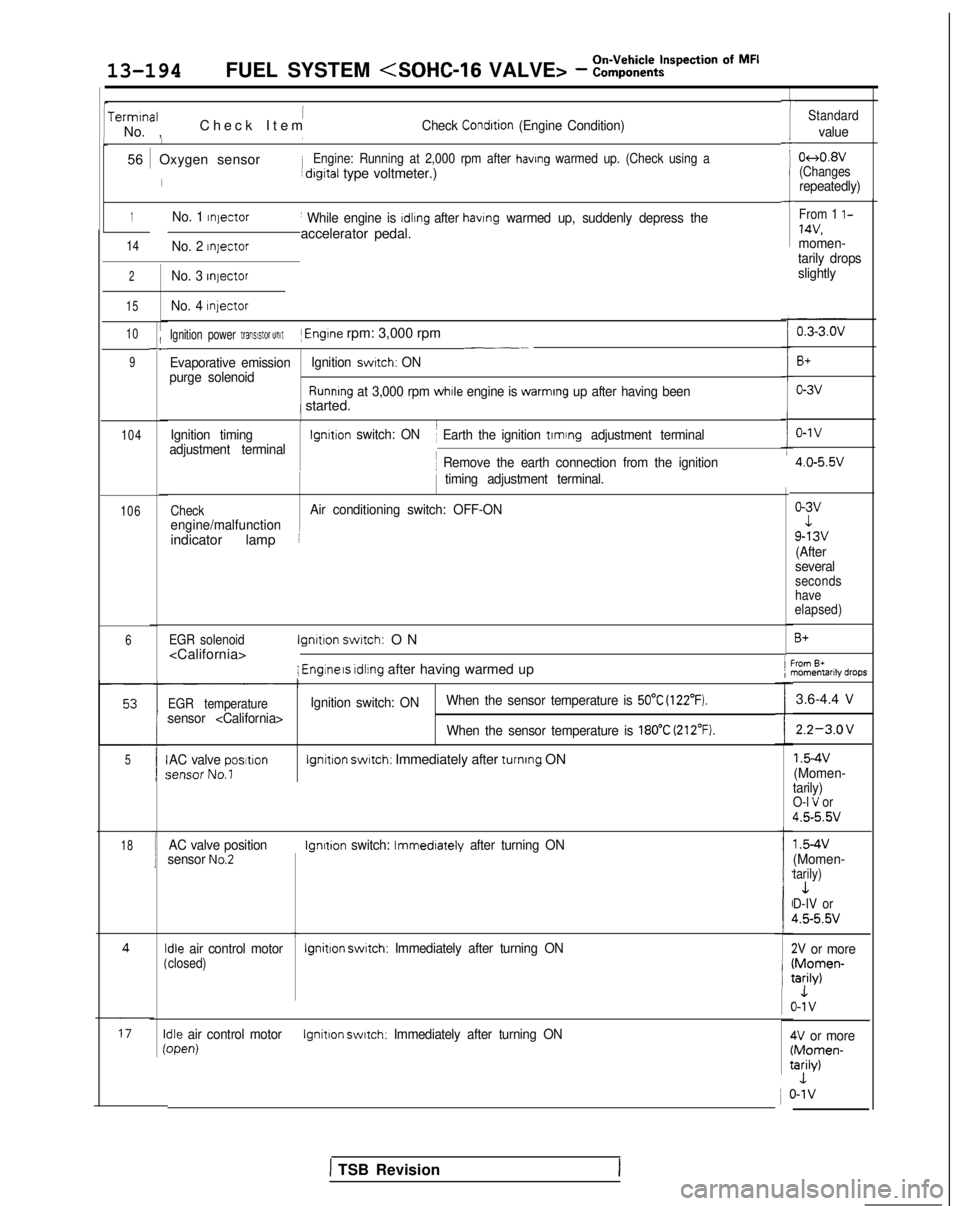

TermrnalI

No. ,Check Ite

m

,Check Condrtion (Engine Condition)Standard

value

OttO.8V(Changesrepeatedly)

TFrom 1 l-14v.momen-

tarily drops

slightly

B+

o-1v

4.0-5.5v

o-3v19-13v

(After

several

seconds

have

elapsed)

B+

‘rom B+nomentarlly dropIS

I

56 1 Oxygen sensoriEngine: Running at 2,000 rpm after havrng warmed up. (Check using a

I ~

drgltal type voltmeter.)

3.6-4.4

V 2.2-3.OV

1.5-4v

(Momen-

tarily)

O-l V or 4.55.5v

1.5-4v

(Momen-

tarily)1D-IV or4.5-5.5v

2V or moreIMomen-tarily)LI-1 v

4V or moreMomen-:arily)1 I-1v

No. 1 Injector

No. 2 Injector

’ While engine is Idling after having warmed up, suddenly depress the

accelerator pedal.

1

14

2No. 3 Injector

15No. 4 Injector

Ignition power transistor unit~

Engine rpm: 3,000 rpm___-

Evaporative emission Ignition swatch: ON

purge solenoid

Runnrng at 3,000 rpm while engine is warmrng up after having beeni started.I

10II-

9

104Ignition timing

adjustment terminallgnttion switch: ON1 Earth the ignition trming adjustment terminal

I Remove the earth connection from the ignition

timing adjustment terminal.

CheckAir conditioning switch: OFF-ON

engine/malfunction

indicator lamp i

106

6

EGR solenoid

N

; Engine IS idling after having warmed up/j

EGR temperaturesensor

Ignition switch: ON

When the sensor temperature is

50°C (122°F).

When the sensor temperature is 180°C (212°F).

I 1I

AC valve positlonsensor No.1Ignition switch: Immediately after turnrng ON5

18

AC valve position

sensor No.2lgnltion switch: lmmedlately after turning ON

dle air control motorclosed)Ignition switch: Immediately after turning ON

3le air control motor wen)lgnitlon switch:

Immediately after turning ON1

( t

i (

1 TSB Revision

Page 337 of 1273

Fuel Tank/Fuel Line and Vapor Line/

FUEL SYSTEM (SOHC-16 VALVE> - Fuel Filter13-195

FUEL TANK

Refer to P.13-109.

FUEL LINE AND VAPOR LINE

Refer to P.13-113.

FUEL FILTER

Refer to P.13-115.

TSB Revision

Page 338 of 1273

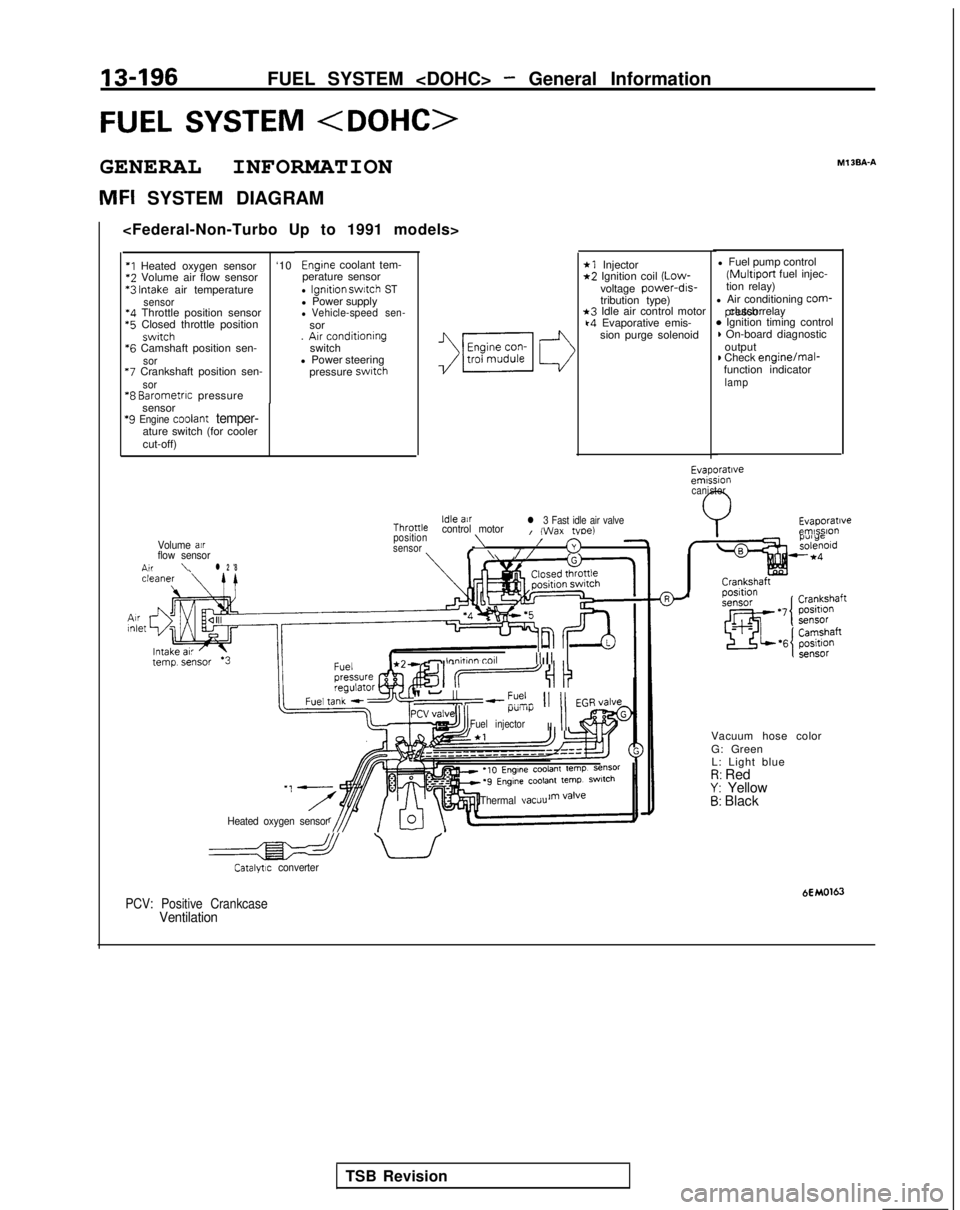

13-196FUEL SYSTEM

FUEL SYSTEM

GENERAL INFORMATION

MFI SYSTEM DIAGRAMMl

3BA-A

*1 Injector*2 Ignition coil

(Low-

voltage power-drs-

tribution type)

*3 Idle air control motork4 Evaporative emis-

sion purge solenoid l Fuel pump control (Multiport

fuel injec-

tion relay)

l Air conditioning

corm- pressor clutch relay

* Ignition timing control) On-board diagnostic

output

) Check engine/mal-

function indicator

lamp

Engine coolant tem-

perature sensor

l Ignition swatch STl Power supplyl Vehicle-speed sen-sor

. Arr conditioning

switch

l Power steering

pressure

swatch

‘I Heated oxygen sensor ‘10*2

Volume air flow sensor *3

Intake air temperaturesensor‘4 Throttle position sensor *5

Closed throttle position

swrtch *6

Camshaft position sen-

sor “7

Crankshaft position sen-

sor“8 Barometrrc pressure

sensor

‘9 Engine coolant temper-ature switch (for cooler

cut-off)

Evaporatrveemrssion canister

Evaporatrveemlsslo”Idle airThronlecontrol motorl 3 Fast idle air valveI (Wax tvoe)position\Volume air/sensor3flow sensorf \//n,r\l 2 '8

- lnnhnn toll III1 II

II-“,--?% 11 11 EGR,/alveI.l”lll)i

Fuel injectorII

II

Vacuum hose color

G: Green

L: Light blue

I?: RedY: Yellow5: Black

Heated oxygen sensor Thermal

vacuu

a uCatalytrc converter

HMO163PCV: Positive CrankcaseVentilation

TSB Revision

Page 339 of 1273

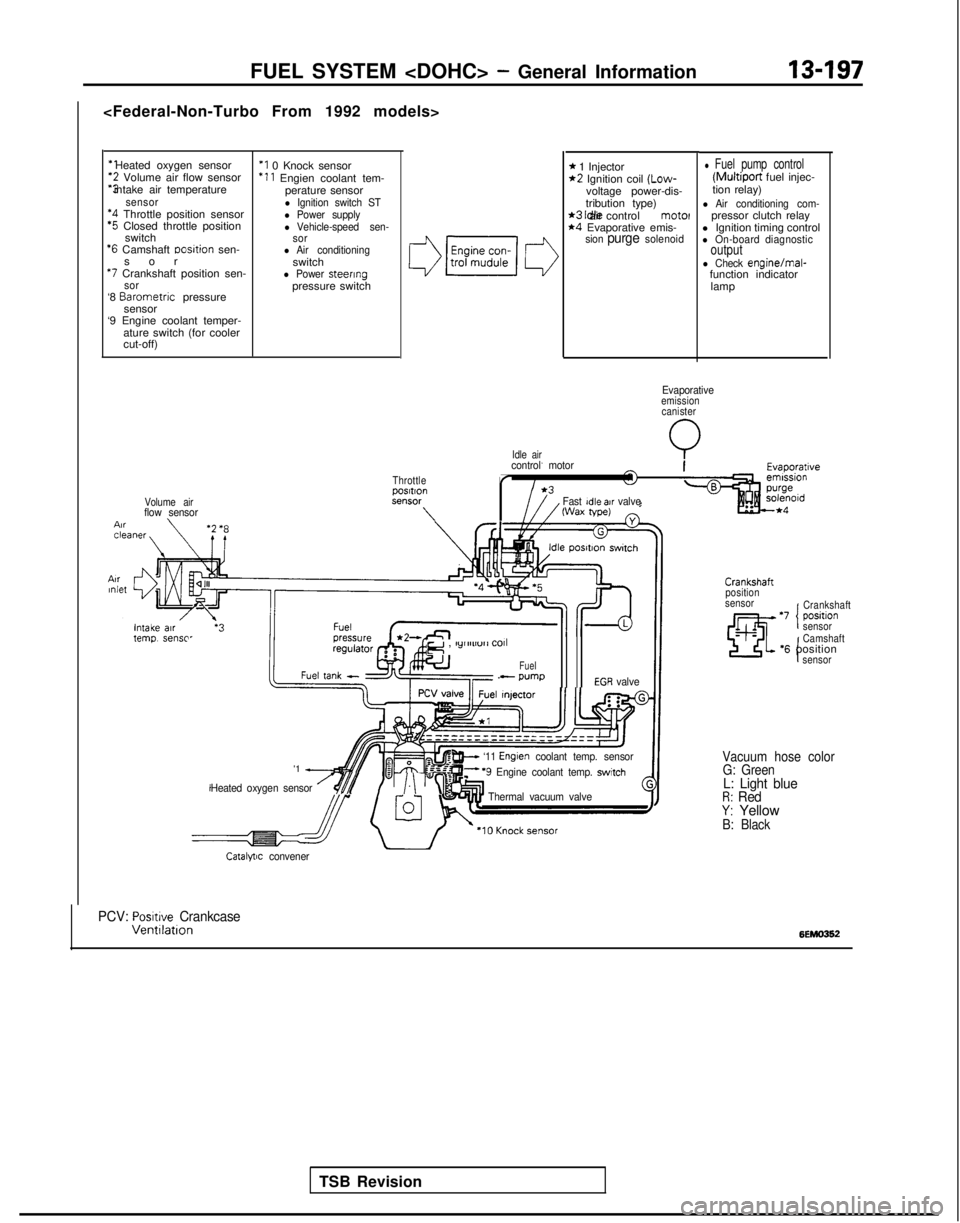

‘1 Heated oxygen sensor‘2 Volume air flow sensor

“3 intake air temperature

sensor‘4 Throttle position sensor‘5 Closed throttle position

switch

‘6 Camshaft Dosltion sen-

so

r

*7 Crankshaft position sen-sor‘8

Barometnc

pressure

sensor

‘9 Engine coolant temper-

ature switch (for cooler

cut-off)

‘I 0 Knock sensor ‘11

Engien coolant tem-

perature sensor

l Ignition switch STl Power supplyl Vehicle-speed sen-

sor

l Air conditioningswitchl Power steeringpressure switch

Volume airflow sensor \

Idle air

FUEL SYSTEM

* 1 Injector*2 Ignition coil (Low-

voltage power-dis-

tribution type)

*3 Idle air control motel*4 Evaporative emis-sion purge solenoid

l Fuel pump control (Multiport

fuel injec-

tion relay)

l Air conditioning com-pressor clutch relay

l Ignition timing control

l On-board diagnosticoutputl Check engine/mal-

function indicator

lamp

Evaporativeemissioncanister

Q

ThrottlepOSltlOnSt?“SW

\

control motor

r

Fast Idle air valveWax tape)

TSB Revision

e , lylllll”rl

COll

Fuel- wmpEGR valve

'1 A

Heated oxygen sensor /$$y/.\‘“I

w ‘11 Englen coolant temp. sensorF ‘9 Engine coolant temp. switch

Thermal vacuum valve

Crankshaft

position

sensor

‘7 positlon ICrankshaft

sensor

I

Camshaft‘6 positionsensor

Vacuum hose color G: Green

L: Light blueR: RedY: YellowB: Black

Catalytic convener

PCV: Posmve CrankcaseVentllatlon6EMO362

Page 340 of 1273

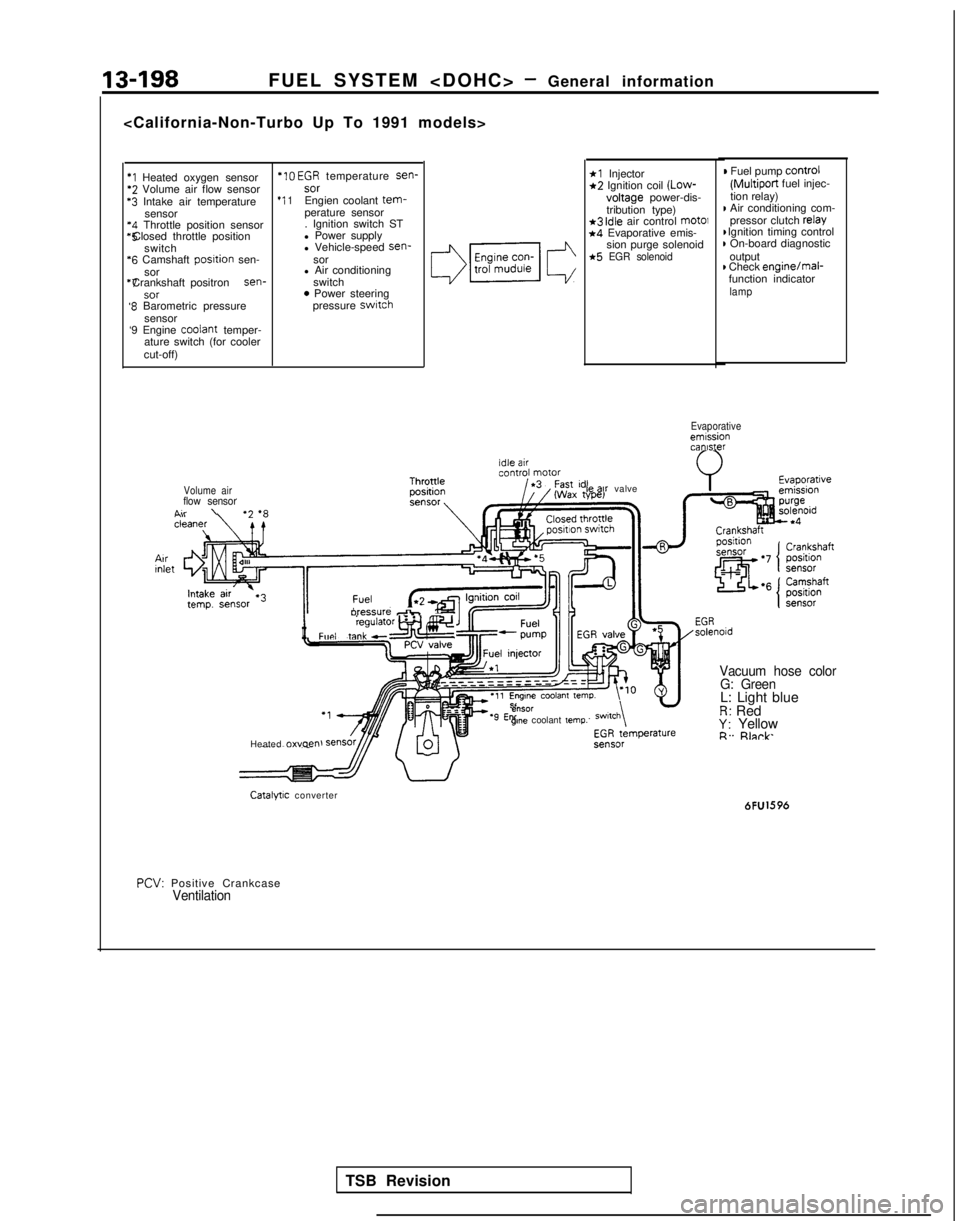

13-198FUEL SYSTEM

*I Heated oxygen sensor *IO

EGR temperature sen-*2 Volume air flow sensor

sor‘3 Intake air temperature

*I 1Engien coolant tem-sensor

perature sensor‘4 Throttle position sensor . Ignition switch ST*5 Closed throttle position

l Power supply

switch l Vehicle-speed sen-

‘6 Camshaft

posltion

sen- sor

sor l Air conditioning“7 Crankshaft positron sen-

switch

SOT0 Power steering‘8 Barometric pressure pressure switch

sensor

‘9 Engine coolant

temper-

ature switch (for cooler

cut-off)

*l Injector*2 Ignition coil (Low-

voltage

power-dis-

tribution type)

*3 idle air control mot01*4 Evaporative emis- sion purge solenoid

*5 EGR solenoid

) Fuel pump control

(Multiport

fuel injec-

tion relay)

I Air conditioning com- pressor clutch relay I Ignition timing control

) On-board diagnostic

output

) Check enginejmal-

function indicator

lamp

Evaporativeemissioncanister

Volume air

flow sensorA..\

II

oressure db,Fun, taw”l”‘“‘~

Heated 0~““~” le

ax valve

e”SOrgme coolant temp.

Vacuum hose color

G: Green

L: Light blueR: RedY: YellowR. Rlnrk

Catalytic converter 6FU1596

PCV:

Positive Crankcase

Ventilation

TSB Revision